Abstract

This paper addresses the situation of an industrial park in Mexico from the perspective of its community. It exposes a case study approach with the points of view of residents, businesses, and authorities to improve the socioeconomic conditions of the region: Sahagun, Hidalgo. The result of this article comes from a project ran by the Ministry of Economy of the state, to trigger the development of this area. The background of the topic is presented, its theoretical basis, and the methodological design. Finally, an integrative model is exposed to show the necessary actions to articulate enterprises—the society and the government to develop the town.

1. Introduction

The industrial park of Sahagun city is in the municipality of Tepeapulco, and is one of the most important of the central state of Hidalgo, in Mexico. The park is the main economic engine of this region, since there are in its facilities important enterprises of the metal-mechanic industry. Some of these enterprises work with local suppliers helping, by this means, the region and its economy. However, not all of the companies share the same practices and, frequently, they do not trust local suppliers due to the number of requirements needed to be incorporated in their productive processes.

Therefore, Sahagun city does not have a formal integration of local producers for the park, and there is not enough support from the different government levels to handle the time, technology and, investment required. This has led to the perception that the local and regional economy does not prosper, due mainly to the bad management of the government and labor unions in recent years. Consequently, this has led to a decline in this important industrial zone.

Based on this situation, the Ministry of Economy of the state began a study to propose a strategy for the integral development of this region, favoring enterprises that use mainly local suppliers, and aiming to benefit the society in the long-term. Therefore, this paper presents an integrative enterprise–society–government model, based on the case study of this industrial park, which proposes solutions in this respect. The background of the problem and a compilation of the most important data of the metal-mechanic industry are included; also, the methodological design of the project under a case study approach is presented with its respective results and, finally, the solutions and conclusions are detailed. The aim of the proposal is to develop a model suitable for the situation of the state of Hidalgo to integrate a foreign enterprise with local suppliers, comprehending the effects of the government politics and its impact on society. To our knowledge, there are no similar studies in the Mexican context, because is difficult to have access to enterprises’ information. For this reason, it could be used in other regions of Mexico.

2. Theoretical Framework

2.1. Background of the Problem

Despite the efforts of the government to integrate companies and society, policies created for this purpose, more than facilitating the integration of enterprises, contribute to separating them, and this does not benefit society (Bernstein and Lu 2009)—at least not in the long-term—since the only result obtained through this is poorly paid jobs. Additionally, it is necessary to adapt government policies that regulate these clusters to achieve productivity. However, the government invests a lot of time in generating these changes and consequently the expected benefits are not tangible for society (Lehmann and Benner 2015). Mintzberg (1996) states the notion that while an independent organization from the state is free, people are not. If the government frees enterprises, fostering open markets improves the distribution of goods, but the local population does not benefit directly from their insertion in the enterprises and from industrial activities. On the other hand, if the government has a total control of industrial activity, it does not generate significant benefits. It is evident that in none of these two extremes, citizens have participation on the companies as customers, or as small suppliers, and additional efforts are needed to achieve a real connection enterprise–society–government. Some successful examples of this type of connection in a supply chain are the agricultural cooperatives and clusters, especially in the U.S.A and Western Europe (Mintzberg 1996). Nevertheless, this success has been achieved thanks to individual efforts more than systematic government policies. So, to understand the types of relationships that could come, outside companies in a supply chain, a review of its fundamental theories is presented. Konstantynova and Lehmann (2017) carry out a study on clusters in different European countries, with the proposals explored and the cross-synthesis of cases, it can be said that the institutional variables cancel out the positive character of the cluster association applied and, therefore, the benefits are not perceived by the society. Okamuro and Nishimura (2015) conclude in their study that government policies support the development and functioning of clusters nationwide, but they can work better locally.

In a different integration approach, recent studies show how to optimize the supply chain through mathematical programming and metaheuristics (Syarif et al. 2002; Chopra and Meindl 2003; Yeh 2005). However, the situation of Sahagun and many regions in Mexico is complicated from the perspective of its government and society. Even more, close relationships between factories and customers with suppliers do not exist. For this reason, a model that not only includes strategies to potentiate the supply chain (suppliers–enterprise–customers), but also includes these variables, is required. China has been a global manufacturing center since it has good firms that have incorporated the supply chain management into their operational strategies (Zhao et al. 2011; Qi et al. 2017). Therefore, China turns to be a key reference for this purpose and, since Mexico has the potential to become a global manufacturing center as well, good Chinese practices could be implemented.

Qi et al. (2017) developed a simple model that allows to understand the relations between strategies of operation, strategies of the supply chain, and the company’s performance. This model was tested with Chinese manufacturing companies. Results show that the supply chain is based on lean manufacturing, and has priorities in cost, quality, and delivery, while the term ‘agile supply chain’ is settled for companies that want flexibility in their strategy. To understand the difference between ‘lean’ and ‘agile’, it is necessary to consider that both kinds of supply chains have external and internal integration processes, but the lean supply chain has a significant impact on the exterior, compared to the agile supply chain. Integration of the supply chain can be understood as the degree of collaboration that exists with the internal functions of the firm and with the external members, in order to manage the processes to achieve effective and efficient flows of products, services, and information, along with money and decisions with the objective of providing the maximum value to the customer, considering two variables: power and commitment, which significantly affect outer relationships (Zhao et al. 2008, 2011).

Lean supply chains emphasize waste reduction and reduction of disruptions while providing goods, services, and technologies from suppliers to customers. These supply chains adopt different management techniques such as ‘lean thinking’ and practices such as JIT, Kanban, and TQM to reduce costs, achieve product quality, and decrease lead times (Ardalan and Díaz 2012). This works best for high demands that can be easily predicted, but in volatile markets, the agile supply chain provides better, faster, and better supply response giving greater importance to customer requirements (Kisperska-Moron and De Haan 2011). Also, allow to have the adequate number of on-time parts from different suppliers and detect changes in demand quickly, concentrating on the value of the product (Ahmad and Schroeder 2001).

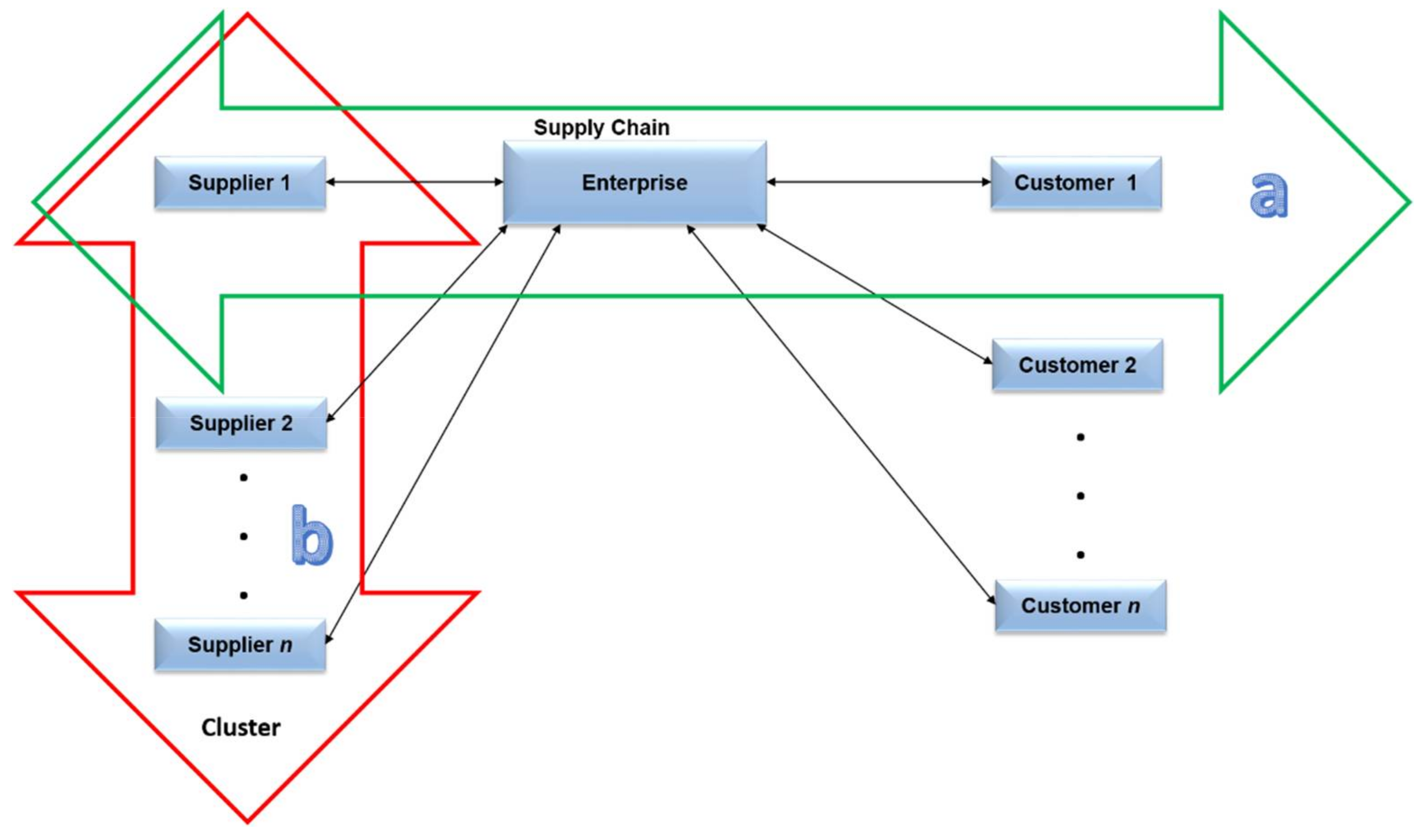

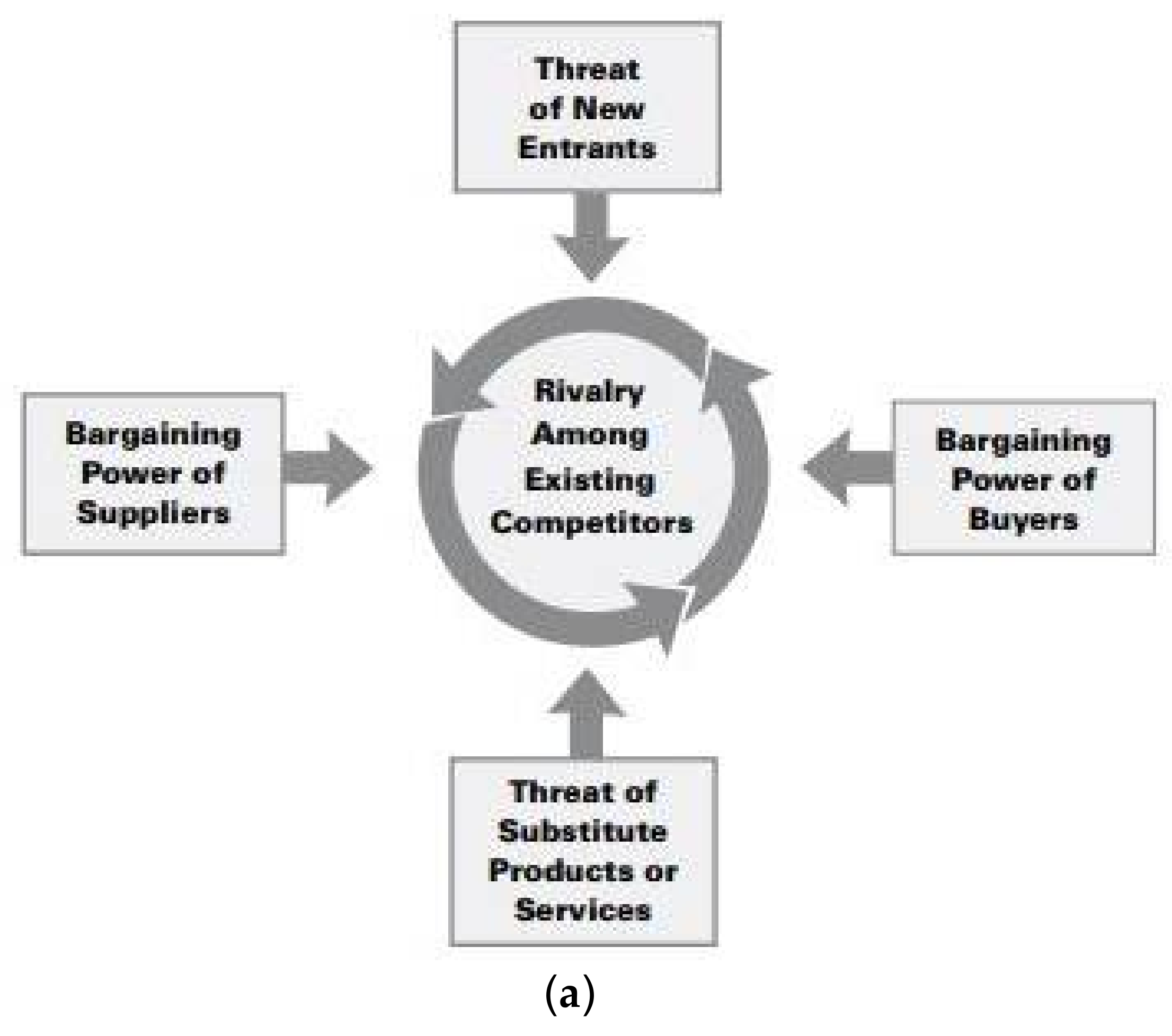

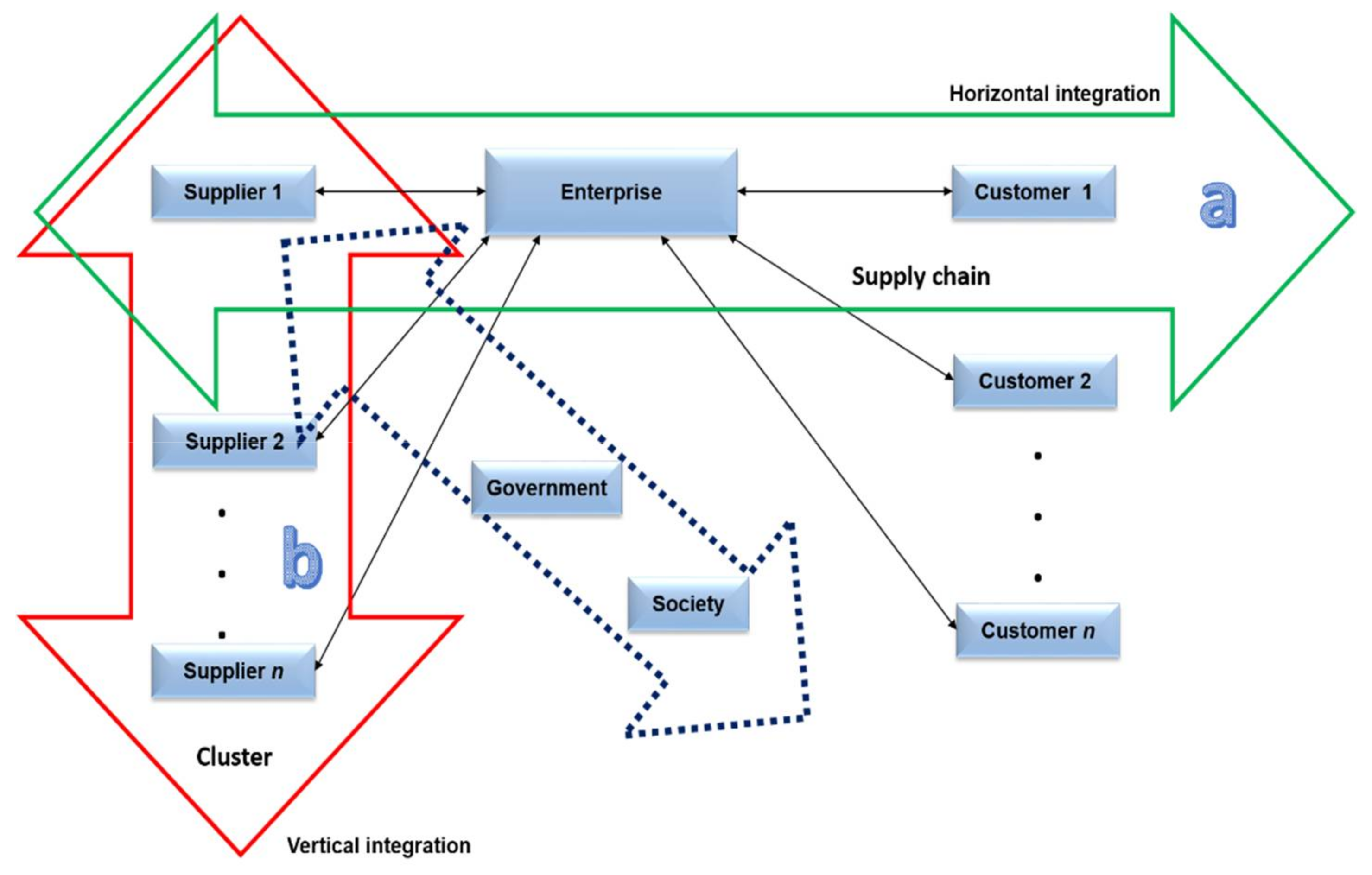

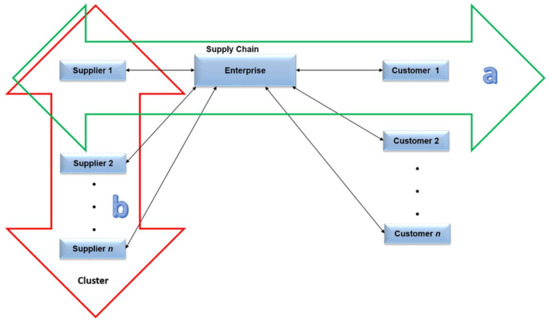

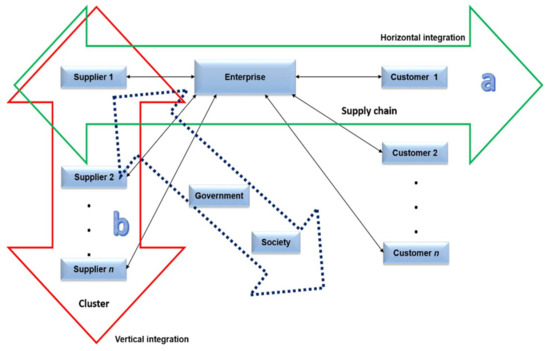

Hence, theoretically there are two types of relationships: horizontal (see ‘a’ in Figure 1), which are those that suppliers have with companies and customers; and, vertical which comprehend the supply chain integration and business clusters (see ‘b’ in Figure 1).

Figure 1.

Types of integration with suppliers. Author’s own elaboration.

So, there is a need to propose and validate theories of operations and supply chain strategies in diverse cultural contexts (Qi et al. 2017), especially in Mexico. According to several authors (Cruz-Sotelo et al. 2017; Durán-Encalada and Duhamel 2014; García-Reyes and Giachetti 2010), supply chain management is, in Mexico, a recent discipline under development, and has not received support enough for its growing and professionalization. It is imperative to develop tropicalized models because proper positioning in the global value chain is a key strategy for the sustainability of the involved firms, especially small and medium enterprises (SME) (Albors-Garrigos et al. 2014).

Proper studies focus supply chain management in Mexico on: logistics procedures, domestic value and general challenges (Gereffi 2008; Blyde 2014). Nevertheless, they do not establish the maturity point of the general industrial overview in the country. This situation is even more evident when comparing industrial parks of other economies, such as China, which has adopted the integration of supply chains as the growing model for its enterprises, and as stated before, could be the reference for the industrial development in Mexico.

Meanwhile the general landscape show limitations in studies and advances on SCM in Mexico, for the case of the central state of Hidalgo, this is even more restricted, since there are no antecedents of formal supply chain management studies for the region.

Thus, the relationships established in Figure 1 as enterprise—supplier (b) result in associations that get the name of industrial clusters. An industrial cluster is the agglomeration of enterprises dedicated to the same activity where multiple relationships are found among the entities that comprise it (Mintzberg 1996). Clusters appeared the last decade and, even they bring positive effects to small companies; normally, the society has only found the benefit of bad paid jobs, and in many cases, conditions of violence and poverty (Schmitz 1995, 2005, 2006). Thus, it is necessary to initiate new dynamics, where the people find benefits from the creation of clusters, especially in small communities. Vives (2006), stated that long-term sustained benefit only happens when a strategy based in large enterprises that cooperate with small organizations is implemented; but, to be efficient, government support is mandatory. Another form to achieve the same result is that the state dictates policies in economic and environment issues, which contribute to reach tangible benefits to the society. This has been achieved in developed countries. However, in contrast with developing countries, there are yet political obstacles to achieve it, such as the corruption that prevents large enterprises from operating normally, generating little or any benefits in the long-term for the society. So, most clusters of small and medium enterprises in developing countries have been successful in becoming more competitive companies, but they have faced several problems such as political obstacles (Schmitz 2000; Lopez 2007).

The literature about competitiveness in clusters is vast but poor about how and in what form they have benefitted society (Puppim 2008). Global change, public policies, and socially responsible companies have contributed to the clusters’ success, but how to include and improve the local society was the objective from economical authorities and the motivation of this paper.

How well a cluster can be run and be competitive should do in how relationships are established between the different involved actors (Humphrey 2003). The government should foster these relationships, but above all, its interventions should help to directly benefit the communities. Even that the state has influenced in some policies such as the development of industrial parks, this does not provide a direct benefit to the society.

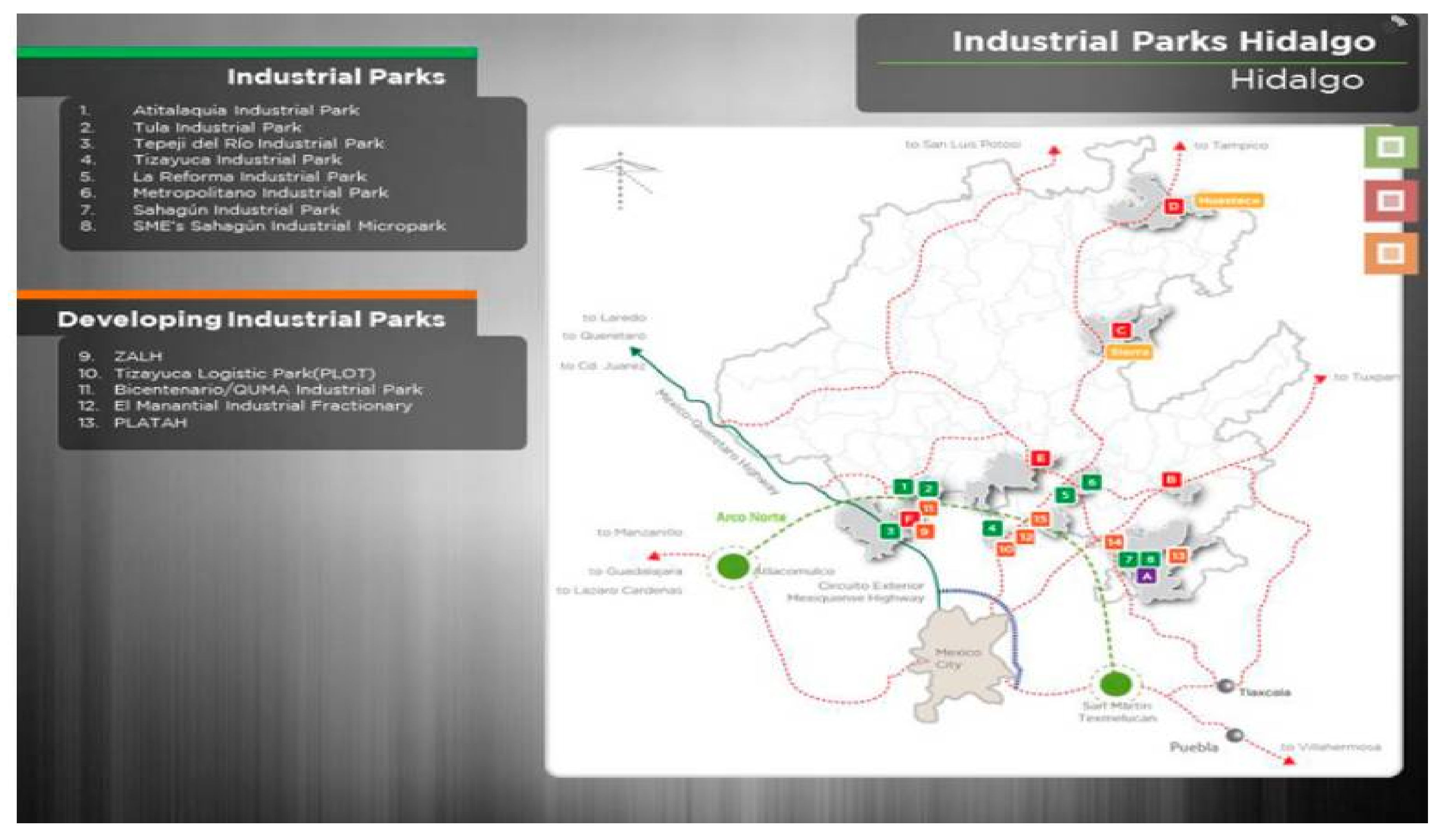

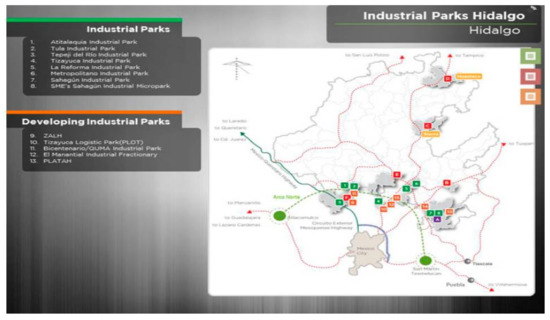

Hence it is necessary to link the concept of cluster with the industrial park. According to the official Mexican Norm R-046-SCFI, an industrial park is a “geometric surface delimitated and designed especially to be an industrial facility” (Mexican Ministry of Economy and Mexican Norm for Industrial Parks 2005). Carrasco (2009), highlights that it is not enough to install a park to foster development, public policies are needed to promote enterprises and society benefitting from this development; something that, despite the installation of several industrial parks in the state of Hidalgo, has not occurred in Sahagun City, according to Figure 2.

Figure 2.

Industrial facilities in the state of Hidalgo, Mexico. Corporación de Fomento de Infraestructura Industrial (2016).

2.2. Metal Mechanic Industry, National, and Local Context

The metal mechanic industry is the sector responsible for obtaining and transforming products from ferrous and non-ferrous metal; it uses as main supplies products from the steel industry, the metal mechanic industry and its respective processes, contribute in an important way to the economy of any nation, not only for their technological impact, but also for their participation in several industrial sectors; such as the automotive, construction, mining, and agricultural sectors.

Mexico’s place as producer of iron and steel is the 13th. This production contributes to the existence of participation in the metal mechanic industry (Mexican Ministry of Economy 2011). The metal mechanic sector provides the 38.5% of the Mexican GDP this percentage comes from two main industrial activities: metal industries and machinery and equipment industry. In this context, the state of Hidalgo contributes 0.03% of the total GDP, representing a minimum level of production in contrast with other Mexican states that conform the metal mechanic sector. This, partially due to the level of maturity of its industry, which is in a developing stage and so, SMEs cover most of the state productive system needs of this sector. Thus, the GDP that provides the Hidalgo state in the metal mechanic sector is 6.06% (Mexican Ministry of Economy 2011) that comes also from two main industrial activities: metal industries and machinery and equipment industries.

The industrial complex of Sahagun city is in the municipality of Tepeapulco Hidalgo, it was created by an initiative of the federal government to foster the economy of the region in the 1960s as a part of the process of creation of state-owned enterprises; it is mainly constituted of companies from the metal mechanic sector. This complex once had 15,000 employees and was the most important employment provider in the region. However, because of the economic and labor circumstances of Mexico’s economy, all the state-owned companies are now privatized. This situation, coupled with a harmful union culture in the region, significantly decreased the importance of the park. Nevertheless, the facilities of the complex remain, and nowadays they have a new dynamic.

In this context, the ministry of economy of Hidalgo carried out several projects for the regional development, based in the creation of industrial clusters conformed by local suppliers. Our project comes from this initiative. Hence, we selected a transnational enterprise with good practices, whose name is not provided due to confidentiality reasons. Therefore, with the information of the company and, through the opinions of its suppliers, executives and the society of Sahagun City, we focused on proposing a model that aids authorities and managers of the park to define a proper way to manage the industrial plant and lead us to the results that are reported in this paper.

3. Methodology

3.1. Hybrid Model

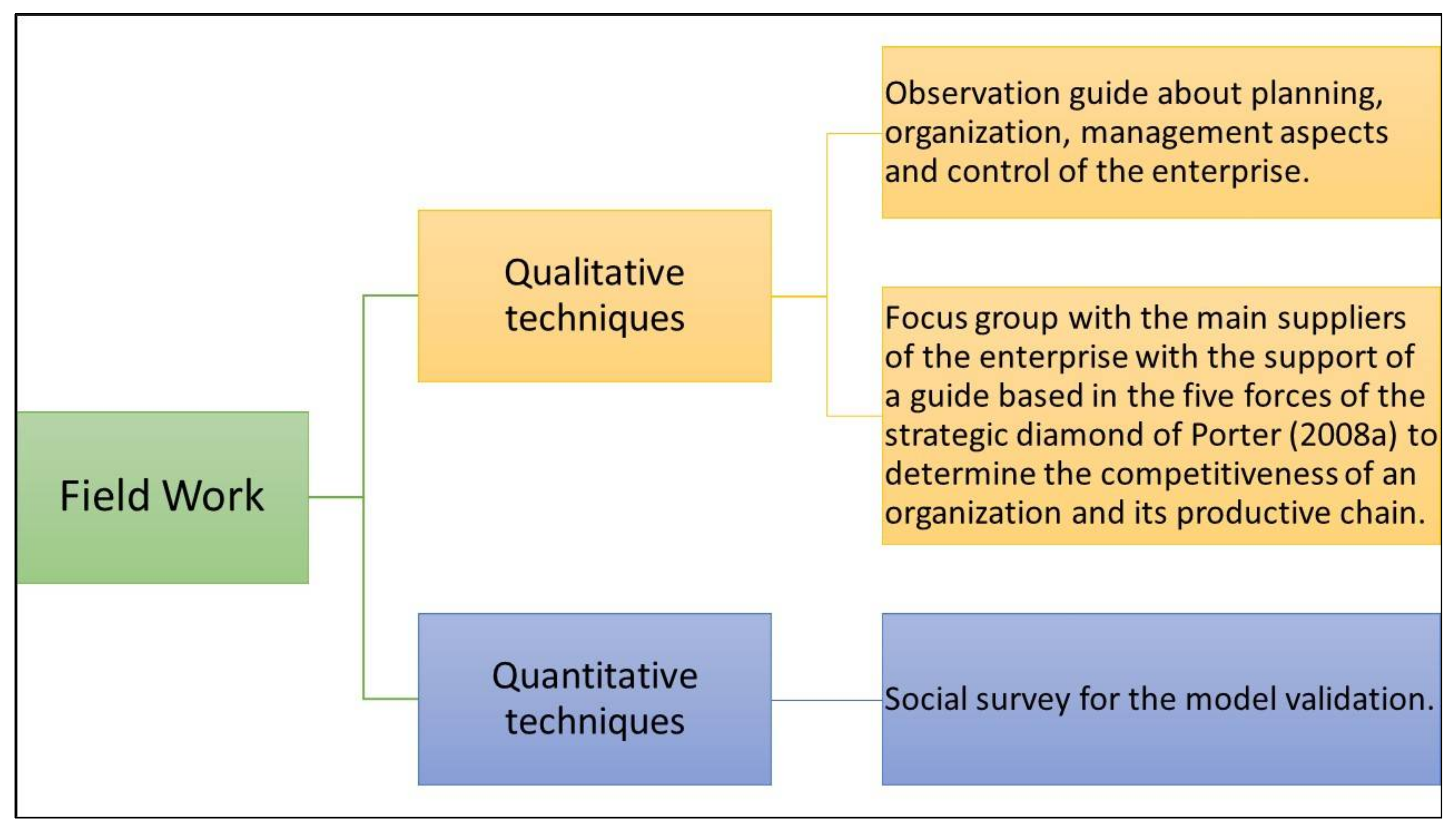

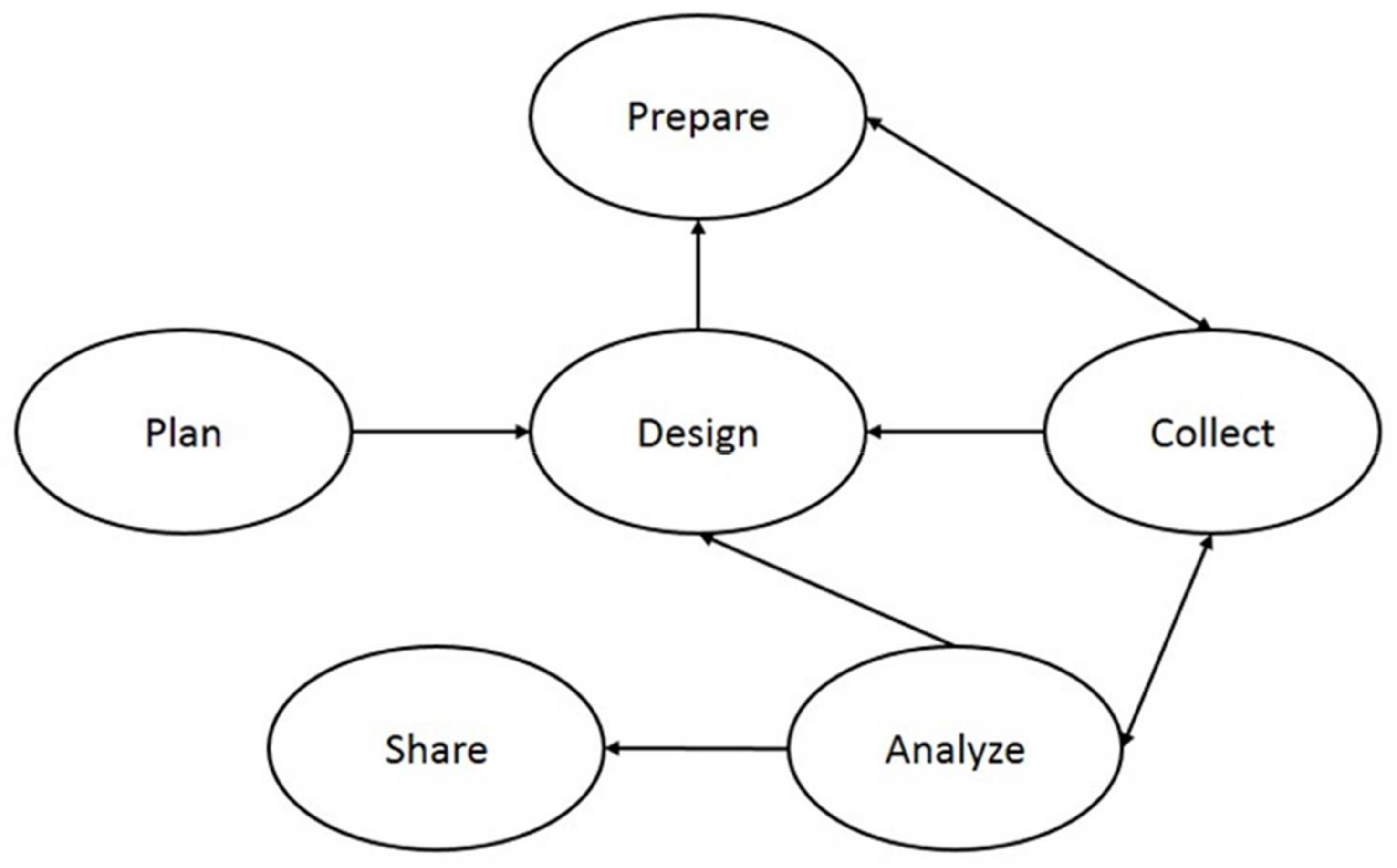

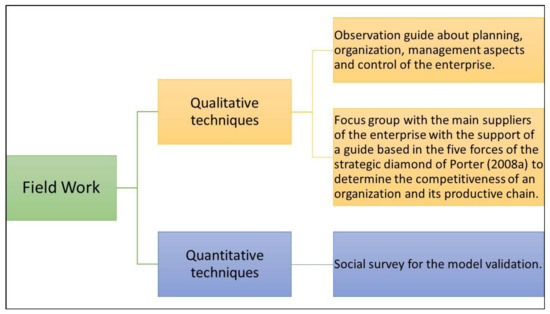

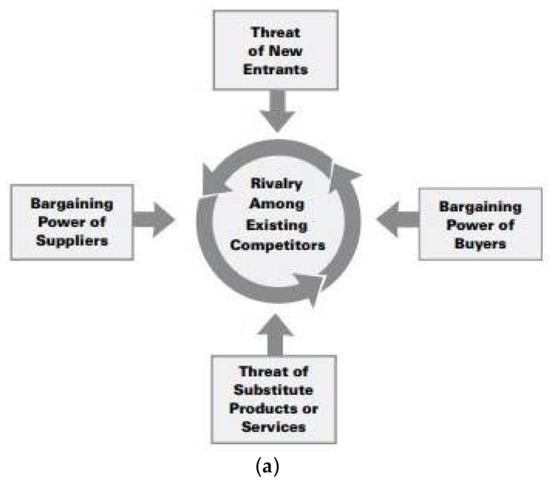

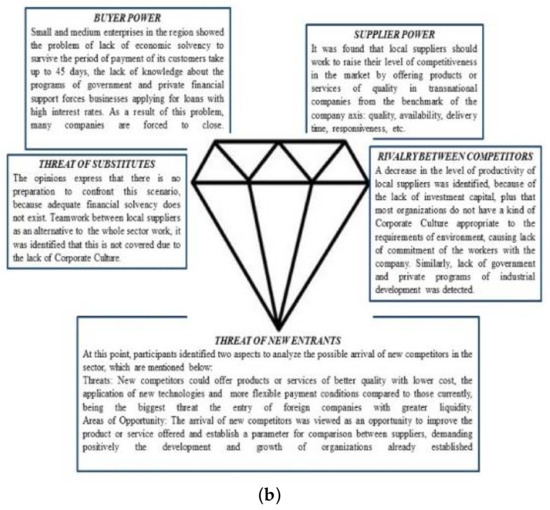

Chavez and Fonseca (2013), point out that a “methodological challenge in the analysis of production frontiers is to separate region-specific technological characteristics from technical efficiency”. So, we started form a holistic methodological approach based in the General Systems Theory and, particularly, in the methodology of soft systems of Peter Checkland, that defines the status of any given problem situation to be then contrasted with the ideal state, through systemic thinking (Checkland 1999). For data gathering and analysis from a sectorial perspective, the strategic diamond of Michael Porter was considered, which defines the relationships between competitors, rivals, suppliers, consumers, and substitute products; this serves as a base for the designing of instruments of research and for the conformation of the strategic methodology. For the application of techniques, a team of three observers and six pollsters was integrated. Audio and video recording equipment and observation rooms were used as well. The methodological strategy, considered a hybrid design (Figure 3): quali-quantitative, applied in the months between November 2012 and January 2013 in a transnational enterprise located in Sahagun City where we worked with local suppliers of this company.

Figure 3.

Hybrid methodological design. Author’s elaboration.

The actions performed were:

- Documentary analysis to formulate a sectorial context at international, national, and state levels from the economic, technological, regulatory and social domains, through information sources such as sectorial indexes, official reports from industrial activities, and newspaper articles.

- Field work through in situ inspections that included the applications of the following techniques:

- Observation guide about planning, organization, management aspects, and control of the enterprise.

- Focus group with the main suppliers of the enterprise with the support of a guide based in the five forces of the strategic diamond of Porter (2008) to determine the competitiveness of an organization and its productive chain.

- Social survey for the model validation.

- Cabinet study for the integration, analysis, and synthesis of information collected with the following phases:

- Construction of the initial model.

- Statistical analysis using Minitab specialized software which performs basic and advanced features.

- Construction of the final model.

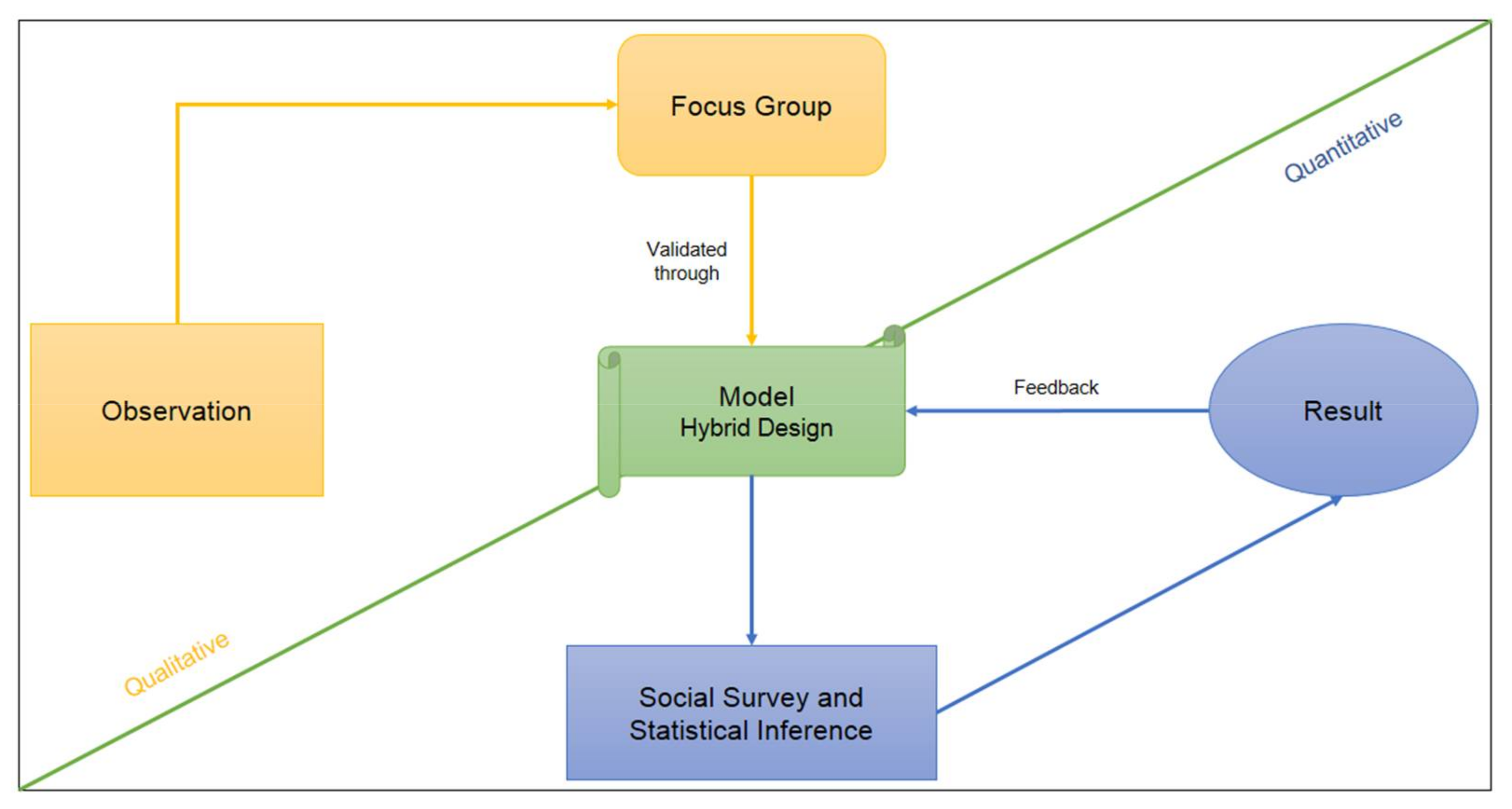

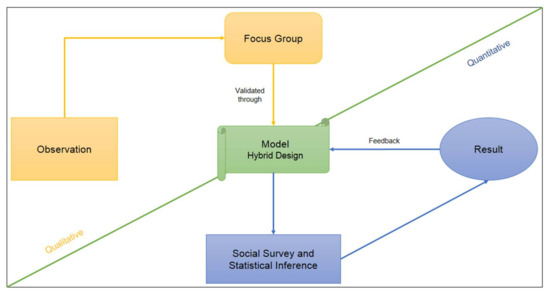

Figure 4 summarizes the methodology applied. Thus, through observations and focus groups, the first version of the model was developed, which was constructed from the social perception based on the social perception survey of the community and validated with statistical inference. In a second step, the definitive version of the model was built and conclusions about it were established.

Figure 4.

Methodological sequence established for the construction of the model. Author’s elaboration.

The methodology is summarized in Figure 4:

3.2. Focus Group

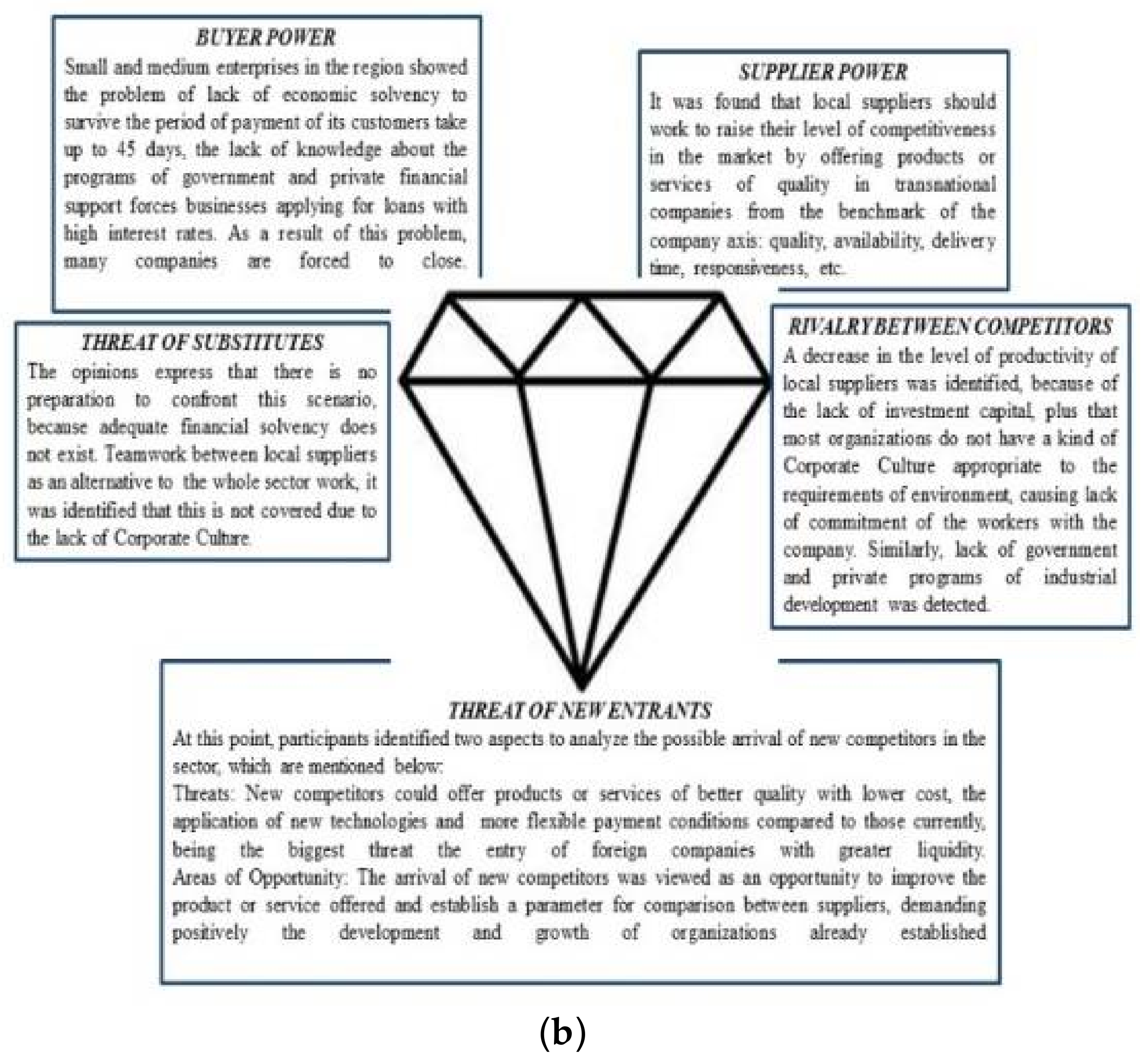

Focus group questions were done with all the local suppliers of the company following Porter’s diamond (2008), Figure 5.

Figure 5.

(a) Porter’s diamond (2008); (b) Author’s elaboration according to Porter’s Diamond.

3.3. Social Survey

The second part of the construction of the model consisted in evaluating the perception of the citizens of Sahagun City, from a social survey. The design of instruments was based on the methodology of Montaño et al. (2012) and validated through nominal group sessions carried out with suppliers of the core company, who indicated the main items of social impact. The questionnaires were validated through the technique of experts consulting through researchers in the areas of economics and demography of the Autonomous University of Hidalgo.

Then, statistical inference was performed using the software Minitab 16.0. To feed the model, survey questions were selected, which are discussed later in the paper. To meet the criterion of representativeness of the population a sample of 380 members of the society were randomly selected, it is worth noting that such surveys were applied in public squares and the municipal market at several times, where the only requirement was that all participants were over 18 years old. The following formula was used to calculate the sample size (Devore 2005)

- n = the sample size.

- N = population size, which in this case was of 28,566 inhabitants according to the National Institute of Statistics and Geography of Mexico (Instituto Nacional de Estadística y Geografía 2010).

- σ = standard deviation of the population, that usually when it is unknown, normally a constant value of 0.5 is used.

- Z = value obtained by confidence levels. The most usual is to select 95% confidence level that it is equal to 1.96.

- e = acceptable error limit, usually a value varying from 1% (0.01) and 9% (0.09), for purposes of this study and for convenience 0.05 was used.

After that, statistical inference was performed to get an estimate of how people think in different areas highlighted in the social survey with 95% confidence. To justify the inference, a representative sample is assumed and, the observations collected are random variables with normal distribution, as presented in the following formula size (Devore 2005):

If is the success rate of a random sample of size n and , an approximate confidence interval of (1 − α) 100% for the binomial parameter p is given by

where z is the z value that has an area of α/2 to the right side of the normal distribution. The questions used to validate and feed the model are presented in the paragraphs below.

Finally, for the analysis of all the collected data, the case study approach (Yin 2013), was followed to understand the situation of industrial parks in Hidalgo. According to Yin (2009), the case study methodology leads to carry out an in-depth analysis of the phenomena of study, giving a real panorama of the object or situation under research.

Therefore, due to the configuration of the industrial plant of the region which comprehends 10 industrial parks and 3 industrial complexes, a treatment of composition and theory building of the topic, under the approach of the case study method (Figure 6), was used; establishing the geographical limits of the industrial zone of the Municipality of Tepeapulco in its design.

Figure 6.

Case study methodology. Yin (2009).

4. Results

4.1. Focus Group Result

With the information provided it was possible to conclude that regarding to Supply Chain relationships (see ‘a’ in Figure 1), suppliers do not have an ‘agile’ or ‘lean’ relationship. Because these are providers of auxiliary services for the company and, only have a minimal relationship with it. Regarding relationships type b (cluster type, ‘b’ in Figure 1), the companies under study do not have a vision about this kind of integration.

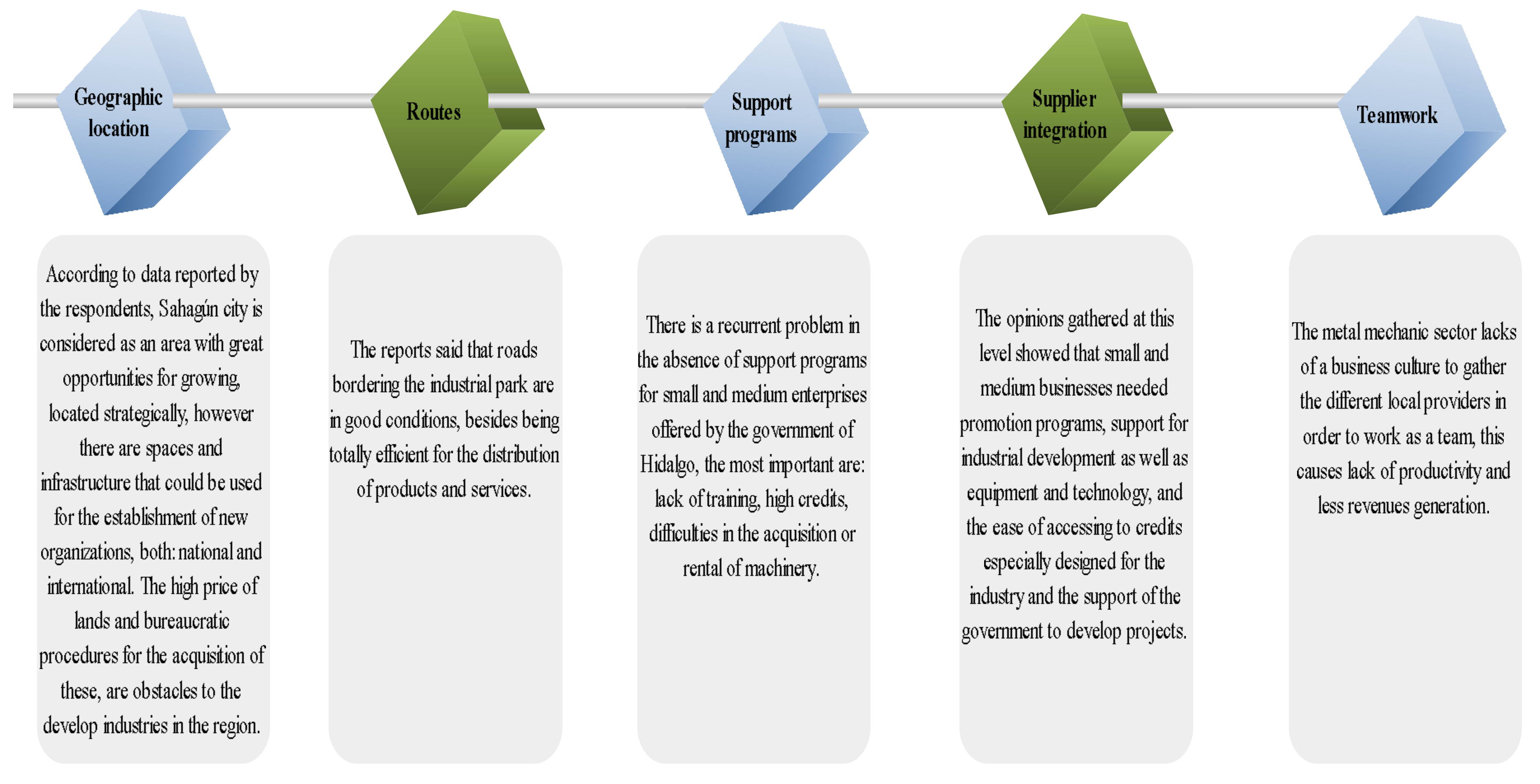

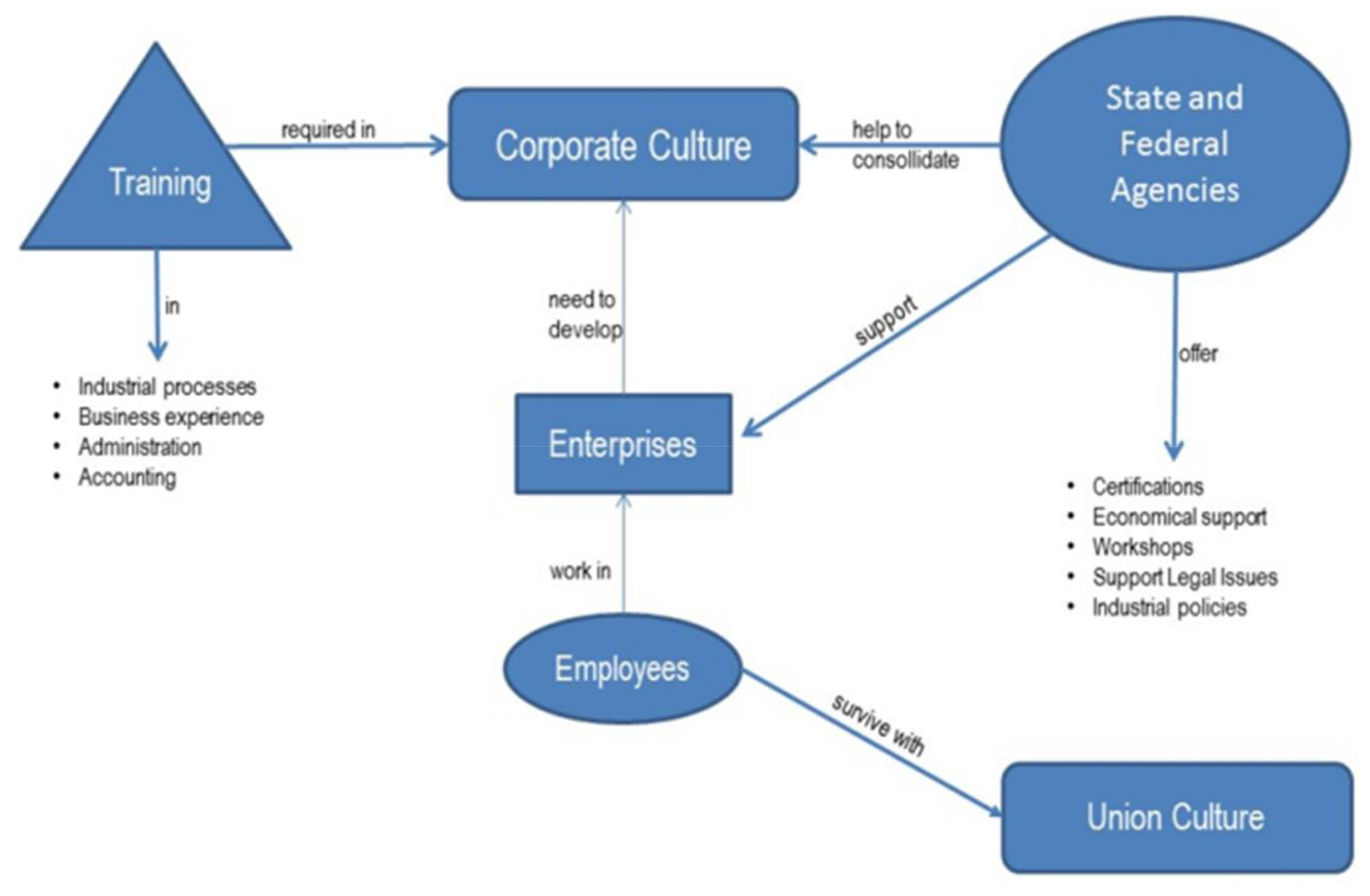

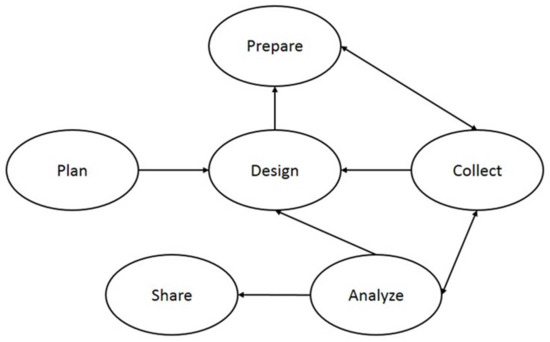

So, the most important aspects identified in the study highlighted that, since they did not have government support, the greatest threat for these small enterprises were competitors, who could offer products with higher quality and more flexible payment terms. A total lack of training was also mentioned, specially the one that allows suppliers to function as formal businesses. Furthermore, the lack of “corporate culture” was also pointed out, understood as the resources and capacities available for the company, which generate intangible assets and/or inimitable strategies considered as explanatory variables of the business competitive success (Barney 1991). According to Figure 7, Sahagun City is located strategically with roads in good condition; however, it does not have the necessary infrastructure and there are many unexploited lands due to difficult procedures to acquire them and exorbitant costs imposed by the authorities for property purchase. Similarly, the lack of government programs that promote training and the lack of economic credits were pointed out.

Figure 7.

Production Chain. Author’s elaboration from information obtained in the focus group.

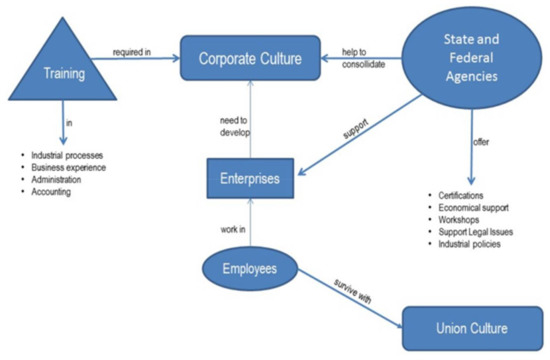

With the information obtained, the first version of a model was developed as shown in Figure 8. This model shows mainly the necessity of government support to create corporate culture in small and medium enterprises, because they do not know fundamentally, conceptual elements to operate as companies and to be competitive in the long-term. Generally, the need for training in strategic planning, accounting, administration, industrial processes, etc., can be observed. The government should also provide financial support, since the credits offered are currently very high. Besides, as pointed out by Gozgor (2016), “the effect of international trade on employment transformation can only exist in the shifting from manufacturing to services”. So, certifications, workshops, and support in legal matters among others, was also identified as a requirement.

Figure 8.

Primary version of the integrative model. Source: Author’s elaboration from information obtained in the focus group.

4.2. Social Survey Results

(a) Educative Level

This was one of the relevant questions in the survey, since it allows measuring the schooling level of the population and, consequently, their level of training. In this question, the explanation is supported with the statistical part (Table 1), and in subsequent sections, only the results are presented. In this case, the results obtained show that 86.47%, (329 of 380 surveyed) responded that they have a level of schooling lower than high school; then that is the proportion used to carry out the inferential analysis in Minitab 16.0.

Table 1.

Statistical inference in Minitab 16.0, level of education.

While making inferences about the entire population of Sahagun City, a confidence interval is calculated with 95% confidence; hence we can say that, between 82.18% and 90.76% have a level of education of high school or lower.

(b) Basic Services in Sahagun City

Statistical inference was conducted on the perception of citizens in basic services. In each case, the confidence intervals obtained with 95% confidence level are presented. The options for each question, for example, in education that are presented in Table 2 included a quality scale based in a structure of multiple choice: very bad, bad, fair, good, and very good.

Table 2.

Basic services, education, statistical inference.

This means that between 57.90% and 69.95% of the whole population believe that education is regular, between 19.56% and 30.43% think that it is good, and between 63.84% and 86.96% combined, believe that education is regular, bad, and very bad; these aspects being very important for the consolidation of the proposed model.

For the other indicators, the sum of regular and very poor is considered in Table 3.

Table 3.

Basic services, statistical inference.

From the previous table, we can observe that the best opinions were in water, streetlight, garbage collection and transportation. However, it can be inferred that more than 60% of the whole population thinks that services are regular and even bad; and so there is much to be improved at this respect.

(c) Opinions of the Industrial Park

Inferences about the perception that citizens have about the industrial park were also performed. Results are shown in Table 4.

Table 4.

Opinions of the industrial park, statistical inference.

The opinion of the citizens about the industrial park is good, since they believe that it creates jobs and improves the welfare of the community; but they think it is misdirected by the authorities and, it is a mismanaged resource that shows a lack of investment. This information had also been previously obtained through the focus group.

(d) Development Factors of the Industrial Park

Other aspects considered in the survey were the factors of development of the industrial park that are shown in Table 5.

Table 5.

Development factors of the industrial park, statistical inference.

Thus, the perception of citizens establishes that the two most notable features that support the development, are industrial training and investment in infrastructure; consistently, the same conclusion was obtained in the focus group.

In this sense, it can be said that for the types of relationships that suppliers have with the company, types ‘a’ or ‘b’ (Figure 9), for the specific case of Mexico , it is necessary to consider the government as a determiner in the integration of supply chains, and a promoter of the benefit towards society.

Figure 9.

Real supply chain integration in Sahagun City. Source: Author’s elaboration.

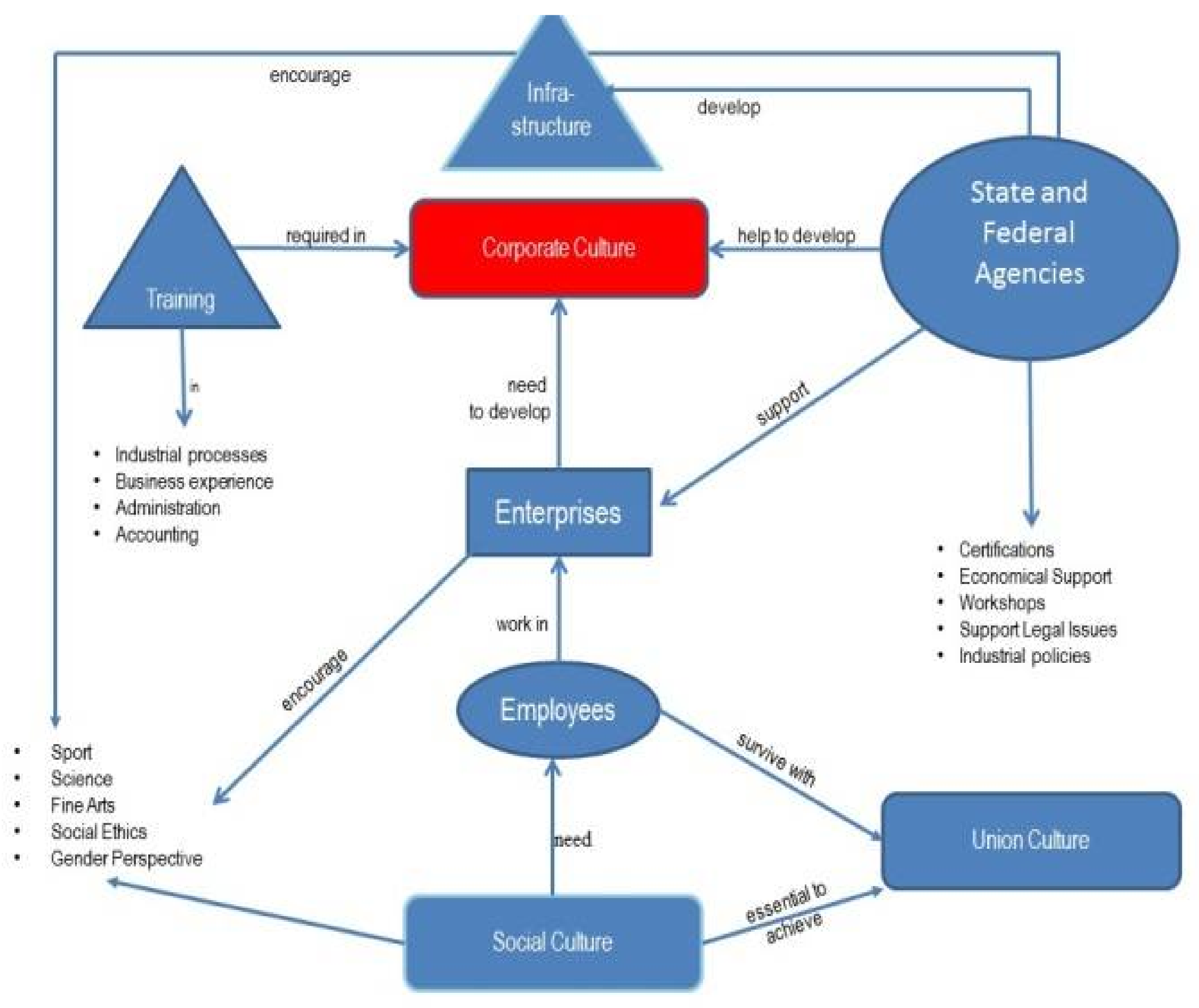

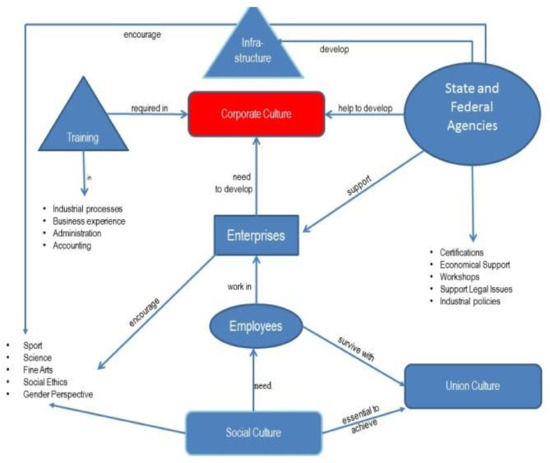

With these results the second version of the model was developed. It is worth highlighting that the social survey partially helped to validate it, and through a methodological design the focus group complemented the process. A notorious difference in this second version is that the social part was included in the business–society–government model. The model is shown in Figure 10.

Figure 10.

Integrative model enterprise–society–government. Source: Author’s own elaboration. Source: Author’s elaboration.

5. Discussion

For the Mexican cultural context, SCM becomes the driving force which encourages changes within the companies emanating from sectorial, political, and governmental supports as well as from international trends.

Besides, society results in a decisive factor of influence, due to its socio-demographic configuration—which includes education, age, socioeconomic stratum, community participation, and perception of the environment—to generate the conditions of viability, adoption, and success of business changes.

In addition, values and beliefs within the Mexican business culture not only establish relationships between companies and consumers, but among stakeholders, authorities, competitors, and the society in general; this allows the supply chain to function (Arato et al. 2017).

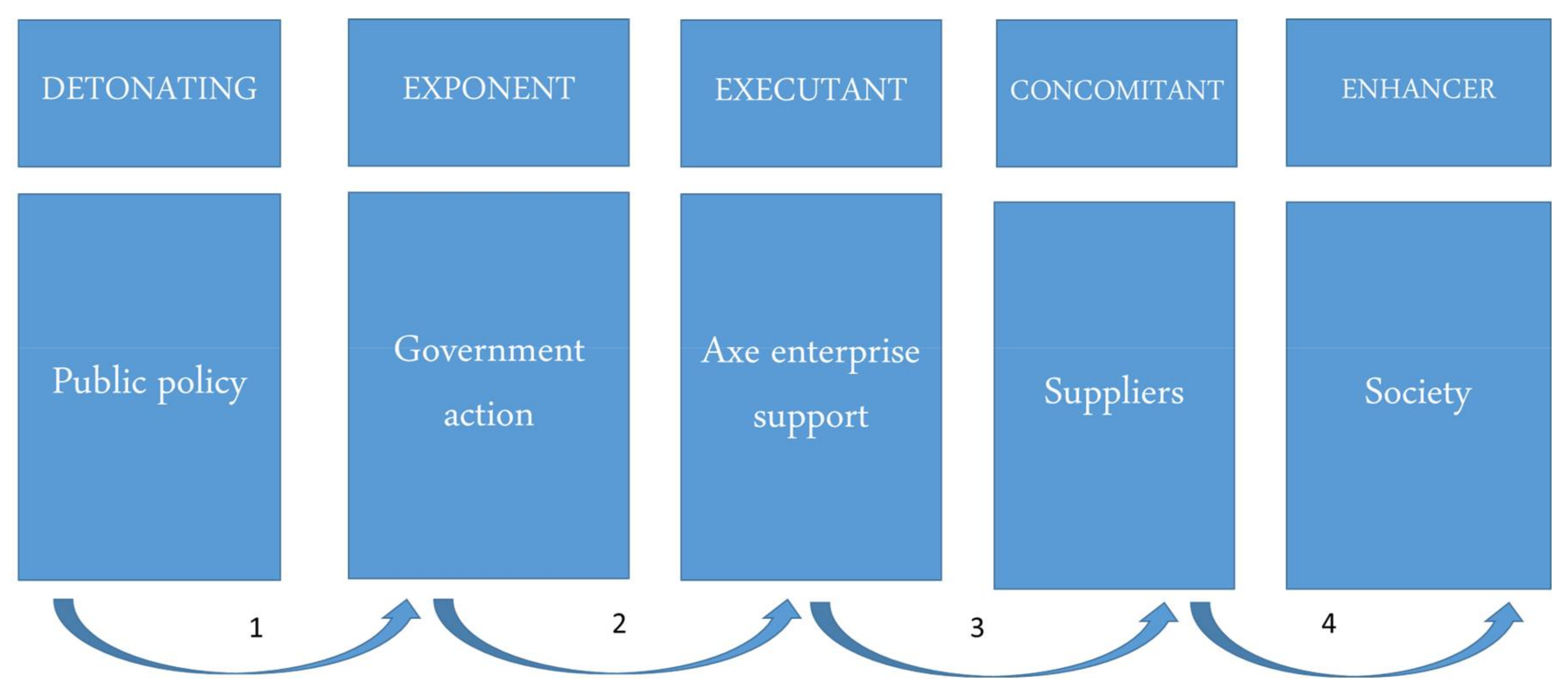

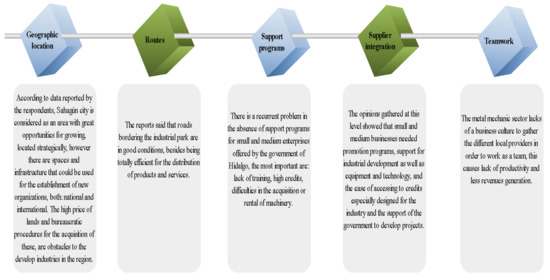

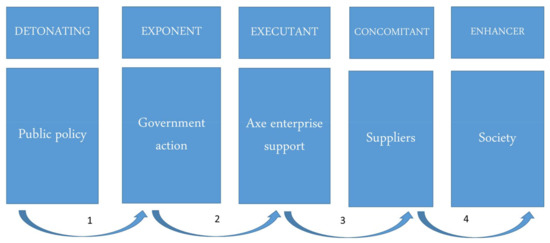

Therefore, based on the results achieved in the study, it was possible to establish a sequential flow that, particularly for the Mexican context enables the integration of suppliers. This flow is shown in Figure 11.

Figure 11.

Sequential flow to enable the integration of suppliers. Source: author’s elaboration.

There are four transition stages in the sequential flow. In the first stage, the implementation of the public policy determines the government action, where authorities lead the procedure, involve all the possible actors and expose the intention. The second transition stage consists of selecting a core enterprise where the policy might be applied, for integration this enterprise is the executant. During the third transition stage, the suppliers converge in a concomitant effort to align their products and services to the requirements and inner demands of the axis enterprise. Finally, in the fourth stage, suppliers become the link with society, making use of its tangible and intangible assets as incomes for their activities, and returns benefits to the society. This sequential flow could be applied in the Mexican context for suppliers’ integration.

6. Model

One of the most important factors to develop companies that supply products and services of the metal-mechanic industry in the industrial park of Sahagun City, is the existence of a corporate culture. Most providers in this municipality operate technically through their experience; based on skills and abilities they acquired during the industrial boom that occurred in this place in the 1960s and 1970s, but they do not have any formal administrative knowledge for effective and efficient operations as companies. They also lack a long-term vision and enough strategies for development. They are totally dependent on large corporations with whom they must negotiate their services to stay in business, sometimes in disadvantageous conditions—completely in the game of supply and demand. Therefore, they are vulnerable to the arrival of new competitors offering a better price or service, and they can easily be replaced, leaving the region without sources of income.

Therefore, there is an imminent need to create special programs for all small and medium businesses, where state and federal agencies foster them to develop a corporate culture, allowing them to clear out their goals, and reach them. In addition, among existing programs with similar aims, it is mandatory to publicize them among all the local suppliers, to get their benefits in the short, medium, and long-term, so they could offer their products and services not only to one company, but several and in different markets.

Popkova et al. (2015) state that “no country under the modern conditions can effectively develop, occupy a worthy place in the international division of labor without proper scientific and technical potential”. Therefore, training plays an important role in the development of suppliers, especially in industrial processes. Management and accounting are also required to operate any business. Through training in these areas, business expertise should be increased exponentially. More specifically, there should be a place in Sahagun City where free counseling about legal, accounting, and administrative issues can be provided. This place should also be a forum, where small and medium entrepreneurs who have had some success could expose their best strategies and guide any other company from a collaborative perspective rather than competition. This space could also serve for state and federal agencies to share their programs of financial support and, they could organize workshops, discuss about industrial policies and foster certifications for companies which require them.

Credits for machinery and land are also necessary to allow small business owners become “formal and real companies” as expressed by respondents with the minimum conditions to operate and provide services of quality.

The development of enterprises would benefit workers in the region, which also needs a social culture—understood as the set of training, relational, and competitive values—that allows workers to conduct themselves in compliance with the rules and customs of their community to perform properly, remunerate enterprises and the region in general, cause as Nystroms refers “regions that have been locked in by a certain industrial structure now are revitalized through a process that replaces stagnating industries with more expansive ones”. It was observed clearly that it is necessary that in both existing companies and state and federal agencies, sports, culture, fine arts, social ethics, and gender perspective should be fomented through campaigns, exhibitions, competitions, theatrical performances, and other activities that encourage workers to be part of the community and acquire a commitment to it.

Also, an opportunity was observed on the issue of ‘gender perspective’, to completely fade away the idea that women can work in companies only in cleaning services or as secretaries; creating programs that promote gender equality, professional development, and offer equitable opportunities; leading companies to have then, more female workers for example, 30% of its workforce and promoting respect for the integrity and ability of women. With this ‘social culture’, not only the development of enterprises, but community development and economic dynamics of the entire region can be promoted. By having this ‘social culture’ along with a better standard of living and, with better thoughts about the workplace, employees will be open to achieve a new and updated union culture, necessary for the survival of the companies of the region.

Thus, a new ‘union culture’ means that the employees’ perception about the union is only for the defense of their rights when necessary, and not to support their irresponsibility. When we talked to employees, and owners of small and medium businesses, we observed that they were aware that the industrial zone of Sahagun City, was severely affected by unions. Then, for them it is necessary that even young people appreciate the importance of a real ‘organizational culture’ and change their point of view, to visions of integration and mutual collaboration between the enterprises and the workforce.

7. Proposed Actions

Based on the integrative enterprise–society–government model, some proposals for specific solutions were developed to solve out the different problems identified in Sahagun City:

- (a)

- Establishing a specialized metrology center for the metal-mechanic sector, expecting as a result, a substantial reduction of costs and downtime at addressing the demands for these kinds of services.

- (b)

- Integrating a chain of indirect suppliers with the aim to create a package of specialized services for both, the core enterprise of this study, as well as for those large companies that decide to opt for such model.

- (c)

- Providing specialized consultancy to micro and small enterprises in terms of process management, accounting, planning, production, certifications, and legal issues to develop a better corporate culture.

- (d)

- Restoring transport routes in the industrial park and surrounding areas to improve the efficiency of the operations of companies that are based there and the image of the region.

- (e)

- Creating an adequate infrastructure for the establishment of banking institutions, as well as other facilities like shopping malls, that would benefit not only to companies but to the community in general.

- (f)

- Increasing the dissemination of existing programs on business development and provide consultancy and training to entrepreneurs and society in general about the use of tools and support provided by government.

- (g)

- Increasing the amount of government support, and the reduction of procedures for the application and a quicker release of credits by government agencies.

- (h)

- Creating schools that foster knowledge of the metal-mechanic industry, decreasing the recruitment of workers from outside the region and thereby reducing the unemployment rate, and increasing the quality of life of people that live in the area.

- (i)

- Installing a business concept hotel that meets the needs of accommodation and food for the general population and personnel linked to enterprises.

- (j)

- Increasing the number of public sports areas for the development of physical and social activities as well as health care, improving the quality of life of workers and local population.

8. Conclusions

This paper describes a business–society–government model for the development of the industrial park of Sahagun City. The methodological basis and the outcomes obtained can work as references for other zones in similar situations.

This qualitative and quantitative case study was developed in two phases, the first one, where a series of focus group interviews were carried out with suppliers of a transnational company and, the second one, where the model was validated and complemented through surveys to the citizens of the community.

The model can identify the need to coordinate the efforts of enterprises, society, and state agencies to achieve economic, social, labor, industrial, and community development, not only in the industrial park, but in the community in general.

Therefore, the proposed solutions are aimed to achieve the integral development of Sahagun City, fostering that companies mainly use local suppliers but, above all, that a long-term benefit for the society can be achieved, as well as a more extensive and successful development of the park that stimulates the generation of improvements of the quality of life of the inhabitants of the area. It is expected that the design of the model can be replicated with other regions of the country, or other countries with similar conditions and, that the methodological design can work as a guide for the development of other proposals and similar models.

As pointed by the literature reviewed, this study highlights the importance of the government in the development process and implementation of clusters, which demand the participation of all the actors involved in supplier integration of the region.

Finally, in the industrial park of Sahagun City, there is not a business culture oriented to the integration of suppliers, with the government being the determining factor of such developments. Therefore, the model demonstrated here shows a way to articulate the correlated elements identified in the process: government and society, which turn to be key factors for successful practices of supply chain integration in the Mexican context. For this purpose, the sequential flow of the Figure 11 could be applied. The results emanated from this research were considered by the authorities to create policies, regarding the development of the park. The impact of the strategies presented in this paper will required further research, taking into consideration the new context of the region and government or the state. In Table 6, findings, limitations and value added are mentioned.

Table 6.

Findings, limitations, and value added.

Author Contributions

Antonio Oswaldo Ortega Reyes: State of the Art, Research Methodology, Interviews to the suppliers in the Focal Group, Analysis and Discussion of Results, Review and Contributions to the Integrative Model, Conclusions, Writing and Editing of Article. Eva Selene Hernández Gress: State of the Art, Interviews to the suppliers in the Focal Group, Statistical Analysis of the Social Surveys, Integrative Model, Analysis and Discussion of Results, Conclusions, Writing and Editing of Article. Carlos Robles Acosta: Contributions and review to the research methodology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmad, Sohel, and Roger G. Schroeder. 2001. The impact of electronic data interchange on delivery performance. Production Operations Management 10: 16–30. [Google Scholar] [CrossRef]

- Albors-Garrigos, Jose, Blanca de Miguel Molina, and Maria de Miguel Molina. 2014. Positioning in the Global Value Chain as a Sustainable Strategy: A Case Study in a Mature Industry. Administrative Sciences 4: 155–72. [Google Scholar] [CrossRef]

- Arato, Miguel, Stijn Speelman, Joost Dessein, and Guido Van Huylenbroeck. 2017. Assessment of socio-economic configuration of value chains: A proposed analysis framework to facilitate integration of small rural producers with global agribusiness. International Food and Agribusiness Management Review 20: 25–43. [Google Scholar] [CrossRef]

- Ardalan, Ali, and Rafael Díaz. 2012. NERJIT: Using net requirement data in kanban-controlled jumbed flow shops. Production Operations Management 21: 606–18. [Google Scholar] [CrossRef]

- Barney, Jay. 1991. Firm resources and sustained competitive advantage. Journal of Management 17: 99–120. [Google Scholar] [CrossRef]

- Bernstein, Thomas P., and Xiaobo Lu. 2009. Taxation without Representation Peasants, the Central and Local States in Reform China. The China Quarterly 163: 742–63. [Google Scholar] [CrossRef]

- Blyde, Juan S. 2014. The participation of Mexico in global supply chains: The challenge of adding Mexican value. Applied Economics Letters 21: 501–4. [Google Scholar] [CrossRef]

- Carrasco, Ana Grisel Maldonado. 2009. Parques industriales de México: Dos perspectivas de desarrollo. Comercio Exterior 59: 60–70. [Google Scholar]

- Chavez, Juan Carlos, and Felipe J. Fonseca. 2013. Technical Efficiency, Development, and Productivity Gap in Mexico. Regional and Sectoral Economic Studies 13: 43–58. [Google Scholar]

- Checkland, Peter. 1999. Systems Thinking, Systems Practice: Includes a 30-Year Retrospective. 1a Edición: Estados Unidos de América. Hoboken: John Wiley and Sons, p. 424. ISBN 13 978-0471986065. [Google Scholar]

- Chopra, Sunil, and Peter Meindl. 2003. Supply Chain Management: Strategy, Planning and Operation. Upper Saddle River: Prentice Hall. [Google Scholar]

- Corporación de Fomento de Infraestructura Industrial. 2016. Infraestructura Industrial de Hidalgo. Available online: http://cofoin.hidalgo.gob.mx/?=49 (accessed on 10 August 2016).

- Cruz-Sotelo, Samantha E., Sara Ojeda-Benítez, Jorge Jáuregui Sesma, Karla I. Velázquez-Victorica, Néstor Santillán-Soto, O. Rafael García-Cueto, Víctor Alcántara Concepción, and Camilo Alcántara. 2017. E-Waste Supply Chain in Mexico: Challenges and Opportunities for Sustainable Management. Sustainability 9: 503. [Google Scholar] [CrossRef]

- Devore, Jay. 2005. Probabilidad y Estadística para Ingeniería y Ciencias, 6th ed. Bañuelos Saucedo (revisor técnico). México: Thomson, p. 794. ISBN 970-686-457-1. [Google Scholar]

- Durán-Encalada, Jorge Alberto, and François Bernard Duhamel. 2014. Logistics service characteristics and supply chain priorities for freight management: A Mexican case. Academia Revista Latinoamericana de Administración 27: 236–66. [Google Scholar] [CrossRef]

- García-Reyes, Heriberto, and Ronald Giachetti. 2010. Using experts to develop a supply chain maturity model in Mexico. Supply Chain Management: An International Journal 15: 415–24. [Google Scholar] [CrossRef]

- Gereffi, Gary. 2008. Development models and industrial upgrading in China and Mexico. European Sociological Review 25: 37–51. [Google Scholar] [CrossRef]

- Gozgor, Giray. 2016. International Trade and Manufacturing Employment in Developed Economies: An Empirical Study. Regional and Sectoral Economic Studies 16: 5–16. [Google Scholar]

- Humphrey, John. 2003. Opportunities of SMES in Developing Countries to Upgrade Global Economy, 1st ed. Suiza: International Labour Organization Publications, p. 38. ISBN 92-2-113-68-84. [Google Scholar]

- Instituto Nacional de Estadística y Geografía. 2010. Estados Unidos Mexicanos. Perfil Sociodemográfico, Censo de Población y Vivienda. Aguascalientes: Instituto Nacional de Estadística y Geografía, p. 281. ISBN 978-607-494-531-7. [Google Scholar]

- Kisperska-Moron, Danuta, and Job De Haan. 2011. Improving supply chain performance to satisfy final customers: “leagile” experiences on a polish distributor. International Journal of Production Economics 133: 127–34. [Google Scholar] [CrossRef]

- Konstantynova, Anastasiia, and Tine Lehmann. 2017. Cluster Activities in Different Institutional Environments. Case Studies of ICT-Clusters from Austria, Germany, Ukraine and Serbia. Administrative Sciences 7: 11. [Google Scholar] [CrossRef]

- Lehmann, Tine, and Maximilian Benner. 2015. Cluster Policy in the Light of Institutional Context—A Comparative Study of Transition Countries. Administrative Sciences 5: 188–212. [Google Scholar] [CrossRef]

- Lopez, Lira Nidia. 2007. Elementos de integración de microempresas comerciales en el oriente del Estado de México en el siglo XXI. Contaduría y Administración 221: 109–36. [Google Scholar]

- Mexican Ministry of Economy. 2011. Estados Unidos Mexicanos, Monografía del Sector Siderúrgico de México, Dirección General de Industrias Pesadas y de Alta Tecnología. Mexico: Secretaría de Economía, p. 28. [Google Scholar]

- Mexican Ministry of Economy, and Mexican Norm for Industrial Parks. 2005. NMX-R046-SCFI, Estados Unidos Mexicanos. Mexico: Secretaría de Economía. [Google Scholar]

- Mintzberg, Henry. 1996. Managing Government Governing Management. Harvard Business Review 74: 75–83. [Google Scholar]

- Montaño Arango, Oscar, José Ramón Corona-Armenta, Jaime Garnica-González, Heriberto Niccolas-Morales, Pablo Martínez-Castelán, and Antonio Oswaldo Ortega-Reyes. 2012. Modelo sistémico para la conformación de un cluster turístico regional de naturaleza sustentable. Economía, Sociedad y Territorio 12: 493–525. [Google Scholar] [CrossRef][Green Version]

- Okamuro, Hiroyuki, and Junichi Nishimura. 2015. Local Management of National Cluster Policies: Comparative Case Studies of Japanese, German, and French Biotechnology Clusters. Administrative Sciences 5: 213–39. [Google Scholar] [CrossRef]

- Popkova, Elena G., Sergei A. Abramov, Lilia V. Ermolina, and Evgenii V. Gandin. 2015. Strategic Effectiveness Evaluation as Integral Part of the Modern Enterprise. Asian Social Science 11: 16–21. [Google Scholar] [CrossRef][Green Version]

- Porter, Michael E. 2008. Las cinco fuerzas competitivas que le dan forma a la estrategia. Harvard Business Review 86: 58–77. [Google Scholar]

- Puppim, de Oliveira Jose. 2008. Upgrading Clusters and Small Enterprises in Developing Countries: Enviromental, Labor, Innovation and Social Issues, 1st ed. New York: Ashgate Publishing Limited, p. 196. ISBN 978-0-7546-72975. [Google Scholar]

- Qi, Yinan, Baofeng Huo, Zhiqiang Wang, and Hoi Yan Jeff Yeung. 2017. The impact of operations and supply chain strategies on integration and performance. International Journal of Production Economics 185: 162–74. [Google Scholar] [CrossRef]

- Schmitz, Hubert. 1995. Small shoemakers and Fordist Giants: Tale of a supercluster. World Development 23: 9–28. [Google Scholar] [CrossRef]

- Schmitz, Hubert. 2000. Does Local Co-operation Matter? Evidence from Industrial Clusters in South Asia and Latin America. Oxford Development Studies 28: 23–336. [Google Scholar] [CrossRef]

- Schmitz, Hubert. 2005. Value Chain Analysis for Policy Makers and Practitioners, 1st ed. Suiza: International Labour Organization Publications, p. 74. ISBN 92-2-117738-6. [Google Scholar]

- Schmitz, Hubert. 2006. Local enterprises in the Global Economy Issues of Governance and Upgrading. Growth and Change a Journal of Urban and Regional Policy 3: 320–22. [Google Scholar] [CrossRef]

- Syarif, Admi, YoungSu Yun, and Mitsuo Gen. 2002. Study on multi-stage logistic chain network: A spanning tree based genetic algorithm approach. Computational Industrial Engineering 43: 299–314. [Google Scholar] [CrossRef]

- Vives, Antonio. 2006. Social and Enviromental responsability in small and medium enterprises in Latin America. The Journal of Corporate Citizenship 21: 39–50. [Google Scholar] [CrossRef]

- Yeh, Wei-Chang. 2005. A hybrid heuristic algorithm for the multistage supply chain network problem. International Journal of Advanced Manufacturing Technology 26: 675–85. [Google Scholar] [CrossRef]

- Yin, Robert K. 2009. Case Study Research. Applied Social Research Methods Series Volume 5, 4th ed. Thousand Oaks: SAGE Publications, Inc. [Google Scholar]

- Yin, Robert K. 2013. Case Study Research: Design and Methods. Thousand Oaks: Sage Publications. [Google Scholar]

- Zhao, Xiande, Baofeng Huo, Barbara B. Flynn, and Jeff Hoi Yan Yeung. 2008. The impact of power and relationship commitment on the integration between manufacturers and customer in a supply chain. Journal of Operations Management 26: 368–88. [Google Scholar] [CrossRef]

- Zhao, Xiande, Baofeng Huo, Willem Selen, and Jeff Hoi Yan Yeung. 2011. The impact of internal integration and relationship commitment on external integration. Journal of Operations Management 29: 17–32. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).