Abstract

Over the years, solar collecting systems have gained interest in renewable energy. This study investigated improving the efficiency of the working fluid in thermal solar systems by using nanofluids with three concentrations of alumina, 0.1, 0.3, and 0.5 wt%. The UV-vis absorbance, electronic conductivity, and thermal transfer properties of the nanofluids were analyzed, and the thermal changes with exposure to solar radiation in an experimental collector system were measured by pyranometer. The electronic conductivity, thermal conductivity, and UV-vis absorbance increased with the alumina concentration. Moreover, the temperatures of the nanofluids increased more under solar irradiation than that of distilled water. This implies that the alumina nanofluids absorb solar energy more efficiently than water. The findings of this study suggest that the use of both alumina nanofluids and nanoparticles will improve the efficiency of thermal solar power systems.

1. Introduction

Solar energy can be directly utilized in the form of either photovoltaic or thermal energy. The conversion efficiency of solar photovoltaic energy from solar cells using polysilicon materials has reached 24%, which, when compared with the maximum theoretical conversion efficiency for solar photovoltaics of 29%, suggests that the photovoltaic conversion efficiency has reached its maximum. Solar thermal energy, in contrast, has received comparatively little attention.

The utilization of solar thermal energy can be divided into low-, medium-, and high-temperature areas. Low-temperature systems (below 100 °C) generally use a small flat-plate collector to collect and accumulate thermal energy for heating and supplying hot water to buildings, mainly small households [1]. Mid-temperature systems (300 °C or less) serve as an auxiliary heat source for the heating and cooling of buildings, as well as industrial manufacturing processes using a vacuum tube or trough collector. High-temperature systems (above 300 °C) serve as solar power plants. Basically, this power generation method drives a steam turbine that in turn drives multiple generators up to 25 kW in capacity in the form of distributed generation [2].

Thermal solar energy depends strongly on the surrounding environment, making it difficult to obtain precise amounts of energy or sufficient amounts when needed, and thus, supplementary devices are necessary. A thermal solar power plant requires three basic facilities: a heat collecting unit, heat storage unit, and utilization unit. The heat collecting unit increases the temperature of the working fluid by collecting solar thermal energy; the heat storage unit collects and stores the thermal energy from the high-temperature working fluid; and the utilization unit converts the heat energy into useable energy. All thermal solar systems require a working fluid to transport and utilize the heat energy absorbed from the sun; air, water, steam, and molten salt are current examples of working fluids [3].

The nanofluid theoretically suggested by Maxwell [4] in 1873 was not viable at the time due to the absence of nanoparticle fabrication technology, but today, research on and fabrication of various nanofluids are ongoing. In 1975, Ahuja [5] reported that a fluid with a micrometer-sized particle dispersion showed promising thermal properties but could not be applied to actual cooking systems due to blockage and corrosion of pipes from particle precipitation. In 1995, Choi [6] of the Argonne National Laboratory research team in the United States first introduced the term “nanofluid,” which was defined as a fluid in which nanoparticles less than 100 nm in size are dispersed. The authors reported that the thermal conductivity of nanofluids is significantly higher than that of conventional heat transfer fluids. In particular, it has since been reported that the thermal conductivity of nanofluids is more than 10% higher than that of other fluids, even at a small nanoparticle volume ratio, and the heat transfer properties are greatly improved compared with those of conventional fluids [7].

Gude et al. [1] studied the energy and emission duration of solar collector systems in South Korea and suggested the need for heat energy storage based on the theoretical results. El Fadar et al. [8] and Fan et al. [9] demonstrated the feasibility of a lightweight adsorption refrigeration system that is efficiently driven by a combination of a solar parabolic trough collector (PTC) and heat pipes; they also proved that the PTC is useful for improving solar adsorption refrigeration systems. Additionally, the authors concluded that this technology meets the requirements for not only cooling, freezing, ice manufacturing, and condensing purposes but also for energy and environmental conservation. Laing et al. [10] reported that a heat storage system with a modular configuration meets the required storage capacity for the evaporation section and is thus a promising option for application in direct steam generation plants. Zambolin and Del Col [11] compared the characteristics of a standard glass plate collector and vacuum tube collector by evaluating the efficiencies based on corrected and quasi-static conditions. Dincer and Dost [12] demonstrated that the use of a thermal energy storage system is essential in solar energy systems due to variable solar inputs. Mahian et al. [13] studied the effect of nanofluids on the performance of solar collectors and water heaters and found a dependency on the nanofluid volume fraction and particle size. Yousefi et al. [14,15] reported the use of alumina (Al2O3) nanofluid as the working fluid for flat-plate solar collectors and demonstrated its higher efficiency than water. Mokhatab et al. [16] investigated nanotechnology in general and reported that nanotechnology is more innovative, precise, and future-oriented than other technologies. Balandin [17] reviewed the thermal properties of graphene, carbon nanotubes, and nanostructured carbon materials with different irregularities and assessed their potential applications in thermal management. Wang et al. [18] studied the dispersibility and thermal conductivity of single-walled carbon nanotubes (SWCNTs) and reported that nanofluid dispersions of shorter SWCNTs have a higher thermal conductivity than resin-pristine SWCNT composites. Kim et al. [19] confirmed that thermal conductivity increased with nanofluid concentration and showed that the efficiency of the nanofluids improved in the order of multi-walled carbon nanotubes (MWCNTs), CuO, Al2O3, TiO2, and SiO2 based on their thermal performance in a U-type solar collector. Wen and Ding [20] experimentally examined pool boiling using γ-alumina nanofluids and confirmed that the heat transfer performance increased with γ-alumina particle concentration. Huang et al. [21] observed the changes in pressure and continuous transfer performance of alumina and MWCNT nanofluids in chevron plate heat exchangers and reported that the nanofluid viscosity increased with nanoparticle concentration, leading to a pressure drop significantly higher than that of water. Teng et al. [22] measured the thermal conductivity of alumina nanofluids depending on the diameter of the alumina particles and temperature and reported a higher thermal conductivity with smaller particles and higher temperatures. Wu et al. [23] studied the thermal properties of alumina nanofluids for use as a new phase-change material in cooling systems and concluded that the addition of alumina nanoparticles alone reduced the solidification time of the fluid and thus improved the performance of the refrigeration system. Kim et al. [24] examined the performance of a U-type solar collector according to the concentration and particle size of alumina nanofluids and reported that the nanofluid thermal conductivity increased with increasing nanofluid concentration and decreasing alumina nanoparticle size. Tong et al. [25] analyzed the thermal performance of enclosed-type evacuated U-tube solar collectors using a MWCNT nanofluid as the working fluid and demonstrated that the heat transfer coefficient between the tube and working fluid is higher than that of water. Huminic and Huminic [26] investigated the heat transfer properties of two-phase closed thermosyphons using SiC nanofluids and confirmed that increasing the SiC nanofluid concentration increases the thermal conductivity and heat transfer performance compared with water.

Contrary to previous studies in which the nanofluid was found to change the efficiency of the thermal solar energy system, in this study, alumina nanofluids were applied with different concentrations as the working fluid in a thermal solar energy collection system. The heat transfer characteristics according to alumina nanofluid concentration when applied to an actual solar collector system by analyzing the solar heat absorption characteristics of the nanofluids with a good dispersibility according to their concentration and performance in a real environment were examined.

2. Experimental

2.1. Sample Preparation

For making the nanofluid, the distilled water (DW) and -Alumina nanoparticles were used. The DW produced through the membrane type DW maker maintained the water quality under 10 ppm of total dissolved solids (TDS). According to the specification of the nanoparticle supplier, the nanoparticle size was 40 nm, the density was 3.9 g/cm3, and the heat conductivity was 42.34 W/m·K. Alumina nanofluids were prepared at concentrations of 0.5, 0.3, and 0.1 wt%, and distilled water (DW) was also tested for comparison. According to Rehman et al. [27], who experimentally studied the sedimentation and the dispersion behavior of alumina-water nanofluids with the dependence on time, it was reported that 3.0 and 5.0 wt% alumina nanofluids with 3 h ultrasonic time had the best dispersion results. In this study, the coalesced Alumina nanoparticles were mixed with the DW and then excited by using an ultrasonic exciter to split the coalesced particles into their original size and to uniformly disperse the nanoparticles in the base liquid. Excitation frequency and period were 42 kHz and 3 h, respectively.

2.2. Characterization

The UV/VIS spectrophotometer (X-ma 3000 Series Spectrophotometer, Human Co., Ltd., Seoul, Korea) was used to investigate the dispersion degree of nanoparticles in the nanofluid. The LAMBDA system, which was based on the hot-wire method, was performed for measuring the thermal conductivity of nanofluid. This wire served as both the heating unit and thermometer, as there is a linear relationship between the electrical resistance and the temperature of the wire. The detailed process was introduced in previous studies [28]. The electrical conductivity of fluids with nanoparticles was used in this study. Calibration was performed with standard potassium chloride (1.41, 12.86 μS/cm) solutions before the measurement. The nanofluid temperature variation with solar radiation was investigated through a data logger with the capacity of 10 to 40 input channels and a 200–1100 °C range.

2.3. Apparatus and Measurement of Solar System Performance According to Nanofluid Concentration

A 1000 mL glass beaker was used as a solar collector, and the inlet of the nanofluid was sealed with wrap to prevent evaporation. To prevent precipitation of the nanofluid and create flow conditions similar to those of working fluid within a solar collector, a DC motor and fan were installed. The DC motor (9 V, 500 mA) was operated at either 96 or 325 rpm; at 325 rpm, precipitation did not occur. The DC supply device used an input of 220 V, 60 Hz, and 0.5 A, and a fast charger for mobile phones with an output voltage of 9 V and an output current of 2 A were used. The DC motors were connected in parallel to the supply device so that 500 mA of current could be supplied to a voltage of 9 V in order to fully utilize the motor performance. This detailed measurement system has been introduced in previous studies [29].

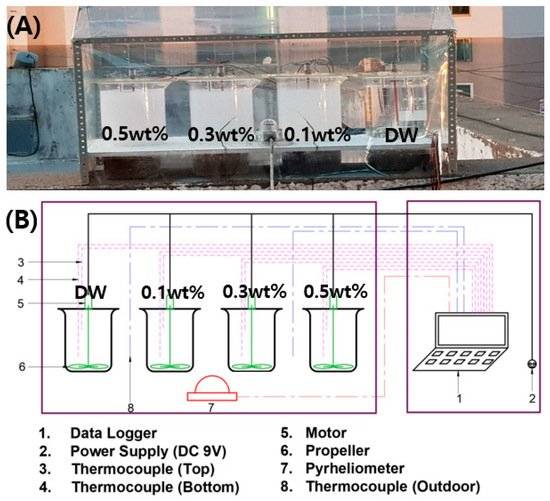

Figure 1A shows a photograph of the experimental apparatus, and Figure 1B shows a schematic diagram. The ingot on the beaker that was used to fix the motor was later replaced by acrylic plates to prevent shadows. Thermocouples were installed in the solar system to check the outside temperature and working fluid temperature, and a pyranometer was installed to measure the solar radiation. All thermocouples were installed with a length of 2.5 m to eliminate any measurement errors associated with length-dependent resistance. To minimize the temperature measurement error, two thermocouples were installed in each beaker, and the temperature of each fluid was collected by a data logger. A commercial drone fan was installed in the motor to prevent precipitation, and all experiments were conducted under the same conditions. Thus, the flow rate of the fluid within the container was not considered.

Figure 1.

(A) Experimental apparatus and (B) schematic diagram.

3. Results and Discussion

3.1. Dispersion Measurement of Alumina Nanofluids

A uniform dispersion and stable suspension of nanoparticles in the dispersing media are essential for nanofluid applications since they determine the final properties [30]. Especially, solar absorption capacity depends on the dispersion of nanoparticles in nanofluids. Therefore, the dispersion of alumina nanofluids can be characterized using UV-vis spectroscopy in this study.

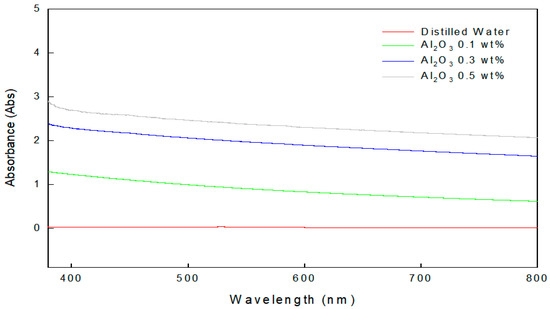

The dispersions of alumina nanofluids at concentrations of 0.5, 0.3, and 0.1 wt% were measured by UV-vis spectroscopy. Figure 2 shows that the higher the concentration, the higher the absorbance, which indicates that increasing the concentration results in a higher solar absorption capacity.

Figure 2.

UV-vis absorbance of the base liquid (distilled water (DW)) and nanofluids with three different alumina concentrations.

3.2. Thermal Conductivity of Alumina Nanofluids

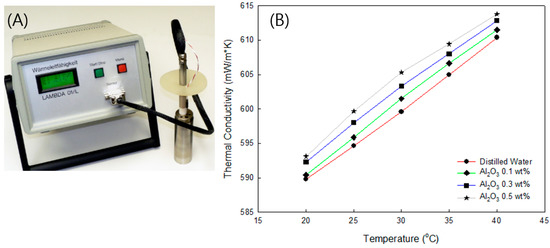

Nanofluid thermal conductivity is an important transport property for practical applications. As seen in Figure 3A, in this study, thermal conductivity was measured with respect to temperature by the lambda system. The LAMBDA system measures the thermal conductivity of fluids according to ASTM D 2717. The measurement principle is based on a resistance measurement using a hot-wire with a diameter of only 100 μm. The sample temperature was controlled by a special double-jacket heating/cooling device which provided a homogeneous temperature distribution. It was calibrated with DW before measurements. For a better comparison, alumina nanofluids were measured and plotted. Therefore, as shown in Figure 3B, thermal conductivity increased with alumina concentration. Which indicates that increasing the concentration results in a higher thermal conductivity. The thermal conductivity was increased with a temperature due to the increased intermolecular collision. The measured thermal conductivities showed the traditional liquid characteristic, and the thermal conductivity was increased with the nanoparticle concentration.

Figure 3.

(A) Thermal conductivity measuring system; (B) thermal conductivity of DW and alumina nanofluids.

3.3. Electrical Conductivity of Alumina Nanofluids

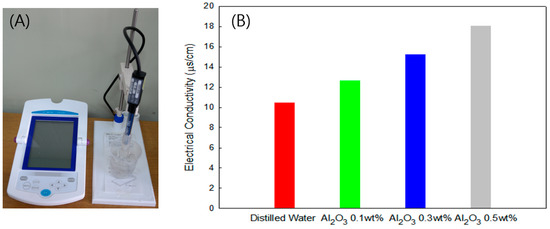

The electrical conductivity value is a unique property in the field of microelectronics and electromechanical instruments. To confirm the dispersion characteristics, electrical conductivity was also measured for different alumina concentrations by a conductivity meter. An electrical conductivity meter (Model CM-25R) is a contacting-type conductivity sensor usually consisting of electrodes. The titanium–palladium alloy electrode was specifically sized and spaced to provide a known cell constant. The photograph of the conductivity meter (Model CM-25R, DKK-TOA Co., Ltd., Tokyo, Japan) is shown in Figure 4A. Before the measurement, the calibration was performed with a potassium chloride standard solution. Figure 4B shows the electrical conductivity of each concentration of nanofluids. In case of 0.5 wt%, the increased electrical conductivity was 73.2% compared to the base fluid (DW). As shown in Figure 4, the electrical conductivity also increased with alumina concentration.

Figure 4.

(A) Electrical conductivity Meter; (B) electrical conductivity of DW and alumina nanofluids.

3.4. Solar System Performance Depending on Alumina Concentration

An experimental apparatus was installed, and the data with respect to the amount of solar radiation were graphically represented. The accumulated time was cumulative with an increment of 1 corresponding to 1 min beginning at 00:00 on January 1, 2018. Stable temperature distributions were observed on September 22 and 24 due to relatively stable solar radiation. Accordingly, the experimental results for these days were analyzed.

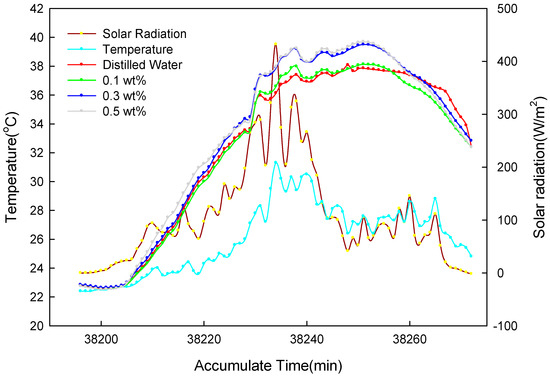

3.4.1. Temperature Distribution of Nanofluid According to Solar Radiation on September 22

Figure 5 shows the solar radiation and temperature distribution measured on September 22. There was an increase of 13.54 °C in the DW and of 13.97, 15.23, and 15.42 °C in the 0.1, 0.3, and 0.5 wt% alumina nanofluids, respectively. These, respectively, equate to 3.1%, 12.5%, and 13.9% temperature increases compared with DW. The experimental results are also given in Table 1.

Figure 5.

Temperature and solar radiation according to accumulated time (22 September 2018).

Table 1.

Changes in DW and alumina nanofluid temperatures on 22 September 2018.

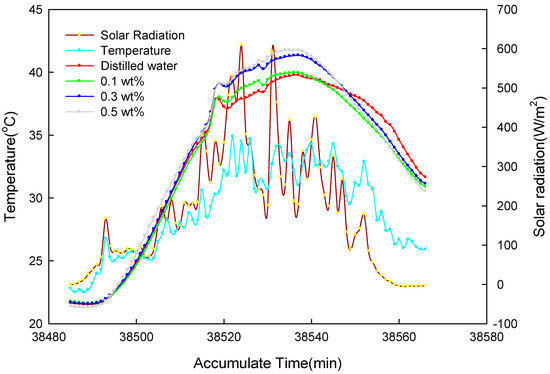

3.4.2. Temperature Distribution of Nanofluids According to Solar Radiation on September 24

According to the analysis of solar radiation and temperature distribution shown in Figure 6, DW increased by 18.13 °C, and the 0.1, 0.3, and 0.5 wt% alumina nanofluid temperatures increased by 18.21, 19.59, and 20.23 °C corresponding to percentage increases of 0.4%, 8.1%, and 11.6%, respectively, compared with DW. The results are shown in Table 2. Thus, it can be concluded that an increase in nanofluid concentration leads to increased nanofluid heat absorption. The experimental results showed that the 0.3 wt% nanofluid exhibited the highest efficiency when considering the efficiency of the alumina nanofluid.

Figure 6.

Temperature and solar radiation according to accumulated time (24 September 2018).

Table 2.

Changes in DW and alumina nanofluid temperatures on 24 September 2018.

4. Conclusions

With the consideration of using renewable energy in the industry, direct absorption solar collectors have been reported for a variety of applications such as water heating. However, solar collectors have limited efficiency due to poor absorption characteristics of the working fluid. Therefore, in this study, the solar heat collection system was investigated by conducting quantitative performance experiments using DW as the base fluid and three alumina nanofluids at 0.1, 0.3, and 0.5 wt% and measuring the solar radiation in a real environment.

The characteristics of the alumina nanofluid were experimentally studied by using an actual solar collector system. It shows that dispersibility is a very important factor for absorbing the solar heat source. As a result, the following conclusions were obtained.

- The UV-vis absorbance of the nanofluids increased with alumina concentration and reached a maximum for the 0.5 wt% nanofluid, demonstrating its potential for solar thermal systems.

- The electrical conductivity of the nanofluids increased with alumina concentration. The electrical conductivities of the 0.1, 0.3, and 0.5 wt% alumina nanofluids were 21.3%, 46.2%, and 73.2% higher, respectively, than that of DW.

- The thermal conductivity of the nanofluids increased with alumina concentration and with temperature. The thermal conductivities of the 0.1, 0.3, and 0.5 wt% alumina nanofluids were 0.32%, 0.62%, and 0.95% higher, respectively, than that of DW.

- In a real thermal solar collection system, the temperature increases for the 0.1, 0.3, and 0.5 wt% alumina nanofluids were 3.1%, 12.5%, and 13.9% higher, respectively, than that of DW. The optimum fluid condition was determined as 0.3 wt% alumina due to greatest thermal increase by concentration.

In general, the fluid temperature increased with the concentration of alumina in the nanofluid, but significantly better results can be obtained when optimizing the fluid dispersibility and stability. This study shows that there are various factors that must be considered in future research on the utilization of thermal solar energy in the development of alternative energy sources. Aside from alumina nanofluids, using multiple types of nanoparticles and various dispersion methods could further improve the efficiency. We believe that this study will aid in finding solutions for the utilization of solar thermal energy, which has been developed at a slower pace than solar photovoltaic power due to efficiency issues, to ultimately develop an optimal solar system.

Author Contributions

Y.L. and H.J.; conceptualization, S.K.; data curation, S.K.; formal analysis, methodology, Y.L. and H.J.; investigation, Y.L.; validation, Y.L.; writing—original draft, J.-T.P.; resources A.D.; supervision, writing-review, editing, S.K. and A.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and future Planning (No. 2017R1A2B4007620).

Conflicts of Interest

This manuscript has not been published or presented elsewhere in part or in entirety and is not under consideration by another journal. We have read and understood your journal’s policies, and we believe that neither the manuscript nor the study violates any of these. There are no conflicts of interest to declare.

References

- Gude, V.G.; Nirmalakhandan, N.; Deng, S.; Maganti, A. Low temperature desalination using solar collectors augmented by thermal energy storage. Appl. Energy 2012, 91, 466–474. [Google Scholar] [CrossRef]

- Barlev, D.; Vidu, R.; Stroeve, P. Innovation in concentrated solar power. Sol. Energy Mater. Sol. Cells 2011, 95, 2703–2725. [Google Scholar] [CrossRef]

- Wen, D.; Lin, G.; Vafaei, S.; Zhang, K. Review of nanofluids for heat transfer applications. Particuology 2009, 7, 141–150. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Clarendon Press: Oxford, UK, 1873. [Google Scholar]

- Ahuja, S. Augmentation of heat transfer in laminar flow of polystyrene suspensions. J. Appl. Phys. 1975, 46, 3408–3425. [Google Scholar] [CrossRef]

- Choi, S.U.S. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Developments and Applications of Non-Newtonian Flows; American Society of Mechanical Engineers Fluid Engineering Division: New York, NY, USA, 1995; Volume 231, pp. 99–105. [Google Scholar]

- Jang, S.P.; Choi, S.U.S. The role of Brownian motion in the enhanced thermal conductivity of nanofluids. Appl. Phys. Lett. 2004, 84, 4316–4318. [Google Scholar] [CrossRef]

- El Fadar, A.; Mimet, A.; Azzabakh, A.; Pérez-García, M.; Castaing, J. Study of a new solar adsorption refrigerator powered by a parabolic trough collector. Appl. Therm. Eng. 2009, 29, 1267–1270. [Google Scholar] [CrossRef]

- Fan, Y.; Luo, L.; Souyri, B. Review of solar sorption refrigeration technologies: Development and applications. Renew. Sustain. Energy Rev. 2007, 11, 1758–1775. [Google Scholar] [CrossRef]

- Laing, D.; Bahl, C.; Bauer, T.; Lehmann, D.; Steinmann, W.D. Thermal energy storage for direct steam generation. Sol. Energy 2011, 85, 627–633. [Google Scholar] [CrossRef]

- Zambolin, E.; Del Col, D. Experimental analysis of thermal performance of flat plate and evacuated tube solar collectors in stationary standard and daily conditions. Sol. Energy 2010, 84, 1382–1396. [Google Scholar] [CrossRef]

- Dincer, I.; Dost, S. A perspective on thermal energy storage systems for solar energy applications. Int. J. Energy Res. 1996, 20, 547–557. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Kalogirou, S.A.; Pop, I.; Wongwises, S. A review of the applications of nanofluids in solar energy. Int. J. Heat Mass Trans. 2013, 57, 582–594. [Google Scholar] [CrossRef]

- Yousefi, T.; Veysi, F.; Shojaeizadeh, E.; Zinadini, S. An experimental investigation on the effect of Al2O3–H2O nanofluid on the efficiency of flat-plate solar collectors. Renew. Energy 2012, 39, 293–298. [Google Scholar] [CrossRef]

- Yousefi, T.; Veisy, F.; Shojaeizadeh, E.; Zinadini, S. An experimental investigation on the effect of MWCNT-H2O nanofluid on the efficiency of flat-plate solar collectors. Exp. Therm. Fluid Sci. 2012, 39, 207–212. [Google Scholar] [CrossRef]

- Mokhatab, S.; Fresky, M.A.; Islam, M.R. Applications of nanotechnology in oil and gas E&P. J. Pet. Technol. 2006, 58, 48–51. [Google Scholar]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liang, R.; Wang, B.; Zhang, C. Dispersion and thermal conductivity of carbon nanotube composites. Carbon 2009, 47, 53–57. [Google Scholar] [CrossRef]

- Kim, H.; Ham, J.; Park, C.; Cho, H. Theoretical investigation of the efficiency of a U-tube solar collector using various nanofluids. Energy 2016, 94, 497–507. [Google Scholar] [CrossRef]

- Wen, D.; Ding, Y. Experimental investigation into the pool boiling heat transfer of aqueous based γ-alumina nanofluids. J. Nanopart. Res. 2005, 7, 265–274. [Google Scholar] [CrossRef]

- Huang, D.; Wu, Z.; Sunden, B. Pressure drop and convective heat transfer of Al2O3/water and MWCNT/water nanofluids in a chevron plate heat exchanger. Int. J. Heat Mass Trans. 2015, 89, 620–626. [Google Scholar] [CrossRef]

- Teng, T.P.; Hung, Y.H.; Teng, T.C.; Mo, H.E.; Hsu, H.G. The effect of alumina/water nanofluid particle size on thermal conductivity. Appl. Therm. Eng. 2010, 30, 2213–2218. [Google Scholar] [CrossRef]

- Wu, S.; Zhu, D.; Li, X.; Li, H.; Lei, J. Thermal energy storage behavior of Al2O3–H2O nanofluids. Thermochim. Acta 2009, 483, 73–77. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.; Cho, H. Experimental study on performance improvement of U-tube solar collector depending on nanoparticle size and concentration of Al2O3 nanofluid. Energy 2017, 118, 1304–1312. [Google Scholar] [CrossRef]

- Tong, Y.; Kim, J.; Cho, H. Effects of thermal performance of enclosed-type evacuated U-tube solar collector with multi-walled carbon nanotube/water nanofluid. Renew. Energy 2015, 83, 463–473. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A. Heat transfer characteristics of a two-phase closed thermosyphons using nanofluids. Exp. Therm. Fluid Sci. 2011, 35, 550–557. [Google Scholar] [CrossRef]

- Rehman, H.; Batmunkh, M.; Jeong, H.; Chung, H. Sedimentation Study and Dispersion Behavior of Al2O3–H2O Nanofluids with Dependence of Time. Adv. Sci. Lett. 2012, 6, 96–100. [Google Scholar] [CrossRef]

- Bentley, J.P. Temperature sensor characteristics and measurement system design. J. Phys. E Sci. Instrum 1984, 17, 430. [Google Scholar] [CrossRef]

- Ghafurian, M.M.; Niazmand, H.; Dastjerd, F.T.; Mahian, O. A study on the potential of carbon-based nanomaterials for enhancement of evaporation and water production. Chem. Eng. Sci. 2019, 207, 79–90. [Google Scholar] [CrossRef]

- Ghafurian, M.M.; Akbari, Z.; Niazmand, H.; Mehrkhah, R.; Wongwises, S.; Mahian, O. Effect of sonication time on the evaporation rate of seawater containing a nanocomposite. Ultrason. Sonochem. 2020, 61, 104817. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).