Abstract

Insecticide testing facilities that evaluate a variety of vector control products may generate a large number of hazardous wastes from routine operations. These wastes originate from degraded technical grade materials, sprayed substrates with Indoor Residual Spraying (IRS), and redundant stock or working insecticidal solutions. The washing of Long-Lasting Insecticidal Nets (LLINs) during preparation for laboratory and experimental hut trials also contribute to wastewater with insecticide content. Human and environmental exposure to insecticidal waste can occur during transport, categorization, storage, and disposal, resulting in environmental pollution and potential health effects. Various national and international guidelines have been devised for safe disposal and should be strictly followed to avoid adverse effects on humans or environment. To facilitate proper insecticidal waste management, this paper outlines simple but safe practices derived from international and national guidelines that can be adopted by other similar facilities. National and international policies related to chemical management were reviewed and translated into Standard Operating Procedures (SOPs), training pathways, and manuals. National Environmental Management Council (NEMC) assessed the test facility and recommended disposal procedures. NEMC recommendations were followed to construct the soak pits for liquid waste disposal while chemical transporters and incinerators were contracted for solid waste disposal. An environmental expert was contracted for environmental audit and annual monitoring. Studies and activities at the facility were evaluated for their waste generation index. Safety manual and SOPs on risk assessment, waste management and disposal, handling hazardous materials, health and safety procedures, and chemical usage were written. At KCMUCo-PAMVERC, an annual average of 0.02 and 24.9 cubic meters of liquid waste, which mainly includes a mixture of water, insecticides, and solvents, were generated from laboratory experiments (phase I) and semi-field LLIN experiments (phase II), respectively, while the IRS semi-field experiments generated an annual average of 88 L of liquid waste and 6.3 tons of solid waste. An annual average of 0.18 cubic meters of liquid waste results from other sources, including expired laboratory reagents. Well-translated national and international policies/regulations may be adopted by insecticide test facilities for proper and effective waste disposal.

1. Introduction

Malaria control and prevention relies on the use of insecticides in the form of treated bed nets or residual spraying in households [1,2]. The problem of increased insecticide resistance in vectors inspires innovation in alternative insecticides, which in turn inspires innovation of assessment procedure until final registration for public health use [3]. During this process, every stage of pesticide evaluation, from storage to use and equipment cleanup, generates waste [4].

Despite deficiencies in the legislative and regulatory frameworks for public health pesticides among WHO member states in countries with a high burden of vector-borne diseases [5,6], there is a steady increase in pesticide importation and use in East Africa [6]. For example, in Tanzania, 2500 tons of agricultural and public health use pesticides were imported in 2003 compared to only 500 tons in 2000, with 18% of total imported pesticides dedicated for public health [6]. The number of pesticides imported in Tanzania in 2015 has tripled the 2007 pesticide importation [7,8]. Exposure to insecticides and its wastes has been shown to cause both adverse effects to human health [9] and the environment [10,11]. Prior to 1990, there was no systematic guidelines for disposal of insecticide-contaminated wastes [4]. In the 1990s, the Commission on Agrochemicals and the Environment, later renamed the Advisory Committee on Crop Protection Chemistry, within the Division of Chemistry under the Environment of the International Union of Pure and Applied Chemistry (IUPAC) initiated a critical analysis of strategies and methods for disposal of pesticide-contaminated wastes [4,10]. Among the key objectives of this analysis was to explain practicability of waste disposal technologies recommended for small waste generators which could not afford sophisticated technologies. Most of the test facilities that evaluate different vector control insecticidal products fall under the small waste generators category.

Most of the procedures recommended for waste reduction, and disposal in the Food and Agriculture Organization documents [12,13] and other researchers [4] are at large recommended by Tanzania’s National Environmental Management Council (NEMC) [14,15]. However, most facilities still lack the capacity to analyze and characterize wastes, e.g., by gas or high-performance liquid chromatography (HPLC). A relatively cheap technique for characterization, thin layer chromatography (TLC), which is considered suitable for testing facilities in developing countries, still requires expensive purified organic solvents that make the option prohibitive. As a result, the Kilimanjaro Christian Medical University College-Pan African Malaria Vector Research Consortium (KCMUCo-PAMVERC) in Tanzania has relied on NEMC inspection for waste characterization and disposal advice. The NEMC is mandated under the Tanzanian Environmental Management Act (EMA) Cap.191 of 2004 to oversee environmental management issues and implements the resolutions of the Stockholm declaration [16] at a national level. Relevant national legislation and Acts of Government are also closely followed. This paper describes a case of insecticides testing facility, KCMUCo-PAMVERC, in northern-eastern Tanzania where different technologies, national, and international guidelines have been adopted.

2. Materials and Methods

2.1. Study Site

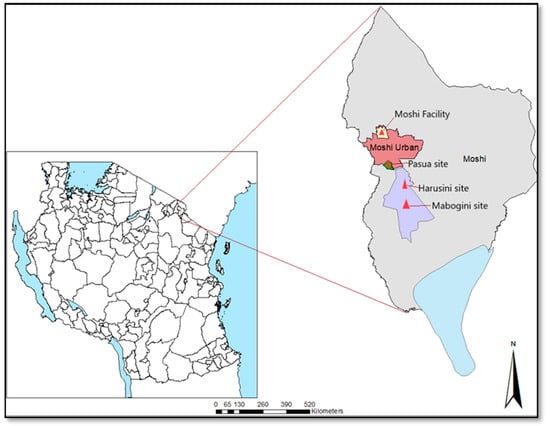

The site for this study was Moshi in Kilimanjaro Region, north-eastern Tanzania. KCMUCo-PAMVERC is one of the test facilities in Tanzania that evaluates insecticides for public health use [17]. It has its insecticide testing facilities at Moshi urban (Longuo B), Pasua and Mabogini (Figure 1). It is the first African vector control test facility to achieve the Organization for Economic Co-operation and Development principles of Good Laboratory Practice (OECD-GLP) accreditation [18].

Figure 1.

A map of Tanzania indicating the KCMUCo-PAMVERC sites involved with insecticide testing.

2.2. Key Policies and Guidelines for Insecticidal Waste Management

KCMUCo-PAMVERC test facility, through its management and health and safety committee, reviewed available national and international policies that provide guidance in all aspects of pesticide handling, formulation, import and export, registration, and disposal. The following Tanzania national policies/acts were reviewed include the National Environmental Action Plan (NEAP) 2013–2018 [19], which advocates for strengthened solid waste management system to manage degradation of environment as a result of poor waste management; Environmental Management Act (EMA), 2004 [20], which governs measures for sustainable management of the environment, prevention and control of pollution, waste management, regulation of compliance, impact and risk assessment, and Environmental Impact Assessment requirements; Industrial and Consumer Chemicals (Management and Control) Act, No. 3, 2003; which provides for the: control of production, importation, exportation, transportation, storage of chemicals, and management of industrial and consumer chemicals, including associated wastes; Land Use Planning Act No. 6, 2007, which requires waste disposal sites to be included in land use plans; Occupational Health and Safety Act, 2003, which regulates the safety, health, and welfare of workers, places of work, protection of persons, against hazards to health and safety arising out of, or in connection with, activities of persons at work; Public Health Act, 2009, which prohibits the discharge of oil, grease, ballast, waste, sewage, or any other polluting substance into the environment; Environmental Impact Assessment and Audit Regulations, 2005 and 2018 amendments, which emphasizes on environmental audits and monitoring; Environmental Management (Air Quality Standards) Regulations, 2007, which empowers NEMC to issue air pollutant emission permits, enforce compliance, undertake emergency prevention, and issue stop orders; Environmental Management (Hazardous Waste Control and Management) Regulations, 2009, which details the requirements and responsibilities for controlling and managing hazardous waste in Tanzania; Environmental Management (Soil Quality Standards) Regulations, 2007, which details hazardous waste management, registration, and discharge permit for polluting activities; Environmental Management (Solid Waste) Regulations, 2009, which detail the requirements and responsibilities for managing solid waste in Tanzania; Tropical Pesticides Research Institute Act No. 18, 1979, the Pesticides Control Regulations (1984), Plant Protection Act (1997), and Plant Protection Regulation (1999).

Tanzania abides to several internationalregulations of which the following were reviewed; Montreal Protocol for the Protection of the Ozone Layer 1993 [21], Basel Convention on the Control of Transboundary Movements of Hazardous, Wastes and their Disposal, 1993,Bamako Convention on the Ban of the Import into Africa and the Control of Transboundary Movement and Management of Hazardous Wastes within Africa, 1993 [22,23], Convention Concerning Safety in the Use of Chemicals at Work (ILO convention 170), 1999, Rotterdam Convention on the Prior Informed Consent Procedure for Certain Hazardous, Chemicals and Pesticides in International Trade, 2002 and Stockholm Convention on Persistent Organic Pollutants, 2004.

Tanzania is also committed to the Strategic Approach to International Chemicals Management (SAICM 2006) to achieve sound chemicals management.

These policies were then translated and converted to facility’s Standard Operating Procedures (SOPs) on risk assessment, handling hazardous materials, health and safety procedures, chemical usage, and waste management and disposal.

2.3. Training and Internal Guidelines

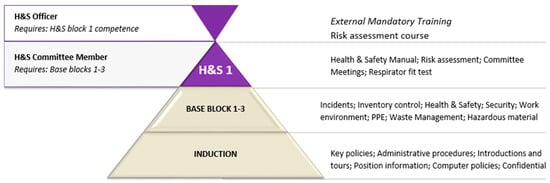

The facility identified appropriate mandatory training including chemical handling for the Health and Safety Committee members and department members who are involved with handling of chemicals (Figure 2). The trainings are offered by the Tanzania Occupational Safety and Health Authority and Tanzania Plant Health and Pesticides Authority.

Figure 2.

Training pathway for the Health and Safety committee members at KCMUCo-PAMVERC.

Similarly, all staff who handle chemicals undergo mandatory training that covers training in safe use and disposal of chemicals. Additionally, specific waste disposal SOPs, safety manual, as well as simplified guidelines for internal use have been generated for proper management of facility wastes. The test facility staff have been trained and assessed annually for their competence.

2.4. Procedures for Insecticidal Waste Management

2.4.1. Facility Inspection by National Authority

To comply with national requirements, the KCMUCo-PAMVERC test facility consulted the NEMC for chemical waste inspection and guidance on the management and disposal of its obsolete pesticides, pesticide-contaminated wastes, and other chemical reagents at its premises. This is in line with the OECD-GLP document [24], which encourages facilities to comply with national requirements for the disposal of chemicals and biological products. The NEMC assessment was based on the type, quality, and quantities of pesticides eligible for disposal. The storage conditions, packaging materials, and labels were also assessed. Furthermore, other pertinent information on disposal recommendations was reviewed.

2.4.2. Identifying Waste Generation Points and Developing a Management Plan

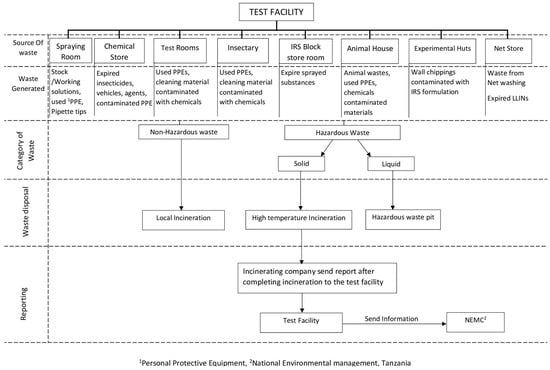

After the inspection, NEMC-CMAC suggested the use of standardized incinerators for the disposal of solid chemical wastes and waste pit for the hazardous liquid chemical waste. NEMC provided the test facility with a blueprint for waste pit construction. From the NEMC inspection report and blueprint, KCMUCo-PAMVERC has been able to identify all sources that generate waste and has drawn a waste management plan, as indicated in Figure 3.

Figure 3.

Test facility waste management pathway.

2.4.3. Categorization of Wastes Generated

Depending on the type of waste, different disposal procedures apply. At the KCMUCo-PAMVERC test facility, wastes have been categorized into hazardous and non-hazardous (normal) waste. Hazardous wastes have been further categorized into liquid and solid hazardous waste (Figure 2). The liquid waste includes obsolete technical grade insecticidal formulations, novel insecticide formulations, vehicles (solvents), reagents, cleaning solutions (10% bleach and 70% ethanol), water from net washing, insecticide residue from compressional spray tanks, waste solutions from cleaning the Potter Spray Tower (Burkard Scientific, Uxbridge, UK), used for spraying 10 cm diameter blocks of various materials.

The solid hazardous wastes include technical grade insecticides, novel insecticide formulations, insecticide-treated test papers, insecticide-treated substrates, insecticide-treated wall chippings from indoor residual spraying hut trials, insecticide-sprayed materials such as plastic sheets and hessian, LLINs and dipped nets (whole nets and net pieces), insecticide-contaminated consumables (including expired/used Personal Protective Equipment, metallic spare parts of spraying equipment), and sharps. Non-hazardous wastes from insectaries, laboratories, offices, and field stations are collected and incinerated in our locally built incinerator. They include obsolete non-chemical materials.

2.4.4. Waste Packaging and Containment

Various containment measures have been established to prevent hazardous waste leaking into the environment or human exposures. Apart from environmental risk assessment of the hazardous waste pits, which is recommended by NEMC-CMAC, solid waste is stored in intact and leak-proof containers within a restricted entry enclosure protected from rain. These enclosures have been reinforced with wire mesh to prevent small reptiles from reaching the enclosure.

Wall chippings are packed into special bags (with 2 bags—outer polypropylene bag and inner multi-layered hermetic bag) and labelled with insecticide name, concentration, technician name, and date of collection and transportation to the temporary storage site situated at Harusini field site in Lower Moshi until the scheduled date of transportation to disposal. Special cabinets, Armorgard FlamStor Cabinet™ (Armorgard Ltd, Hampshire, UK), are used for keeping hazardous substances safe, organized, and accessible with the specially designed flameproof vents to prevent build-up of fumes.

2.4.5. Implementation of Solid and Liquid Hazardous Chemical Wastes Disposal

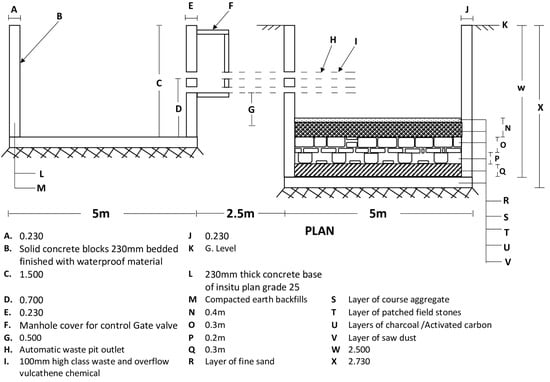

KCMUCo-PAMVERC insecticide testing facility identified and contracted an independent company for incinerating the hazardous solid waste. The incineration temperature is high enough to burn insecticides into smoke-nil combustion gases that are similar to those generated by wood burning [4]. Insecticide incineration at lower temperatures is not recommended, as it tends to produce toxic intermediate products [25]. To be able to transport the chemical wastes, a NEMC registered transporting company was contracted that meets all requirements for transporting hazardous materials [26]. As for the hazardous liquid chemical waste disposal, the facility contracted a construction company to build the waste pit for liquid waste disposal based on the NEMC blueprint (Figure 4 and Figure 5). The structure presents a mechanism similar to that used for carbon-adsorption treatment of pesticides containing wastewater [27].

Figure 4.

Hazardous waste pit schematic blueprint provided by NEMC. A, C, D, E, G, and J are measurements in meters.

Figure 5.

A picture of constructed waste pit at KCMUCo-PAMVERC, Tanzania.

The non-hazardous waste is collected routinely and incinerated in a local constructed incinerator (Figure 6). The design of this incinerator followed structure defined by Omorogie [28], this design is preferable to open air burning, and it provide good efficiency for non-toxic solid wastes generated at the offices and insectaries such as papers, empty boxes, and guinea pig-used hay beddings.

Figure 6.

A locally constructed incinerator at KCMUCo-PAMVERC.

2.4.6. Internal and External Monitoring for Waste Management

The facility established the Health and Safety Committee to oversee operations. The committee provides training on laboratory safety rules, organizes annual waste disposal, reports and responds to non-conformance incidents, and any accidents and emergencies. It also performs the quarterly and annual risk assessments for study-related procedures and routine facility operations. The facility has also contracted an environmental expert for annual monitoring of the waste disposal procedures.

2.5. Analysis of Waste Generation Index

Waste disposal records from 2018 to 2021 were summarized and analyzed to determine waste contribution of LLINs and IRS as main product evaluation studies (Table 1).

Table 1.

Insecticidal waste generated per year from 2018 to 2021 at KCMUCo-PAMVERC.

3. Results

From the review of policies, the KCMUCo-PAMVERC test facility has been able to generate the following documents for proper waste disposal:

- i.

- Safety manual

- ii.

- Standard Operating Procedures (SOPs) on risk assessment, waste management and disposal, handling hazardous materials, health and safety procedures, and chemical usage.

The following table (Table 1) summarizes the amount of chemical waste (both liquid and solid) that was generated by the test facility from 2018 to 2021, while Table 2 indicates typical wastes from each activity. Most of the waste was generated by Phase II studies through washing of LLINs (liquid waste) and cement plaster wall chippings from experimental huts (solid waste). WHO Phase I and II studies are insecticide testing required by WHO [29,30] to meet their pesticide efficacy criteria in the laboratory (I) and in controlled simulated household trials (experimental huts) of IRS and LLINs (II). The washing of a single net 20 times, as required by WHO, creates 0.6 cubic meters of low-level insecticide contaminated wastewater.

Table 2.

Typical insecticidal wastes from various activities.

4. Discussion

Substantial amounts of insecticidal wastes can be generated by any insecticide testing facility. The annual waste records in this test facility indicate up to 6.3 tonnes of insecticidal solid waste and approximately 25 cubic meters of low-level insecticide contaminated water were generated. Such a considerable high amount requires proper handling and disposal guided by national and international policies. In many African countries, including Tanzania, there are various policies and regulations about disposal of such pesticides. Although such policies and regulations are in place, its implementation is rather weak, mostly due to heavy investments that are beyond the financial resources available in these counties, and lack of awareness, which leads to poor management of pesticide waste. Lack of concern, motivation, awareness, and high costs are some of the problems that may impact upon good waste management [31,32]. High costs related to waste package, transportation, and incineration are experienced. Waste coming from experimental huts chippings requires a large number (>300) of special double layer bags per one site, the cost of each bag being approximately 5 dollars, while waste transportation and incineration costs are approximately 810 dollars per ton. However, transport cost is directly related to waste bulkiness and distance from the collection point to the incineration point. This type of challenge in Africa is too large and has triggered the Food and Agriculture Organization to request major chemical industries to collaborate in the clean-up and disposal of obsolete pesticides [25].

Despite those challenges, the insecticide test facilities (ITF) can easily adopt and comply to the national and international guidelines, policies, and regulations for proper insecticide waste disposal. To make this possible, insecticide testing facilities should follow the Principles of Good Laboratory Practice (GLP), which this site has done and achieved. The new classes of insecticides or formulations require a separate inspection and guidance from national authorities. The new paradigm of vector control, based on the use of insecticide mixtures, presents new challenges in determining effective disposal (4).

The findings and their implications should be discussed in the broadest context possible. This document describes what this ITF has done to acquire GLP status and, within this context, has improved containment and disposal contaminated waste in the hope that other facilities will follow suite and also achieve this status. It is not perfect, but it is a start, and other institutions and facilities, on reading this document, may improve on our limited achievements. The government should advocate more environmentally friendly insecticide waste disposal, such as combining incineration with energy recovery technology to offset fossil fuel usage and the associated CO2 emissions or build capacity for biodegradation of insecticidal waste [33,34]. Since insecticides are classified as hazardous waste, they must be disposed of correctly by a licensed service provider.

5. Conclusions

Simple, safe, and effective management of insecticidal waste is not only a legal necessity but also a social responsibility to ensure human and environment health are not negatively affected. This paper outlined simple but safe practices derived from international and national guidelines that can be adopted by other similar facilities.

Thorough inspections of waste generation and management caused by insecticidal testing facilities are paramount.

Facilities must make a concerted effort to ensure that the obsolete and/or unwanted pesticides are properly managed. This includes collection, segregation, containment, transport, risk assessment, and disposal. Judicious and minimal procurement and use of insecticides means less waste generated, less cost for disposal, a safer working environment, and more efficient waste disposal systems. To ensure sustainability, facilities should introduce and apply practices which reduce costs related to waste management and disposal, but not at the expense of human population safety and the environment, which are of paramount importance.

Author Contributions

Conceptualization, A.M., S.A., M.J.K. and F.M.; methodology, A.M., S.A., M.J.K. and F.M.; investigation, A.M., S.A., M.J.K., M.W.R. and F.M.; resources, A.M., S.A., M.J.K. and F.M.; writing—original draft preparation, S.A. and A.M.; writing—review and editing, A.M., S.A., M.J.K., J.M., N.J.M., M.F.S., M.J., R.K., B.M., A.J., M.W.R. and F.M.; supervision, J.M., N.J.M., M.W.R. and F.M.; project administration and management, A.M., S.A., M.F.S., M.J.K. and N.J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thanks the whole team at the KCMUCo and PAMVERC for their invaluable contribution to this study. We are particularly indebted to Felista Edward and Samweli Mshiro for sharing their invaluable ideas to this work.

Conflicts of Interest

The authors declare that they have no competing interests.

Abbreviations

| EMA | Environmental Management Act |

| GLP | Good Laboratory Practice |

| HPLC | High Performance Liquid Chromatography |

| IRS | Indoor Residual Spraying |

| KCMUCo | Kilimanjaro nChristian Medical Universtity College |

| LLINs | Long Lasting Insecticidal nets |

| NEAP | National Environmental Action Plan |

| NEMC | National Environmental Management Council |

| PAMVERC | Pan African Malaria Vector Research Consortium |

| SOPs | Standard Operating Procedures |

| WHO | World Health Organization |

References

- Lengeler, C. Insecticide-treated bed nets and curtains for preventing malaria. Cochrane Database Syst. Rev. 2004, 2, CD000363. [Google Scholar] [CrossRef]

- Pluess, B.; Tanser, F.C.; Lengeler, C.; Sharp, B.L. Indoor residual spraying for preventing malaria. Cochrane Database Syst. Rev. 2010, 2010, CD006657. [Google Scholar] [CrossRef]

- Lees, R.; Praulins, G.; Davies, R.; Brown, F.; Parsons, G.; White, A.; Ranson, H.; Small, G.; Malone, D. A testing cascade to identify repurposed insecticides for next-generation vector control tools: Screening a panel of chemistries with novel modes of action against a malaria vector. Gates Open Res. 2019, 3, 1464. [Google Scholar] [CrossRef] [PubMed]

- Felsot, A.S.; Racke, K.D.; Hamilton, D.J. Disposal and degradation of pesticide waste. Rev. Environ. Contam. Toxicol. 2003, 177, 123–200. [Google Scholar] [CrossRef] [PubMed]

- Matthews, G.; Zaim, M.; Yadav, R.S.; Soares, A.; Hii, J.; Ameneshewa, B.; Mnzava, A.; Dash, A.P.; Ejov, M.; Tan, S.H.; et al. Status of legislation and regulatory control of public health pesticides in countries endemic with or at risk of major vector-borne diseases. Environ. Health Perspect. 2011, 11, 1517–1522. [Google Scholar] [CrossRef] [PubMed]

- Loha, K.M.; Lamoree, M.; Weiss, J.M.; de Boer, J. Import, Disposal, and Health Impacts of Pesticides in the East Africa Rift (EAR) Zone: A Review on Management and Policy Analysis. Crop Prot. 2018, 112, 322–331. [Google Scholar] [CrossRef]

- Agenda. A Case Study on Trade and Utilization of Pesticides in Tanzania: Implication to Stockpiling. Final Report, Dar-es-Salaam, Tanzania. 2006. Available online: http://www.panuk.org/archive/Projects/Obsolete/14.%20Babati%20Case%20Study_Tanzania.pdf (accessed on 19 February 2022).

- TPRI. Registered Plant Protection Substances for Use in the United Republic of Tanzania; Tropical Pesticides Research Institute, Ministry of Agriculture, Livestock and Fisheries: Arusha, Tanzania, 2015. [Google Scholar]

- Bradberry, S.M.; Cage, S.A.; Proudfoot, A.T.; Vale, J.A. Poisoning due to pyrethroids. Toxicol. Rev. 2005, 24, 93–106. [Google Scholar] [CrossRef] [PubMed]

- Ware, G. Reviews of Environmental Contamination and Toxicology: Continuation of Residue Reviews, 1990th ed.; Springer: New York, NY, USA, 1989. [Google Scholar]

- Antwi, F.B.; Reddy, G.V. Toxicological effects of pyrethroids on non-target aquatic insects. Environ. Toxicol. Pharmacol. 2015, 40, 915–923. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization. Guidelines on Management Options for Empty Pesticide Containers. 2008. Available online: https://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/Code/Containers08.pdf (accessed on 19 January 2022).

- FAO. Environmental Management Tool Kit for Obsolete Pesticides; Food and Agriculture Organization: Geneva, Switzerland, 2020; Available online: https://www.fao.org/fileadmin/templates/obsolete_pesticides/Guidelines/EMTK4xweb_nov_small.pdf (accessed on 19 January 2022).

- Malisa, A. Situation, Challenges and Plans for Environment Statistics in Tanzania. 2007. Available online: https://unstats.un.org/unsd/ENVIRONMENT/envpdf/UNSD_UNEP_ECA%20Workshop/Tanzania.pdf (accessed on 19 February 2022).

- NEMC. The National Environmental Research Agenda for Tanzania 2017–2022. National Environmental Management Council of Tanzania. 2017. Available online: https://www.nemc.or.tz/uploads/publications/sw-1576226565 (accessed on 19 February 2022).

- Weiss, E.B. United Nations conference on environment and development. Int. Leg. Mater. 1992, 31, 814–817. [Google Scholar] [CrossRef]

- KCMU College-PAMVERC. Pan-African Malaria Vector Research Consortium (PAMVERC). 2021. Available online: https://pamverc.or.tz/indexs.php?pamvercdataset=pamverc_research (accessed on 19 February 2022).

- Begg, S.; Wright, A.; Small, G.; Mosha, F.; Kirby, M.; Snetselaar, J.; Aziz, S.; Bharmal, J.; Dacombe, R.; Bates, I. Developing laboratory capacity for Good Laboratory Practice certification: Lessons from a Tanzanian insecticide testing facility. Gates Open Res. 2020, 12, 4–59. [Google Scholar] [CrossRef] [PubMed]

- Pallagyo, D.M. Environmental law in Tanzania; How far have we gone. Law Env’t Dev. J. 2007, 3, 26. [Google Scholar]

- NEMC. The Environmental Management Act. Available online: https://www.nemc.or.tz/uploads/publications/sw-1576228517-ema%20act2004.pdf. (accessed on 19 January 2022).

- UNEP Ozone Secretariat. Montreal Protocol—Achievements to Date and Challenges Ahead. United Nations Environmental Program. 2015. Available online: http://42functions.net/en/MP_achievements_challenges.php (accessed on 19 February 2022).

- Sundram, M.S. Basel Convention on Transboundary Movement of Hazardous Wastes: Total Ban Amendment. Pace Int’l L. Rev. 1997, 9, 1. Available online: http://digitalcommons.pace.edu/pilr/vol9/iss1/1 (accessed on 19 January 2022).

- Ovink, B.J. Transboundary shipments of toxic waste: The Basel and Bamako Conventions: Do Third World countries have a choice. Dick. J. Int’l L. 1994, 13, 281. [Google Scholar]

- OECD. Series on Principles of Good Laboratory Practice (GLP) and Compliance Monitoring—OECD. 2022. Available online: https://www.oecd.org/chemicalsafety/testing/oecdseriesonprinciplesofgoodlaboratorypracticeglpandcompliancemonitoring.htm. (accessed on 10 January 2022).

- Kennedy, M.V.; Stojanovic, B.J.; Shuman, F.L., Jr. Chemical and thermal methods for disposal of pesticides. Residue Rev. 1969, 29, 89–104. [Google Scholar] [CrossRef] [PubMed]

- Leonelli, P.; Bovincini, S.; Spadoni, G. Hazardous Materials Transportation: A Risk-Analysis-Based Routing Methodology. J. Hazard Mater. 2000, 71, 283–300. [Google Scholar] [CrossRef]

- Hu, J.; Shang, R.; Heijman, B.; Rietveld, L. Reuse of spent granular activated carbon for organic micro-pollutant removal from treated wastewater. J. Environ. Manag. 2015, 1, 98–104. [Google Scholar] [CrossRef] [PubMed]

- Omoregie, M.J.; Odibi, T.I. Design and fabrication of a domestic incinerator. J. Appl. Sci. Environ Manag. 2017, 21, 981. [Google Scholar] [CrossRef][Green Version]

- World Health Organization. Guidelines for Testing Mosquito Adulticides for Indoor Residual Spraying and Treatment of Mosquito Nets. 2006. World Health Organization. Available online: https://apps.who.int/iris/handle/10665/69296 (accessed on 10 January 2022).

- WHO. Guidelines for Laboratory and Field-Testing of Long-Lasting Insecticidal Nets; WHO/HTM/NTD/WHOPES/2013.3; WHO: Geneva, Switzerland, 2013. [Google Scholar]

- FAO. FAO Requires Financial Support for the Disposal of Obsolete Pesticides in Africa and the Near East; Food and Agriculture Organization: Geneva, Switzerland, 2022; Available online: https://www.fao.org/NEWS/1998/980307-e.htm (accessed on 19 May 2022).

- Velzy, C.; Feldman, J.; Trichon, M. Incineration technology for managing biomedical wastes. Waste Manag. Res. 1990, 8, 293–298. [Google Scholar] [CrossRef]

- Singh, B.K.; Walker, A. Microbial degradation of organophosphorus compounds. FEMS Microbiol. Rev. 2006, 30, 428–471. [Google Scholar] [CrossRef] [PubMed]

- Hlihor, R.M.; Gavrilescu, M.; Tavares, T.; Favier, L.; Olivieri, G. Bioremediation: An Overview on Current Practices, Advances, and New Perspectives in Environmental Pollution Treatment. Biomed. Res. Int. 2017, 2017, 6327610. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).