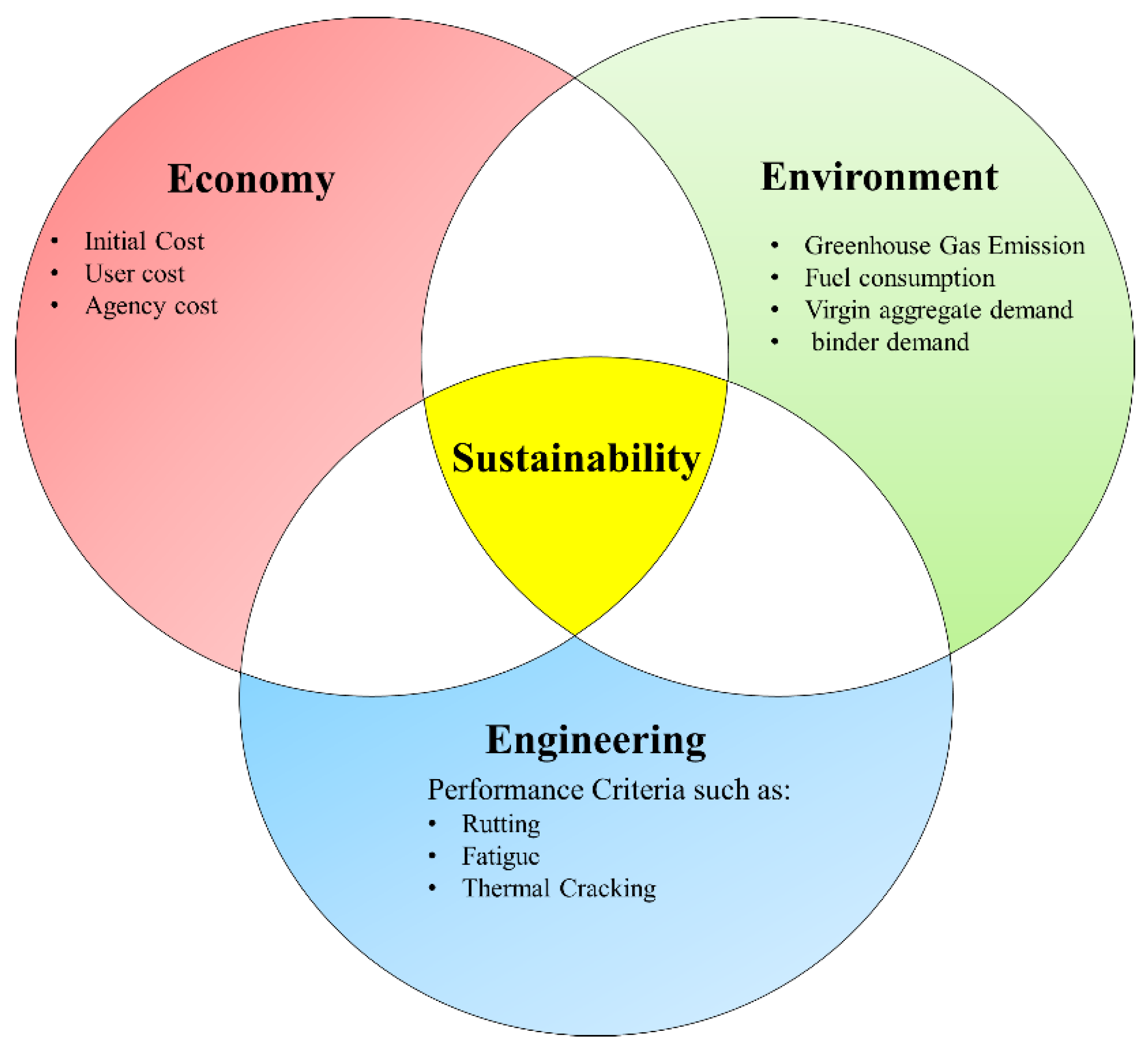

Sustainability Assessment of Green Asphalt Mixtures: A Review

Abstract

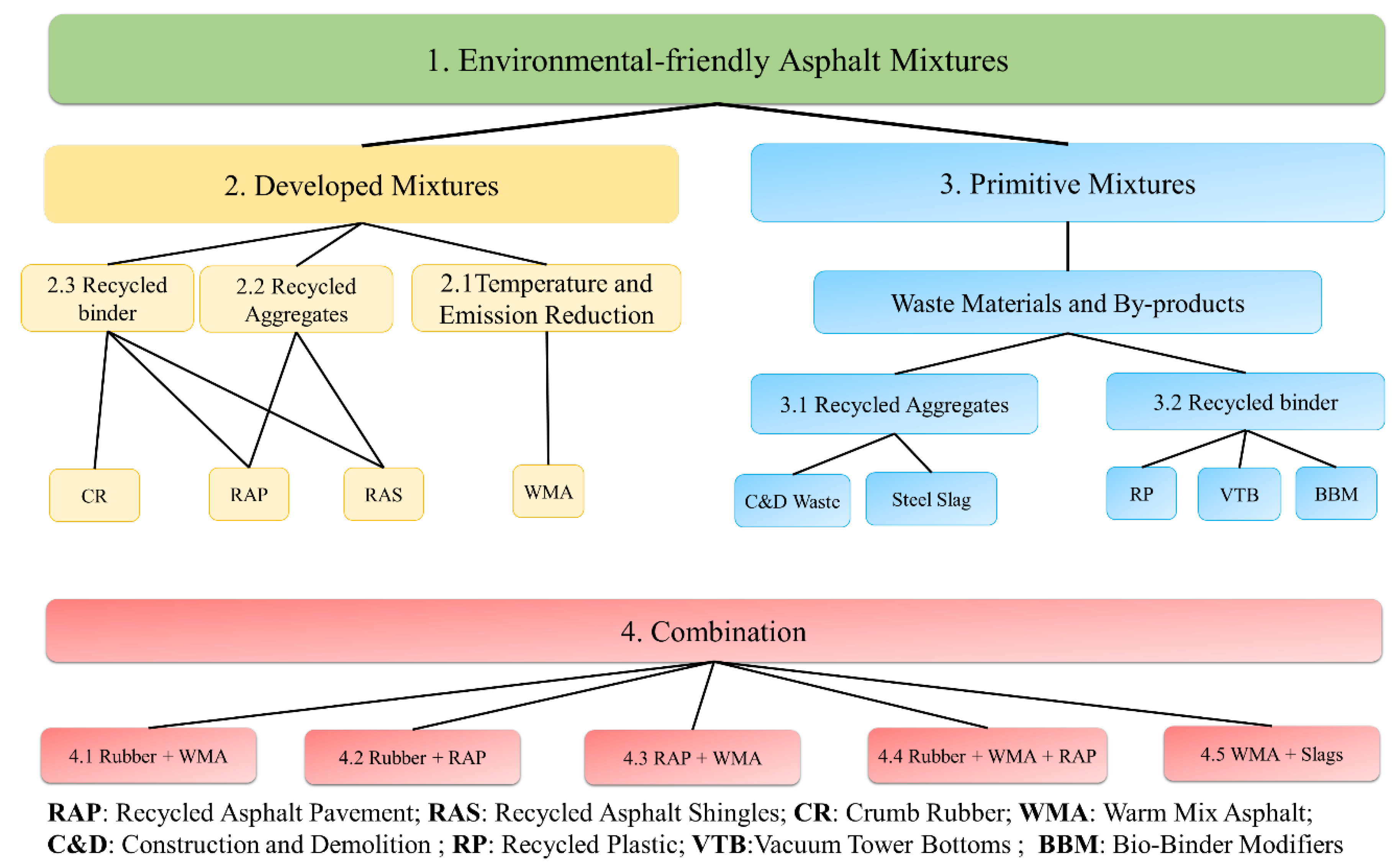

1. Introduction

2. Developed Mixtures

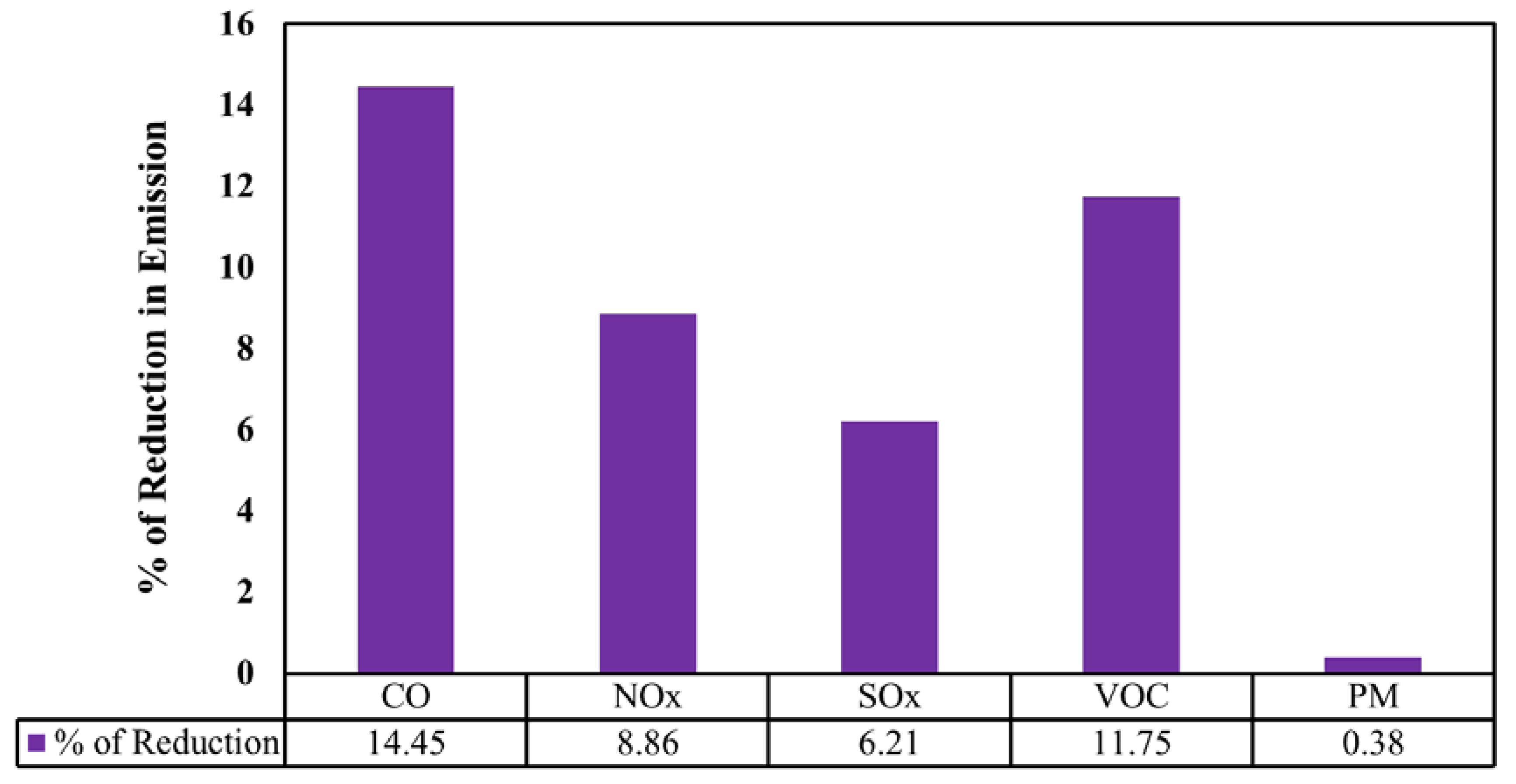

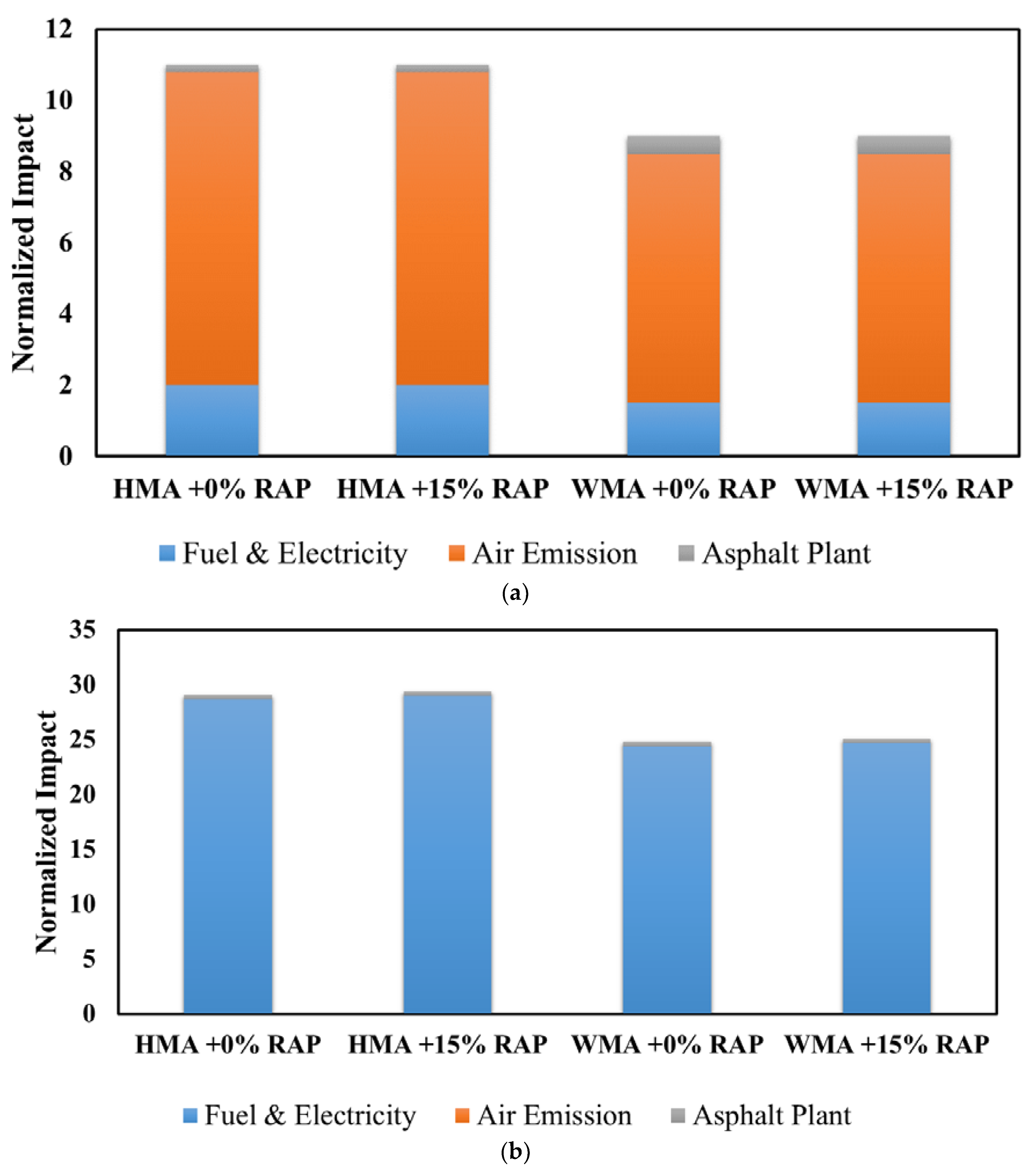

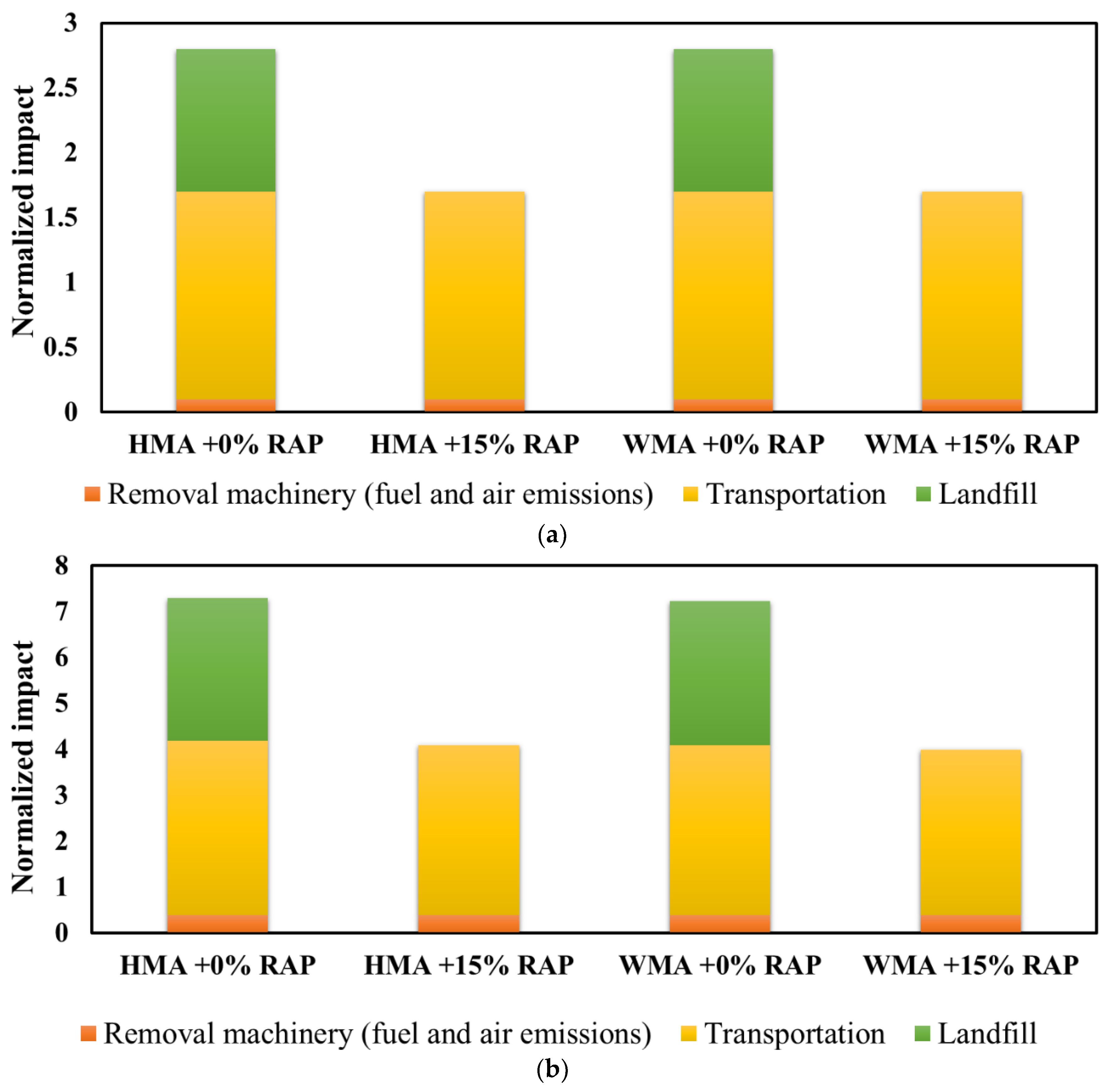

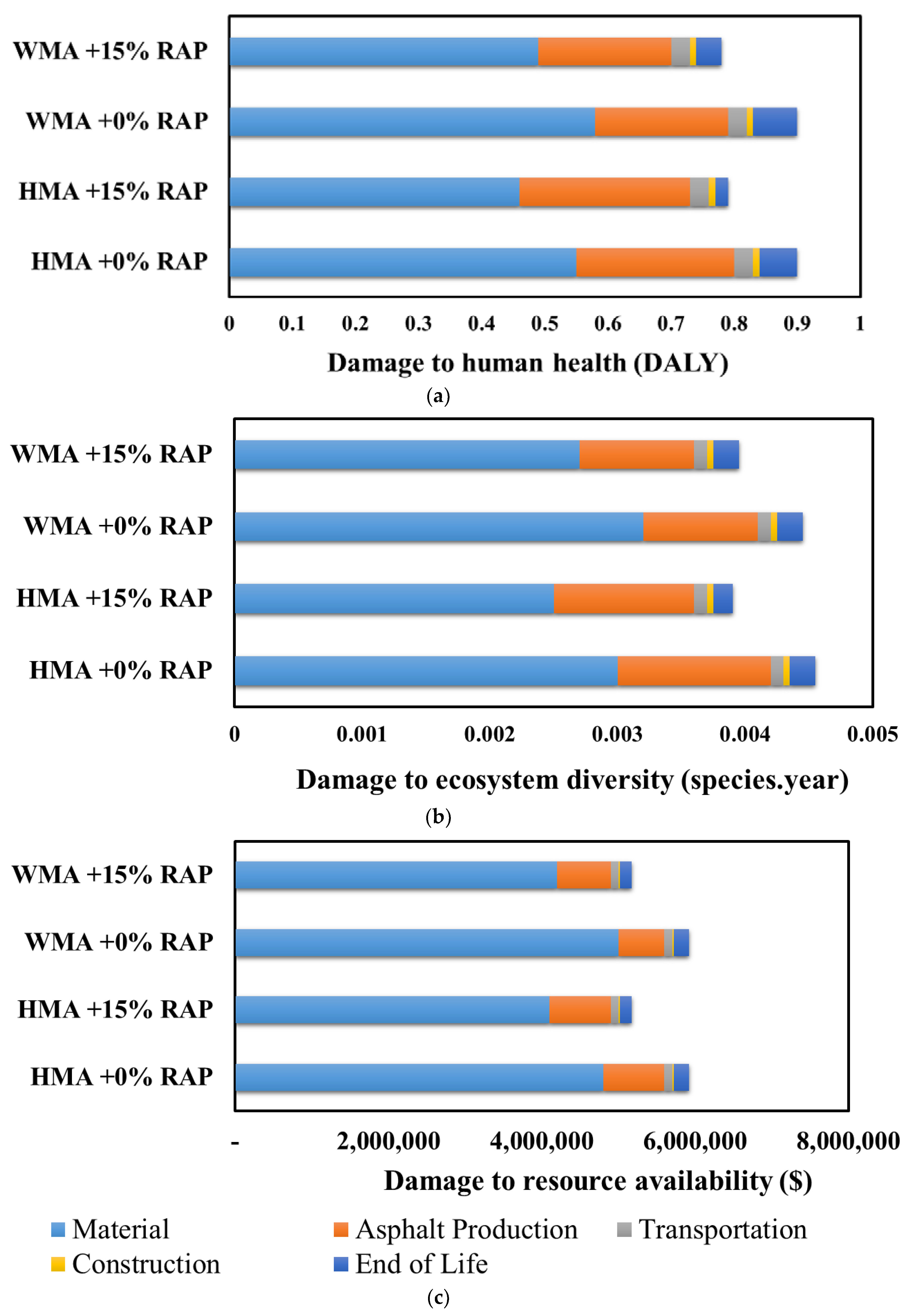

2.1. Temperature and Emission Reduction (WMA)

WMA Technologies

- Reduction in energy consumption at the plant;

- Increase in payments due to achieving higher in-place densities;

- Extended paving seasons; and

- The possibility of removing antistripping additives for some WMA additives.

2.2. Waste Materials and By-Products

Recycled Aggregate

- Existing pavement byproduct such as reclaimed asphalt pavement (RAP) and reclaimed asphalt shingles (RAS) materials;

- Construction and demolition (C and D) waste materials such as tiles and bricks; and

- The byproduct from industry, such as copper or steel slags.

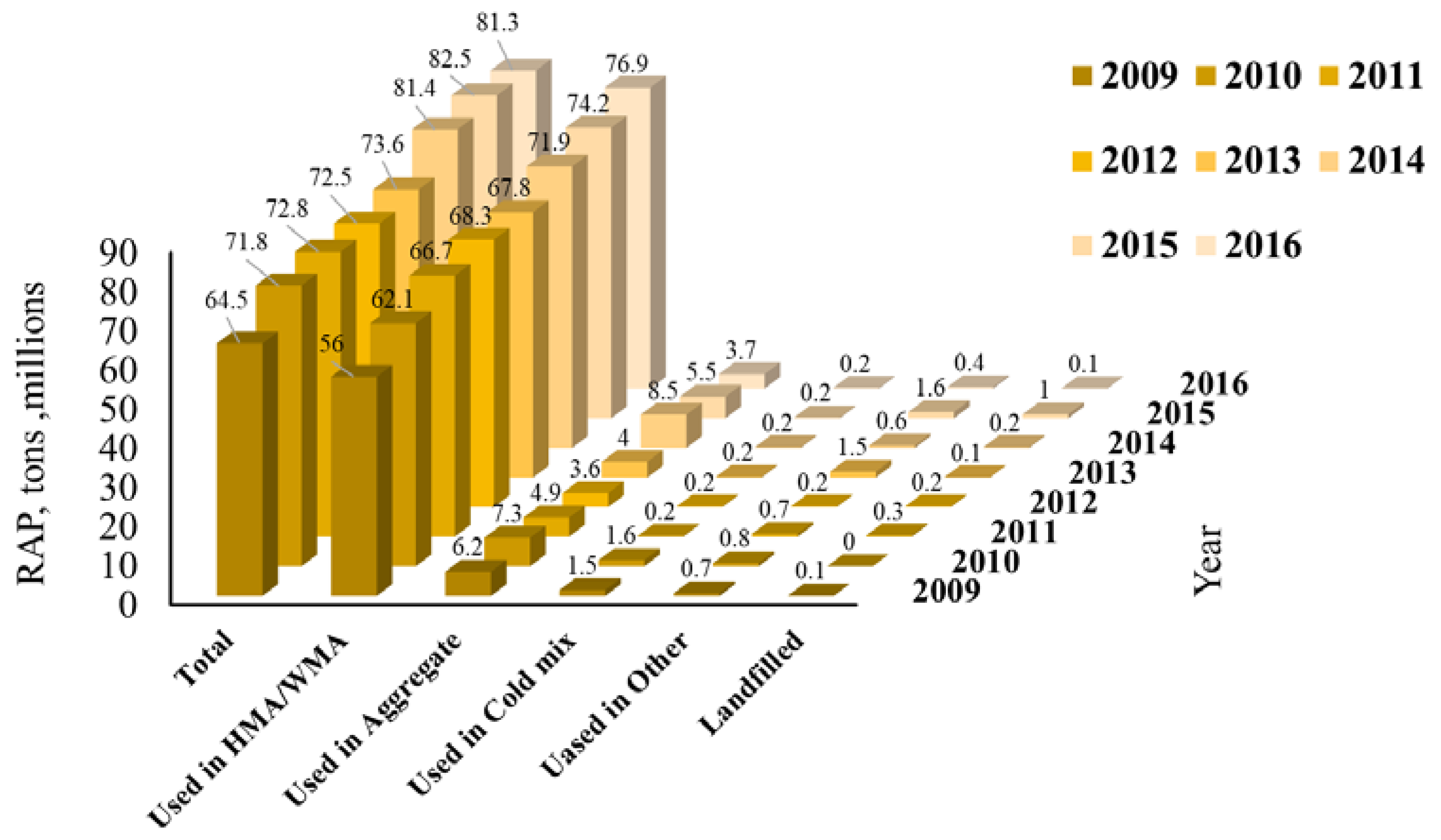

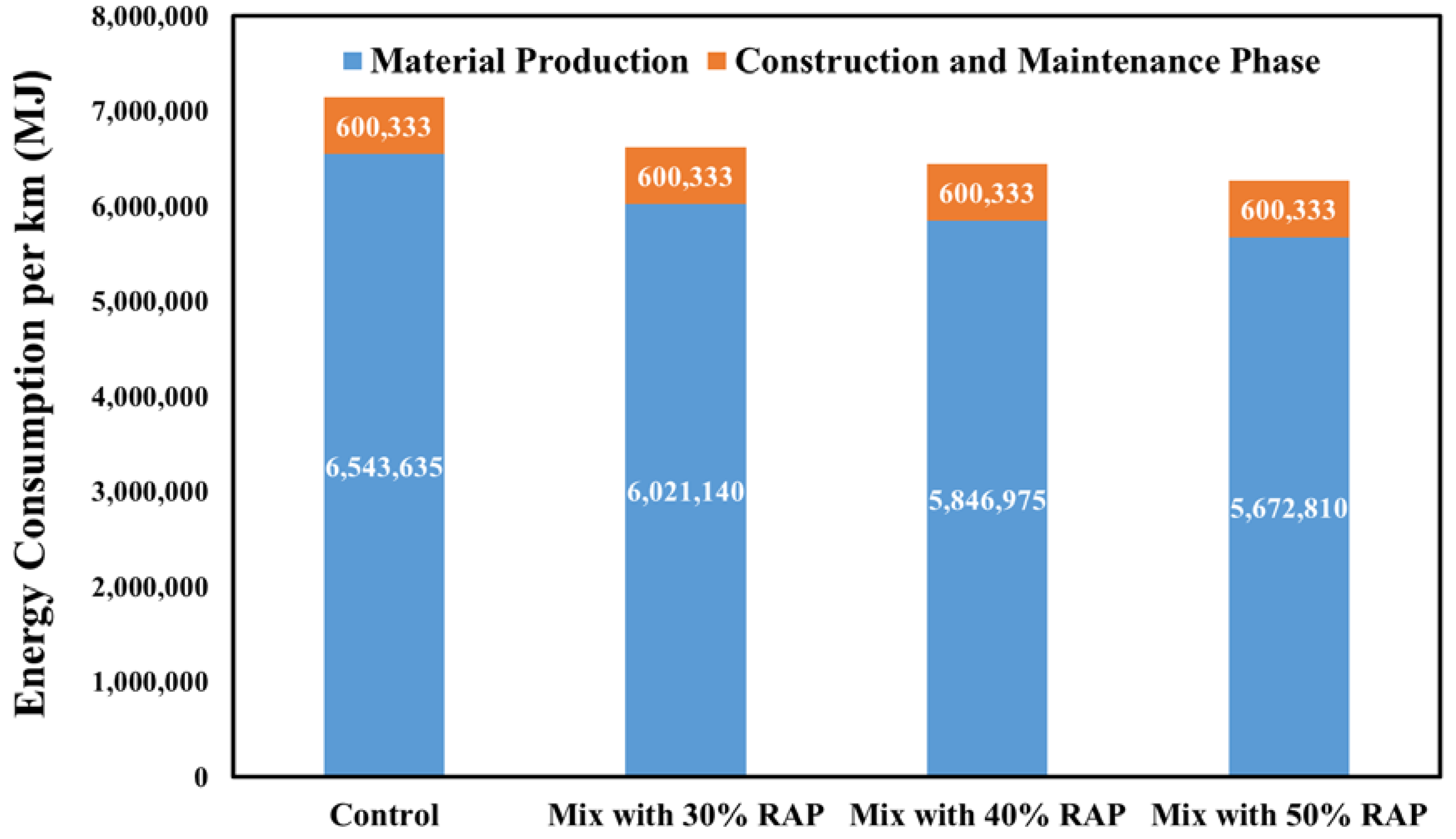

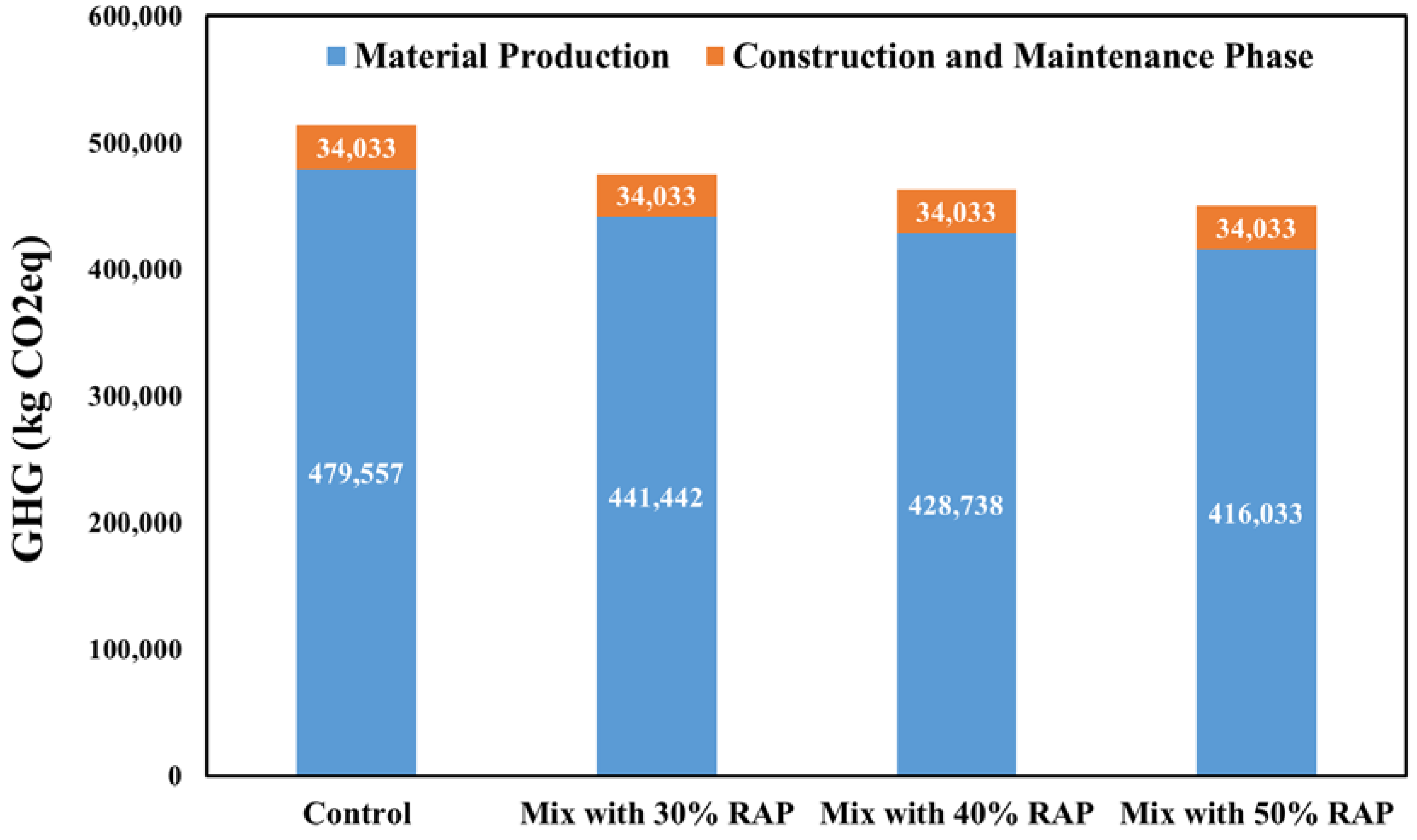

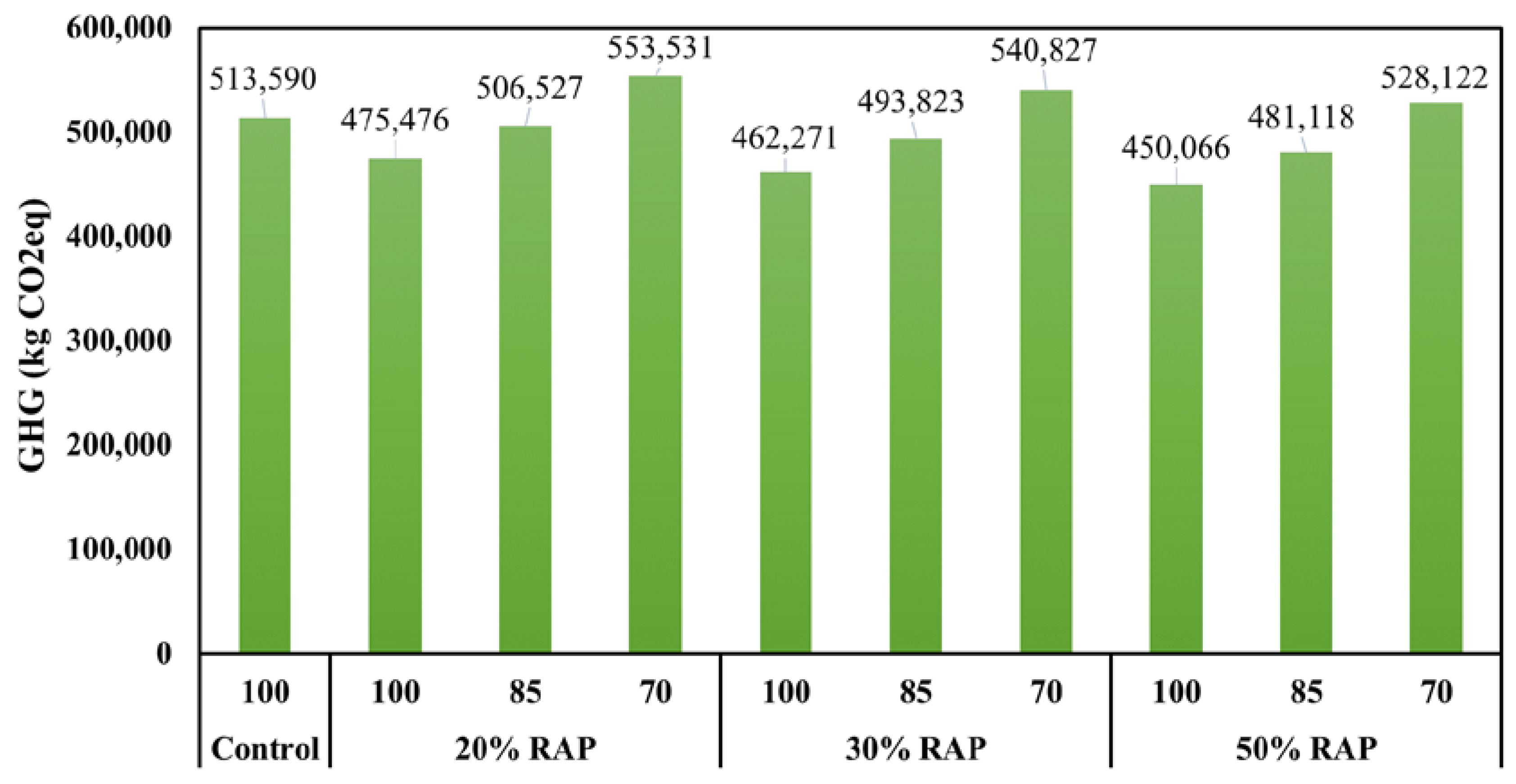

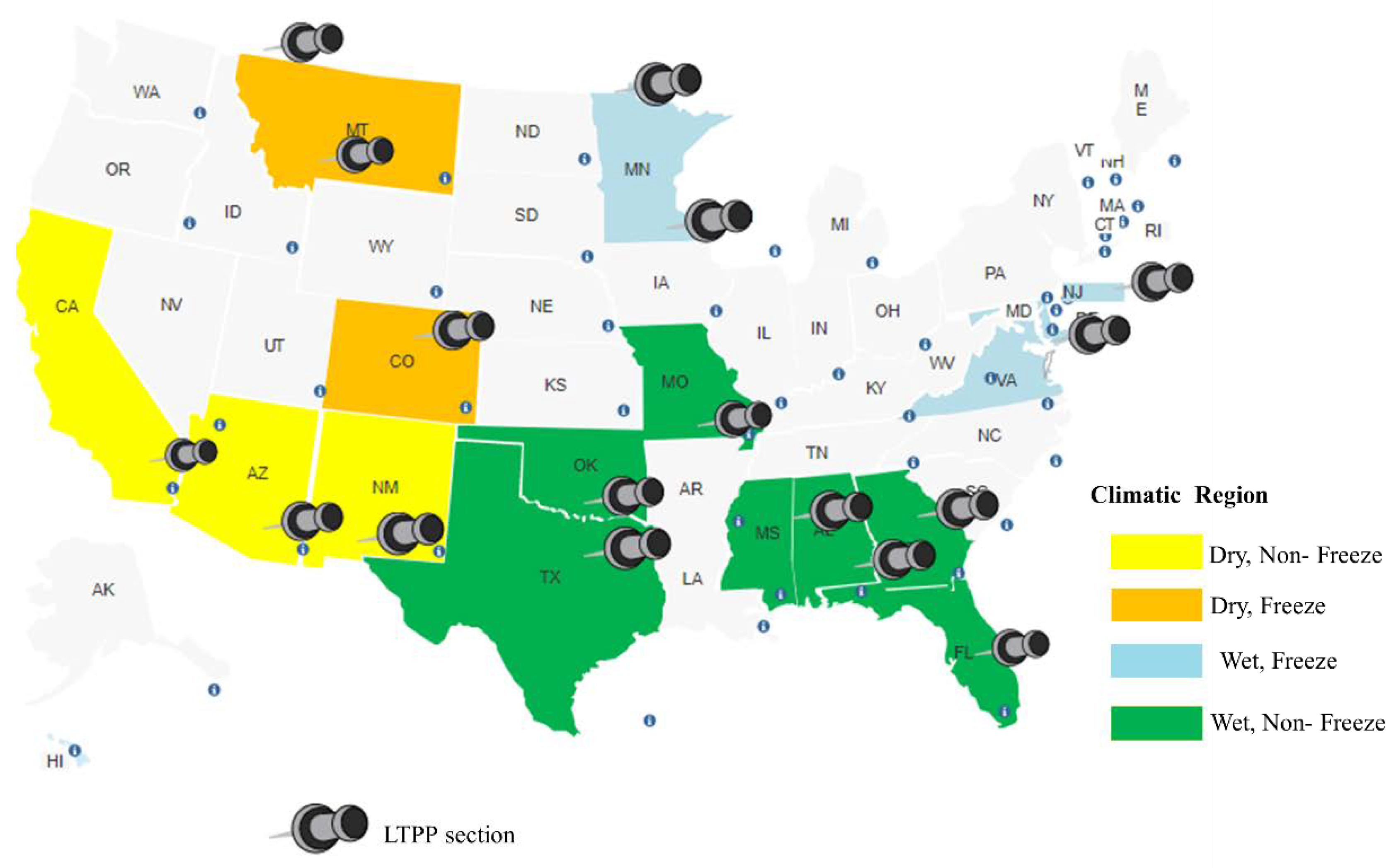

Reclaimed Asphalt Pavement (RAP)

- High variability in RAP due to different RAP sources;

- Demolition and milling processes; and

- Aged asphalt binder of RAP.

- Slightly effects on longitudinal cracking, transverse cracking, and roughness;

- A little-reduced fatigue resistance;

- Weakened pavement structure; and

- Increased rutting resistance.

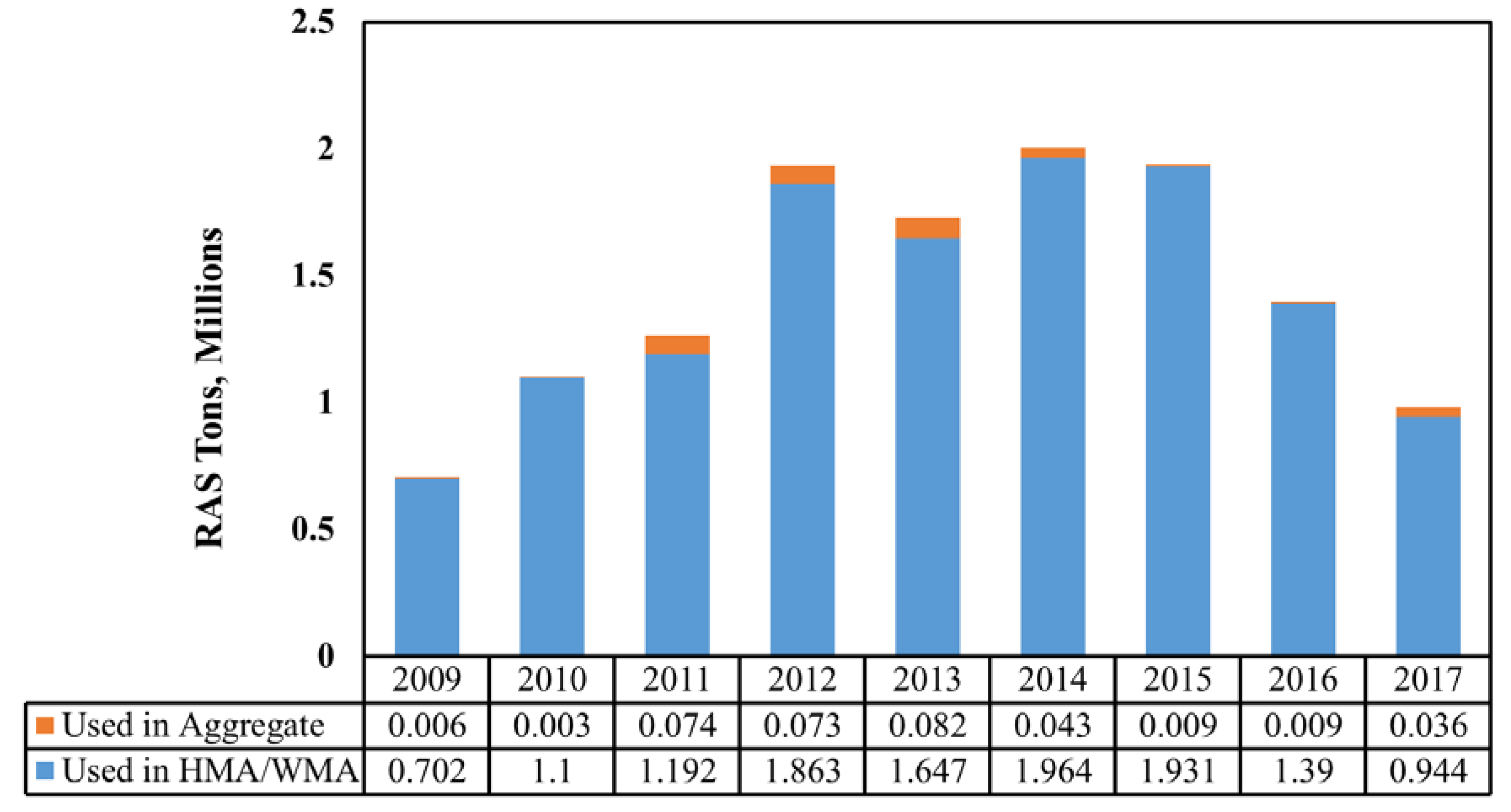

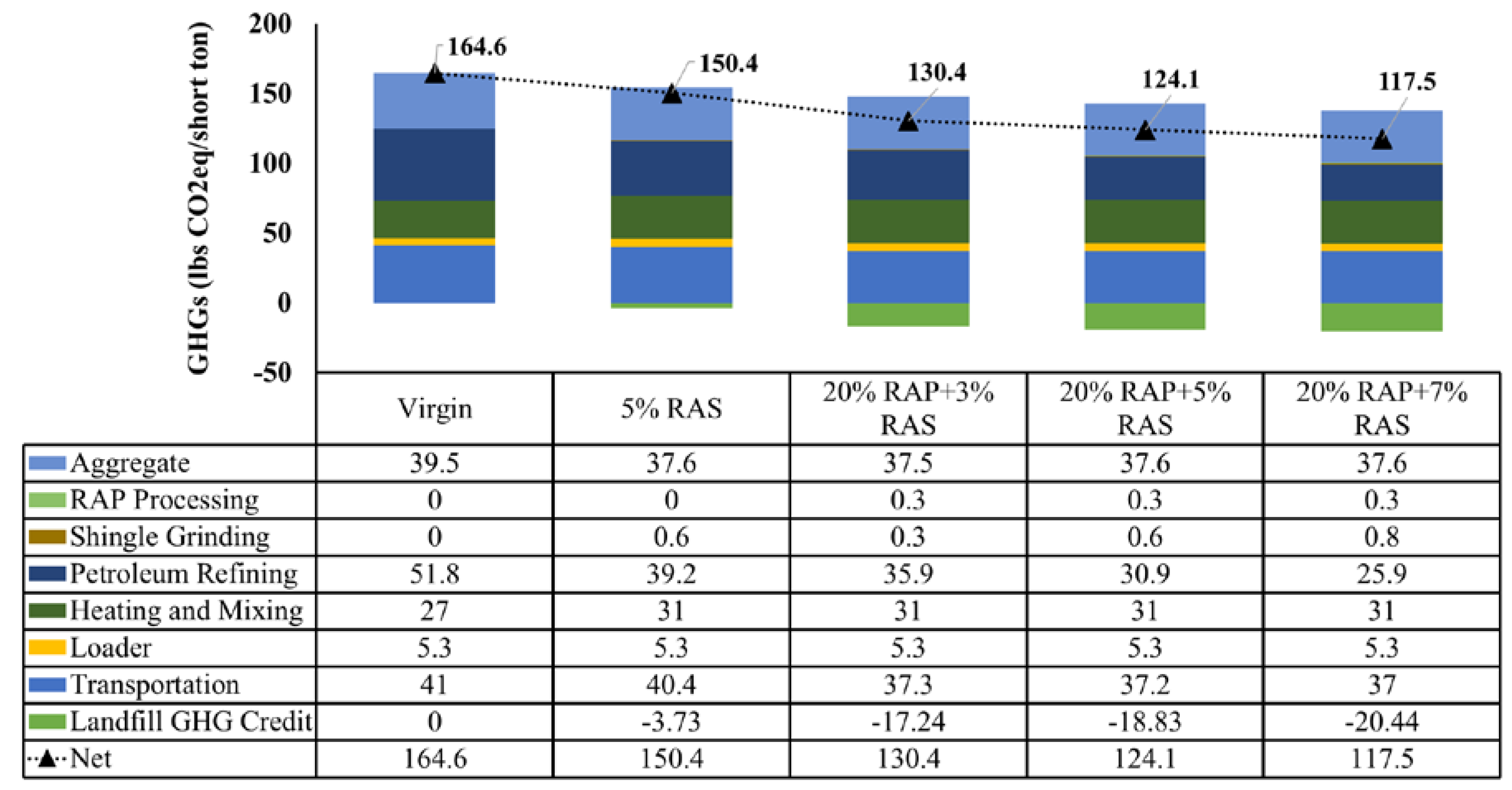

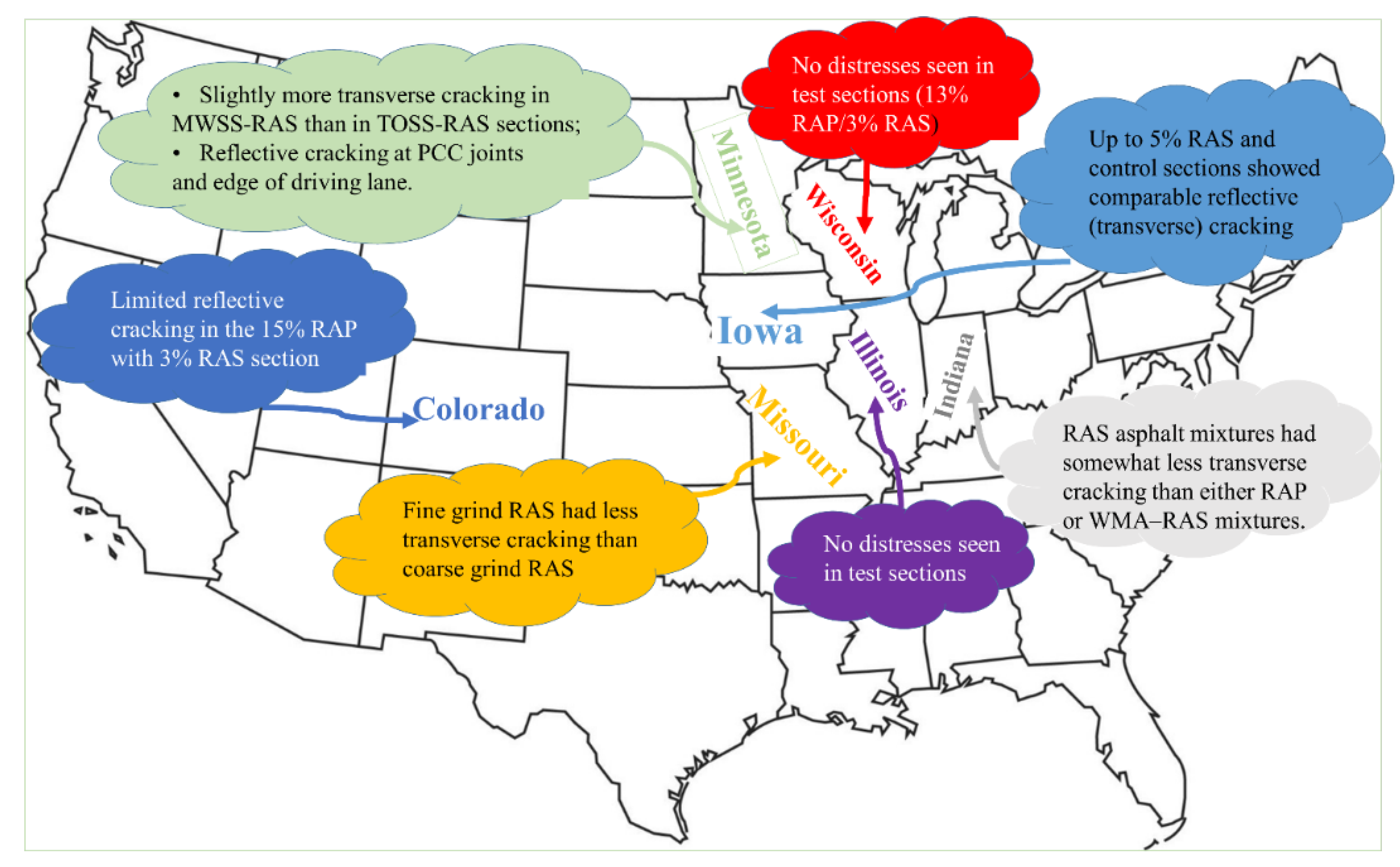

Recycled Asphalt Shingles (RAS)

2.3. Modified Binders

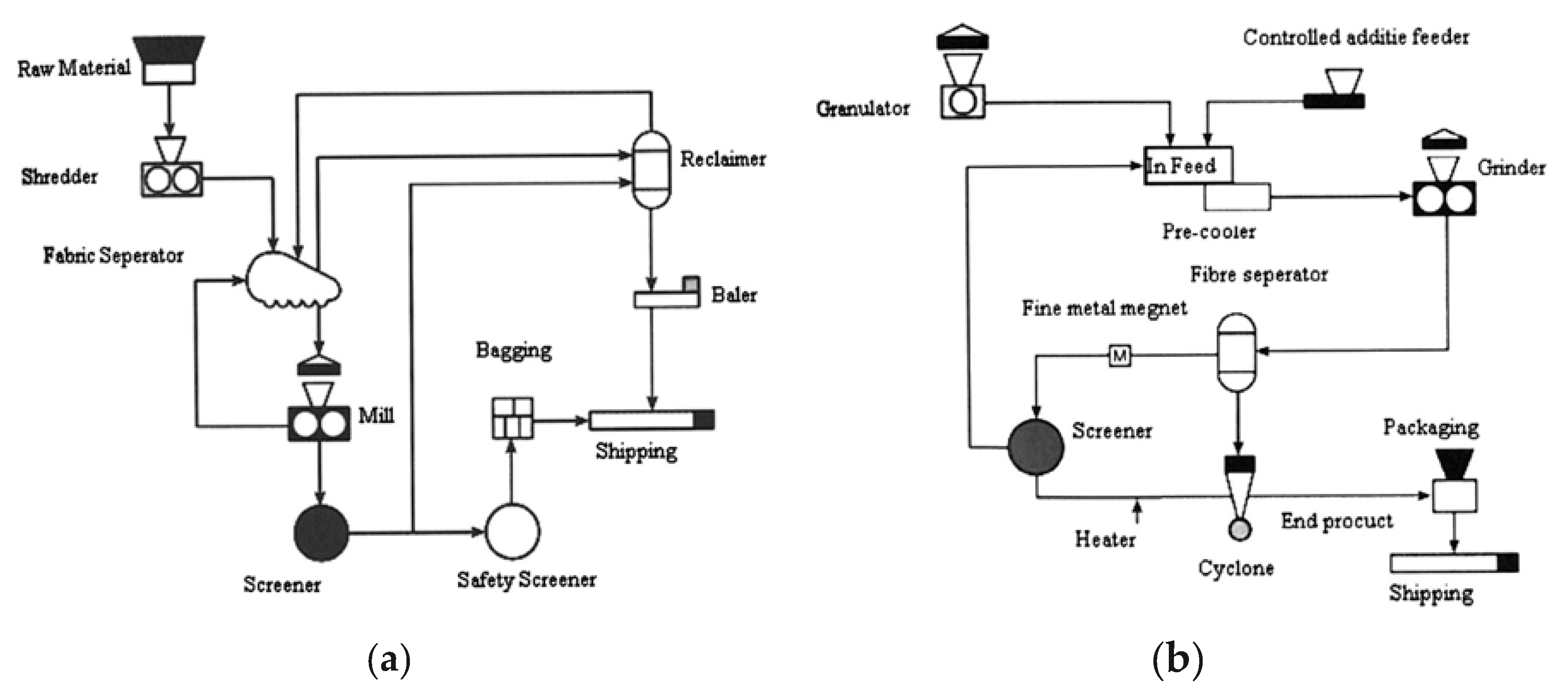

Crumb Rubber Modifier (CRM)

- Energy recovery: used as an alternative to fossil fuels;

- Chemical processing: such as pyrolysis, thermolysis and gasification; and

- Granulate recovery: shredding and chipping processes to cut up ELTs into small pieces of different sizes.

- Ambient grinding: ground ELFs at ordinary room temperature. This method is the most common approach and the most cost-effective method of processing ELT materials (Figure 15a);

- Cryogenic grinding: freezing the ELFs with liquid nitrogen to a temperature between −87 to −198 °C and breaking down the brittle ELFs using a hammer mill (Figure 15b);

- Wet-grinding: grinding into a liquid medium, usually water, using two closely spaced grinding wheels.

- Hydro jet size reduction: grind the material using pressurized water (around 55,000 psi).

- Improve the durability of asphalt mixtures;

- improve aging and oxidation;

- reduced fatigue and reflection cracking;

- lower maintenance costs and lower noise generation; and

- Improve skid resistance.

3. Primitive Mixtures

3.1. Waste Materials and By-Products

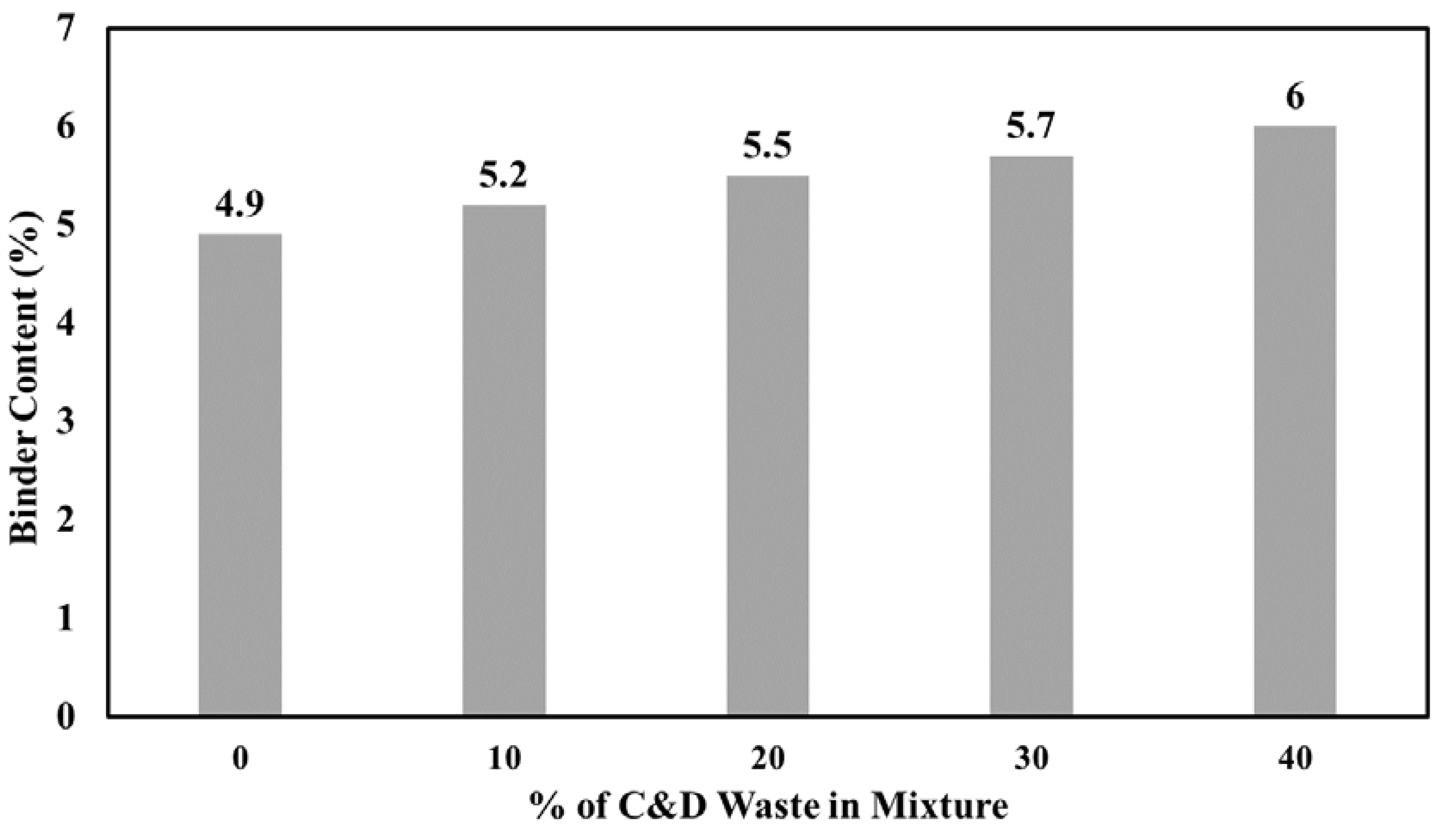

Construction and Demolition Waste

Copper and Steel Slag

3.2. Recycled and Bio-Binder

Recycled Plastic (RP)

Vacuum Tower Bottoms (VTB)

Bio-Binder Modifiers (BBM)

4. Combinations

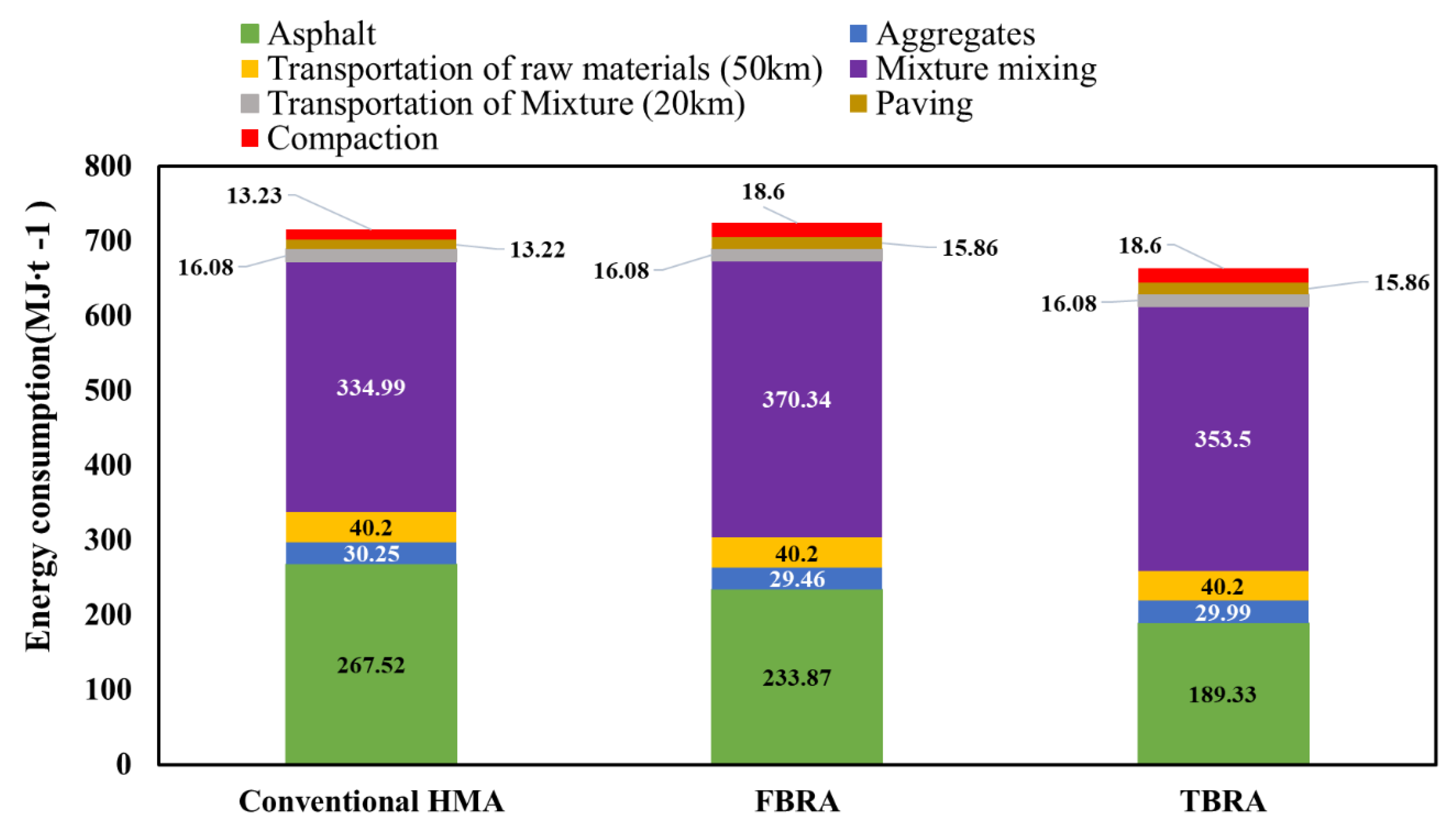

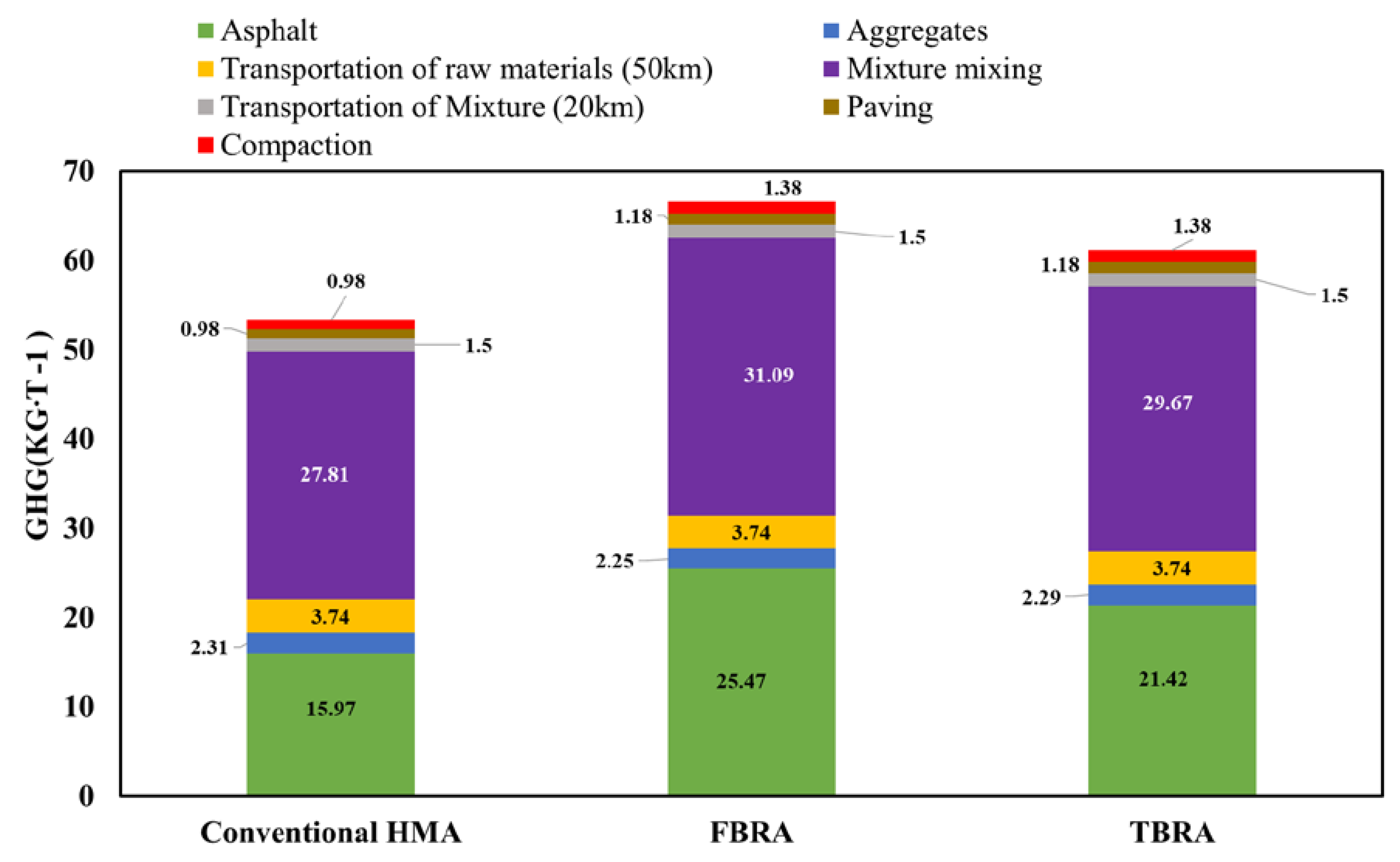

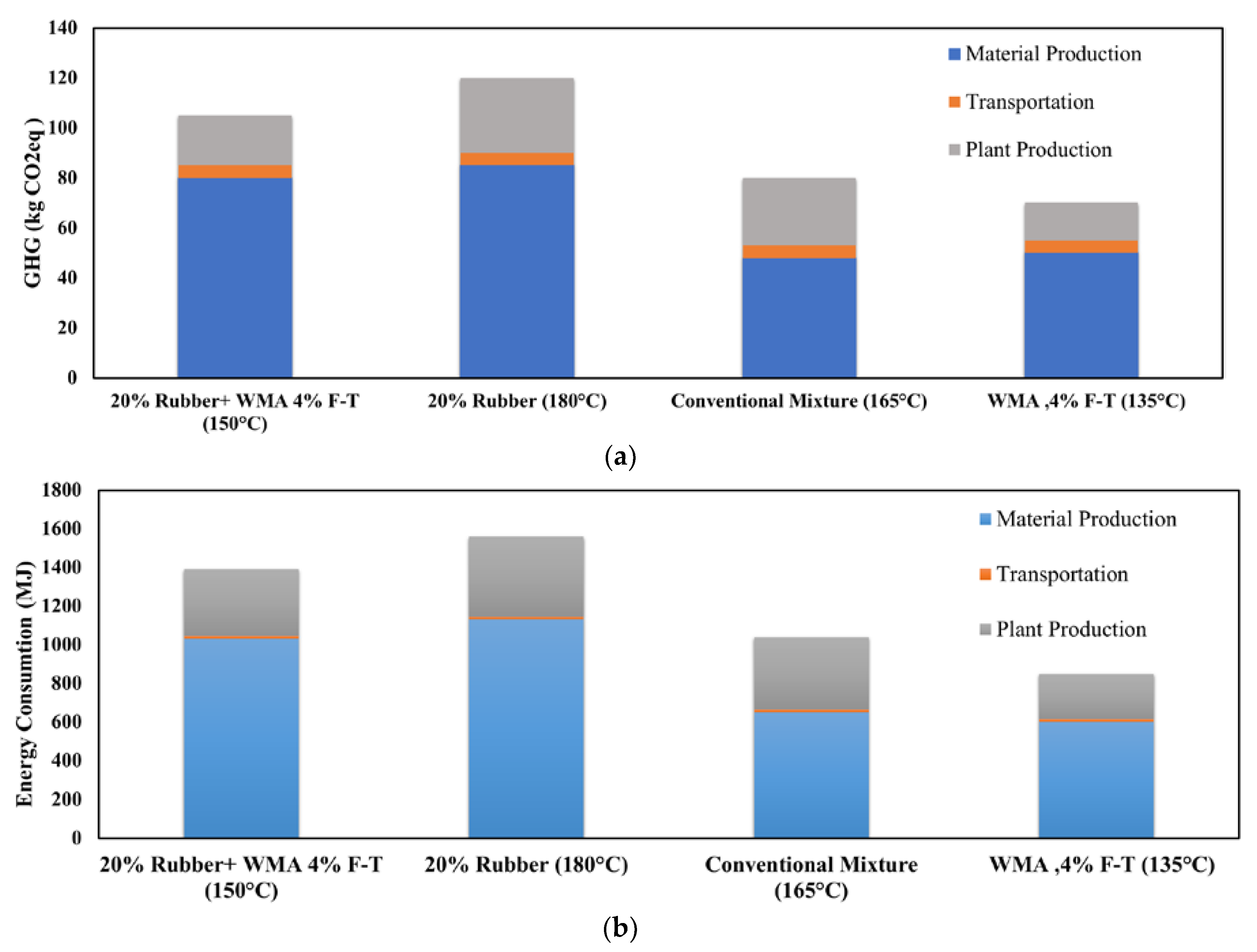

4.1. Rubberized Asphalt and WMA

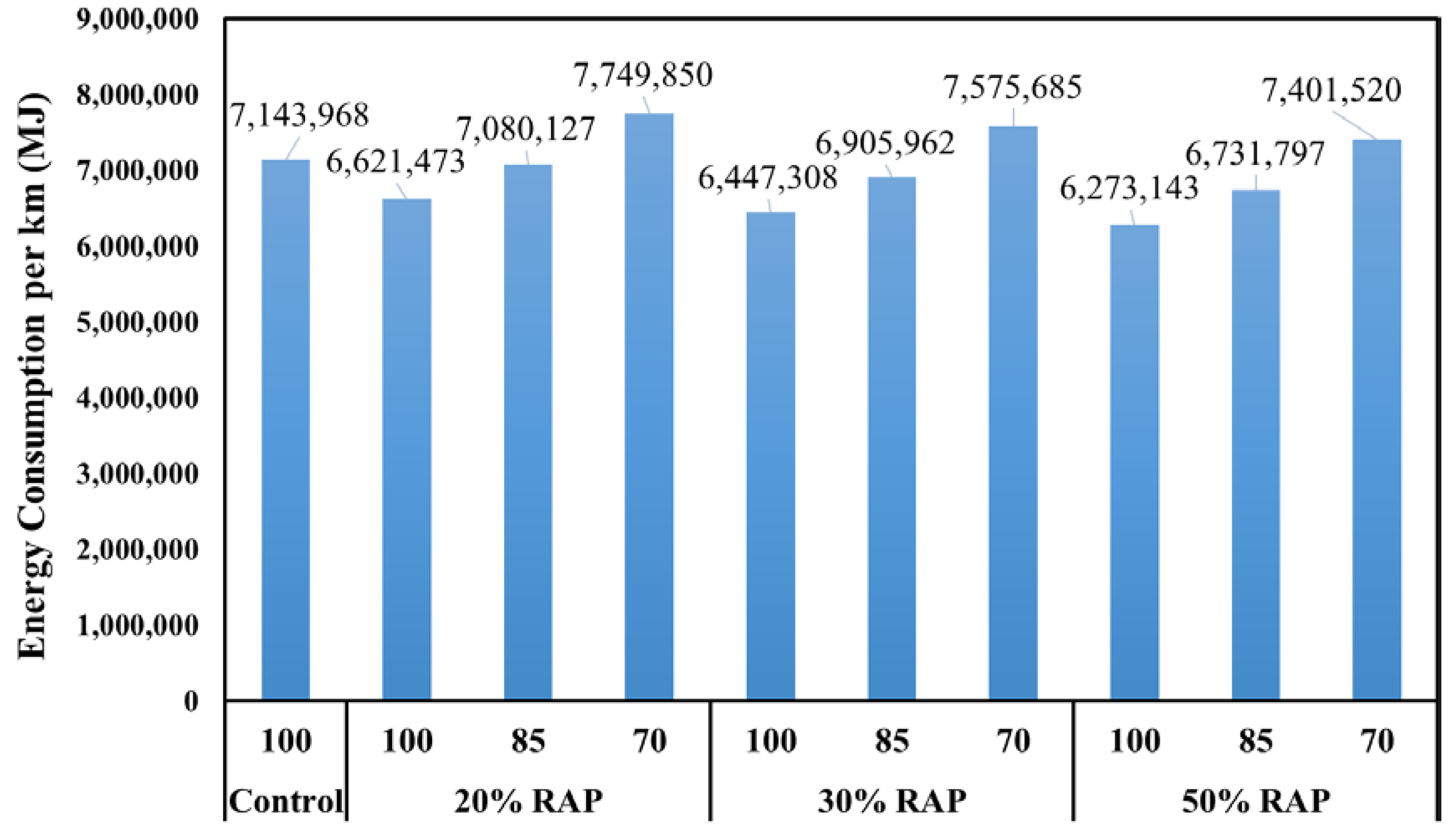

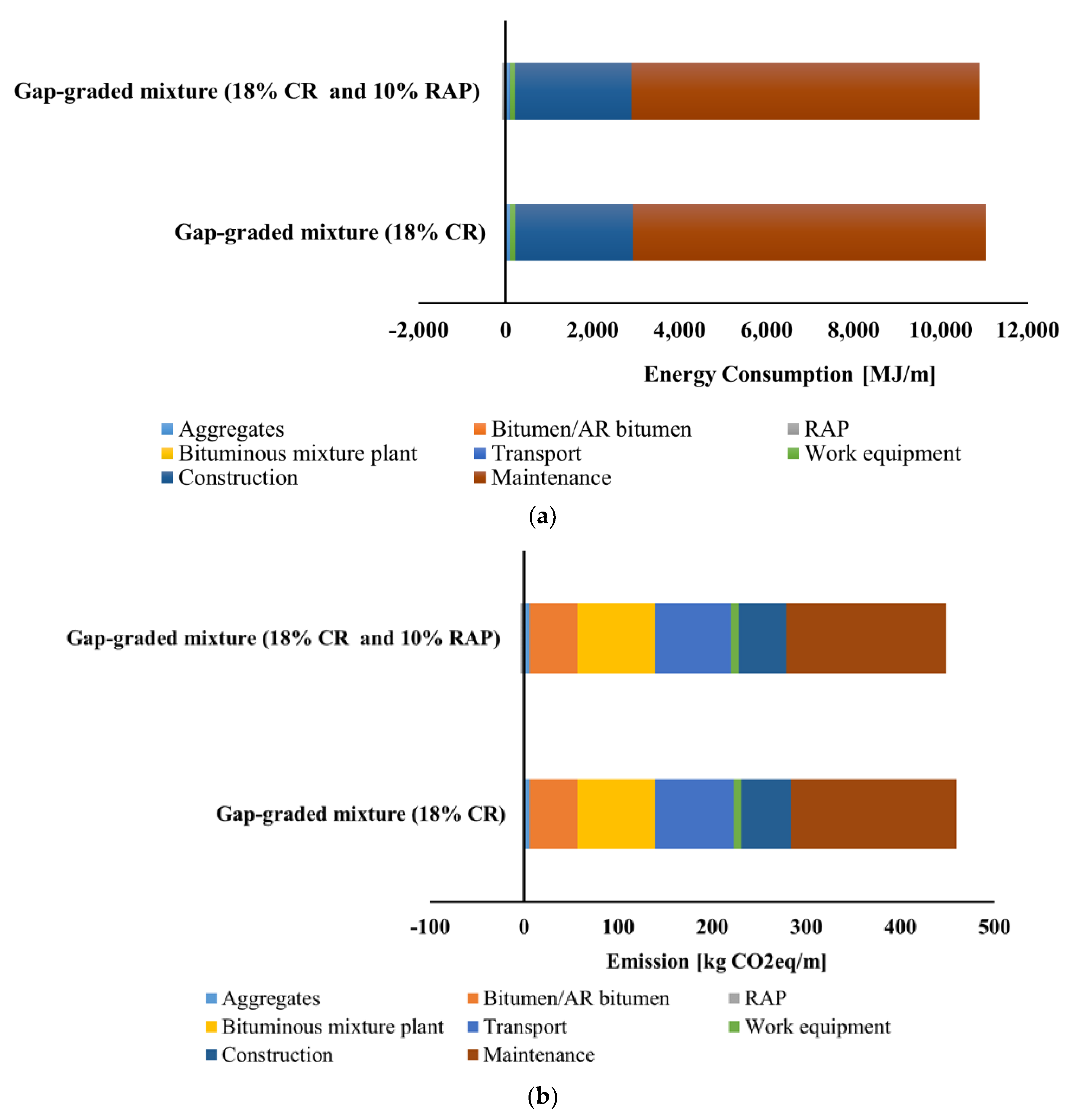

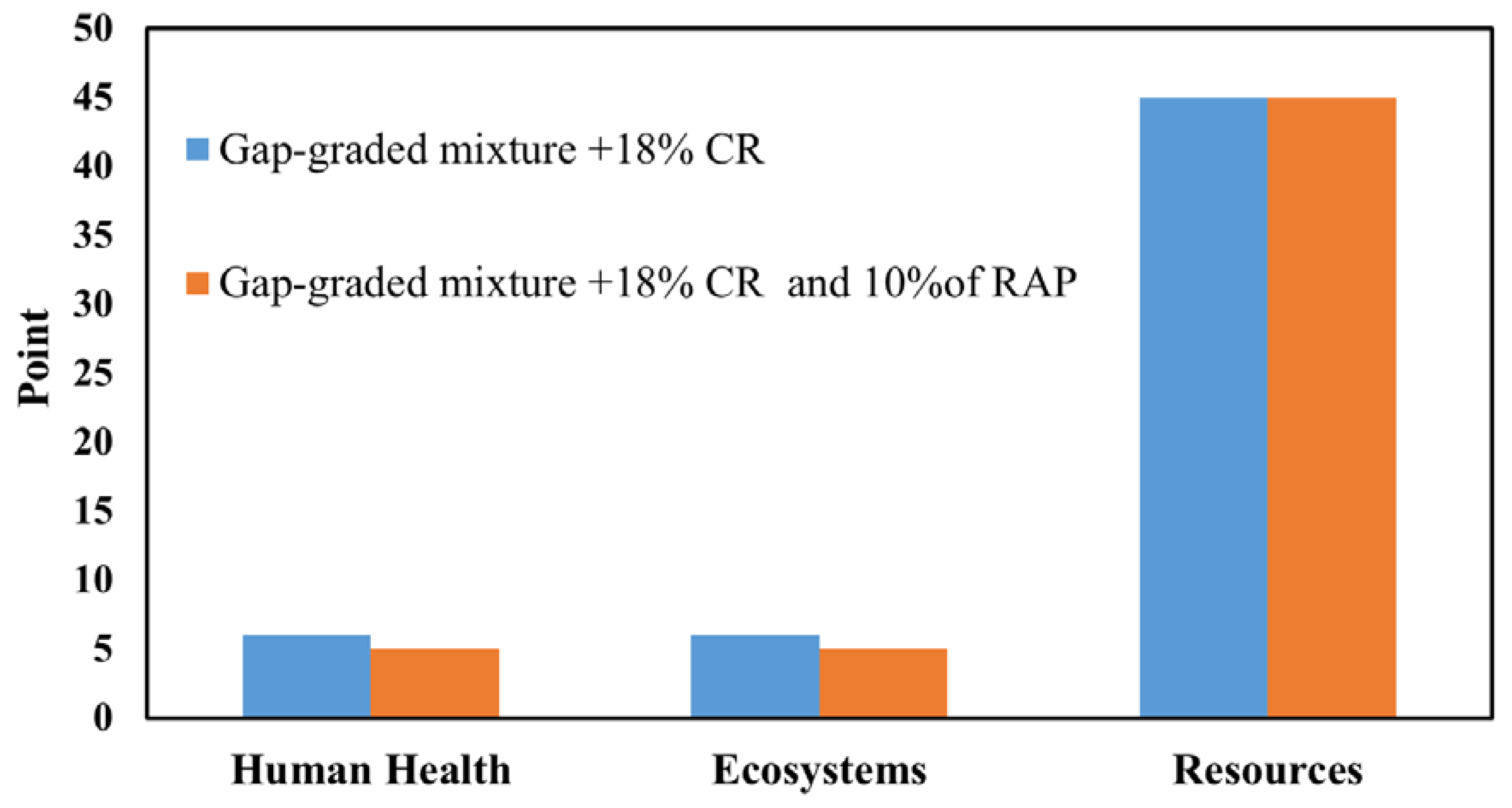

4.2. Rubberized Asphalt with RAP

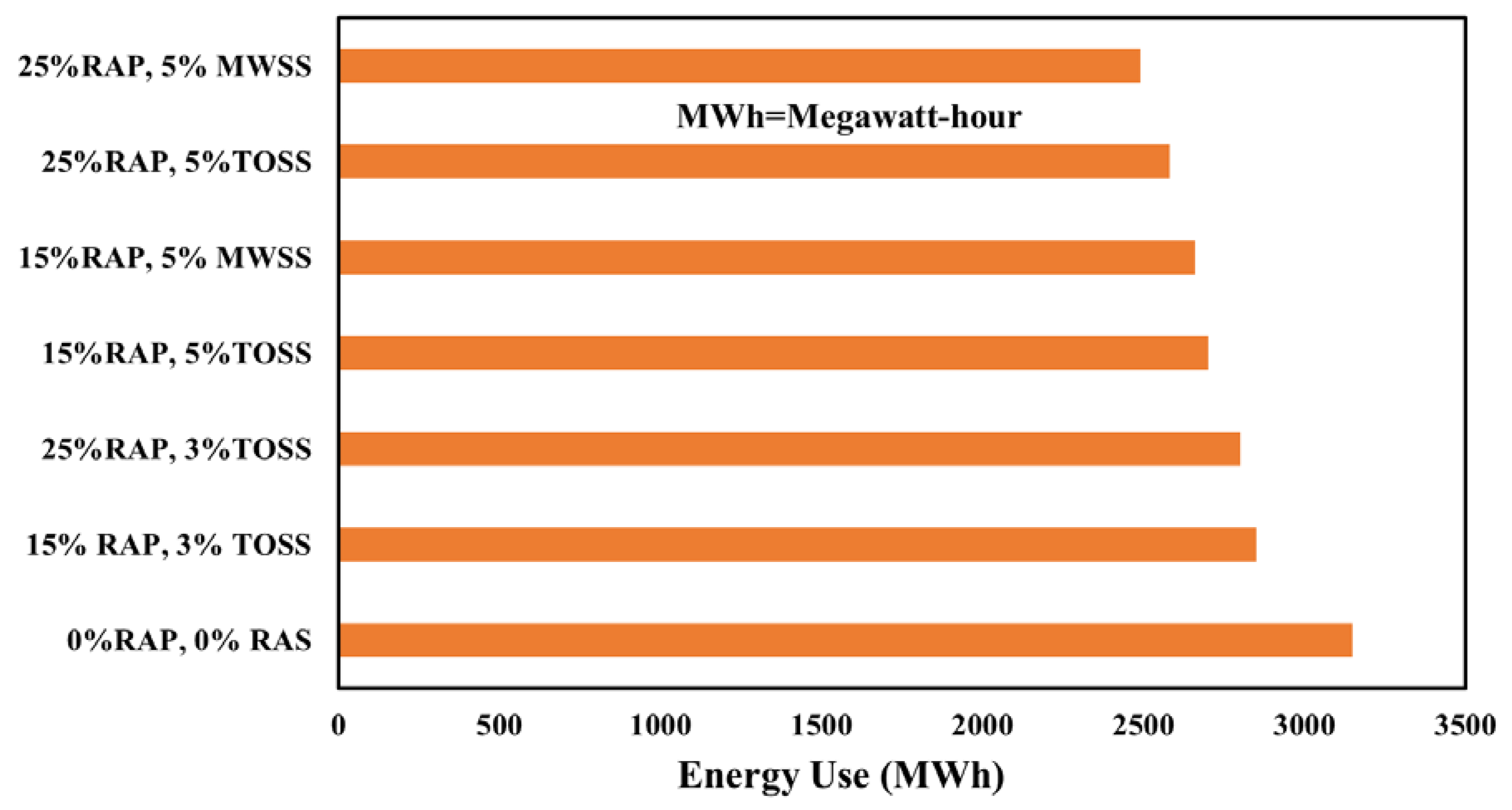

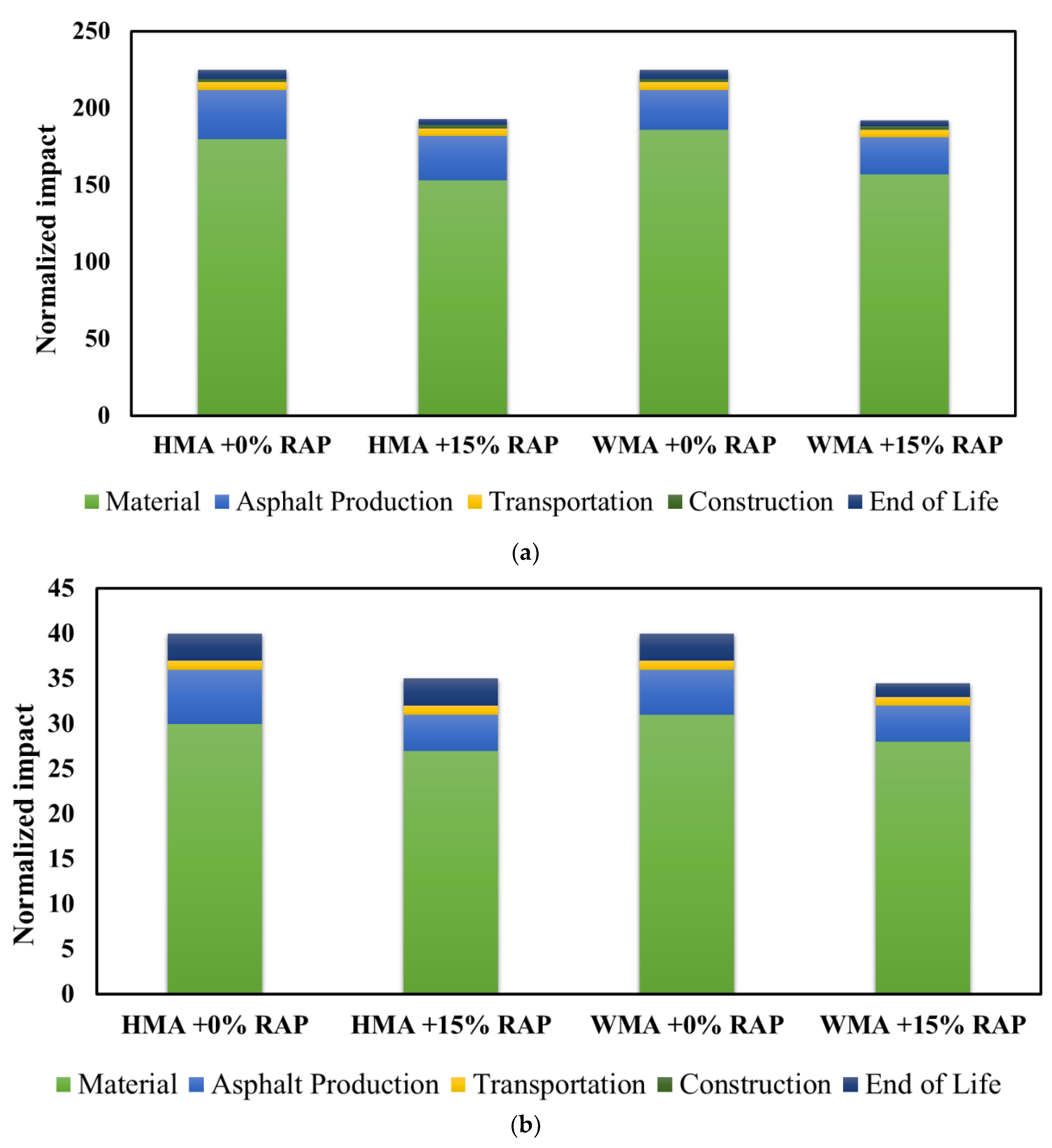

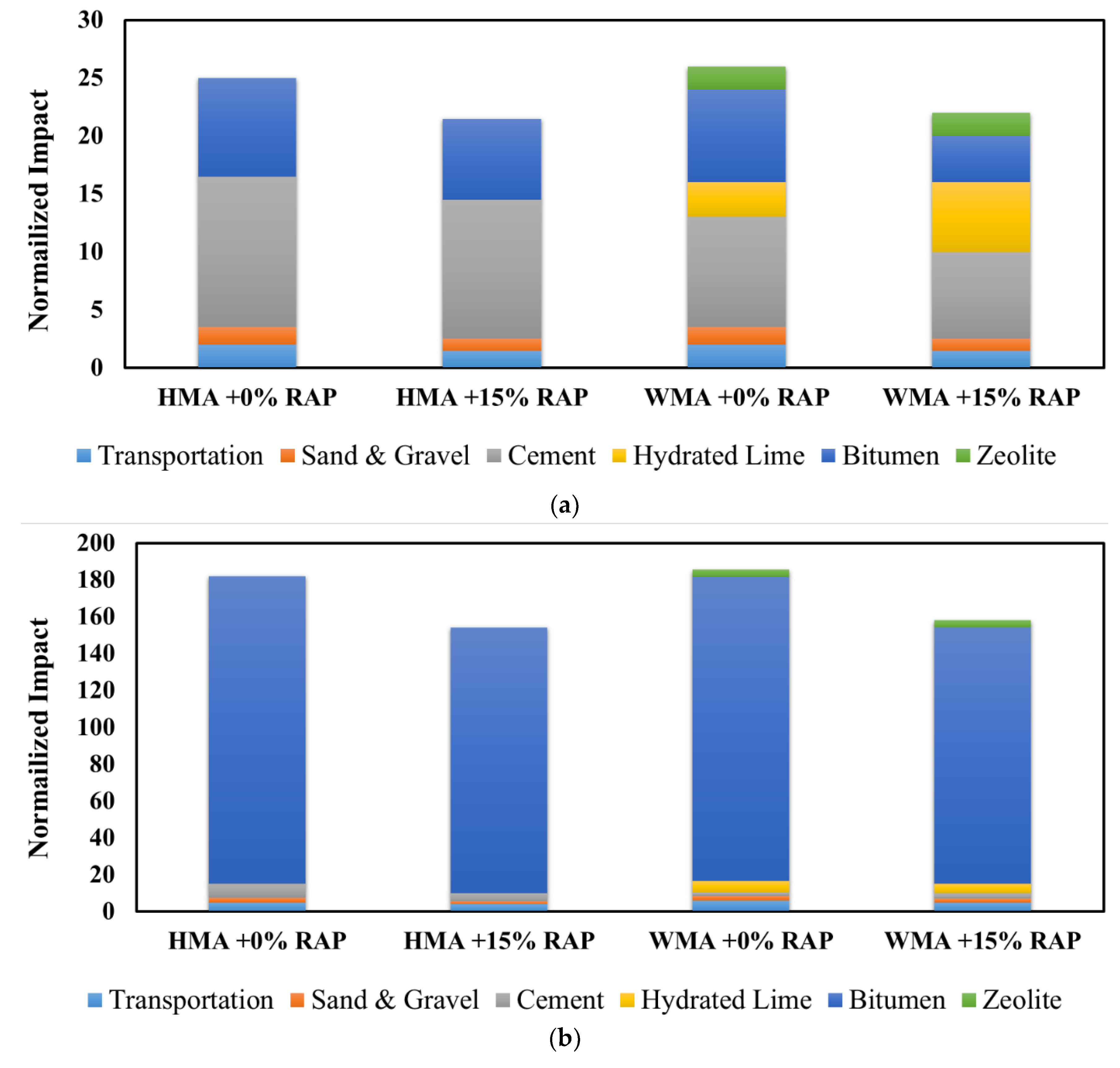

4.3. RAP and WMA

4.4. Rubberized Asphalt Containing WMA Additive and RAP

4.5. Slags and WMA

5. Summary, Conclusions, and Recommended Future Study

Funding

Acknowledgments

Conflicts of Interest

References

- Hansen, K.R.; Copeland, A. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2016; National Asphalt Pavement Association: Lanham, MD, USA, 2017; No. IS 138(7e). [Google Scholar]

- Kahn, B. We Just Breached the 410 Parts Per Million Threshold, Climate Central, Archived News. Available online: https://www.climatecentral.org/news/we-just-breached-the-410-parts-per-million-threshold-21372 (accessed on 14 June 2019).

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- EAPA; NAPA. The Asphalt Paving Industry: A Global Perspective, 2nd ed.; European Asphalt Pavement Association: Brussels, Belgium; National Asphalt Pavement Association: Lanham, MD, USA, 2011. [Google Scholar]

- Notani, M.A.; Nejad, F.M.; Fini, E.H.; Hajikarimi, P. Low-Temperature Performance of Toner-Modified Asphalt Binder. J. Transp. Eng. Part B Pavements 2019, 145, 04019022. [Google Scholar] [CrossRef]

- D’Angelo, J.; Harm, E.; Bartoszek, J.; Baumgardner, G.; Corrigan, M.; Cowsert, J.; Harman, T.; Jamshidi, M.; Jones, W.; Newcomb, D.; et al. Warm-Mix asphalt: European Practice; US Departmen of Transportation: Washington, DC, USA, 2008. [Google Scholar]

- West, R.; Rodezno, C.; Julian, G.; Prowell, B.; Frank, B.; Osborn, L.V.; Kriech, T. Field Performance of Warm Mix Asphalt Technologies; NCHRP Report 779; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar]

- Martin, A.E.; Arambula, E.; Yin, F.; Park, E.S. Validation of Guidelines for Evaluating the Moisture Susceptibility of WMA Technologies; Transportation Research Board: Washington, DC, USA, 2016; No. Project 09-49B. [Google Scholar]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm Mix Asphalt: An overview. J. Clean. Prod. 2012. [Google Scholar] [CrossRef]

- Newcomb, D.E.; Arambula, E.; Yin, F.; Zhang, J.; Bhasin, A.; Li, W.; Arega, Z. Properties of Foamed Asphalt for Warm Mix Asphalt Applications; Transportation Research Board: Washington, DC, USA, 2015; No. Project 09-53. [Google Scholar]

- Mirzababaei, P. Effect of zycotherm on moisture susceptibility of Warm Mix Asphalt mixtures prepared with different aggregate types and gradations. Constr. Build. Mater. 2016, 116, 403–412. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Shishehbor, M.; Pouranian, M.R.; Imaninasab, R. Evaluating the adhesion properties of crude oil fractions on mineral aggregates at different temperatures through reactive molecular dynamics. Pet. Sci. Technol. 2018, 36, 2084–2090. [Google Scholar] [CrossRef]

- Shishehbor, M.; Pouranian, M.R.; Ramezani, M.G. Molecular investigations on the interactions of graphene, crude oil fractions and mineral aggregates at low, medium and high temperatures. Pet. Sci. Technol. 2019, 1–8. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). Warm Mix Asphalt Technologies and Research. Available online: https://www.fhwa.dot.gov/pavement/asphalt/wma.cfm (accessed on 14 June 2019).

- National Academies of Sciences, Engineering, and Medicine (NASEM). Long-Term Field Performance of Warm Mix Asphalt Technologies; The National Academies Press: Washington, DC, USA, 2017. [Google Scholar]

- Kristjansdottir, O. Warm Mix Asphalt for Cold Weather Paving; University of Washington: Seattle, WA, USA, 2006; No. WA-RD 650.1. [Google Scholar]

- Oliveira, J.; Silva, H.; Fonseca, P.; Kim, Y.; Hwang, S.; Pyun, J.; Lee, H. Laboratory and field study of a WMA mixture produced with a new temperature reduction additive. In Proceedings of the 2nd International Conference on Warm Mix Asphalt, St. Louis, Mo, USA, 11–13 October 2011; pp. 11–13. [Google Scholar]

- Middleton, B.; Forfylow, R.W. Evaluation of warm-mix asphalt produced with the double barrel green process. Transp. Res. Rec. 2009, 2126, 19–26. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Perveneckas, Z. Analysis and evaluation of possibilities for the use of warm mix asphalt in Lithuania. Balt. J. Road Bridge Eng. 2009, 4, 80–86. [Google Scholar] [CrossRef]

- Powers, D. Warm Mix Asphalt. ODOT Field Trials. Presented at 2009 Ohio Asphalt Paving Conference, Columbus, OH, USA, 4 February 2009. [Google Scholar]

- Capitão, S.D.; Picado-Santos, L.G.; Martinho, F. Pavement engineering materials: Review on the use of warm-mix asphalt. Constr. Build. Mater. 2012, 36, 1016–1024. [Google Scholar]

- McIver, J. Evotherm—Warm Mix Asphalt Technology. Available online: http://warmmixasphalt.com/submissions/54_20080101_Jonathan McIver-Evotherm.pdf (accessed on 14 June 2019).

- Davidson, J.K.; Pedlow, R. Reducing Paving Emissions Using Warm Mix Technology. In Proceedings of the Annual Conference-Canadian Technical Asphalt Association, Niagara Falls, ON, Canada, 18–21 November 2007; Polyscience Publications: Laval, QC, Canada, 2007; Volume 52, p. 39. [Google Scholar]

- Larsen, O.R.; Moen, Ø.; Robertus, C.; Koenders, B.G. WAM Foam asphalt production at lower operating temperatures as an environmental friendly alternative to HMA. In Proceedings of the 3rd Eurasphalt & Eurobitume Congress, Vienna, Austria, 12–14 May 2004. [Google Scholar]

- De Groot, P.C.; Bowen, C.; Koenders, B.G.; Stoker, D.A.; Larsen, O.; Johansen, J. A comparison of emissions from hot mixture and warm asphalt mixture production. In Proceedings of the IRF Congress, Paris, France, June 2001. [Google Scholar]

- Sargand, S.; Figueroa, J.L.; Edwards, W.; Al-Rawashdeh, A.S. Performance Assessment of Warm Mix Asphalt (WMA) Pavements; Ohio Research Institute for Transportation and the Environment: Athens, OH, USA, 2009. [Google Scholar]

- Ziari, H.; Moniri, A.; Ayazi, M.J.; Nakhaei, M. Investigation of rutting performance of wma mixtures containing copper slag. Int. J. Transp. Eng. 2016, 3, 227–235. [Google Scholar]

- Bennert, T. Evaluation of Warm Asphalt Technology—Feasibility Study; NJDOT Project, 1; New Jersey Department of Transportation Bureau of Research and Technology: Trenton, NJ, USA, 2008. [Google Scholar]

- Bonaquist, R.F. Mix Design Practices for Warm Mix Asphalt; Transportation Research Board: Washington, DC, USA, 2011; Volume 691. [Google Scholar]

- Kristjánsdóttir, Ó.; Muench, S.; Michael, L.; Burke, G. Assessing potential for warm-mix asphalt technology adoption. Transp. Res. Rec. J. Transp. Res. Board 2007, 2040, 91–99. [Google Scholar] [CrossRef]

- Jones, D.; Wu, R.; Tsai, B.W.; Harvey, J.T. Warm-Mix Asphalt Study: First-Level Analysis of Phase 2 HVS and Laboratory Testing and Phase 1 and Phase 2 Forensic Assessments: No. UCPRC-RR-2009-02; University of California Pavement Research Center: UC Davis, UC Berkley, July 2009. [Google Scholar]

- Estakhri, C.K.; Button, J.W.; Alvarez, A.E. Field and Laboratory Investigation of Warm Mix Asphalt in Texas; Texas A & M University: College Station, TX, USA, 2010; No. FHWA/TX-10/0-5597-2. [Google Scholar]

- Prowell, B.D.; Hurley, G.C.; Frank, B. Warm-Mix Asphalt: Best Practices; National Asphalt Pavement Association: Lanham, MD, USA, 2011. [Google Scholar]

- Hurley, G.C.; Prowell, B.D. Evaluation of Sasobit for use in warm mix asphalt. NCAT Rep. 2005, 5, 1–27. [Google Scholar]

- Hurley, G.; Prowell, B. Evaluation of EvothermTM for Use in Warm Asphalt Mixes; Auburn University: Auburn, AL, USA, NCAT Report 06-02; 2006. [Google Scholar]

- Diefenderfer, S.D.; Hearon, A. Laboratory Evaluation of a Warm Asphalt Technology for Use in Virginia; Virginia Transportation Research Council: Charlottesville, VA, USA, 2008; No. FHWA/VTRC 09-R11. [Google Scholar]

- Cooper, S.B. Evaluation of HMA Mixtures Containing Sasobit; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2009; No. 06-1TA. [Google Scholar]

- Zelelew, H.; Paugh, C.; Corrigan, M.R. Warm-Mix Asphalt Laboratory Permanent Deformation Performance in State of Pennsylvania: Case Study; Transportation Research Board: Washington, DC, USA, 2011; No. 11–2784. [Google Scholar]

- Xiao, F.; Punith, V.S.; Amirkhanian, S.N. Effects of non-foaming WMA additives on asphalt binders at high performance temperatures. Fuel 2012, 94, 144–155. [Google Scholar] [CrossRef]

- Mejías-Santiago, M.; Doyle, J.D.; Rushing, J.F. Accelerated pavement testing of warm-mix asphalt for heavy-traffic airfields. Transp. Res. Rec. 2014, 2456, 11–20. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Imaninasab, R.; Shishehbor, M. The effect of temperature and stress level on the rutting performance of modified stone matrix asphalt. Road Mater. Pavement Des. 2018, 1–13. [Google Scholar] [CrossRef]

- Corrigan, M.; Paugh, C.; Reddy, J.R.; Petty, D.W.; Bradford, T.; Lewis, B.A. Mobile Asphalt Testing Laboratory Program; Final Report; Federal Highway Administration: Washington, DC, USA, 2010. [Google Scholar]

- Diefenderfer, S.D.; Hearon, A.J. Performance of Virginia’s Warm-Mix Asphalt Trial Sections; Virginia Transportation Research Council: Charlottesville, VA, USA, 2010; No. VTRC 10-R17; FHWA/VTRC 10-R17. [Google Scholar]

- Kvasnak, A.; Moore, J.; Taylor, A.; Prowell, B. Preliminary Evaluation of Warm Mix Asphalt Field Demonstration: Franklin, Tennessee; Final Report 10-01; Auburn University: Auburn, AL, USA, 2010. [Google Scholar]

- Aschenbrener, T.; Schiebel, B.; West, R. Three-year evaluation of the Colorado Department of Transportation’s warm mix asphalt experimental feature on I-70 at Silverthorne, Colorado. NCAT Rep. 2011, 11, 2. [Google Scholar]

- West, R.; Timm, D.; Willis, R.; Powell, B.; Tran, N.; Watson, D.; Sakhaeifar, M.; Brown, R.; Robbins, M.; Vargas-Nordcbeck, A.; et al. Phase IV NCAT Pavement Test Track Findings; Auburn University: Auburn, AL, USA, 2012. [Google Scholar]

- Ghabchi, R.; Singh, D.; Zaman, M. Laboratory evaluation of stiffness, low-temperature cracking, rutting, moisture damage, and fatigue performance of WMA mixes. Road Mater. Pavement Des. 2015, 16, 334–357. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit®: State-of-the-Art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Notani, M.A.; Moghadas Nejad, F.; Khodaii, A.; Hajikarimi, P. Evaluating fatigue resistance of toner-modified asphalt binders using the linear amplitude sweep test. Road Mater. Pavement Des. 2018, 1–14. [Google Scholar] [CrossRef]

- Goh, S.W.; You, Z. Moisture damage and fatigue cracking of foamed warm mix asphalt using a simple laboratory setup. In Transportation and Development Institute Congress 2011: Integrated Transportation and Development for a Better Tomorrow; American Society of Civil Engineering (ASCE): Reston, Virginia, USA, 2011; pp. 762–771. [Google Scholar]

- Das, P.K.; Tasdemir, Y.; Birgisson, B. Low temperature cracking performance of WMA with the use of the Superpave indirect tensile test. Constr. Build. Mater. 2012, 30, 643–649. [Google Scholar] [CrossRef]

- Hill, B.; Behnia, B.; Hakimzadeh, S.; Buttlar, W.G.; Reis, H. Evaluation of low-temperature cracking performance of warm-mix asphalt mixtures. Transp. Res. Rec. 2012, 2294, 81–88. [Google Scholar] [CrossRef]

- Sholar, G.; Nash, T.; Musselman, J.; Upshaw, P. FDOT’s Experience with Warm Mix Asphalt; Report No. 09-527; Florida Department of Transportation: Gainesville, FL, USA, 2009. [Google Scholar]

- Willis, J.R. Life-Cycle Assessment of 2012 NCAT Pavement Test Track Green Group Mixtures; Auburn University: Auburn, AL, USA, 2014; No. NCAT Report 14-02. [Google Scholar]

- Mazumder, M.; Sriraman, V.; Kim, H.H.; Lee, S.J. Quantifying the environmental burdens of the hot mix asphalt (HMA) pavements and the production of warm mix asphalt (WMA). Int. J. Pavement Res. Technol. 2016, 9, 190–201. [Google Scholar] [CrossRef]

- Leng, Z.; Al-Qadi, I.L.; Cao, R. Life-cycle economic and environmental assessment of warm stone mastic asphalt. Transp. A Transp. Sci. 2018, 14, 562–575. [Google Scholar] [CrossRef]

- Wen, H. Use of fracture work density obtained from indirect tensile testing for the mix design and development of a fatigue model. Int. J. Pavement Eng. 2013, 14, 561–568. [Google Scholar] [CrossRef]

- Horvath, A. Earlier Faculty Research Title Life-Cycle Environmental and Economic Assessment of Using Recycled Materials for Asphalt Pavements. Available online: https://escholarship.org/uc/item/5jz3x91z(2003) (accessed on 14 June 2019).

- Epps, J.A.; Little, D.N.; Holmgreen, R.J.; Terrel, R.L. Guidelines for Recycling Pavement Materials; NCHRP Report; National Research Council: Washington, DC, USA, 1980. [Google Scholar]

- Epps, J.A. Uses of Recycled Rubber Tires in Highways; Transportation Research Board; National Research Council: Washington, DC, USA, 1994; Volume 198. [Google Scholar]

- West, R. Reclaimed Asphalt Pavement Management: Best Practices; NCAT Draft Report; National Center for Asphalt Technology: Auburn, AL, USA, 2010. [Google Scholar]

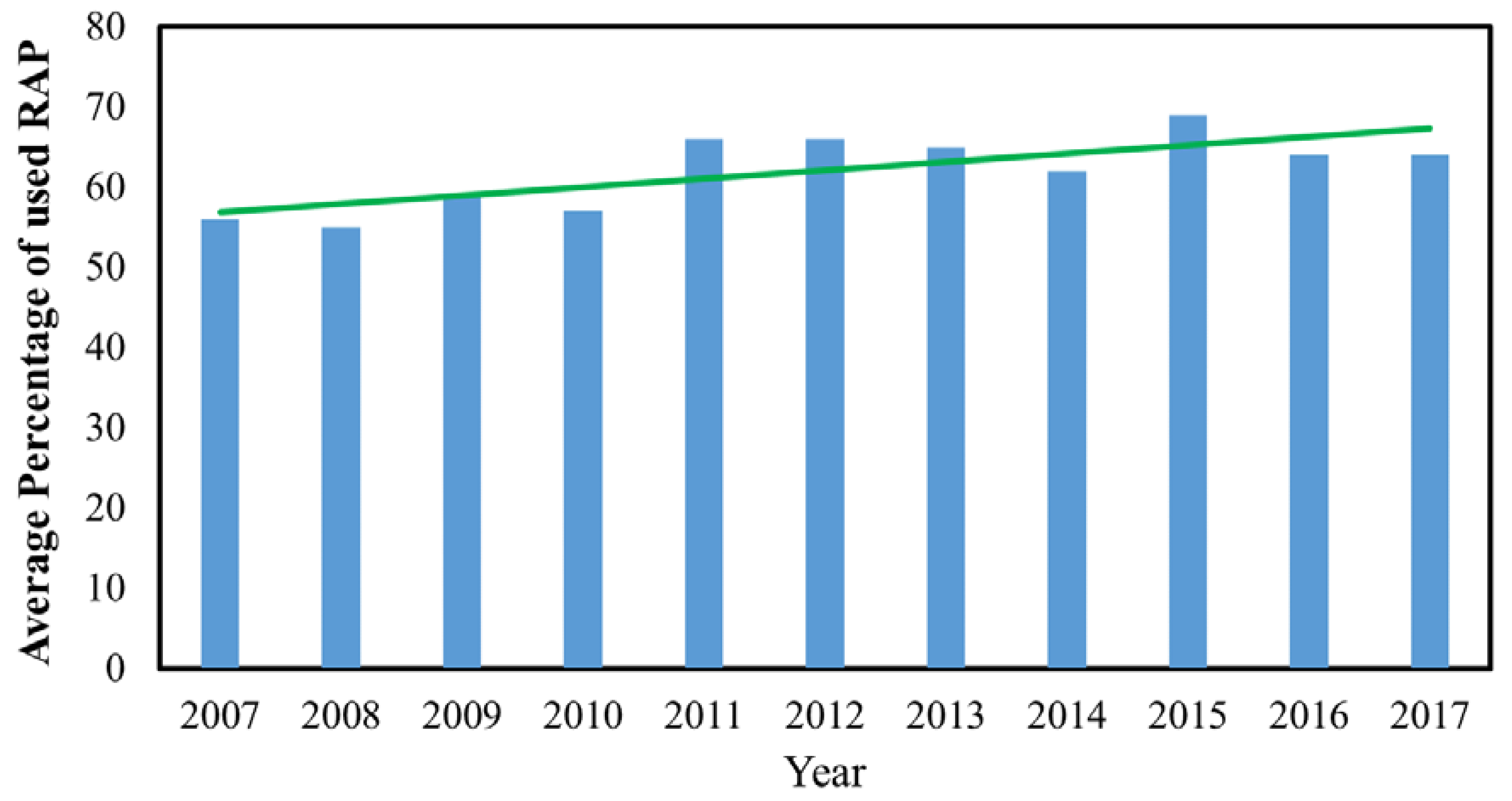

- European Asphalt Pavement Association. Asphalt in Figures 2007–2017. Brysseli: European Asphalt Pavement Association. Available online: https://eapa.org/asphalt-in-figures/(2019) (accessed on 14 June 2019).

- Stroup-Gardiner, M. Use of Reclaimed Asphalt Pavement and Recycled Asphalt Shingles in Asphalt Mixtures; Transportation Research Board: Washington, DC, USA, 2016; No. Project 20-05, Topic 46-05. [Google Scholar]

- Williams, B.A.; Copeland, A.; Ross, T.C. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2017; National Asphalt Pavement Association: Lanham, MD, USA, 2018; No. Information Series 138. [Google Scholar]

- Ventura, A.; Monéron, P.; Jullien, A. Environmental impact of a binding course pavement section, with asphalt recycled at varying rates: Use of life cycle methodology. Road Mater. Pavement Des. 2008, 9 (Suppl. 1), 319–338. [Google Scholar] [CrossRef]

- Nicuta, A.M. Life cycle assessment study for new and recycled asphalt pavements. Bul. Inst. Politeh. Lasi. Sect. Constr. Arhit. 2011, 57, 81. [Google Scholar]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement Des. 2012, 13 (Suppl. 1), 183–208. [Google Scholar] [CrossRef]

- Wayman, M.; Andersson-Sköld, Y.; Bergman, R.; Huang, Y.; Parry, T.; Raaberg, J.; Enell, A. Life Cycle Assessment of Reclaimed Asphalt; Project Report 7FP Re-Road; European Commission, 2012. [Google Scholar]

- Vidal, R.; Moliner, E.; Martínez, G.; Rubio, M.C. Life cycle assessment of hot mix asphalt and zeolite-based warm mix asphalt with reclaimed asphalt pavement. Resour. Conserv. Recycl. 2013, 74, 101–114. [Google Scholar] [CrossRef]

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Anthonissen, J.; Braet, J. Life cycle assessment of bituminous pavements produced at various temperatures in the Belgium context. Transp. Res. Part D Transp. Environ. 2015, 41, 306–317. [Google Scholar] [CrossRef]

- Anthonissen, J.; Braet, J. Review and environmental impact assessment of green technologies for base courses in bituminous pavements. Environ. Impact Assess. Rev. 2016, 60, 139–147. [Google Scholar] [CrossRef]

- Leyssens, D.; Verstappen, B.; Huybrechts, D. Best Available Techniques for Asphalt Plants [Beste Beschikbare Technieken voor asfaltcentrales]. BBT-kenniscentrum VITO, Mol. 2013. [Google Scholar]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Carpenter, S.H.; Roberts, G.; Ozer, H.; Aurangzeb, Q.; Elseifi, M.; Trepanier, J. Determination of Usable Residual Asphalt Binder in RAP; Research Report ICT-09-031; Illinois Center for Transportation (ICT): Rantoul, IL, USA, 2009. [Google Scholar]

- Kandhal, P.S.; Mallick, R.B. Pavement Recycling Guidelines for State and Local Governments: Participant’s Reference Book; National Center for Asphalt Technology: Auburn, AL, USA, Report Number FHWA-SA-98-042.

- Franke, R.; Ksaibati, K. A methodology for cost-benefit analysis of recycled asphalt pavement (RAP) in various highway applications. Int. J. Pavement Eng. 2015, 16, 660–666. [Google Scholar] [CrossRef]

- Kandhal, P.S.; Rao, S.S.; Watson, D.E.; Young, B. Performance of recycled hot-mix asphalt mixtures in Georgia. Transp. Res. Rec. 1995, 1507, 67–77. [Google Scholar]

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B.K. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- McDaniel, R.S.; Shah, A.; Huber, G. Investigation of Low-and High-Temperature Properties of Plant-Produced RAP Mixtures; 2012; No. FHWA-HRT-11-058. [Google Scholar]

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review; Federal Highway Administration, IL, USA (March 2007), Report No.: FHWA-ICT-07-001. Contract No.: ICT R27-11.

- Huang, B.; Zhang, Z.; Kingery, W.; Zuo, G. Fatigue crack characteristics of HMA mixtures containing RAP. In Proceedings of the Fifth International RILEM Conference on Reflective Cracking in Pavements, Limoges, France, 5–7 May 2004; RILEM Publications SARL: Paris, France, 2004; pp. 631–638. [Google Scholar]

- Wiser, L. Statistical Analysis of Performance of Recycled Hot Mix Asphalt Overlays in Flexible Pavement Rehabilitation; 2011; No. FHWA-HRT-11-051. [Google Scholar]

- Gong, H.; Huang, B.; Shu, X. Field performance evaluation of asphalt mixtures containing high percentage of RAP using LTPP data. Constr. Build. Mater. 2018, 176, 118–128. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Miller, J.A. Effects of rejuvenating agents on superpave mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2007, 19, 376–384. [Google Scholar] [CrossRef]

- Lopes, M.; Gabet, T.; Bernucci, L.; Mouillet, V. Durability of hot and warm asphalt mixtures containing high rates of reclaimed asphalt at laboratory scale. Mater. Struct. 2015, 48, 3937–3948. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Diefenderfer, B.K.; Diefenderfer, S.D. Rutting resistance of asphalt concrete mixtures that contain recycled asphalt pavement. Transp. Res. Rec. 2011, 2208, 9–16. [Google Scholar] [CrossRef]

- Abdulshafi, O.; Fitch, M.; Kedzierski, B. Determination of Recycled Asphalt Pavement (RAP) Content in Asphalt Mixes Based on Expected Mixture Durability; Ohio State University, Dept. of Civil and Environmental Engineering and Geodetic Science: Columbus, USA, 2002; No. FHWA/OH-2002/037. [Google Scholar]

- Daniel, J.S.; Lachance, A. Mechanistic and volumetric properties of asphalt mixtures with recycled asphalt pavement. Transp. Res. Rec. 2005, 1929, 28–36. [Google Scholar] [CrossRef]

- Li, X.; Marasteanu, M.; Williams, R.; Clyne, T. Effect of reclaimed asphalt pavement (proportion and type) and binder grade on asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 2008, 2051, 90–97. [Google Scholar] [CrossRef]

- Krishna Swamy, A.; Mitchell, L.F.; Hall, S.J.; Daniel, J.S. Impact of RAP on the volumetric, stiffness, strength, and low-temperature properties of HMA. J. Mater. Civ. Eng. 2010, 23, 1490–1497. [Google Scholar] [CrossRef]

- Colbert, B.; You, Z. The determination of mechanical performance of laboratory produced hot mix asphalt mixtures using controlled RAP and virgin aggregate size fractions. Constr. Build. Mater. 2012, 26, 655–662. [Google Scholar] [CrossRef]

- Roque, R.; Yan, Y.; Cocconcelli, C.; Lopp, G. Perform an Investigation of the Effects of Increased Reclaimed Asphalt Pavement (RAP) Levels in Dense Graded Friction Courses; University of Florida: Gainesville, FL, USA, 2015. [Google Scholar]

- Maupin, G.W.; Diefenderfer, S.D.; Gillespie, J.S. Evaluation of Using Higher Percentages of Recycled Asphalt Pavement in Asphalt Mixes in Virginia; Virginia Transportation Research Council: Charlottesville, VA, USA, 2008; No. VTRC 08-R22. [Google Scholar]

- Watson, D.; Vargas-Nordcbeck, A.; Moore, J.; Jared, D.; Wu, P. Evaluation of the use of reclaimed asphalt pavement in stone matrix asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 2008, 2051, 64–70. [Google Scholar] [CrossRef]

- Willis, J.R.; Turner, P.; Julian, G.; Taylor, A.J.; Tran, N.; Padula, F. Effects of Changing Virgin Binder Grade and Content on RAP Mixture Properties; Auburn University: Auburn, AL, USA, NCAT Report; 2012. [Google Scholar]

- Zhou, F.; Button, J.W.; Epps, J.A. Best Practice of Using RAS in HMA; Texas Transportation Institute: College Station, TX, USA, 2012; Volume 7. [Google Scholar]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M. Comparative evaluation of warm mix asphalt containing high percentages of reclaimed asphalt pavement. Constr. Build. Mater. 2013, 44, 92–100. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Maupin, G.W.; Diefenderfer, B.K. Design of a High-Binder—High-Modulus Asphalt Mixture; Virginia Transportation Research Council: Charlottesville, VA, USA, 2006; No. VTRC 07-R15. [Google Scholar]

- Shu, X.; Huang, B.; Shrum, E.D.; Jia, X. Laboratory evaluation of moisture susceptibility of foamed warm mix asphalt containing high percentages of RAP. Constr. Build. Mater. 2012, 35, 125–130. [Google Scholar] [CrossRef]

- Vukosavljevic, D. Fatigue Characteristics of Field HMA Surface Mixtures Containing Recycled Asphalt Pavement (RAP). PhD diss., University of Tennessee, Knoxville, TN, USA, 2006. [Google Scholar]

- Miró, R.; Valdés, G.; Martínez, A.; Segura, P.; Rodríguez, C. Evaluation of high modulus mixture behaviour with high reclaimed asphalt pavement (RAP) percentages for sustainable road construction. Constr. Build. Mater. 2011, 25, 3854–3862. [Google Scholar] [CrossRef]

- Goh, S.W.; You, Z. Mechanical properties of porous asphalt pavement materials with warm mix asphalt and RAP. J. Transp. Eng. 2011, 138, 90–97. [Google Scholar] [CrossRef]

- Tapsoba, N.; Sauzéat, C.; Di Benedetto, H.; Baaj, H.; Ech, M. Behaviour of asphalt mixtures containing reclaimed asphalt pavement and asphalt shingle. Road Mater. Pavement Des. 2014, 15, 330–347. [Google Scholar] [CrossRef]

- Sharifi, N.P.; McKay, Z.; Blankenship, P.; Mahboub, K.C.; Anderson, R.M. Assessing Binder Blending Level in Asphalt Mixtures Containing Recycled Asphalt Shingles. J. Mater. Civ. Eng. 2019, 31, 04019144. [Google Scholar] [CrossRef]

- Cochran, K.M. Construction and Demolition Debris Recycling: Methods, Markets, and Policy; 2006; Volume 70, p. 2. [Google Scholar]

- Lee, R.E.; Epps, J.A. Reducing Greenhouse Gas Emissions in Asphalt Paving Operations. Presented at Green Streets and Highway Conference, Denver, CO, USA, 14–17 November 2010. [Google Scholar]

- Lee, W.J.; Chao, W.H.; Shih, M.; Tsai, C.H.; Chen, T.J.H.; Tsai, P.J. Emissions of polycyclic aromatic hydrocarbons from batch hot mix asphalt plants. Environ. Sci. Technol. 2004, 38, 5274–5280. [Google Scholar] [CrossRef] [PubMed]

- Krivit, D. Recycling Tear-Off Asphalt Shingles: Best Practices Guide; The Construction Materials Recycling Association: Eola, IL, USA, 2007. [Google Scholar]

- Hansen, K.R. Guidelines for the Use of Reclaimed Asphalt Shingles in Asphalt Pavements; National Asphalt Pavement Association (NAPA): Lanham, MD, USA, 2009. [Google Scholar]

- Newcomb, D.E.; Epps, J.A.; Zhou, F. Use of RAP & RAS in High Binder Replacement Asphalt Mixtures: A Synthesis; Special Report 213; National Asphalt Pavement Association: Lanham, MD, USA, 2016. [Google Scholar]

- Robinette, C.; Epps, J. Energy, emissions, material conservation, and prices associated with construction, rehabilitation, and material alternatives for flexible pavement. Transp. Res. Rec. 2010, 2179, 10–22. [Google Scholar] [CrossRef]

- Marasteanu, M.; Austin, J.; Moon, K.H. Recycling Asphalt Roofing Shingles in Asphalt Pavements; CURA Reporter; Spring: Berlin/Heidelberg, Germany, 2012; No. 42, 1-4. [Google Scholar]

- Leblance, R. Markets for Recycled Asphalt Shingles, the Balance Small Business Website, Sustainable Business. Available online: https://www.thebalancesmb.com/markets-for-recycled-asphalt-shingles-2877752.

- Zhou, F.; Li, H.; Hu, S.; Button, J.W.; Epps, J.A. Characterization and Best Use of Recycled Asphalt Shingles in Hot-Mix Asphalt; Report FHWA/TX-13/0-6614-2; Texas A&M Transportation Institute, Texas A&M University: College Station, TX, USA, 2013. [Google Scholar]

- Foo, K.Y.; Hanson, D.I.; Lynn, T.A. Evaluation of roofing shingles in hot mix asphalt. J. Mater. Civ. Eng. 1999, 11, 15–20. [Google Scholar] [CrossRef]

- Boyle, M. Materials-Related Forensic Analysis and Specialized Testing: Laboratory Evaluation of Hot-Mix Asphalt (HMA) Mixtures Containing Recycled or Waste Product Materials Using Performance Testing; Pennsylvania Department of Transportation: Harrisburg, USA, July 2005; No. FHWA-PA-2005-006+ 98-32 (19). [Google Scholar]

- McGraw, J.; Johnson, E.; Johnson, G.; Dai, S.; Linell, D.; Watson, M. Incorporation of Recycled Asphalt Shingles in Hot-Mixed Asphalt Pavement Mixtures; Report Number MN/RC, 8; 2010. [Google Scholar]

- Cooper, S.; Mohammad, L.; Elseifi, M. Laboratory performance of asphalt mixtures containing recycled asphalt shingles. Transp. Res. Rec. J. Transp. Res. Board 2014, 2445, 94–102. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Holcombe, E.; Kim, S.S.; Abbas, A.; Kaya, S. Multi-scale evaluation of the effect of ras on the fracture properties of asphalt mixtures. Constr. Build. Mater. 2018, 175, 126–133. [Google Scholar] [CrossRef]

- Tran, N.H.; Taylor, A.; Willis, R. Effect of Rejuvenator on Performance Properties of HMA Mixtures with High RAP and RAS Contents; Auburn University: Auburn, AL, USA, NCAT Report, 12-05; 2012. [Google Scholar]

- Booshehrian, A.; Mogawer, W.S.; Vahidi, S. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, RAP/RAS mixtures. J. Assoc. Asph. Paving Technol. 2013, 193–213. [Google Scholar]

- Williams, R.C.; Cascione, A.; Yu, J.; Haugen, D.; Marasteanu, M.; McGraw, J. Performance of Recycled Asphalt Shingles in Hot Mix Asphalt; Institute for Transportation, Iowa State University: Ames, IA, USA, 2013; No. TPF-5 (213). [Google Scholar]

- Federal Highway Administration Mixture Expert Task Group (a), Asphalt Mixture ETG Meeting Technical Report, Baton Rouge, La.; 17–19 September 2014. Available online: http://www.asphaltpavement.org/PDFs/Engineering_ETGs/Binder_201409/Binder%20ETG%20Mtg_Report_09%202014%20Baton%20Rouge.pdf (accessed on 14 June 2019).

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Heitzman, M. Design and construction of asphalt paving materials with crumb rubber modifier. Transp. Res. Rec. 1992, 1339, 1–9. [Google Scholar]

- Chesner, W.H.; Collins, R.J.; MacKay, M.H. User Guidelines for Waste and By-Product Materials in Pavement Construction; 1998; No. FHWA-RD-97-148. [Google Scholar]

- Fini, E.H. Producing a Sustainable, Bio-Based Alternative to Petroleum-Based Asphalt Binder; National Research Council: Washington, DC, USA, 2016; No. NCHRP IDEA Project 171. [Google Scholar]

- Antunes, I.; Murachelli, A. Analysis of environmental sustainability in the rehabilitation of existing pavements using Asphalt Rubber hot mixes. In Proceedings of the Asphalt Rubber 2009 Conference, Nanjing, China, 2–4 November 2009; pp. 2–4. [Google Scholar]

- Bartolozzi, I.; Antunes, I.; Rizzi, F. The environmental impact assessment of asphalt rubber: Life cycle assessment. In Proceedings of the 5th Asphalt Rubber” Roads of the Future” International Conference, Munich, Germany, 23–26 October 2012; 2012; pp. 799–819. [Google Scholar]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- Zhu, H.; Cai, H.; Yan, J.; Lu, Y. Life cycle assessment on different types of asphalt rubber pavement in China. In Proceedings of the International Symposium on Pavement LCA, Davis, CA, USA, 14–16 October 2014. [Google Scholar]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A.; Lanotte, M. Life cycle assessment of road pavements containing crumb rubber from end-of-life tires. In Proceedings of the International Symposium on Pavement LCA 2014, Davis, CA, USA, 14–16 October 2014. [Google Scholar]

- Hicks, R.; Epps, J.A. Life Cycle Costs Analysis of Asphalt Rubber Paving Materials; Industry Report; The Rubber Pavements Association: Tempe, AZ, USA, 2003. [Google Scholar]

- Cheng, D.; Hicks, R.G. Life-Cycle Cost Analysis Comparison of Rubberized and Conventional Hot-Mix Asphalt in California; 2012; No. 12-0895. [Google Scholar]

- Souliman, M.I.; Mamlouk, M.; Eifert, A. Cost-effectiveness of rubber and polymer modified asphalt mixtures as related to sustainable fatigue performance. Procedia Eng. 2016, 145, 404–411. [Google Scholar] [CrossRef]

- McQuillen, J.L., Jr.; Takallou, H.B.; Hicks, R.G.; Esch, D. Economic analysis of rubber-modified asphalt mixes. J. Transp. Eng. 1988, 114, 259–277. [Google Scholar] [CrossRef]

- Jung, J.S.; Kaloush, K.E.; Way, G.B. Life Cycle Cost Analysis: Conventional Versus Asphalt-Rubber Pavements; Rubber Pavements Association: Tempe, AZ, USA, 2002. [Google Scholar]

- Bahia, H.U.; Davies, R. Effect of crumb rubber modifiers (CRM) on performance related properties of asphalt binders. Asph. Paving Technol. 1994, 63, 414. [Google Scholar]

- Saboundjian, S.; Raad, L. Performance of rubberized asphalt mixes in Alaska. Transp. Res. Rec. J. Transp. Res. Board 1997, 1583, 52–61. [Google Scholar] [CrossRef]

- Huang, B.; Mohammad, L.N.; Graves, P.S.; Abadie, C. Louisiana experience with crumb rubber-modified hot-mix asphalt pavement. Transp. Res. Rec. 2002, 1789, 1–13. [Google Scholar] [CrossRef]

- Losa, M.; Leandri, P.; Cerchiai, M. Improvement of pavement sustainability by the use of crumb rubber modified asphalt concrete for wearing courses. Int. J. Pavement Res. Technol. 2012, 5, 395–404. [Google Scholar]

- Yuan, H.; Shen, L. Trend of the research on construction and demolition waste management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Wu, S.; Zhong, J.; Zhu, J.; Wang, D. Influence of demolition waste used as recycled aggregate on performance of asphalt mixture. Road Mater. Pavement Des. 2013, 14, 679–688. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Mechanical properties of hot-mix asphalt made with recycled concrete aggregates coated with bitumen emulsion. Constr. Build. Mater. 2014, 55, 350–358. [Google Scholar] [CrossRef]

- Fatemi, S.; Imaninasab, R. Performance evaluation of recycled asphalt mixtures by construction and demolition waste materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Pérez, I.; Pasandín, A.R. Recycled construction and demolition waste in Cold Asphalt Mixtures: Evolutionary properties. J. Clean. Prod. 2016, 112, 588–598. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Kandhal, P.; Hoffman, G. Evaluation of steel slag fine aggregate in hot-mix asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 1997, 1583, 28–36. [Google Scholar] [CrossRef]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of steel slag aggregate in asphalt concrete mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef]

- Ameri, M.; Mohammadi, M.H.; Motevalizadeh, S.M.; Mousavi, A. Experimental study to investigate the performance of cold in-place recycling asphalt mixes. In Proceedings of the Institution of Civil Engineers–Transport; Thomas Telford Ltd.: London, UK, 2018; pp. 1–11. [Google Scholar]

- Hassan, H.F.; Al-Jabri, K. Laboratory Evaluation of Hot-Mix Asphalt Concrete Containing Copper Slag Aggregate. J. Mater. Civ. Eng. 2011, 23, 879–885. [Google Scholar] [CrossRef]

- Ho, S.; Church, R.; Klassen, K.; Law, B.; MacLeod, D.; Zanzotto, L. Study of recycled polyethylene materials as asphalt modifiers. Can. J. Civ. Eng. 2006, 33, 968–981. [Google Scholar] [CrossRef]

- Awwad, M.T.; Shbeeb, L. The use of polyethylene in hot asphalt mixtures. Am. J. Appl. Sci. 2007, 4, 390–396. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Razali, A.R.; Razelan, I.S.M. Utilization of polyethylene terephthalate (PET) in asphalt pavement: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 203, p. 012004. [Google Scholar]

- Fang, C.; Yu, R.; Li, Y.; Zhang, M.; Hu, J.; Zhang, M. Preparation and characterization of an asphalt-modifying agent with waste packaging polyethylene and organic montmorillonite. Polym. Test. 2013, 32, 953–960. [Google Scholar] [CrossRef]

- Sojobi, A.O.; Nwobodo, S.E.; Aladegboye, O.J. Recycling of polyethylene terephthalate (PET) plastic bottle wastes in bituminous asphaltic concrete. Cogent Eng. 2016, 3, 1133480. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Ahmadinia, E. Performance evaluation of utilization of waste Polyethylene Terephthalate (PET) in stone mastic asphalt. Constr. Build. Mater. 2012, 36, 984–989. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test. Mater. Des. 2014, 53, 317–324. [Google Scholar] [CrossRef]

- Hassani, A.; Ganjidoust, H.; Maghanaki, A.A. Use of plastic waste (poly-ethylene terephthalate) in asphalt concrete mixture as aggregate replacement. Waste Manag. Res. 2005, 23, 322–327. [Google Scholar] [CrossRef] [PubMed]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Zoorob, S.E.; Suparma, L.B. Laboratory design and investigation of the properties of continuously graded Asphaltic concrete containing recycled plastics aggregate replacement (Plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- Qadir, A.; Imam, M. Use of recycled plastic waste aggregate as a partial substitution material in pavement structure. In 2005 International Symposium on Pavement Recycling; Sao Paulo, Brazil, March 2005. [Google Scholar]

- Podolsky, J.H.; Buss, A.; Williams, R.C.; Hern Andez, N.; Cochran, E.W. Rejuvenation of vacuum tower bottoms through bio-derived materials for use in paving flexible roadways. J. Clean. Prod. 2017, 143, 1081–1093. [Google Scholar] [CrossRef]

- Mortazavi, S.B.; Rasoulzadeh, Y.; Yousefi, A.A.; Khavanin, A. Properties of modified bitumen obtained from vacuum bottom by adding recycled waste polymers and natural bitumen. Iran. Polym. J. 2010, 19, 197–205. [Google Scholar]

- Wielinski, J.C.; Kriech, A.J.; Huber, G.A.; Horton, A.; Osborn, L.V. The impact of asphalt blended with re-refined vacuum tower bottoms (RVTB) and its effect on HMA mixture performance. In Proceedings of the Fifty-Ninth Annual Conference of the Canadian Technical Asphalt Association, Winnipeg, Manitoba, November 2014; Volume 59, pp. 402–426. [Google Scholar]

- Bennert, T.; Ericson, C.; Pezeshki, D.; Corun, R. Fatigue Performance of Re-Refined Engine Oil Bottom—Modified Asphalt: Laboratory Study. Transp. Res. Rec. J. Transp. Res. Board 2016, 2574, 1–16. [Google Scholar] [CrossRef]

- D’Angelo, J.A.; Grzybowski, K.; Lewis, S.; Walker, R. Evaluation of the Performance Properties of Asphalt Mixes Produced with Re-Refined Heavy Vacuum Distillate Bottoms. In Proceedings of the Canadian Technical Asphalt Association; 2013; Volume 58, pp. 273–290. [Google Scholar]

- Amini, A.; Imaninasab, R. Investigating the effectiveness of Vacuum Tower Bottoms for Asphalt Rubber Binder based on performance properties and statistical analysis. J. Clean. Prod. 2018, 171, 1101–1110. [Google Scholar] [CrossRef]

- Seidel, J.C.; Haddock, J.E. Soy fatty acids as sustainable modifier for asphalt binders. In Alternative Binders for Sustainable Asphalt Pavements; Transportation Research Circular: Washington, DC, USA, 2012. [Google Scholar]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E. Preliminary examination of soybean oil derived material as a potential rejuvenator through Superpave criteria and asphalt bitumen rheology. Constr. Build. Mater. 2017, 149, 826–836. [Google Scholar] [CrossRef]

- Portugal, A.C.X.; Lucena, L.C.D.F.L.; Lucena, A.E.D.F.L.; da Costa, D.B. Rheological performance of soybean in asphalt binder modification. Road Mater. Pavement Des. 2018, 19, 768–782. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E. Investigation of fatigue and thermal cracking behavior of rejuvenated reclaimed asphalt pavement binders and mixtures. Int. J. Fatigue 2017, 108, 90–95. [Google Scholar] [CrossRef]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar]

- Hill, B.; Oldham, D.; Behnia, B.; Fini, E.H.; Buttlar, W.G.; Reis, H. Evaluation of low temperature viscoelastic properties and fracture behavior of bio-asphalt mixtures. Int. J. Pavement Eng. 2018, 19, 362–369. [Google Scholar] [CrossRef]

- Wen, H.; Bhusal, S.; Wen, B. Laboratory evaluation of waste cooking oil-based bioasphalt as an alternative binder for hot mix asphalt. J. Mater. Civil Eng. 2012, 25, 1432–1437. [Google Scholar]

- Bailey, H.K.; Phillips, P. Asphalt Rejunevation. U.S. Patent Application No. 12/461,234, August 2010. [Google Scholar]

- Asli, H.; Karim, M.R. Implementation of Waste Cooking Oil as RAP Rejuvenator. J. East. Asia Soc. Transp. Stud. 2011, 9, 1336–1350. [Google Scholar]

- Zamhari, K.A.; Yunus, M.; Nizam, K.; Hermadi, M.; Adan, A.A. A Study on the Technical Viability of Utilizing Used Lubricating Oil as Rejuvenating Agent in Relaimed Asphalt Pavement. Ph.D. Thesis, Universiti Tun Hussein Onn Malaysia, Batu Pahat, Malaysia, 2011. [Google Scholar]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil–rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Widyatmoko, I. Mechanistic-empirical mixture design for hot mix asphalt pavement recycling. Constr. Build. Mater. 2008, 22, 77–87. [Google Scholar] [CrossRef]

- Borhan, M.N.; Suja, F.; Ismail, A.; Rahmat, R.A.O.K. The effects of used cylinder oil on asphalt mixes. Eur. J. Sci. Res. 2009, 28, 398–411. [Google Scholar]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical characterization of biobinder from swine manure: Sustainable modifier for asphalt binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Akisetty, C.K.K. Evaluation of Warm Asphalt Additives on Performance Properties of CRM Binders and Mixtures. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2008. [Google Scholar]

- Xiao, F.; Zhao, P.W.; Amirkhanian, S.N. Fatigue behavior of rubberized asphalt concrete mixtures containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 3144–3151. [Google Scholar] [CrossRef]

- Akisetty, C.; Xiao, F.; Gandhi, T.; Amirkhanian, S. Estimating correlations between rheological and engineering properties of rubberized asphalt concrete mixtures containing warm mix asphalt additive. Constr. Build. Mater. 2011, 25, 950–956. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Rodríguez-Alloza, A.M.; Gallego, J.; Pérez, I.; Bonati, A.; Giuliani, F. High and low temperature properties of crumb rubber modified binders containing warm mix asphalt additives. Constr. Build. Mater. 2014, 53, 460–466. [Google Scholar] [CrossRef]

- Akisetty, C.K.; Lee, S.-J.; Amirkhanian, S.N. Effects of Compaction Temperature on Volumetric Properties of Rubberized Mixes Containing Warm-Mix Additives. J. Mater. Civ. Eng. 2009, 21, 409–415. [Google Scholar] [CrossRef]

- Wang, H.; Dang, Z.; You, Z.; Cao, D. Effect of warm mixture asphalt (WMA) additives on high failure temperature properties for crumb rubber modified (CRM) binders. Constr. Build. Mater. 2012, 35, 281–288. [Google Scholar] [CrossRef]

- Yu, X.; Leng, Z.; Wang, Y.; Lin, S. Characterization of the effect of foaming water content on the performance of foamed crumb rubber modified asphalt. Constr. Build. Mater. 2014, 67, 279–284. [Google Scholar] [CrossRef]

- Ziari, H.; Naghavi, M.; Imaninasab, R. Performance evaluation of rubberised asphalt mixes containing WMA additives. Int. J. Pavement Eng. 2018, 19, 623–629. [Google Scholar] [CrossRef]

- Yu, X.; Leng, Z.; Wei, T. Investigation of the rheological modification mechanism of warm-mix additives on crumb-rubber-modified asphalt. J. Mater. Civ. Eng. 2013, 26, 312–319. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.V.Z.R.; Van Zelm, R. A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Report I: Characterisation; Leiden University: Leiden, The Netherlands, 2008. [Google Scholar]

- Xiao, F.; Amirkhanian, S.N. Laboratory investigation of utilizing high percentage of RAP in rubberized asphalt mixture. Mater. Struct. 2010, 43, 223. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N. Laboratory investigation of moisture damage in rubberised asphalt mixtures containing reclaimed asphalt pavement. Int. J. Pavement Eng. 2009, 10, 319–328. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Jia, X.; Woods, M. Laboratory performance evaluation of warm-mix asphalt containing high percentages of reclaimed asphalt pavement. Transp. Res. Rec. 2012, 2294, 98–105. [Google Scholar] [CrossRef]

- Zhao, W.; Xiao, F.; Amirkhanian, S.N.; Putman, B.J. Characterization of rutting performance of warm additive modified asphalt mixtures. Constr. Build. Mater. 2012, 31, 265–272. [Google Scholar] [CrossRef]

- Nejad, F.M.; Azarhoosh, A.; Hamedi, G.H.; Roshani, H. Rutting performance prediction of warm mix asphalt containing reclaimed asphalt pavements. Road Mater. Pavement Des. 2014, 15, 207–219. [Google Scholar] [CrossRef]

- Saleh, M. Laboratory evaluation of warm mix asphalt incorporating high RAP proportion by using evotherm and sylvaroad additives. Constr. Build. Mater. 2016, 114, 580–587. [Google Scholar]

- Timm, D.H.; Willis, J.R.; Kvasnak, A. Full-scale structural evaluation of fatigue characteristics in high reclaimed asphalt pavement and warm-mix asphalt. Transp. Res. Rec. 2011, 2208, 56–63. [Google Scholar] [CrossRef]

- Tao, M.; Mallick, R.B. Effects of warm-mix asphalt additives on workability and mechanical properties of reclaimed asphalt pavement material. Transp. Res. Rec. 2009, 2126, 151–160. [Google Scholar] [CrossRef]

- Hill, B.; Behnia, B.; Buttlar, W.G.; Reis, H. Evaluation of warm mix asphalt mixtures containing reclaimed asphalt pavement through mechanical performance tests and an acoustic emission approach. J. Mater. Civ. Eng. 2012, 25, 1887–1897. [Google Scholar] [CrossRef]

- Mogawer, W.; Austerman, A.; Mohammad, L.; Kutay, M.E. Evaluation of high RAP-WMA asphalt rubber mixtures. Road Mater. Pavement Des. 2013, 14 (Suppl. 2), 129–147. [Google Scholar] [CrossRef]

| WMA Processes | Product | Description | Additive Dosage | Production Temp. (Reduction Range) | |

|---|---|---|---|---|---|

| Foaming | Water-containing | Aspha-Min | Water-containing technology using zeolites | 0.3% by total weight of the mix | (20–30 °C) |

| Advera | Water-containing technology using zeolites | 0.25% by total weight of the mix | (10–30 °C) | ||

| Water-based | Double Barrel Green | Water-based foaming process | 2% water by mass of bitumen; anti-strip agent | 116–135 °C | |

| Ultrafoam GX | Water-based foaming process | 1–2% water by mass of bitumen | Not specified | ||

| LT Asphalt | Foam bitumen with hydrophilic Additive | 0.5–1% by mass of bitumen | 90 °C | ||

| WAM-Foam | Soft binder coating followed by foamed hard binder | 2–5% water by mass of the hard binder | 100–120 °C | ||

| Low Energy Asphalt | Hot coarse aggregate mixed with wet sand | 3% water with fine sand | <100 °C | ||

| Low Emission Asphalt | Hot coarse aggregate mixed with wet sand, combined with chemicals | 3% water with fine sand; 0.4% bitumen weight | 90 °C | ||

| LEAB | Direct foam with binder additive. Mixing of aggregates below water boiling point | 0.1% of bitumen weight of coating and adhesion additive | 90 °C | ||

| Organic additives | Sasobit | Fischer-Tropsch (F-T) wax | Approx. 2.5% by weight of binder in Germany; 1–1.5%, in the USA. | (20–30 °C) | |

| Rheofalt LT-70 | Fischer-Tropsch wax | 1–3% | 110–140 °C | ||

| Asphaltan B | Refined Montan wax with fatty acid amide for rolled asphalt | 2.0–4.0% by mass of bitumen | (20–30 °C) | ||

| Licomont BS | Fatty acid amide | 3.0% by mass of bitumen | (20–30 °C) | ||

| 3E LT or Ecoflex | Proprietary | not specified | (30–40 °C) | ||

| RH | polyethylene wax | 1–3% by mass of bitumen | (30 °C) | ||

| Chemical Additives | Evoterm Technologies | Chemical packages, with or without water | 0.5% of the mass of bitumen emulsion. The emulsion contains 70% of bitumen | 85–115 °C | |

| Cecabase RT | Chemical package | 0.2–0.4% by mixture weight | (30 °C) | ||

| Rediset | Cationic surfactants and an organic additive | 1.5–2% of bitumen weight | (30 °C) | ||

| Revix | Surface-active agents, waxes, processing aids, polymers | Not specified | (15–25 °C) | ||

| Iterlow T | 0.3–0.5% by mass of bitumen | 120 °C | |||

| Zycothem | Nanomaterial liquid anti-strip agent | 0.1–0.15% by mass of bitumen | (~20 °C) | ||

| Fuel Source | Price of Additive (USD per Ton) | Reduced Energy Costs (USD per Ton) | Increased Production Cost (USD per Ton) | ||||

|---|---|---|---|---|---|---|---|

| Oil Fuel (Iceland) | Diesel (HI, USA) | Natural Gas (IL, USA) | Oil Fuel (Iceland) | Diesel (HI, USA) | Natural Gas (IL, USA) | ||

| WMA 20% (Sasobit) | 1.3–2.6 | 1.3 | 1.7 | 0.6 | 0–1.3 | −0.4–0.9 | 0.6–2 |

| WMA 30%(Aspha-min) | 3.96 | 1.9 | 2.6 | 0.83 | 2.06 | 1.36 | 3.13 |

| WMA 40% (Foam) | 0.3 | 2.6 | 3.5 | 1.1 | −2.3 | −3.2 | −0.8 |

| Emission Component | Oliveira et al. [18] | Middleton and Forfylow [19] | Vaitkus et al. [20] | Powers [21] | D’Angelo et al. [6]; Capitão et al. [22] | McIver [23] | Davidson and Pedlow [24] | Larsen et al. [25] | De Groot et al. [26] |

|---|---|---|---|---|---|---|---|---|---|

| CO2 | 32 | 10.9 | 30–40 | 13.8 | 15–40 | 46 | 17.4 | 31.4 | 31 |

| SO2 | 24 | −14.3 | 35 | - | 20–35 | 81 | −17.2 | - | - |

| VOC | - | - | 50 | 31.9 | 50 | 30 | 20 | - | - |

| CO | 18 | 10.4 | 10–30 | - | 10–30 | 63 | 19.5 | 28.5 | 29 |

| NOX | 33 | 8.3 | 60–70 | 16.1 | 60–70 | 58 | 20 | 61.5 | 62 |

| Dust | - | - | 20–25 | - | 25–55 | - | - | - | - |

| Cost and Potential Economic Benefits | WMA Type | ||

|---|---|---|---|

| Water Injection Foaming | Additive | ||

| Typical technology cost ($/ton) | $0.08 | $2.50 | |

| Assumed temperature reduction (°C) | 13 | 25 | |

| Typical energy savings ($/ton) | Natural Gas | $0.16 | $0.31 |

| Recycled fuel oil (RFO) | $0.39 | $0.79 | |

| Typical incentive/disincentive spec. savings ($/ton) | Density improvement | 0 to $1.13 | 0 to $1.13 |

| Possible savings from eliminated antistripping agent | Hydrated lime | 0 | 0 to $1.50 |

| Liquid ASA | 0 | 0 to $0.75 | |

| Evaluation Type | References |

|---|---|

| Laboratory | [8,35,36,37,38,39,40,41,42] |

| Short-term | [7,43,44,45,46] |

| Long-term | [6,16] |

| Performance | Determinant Parameter | Specification/Reference |

|---|---|---|

| Moisture Susceptibility | Tensile strength ratio (TSR) | AASHTO T 283 |

| Rutting | Rutting resistance index (RRI) | Hamburg wheel tracking (HWT), AASHTO T 324 |

| Dynamic modulus (E*) at 30 °C | AASHTO TP 79 | |

| Creep compliance at 30 °C | AASHTO T 322 | |

| Binder Performance Grade (PG) | AASHTO T 315 | |

| Multiple Stress Creep Recovery parameter (Jnr) | AASHTO TP70 and AASHTO MP19 | |

| transverse cracking | Fracture work density value at −10 °C | Indirect tensile (IDT), AASHTO T 322 |

| Dynamic modulus (E*) at −10 °C | AASHTO TP 79 | |

| Indirect tensile strength at 20 °C | ASTM D6931 | |

| Creep compliance at 0 °C | AASHTO T 322 | |

| Vertical failure deformation at 20 °C | [58] | |

| Longitudinal cracking. | Indirect tensile strength | IDT test at 20 °C |

| Vertical failure deformation at 20 °C | [58] | |

| Horizontal failure strain from the IDT test at 20 °C | [58] | |

| Creep compliance at −10 °C | AASHTO T 322 |

| Country | % of Available RAP Used in Asphalt Mixture | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2017 | 2016 | 2015 | 2014 | 2013 | 2012 | 2011 | 2010 | 2009 | 2008 | 2007 | |

| Austria | 60 | 40 | 45 | - | 98 | 98 | 95 | 88 | 90 | - | 25 |

| Belgium | 95 | 81 | 64 | 72 | 61 | 61 | 65 | 57 | 57 | 55 | 50 |

| Czech Republic | 34 | 47 | 52 | 46 | 43 | 52 | 49 | 50 | 50 | 55 | 85 |

| Denmark | 67 | 65 | 100 | 54 | 83 | 77 | 80 | 56 | 55 | 59 | 57 |

| France | 70 | 70 | 90 | 64 | 64 | 62 | 45 | 40 | 41 | 25 | 15 |

| Germany | 85 | 87 | 28 | 90 | 90 | 87 | 84 | 82 | 82 | 82 | 82 |

| Hungary | 95 | 90 | 100 | 90 | 90 | 100 | 100 | 27 | 66 | 44 | - |

| Italy | 23 | 50 | 50 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Netherlands | 82 | 82 | 80 | 85 | 76 | 95 | 98 | 75 | 74 | 83.5 | 90 |

| Norway | 31 | 37 | 38 | 23 | 26 | 21 | 18 | 40 | 24 | 21 | 34 |

| Slovakia | 98 | 98 | 99 | 99 | 95 | 95 | 94 | 93 | - | - | - |

| Slovenia | 39 | 43 | 100 | 25 | 46 | 50 | 50 | 50 | 100 | 100 | 60 |

| Spain | 83 | 68 | 96 | 100 | 93 | 77 | 83 | 81 | 66 | 70 | 60 |

| Sweden | - | 93 | 95 | 90 | 90 | 85 | 80 | 80 | 95 | 95 | 95 |

| Turkey | 15 | 4 | 2 | 6 | 4 | 7 | 23 | 19 | 3 | 2 | - |

| Average | 64 | 64 | 69 | 62 | 65 | 66 | 66 | 57 | 59 | 55 | 56 |

| RAP Content (%) | Total Needed Binder (%) | Virgin Binder (%) | Recovered Binder (%) | Reduced Virgin Binder (%) |

|---|---|---|---|---|

| 0 | 5.9 | 5.9 | 0 | 0 |

| 20% | 5.7 | 4.8 | 0.9 | 15.8 |

| 40% | 5.65 | 3.8 | 1.85 | 32.7 |

| Region | Average Saving (%) | ||

|---|---|---|---|

| South Central | 10–13 | ||

| North Central | 20 | ||

| Southwest | 4–18 | ||

| Northwest | 24–26 | ||

| % of RAP | Cost/ton | Saving $/ton | Saving (%) |

| 0 | 11.9 | - | - |

| 20 | 10.26 | 1.64 | 14 |

| 30 | 9.44 | 2.46 | 21 |

| 40 | 8.62 | 3.28 | 28 |

| 50 | 7.8 | 4.1 | 34 |

| Material | Material Quantity, Million Tons | Aggregate Cost Savings ($ Billion) | Asphalt Binder Cost Savings ($ Billion) | Total Cost Savings ($ Billion) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | |

| RAP | 74.2 | 76.9 | 76.2 | 0.663 | 0.713 | 0.734 | 1.787 | $1.333 | 1.393 | 2.450 | 2.046 | 2.127 |

| Performance/Testing Parameter | Effect | References | ||||

|---|---|---|---|---|---|---|

| Same | Increase | Decrease | Mixed | |||

| Stiffness | Dynamic Modulus (E*) | √ | √ | [81,87,90,91,92,93,94,95] | ||

| Phase Angle | √ | |||||

| Rutting | Deflection | √ | √ | [87,89,94,96,97,98,99,100,101] | ||

| Creep Stiffness | √ | [91] | ||||

| Creep Flow Time | √ | [90] | ||||

| Moisture Susceptibility | Moisture Sensitivity | √ | √ | [96,100,102,103] | ||

| Toughness Index | √ | [104,105,106] | ||||

| Cracking | Fatigue | √ | √ | √ | √ | [81,87,90,96,97,100,101,104] |

| Reflective | √ | [98] | ||||

| Thermal | √ | √ | [68,74,76,100,101,107] | |||

| Material | Material Quantity, Million Tons | Aggregate Cost Savings ($ Billion) | Asphalt Binder Cost Savings ($ Billion) | Total Cost Savings ($ Billion) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | |

| RAS | 1.931 | 1.390 | 0.944 | 0.009 | 0.007 | 0.005 | 0.186 | 0.096 | 0.069 | 0.195 | 0.103 | 0.074 |

| Location | Mixture Types in Test Section | |

|---|---|---|

| 3 years | Indiana | HMA-RAS; HMA-RAP;WMA-RAS: Overlay over thick HMA over PCC |

| Iowa | 0,4,5,6% RAS | |

| Minnesota | 5% MWSS-RAS; 5% TOSS-RAS; 30% RAP | |

| Missouri | 15% RAP; 10% RAP/5% Fine TOSS-RAS; 10% RAP + 5% Coarse TOSS-RAS | |

| 1 year | Illinois | PG 70-28, Polymer, 5% TOSS- RAS; PG 70-28L 5% TOSS-RAS,SMA; PG 58-28 Ground Tire Rubber (12%), 5% TOSS-RAS, SMA; PG 70-28, Polymer, 11% RAP + 3% TOSS-RAS, SMA; PG 70-28L, 11% RAP + 3% TOSS-RAS, SMA; PG 58-28 Ground Tire Rubber (12%), 11% RAP + 3% TOSS-RAS, SMA |

| Wisconsin | 13% RAP + 3% TOSS-RAS, WMA; 13% RAP + 3% TOSS-RAS; 20% RAP; 15% RAP + 3% MWSS-RAS: Overlay over 4-in. HMA over PCC | |

| 1.5 Years | Colorado | Same as Wisconsin’s sections |

| Impact Category | Units | CRM HMA | Conventional HMA | Saving (%) |

|---|---|---|---|---|

| Abiotic depletion | kg Sb eq | 4.70 × 109 | 6.90 × 109 | 32 |

| Acidification | kg SO2 eq | 2.01 × 109 | 2.92 × 109 | 31 |

| Eutrophication | kg PO4 eq | 4.08 × 109 | 5.94 × 109 | 31 |

| Global warming (GWP100) | kg CO2 eq | 3.17 × 109 | 4.66 × 109 | 32 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 8.08 × 10−3 | 1.18 × 10−2 | 32 |

| Human toxicity | kg 1,4-DB eq | 1.25 × 109 | 1.81 × 109 | 31 |

| Fresh water aquatic ecotox. | kg 1,4-DB eq | 4.59 × 109 | 6.86 × 108 | 33 |

| Marine aquatic ecotoxicity | kg 1,4-DB eq | 1.27 × 107 | 1.89 × 107 | 33 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 1.28 × 109 | 1.92 × 109 | 33 |

| Photochemical oxidation | kg C2H4 eq | 9.10 × 109 | 1.34 × 109 | 32 |

| Size of Project | Conventional HMA | Rubberized HMA | ||

|---|---|---|---|---|

| Average($/ton) | Standard Deviation ($/ton) | Average($/ton) | Standard Deviation ($/ton) | |

| Large | 80 | 13.95 | 91.7 | 12.8 |

| Medium | 83.86 | 16.66 | 91.47 | 15.01 |

| Project Size | Total Cost (Present Value) | Conventional HMA | Rubberized HMA | Percent Savings | ||

|---|---|---|---|---|---|---|

| Agency Cost/ln Mile ($1000) | User Cost/ln Mile ($1000) | Agency Cost/ln Mile ($1000) | User Cost/ln Mile ($1000) | |||

| Interstate Project | ||||||

| Large | Mean | 365.61 | 2.24 | 306.70 | 0.92 | 17.29% |

| Study | 27.12 | 0.17 | 22.57 | 0.07 | ||

| Medium | Mean | 391.71 | 23.26 | 330.07 | 14.24 | 17.38% |

| Study | 28.82 | 1.71 | 24.29 | 1.05 | ||

| State Routes Projects | ||||||

| Large | Mean | 361.26 | 1.37 | 285.10 | 1.83 | 21.00% |

| Study | 26.64 | 0.11 | 21.02 | 0.15 | ||

| Medium | Mean | 389.84 | 1.19 | 307.44 | 0.47 | 22.00% |

| Study | 28.69 | 0.09 | 22.62 | 0.03 | ||

| US Routes Projects | ||||||

| Large | Mean | 370.38 | 0.33 | 230.61 | 0.11 | 37.50% |

| Study | 27.25 | 0.03 | 16.965 | 0.02 | ||

| Year | Convectional HMA | Rubberized HMA | Difference | |||

|---|---|---|---|---|---|---|

| Maintenance Cost ($) | User Cost ($1000) | Maintenance Cost ($) | User Cost ($1000) | Maintenance Cost ($) | User Cost ($1000) | |

| 0 | 1,515,008 1 | 0 | 875,776 1 | 0 | 639,232 | |

| 5 | 1844 | 12,296 | 1317 | 12,325 | 527 | −29 |

| 10 | 7477 | 12,705 | 4295 | 12,288 | 3182 | 417 |

| 15 | 10,471 | 13,288 | 5853 | 12,890 | 4618 | 398 |

| 20 | 11,998 | 13,981 | 6471 | 13,172 | 5527 | 809 |

| 25 | 12,649 | 14,800 | 6683 | 13,565 | 5966 | 1235 |

| Process | Products | Applications | Route | Mix Function | |

|---|---|---|---|---|---|

| Wet | ISI (Arizona) Wet | SAMI | US 61 | Interlayer | |

| OGFC | US 61 | WC | |||

| Gap-graded | US 61 | WC | |||

| LA 15 | WC | ||||

| Rouse Wet | Dense-graded | LA 15 | WC, BC | ||

| Neste Wright | Dense-graded | US 84 | WC, BC | ||

| Dry | Generic Dry | Gap-graded | US 167 | WC | |

| Rouse Dry | Dense-graded | US 167 | WC, BC | ||

| PlusRideTM Dry | Gap-graded | LA 1040 | WC | ||

| Summary of Finding | |||||

| Type | Test | Parameter | Finding | ||

| Laboratory | Marshall | Stability | Control mixtures ≥ CRM mixtures; Gap-graded CRM mixtures < dense-graded CRM mixtures. | ||

| Flow | Gap-graded CRM mixtures > control mixtures; dense-graded CRM mixtures ≈ control mixtures | ||||

| ITS | ITS value | Control mixtures > CRM wearing course mixtures. | |||

| ITS strain | CRM asphalt wearing course mixtures > Conventional HMA waring control mixes (Except for LA-1040); | ||||

| Indirect Tensile Resilient Modulus | MR | At 5 °C and 25 °C: Conventional HMA control mixes > CRM asphalt mixtures; At 40°: Conventional HMA control mixtures ≈ gap-graded CRM asphalt mixtures in US-61 and LA-1040 project | |||

| Field | Dynaflect Test | SN | CRM wet-processed > Conventional HMA control mixes sections. CRM dry-processed pavement < Conventional HMA control mixes sections | ||

| Modulus Value | CRM asphalt mixtures > conventional HMA control mixes except for the OGFC with Arizona wet CRM (US-61) and the gap-graded mix with PlusRide dry CRM, | ||||

| pavement profiles | IRI1 | On LA-1040: CRM mixtures slightly > control section; On LA-15, US-84, and US-167: CRM mixture ≈ or < control sections | |||

| Rut depth 1 | CRM mixtures ≈ or significantly < control mixtures (Except for US-61); On US-61: Gap- graded CRM (17% Arizona wet) > control section, open-graded CRM (17% Arizona wet) ≈ control section. | ||||

| Performance Parameter | Effect | References | |||

|---|---|---|---|---|---|

| Same | Increase | Decrease | Mixed | ||

| Effects on Aged Binder | |||||

| Penetration | √ | [183,184,185,186] | |||

| Viscosity | √ | √ | [183,187] | ||

| Effects on Performance | |||||

| Fatigue Resistance | √ | [185,188] | |||

| Rutting Resistance | √ | [188,189] | |||

| Stiffness | √ | [183] | |||

| Phase | Sub-Phase | Cost Impact | |

|---|---|---|---|

| Production | Raw Material | Aggregate | The same |

| Binder | Increased | ||

| Plant | Decreased | ||

| Construction | Transport | The same | |

| Paving | The same | ||

| Compaction | Decreased | ||

| Maintenance | Decreased | ||

| Mixture Type | Performance | Description | ||||

|---|---|---|---|---|---|---|

| Rutting | Moisture | Thermal | Fatigue | |||

| Developed Environmentally-Friendly Asphalt Mixtures | ||||||

| WMA | Foam |  |  |  |  |

|

| Wax |  |  |  |  | ||

| Chemical | NS |  |  |  | ||

| RAP |  |  |  |  | A function of type and amount of RAP aggregates, and the used virgin binders | |

| RAS |  |  |  |  | For small amount of RAS (3 to 5%) | |

| RAP/RAS with Rejuvenators |  |  |  |  | At optimum percentage of the studied rejuvenators | |

| CRM |  |  |  |  | Results Based on the ‘wet’ process | |

| Primitive Environmentally-Friendly Asphalt Mixtures | ||||||

| C and D Waste |  |  | NS |  |

| |

| Copper and steel Slag |  |  |  |  | ||

| PET |  |  |  |  | ||

| VTB |  | NS |  |  | ||

| Bio-Binders | SAS |  | NS |  |  | |

| Wood Waste |  | NS |  |  | ||

| Cocking Oils |  | NS |  |  | ||

| Swine manure |  | NS |  |  | ||

| Combination | ||||||

| CRM + WMA |  |  |  |  |

| |

| CRM + RAP |  |  |  |  | ||

| RAP + WMA |  |  |  |  | ||

| CRM + RAP + WMA |  |  |  |  | ||

| Slags + WMA |  |  |  |  | ||

: Positive effect;

: Positive effect;  : Negative effect;

: Negative effect;  : Same effect;

: Same effect;  : both positive and negative effect observed; NS: Not studied.

: both positive and negative effect observed; NS: Not studied.| Mixture Type | Economic Impact | Environmental Impact | LCA Phase | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Production | Construction | Maintenance | End-of-Life | ||||||

| Initial | LCCA | Raw Materials | Plant | Compaction | |||||

| Aggregate | Binder | ||||||||

| Developed Environmentally-Friendly Asphalt Mixtures | |||||||||

| WMA |  |  | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| RAP |  |  | Emission |  |  |  |   |  |  |

| Energy |  |  |  |   |  |  | |||

| RAS |  |  | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| CRM |  |  | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| Primitive Environmentally-Friendly Asphalt Mixtures | |||||||||

| C and D | NS | NS | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| Slags | NS | NS | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| RP | NS | NS | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| VTB | NS | NS | Emission |  |  | NS |  |  |  |

| Energy |  |  | NS |  |  |  | |||

| Bio-Binders | NS | ||||||||

| Combinations | |||||||||

| CRM + WMA |  |  | emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| CRM + RAP | NS | NS | Emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| RAP + WMA | NS | NS | emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| CRM + RAP + WMA | NS | NS | emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

| Slag+ WMA | NS | NS | emission |  |  |  |  |  |  |

| Energy |  |  |  |  |  |  | |||

: Positive effect;

: Positive effect;  : Negative effect;

: Negative effect;  : Same effect;

: Same effect;  : both positive and negative effect reported; NS: Not studied.

: both positive and negative effect reported; NS: Not studied.© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pouranian, M.R.; Shishehbor, M. Sustainability Assessment of Green Asphalt Mixtures: A Review. Environments 2019, 6, 73. https://doi.org/10.3390/environments6060073

Pouranian MR, Shishehbor M. Sustainability Assessment of Green Asphalt Mixtures: A Review. Environments. 2019; 6(6):73. https://doi.org/10.3390/environments6060073

Chicago/Turabian StylePouranian, M. Reza, and Mehdi Shishehbor. 2019. "Sustainability Assessment of Green Asphalt Mixtures: A Review" Environments 6, no. 6: 73. https://doi.org/10.3390/environments6060073

APA StylePouranian, M. R., & Shishehbor, M. (2019). Sustainability Assessment of Green Asphalt Mixtures: A Review. Environments, 6(6), 73. https://doi.org/10.3390/environments6060073