Characterization of Recycled Wood Chips, Syngas Yield, and Tar Formation in an Industrial Updraft Gasifier

Abstract

:1. Introduction

2. Materials and Methods

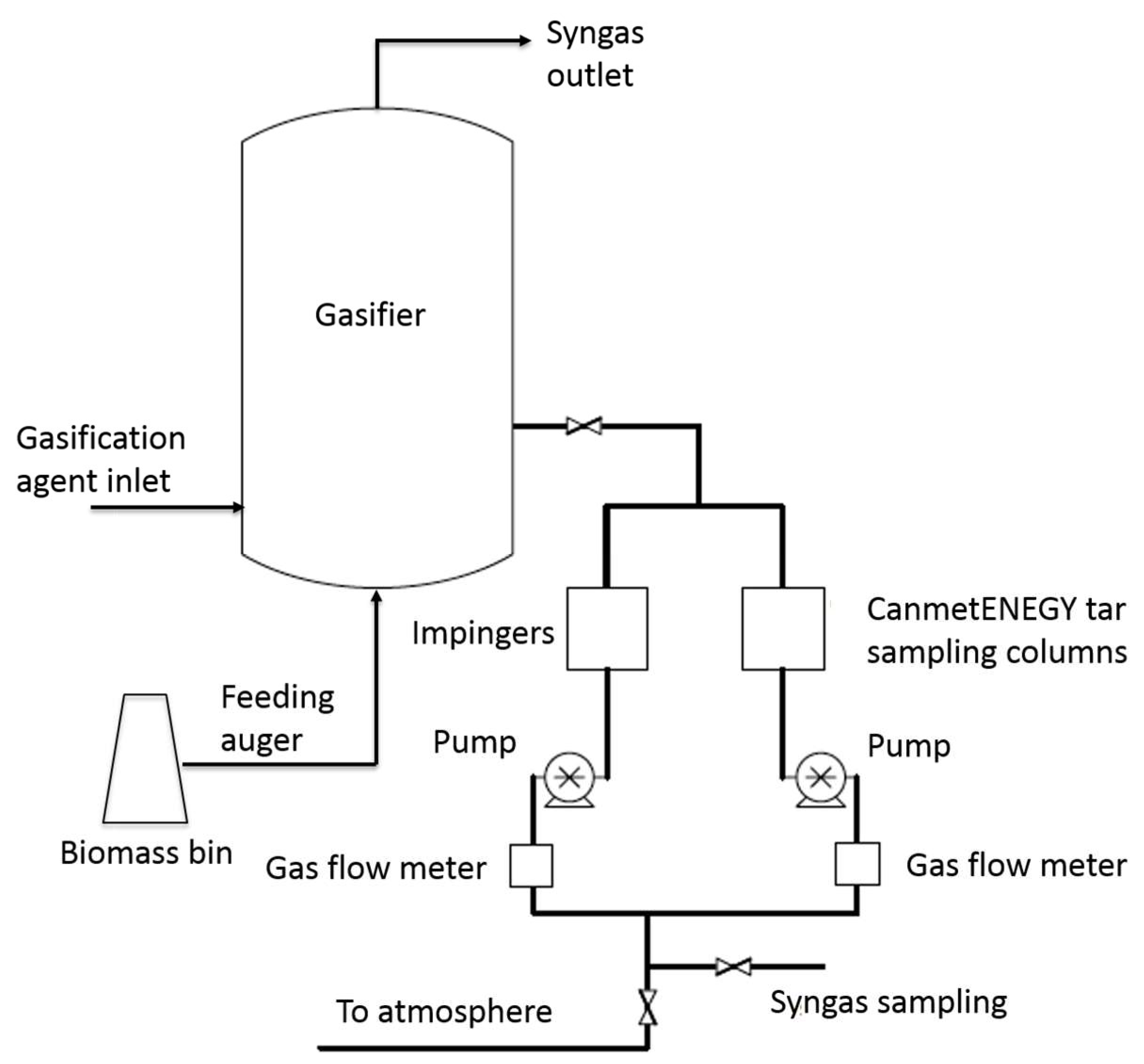

2.1. Gasifiers

2.2. Gas and Tar Sampling

2.3. Biomass Fuel Sampling

2.4. Test Procedure

3. Results

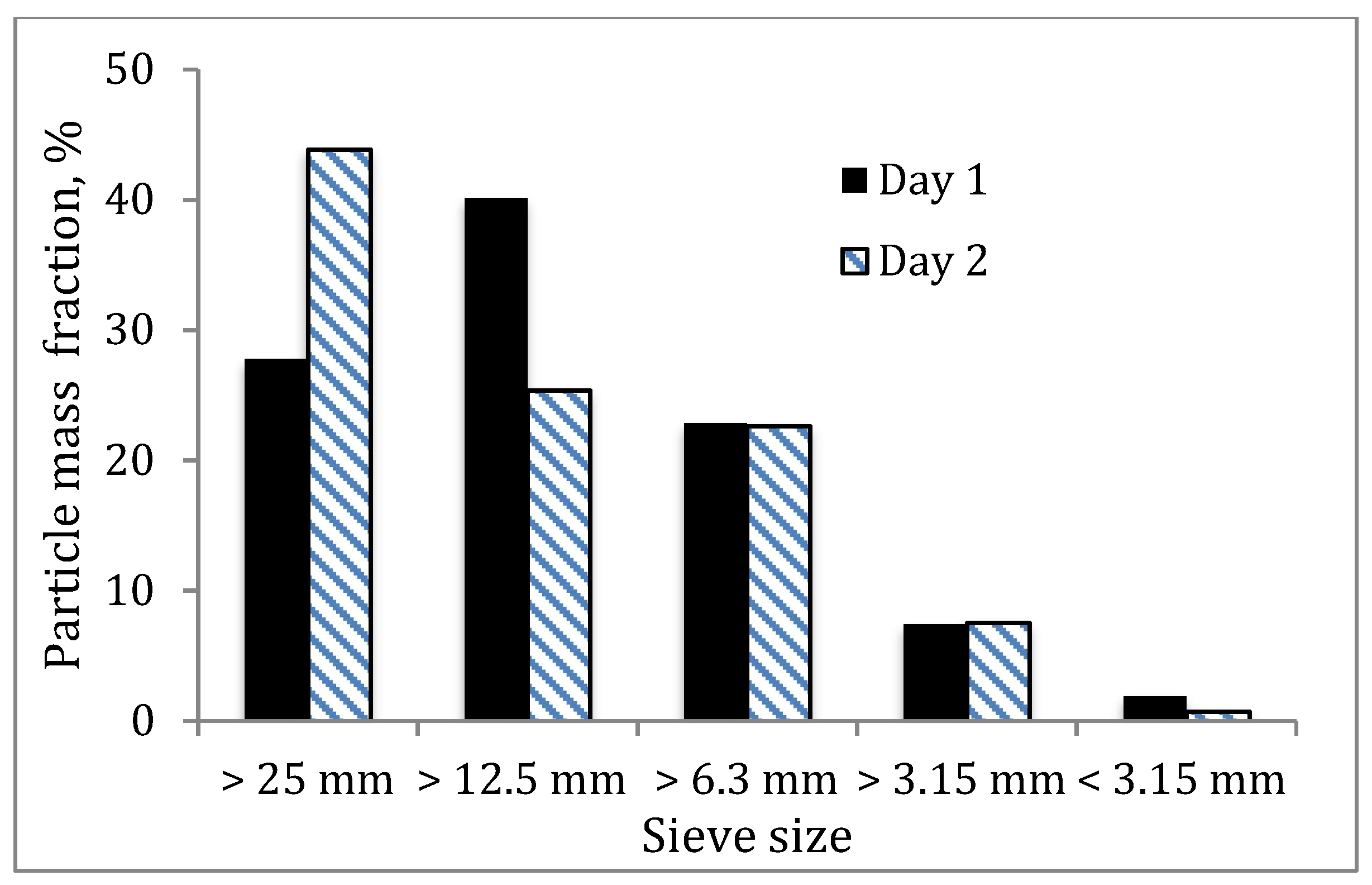

3.1. Fuel Properties

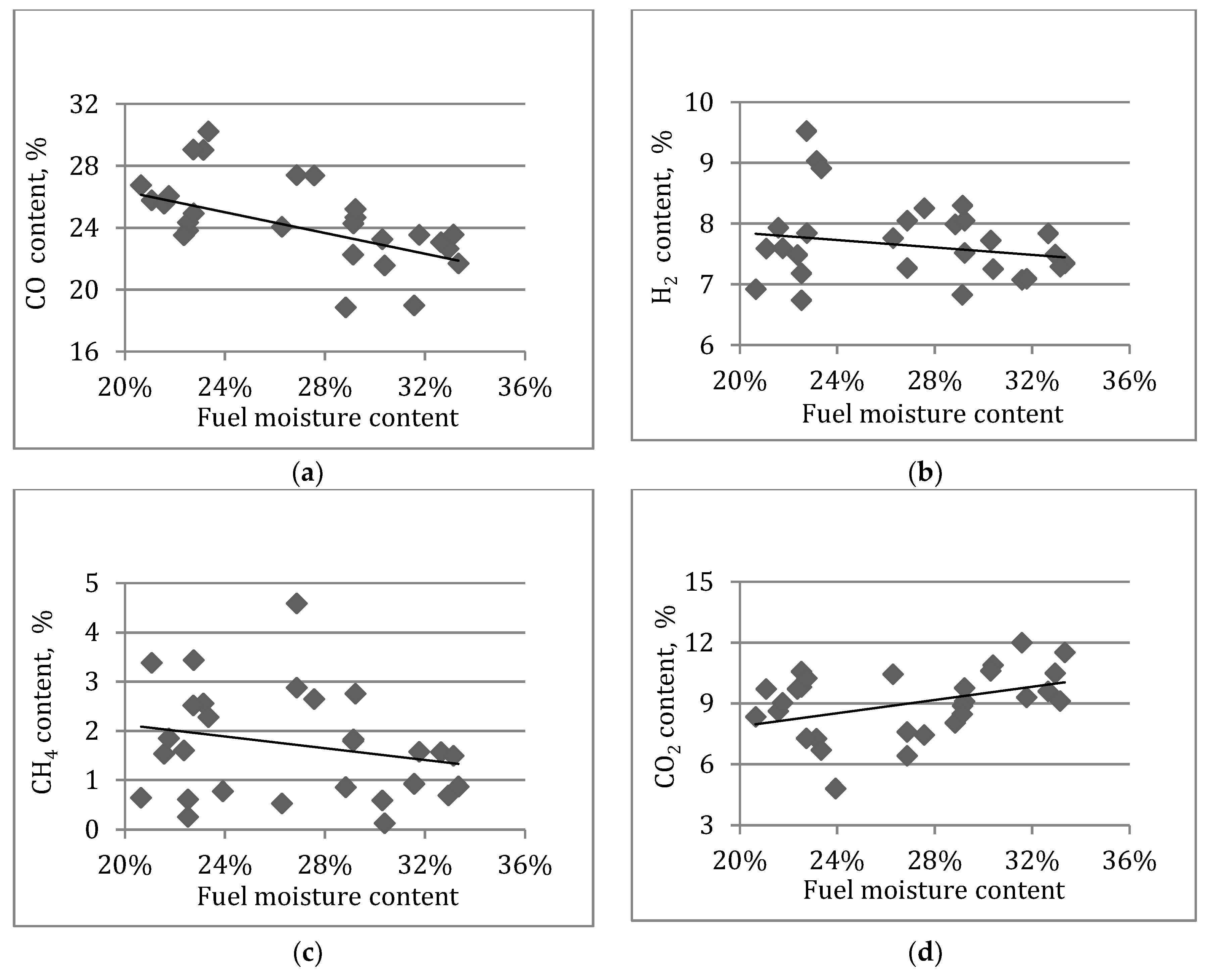

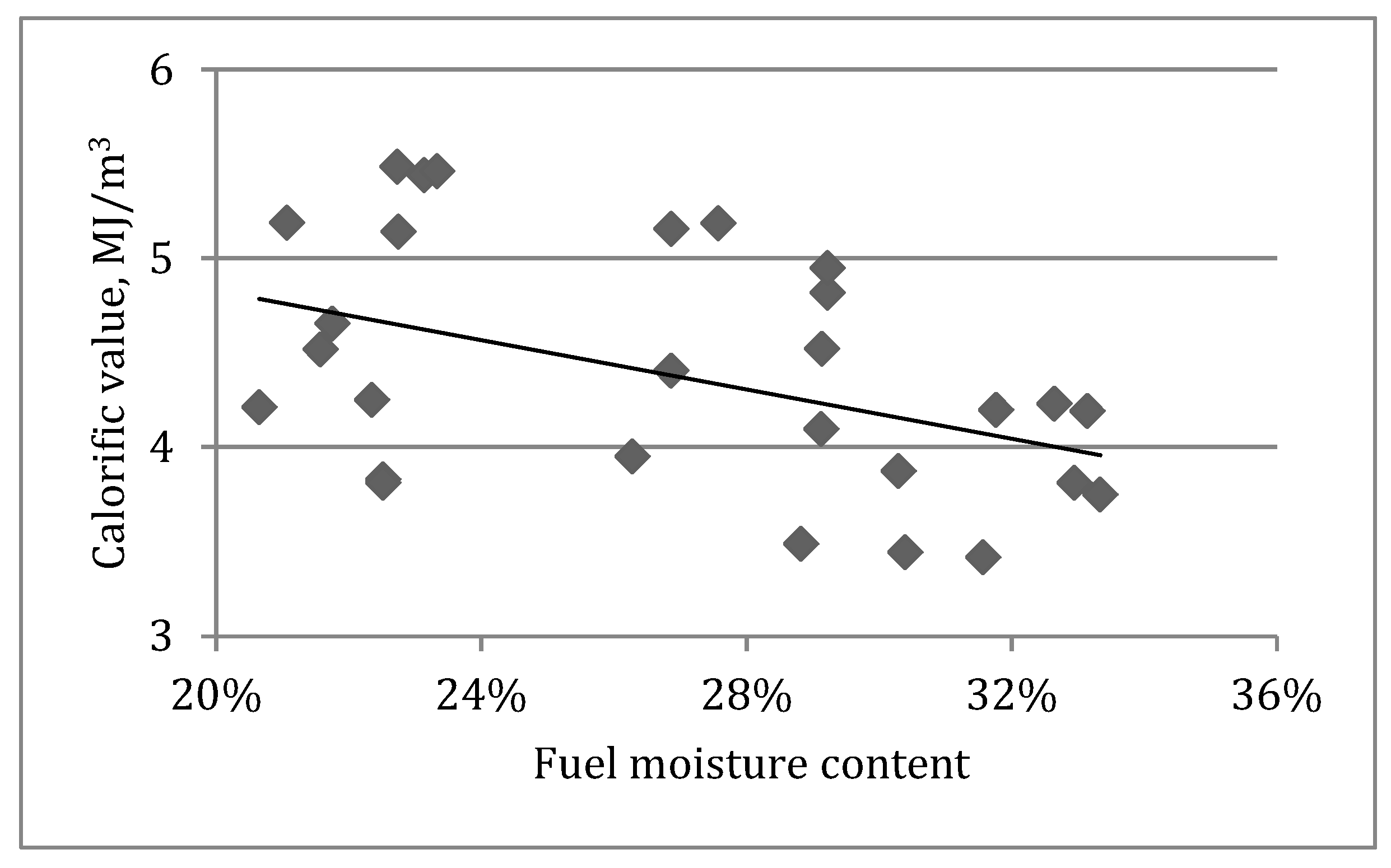

3.2. Syngas Composition

Syngas Composition and Fuel Properties

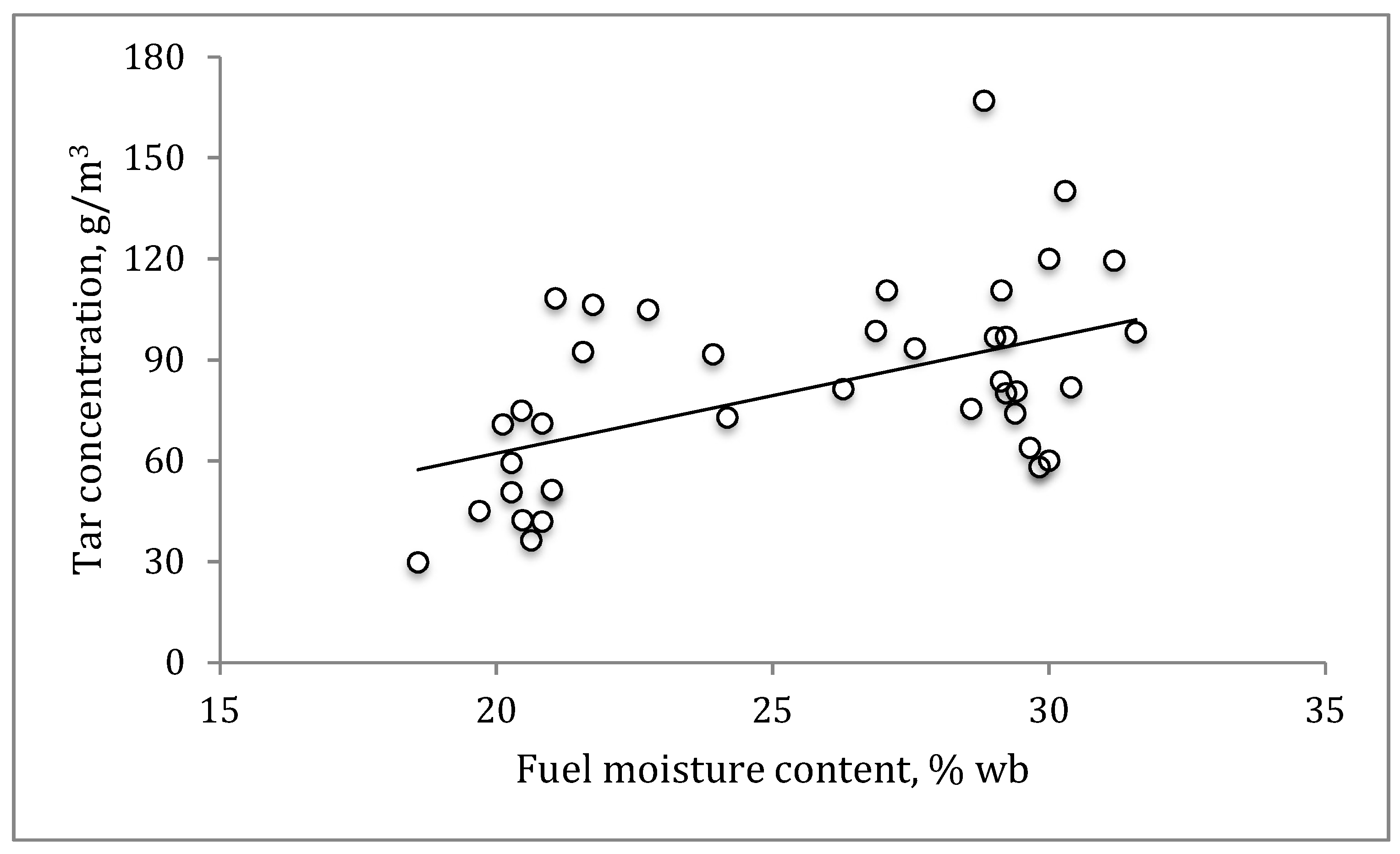

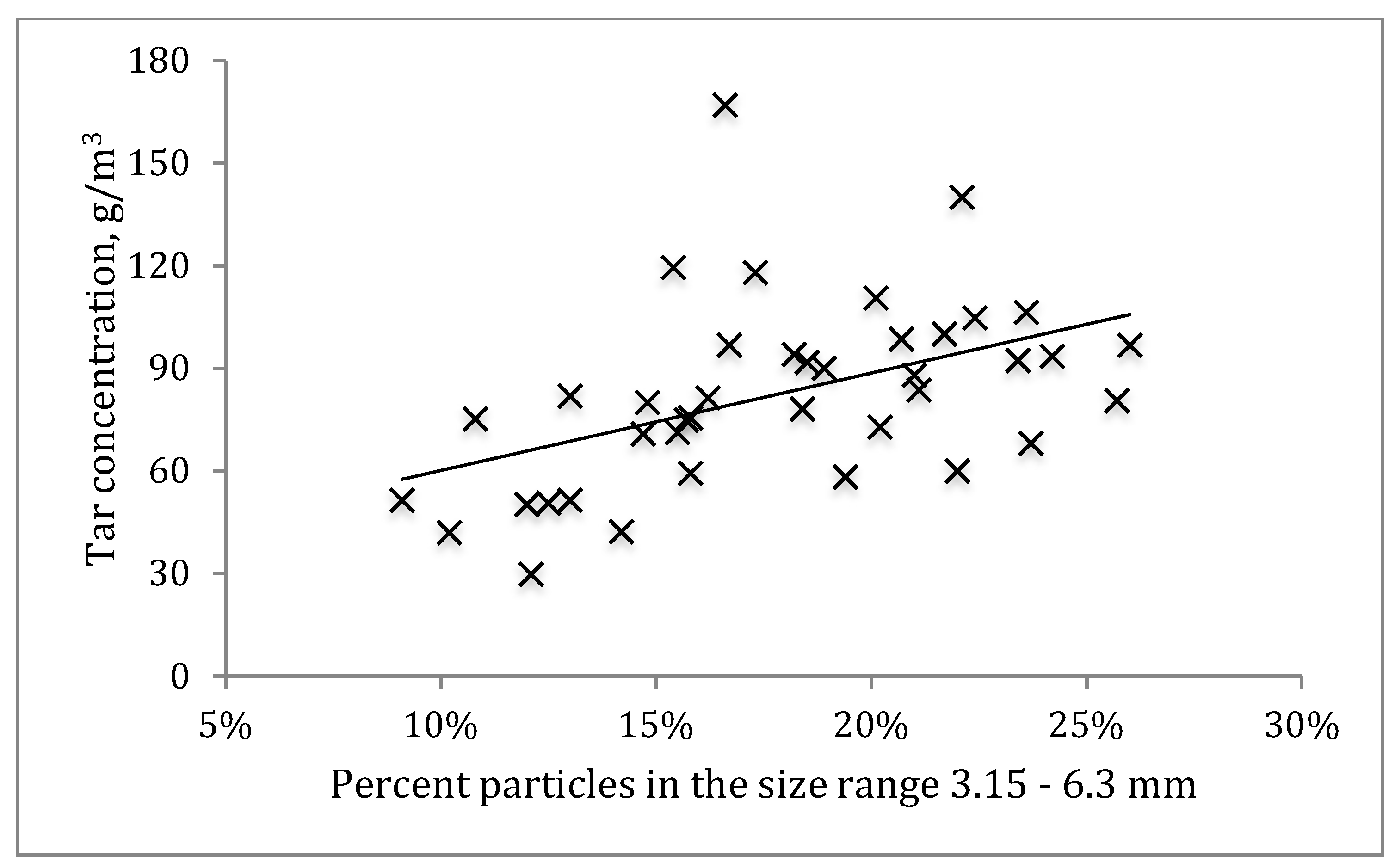

3.3. Tar Concentration

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heidenreich, S.; Foscolo, P.U. New concepts in biomass gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- Oveisi, E.; Sokhansanj, S.; Lau, A.; Lim, C.J.; Bi, X.; Ebadian, M.; Preto, F.; Mui, C.; Gill, R. In-depot upgrading the quality of fuel chips for a commercial gasification plant. Biomass Bioenergy 2018, 108, 138–145. [Google Scholar] [CrossRef]

- Bridgwater, A.V. The technical and economic feasibility of biomass gasification for power generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Monteiro, E.; Sotton, J.; Bellenoue, M.; Moreira, N.A.; Malheiro, S. Experimental study of syngas combustion at engine-like conditions in a rapid compression machine. Exp. Therm. Fluid Sci. 2011, 35, 1473–1479. [Google Scholar] [CrossRef]

- Rajvanshi, A.K. Biomass gasification. Altern. Energy Agric. 1986, 2, 82–102. [Google Scholar]

- Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D. Biofuels production by biomass gasification: A review. Energies 2018, 11, 811. [Google Scholar] [CrossRef]

- Van Der Drift, A.; Van Doorn, J.; Vermeulen, J.W. Ten residual biomass fuels for circulating fluidized-bed gasification. Biomass Bioenergy 2001, 20, 45–56. [Google Scholar] [CrossRef]

- Huang, S.; Wu, S.; Wu, Y.; Gao, J. Structure characteristics and gasification activity of residual carbon from updraft fixed-bed biomass gasification ash. Energy Convers. Manag. 2017, 136, 108–118. [Google Scholar] [CrossRef]

- Carpenter, D.L.; Bain, R.L.; Davis, R.E.; Dutta, A.; Feik, C.J.; Gaston, K.R.; Jablonski, W.; Phillips, S.D.; Nimlos, M.R. Pilot-scale gasification of corn stover, switchgrass, wheat straw, and wood: 1. Parametric study and comparison with literature. Ind. Eng. Chem. Res. 2010, 49, 1859–1871. [Google Scholar] [CrossRef]

- Chopra, S.; Jain, A. A review of fixed bed gasification systems for biomass. Agric. Eng. Int. CIGR 2007, 9, 1–23. [Google Scholar]

- Bharadwaj, A.; Baxter, L.L.; Robinson, A.L. Effects of intraparticle heat and mass transfer on biomass devolatilization: Experimental results and model predictions. Energy Fuels 2004, 18, 1021–1031. [Google Scholar] [CrossRef]

- Chan, W.C.R.; Kelbon, M.; Krieger, B.B. Modelling and experimental verification of physical and chemical processes during pyrolysis of a large biomass particle. Fuel 1985, 64, 1505–1513. [Google Scholar] [CrossRef]

- Couto, N.D.; Silva, V.B.; Monteiro, E.; Rouboa, A. Assessment of municipal solid wastes gasification in a semi-industrial gasifier using syngas quality indices. Energy 2015, 93, 864–873. [Google Scholar] [CrossRef]

- Qin, Y.H.; Feng, J.; Li, W.Y. Formation of tar and its characterization during air-steam gasification of sawdust in a fluidized bed reactor. Fuel 2010, 89, 1344–1347. [Google Scholar] [CrossRef]

- Palma, C.F. Model for biomass gasification including tar formation and evolution. Energy Fuels 2013. [Google Scholar] [CrossRef]

- Abu El-Rub, Z.; Bramer, E.; Brem, G. Review of catalysts for tar elimination in biomass gasification processes. Ind. Eng. Chem. Res. 2004, 45, 75–80. [Google Scholar] [CrossRef]

- Milne, T.A; Evans, R.J. Biomass gasifier “tars”: Their nature, formation, and conversion. Constraints 1998. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory; Academic Press: London, UK, 2013; ISBN 9780123964885. [Google Scholar]

- Li, X.T.; Grace, J.R.; Lim, C.J.; Watkinson, A.P.; Chen, H.P.; Kim, J.R. Biomass gasification in a circulating fluidized bed. Biomass Bioenergy 2004, 26, 171–193. [Google Scholar] [CrossRef]

- Van Paasen, S.V.B.; Kiel, J.H.A. Tar formation in a fluidised-bed gasifier: Impact of fuel properties and operating conditions. Kardiol. Pol. 2004, 67, 58. [Google Scholar]

- Atnaw, S.M.; Sulaiman, S.A.; Yusup, S. Influence of fuel moisture content and reactor temperature on the calorific value of Syngas resulted from gasification of oil palm fronds. Sci. World J. 2014. [Google Scholar] [CrossRef] [PubMed]

- James, R.; Arthur, M.; Yuan, W.; Boyette, M.D. The Effect of Biomass Physical Properties on Top-Lit Updraft Gasification of Woodchips. Energies 2016, 9, 283. [Google Scholar] [CrossRef]

- James, A.M.; Yuan, W.; Boyette, M.D.; Wang, D. The effect of air flow rate and biomass type on the performance of an updraft biomass gasifier. BioResources 2015, 10, 3615–3624. [Google Scholar] [CrossRef]

- Chianese, S.; Fail, S.; Binder, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Blasi, A.; Musmara, D. Experimental investigations of hydrogen production from CO catalytic conversion of tar rich syngas by biomass gasification. Catal. Today 2016, 277, 182–191. [Google Scholar] [CrossRef]

- Bronson, B.; Gogolek, P.; Mehrani, P.; Preto, F. Experimental investigation of the effect of physical pre-treatment on air-blown fluidized bed biomass gasification. Biomass Bioenergy 2016, 88, 77–88. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 3): Gasification technologies. Bioresour. Technol. 2002, 83, 55–63. [Google Scholar] [CrossRef]

- Dai, J.; Cui, H.; Grace, J.R. Biomass feeding for thermochemical reactors. Prog. Energy Combust. Sci. 2012, 38, 716–736. [Google Scholar] [CrossRef]

- Tourigny, G.; Bronson, B.; Robinson, T.; Preto, F. Design and Operation of a New Sampling Device for the Measurement of Tar in Biomass Producer Gas; Confidential CanmetENERGY-Ottawa report No. CanmetENERGY-Ottawa/BIOLAB 2013-07; NRCan: Ottawa, ON, Canada, 2013.

- Kiel, J.; Van Paasen, S.; Neeft, J. Primary Measures to Reduce tar Formation in Fluidised-Bed Biomass Gasifiers; Report No. Ecn-C-04-014; Energy Research Centre of the Netherlands: Petten, The Netherlands, 2004. [Google Scholar]

- Van de Kamp, W.; De Wild, P.; Zielke, U.; Suomalainen, M.; Knoef, H.; Good, J.; Liliedahl, T.; Unger, C.; Whitehouse, M.; Neeft, J.; et al. Tar measurement standard for sampling and analysis of tars and particles in biomass gasification product gas. In Proceedings of the 14th European Biomass Conference & Exhibition, Paris, France, 17–21 October 2005; pp. 791–794. [Google Scholar]

- European Comitte for Standardisation (CEN). Biomass Gasification–Tar and Particles in Product Gases—Sampling and Analysis; CEN/TS 15439; European Comitte for Standardisation: Brussels, Belgium, 2006. [Google Scholar]

- Robinson, T. Bubbling Fluidized Bed Gasification of Biomass and Refuse Derived Fuel; University of Ottawa: Ottawa, ON, Canada, 2015. [Google Scholar]

- European Comitte for Standardisation (CEN). Solid biofuels—Sampling—Part 1: Methods for Sampling; CEN/TS 14778-1; European Comitte for Standardisation: Brussels, Belgium, 2005. [Google Scholar]

- European Comitte for Standardisation (CEN). Solid Biofuels—Methods for the Determination of Moisture Content: Oven Dry Method; CEN/TS 14774; European Comitte for Standardisation: Brussels, Belgium, 2005. [Google Scholar]

- Sun, Q.; Yu, S.; Wang, F.; Wang, J. Decomposition and gasification of pyrolysis volatiles from pine wood through a bed of hot char. Fuel 2011, 90, 1041–1048. [Google Scholar] [CrossRef]

- Maniatis, K. Progress in Biomass Gasification: An Overview. Prog. Thermochem. Biomass Convers. 2008, 1–31. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.; Champagne, P. Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- Zhang, W. Automotive fuels from biomass via gasification. Fuel Process. Technol. 2010, 91, 866–876. [Google Scholar] [CrossRef]

- Phuphuakrat, T.; Nipattummakul, N.; Namioka, T.; Kerdsuwan, S.; Yoshikawa, K. Characterization of tar content in the syngas produced in a downdraft type fixed bed gasification system from dried sewage sludge. Fuel 2010, 89, 2278–2284. [Google Scholar] [CrossRef]

| Parameter | Moisture Content (% wb) | Bulk Density (kg/m3) | Ash Content (% db) | Calorific Value (MJ/kg) |

|---|---|---|---|---|

| Average | 26.8 | 150.7 | 1.06 | 19.20 |

| Standard deviation | 4.3 | 17.3 | 0.28 | 0.65 |

| Coefficient of variation | 0.15 | 0.11 | 0.27 | 0.03 |

| Parameter | Measured Value (%) | Expected Range from Gasifier Specs (%) |

|---|---|---|

| Volatiles | 83.0 | 70–85 |

| Fixed carbon | 16.5 | 15–25 |

| Carbon | 54.6 | 48–52 |

| Hydrogen | 5.80 | 5–6 |

| Oxygen | 39.0 | 36–44 |

| Nitrogen | 0.09 | <0.2 |

| Sulphur | 0.02 | <0.025 |

| Chlorine | 0.04 | <0.025 |

| Species | CEN/TS 15439 Method | CE-O Device | ||||||

|---|---|---|---|---|---|---|---|---|

| Ave | StdDev | Min | Max | Ave | StdDev | Min | Max | |

| H2 | 9.1 | 0.5 | 8.4 | 9.9 | 8.0 | 1.2 | 6.0 | 9.8 |

| O2 | 0.7 | 0.6 | 0.3 | 2.1 | 0.7 | 0.4 | 0.3 | 1.3 |

| N2 | 57.3 | 1.9 | 54.6 | 61.3 | 57.2 | 2.3 | 53.7 | 61.7 |

| CH4 | 1.3 | 0.3 | 0.8 | 1.9 | 2.0 | 0.5 | 1.1 | 2.7 |

| CO | 19.8 | 2.0 | 16.7 | 21.9 | 20.1 | 1.6 | 18.0 | 22.7 |

| CO2 | 11.9 | 0.7 | 10.8 | 12.7 | 12.0 | 0.8 | 10.7 | 13.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oveisi, E.; Sokhansanj, S.; Lau, A.; Lim, J.; Bi, X.; Preto, F.; Mui, C. Characterization of Recycled Wood Chips, Syngas Yield, and Tar Formation in an Industrial Updraft Gasifier. Environments 2018, 5, 84. https://doi.org/10.3390/environments5070084

Oveisi E, Sokhansanj S, Lau A, Lim J, Bi X, Preto F, Mui C. Characterization of Recycled Wood Chips, Syngas Yield, and Tar Formation in an Industrial Updraft Gasifier. Environments. 2018; 5(7):84. https://doi.org/10.3390/environments5070084

Chicago/Turabian StyleOveisi, Ehsan, Shahab Sokhansanj, Anthony Lau, Jim Lim, Xiaotao Bi, Fernando Preto, and Cliff Mui. 2018. "Characterization of Recycled Wood Chips, Syngas Yield, and Tar Formation in an Industrial Updraft Gasifier" Environments 5, no. 7: 84. https://doi.org/10.3390/environments5070084

APA StyleOveisi, E., Sokhansanj, S., Lau, A., Lim, J., Bi, X., Preto, F., & Mui, C. (2018). Characterization of Recycled Wood Chips, Syngas Yield, and Tar Formation in an Industrial Updraft Gasifier. Environments, 5(7), 84. https://doi.org/10.3390/environments5070084