Optimization of Management Processes in Assessing the Quality of Stored Grain Using Vision Techniques and Artificial Neural Networks

Abstract

1. Introduction

2. Aim and Scope of Work

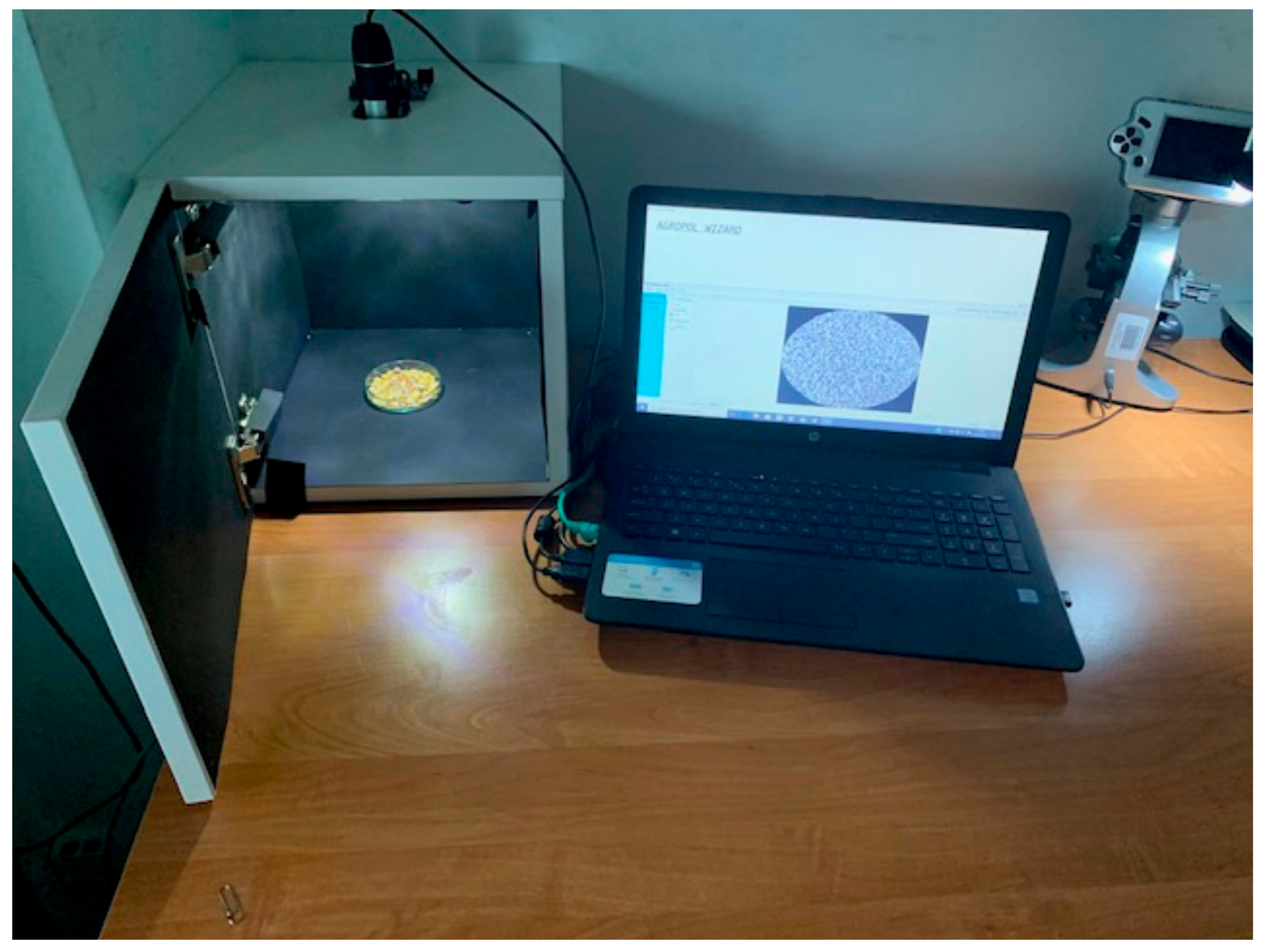

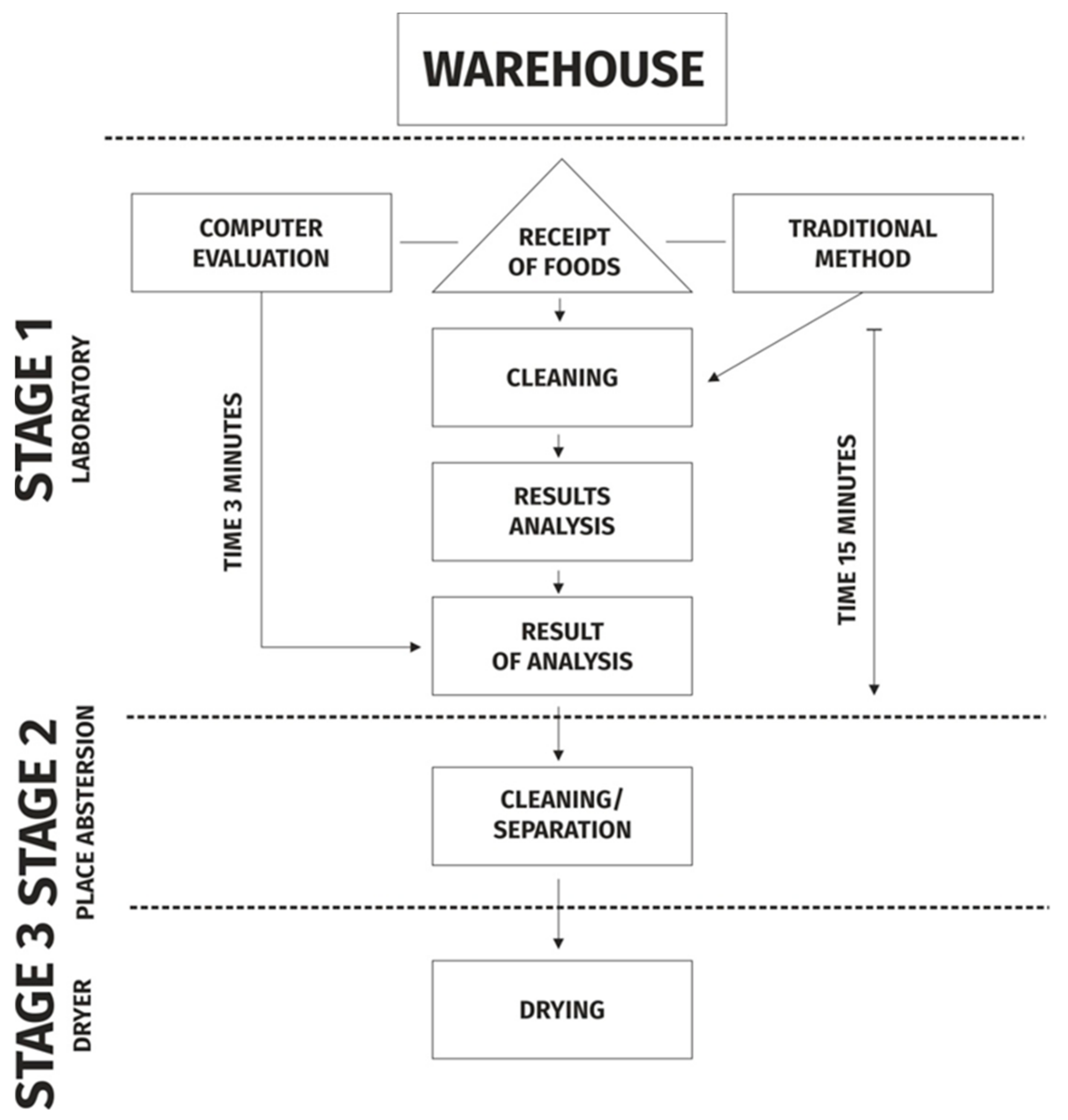

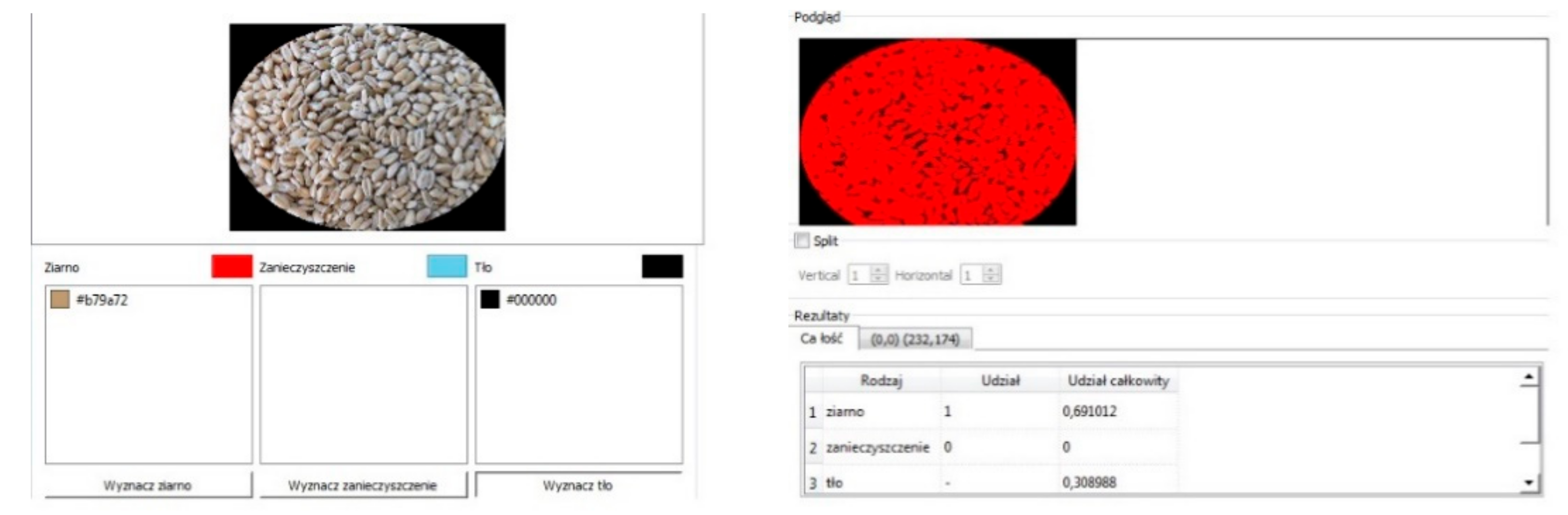

3. Materials and Methods

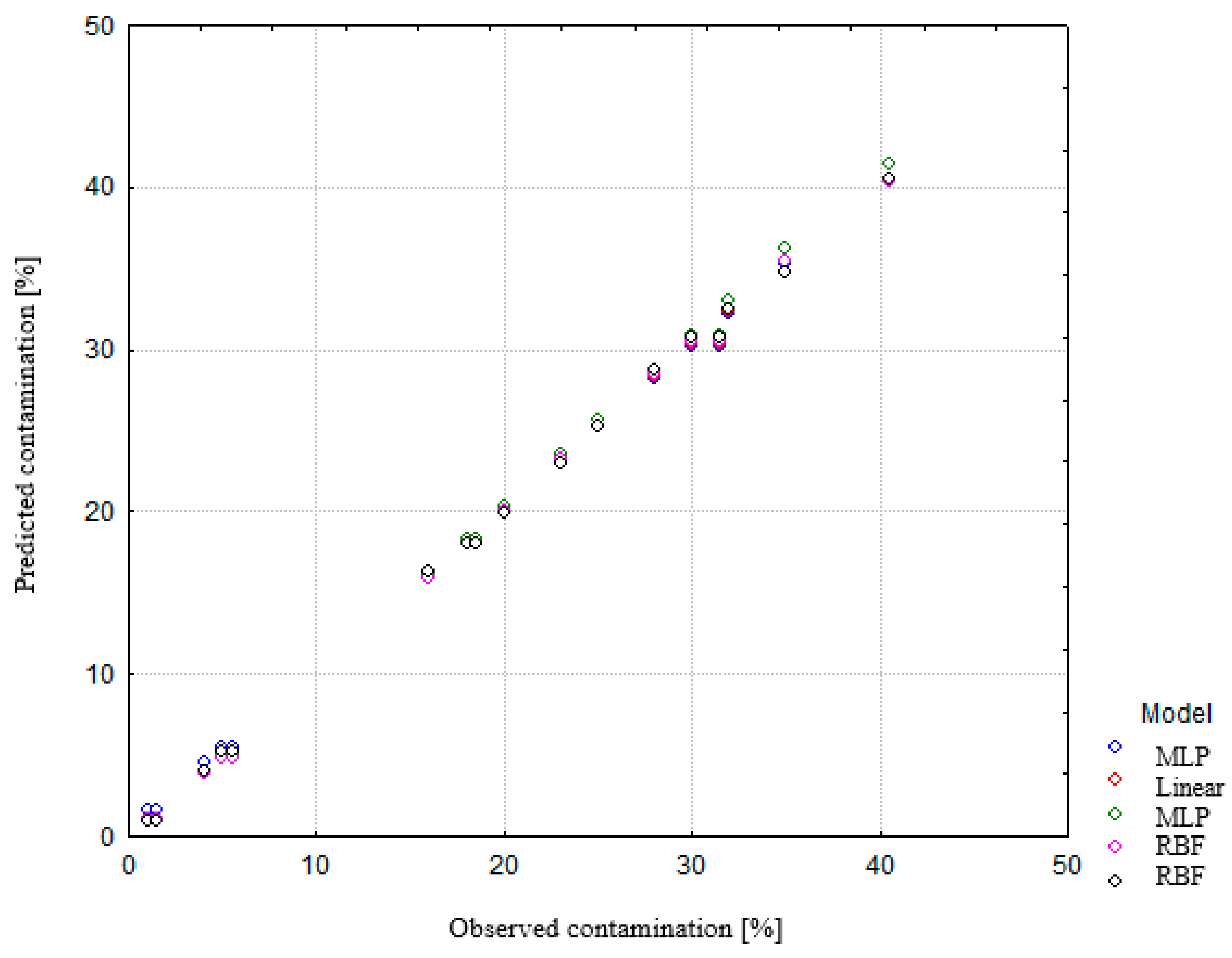

- -

- input variable: binding quantity in percentage using the traditional (weight-sieve) method for 22 samples,

- -

- output variable: binding quantity in percentage by computer image analysis, for 22 trials,

- -

- designed models: three-line network, four-layer perceptron, four-layer perceptron,

- -

- activation function: linear.

- (+) direct revenue—taxable revenue,

- (−) tax-deductible costs, and

- (=) profit (+)/loss (−)—operating profit

- -

- material cleaning,

- -

- drying

- -

- handling inside the warehouse.

4. Straight Payback Period

5. Analysis and Discussion of Results

- The ability to identify current and prospective innovation needs in terms of process and product innovation [30].

- The ability to implement innovative projects and technical means of production and innovative products into the systems of innovative end users—customers.

- Joint R&D work in cooperation with external entities.

- Ordering R&D work fromexternal entities, employing third-party workers.

- Exchange of technical knowledge with other scientific centers.

- Construction of complete prototypes in the company [31].

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAO. FAO Food Outlook; FAO: Rome, Italy, 2016; p. 139. [Google Scholar]

- EU. EU Cereals Balance Sheet 2016/17 and Forecast 2017/18; European Union: Brussels, Belgium, 2016; p. 17. [Google Scholar]

- Alexandratos, N.; Bruinsma, J. World agriculture towards 2030/2050: The 2012 revision. In ESA Working Paper Rome; FAO: Rome, Italy, 2012. [Google Scholar]

- Godfray, H.C.J.; Garnett, T. Food security and sustainable intensification. Philos. Trans. Biol. Sci. 2014, 369, 273. [Google Scholar] [CrossRef] [PubMed]

- Rusinek, R.; Tys, J.; Wroniak, M.; Anders, A. Przechowywanie nasion rzepaku zagrożenia. Autobusy Technika Eksploatacja Systemy Transportowe 2011, 12, 369–374. [Google Scholar]

- Nellist, M.E. Bulk storage drying in theory and practice. J. R. Agric. Soc. Engl. 1998, 159. [Google Scholar]

- Kręcidło, Ł.; Krzyśko-Łupicka, T. Sensitivity of molds isolated from warehouses of food production facility on selected essential oils. Inżynieria Ekol. 2015, 43, 100–108. [Google Scholar] [CrossRef]

- Broda, M.; Grajek, W. Mikroflora ziaren zbóż i metody redukcji skażenia mikrobiologicznego. Zesz. Probl. Post. Nauk Roln. 2009, 2, 19–30. [Google Scholar]

- Abdullah, M.Z.; Guan, L.C.; Lim, K.C.; Karim, A.A. The applications of computer vision system and tomographic radar imaging for assessing physical properties of food. J. Food Eng. 2004, 61, 125–135. [Google Scholar] [CrossRef]

- Sànchez, A.J.; Albarracin, W.; Grau, R.; Ricolfe, C.; Barat, J.M. Control of ham salting by using image segmentation. Food Control 2008, 19, 135–142. [Google Scholar] [CrossRef]

- Du, C.J.; Sun, D.-W. Correlating shrinkage with yield, water content and texture of pork ham by computer vision. J. Food Process. Eng. 2005, 28, 219–232. [Google Scholar] [CrossRef]

- Iqbal, A.; Valous, N.A.; Mendoza, F.; Sun, D.-W.; Allen, P. Classification of presliced pork and Turkey ham qualities based on image color and textural features and their relationships with consumer responses. Meat Sci. 2010, 84, 455–465. [Google Scholar] [CrossRef]

- Li, J.; Liao, G.; Ou, Z.; Jin, J. Rapeseed seeds classification by machine vision. In Proceedings of the Workshop on Intelligent Information Technology Application (IITA 2007), Zhang Jiajie, China, 2–3 December 2007. [Google Scholar]

- Szwedziak, K. Artifical neutral networks and computer image analysis of selected quality parameters of pea seeds. E3S Web Conf. 2019, 132, 1027. [Google Scholar] [CrossRef]

- Szwedziak, K. The use of vision techniques for the evaluation of selected quality parameters of maize grain during storage. E3S Web Conf. 2019, 132, 01026. [Google Scholar] [CrossRef]

- Chai, T. Industrial process control systems: Research ststus and development direction. Sci. Sin. Inf. 2016, 46. [Google Scholar] [CrossRef]

- Qian, F.; Zhong, W.; Du, W. Fundamental theories and key technologies for smart and optimal manufacturing in the process industry. Engineering 2017, 3, 154–160. [Google Scholar] [CrossRef]

- Visen, N.S.; Paliwal, J.; Jayas, D.S.; White, N.D.G. Image analysis of bulk grain samples using neural networks. Can. Biosyst. Eng. 2004, 46, 11–15. [Google Scholar]

- Wilson, A.D.; Baietto, M. Applications and Advances in Electronic-Nose Technologies. Sensors 2009, 9, 5099–5148. [Google Scholar] [CrossRef]

- Brattoli, M.; Cisternino, E.; Dambruoso, P.R.; de Gennaro, G.; Giungato, P.; Mazzone, A.; Palmisani, J.; Tutino, M. Gas Chromatography Analysis with Olfactometric Detection (GC-O) as a Useful Methodology for Chemical Characterization of Odorous Compounds. Sensors 2013, 13, 16759–16800. [Google Scholar] [CrossRef]

- Mladenov, M.; Dejanov, M. Analysis of the possibilities for separator color and texture features. In Proceedings of the International Conference on Computer Systems and Technologies, Rousse, Bulgaria, 17–18 June 2004. [Google Scholar]

- Manickavasagab, A.; Sathya, G.; Jayas, D.S.; White, N.D.G. Wheat class identification using monochrome images. J. Cereal Sci. 2008, 47, 518–527. [Google Scholar] [CrossRef]

- Majumdar, S.; Jayas, D.S.; Symons, S.J. Textural features for grain identification. Agric. Eng. J. 1999, 8, 213–222. [Google Scholar]

- Mohan, A.L.; Jayas, D.S.; White, N.D.G.; Karunakaran, C. Classification of bulk oilseeds, specialty seeds and pulses using their reflectance characteristics. In Proceedings of the International Quality Grains, Indianapolis; Purdue University: Indianapolis, IN, USA, 2004; Available online: https://books.google.de/books/about/Proceedings_of_the_2004_International_Qu.html?id=G_W2DAEACAAJ&redir_esc=y (accessed on 13 August 2020).

- Gonzales-Barron, U.; Butler, F. Statistical and spectral texture analysis methods for discrimination of bread crumb images. In Proceedings of the IUFoST World Congres of Food Science and Technology, Nantes, France, 17–21 September 2006. [Google Scholar]

- Liu, Z.; Cheng, F.; Ying, Y.; Rao, X. Identification of rice seed varieties using neural network. J. Zhejiang Univ. Sci. 2005, 6, 1095–1100. [Google Scholar] [CrossRef]

- Szwedziak, K.; Polańczyk, E.; Grzywacz, Ż.; Niedbała, G.; Wojtkiewicz, W. Neural Modeling of the Distribution of Protein, Water and Gluten in Wheat Grains during Storage. Sustainability 2020, 12, 5050. [Google Scholar] [CrossRef]

- Białobrzewski, I. Wykorzystanie sieci neuronowej do estymacji wartości wilgotności względnej powietrza na podstawie wartości jego temperatury. Inżynieria Rol. 2005, 1, 15–22. [Google Scholar]

- Białobrzewski, I.; Markowski, M.; Bowszys, J. Symulacyjny model zmian pola temperatury w silosie zbożowym. Inżynieria Rol. 2005, 8, 23–30. [Google Scholar]

- Dworczak, M.; Szlasa, R. Wpływ Innowacji na Wzrost Konkurencyjności Przedsię-Biorstw. Zarzadzanie Innowacjami; Oficyna Wydawnicza Politechniki Warszawskiej: Warsaw, Poland, 2001; pp. 177–180. [Google Scholar]

- Kolarz, M. Wpływ Zagranicznych Inwestycji Bezpośrednich na Innowacyjność Przedsiębiorstw w Polsce; Wydawnictwo Uniwersytetu Śląskiego: Katowice, Poland, 2006. [Google Scholar]

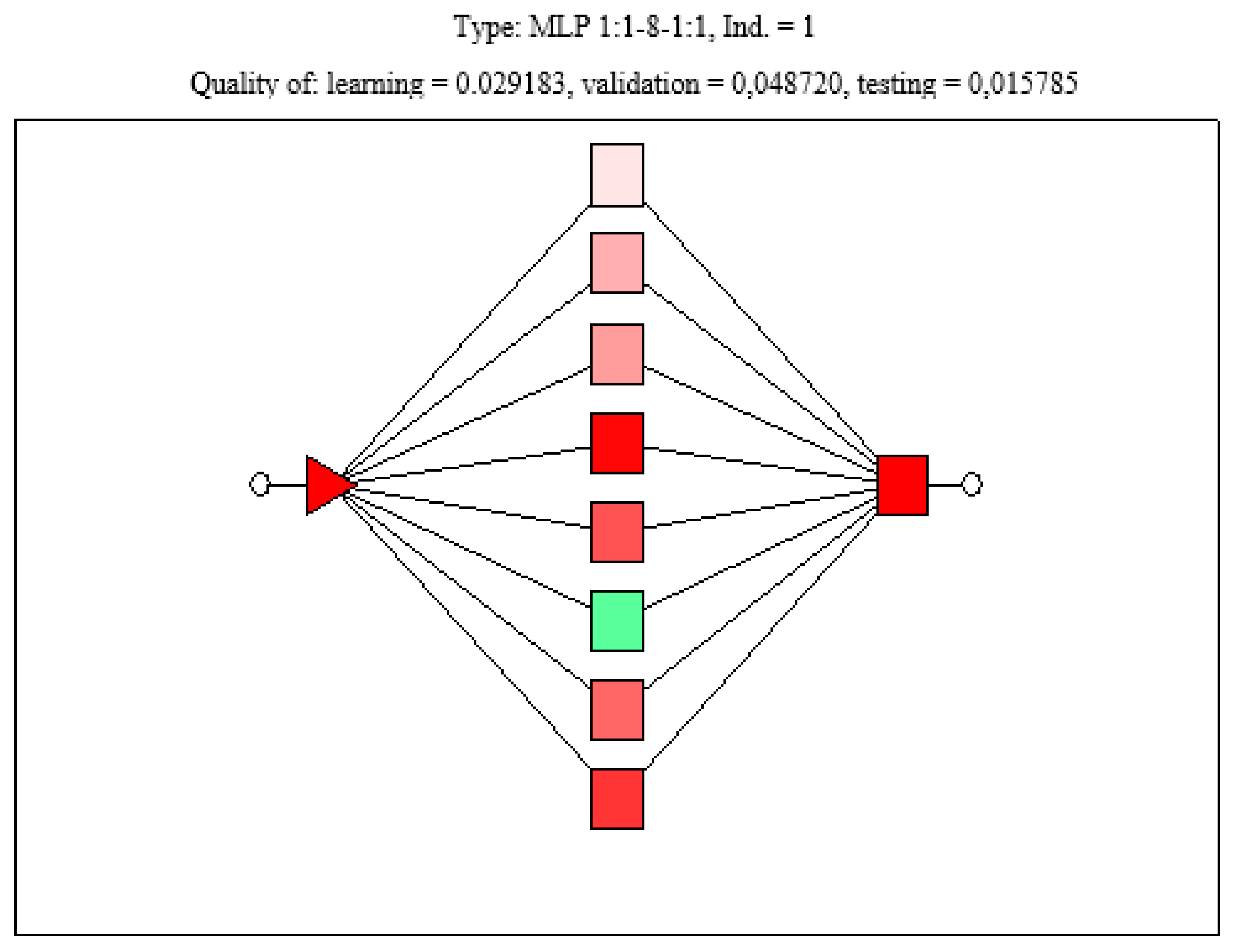

| Type of Network | Network Diagram | Quality of Learning | Quality of Validation | Quality of Testing | Learning Error | Validation Error | Testing Error | Number of Input Nodes | Number of Hidden Layers |

|---|---|---|---|---|---|---|---|---|---|

| Linear | 1:1-1:1 | 0.969 | 1.007 | 1.001 | 0.283 | 0.179 | 0.708 | 1. | 0 |

| MLP | 1:1-11-1:1 | 1.151 | 0.99 | 0.99 | 0.340 | 0.142 | 0.790 | 1. | 11 |

| MLP | 1:1-11-1:1 | 1.293 | 0.97 | 0.99 | 0.378 | 0.141 | 0.775 | 1. | 11 |

| RBF | 1:1-2-1:3 | 0.678 | 0.565 | 0.825 | 0.106 | 0.047 | 0.266 | 1. | 2 |

| RBF | 1:1-3-1:1 | 0.624 | 0.325 | 0.687 | 0.09 | 0.029 | 0.245 | 1. | 3 |

| Time to Perform the Task | The Laboratory Is Able to Handle Shipments of 20 t of Grain | Operating Profit PLN/Day | |

|---|---|---|---|

| Traditional method | 15 min | 68 times | 16,324 |

| New vision method | 3/5 min | 204 times | 31,248.80 |

| Model Type | MLP | Linear | RBF | RBF | MLP |

|---|---|---|---|---|---|

| Correlation coefficient | 0.98 | 0.99 | 0.98 | 0.95 | 0.45 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szwedziak, K.; Grzywacz, Ż.; Polańczyk, E.; Bębenek, P.; Olejnik, M. Optimization of Management Processes in Assessing the Quality of Stored Grain Using Vision Techniques and Artificial Neural Networks. Appl. Sci. 2020, 10, 5721. https://doi.org/10.3390/app10165721

Szwedziak K, Grzywacz Ż, Polańczyk E, Bębenek P, Olejnik M. Optimization of Management Processes in Assessing the Quality of Stored Grain Using Vision Techniques and Artificial Neural Networks. Applied Sciences. 2020; 10(16):5721. https://doi.org/10.3390/app10165721

Chicago/Turabian StyleSzwedziak, Katarzyna, Żaneta Grzywacz, Ewa Polańczyk, Piotr Bębenek, and Marian Olejnik. 2020. "Optimization of Management Processes in Assessing the Quality of Stored Grain Using Vision Techniques and Artificial Neural Networks" Applied Sciences 10, no. 16: 5721. https://doi.org/10.3390/app10165721

APA StyleSzwedziak, K., Grzywacz, Ż., Polańczyk, E., Bębenek, P., & Olejnik, M. (2020). Optimization of Management Processes in Assessing the Quality of Stored Grain Using Vision Techniques and Artificial Neural Networks. Applied Sciences, 10(16), 5721. https://doi.org/10.3390/app10165721