Institutional, Resource-Based, Stakeholder and Legitimacy Drivers of Green Manufacturing Adoption in Industrial Enterprises

Abstract

1. Introduction

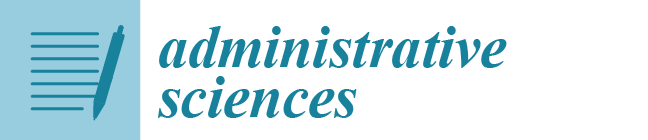

2. Theoretical Framework

2.1. Institutional Theory

2.2. Resource-Based View

2.3. Stakeholder Theory

2.4. Legitimacy Theory

2.5. Integration of Institutional, Resource-Based, Stakeholder, and Legitimacy Perspectives

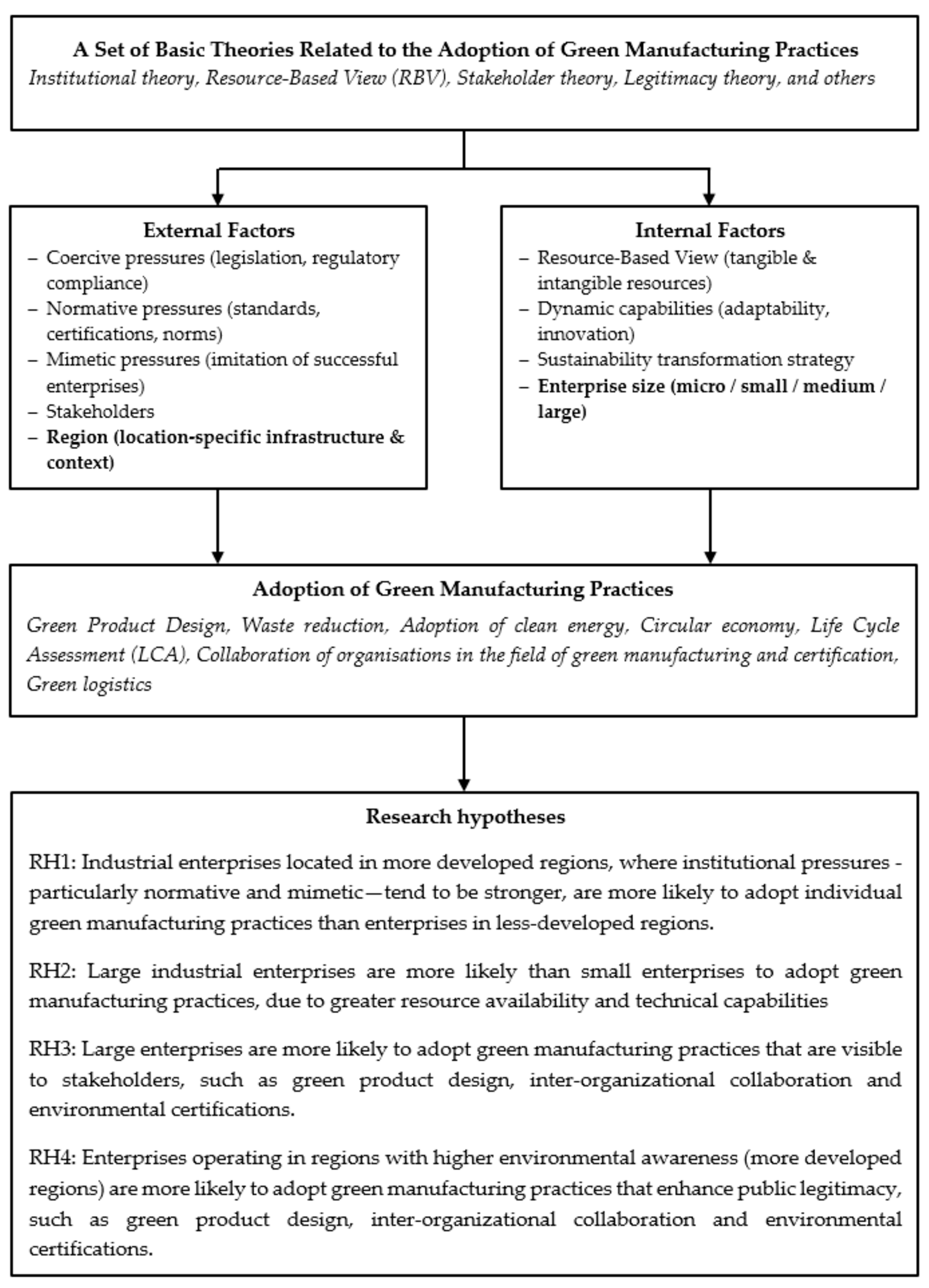

3. Materials and Methods

- pi denotes the probability that enterprise i adopts the given practice;

- Size is the size of the enterprise;

- Region is the region in which the enterprise is located;

- β0, β1, β2 is a constant and coefficient of the logistic regression.

4. Results

4.1. Level of Green Manufacturing Adoption

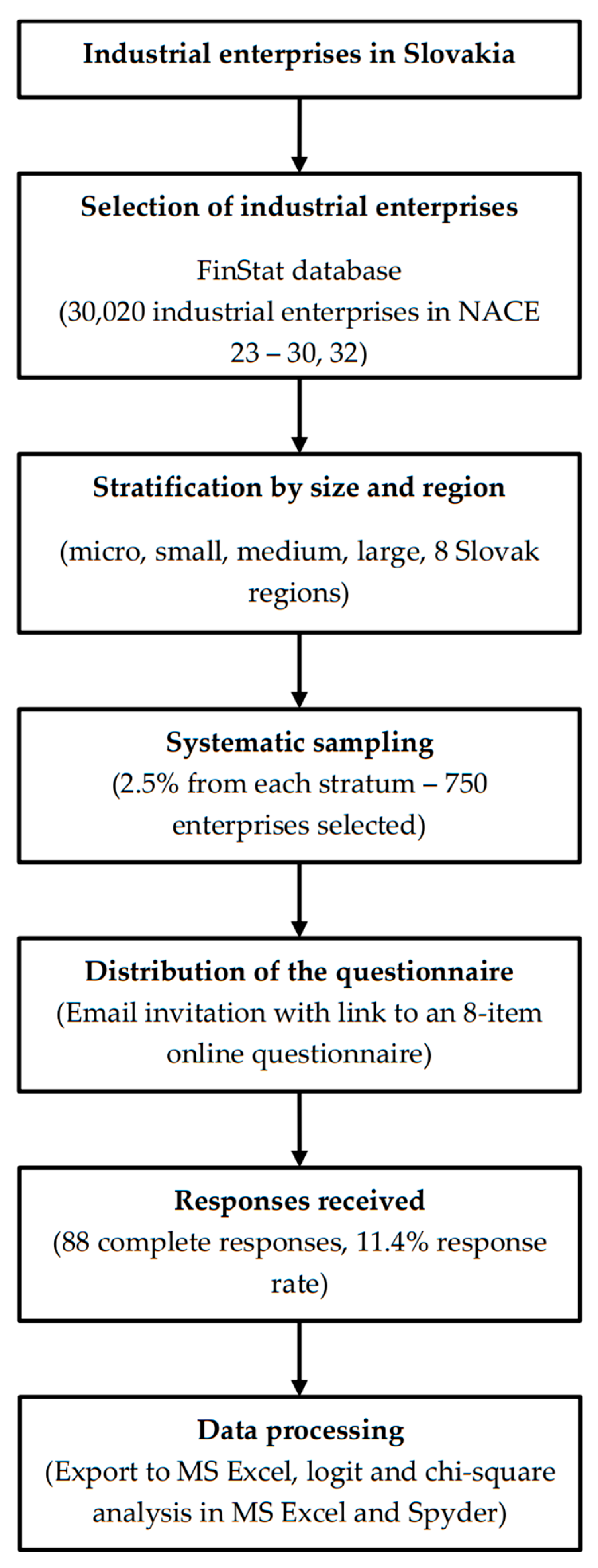

4.2. Regional Differences in the Adoption of Green Manufacturing Practices

4.3. Differences in the Adoption of Green Manufacturing Practices According to Enterprise Size

- Sustainable Product Design

- Resource Conservation

- Adoption of Clean Energy

- Waste Reduction

- Life Cycle Assessment (LCA)

- Collaboration

- Green Logistics

5. Discussion

6. Conclusions

- Invest in research and development of green technologies and processes.

- Actively seek out calls for proposals and financial support for technologies that promote green manufacturing.

- Strengthen cooperation with partners and stakeholders.

- Educate employees and develop green competencies.

- Regularly assess environmental performance and set sustainability goals.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abualfaraa, W., Salonitis, K., Al-Ashaab, A., & Ala’raj, M. (2020). Lean-green manufacturing practices and their link with sustainability: A critical review. Sustainability, 12(3), 981. [Google Scholar] [CrossRef]

- Acquah, I. S. K., Baah, C., Agyabeng-Mensah, Y., & Afum, E. (2023). Green procurement and green innovation for green organizational legitimacy and access to green finance: The mediating role of total quality management. Global Business and Organizational Excellence, 42(3), 24–41. [Google Scholar] [CrossRef]

- Al-Hakimi, M. A., Al-Swidi, A. K., Gelaidan, H. M., & Mohammed, A. (2022). The influence of green manufacturing practices on the corporate sustainable performance of SMEs under the effect of green organizational culture: A moderated mediation analysis. Journal of Cleaner Production, 376, 134346. [Google Scholar] [CrossRef]

- Andersén, J. (2021). A relational natural-resource-based view on product innovation: The influence of green product innovation and green suppliers on differentiation advantage in small manufacturing firms. Technovation, 104, 102254. [Google Scholar] [CrossRef]

- Baah, C., Afum, E., Agyabeng-Mensah, Y., Osei, R., & Anarfi, E. (2022). Stakeholder influence on adoption of circular economy principles: Measuring implications for satisfaction and green legitimacy. Circular Economy and Sustainability, 2, 91–111. [Google Scholar] [CrossRef]

- Baah, C., Opoku-Agyeman, D., Acquah, I. S. K., Agyabeng-Mensah, Y., Afum, E., Faibil, D., & Abdoulaye, F. A. M. (2021). Examining the correlations between stakeholder pressures, green manufacturing practices, enterprise reputation, environmental and financial performance: Evidence from manufacturing SMEs. Sustainable Manufacturing and Consumption, 27, 100–114. [Google Scholar] [CrossRef]

- Baeshen, Y., Soomro, Y. A., & Bhutto, M. Y. (2021). Determinants of green innovation to achieve sustainable business performance: Evidence from SMEs. Frontiers in Psychology, 12, 767968. [Google Scholar] [CrossRef]

- Barbieri, N., Consoli, D., Napolitano, L., Perruchas, F., Pugliese, E., & Sbardella, A. (2023). Regional technological capabilities and green opportunities in Europe. Journal of Technology Transfer, 48, 749–778. [Google Scholar] [CrossRef]

- Bello-Pintado, A., Machuca, J. A. D., & Danese, P. (2023). Stakeholder pressures and sustainability practices in manufacturing: Consideration of the economic development context. Business Strategy and the Environment, 32(7), 4084–4102. [Google Scholar] [CrossRef]

- Bhandari, K. R., Ranta, M., & Salo, J. (2022). The resource-based view, stakeholder capitalism, ESG, and sustainable competitive advantage: The enterprise’s embeddedness into ecology, society, and governance. Business Strategy and the Environment, 31(5), 2073–2087. [Google Scholar] [CrossRef]

- Bıçakcıoğlu-Peynirci, N., & Tanyeri, M. (2022). Stakeholder and resource-based antecedents and performance outcomes of green export business strategy: Insights from an emerging economy. International Journal of Emerging Markets, 17(1), 1–46. [Google Scholar] [CrossRef]

- Buttol, P., Buonamici, R., Naldesi, L., Zamagni, A., Masoni, P., & Russo, C. (2012). Integrating services and tools in an ICT platform to support eco-innovation in SMEs. Clean Technologies and Environmental Policy, 14, 211–221. [Google Scholar] [CrossRef]

- Calza, F., Parmentola, A., & Tutore, I. (2017). Types of green innovations: Ways of implementation in a non-green industry. Sustainability, 9(8), 1301. [Google Scholar] [CrossRef]

- Chen, C., & Panichakarn, B. (2024). Can company size and region shape the sustainability landscape? Exploring their moderating effects on green innovation in Chinese manufacturing. International Journal of Information Systems and Supply Chain Management, 17(1), 18. [Google Scholar] [CrossRef]

- Chen, J. C., & Roberts, R. W. (2010). Toward a more coherent understanding of the organization–society relationship: A theoretical consideration for social and environmental accounting research. Journal of Business Ethics, 97(4), 651–665. [Google Scholar] [CrossRef]

- Chen, Y., Zhu, Q., & Sarkis, J. (2024). Heterogeneity in corporate green supply chain practice adoption: Insights from institutional fields. Business Strategy and the Environment, 33(2), 389–406. [Google Scholar] [CrossRef]

- DiMaggio, P. J., & Powell, W. W. (1983). The iron cage revisited: Institutional isomorphism and collective rationality in organizational fields. American Sociological Review, 48(2), 147–160. [Google Scholar] [CrossRef]

- Dornfeld, D. A. (2013). Green manufacturing: Fundamentals and applications. Springer. [Google Scholar]

- European Commission. (2003). Commission recommendation of 6 May 2003 concerning the definition of micro, small and medium-sized enterprises (2003/361/EC). Official Journal of the European Union L, 124, 36–41. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32003H0361 (accessed on 30 June 2025).

- Freeman, R. E. (1984). Strategic management: A stakeholder approach. Pitman. [Google Scholar]

- Freeman, R. E., Dmytriyev, S. D., & Phillips, R. A. (2021). Stakeholder theory and the resource-based view of the enterprise. Journal of Management, 47(7), 1757–1770. [Google Scholar] [CrossRef]

- Fu, Y., Supriyadi, A., Wang, T., Wang, L., & Cirella, G. T. (2020). Effects of regional innovation capability on the green technology efficiency of China’s manufacturing industry: Evidence from listed companies. Energies, 13(20), 5467. [Google Scholar] [CrossRef]

- Gavronski, I., Klassen, R. D., Vachon, S., & do Nascimento, L. F. M. (2011). A resource-based view of green supply management. Transportation Research Part E: Logistics and Transportation Review, 47(6), 872–885. [Google Scholar] [CrossRef]

- Gomes, S., Pinho, M., & Lopes, J. M. (2023). From environmental sustainability practices to green innovations: Evidence from small and medium-sized manufacturing companies. Corporate Social Responsibility and Environmental Management, 31(3), 1677–1687. [Google Scholar] [CrossRef]

- Grashof, N., & Basilico, S. (2024). Divergent paths for green transition: Regional disparities in technology diversification. Regional Studies, 59(1), 2363327. [Google Scholar] [CrossRef]

- Grillitsch, M., & Hansen, T. (2019). Green industry development in different types of regions. European Planning Studies, 27(11), 2163–2183. [Google Scholar] [CrossRef]

- Haleem, A., Javaid, M., Singh, R. P., Suman, R., & Qadri, M. A. A. (2023). A pervasive study on green manufacturing towards attaining sustainability. Green Technologies and Sustainability, 1(2), 100018. [Google Scholar] [CrossRef]

- Jabbour, C. J. C., Seuring, S., de Sousa Jabbour, A. B. L., Jugend, D., Fiorini, P. D. C., Latan, H., & Izeppi, W. C. (2020). Stakeholders, innovative business models for the circular economy and sustainable performance of enterprises in an emerging economy facing institutional voids. Journal of Environmental Management, 264, 110416. [Google Scholar] [CrossRef]

- Jiang, Y., Mintah Ampaw, E., Asante, D., & Ayambire, R. A. (2024). Green innovation dynamics in Chinese manufacturing enterprises: A new institutional and stakeholder theory inquiry. Environment, Development and Sustainability. [Google Scholar] [CrossRef]

- Jum’a, L., Ikram, M., Alkalha, Z., & Alaraj, M. (2022). Factors affecting managers’ intention to adopt green supply chain management practices: Evidence from manufacturing enterprises in Jordan. Environmental Science and Pollution Research, 29, 5605–5621. [Google Scholar] [CrossRef]

- Kannan, D., Shankar, K. M., & Gholipour, P. (2022). Paving the way for a green transition through mitigation of green manufacturing challenges: A systematic literature review. Journal of Cleaner Production, 368, 132578. [Google Scholar] [CrossRef]

- Karuppiah, K., Sankaranarayanan, B., Ali, S. M., Chowdhury, P., & Paul, S. K. (2020). An integrated approach to modeling the barriers in implementing green manufacturing practices in SMEs. Journal of Cleaner Manufacturing, 265, 121737. [Google Scholar] [CrossRef]

- Khan, M., Ajmal, M. M., Jabeen, F., Talwar, S., & Dhir, A. (2023). Green supply chain management in manufacturing firms: A resource-based viewpoint. Business Strategy and the Environment, 32(4), 1603–1618. [Google Scholar] [CrossRef]

- Li, Y., Ye, F., Dai, J., Zhao, X., & Sheu, C. (2019). The adoption of green practices by Chinese firms: Assessing the determinants and effects of top management championship. International Journal of Operations & Production Management, 39(4), 550–572. [Google Scholar] [CrossRef]

- Lin, R.-J., & Sheu, C. (2012). Why do firms adopt/implement green practices?—An institutional theory perspective. Procedia—Social and Behavioral Sciences, 57, 533–540. [Google Scholar] [CrossRef]

- Lin, W.-L., Cheah, J.-H., Azali, M., Ho, J. A., & Yip, N. (2019). Does enterprise size matter? Evidence on the impact of the green innovation strategy on corporate financial performance in the automotive sector. Journal of Cleaner Manufacturing, 229, 974–988. [Google Scholar] [CrossRef]

- Liu, Z., Li, R., Zhang, X. T., Shen, Y., Yang, L., & Zhang, X. (2021). Inclusive green growth and regional disparities: Evidence from China. Sustainability, 13(21), 11651. [Google Scholar] [CrossRef]

- Malik, S. Y., Cao, Y., Mughal, Y. H., Kundi, G. M., Mughal, M. H., & Ramayah, T. (2020). Pathways towards sustainability in organizations: Empirical evidence on the role of green human resource management practices and green intellectual capital. Sustainability, 12(8), 3228. [Google Scholar] [CrossRef]

- Marin, G., Marzucchi, A., & Zoboli, R. (2015). SMEs and barriers to eco-innovation in the EU: Exploring different enterprise profiles. Journal of Evolutionary Economics, 25, 671–705. [Google Scholar] [CrossRef]

- Mazraani, G., Giovannetti, G., Capone, P., & Fava, S. (2025). Green supply chain management and environmental performance in small, medium and large-sized Italian manufacturing companies. American Journal of Environment and Climate, 4(1), 21–36. [Google Scholar] [CrossRef]

- McGahan, A. M. (2021). Integrating insights from the resource-based view of the enterprise into the new stakeholder theory. Journal of Management, 47(7), 1734–1756. [Google Scholar] [CrossRef]

- Mitra, S., & Datta, P. P. (2013). Adoption of green supply chain management practices and their impact on performance: An exploratory study of Indian manufacturing firms. International Journal of Production Research, 52(7), 2085–2107. [Google Scholar] [CrossRef]

- Okorie, O., Russell, J., Cherrington, R., Fisher, O., & Charnley, F. (2023). Digital transformation and the circular economy: Creating a competitive advantage from the transition towards Net Zero Manufacturing. Resources, Conservation and Recycling, 189, 106756. [Google Scholar] [CrossRef]

- Ozdemir, S., Fernandez de Arroyabe, J. C., Sena, V., & Gupta, S. (2023). Stakeholder diversity and collaborative innovation: Integrating the resource-based view with stakeholder theory. Journal of Business Research, 164, 113955. [Google Scholar] [CrossRef]

- Qi, G., Zeng, S., Chiming, T., Yin, H., & Zou, H. (2013). Stakeholders’ influences on corporate green innovation strategy: A case study of manufacturing firms in China. Corporate Social Responsibility and Environmental Management, 20(1), 1–14. [Google Scholar] [CrossRef]

- Rashid, A., Rasheed, R., & Ngah, A. H. (2024). Achieving sustainability through multifaceted green functions in manufacturing. Journal of Global Operations and Strategic Sourcing, 17(2), 402–428. [Google Scholar] [CrossRef]

- Saeed, A., Jun, Y., Nubuor, S. A., Priyankara, H. P. R., & Jayasuriya, M. P. F. (2018). Institutional pressures, green supply chain management practices on environmental and economic performance: A two theory view. Sustainability, 10(5), 1517. [Google Scholar] [CrossRef]

- Sangwan, K. S., & Choudhary, K. (2018). Benchmarking manufacturing industries based on green practices. Benchmarking: An International Journal, 25(6), 1746–1761. [Google Scholar] [CrossRef]

- Shahzad, M., Qu, Y., Rehman, S. U., & Zafar, A. U. (2022). Adoption of green innovation technology to accelerate sustainable development among manufacturing industry. Journal of Innovation & Knowledge, 7(4), 100231. [Google Scholar] [CrossRef]

- Singh, S. K., Del Giudice, M., Chiappetta Jabbour, C. J., Latan, H., & Sohal, A. S. (2022). Stakeholder pressure, green innovation, and performance in small and medium-sized enterprises: The role of green dynamic capabilities. Business Strategy and the Environment, 31(1), 500–514. [Google Scholar] [CrossRef]

- Siyal, A. W., Chen, H., Shahzad, F., & Bano, S. (2023). Investigating the role of institutional pressures, technology compatibility, and green transformation in driving manufacturing industries toward green development. Journal of Cleaner Production, 428, 139416. [Google Scholar] [CrossRef]

- Soewarno, N., Tjahjadi, B., & Fithrianti, F. (2019). Green innovation strategy and green innovation: The roles of green organizational identity and environmental organizational legitimacy. Management Decision, 57(11), 3061–3078. [Google Scholar] [CrossRef]

- Testa, F., Boiral, O., & Iraldo, F. (2018). Internalization of environmental practices and institutional complexity: Can stakeholder pressures encourage greenwashing? Journal of Business Ethics, 147(2), 287–307. [Google Scholar] [CrossRef]

- Ullah, S., Khan, F. U., & Ahmad, N. (2022). Promoting sustainability through green innovation adoption: A case of manufacturing industry. Environmental Science and Pollution Research, 29, 21119–21139. [Google Scholar] [CrossRef]

- Vrchota, J., Pech, M., Rolínek, L., & Bednář, J. (2020). Sustainability outcomes of green processes in relation to Industry 4.0 in manufacturing: Systematic review. Sustainability, 12(15), 5968. [Google Scholar] [CrossRef]

- Wernerfelt, B. (1984). A resource-based view of the enterprise. Strategic Management Journal, 5(2), 171–180. [Google Scholar]

- Yang, J., Zuo, Z., Li, Y., & Guo, H. (2024). Manufacturing enterprises move towards sustainable development: ESG performance, market-based environmental regulation, and green technological innovation. Journal of Environmental Management, 372, 123244. [Google Scholar] [CrossRef]

- Yang, Y., & Liu, H. (2024). Sustainable media and green innovation: The impact of sustainable atmosphere and environmental regulation on manufacturing enterprises. Sustainability, 16(8), 3255. [Google Scholar] [CrossRef]

- Yuan, B., & Cao, X. (2022). Do corporate social responsibility practices contribute to green innovation? The mediating role of green dynamic capability. Technology in Society, 68, 101868. [Google Scholar] [CrossRef]

- Yuchi, Q., Wang, N., Jiang, Q., & He, Z. (2022). Green manufacturing. In Enterprises’ green growth model and value chain reconstruction. Springer. [Google Scholar] [CrossRef]

- Yusup, M. Z., Wan Mahmood, W. H., Salleh, M. R., & Muhamad, M. R. (2014). The influence factor for the successful implementation of cleaner manufacturing: A review. Jurnal Teknologi, 67(1), 109–114. [Google Scholar] [CrossRef]

- Zhang, F., & Zhu, L. (2019). Enhancing corporate sustainable development: Stakeholder pressures, organizational learning, and green innovation. Business Strategy and the Environment, 28(6), 1012–1026. [Google Scholar] [CrossRef]

- Zhang, H., He, J., Shi, X., Hong, Q., Bao, J., & Xue, S. (2020). Technology characteristics, stakeholder pressure, social influence, and green innovation: Empirical evidence from Chinese express companies. Sustainability, 12(7), 2891. [Google Scholar] [CrossRef]

- Zhang, W., Xu, N., Li, C., Cui, X., Zhang, H., & Chen, W. (2023). Impact of digital input on enterprise green productivity: Micro evidence from the Chinese manufacturing industry. Journal of Cleaner Manufacturing, 414, 137272. [Google Scholar] [CrossRef]

- Zhou, M., Govindan, K., Xie, X., & Yan, L. (2021). How to drive green innovation in China’s mining enterprises? Under the perspective of environmental legitimacy and green absorptive capacity. Resources Policy, 72, 102038. [Google Scholar] [CrossRef]

- Zhu, Q., Sarkis, J., & Lai, K.-h. (2013). Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. Journal of Purchasing and Supply Management, 19(2), 106–117. [Google Scholar] [CrossRef]

| Absolute Frequency | Relative Frequency | |

|---|---|---|

| Micro Business/up to 10 employees | 10 | 11.36% |

| Small Business/up to 50 employees | 23 | 26.14% |

| Medium Business/up to 250 employees | 37 | 42.05% |

| Large Business/more than 250 employees | 18 | 20.45% |

| Absolute Frequency | Relative Frequency | |

|---|---|---|

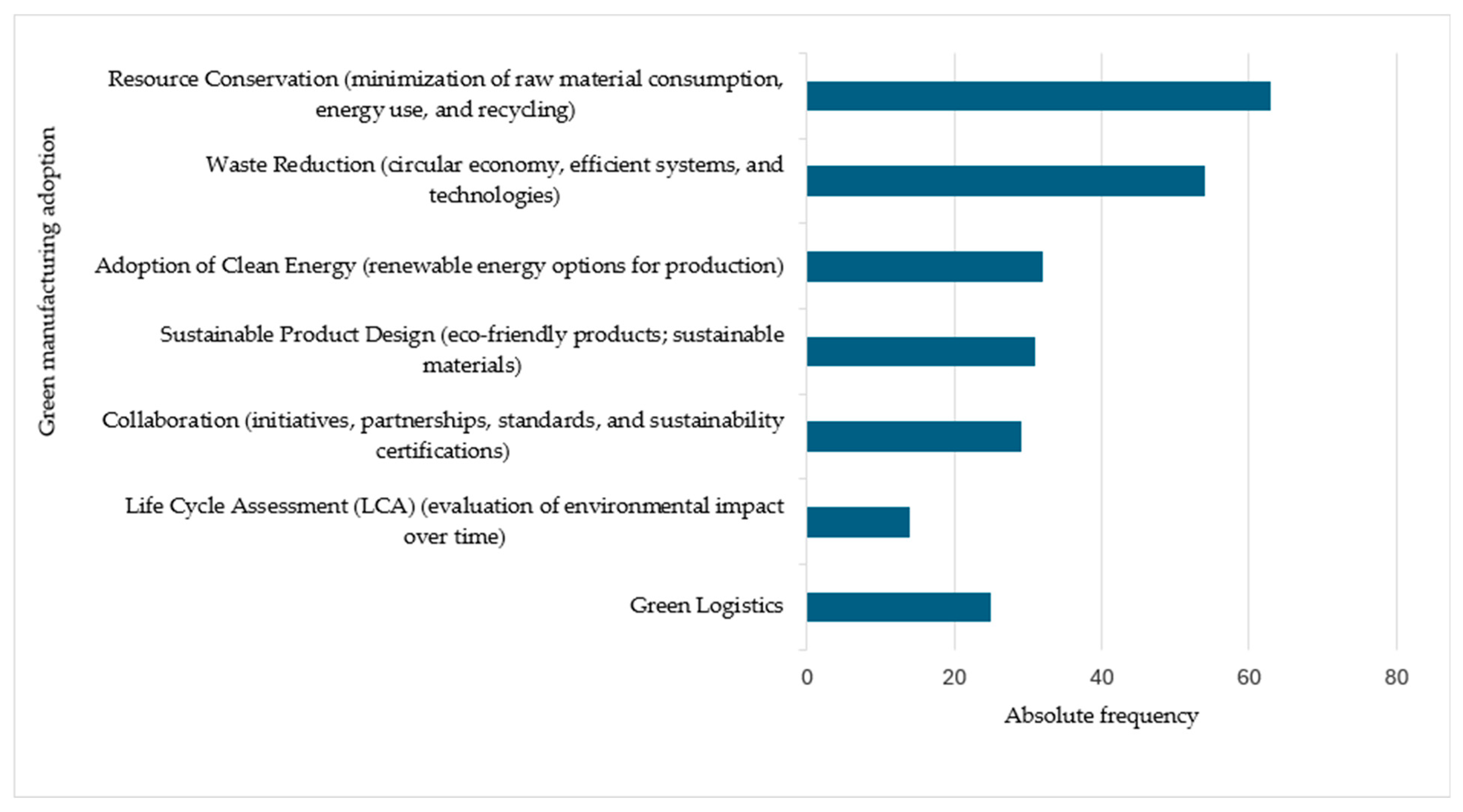

| Resource Conservation | 63 | 71.6% |

| Waste Reduction | 54 | 61.4% |

| Adoption of Clean Energy | 32 | 36.4% |

| Sustainable Product Design | 31 | 35.2% |

| Collaboration | 29 | 33.0% |

| LCA | 14 | 15.9% |

| Green Logistics | 25 | 28.4% |

| Green Manufacturing Practices /Region | Sustainable Product Design | Resource Conservation | Adoption of Clean Energy | Waste Reduction | Life Cycle Assessment (LCA) | Collaboration | Green Logistics | Total |

|---|---|---|---|---|---|---|---|---|

| Bratislava Region | 3 23.1% | 8 61.5% | 4 30.8% | 9 69.2% | 3 23.1 | 4 30.8 | 5 38.5 | 13 100% |

| Banská Bystrica Region | 2 18.2% | 9 81.8% | 3 27.3% | 7 63.6% | 2 18.2% | 5 45.5% | 3 27% | 11 100% |

| Košice Region | 2 33.3% | 6 100% | 4 66.7% | 5 83.3% | 1 16.7% | 2 33.3% | 2 33.3% | 6 100% |

| Nitra Region | 3 42.9 | 5 71.4 | 0 0% | 5 71.4% | 1 14.3% | 3 42.9% | 2 28.6% | 7 100% |

| Trenčín Region | 8 36.4% | 12 54.5% | 7 31.8% | 8 36.4% | 3 13.6% | 4 18.2% | 6 27.3% | 22 100% |

| Trnava Region | 6 50% | 9 75% | 5 41.7% | 8 66.7% | 2 16.7% | 5 41.7% | 3 25% | 12 100% |

| Prešov Region | 2 22.2% | 8 88.9% | 4 44.4% | 6 66.7% | 1 11.1% | 4 44.4% | 2 22% | 9 100% |

| Žilina Region | 5 62.5% | 6 75% | 5 62.5% | 6 75% | 1 12.5% | 2 25% | 2 25% | 8 100% |

| ∑Sum | 31 35.2% | 63 71.6% | 32 36.4% | 54 61.4% | 14 15.9% | 29 33% | 25 28.4% | 88 100% |

| Categories of Enterprises/Green Manufacturing Practices | Large Enterprises | Medium Enterprises | Small Enterprises | Micro Enterprises | ∑ Sum |

|---|---|---|---|---|---|

| Sustainable Product Design | 9 | 10 | 7 | 5 | 31 |

| Resource Conservation | 15 | 27 | 16 | 5 | 63 |

| Adoption of Clean Energy | 4 | 20 | 8 | 0 | 32 |

| Waste Reduction | 17 | 26 | 10 | 1 | 54 |

| Life Cycle Assessment (LCA) | 5 | 5 | 3 | 1 | 14 |

| Collaboration | 12 | 11 | 5 | 1 | 29 |

| Green Logistics | 7 | 10 | 6 | 2 | 25 |

| Number of respondents | 18 | 37 | 23 | 10 | 88 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | −1.0070 (*) | 0.3653 | 0.0965 | −0.6274 (*) |

| Enterprise Size Micro | 1.0499 | 2.8575 | 0.9631 | 0.6589 |

| Enterprise Size Small | 0.0306 | 1.0310 | 0.1878 | 0.0183 |

| Enterprise Size Large | 1.1762 | 3.2420 | 0.1077 | 0.7249 (*) |

| Region Banská Bystrica | −1.0151 | 0.3624 | 0.277 | −0.6369 |

| Region Bratislava | −0.3964 | 0.6727 | 0.6412 | −0.2343 |

| Region Košice | −0.3411 | 0.7110 | 0.7439 | −0.1835 |

| Region Nitra | 0.0065 | 1.0066 | 0.9946 | 0.0151 |

| Region Prešov | −0.4172 | 0.6589 | 0.6634 | −0.2228 |

| Region Trnava | 0.4431 | 1.5575 | 0.5578 | 0.2778 |

| Region Žilina | 1.5064 (*) | 4.5103 | 0.0924 | 0.9393 (*) |

| McFadden Pseudo R2 | 0.0994 | 0.1008 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | 0.2797 | 1.3228 | 0.6313 | 0.1790 |

| Enterprise Size Micro | −0.7536 | 0.4707 | 0.8155 | −0.4634 |

| Enterprise Size Small | −0.1557 | 0.8559 | 0.3429 | −0.0972 |

| Enterprise Size Large | 0.5226 | 1.6865 | 0.5468 | 0.2970 |

| Region Banská Bystrica | 1.2189 | 3.3835 | 0.1790 | 0.7000 |

| Region Bratislava | 0.3238 | 1.3824 | 0.6739 | 0.1987 |

| Region Košice | 23.3707 | 14,117,642,617.6639 | 0.9997 | 5.6183 |

| Region Nitra | 0.4284 | 1.5348 | 0.6711 | 0.2674 |

| Region Prešov | 1.7890 | 5.9834 | 0.1254 | 1.0367 |

| Region Trnava | 0.9662 | 2.6281 | 0.2358 | 0.5977 |

| Region Žilina | 0.8787 | 2.4077 | 0.3550 | 0.5340 |

| McFadden Pseudo R2 | 0.1114 | 0.1108 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | 0.2827 | 1.3267 | 0.6411 | 0.1925 |

| Enterprise Size Micro | −23.4696 | 0.0000 | 0.1130 | −8.3738 |

| Enterprise Size Small | −1.0161 | 0.3620 | 0.9994 | −0.6361 |

| Enterprise Size Large | −1.7697 (**) | 0.1704 | 0.0357 | −1.0982 (**) |

| Region Banská Bystrica | −0.5223 | 0.5932 | 0.5610 | −0.3595 |

| Region Bratislava | −0.7649 | 0.4654 | 0.3753 | −0.4960 |

| Region Košice | 1.7104 | 5.5314 | 0.1168 | 1.0634 |

| Region Nitra | −106.8328 | 0.0000 | 1.0000 | −6.0617 |

| Region Prešov | −0.1239 | 0.8835 | 0.8882 | −0.1030 |

| Region Trnava | 0.9036 | 2.4685 | 0.3099 | 0.5407 |

| Region Žilina | 0.6355 | 1.8880 | 0.4884 | 0.3841 |

| McFadden Pseudo R2 | 0.2382 | 0.2397 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | −0.3151 | 0.7297 | 0.6142 | −0.1807 |

| Enterprise Size Micro | −3.2446 (***) | 0.0390 | 0.1052 | −1.9387 (***) |

| Enterprise Size Small | −1.0503 | 0.3498 | 0.0083 | −0.6234 |

| Enterprise Size Large | 2.2905 (**) | 9.8803 | 0.0497 | 1.2917 (**) |

| Region Banská Bystrica | 0.9616 | 2.6158 | 0.2979 | 0.5860 |

| Region Bratislava | 1.7732 (*) | 5.8898 | 0.0541 | 1.0481 (*) |

| Region Košice | 1.8554 | 6.3942 | 0.1687 | 1.1254 |

| Region Nitra | 0.9619 | 2.6166 | 0.4325 | 0.4127 |

| Region Prešov | 1.1306 | 3.0976 | 0.2258 | 0.6699 |

| Region Trnava | 2.0276 (**) | 7.5959 | 0.0476 | 1.1981 (**) |

| Region Žilina | 1.8709 (*) | 6.4943 | 0.0644 | 1.1568 (*) |

| McFadden Pseudo R2 | 0.2949 | 0.2961 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | −2.2787 (***) | 0.1024 | 0.0070 | −1.3115 (***) |

| Enterprise Size Micro | −0.2795 | 0.7562 | 0.6992 | −0.1357 |

| Enterprise Size Small | 0.3325 | 1.3944 | 0.8166 | 0.1633 |

| Enterprise Size Large | 1.4163 | 4.1218 | 0.1108 | 0.8049 |

| Region Banská Bystrica | 0.2265 | 1.2542 | 0.8276 | 0.1806 |

| Region Bratislava | 1.0867 | 2.9646 | 0.2820 | 0.5742 |

| Region Košice | −0.2704 | 0.7631 | 0.8376 | −0.2046 |

| Region Nitra | −0.5641 | 0.5689 | 0.6667 | −0.3638 |

| Region Prešov | −0.1164 | 0.8901 | 0.9272 | −0.0661 |

| Region Trnava | 0.1624 | 1.1763 | 0.8746 | 0.0144 |

| Region Žilina | 0.1983 | 1.2193 | 0.8776 | 0.0818 |

| McFadden Pseudo R2 | 0.0532 | 0.0540 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | −1.9244 (**) | 0.1460 | 0.0109 | −1.1327 (***) |

| Enterprise Size Micro | −1.2255 | 0.2936 | 0.8752 | −0.7325 |

| Enterprise Size Small | −0.1075 | 0.8980 | 0.2948 | −0.0685 |

| Enterprise Size Large | 2.0574 (**) | 7.8254 | 0.0101 | 1.2391 (***) |

| Region Banská Bystrica | 1.3225 | 3.7527 | 0.1549 | 0.7499 |

| Region Bratislava | 1.2689 | 3.5569 | 0.1777 | 0.7202 |

| Region Košice | 0.0387 | 1.0394 | 0.9736 | −0.0294 |

| Region Nitra | 0.3915 | 1.4792 | 0.7197 | 0.2426 |

| Region Prešov | 1.5247 | 4.5939 | 0.1173 | 0.8901 |

| Region Trnava | 1.3689 | 3.9309 | 0.1404 | 0.8260 |

| Region Žilina | 0.8654 | 2.3760 | 0.4164 | 0.4801 |

| McFadden Pseudo R2 | 0.1601 | 0.1612 |

| Variable | Logit Model | Log Odds | p-Value | Probit Model |

|---|---|---|---|---|

| Intercept | −1.1495 (*) | 0.3168 | 0.0653 | −0.6944 (*) |

| Enterprise Size Micro | −0.3562 | 0.7003 | 0.8005 | −0.2556 |

| Enterprise Size Small | 0.1661 | 1.1806 | 0.6968 | 0.0863 |

| Enterprise Size Large | 0.8311 | 2.2960 | 0.2524 | 0.4933 |

| Region Banská Bystrica | −0.0893 | 0.9146 | 0.9164 | −0.0418 |

| Region Bratislava | 0.7190 | 2.0524 | 0.3699 | 0.4389 |

| Region Košice | −0.0370 | 0.9637 | 0.9714 | 0.0011 |

| Region Nitra | −0.3365 | 0.7143 | 0.7414 | −0.1922 |

| Region Prešov | −0.2501 | 0.7788 | 0.7949 | −0.1680 |

| Region Trnava | −0.1543 | 0.8570 | 0.8541 | −0.1253 |

| Region Žilina | −0.0130 | 0.9871 | 0.9894 | −0.0085 |

| McFadden Pseudo R2 | 0.0277 | 0.0287 |

| Pearson’s Chi-Square Tests | |

|---|---|

| Chi-square | 14.3229 |

| df | 42 |

| p | 0.099998 |

| Cramér’s V | 0.098 |

| Pearson’s Chi-Square Tests | |||

|---|---|---|---|

| Chi-Square | df | p | |

| Sustainable Product Design | 4.000 | 3 | 0.2615 |

| Resource Conservation | 3.594 | 3 | 0.3088 |

| Adoption of Clean Energy | 12.299 | 3 | 0.0064 |

| Waste Reduction | 23.777 | 3 | 0.00003 |

| Life Cycle Assessment (LCA) | 2.456 | 3 | 0.4833 |

| Collaboration | 13.127 | 3 | 0.0044 |

| Green Logistics | 1.415 | 3 | 0.7019 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juráček, L.; Jurík, L.; Makyšová, H. Institutional, Resource-Based, Stakeholder and Legitimacy Drivers of Green Manufacturing Adoption in Industrial Enterprises. Adm. Sci. 2025, 15, 311. https://doi.org/10.3390/admsci15080311

Juráček L, Jurík L, Makyšová H. Institutional, Resource-Based, Stakeholder and Legitimacy Drivers of Green Manufacturing Adoption in Industrial Enterprises. Administrative Sciences. 2025; 15(8):311. https://doi.org/10.3390/admsci15080311

Chicago/Turabian StyleJuráček, Lukáš, Lukáš Jurík, and Helena Makyšová. 2025. "Institutional, Resource-Based, Stakeholder and Legitimacy Drivers of Green Manufacturing Adoption in Industrial Enterprises" Administrative Sciences 15, no. 8: 311. https://doi.org/10.3390/admsci15080311

APA StyleJuráček, L., Jurík, L., & Makyšová, H. (2025). Institutional, Resource-Based, Stakeholder and Legitimacy Drivers of Green Manufacturing Adoption in Industrial Enterprises. Administrative Sciences, 15(8), 311. https://doi.org/10.3390/admsci15080311