1. Introduction

The intracanal fracture of nickel–titanium (NiTi) rotary files is still one of the main concerns during root canal therapy. It has been demonstrated by many authors that rotary NiTi files essentially fail for two main reasons: flexural (cyclic) fatigue and torsional failure [

1,

2].

The cyclic fatigue failure of the file occurs because of the repeated compressive and tensile stresses that accumulate at the file’s point of maximum-stress, which is located at the maximum curvature point inside the root canal’s anatomy [

3].

Torsional failure occurs when the tip (or some part of the file) binds (or is blocked inside) the root canal, while the motor continues to rotate until the torsional limits are overcome and a fracture occurs [

4].

The mechanical resistance of NiTi rotary files has been tested in two different ways: cyclic fatigue tests and the torsional test. When investigating cyclic fatigue, instruments are usually rotated inside an artificial curved canal until a fracture occurs at the recommended rotation speed. When investigating the torsional resistance, based on the ADA testing recommendations for stainless steel manual files, the tip is usually locked at 2 mm and its rotation speed is 2 rpm. Unfortunately, there is no ADA standard that describes how to test nickel–titanium rotary files; therefore, studies and their results may differ significantly due to the different testing devices and different methodologies [

5,

6,

7].

Over the past several years, improvements in design, alloys and manufacturing processes have been proposed to increase the mechanical resistance of NiTi rotary files. Several proprietary heat treatment applications have been developed. Studies have shown that thermal treatments (for files with the same geometry and design) enhance the cyclic fatigue lifespan while, at the same time, reducing the torsional resistance of a file [

8,

9,

10]. Some studies have also compared heat-treated files and non-heat-treated files with different cross-sectional designs in cyclic fatigue tests, which demonstrate that heat treatment may not be the most influential parameter for flexural resistance [

11]. Therefore, many other factors can influence mechanical resistance. Data have shown that different cross-sectional designs, tip and taper dimensions, pitch lengths, and operative motions could affect the resistance to both the flexural and torsional stresses [

12,

13,

14]. Additional mass increases the torsional resistance and decreases the fatigue resistance [

15].

However, very few studies have compared instruments of the same design (and different heat treatments) for both torsional and fatigue resistance [

16,

17]. Therefore, in the present study, four commercial instruments, with a similar design and tip and taper dimensions, were tested and compared, in order to assess if and how different heat treatments may affect both the torsional and flexural resistance.

2. Materials and Methods

In the current study, four different NiTi rotary files systems were used: EdgeTaper (ET) (EdgeEndo, Albuquerque, New Mexico, NM, USA) and ProTaper Universal (PTU) (Dentsply Tulsa Dental, Tulsa, OK, USA) for the non-heat treated files, and EdgeTaper Platinum (ETP) (EdgeEndo, Albuquerque, New Mexico, NM, USA) and ProTaper Gold (PTG) (Dentsply Tulsa Dental, Tulsa, OK, USA) for the heat-treated files. Each group consisted of 30 brand new files. F1 instruments with a #20 tip size and 0.07 variable taper were used in this study. All the files were inspected for deformities or visible signs of macroscopical defects. The ETP is made of an annealed heat treated (AHT) nickel–titanium alloy brand, named Fire-wire. The PTG is made of a proprietary heat-treated nickel titanium alloy called Gold-wire; the characteristics of this heat treatment are not disclosed by the manufacturer.

2.1. Cyclic Fatigue Resistance Test

Fifteen files from each of the four groups were used. In the present study, a custom-made cyclic fatigue testing device used in many previous studies by the authors [

18,

19,

20], which allowed a reproducible simulation of an instrument confined in a curved canal, was adopted. The device was composed of two main pieces: a mobile device with a holder connected to the handpiece and a stainless steel artificial canal (

Figure 1). The mobile holder ensured a precise and repeatable insertion of the instrument inside the canal at the same length. The artificial canal exhibited a 90° curvature with a 2 mm radius. Each file was inserted to 16 mm and rotated at 300 rpm with a torque of 2.5 Ncm until fracture occurred, according to the manufacturer’s instructions. For each instrument, the time was stopped as soon as the fracture was visible or audible and registered with a 1/100 s chronometer. The fragments were collected and their length measured using a digital caliber.

2.2. Torsional Resistance Test

Fifteen files from each of the four groups were selected for this test. A repetitive torsional test was performed using an experimental torque-controlled endodontic motor, which allowed the recording of the torque values (sensitivity of 0.01 Ncm) during the instrumentation (Kavo Mastersurg, Biberach, Germany) (

Figure 2). The accuracy and reliability of the device was validated in a previous study [

21]. Each file was firmly secured at 3mm from the tip using a vise. The rotational speed was set to 300 rpm, and rotation was performed in a clockwise motion until a fracture occurred; the torque limit was set at 5.5 Ncm to ensure recording measurements that ranged from 0.1 to 5.5 Ncm. The torque values at the point of fracture were recorded using integrated software in the motor and analyzed using spreadsheet software. The time to fracture in seconds and the length of the fractured segments in millimeters were also recorded.

2.3. Scanning Electron Microscopy

After the cyclic fatigue and torsional tests, the fractured rotary files underwent a scanning electron microscopy (SEM) (Hitachi High-Technologies Corporation, Tokyo, Japan) evaluation [

22]. Before the microscopic observation, all the files were treated with absolute alcohol and immersed in an ultrasonic bath for 180 s, in order to remove debris. After that, the rotary files were dried at room temperature and then mounted on metal stubs, using double-sided adhesive tape. The mounted samples were placed inside the SEM. Finally, all of the fractured fragments were observed under the SEM using a secondary electron detector, in order to evaluate the topographic features of the surface.

2.4. Statistical Analysis

The means and standard deviations were calculated and the data analyzed, using Student’s t-test, for the time to fracture and torque limit comparison between the PTU and ET, the PTG and ETP, and the non-treated and heat-treated files. The fragment length and the time to fracture were analyzed using the 1-way ANOVA and the Bonferroni test for multiple comparisons across the groups. The significance was set at the 95% confidence level for both tests.

3. Results

Table 1 shows the results of the cyclic fatigue and torsional resistance data (mean values and Standard Deviation) for the four tested NiTi file systems. In the cyclic fatigue test, the ETP files showed significantly higher resistance than the PTG (files

p < 0.05). The ET files showed significantly higher cyclic fatigue resistance than the PTU files. When comparing the files produced by the same manufacturers, both the heat-treated files (the ETP and PTG) showed a significantly longer lifespan than the non-heat-treated files. The fractured lengths were found to be comparable, respectively (

p > 0.5).

As shown in

Table 2, in terms of the torsional resistance, the ETP files demonstrated no significant differences, in terms of resistance, when compared to the PTG (files

p < 0.05). Similarly, no significant differences were found between the ET and PTU files. For both manufacturers, the non-heat-treated files showed significantly superior torsional resistance to the heat-treated ones (the ET vs. the ETP, and the PTU vs. the PTG). When the torsional stress was applied, no statistically significant differences were found regarding the time to fracture amongst the four groups; the mean values are reported in

Table 2.

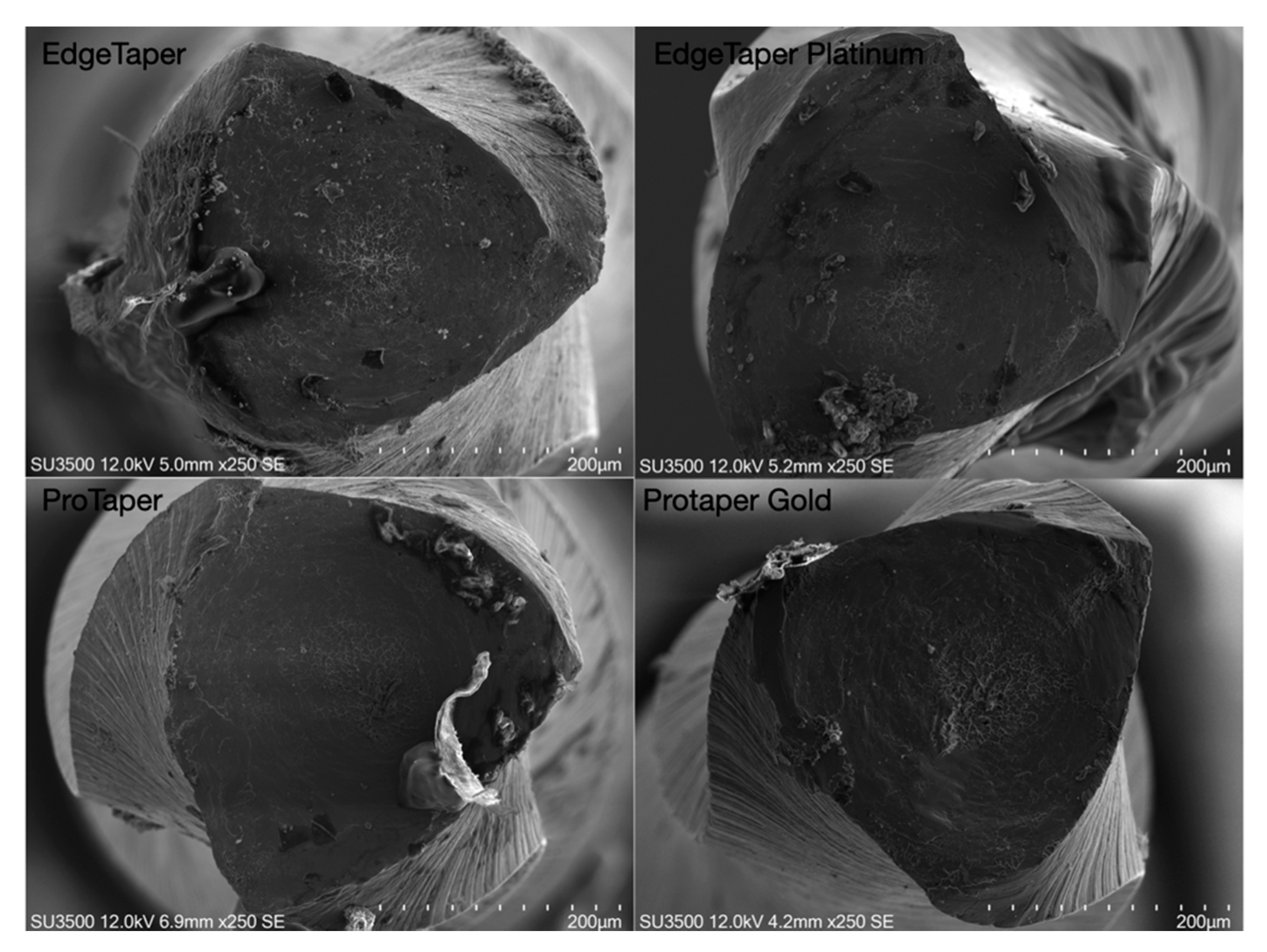

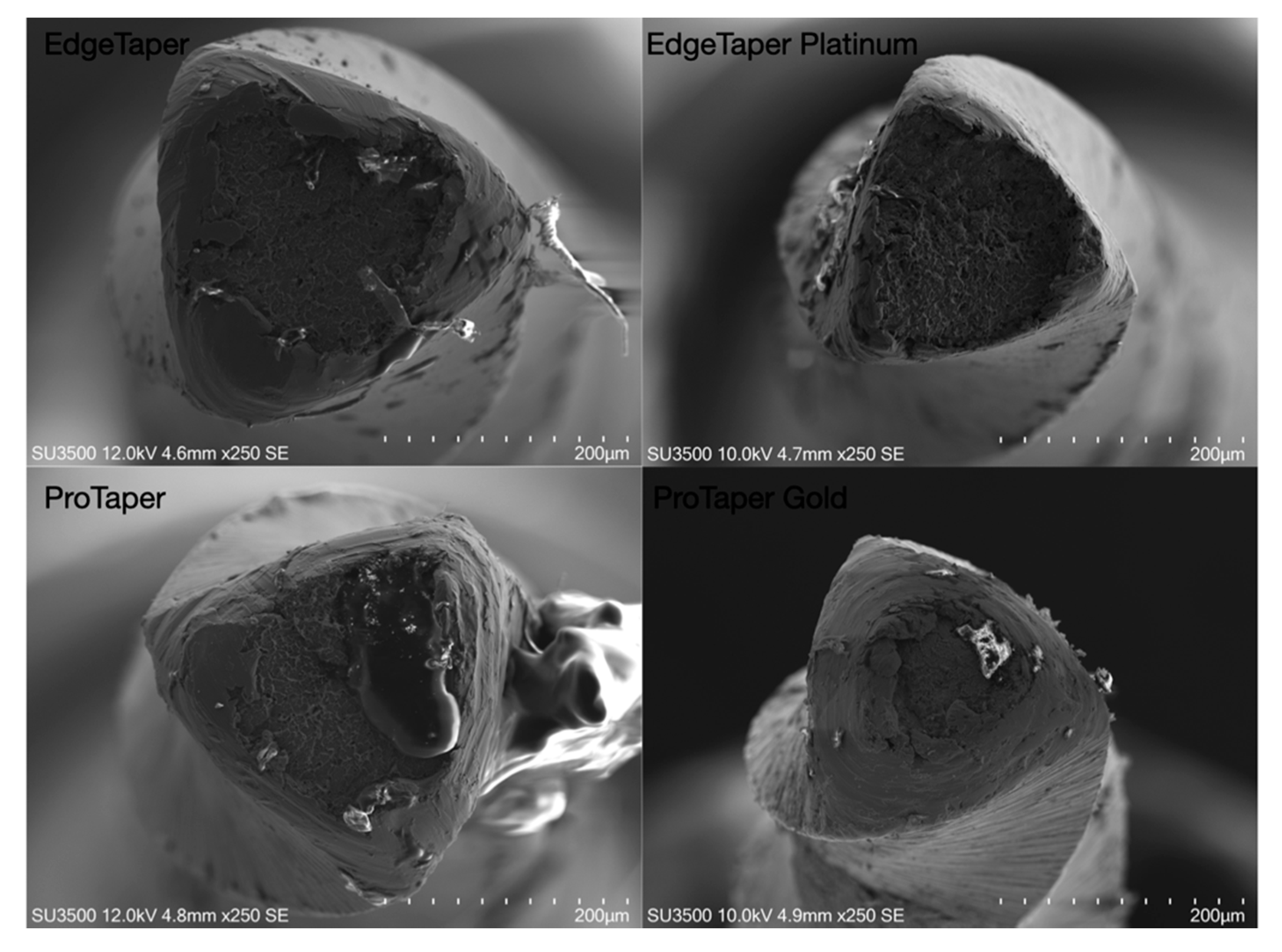

The fractographic analysis of the separated surface is needed to understand the pattern of the leaks that caused the material’s failure and the mechanisms involved in the fracture process [

23,

24]. The surfaces of the fractured files, caused by the torsional failure, present the typical circular abrasion marks (

Figure 3), while the cyclic fatigue failure is characterized by the presence of fatigue striations on the fractured surfaces (

Figure 4). In the current study, the SEM evaluation of the files exhibited the typical fractographic features of flexural and torsional fatigue behavior.

4. Discussion

Despite both flexural and torsional stress occurring simultaneously, very few studies have compared these aspects using both tests [

25,

26]. It has been demonstrated that cyclic flexural loading significantly decreased the torsional resistance of heat-treated rotary files; previous studies also showed that adding torsional loads can move the location of the flexural fracture in the direction of the additionally applied torsional stress [

27,

28].

The torsional resistance was assessed by adopting a technique that is derived from previous studies [

28]. The main difference from the traditional ISO standardized test is that the speed in the present study was the clinical one (300 rpm), while ISO tests are conducted at 2 rpm. This protocol allowed for a more clinically relevant analysis of the time needed to reach the fracture limit of the NiTi rotary files. For the cyclic fatigue test, a static method was used because, in the dynamic fatigue tests, the amplitude of the motions could affect the results. When measuring the torsional resistance, files were tested under very stressful conditions, and the instrument was locked close to the tip. Thus, for the bending tests, the choice was made to subject the files to a similar stressful simulation, using both a severe curvature and a static test [

29].

As shown in the results, the heat treatment processes significantly increased the cyclic fatigue resistance of the NiTi rotary files, while slightly decreasing the torsional resistance. These findings are in accordance with many previously published articles. Such a big improvement in the cyclic fatigue resistance (more than 100%) may have a clinical relevance, even if endodontic rotary files are usually used in vivo for a shorter amount of time and a lower number of cycles. Another advantage of the heat treatment—the increase in the instruments’ flexibility—surely adds more clinical benefits by making the instrumentation easier and reducing the risk of iatrogenic errors. On the other hand, the torsional resistance was decreased by the heat treatment. These findings are in accordance with other studies that have locked the instruments at 3 mm from the tip [

30]. Nevertheless, for all the tested instruments, the mean values of the torque at the point of failure were significantly lower (ranging from 0.93 to 1.08 Ncm) than the torque values recommended by the manufacturers (usually 2–2.5 Ncm). As a consequence, if an instrument is locked inside the canal, the motor will, in any case, provide enough torque to break the file. Interestingly, this could happen in a few seconds, as recorded in this study, for all the instruments. No statistically significant difference in the time to fracture was found between the four tested instruments, showing that the influence of the heat treatment on torsional resistance is probably less relevant. The differences in the torque values and time were minimal, both in terms of the time and force, and probably impossible to be clinically detected. In a cyclic fatigue test, the fracture occurs at the maximum-stress concentration point, which is usually located in the middle of the curvature. In a torsional test, the instrument usually breaks at the point where it is locked. In tapered instruments, the resistance to the bending stress decreases when the diameter increases (more coronally), while the resistance to the torsional stress decreases when the diameter decreases (more apically). For both tests, the stress was applied to a similar portion of the rotary file, in order to minimize the differences that could invalidate the results. In terms of the clinical relevance, and without considering the different stressful conditions related to the specific canal anatomies, the NiTi rotary files have a safer range, in terms of the resistance to bending, when compared to the resistance to the torsional stress. The torsional failure may happen more rapidly and unexpectedly.

The SEM images showed no differences between the heat-treated and non-heat treated files for both manufacturers. All the instruments tested for torsional resistance exhibited the same fractographic patterns, showing shear failure, with concentric abrasion marks and microscopic dimples at the center of the rotation. Similarly, all the four different types of NiTi rotary files tested for cyclic fatigue showed the presence of crack initiation areas and overload. These findings are in accordance with many previously published studies [

31].

Comparing the non-heat-treated NiTi rotary files, the ET and PT showed similar torsional resistance, while the ET showed significantly higher resistance to cyclic fatigue. Since the two tested instruments are very similar, in terms of design and dimensions, such differences may be related to the different alloys or the manufacturing processes (grinding). Comparing the heat-treated NiTi rotary files, the ETP and PTG showed similar torsional resistance, while the ETP showed significantly higher resistance to cyclic fatigue. Since the two tested instruments are very similar, in terms of the design and dimensions, such differences may be related to the different manufacturing processes (the heat treatment and alloy).

5. Conclusions

In conclusion, for both manufacturers, heat treatment revealed a significant impact on increasing the resistance to cyclic fatigue. In contrast, the torsional resistance was not improved by the heat treatments. Moreover, torsional failure may happen rapidly if the files become taper locked, since the recorded torque values at the point of failure were significantly lower than the operative torque values recommended by the manufacturers.

Author Contributions

Conceptualization, G.G. and L.T.; methodology, M.S.; investigation, A.Z.; resources, A.C.; data curation, D.D.N.; writingoriginal draft preparation, G.M.; writingreview and editing, D.D.N.; project administration, G.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cheung, G.S.P. Instrument fracture: Mechanisms, removal of fragments, and clinical outcomes. Endod. Topics 2009, 16, 1–26. [Google Scholar] [CrossRef]

- Gambarini, G. Cyclic fatigue of nickel-titanium rotary instruments after clinical use with low- and high-torque endodontic motors. J. Endod. 2001, 27, 772–774. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Miccoli, G.; Seracchiani, M.; Morese, A.; Piasecki, L.; Gaimari, G.; Di Nardo, D.; Testarelli, L. Fatigue Resistance of New and Used Nickel-Titanium Rotary Instruments: A Comparative Study. Clin. Ter. 2018, 169, e96–e101. [Google Scholar] [PubMed]

- Park, S.Y.; Cheung, G.S.; Yum, J.; Hur, B.; Park, J.K.; Kim, H.C. Dynamic torsional resistance of nickel-titanium rotary instruments. J. Endod. 2010, 36, 1200–1204. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Piasecki, L.; Miccoli, G.; Gaimari, G.; Di Giorgio, R.; Di Nardo, D.; Azim, A.A.; Testarelli, L. Classification and cyclic fatigue evaluation of new kinematics for endodontic instruments. Aust. Endod. J. 2019, 45, 154–162. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Cordaro, M.; Testarelli, L.; Gambarini, G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J. Endod. 2009, 35, 1469–1476. [Google Scholar] [CrossRef]

- Gambarini, G.; Galli, M.; Seracchiani, M.; Di Nardo, D.; Versiani, M.A.; Piasecki, L.; Testarelli, L. In Vivo Evaluation of Operative Torque Generated by Two Nickel-Titanium Rotary Instruments during Root Canal Preparation. Eur. J. Dent. 2019, 13, 556–562. [Google Scholar] [CrossRef]

- Silva, E.J.N.L.; Giraldes, J.F.N.; de Lima, C.O.; Vieira, V.T.L.; Elias, C.N.; Antunes, H.S. Influence of heat treatment on torsional resistance and surface roughness of nickel-titanium instruments. Int. Endod. J. 2019, 52, 1645–1651. [Google Scholar] [CrossRef]

- Gambarini, G.; Galli, M.; Di Nardo, D.; Seracchiani, M.; Donfrancesco, O.; Testarelli, L. Differences in cyclic fatigue lifespan between two different heat treated NiTi endodontic rotary instruments: WaveOne Gold vs EdgeOne Fire. J. Clin. Exp. Dent. 2019, 11, e609–e613. [Google Scholar] [CrossRef]

- Gambarini, G.; Di Nardo, D.; Miccoli, G.; Guerra, F.; Di Giorgio, R.; Di Giorgio, G.; Glassman, G.; Piasecki, L.; Testarelli, L. The Influence of a New Clinical Motion for Endodontic Instruments on the Incidence of Postoperative Pain. Clin. Ter. 2017, 168, e23–e27. [Google Scholar]

- Di Nardo, D.; Galli, M.; Morese, A.; Seracchiani, M.; Ferri, V.; Miccoli, G.; Gambarini, G.; Testarelli, L. A comparative study of mechanical resistance of two reciprocating files. J. Clin. Exp. Dent. 2019, 11, e231–e235. [Google Scholar] [CrossRef] [PubMed]

- Higuera, O.; Plotino, G.; Tocci, L.; Carrillo, G.; Gambarini, G.; Jaramillo, D.E. Cyclic fatigue resistance of 3 different nickel-titanium reciprocating instruments in artificial canals. J. Endod. 2015, 41, 913–915. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Giansiracusa Rubini, A.; Grande, N.M.; Testarelli, L.; Gambarini, G. Cutting efficiency of reciproc and waveone reciprocating instruments. J. Endod. 2014, 40, 1228–1230. [Google Scholar] [CrossRef] [PubMed]

- Gambarini, G.; Miccoli, G.; Seracchiani, M.; Khrenova, T.; Donfrancesco, O.; D’Angelo, M.; Galli, M.; Di Nardo, D.; Testarelli, L. Role of the Flat-Designed Surface in Improving the Cyclic Fatigue Resistance of Endodontic NiTi Rotary Instruments. Materials 2019, 12, 2523. [Google Scholar] [CrossRef] [PubMed]

- Grande, N.M.; Plotino, G.; Pecci, R.; Bedini, R.; Malagnino, V.A.; Somma, F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int. Endod. J. 2006, 39, 755–763. [Google Scholar] [CrossRef]

- Choi, J.; Oh, S.; Kim, Y.C.; Jee, K.K.; Kum, K.; Chang, S. Fracture Resistance of K3 Nickel-Titanium Files Made from Different Thermal Treatments. Bioinorg. Chem. Appl. 2016, 2016, 6374721. [Google Scholar] [CrossRef]

- Jamleh, A.; Alghaihab, A.; Alfadley, A.; Alfawaz, H.; Alqedairi, A.; Alfouzan, K. Cyclic Fatigue and Torsional Failure of EdgeTaper Platinum Endodontic Files at Simulated Body Temperature. J. Endod. 2019, 45, 611–614. [Google Scholar] [CrossRef]

- Al-Sudani, D.; Grande, N.M.; Plotino, G.; Pompa, G.; Di Carlo, S.; Testarelli, L.; Gambarini, G. Cyclic fatigue of nickel-titanium rotary instruments in a double (S-shaped) simulated curvature. J. Endod. 2012, 38, 987–989. [Google Scholar] [CrossRef]

- Plotino, G.; Testarelli, L.; Al-Sudani, D.; Pongione, G.; Grande, N.M.; Gambarini, G. Fatigue resistance of rotary instruments manufactured using different nickel-titanium alloys: A comparative study. Odontology 2014, 102, 31–35. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Mercadé Bellido, M.; Testarelli, L.; Gambarini, G. Influence of temperature on cyclic fatigue resistance of Protaper Gold and Protaper Universal rotary files. J. Endod. 2017, 43, 200–202. [Google Scholar] [CrossRef]

- Gambarini, G.; Seracchiani, M.; Piasecki, L.; Valenti Obino, F.; Galli, M.; Di Nardo, D.; Testarelli, L. Measurement of torque generated during intracanal instrumentation in vivo. Int. Endod. J. 2019, 52, 737–745. [Google Scholar] [CrossRef] [PubMed]

- Relucenti, M.; Miglietta, S.; Bove, G.; Donfrancesco, O.; Battaglione, E.; Familiari, P.; Barbaranelli, C.; Covelli, E.; Barbara, M.; Familiari, G. SEM BSE 3D Image Analysis of Human Incus Bone Affected by Cholesteatoma Ascribes to Osteoclasts the Bone Erosion and VpSEM dEDX Analysis Reveals New Bone Formation. Scanning 2020, 2020, 9371516. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Cheung, G.S. Methods and models to study nickel–titanium instruments. Endod. Topics 2013, 29, 18–41. [Google Scholar] [CrossRef]

- Del Fabbro, M.; Afrashtehfar, K.I.; Corbella, S.; El-Kabbaney, A.; Perondi, I.; Taschieri, S. In Vivo and In Vitro Effectiveness of Rotary Nickel-Titanium vs Manual Stainless Steel Instruments for Root Canal Therapy: Systematic Review and Meta-analysis. J. Evid. Based Dent. Pract. 2018, 18, 59–69. [Google Scholar] [CrossRef]

- Sung, S.Y.; Ha, J.H.; Kwak, S.W.; Abed, R.E.; Byeon, K.; Kim, H.C. Torsional and cyclic fatigue resistances of glide path preparation instruments: G-file and PathFile. Scanning 2014, 36, 500–506. [Google Scholar] [CrossRef]

- Ha, J.H.; Kim, S.K.; Cohenca, N.; Kim, H.C. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J. Endod. 2013, 39, 389–393. [Google Scholar] [CrossRef]

- Acosta, E.C.; Resende, P.D.; Peixoto, I.F.; Pereira, É.S.; Buono, V.T.; Bahia, M.G. Influence of Cyclic Flexural Deformation on the Torsional Resistance of Controlled Memory and Conventional Nickel-titanium Instruments. J. Endod. 2017, 43, 613–618. [Google Scholar] [CrossRef]

- Setzer, F.C.; Böhme, C.P. Influence of combined cyclic fatigue and torsional stress on the fracture point of nickel-titanium rotary instruments. J. Endod. 2013, 39, 133–137. [Google Scholar] [CrossRef]

- Ha, J.H.; Kwak, S.W.; Kim, S.K.; Sigurdsson, A.; Kim, H.C. Effect from Rotational Speed on Torsional Resistance of the Nickel-titanium Instruments. J. Endod. 2017, 43, 443–446. [Google Scholar] [CrossRef]

- Abu-Tahun, I.H.; Ha, J.H.; Kwak, S.W.; Kim, H.C. Evaluation of dynamic and static torsional resistances of nickel-titanium rotary instruments. J. Dent. Sci. 2018, 13, 207–212. [Google Scholar] [CrossRef]

- Yum, J.; Cheung, G.S.; Park, J.K.; Hur, B.; Kim, H.C. Torsional strength and toughness of nickel-titanium rotary files. J. Endod. 2011, 37, 382–386. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).