A Decision-Support Model for Additive Manufacturing Scheduling Using an Integrative Analytic Hierarchy Process and Multi-Objective Optimization

Abstract

1. Introduction

2. Literature Review

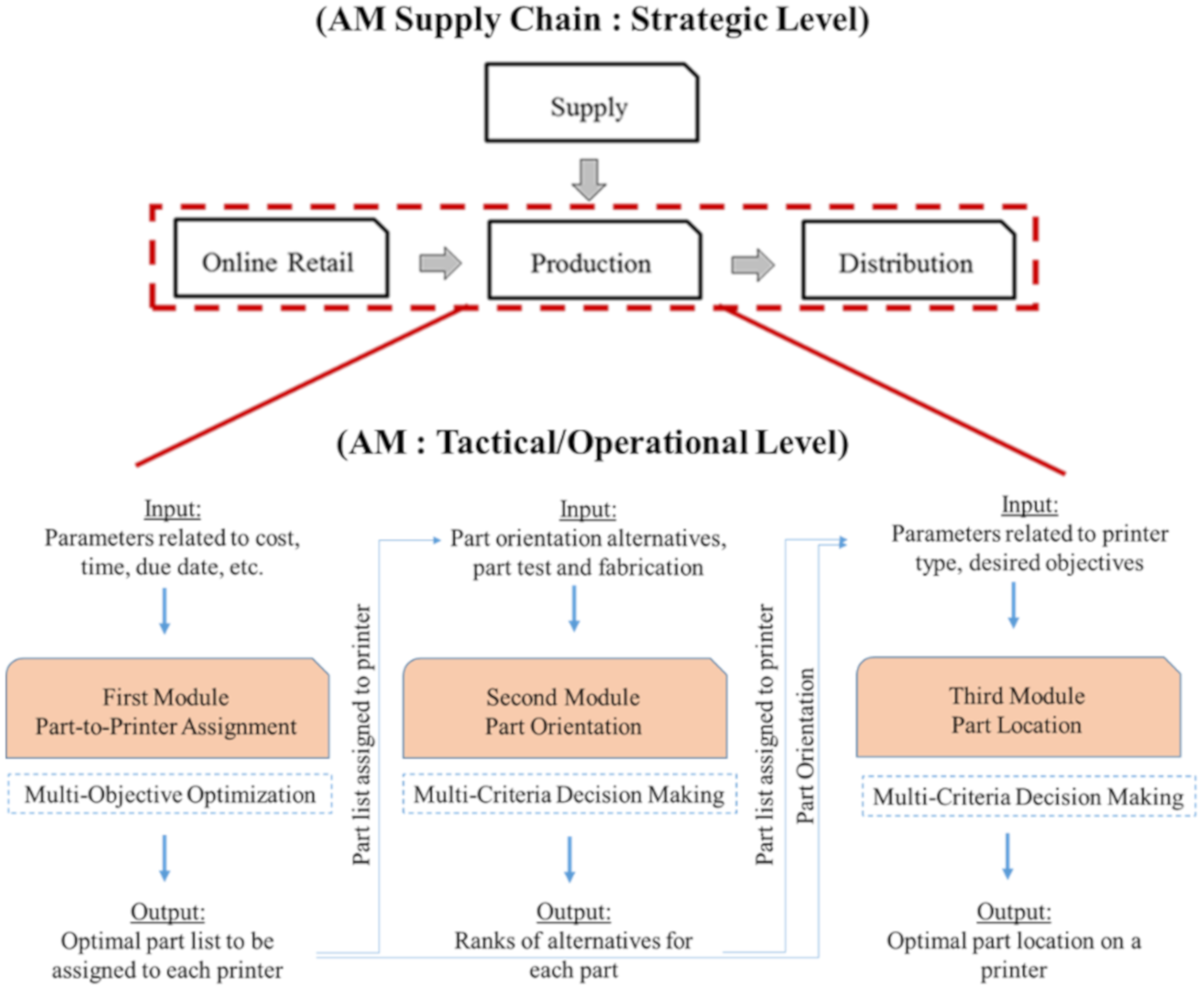

- Researchers typically considered a single economic objective. However, process planning involves multiple conflicting criteria from different stakeholders. Thus, this work employed a multi-objective technique to account for the diverse requirements needed when process planning in AM.

- Existing models generally considered problems at either the production or distribution planning level; the lack of integration between these two problems likely causes sub-optimality for the planners. As such, this work aimed to account for production and distribution planning.

- Process planning in AM involves various stakeholders with often conflicting requirements involving trade-offs. Thus, an AHP approach was introduced as the tool used to assess the decision analysis under multiple criteria to analyze decision-makers’ preferences under the diverse objectives of the multi-objective optimization model.

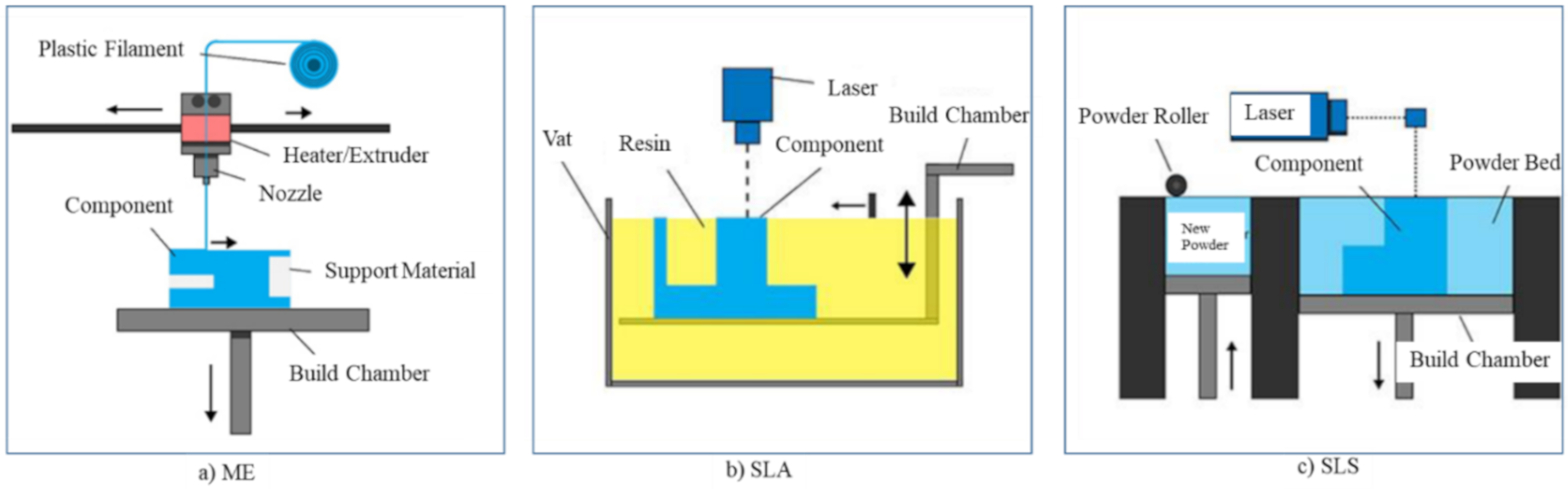

- Rather than investigating a singular AM technology as prior researchers have tended to do, three AM technologies (i.e., ME, SLA, and SLS technologies) were combined and analyzed to review various aspects of AM; in addition, a case study was used to verify and validate the model. In particular, the energy source used and the part nesting or stacking capability of the build chamber were analyzed.

- Although AM planning-related mathematical models were recently proposed in the literature, these models lack integration with the DSS, which prohibits decision-makers that are not familiar with the mathematical notations to properly plan for their actual process. Thus, a decision-support tool was developed here to aid AM practitioners.

3. Multi-Objective Optimization Model

3.1. Problem Statement

3.1.1. Printer Time

3.1.2. Part Nesting/Stacking

3.2. Assumptions

- The printer type required for the parts ordered from customers is known. That is, the customer discusses with the manufacturer and decides beforehand which technology to use for printing. In addition, the manufacturer and customers have agreed on the properties and tolerances of the printed parts on each printer, the material desired for each specific part, and the due date to receive the printed parts.

- In this study, all assigned parts were assumed to be taken out from a printer at the same time to properly associate the time-related parameters for parts to the due date of consumers. In addition, as the total printing time for SLS and SLA depends on the layout in a batch and scanned laser technology, the scanning time for a layer is likely much less than recoating time (z-directional moving) for the printing process. Thus, to simplify the mathematical model, the print time for SLS and SLA technologies was approximated and assumed based on the maximum time of all parts, which are less than the print time for all parts. On the other hand, the print time for ME was approximated and assumed from the print time for all parts.

- Although the SLS printers sometimes need a support structure to avoid deformation from residual stress depending on the specific material used, such as metals, we assumed in this study that the manufacturer can use a surrounding powder in a build chamber to allow part nesting and to use the maximum efficiency of a printer, which is possible for some materials, such as Polyamide. On the other hand, parts to be printed do not stack on top of each other for the ME and SLA printers.

- The time- and cost-related parameters were also simplified and extrapolated from the Magics software version 18.03 from Materilise, Belgium [38] and existing literature (e.g., see [34]) to reduce the complexity of the developed model. For example, the printer cost in this study was approximated from the indirect cost involving the technician, overhead, and machine costs. The part times and costs were directly obtained from an estimate from the Magics software. The part costs, in particular, were approximated from the consumed material for each part, support (if needed), and associated waste; meanwhile, the part print time was inclusive of the printer preparation time, cooling time, and post-processing time.

3.3. Model Notation

3.3.1. Sets and Indices

3.3.2. Parameters

3.3.3. Decision Variables

3.3.4. Other Time-Related Variables

3.4. Multi-Objective Optimization Model

3.4.1. Multi-Objective Function

3.4.2. Constraint Sets

4. Multi-Objective Solution

4.1. Non-Preemptive Solution Approach

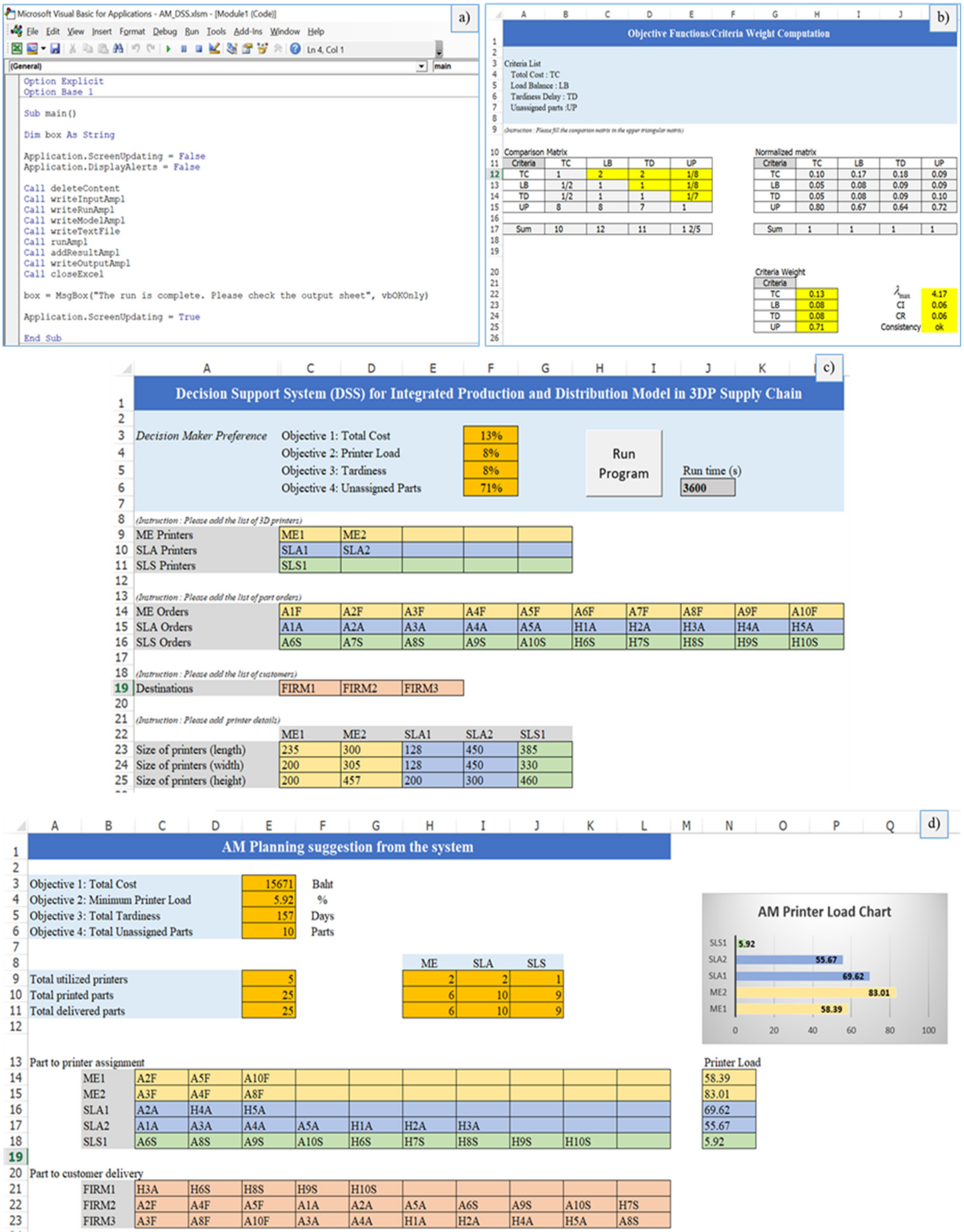

4.2. Analytic Hierarchy Process (AHP)-Based Criteria Weights

5. Case Study and Discussion

5.1. Case Study Data

5.2. Multi-Objective Solution

5.3. Decision-Support System

5.4. Computation Time Result

6. Conclusions and Future Research

Author Contributions

Funding

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. Cirp Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report 2018; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2018. [Google Scholar]

- Ha, S.; Ransikarbum, K.; Kim, N. Phenomenological deformation patterns of 3D printed products in a selective laser sintering process. In Proceedings of the 18th International Conference on Industrial Engineering, Seoul, Korea, 10–12 October 2016; pp. 10–12. [Google Scholar]

- Ha, S.; Ransikarbum, K.; Han, H.; Kwon, D.; Kim, H.; Kim, N. A dimensional compensation algorithm for vertical bending deformation of 3D printed parts in selective laser sintering. Rapid Prototyp. J. 2018, 24, 955–963. [Google Scholar] [CrossRef]

- Kim, N.; Bhalerao, I.; Han, D.; Yang, C.; Lee, H. Improving surface roughness of additively manufactured parts using a photopolymerization model and multi-objective particle swarm optimization. Appl. Sci. 2019, 9, 151. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Kim, N. Multi-criteria selection problem of part orientation in 3D fused deposition modeling based on analytic hierarchy process model: A case study. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 1455–1459. [Google Scholar]

- Ransikarbum, K.; Kim, N. Data envelopment analysis-based multi-criteria decision making for part orientation selection in fused deposition modeling. In Proceedings of the 2017 4th International Conference on Industrial Engineering and Applications (ICIEA), Nagoya, Japan, 21–23 April 2017; pp. 81–85. [Google Scholar]

- Ransikarbum, K.; Pitakaso, R.; Kim, N. Evaluation of Assembly Part Build Orientation in Additive Manufacturing Environment using Data Envelopment Analysis. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 293, p. 02002. [Google Scholar]

- Ransikabum, K.; Yingviwatanapong, C.; Leksomboon, R.; Wajanavisit, T.; Bijaphala, N. Additive Manufacturing-based Healthcare 3D Model for Education: Literature Review and A Feasibility Study. In Proceedings of the 2019 Research, Invention, and Innovation Congress (RI2C), Bangkok, Thailand, 11–13 December 2019; pp. 1–6. [Google Scholar]

- Sculpteo. Comparison between 3D Printing and Traditional Manufacturing Processes for Plastics. 2018. Available online: http://www.sculpteo.com/en/3d-printing (accessed on 5 June 2018).

- Ransikarbum, K.; Ha, S.; Ma, J.; Kim, N. Multi-objective optimization analysis for part-to-Printer assignment in a network of 3D fused deposition modeling. J. Manuf. Syst. 2017, 43, 35–46. [Google Scholar] [CrossRef]

- Taufik, M.; Jain, P.K. Role of build orientation in layered manufacturing: A review. Int. J. Manuf. Technol. Manag. 2013, 27, 47–73. [Google Scholar] [CrossRef]

- Canellidis, V.; Giannatsis, J.; Dedoussis, V. Genetic-algorithm-based multi-objective optimization of the build orientation in Stereolithography. Int. J. Adv. Manuf. Technol. 2009, 45, 714–730. [Google Scholar] [CrossRef]

- Freens, J.P.; Adan, I.J.; Pogromsky, A.Y.; Ploegmakers, H. Automating the production planning of a 3D printing factory. In Proceedings of the IEEE 2015 Winter Simulation Conference (WSC), Huntington Beach, CA, USA, 6–9 December 2015; pp. 2136–2147. [Google Scholar]

- Ransikarbum, K.; Mason, S.J. Multiple-Objective Analysis of Integrated Relief Supply and Network Restoration in Humanitarian Logistics Operations. Int. J. Prod. Res. 2016, 54, 49–68. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Mason, S.J. Goal programming-based post-disaster decision making for integrated relief distribution and network restoration. Int. J. Prod. Econ. 2016, 182, 324–341. [Google Scholar] [CrossRef]

- Velasquez, M.; Hester, P.T. An analysis of multi-criteria decision making methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

- Saaty, T.L. Relative measurement and its generalization in decision making why pairwise comparisons are central in mathematics for the measurement of intangible factors—The analytical hierarchy/network process, RACSAM-Revista de la Real Academia de Ciencias Exactas, Fiscas y naturales. Series A. Mathematics 2008, 102, 251–318. [Google Scholar]

- Saaty, T.L.; Sagir, M. Extending the measurement of tangibles to intangibles. Int. J. Inf. Technol. Decis. Mak. 2009, 8, 7–27. [Google Scholar] [CrossRef]

- ASTM. Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Bourell, D.L.; Beaman, J.J.; Leu, M.C.; Rosen, D.W. A Brief History of Additive Manufacturing and the 2009 Roadmap for Additive Manufacturing: Looking Back and Looking Ahead. In Proceedings of the RapidTech 2009: US-TURKEY Workshop on Rapid Technologies, Istanbul, Turkey, 24–25 September 2009; pp. 5–11. [Google Scholar]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Han, J.Y. A study on the Prototype Modeling Method using 3D Printing. J. Packag. Cult. Des. Res. 2013, 34, 97–109. [Google Scholar]

- 3D Hubs. Available online: https://www.3dhubs.com/ (accessed on 15 January 2020).

- Shapeways. Available online: https://www.shapeways.com/ (accessed on 15 January 2020).

- Achillas, C.; Aidonis, D.; Iakovou, E.; Thymianidis, M.; Tzetzis, D. A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J. Manuf. Syst. 2015, 37, 328–339. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.A.; Harrysson, O.L.A. Additive manufacturing-integrated hybrid manufacturing and subtractive processes: Economic model and analysis. Int. J. Comput. Integr. Manuf. 2016, 29, 473–488. [Google Scholar] [CrossRef]

- Zhang, Y.; Bernard, A.; Harik, R.; Karunakaran, K.P. Build orientation optimization for multi-part production in additive manufacturing. J. Intell. Manuf. 2017, 28, 1393–1407. [Google Scholar] [CrossRef]

- Hasan, S.; Rennie, A.E.W. The Application of Rapid Manufacturing Technologies in the Spare Parts Industry. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–8 August 2008; pp. 584–590. [Google Scholar]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain: Alternative approaches to capacity deployment. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J. Digital manufacturing-driven transformations of service supply chains for complex products. Supply Chain Manag. Int. J. 2014, 19, 421–430. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Thomas, D.S.; Gilbert, S.W. Costs and Cost Effectiveness of Additive Manufacturing. NIST Speical Publ. 2014, 1176, 12. [Google Scholar]

- Verma, A.; Rai, R. Energy efficient modeling and optimization of additive manufacturing processes. In Proc. of Solid Freeform Fabrication Symposium; University of Texas: Austin, TX, USA, 2013; pp. 231–241. [Google Scholar]

- Yoon, H.S.; Lee, J.Y.; Kim, H.S.; Kim, M.S.; Kim, E.S.; Shin, Y.J.; Chu, W.S.; Ahn, S.H. A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 261–279. [Google Scholar] [CrossRef]

- Yao, X.; Moon, S.K.; Bi, G. A Cost-Driven Design Methodology for Additive Manufactured Variable Platforms in Product Families. J. Mech. Des. 2016, 138, 041701. [Google Scholar] [CrossRef]

- Materialise. 2018. Available online: https://www.materialise.com/en (accessed on 30 January 2018).

- Vaidya, O.S.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Chaiyaphan, C.; Ransikarbum, K. Criteria Analysis of Food Safety using the Analytic Hierarchy Process (AHP)-A Case study of Thailand’s Fresh Markets. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 141, p. 02001. [Google Scholar]

- Ho, W. Integrated analytic hierarchy process and its applications—A literature review. Eur. J. Oper. Res. 2008, 186, 211–228. [Google Scholar] [CrossRef]

- Khamhong, P.; Yingviwatanapong, C.; Ransikarbum, K. Fuzzy Analytic Hierarchy Process (AHP)-based Criteria Analysis for 3D Printer Selection in Additive Manufacturing. In Proceedings of the 2019 Research, Invention, and Innovation Congress (RI2C), Bangkok, Thailand, 11–13 December 2019; pp. 1–5. [Google Scholar]

- Fourer, R.; Gay, D.; Kernighan, B. AMPL: A Modeling Language for Mathematical Programming, 2nd ed.; Duxbury Press, Brooks/Cole Publishing: Monterey, CA, USA, 2002. [Google Scholar]

- National Institutes of Health. NIH 3D Print Exchange. 2019. Available online: https://3dprint.nih.gov/ (accessed on 30 January 2019).

| AM Process Type | Printing Time Approximation Based on Energy Source | Part Stacking Requirement in a Build Chamber | ||

|---|---|---|---|---|

| Laser | Extruder | With Nesting | Without Nesting | |

| Material extrusion (ME) | √ | √ | ||

| Stereolithography (SLA) | √ | √ | ||

| Selective laser sintering (SLS) | √ | √ | ||

| Criteria | Total Cost | Load Balance | Total Lateness | Unassigned Parts | Criteria Weight |

|---|---|---|---|---|---|

| Total cost | 1 (0.100) | 2 (0.167) | 2 (0.182) | 1/8 (0.090) | 0.135 |

| Load balance | 1/2 (0.050) | 1 (0.083) | 1 (0.091) | 1/8 (0.090) | 0.078 |

| Total lateness | 1/2 (0.050) | 1 (0.083) | 1 (0.091) | 1/7 (0.103) | 0.082 |

| Unassigned parts | 8 (0.800) | 8 (0.667) | 7 (0.636) | 1 (0.718) | 0.705 |

| Automotive (A) * | Healthcare (H) ** | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CAD File | Length (mm) | Width (mm) | Height (mm) | Volume/ Proj. Area | CAD File | Length (mm) | Width (mm) | Height (mm) | Volume/ Proj. Area |

1  | 214 | 120 | 7 | 179,760/ 25,680 | 1  | 129 | 140 | 230 | 4,153,800/ 18,060 |

2  | 78 | 77 | 45 | 270,270/ 6006 | 2  | 100 | 84 | 118 | 991,200/ 8400 |

3  | 291 | 85 | 88 | 2,176,680/ 24,735 | 3 | 50 | 79 | 27 | 106,650/ 3950 |

4  | 125 | 283 | 26 | 919,750/ 35,375 | 4  | 50 | 48 | 29 | 69,600/ 2400 |

5  | 72 | 24 | 28 | 48,384/ 1728 | 5  | 30 | 100 | 56 | 168,000/ 3000 |

6  | 311 | 48 | 44 | 656,832/ 14,928 | 6  | 43 | 53 | 39 | 88,881/ 2279 |

7  | 185 | 353 | 11 | 718,355/ 65,305 | 7  | 27 | 38 | 25 | 25,650/ 1026 |

8  | 176 | 90 | 60 | 950,400/ 15,840 | 8  | 51 | 102 | 35 | 950,400/ 15,840 |

9  | 89 | 80 | 52 | 370,240/ 7120 | 9  | 83 | 68 | 86 | 485,384/ 5644 |

10  | 135 | 146 | 33 | 650,430/ 19,710 | 10  | 85 | 84 | 7 | 49,980/ 7140 |

| Parameters | Details |

|---|---|

| Cost-Related Parameters | |

| Printer cost ($) | ME (Small 500, Large 800); SLA (Small 600, Large 1000); SLS (Small 1200, Large 1500) |

| Part cost ($) | Magics; ME: Uniform (20, 100); SLA: Uniform (50, 200); SLS: Uniform (100, 300) |

| Part-holding cost ($) | ME: Uniform (20, 100); SLA: Uniform (50, 200); SLS: Uniform (100, 300) |

| Transportation cost ($) | Uniform (5, 10) |

| Production budget ($) | 20,000 a |

| Transportation budget ($) | 20,000 a |

| Part and Printer-Related Parameters | |

| Projection length/width/height (mm.) | ME: Uniform (80, 220); SLA: Uniform (90, 230); SLS: Uniform (100, 250) |

| Shrink-wrap and bounding box volume (mm.) | Magics |

| Printer capacity (mm.) | ME (Small 235 × 200 × 200, Large 300 × 305 × 457); SLA (Small 128 × 128 × 200, Large 450 × 450 × 300); SLS (Small 385 × 330 × 460, Large 700 × 380 × 580) |

| Fraction determining the minimum area/volume of a printer | 3% a |

| Fraction determining the minimum number of parts required to operate a printer | 20% a |

| Logistics-Related Parameters | |

| Transportation distance (km.) | Uniform (50, 100) |

| Demand and order (pieces) | Uniform (5, 30) |

| Shipping capacity (m3) | Uniform (5, 8) |

| Time-Related Parameters | |

| Print time for an individual part (hours) | Magics ME: Uniform (5, 30); SLA: Uniform (10, 35); SLS: Uniform (3, 20) |

| Labor working hours | 8 h/day |

| Lateness computed from the customers’ due dates (days) | U (−5, 5) |

| Wait time for the next period for parts that are not assigned (days) | 7 days |

| Desired Criteria | Z1 | Z2 | Z3 | Z4 | Multi-Objective |

|---|---|---|---|---|---|

| Solve time (s) | 0.141 | 0.062 | 0.547 | 0.062 | 0.453 |

| Assigned printers | ME1 SLA1 SLS1 | ME1, ME2 SLA1, SLA2 SLS1 | ME1, ME2 SLA1, SLA2 SLS1 | ME1, ME2 SLA2 SLS1 | ME1, ME2 SLA1, SLA2 SLS1 |

| Assigned parts | ME1 (A2, 5, 10) SLA1 (H3, 4) SLS1 (A8, 10; H8) | ME1 (A2, 5, 10) ME2 (A3, 4, 8) SLA1 (A2; H3, 5) SLA2 (A1, 3, 4; H1, 2, 4) SLS1 (A6, 8, 9, 10; H6, 7, 8, 9, 10) | ME1 (A2, 5, 10) ME2 (A3, 4, 8) SLA1 (A5; H4, 5) SLA2 (A1, 4, 5; H1, 2, 3) SLS1 (A6, 8, 9; H6, 8, 9, 10) | ME1 (A2, 5, 10 )ME2 (A3, 4, 8) SLA2 (A1, 2, 3, 4, 5; H1, 2, 3, 4, 5) SLS1 (A6, 8, 9, 10; H6, 7, 8, 9, 10) | ME1 (A2, 5, 10) ME2 (A3, 4, 8) SLA1 (A2; H4, 5) SLA2 (A1, 4, 5; H1, 2, 3) SLS1 (A6, 8, 9, 10; H6, 7, 8, 9, 10) |

| Part shipment | Firm 2 (A2, 5, 8, 10, 10; H3, 4, 8) | Firm 1 (A2, 3, 6, 9, 10; H2, 3, 5, 7, 8) Firm 2 (A1, 3, 4, 4, 8, 10; H1, 10) Firm 3 (A2, 5, 8; H4, 6, 9) | Firm 1 (A2, 2, 4, 4, 5; H2, 4, 6, 8, 9) Firm 2 (A3, 8, 8, 9, 10; H5,) Firm 3 (A1, 5, 6; H1, 3, 10) | Firm 1 (A2, 4, 8; H6, 9, 10) Firm 2 (A1, 5, 6, 8, 9, 10, 10; H4, 5) Firm 3 (A2, 3, 3, 4, 5; H1, 2, 3, 7, 8) | Firm 1 (A2, 3, 8; H5) Firm 2 (A2, 4, 5, 6; H2, 4, 5, 7, 8, 9) Firm 3 (A1, 4, 8, 9, 10, 10; H1, 3, 6, 10) |

| Total operating cost ($) | 6,158 | 15,827 | 15,108 | 15,256 | 14,999 |

| Load balance | ME1 (58.39%) ME2 (0%) SLA1 (38.76%) SLS2 (0%) SLS1 (3.05%) | ME1 (58.39%) ME2 (83.01%) SLA1 (79.08%) SLA2 (54.05%) SLS1 (5.92%) | ME1 (58.39%) ME2 (83.01%) SLA1 (69.62%) SLA2 (43.45%) SLS1 (4.76%) | ME1 (58.39%) ME2 (83.01%) SLA1 (0%) SLA2 (61.30%) SLS1 (5.92%) | ME1 (58.39%) ME2 (83.01%) SLA1 (69.62%) SLA2 (43.45%) SLS1 (5.92%) |

| Maximin Load | 0% | 5.92% | 4.76% | 0% | 5.92% |

| Total lateness (days) | 196 | 622 | 138 | 415 | 145 |

| Total parts unassigned (parts) | 22/22 (ME: 7; SLA: 8; SLS: 7) | 6/6 (ME: 4; SLA: 1; SLS: 1) | 8/8 (ME: 4; SLA: 1; SLS: 3) | 5/5 (ME: 4 SLA: 0 SLS: 1) | 6/6 (ME: 4 SLA: 1 SLS: 1) |

| Factors/Levels | Z1 | Z2 | Z3 | Z4 | Multi-Objective | |

|---|---|---|---|---|---|---|

| Printers | 5 | 0.79 | 15.33 | 1818.22 | 1.24 | 1942.39 |

| 10 | 4.01 | 84.88 | 3080.53 | 310.03 | 3420.42 | |

| Parts | 100 | 1.08 | 2.60 | 1298.75 | 183.85 | 1782.87 |

| 500 | 3.72 | 97.61 | 3600 | 127.43 | 3579.94 | |

| Destinations | 5 | 2.52 | 4.28 | 2612.64 | 4.02 | 2644.53 |

| 10 | 2.28 | 95.93 | 2286.11 | 307.26 | 2718.28 | |

| Grand average | 2.40 | 50.11 | 2449.38 | 155.64 | 2681.40 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ransikarbum, K.; Pitakaso, R.; Kim, N. A Decision-Support Model for Additive Manufacturing Scheduling Using an Integrative Analytic Hierarchy Process and Multi-Objective Optimization. Appl. Sci. 2020, 10, 5159. https://doi.org/10.3390/app10155159

Ransikarbum K, Pitakaso R, Kim N. A Decision-Support Model for Additive Manufacturing Scheduling Using an Integrative Analytic Hierarchy Process and Multi-Objective Optimization. Applied Sciences. 2020; 10(15):5159. https://doi.org/10.3390/app10155159

Chicago/Turabian StyleRansikarbum, Kasin, Rapeepan Pitakaso, and Namhun Kim. 2020. "A Decision-Support Model for Additive Manufacturing Scheduling Using an Integrative Analytic Hierarchy Process and Multi-Objective Optimization" Applied Sciences 10, no. 15: 5159. https://doi.org/10.3390/app10155159

APA StyleRansikarbum, K., Pitakaso, R., & Kim, N. (2020). A Decision-Support Model for Additive Manufacturing Scheduling Using an Integrative Analytic Hierarchy Process and Multi-Objective Optimization. Applied Sciences, 10(15), 5159. https://doi.org/10.3390/app10155159