A Comprehensive Approach of Eucalyptus globulus Acid Sulfite Pretreatment for Enzymatic Hydrolysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material Preparation

2.2. Pretreatments

2.3. Analysis of Pretreatment Hydrolysates

2.4. Solid Residues Porosity

2.5. Enzymatic Hydrolysis

2.6. Experimental Errors

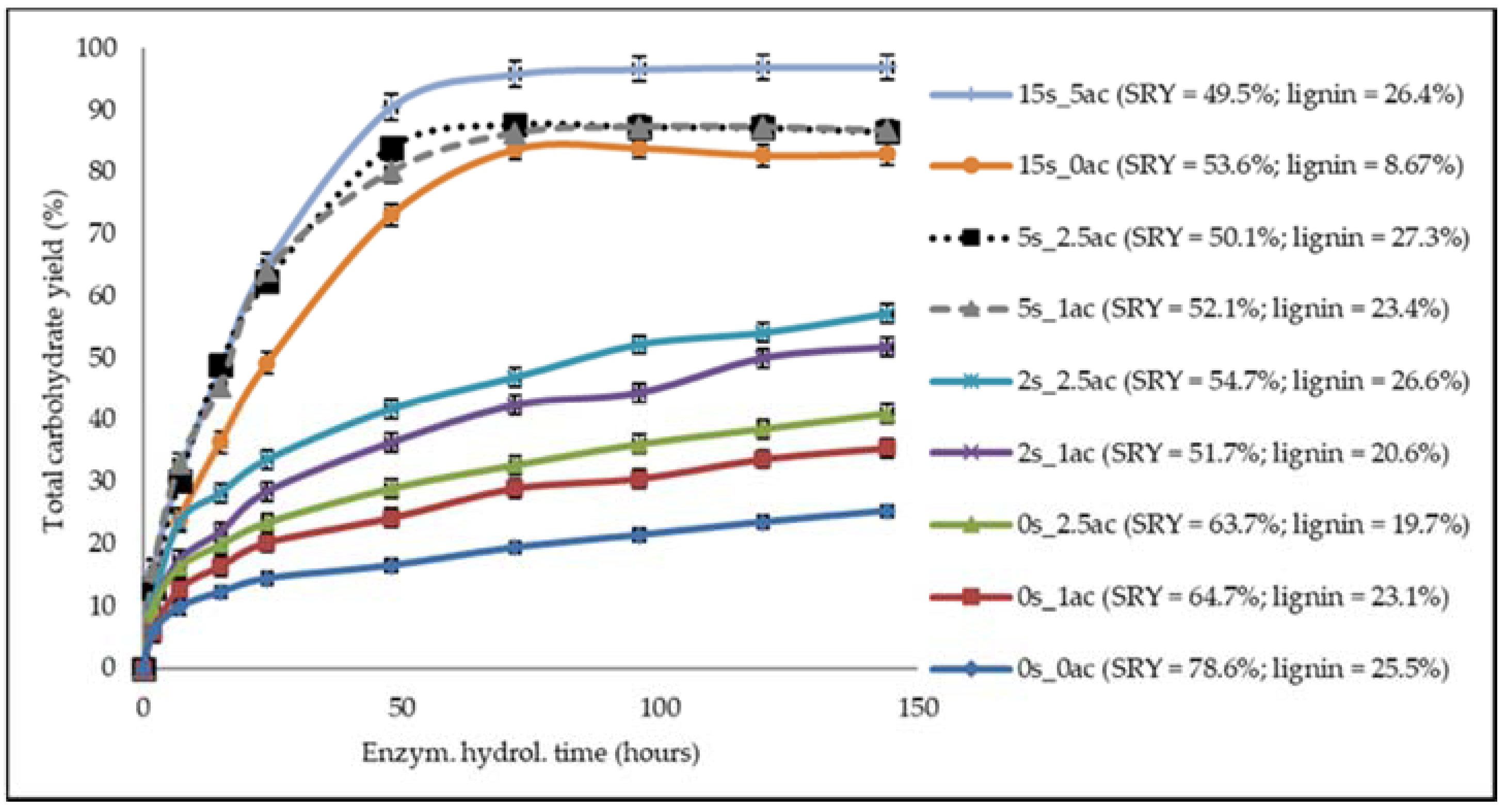

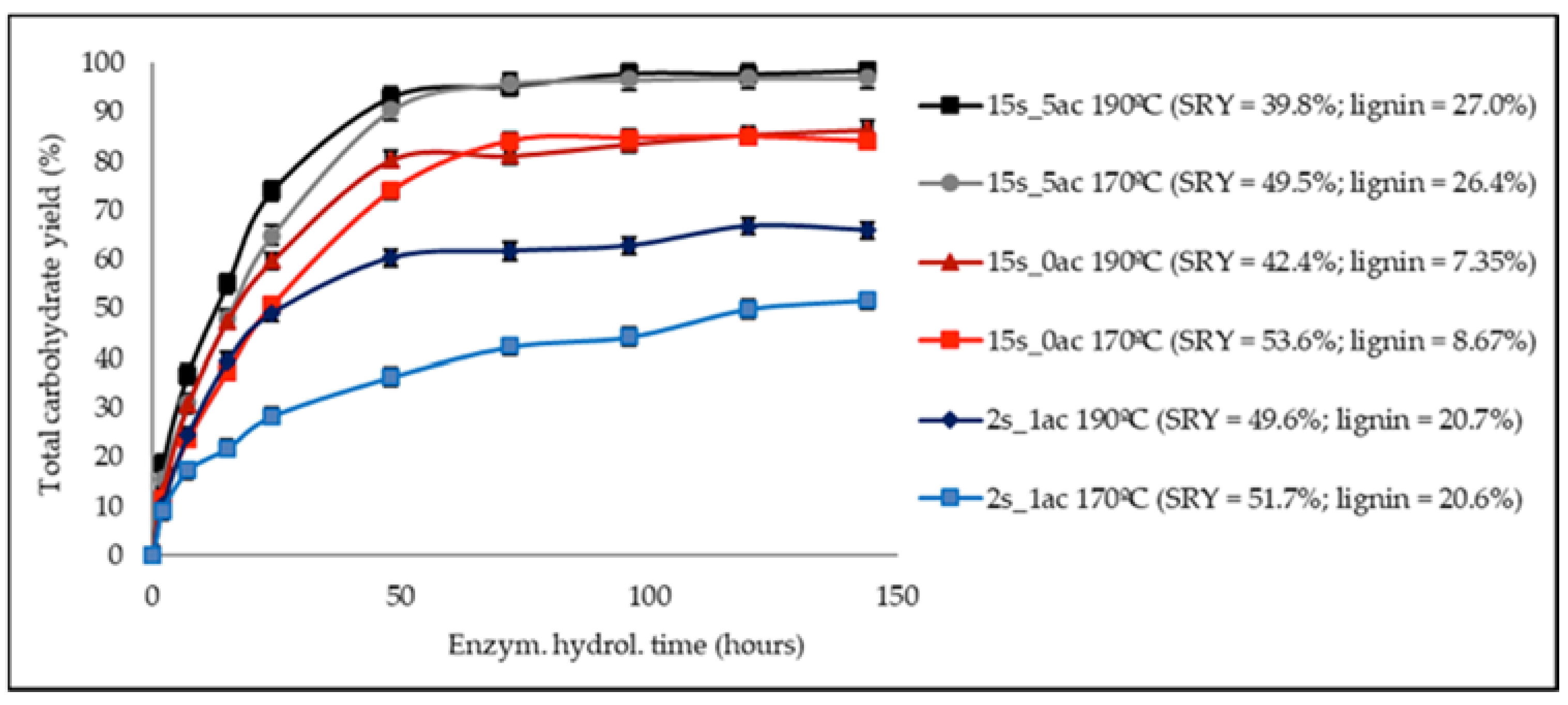

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Pretreatment Hydrolysates (% on Initial Biomass Weight) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbohydrates Yield (%) | Byproducts Yield (%) | SLY b (%) | Total Removal (%) | SRY (%) (Lignin (%)) | Total (%) | |||||||||

| Pretreat Temp (°C) | Time (min) | Pretreat Liquor a | Initial Liquor pH | Final pH | Glucose | XMG | Furfural | HMF | Acetic Acid | Formic Acid | ||||

| 170 | 0 | 0s_0ac | 6.87 | 2.99 | 0.2 | 10.6 | 0.005 | 0.004 | 1.1 | 0.3 | 4.8 | 17.0 | 80.0 (22.4) | 97.0 |

| 15 | 0s_0ac | 6.87 | 2,90 | 0.5 | 12.8 | 0.007 | 0.006 | 1.2 | 0.4 | 5.1 | 20.0 | 78.6 (22.5) | 98.6 | |

| 0 | 0s_1ac | 1.60 | 1.63 | 3.2 | 9.7 | 0.018 | 0.005 | 5.1 | 1.0 | 7.8 | 31.7 | 71.4 (18.5) | 97.3 | |

| 15 | 0s_1ac | 1.60 | 1.47 | 3.4 | 9.9 | 0.020 | 0.006 | 4.2 | 1.0 | 9.9 | 25.9 | 67.7 (18.9) | 96.6 | |

| 0 | 0s_2.5ac | 1.29 | 1.37 | 1.5 | 11.9 | 0.008 | 0.006 | 2.0 | 0.7 | 6.4 | 22.5 | 75.4 (15.3) | 97.9 | |

| 15 | 0s_2.5ac | 1.29 | 1.34 | 2.2 | 13.7 | 0.009 | 0.007 | 3.7 | 0.9 | 7.0 | 27.5 | 69.4 (15.9) | 96.9 | |

| 0 | 2s_1ac | 1.57 | 1.56 | 2.1 | 12.1 | 0.027 | 0.013 | 4.1 | 0.9 | 17.9 | 37.0 | 61.1 (15.8) | 98.1 | |

| 15 | 2s_1ac | 1.57 | 1.62 | 2.3 | 13.7 | 0.030 | 0.015 | 4.3 | 0.8 | 19.8 | 41.0 | 56.0 (16.3) | 97.0 | |

| 0 | 2s_2.5ac | 1.26 | 1.70 | 3.6 | 15.4 | 0.019 | 0.008 | 4.2 | 0.8 | 17.0 | 41.0 | 55.9 (19.9) | 96.9 | |

| 15 | 2s_2.5ac | 1.26 | 1.62 | 4.2 | 16.0 | 0.023 | 0.011 | 4.0 | 0.8 | 19.6 | 44.6 | 52.2 (20.3) | 96.8 | |

| 0 | 15s_0ac | 3.82 | 2.49 | 0.6 | 1.1 | 0.013 | 0.006 | 1.2 | 0.0 | 21.8 | 24.7 | 74.0 (8.9) | 98.7 | |

| 15 | 15s_0ac | 3.82 | 2.24 | 1.7 | 9.7 | 0.228 | 0.036 | 3.8 | 0.0 | 22.2 | 37.7 | 53.6 (7.9) | 91.3 | |

| 0 | 15s_5ac | 1.44 | 1.39 | 1.7 | 9.3 | 0.012 | 0.003 | 2.5 | 0.0 | 18.2 | 31.7 | 67.9 (18.9) | 97.8 | |

| 15 | 15s_5ac | 1.44 | 1.35 | 2.3 | 15.3 | 0.321 | 0.038 | 4.0 | 0.0 | 20.3 | 42.3 | 55.5 (20.5) | 97.8 | |

| Conventional wood chips | ||||||||||||||

| 30 | 5s_1ac | 2.55 | 2.01 | 1.4 | 9.9 | 0.070 | 0.045 | 2.4 | 0.2 | 17.4 | 31.4 | 66.7 (29.7) | 98.1 | |

| 30 | 5s_2.5ac | 2.12 | 1.80 | 2.9 | 9.8 | 0.064 | 0.070 | 3.4 | 0.1 | 18.8 | 35.1 | 59.5 (31.2) | 94.6 | |

| 0 | 15s_0ac | 3.82 | 2.49 | 0.3 | 0.7 | 0.015 | 0.008 | 1.0 | 0.0 | 7.6 | 9.6 | 86.1 (17.1) | 95.7 | |

| 15 | 15s_0ac | 3.82 | 2.24 | 1.0 | 7.5 | 0.042 | 0.007 | 2.3 | 0.0 | 9.9 | 20-7 | 76.1 (19.1) | 96.8 | |

| 30 | 15s_0ac | 3.82 | 2.14 | 2.0 | 13.0 | 0.320 | 0.071 | 3.6 | 0.0 | 12.2 | 31.2 | 66.9 (21.8) | 98.1 | |

| 0 | 15s_5ac | 1.44 | 1.39 | 1.1 | 5.9 | 0.048 | 0.007 | 2.2 | 0.0 | 6.8 | 16.1 | 79.3 (17.7) | 95.4 | |

| 15 | 15s_5ac | 1.44 | 1.35 | 1.9 | 12.9 | 0.153 | 0.027 | 3.5 | 0.0 | 10.8 | 29.3 | 67.3 (21.1) | 96.6 | |

| 30 | 15s_5ac | 1.44 | 1.32 | 2.2 | 14.5 | 0.680 | 0.102 | 4.1 | 0.0 | 11.2 | 32.8 | 63.8 (22.8) | 96.6 | |

References

- Henry, R.J. Evaluation of plant biomass resources available for replacement of fossil oil. Plant Biotechnol. J. 2010, 8, 288–293. [Google Scholar] [CrossRef] [PubMed]

- Lennartsson, P.R.; Erlandsson, P.; Taherzadeh, M.J. Integration of the first and second generation bioethanol processes and the importance of by-products. Bioresour. Technol. 2014, 165, 3–8. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Jameel, H.; Chang, H.; Park, S. The effect of delignification of forest biomass on enzymatic hydrolysis. Bioresour. Technol. 2011, 102, 9083–9089. [Google Scholar] [CrossRef] [PubMed]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Alzagameem, A.; Bergs, M.; Tung-Do, X.; Klein, S.E.; Rumpf, J.; Larkins, M.; Monakhova, Y.; Pude, R.; Schulze, M. Low-Input Crops as Lignocellulosic Feedstock for Second-Generation Biorefineries and the Potential of Chemometrics in Biomass Quality Control. Appl. Sci. 2019, 9, 2252. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Pan, X.J.; Wang, G.S.; Gleisner, R. Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour. Technol. 2009, 100, 2411–2418. [Google Scholar] [CrossRef] [PubMed]

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem. 2013, 15, 550–583. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; van Hooijdonk, G.; Faaij, A.P.C. Ethanol from lignocellulosic biomass: Techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 2005, 28, 384–410. [Google Scholar] [CrossRef]

- Barakat, A.; de Vries, H.; Rouau, X. Dry fractionation process as an important step in current and future lignocellulose biorefineries: A review. Bioresour. Technol. 2013, 134, 362–373. [Google Scholar] [CrossRef]

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef]

- Mansfield, S.D.; Mooney, C.A.; Saddler, J.N. Substrate and enzyme characteristics that limit cellulose hydrolysis. Biotechnol. Progr. 1999, 15, 804–816. [Google Scholar] [CrossRef] [PubMed]

- Mooney, C.A.; Mansfield, S.D.; Touhy, M.G.; Saddler, J.N. The effect of initial pore volume and lignin content on the enzymatic hydrolysis of softwoods. Bioresour. Technol. 1998, 64, 113–119. [Google Scholar] [CrossRef]

- Sun, Q.; Foston, M.; Meng, X.; Sawada, D.; Pingali, S.V.; O’Neill, H.M.; Li, H.; Wyman, C.E.; Langan, P.; Ragauskas, A.J.; et al. Effect of lignin content on changes occurring in poplar cellulose ultrastructure during dilute acid pretreatment. Biotechnol. Biofuels 2014, 7, 150. [Google Scholar] [CrossRef] [PubMed]

- Zoghlami, A.; Paës, G. Lignocellulosic Biomass: Understanding Recalcitrance and Predicting Hydrolysis. Front. Chem. 2019, 7, 874. [Google Scholar] [CrossRef]

- Chundawat, S.P.S.; Bellesia, G.; Uppungundla, N.; Sousa, L.C.; Gao, D.; Cheh, A.M.; Agarwal, U.P.; Bianchetti, C.M.; Phillips, G.N., Jr.; Langan, P.; et al. Restructuring the Crystalline Cellulose Hydrogen Bond Network Enhances its Depolymerization Rate. J. Am. Chem. Soc. 2011, 133, 11163–11174. [Google Scholar] [CrossRef]

- Berthold, J.; Salmén, L. Inverse Size Exclusion Chromatography (ISEC) for Determining the Relative Pore Size Distribution of Wood Pulps. Holzforschung 1997, 51, 361–368. [Google Scholar] [CrossRef]

- Berthold, J.; Salmén, L. Effects of Mechanical and Chemical Treatments on the Pore-Size Distribution in Wood Pulps Examined by Inverse Size-Exclusion Chromatography. J. Pulp. Pap. Sci. 1997, 23, 245–253. [Google Scholar]

- Zhou, H.; Lou, H.; Yang, D.; Zhu, J.Y.; Qiu, X. Lignosulfonate to enhance enzymatic saccharification of lignocelluloses: Role of molecular weight and substrate lignin. Ind. Eng. Res. 2013, 52, 8464–8470. [Google Scholar] [CrossRef]

- Grönqvist, S.; Hakala, T.K.; Kamppuri, T.; Vehviläinen, M.; Hänninen, T.; Liitiä, T.; Maloney, T.; Suurnäkki, A. Fibre porosity development of dissolving pulp during mechanical and enzymatic processing. Cellulose 2014, 21, 3667–3676. [Google Scholar] [CrossRef]

- Pihlajaniemi, V.; Sipponen, M.H.; Liimatainen, H.; Sirvio, J.A.; Nyyssola, A.; Laakso, S. Weighing the factors behind enzymatic hydrolyzability of pretreated lignocellulose. Green Chem. 2016, 18, 1295–1305. [Google Scholar] [CrossRef]

- Meng, X.; Ragauskas, A.J. Recent advances in understanding the role of cellulose accessibility in enzymatic hydrolysis of lignocellulosic substrates. Curr. Opin. Biotechnol. 2014, 27, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Costa, V.L.D.; Gomes, T.P.; Simões, R.M.S. Effect of acid sulphite pretreatment on enzymatic hydrolysis of eucalypt, broom, and pine. J. Wood Chem. Technol. 2016, 36, 63–75. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. Laboratory Analytical Procedure; NREL/TP-510-42618; NREL: Golden, CO, USA, 2008; revised 2010. [Google Scholar]

- Schöning, A.G.; Johansson, G. Colorimetric determination of acid-soluble lignin in semichemical bisulphite pulps and in some woods and plants. Sven. Papp. 1965, 68, 607–613. [Google Scholar]

- Kongdee, A.; Bechtold, T.; Burtscher, E.; Scheinecker, M. The influence of wet/dry treatment on pore structure-the correlation of pore parameters, water retention and moisture regain values. Carbohydr. Polym. 2004, 57, 39–44. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, W. Wood: Chemistry, Ultrastructure, Reactions, 2nd ed.; Walter de Gruyter: Berlin, Germany, 1989; pp. 268–292. [Google Scholar]

- Wang, W.; Zhu, Y.; Du, J.; Yang, Y.; Jin, Y. Influence of lignin addition on the enzymatic digestibility of pretreated lignocellulosic biomasses. Bioresour. Technol. 2015, 181, 7–12. [Google Scholar] [CrossRef]

- Yang, Q.; Pan, X. Correlation between Lignin Physicochemical Properties and Inhibition to Enzymatic Hydrolysis of Cellulose. Biotechnol. Bioeng. 2016, 113, 1213–1224. [Google Scholar] [CrossRef]

- Lou, H.; Zhu, J.Y.; Lan, T.Q.; Lai, H.; Qiu, X. pH-induced lignin surface modification to reduce nonspecific cellulose binding and enhance enzymatic saccharification of lignocelluloses. ChemSusChem 2013, 6, 919–927. [Google Scholar] [CrossRef]

| Pretreatment Hydrolysates (% on Initial Biomass Weight) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbohydrates Yield (%) | Byproducts Yield (%) | SLY b (%) | Total Removal (%) | SRY (%) (Lignin (%)) | Total (%) | ||||||||

| Pretreat Temp (°C) | Pretreat Liquor a | Initial Liquor pH | Final pH | Glucose | XMG | Furfural | HMF | Acetic Acid | Formic Acid | ||||

| 170 | 0s_0ac | 6.91 | 3.09 | 0.4 | 11.2 | 0.007 | 0.006 | 1.5 | 0.5 | 5.3 | 18.9 | 77.4 (25.5) | 98.5 |

| 0s_1ac | 1.60 | 1.41 | 3.5 | 11.5 | 0.024 | 0.008 | 5.1 | 1.0 | 10.6 | 31.7 | 64.7 (23.1) | 96.4 | |

| 0s_2.5ac | 1.29 | 1.33 | 2.7 | 14.5 | 0.010 | 0.009 | 4.6 | 1.2 | 7.5 | 30.5 | 67.3 (19.7) | 97.8 | |

| 2s_1ac | 1.57 | 1.69 | 2.4 | 14.5 | 0.030 | 0.014 | 4.8 | 1.3 | 22.4 | 45.4 | 51.7 (20.6) | 97.1 | |

| 2s_2.5ac | 1.58 | 1.33 | 4.1 | 16.7 | 0.031 | 0.014 | 3.9 | 1.2 | 17.4 | 43.3 | 54.7 (26.6) | 98.0 | |

| 5s_1ac | 2.33 | 1.95 | 2.2 | 17.1 | 0.145 | 0.011 | 4.4 | 0.8 | 21.5 | 46.2 | 52.1 (23.4) | 98.3 | |

| 5s_2.5ac | 1.75 | 1.24 | 5.4 | 16.9 | 0.042 | 0.017 | 4.2 | 1.4 | 20.2 | 48.2 | 50.1 (27.3) | 98.2 | |

| 15s_0ac | 4.26 | 2.71 | 2.8 | 17.1 | 0.092 | 0.053 | 3.4 | 1.0 | 21.3 | 45.7 | 53.6 (8.67) | 99.3 | |

| 15s_5ac | 1.44 | 1.32 | 2.6 | 16.9 | 0.362 | 0.056 | 4.6 | 1.5 | 21.6 | 47.6 | 49.5 (26.4) | 97.1 | |

| 190 | 0s_0ac | 6.85 | 3.02 | 2.4 | 7.00 | 0.028 | 0.014 | 5.7 | 2.7 | 7.3 | 25.1 | 71.8 (26.3) | 96.9 |

| 0s_1ac | 1.65 | 1.83 | 4.8 | 12.7 | 0.035 | 0.017 | 4.5 | 1.7 | 14.5 | 38.3 | 60.4 (18.6) | 98.7 | |

| 2s_1ac | 1.85 | 1.63 | 6.0 | 18.5 | 0.031 | 0.017 | 6.5 | 1.6 | 17.1 | 49.7 | 49.6 (20.7) | 99.3 | |

| 15s_0ac | 4.33 | 2.41 | 4.9 | 19.4 | 0.174 | 0.095 | 6.8 | 1.4 | 22.9 | 55.7 | 42.4 (7.35) | 98.1 | |

| 15s_5ac | 1.84 | 1.34 | 6.5 | 19.2 | 0.199 | 0.104 | 7.2 | 1.7 | 21.3 | 56.2 | 39.8 (27.0) | 96.0 | |

| Pretreatment (170 °C) | WRV (g/g) | Ɛ (WRV) (%) | ΔƐ (SRY) (%) | Ɛ (>2.65 nm) (%) | SSA, (cm2g−1) | Enzymatic Hydrolysis Extent (%) |

|---|---|---|---|---|---|---|

| 0s_0ac | 1.10 | 62.7 | 15.1 | 28 | 1653 | 25.2 |

| 0s_2.5ac | 1.25 | 65.6 | 21.8 | 41.0 | ||

| 2s_1ac | 1.31 | 66.7 | 32.2 | 35 | 5678 | 51.7 |

| 5s_1ac | 1.45 | 69.0 | 31.9 | 86.6 | ||

| 5s_2.5ac | 1.53 | 70.1 | 33.3 | 5578 | 88.7 | |

| 15s_0ac | 1.39 | 67.9 | 30.9 | 1389 | 84.1 | |

| 15s_5ac | 1.43 | 68.6 | 33.7 | 38 | 96.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

D. Costa, V.L.; Costa, A.P.; Amaral, M.E.; S. Simões, R.M. A Comprehensive Approach of Eucalyptus globulus Acid Sulfite Pretreatment for Enzymatic Hydrolysis. Appl. Sci. 2020, 10, 3764. https://doi.org/10.3390/app10113764

D. Costa VL, Costa AP, Amaral ME, S. Simões RM. A Comprehensive Approach of Eucalyptus globulus Acid Sulfite Pretreatment for Enzymatic Hydrolysis. Applied Sciences. 2020; 10(11):3764. https://doi.org/10.3390/app10113764

Chicago/Turabian StyleD. Costa, Vera L., Ana P. Costa, Maria E. Amaral, and Rogério M. S. Simões. 2020. "A Comprehensive Approach of Eucalyptus globulus Acid Sulfite Pretreatment for Enzymatic Hydrolysis" Applied Sciences 10, no. 11: 3764. https://doi.org/10.3390/app10113764

APA StyleD. Costa, V. L., Costa, A. P., Amaral, M. E., & S. Simões, R. M. (2020). A Comprehensive Approach of Eucalyptus globulus Acid Sulfite Pretreatment for Enzymatic Hydrolysis. Applied Sciences, 10(11), 3764. https://doi.org/10.3390/app10113764