Abstract

Lithium’s (Li) value has grown exponentially since the development of Li-ion batteries. It is usually accessed in one of two ways: hard rock mineral mining or extraction from mineral-rich brines. Both methods are expensive and require a rich source of Li. This paper examines the potential of agro-mining as an environmentally friendly, economically viable process for extracting Li from low grade ore. Agro-mining exploits an ability found in few plant species, to accumulate substantial amounts of metals in the above ground parts of the plant. Phyto-mined metals are then retrieved from the incinerated plants. Although the actual amount of metal collected from a crop may be low, the process has been shown to be profitable. We have investigated the suitability of several plant species including: Brassica napus and Helianthus annuus, as Li-accumulators under controlled conditions. Large plant trials were carried out with/without chelating agents to encourage Li accumulation. The question we sought to answer was, can any of the plant species investigated accumulate Li at levels high enough to justify using them to agro-mine Li. Results show maximum accumulated levels of >4000 mg/kg Li in some species. Our data suggests that agro-mining of Li is a potentially viable process.

1. Introduction

Agro-mining describes a process that uses plants to abstract metals from soils [1]. The process ideally harvests metals from high biomass crops which are grown in metal rich soils, particularly those associated with sub-economic mineralization [2]. The crop is harvested, and incineration of the biomass generates a high-grade bio-ore. In some cases, energy is recovered during the incineration process [3]. Agro-mining offers the possibility of exploiting metal rich soil substrates that are otherwise uneconomic to mine, its impact on the environment is minimal compared to conventional mining methods (opencast, underground) [4]. Agro-mining can be thought of as an extension of the same process as growing fuel (alcohol) from crops [5]. The goal is to extract viable amounts of metals from substrates with profit [6]. The agro-mine metal is virtually sulphur free unlike metals extracted from ore bodies, so the smelting process requires less energy and does not contribute significantly to acid rain [7]. The metal concentration of a bio-ore is often higher than conventional ores, therefore requires less storage space. Agro-mining offers an environmentally friendly alternative to energy intensive conventional mining practices [2]. Although agro-mining will not replace conventional mining processes the technology is appealing both economically and socially [8]. Moreover, agro-mining can be an environmentally responsible approach to site remediation [9]. It can also help like any other plant based reclamation process to restore landscapes damaged by mining and industrial activities. Restoration of such landscapes is one of the most pressing issues of modern age [10]. Probably the first record of metal accumulation in a plant was reported in 1855 by the botanist Alexander Carl Heinrich Braun, who reported elevated levels of zinc (Zn) in the Viola calaminaria plant [11]. In 1865 the botanist, Julius von Sachs, in his book ‘Experimental Physiology of Plants’, referred to Thlaspi caerulescens, a plant in the Brassicaceae family to contain over 17% Zn in its ash [12,13]. In 1885 Albert Bernhard Frank reported Thlaspi caerulescens and Viola calaminaria to contain over 10% Zn in the dry leaf matter [2]. In the 1930s elevated levels of selenium (Se) in Astragalus plants was reported [14]. In 1948 Italy, Minguzzi and Vergnano reported a concentration of 7.9% Nickel (Ni) in the dry weight the Alyssum bertollonii plant, a species of low-growing flowering plant also from the Brassicaceae family [13,15]. The most recent rejuvenation of plant metal accumulation technology began in 1976 in the French territory of New Caledonia in the Southwest Pacific where researchers discovered the Sebertia acuminate tree from the Sapotaceae family that perfectly fitted the title of Ni-hyperaccumulator [16]. They were the first group of researchers to use the term hyperaccumulator (HAP). Hyperaccumulator plants absorb extraordinary high levels of metals in their tissues, 100 to 1000 times higher that levels in the substrate in which they grow, they are also very tolerant to high metal soil conditions. They achieve this without apparent harm while growing in their natural habitat [3]. Non-hyperaccumulator plants do not display this trait and when grown on the same substrate will not accumulate metals at an elevated level and may perish. The term has been used extensively ever since in numerous publications. The Ni content within the latex of the tree was recorded at a mean level of 26% and 12% in leaves in its dry mass [16]. Since then a lot of research emphasis has been placed on the evaluation of the metal hyperaccumulating capacity of high biomass plants that can be easily and quickly cultivated using established agronomic practices [4]. Metal HAPs are relatively rare, often occurring in remote areas geographically [17]. It has been found that over 90% of known HAPs occur only on serpentine (ultrabasic) mineralized soils around the world [18]. Metals are regularly stored in plant leaves, especially in the epidermis and the cuticle. They are sequestered by either metal ligand complexation or removal to inactive compartments such as vacuoles and cell walls [19]. Some plants sequester certain toxic metals around the roots while other plants store metals in their stems. The prevailing theory as to why plants accumulate metals in their tissues is protection from insect and animal herbivory as well as protection from disease. In this study only, the leaves were considered when reporting on the metal content of a plant. HAPs can reach metal concentrations of 100 to 1000 times higher than those in non-hyperaccumulating species grown in the same soil [4,13,19]. Many plant species have been discovered which have very high concentrations of metals in their tissue. A list of some metal levels recorded in HAP plants is included in Table 1. Metal accumulating plants are observed in over 500 species across several families, orders and genera of vascular plants and in approximately 0.2% of angiosperms [20]. Plants from the Brassicaceae family feature extensively in the HAP group [21].

Table 1.

Levels of metals recorded in hyperaccumulating plants.

HAP traits include: higher metal content in the leaves of the plant than non-HAP’s, high metal tolerance, low growth rates and low biomass yields [31,32]. Some of these traits like slow growth and low biomass make it somewhat impractical to use these plants for agro-mining; for this reason, more recent research has focused on high biomass crop species and the technology of induced metal accumulation in plants. Induced metal accumulation uses non-HAPs with a large biomass to accumulate significant amounts of metals. One form of induced metal accumulation in plants uses chelating agents. These chelating agents are applied to the soil where they form water-soluble metal organic complexes through dissolution of precipitated compounds and desorption of sorbed elements, making metals more available for plant uptake [33,34]. These chelating agents are added to the soil near the end of the plant-growth phase, the plants are then harvested within several days or a week [9]. The solubilized metals are taken into the plant via the apoplast pathway rather than the symplast pathway [35]. There are numerous studies discussing the efficacy of using chelating agents to induce metal accumulation in plants [35,36]. Probably the best known and most successful chelating agent is ethylenediaminetetraacetic acid (EDTA), first synthesized in 1935 by I.G. Farbenindustrie [37]. EDTA is one of the cheapest and most suitable complexing agents for many technical purposes and has the best cost/performance ratio of all chelates [38]. EDTA is not readily biodegradable, although it experiences some photodegradation at a very slow rate in the environment. Its biodegradation has been demonstrated using specialized bacterial cultures [37,38,39]. The use of EDTA in phytoremediation/phytoextraction has been banned in most countries because of the dangers associated with complexed metals been leached into the environment. The problem with EDTA is that it is persistent in the environment and can easily leach into and accumulate in natural waters, its environmental toxicity has been discussed [40,41]. Levels of 2.2 mg/L EDTA or greater in natural waters can cause problems, but this level is rarely observed [35].

Thousands of tons of EDTA are used every year in industries such as detergent and paper production [37]. EDTA has a low toxicity profile for humans and is commonly used in cosmetics and pharmaceuticals. Its environmental toxicity is also low and limited to point source emissions to natural waters. Environmental risk levels for EDTA in the environment are available [42]. Ethylenediamine-N, N’-disuccinic acid (EDDS) is a biodegradable alternative of EDTA and is its closest performing counterpart. EDDS is readily degraded and one of the more widely studied biodegradable chelating agents, it has seen some commercial application in the detergent industry as a replacement for EDTA [43,44,45]. EDDS has three stereoisomers [SS], [RR], and [SR]/[RS] of which only the [SS]-isomer is 100% biodegradable [46,47]. All works discussed in this paper consider only the [SS]-isomer when referring to EDDS. The biodegradability of several chelating agents in activated sludge has been studied [48]. The authors of this study found that the EDTA molecule remained intact for up to 100 days, whereas EDDS was biodegraded rapidly in the activated sludge. The biodegradation of EDDS has been shown to be effective even in polluted soils [49]. Some metal complexes of EDTA and EDDS are susceptible to photodegradation [40,47,50]. In general, chelating agents which form complexes with relatively low stability constants are readily degradable whereas those forming stronger complexes (i.e., higher stability constants) are more resistant to biodegradation [45]. Crown ethers (Monocyclic polyethers) such as 12-crown-4 have a marked selectivity for alkali metals and are normally used to complex alkali cations like Li. These compounds and similar compounds like cryptands and lariat ethers which have equivalent properties to crown ethers are generally very expensive. The complexation constants for Li are very weak compared to other metals but multidentate ligands do form complexes with Lithium. The Li-EDTA complex has a stability constant of 2.79 while the Li-EDDS complex has a very small stability constant. The stability of an EDDS metal complex is relatively low when compared to an EDTA complex for example, a Ca-EDTA complex has a stability constant of 10.65 while the Ca-EDDS complex is around 4.6. This is especially true for Pb, because of the high stability constant of the Pb-EDTA complex at 18.0 versus the Pb-EDDS complex at 12.7 [28]. Several studies show that chelating agents such as EDTA and EDDS can be used to increase metal mobility in soils making them more available to plants [25,28,34,45,51,52].

EDTA has been used in several induced metal accumulation studies. The addition of EDTA to Pb spiked soil has been shown to increase the Pb content in Canavalia ensiformis and Helianthus annuus plants significantly [53,54]. Alternatively, a weak extraction of Pb using EDDS has been noted several times [35]. In some rare cases EDDS outperforms EDTA for metal uptake in plants, dependent on species and target metal [55]. The effects of the application of EDTA, EDDS and citric acid on the uptake of Cu, Pb, Zn and Cd by the Zea mays and Phaseolus vulgaris plants has been studied, results showed that EDDS was more efficient at solubilizing Cu and Zn than EDTA, and that EDTA was better at solubilizing Pb and Cd than EDDS [56]. In a study of EDDS chelate induced metal accumulation from soil using the Helianthus annuus plant, results showed levels >4000 mg/kg Cu and >300 mg/kg Pb in the plant tissues [57]. The same group of researchers also reported that EDDS outperformed EDTA solubilizing Cu and Zn in solution [58]. Several studies comparing the effectiveness of EDTA and EDDS to induce metal accumulation in plants have been performed [35,59,60,61,62].

Li is taken up easily by most plants but is not thought to be an essential element for plant health [63]. The question of whether plants need Li is still debated [64]. It has not been shown to act as a cofactor in any enzyme or enzymatic transportation system within plants. The concentration of Li in plants is highly variable [65]. The amount of Li in plants is a function of the amount of Li in the soil substrate in which the plants are growing because of this it has been suggested that the concentration of Li in plants is a good guide to the amount present in the soil [66]. One study reports that Li occurs in plants at levels of 0.15 to 0.3 mg/kg [67]. Others report that the amount of Li in plants lies somewhere between 0.2 and 6000 mg/kg [68,69,70]. Li is translocated to the leaves of plants where it is immobilized [71]. Li is known to act upon plants in three ways: at low concentrations it increases resistance to disease and stimulates growth, at high concentrations it inhibits growth and can become toxic to plants with a low tolerance for Li like citrus plants [71]. There are numerous studies showing that at low Li levels, plant growth stimulation has been observed [29,63,64,67,69,72,73,74,75,76,77]. Species of plants tolerant to Li are found mainly in the Solanaceae and Asteraceae families and are also said to include the Ranunculacae and Rosaceae families [66,68,71,78]. In 2013 a new Li accumulator plant was discovered in China Apocynum venetum. This species could potentially be used to geobotanically prospect for Li deposits [79]. Cirsium arvense and Solanum dulcamera have been shown to accumulate Li at 3 to 6 times more than other plants [80]. A study of Brassica juncea’s ability to accumulate Li, V and Cr from Li mine tailings has shown concentrations of Li > 300 mg/kg in the plant [29]. Elevated concentrations of Li have been recorded in many plant species across many fields of research, Table 2 lists some of these species.

Table 2.

Some recorded levels of Li in plants from several Li plant tolerance studies.

2. Materials and Methods

2.1. Reagents

Na salt based chelators were used in this work and were of analytical grade. Disodium ethylenediaminetetraacetate dihydrate, EDTA disodium salt (C10H14N2Na2O8 · 2H2O) (E6635 Sigma Aldrich Ireland Ltd., Vale Road, Arklow, Wicklow, Ireland) was used to prepare all EDTA solutions at 0.05 M. This product is partially soluble in water at room temperature, the gradual addition of a concentrated NaOH solution was used to solubilise the salt. All EDDS solutions were made from a [SS]-EDDS trisodium salt solution in at 0.05M (C10H13N2Na3O8) (92698 Sigma Aldrich Ireland Ltd., Vale Road, Arklow, Wicklow, Ireland). Li solutions for soil spiking were prepared from LiCl salt (203637 Aldrich), ≥99.99% trace metals basis. Li (59916 Sigma Aldrich Ireland Ltd., Vale Road, Arklow, Wicklow, Ireland), K (96665 Sigma-Aldrich) and Na (02397 Sigma-Aldrich), standards (certified reference material), TraceCERT®, 1000 mg/L in HNO3 were used to prepare all working standards for FES determinations. Plants were fertilised using the commercially available fertiliser Miracle-Gro® (Scotts Miracle-grow, Marysville, Ohio, USA)) water soluble all-purpose plant food, Total N—24%, 3.5% ammoniacal nitrogen, 20.5% urea nitrogen, available phosphate—8%, soluble potash—16%, B—0.02%, Cu—0.07%, Fe—0.15%, Mn—0.05%, Mo—0.0005%, Zn—0.06%. Plant and soil digestions were carried out using, nitric acid (225711 Aldrich) (HNO3), 70%, purified by redistillation, ≥99.999% trace metals basis, hydrogen peroxide solution (95321 Sigma-Aldrich) (H2O2), ≥30%, for trace analysis and hydrochloric acid (435570 Sigma-Aldrich) (HCl) reagent grade, 37%. Glassware was thoroughly soaked in dilute HNO3 and rinsed several times with deionized water before use. HNO3 and H2O2 were used as matrix modifiers in all plant working standards. All reagents used were commercially available from Sigma Aldrich Ireland Ltd., Vale Road, Arklow, Wicklow, Ireland apart from Miracle-Gro® which is widely available. Soil used in these experiments was obtained from Westland Horticulture Ltd., 14 Granville Industrial Estate Granville Road Dungannon County Tyrone BT70 1NJ.

2.2. Germination Trials

Seed germination trials were carried out to assess the total germination percentage of 34 plant species in the presence of Li and selected chelating agents. Most plants show tolerances to Li because of the similarity of the element to K and Na which are ubiquitous in all plants. Li also has comparable effects on the metabolic processes of plants to K and Na. Taking this into account the information obtained from these germination trials can only be viewed as general. The trials were conducted this way to narrow down the number of initial plant species to carry on to plant trials. The trials were carried out over 21 days at a temperature of 19 ± 1 °C. Test groups contained 10 replicates of 4 seeds, for each concentration of Li tested (n = 400 seeds per plant tested). Seeds were placed on cotton wool in a petri dish along with 4 mL of a specific concentration of Li solution. The Li solutions ranged from 20 mg/L to 1000 mg/L with controls. Thirty-four species of plants were selected for germination trials, firstly in the presence of Li and then in the presence of Li and EDTA and Li and EDDS. The plants used were: Brassica napus, Brassica oleracea var. capitata, Helianthus annuus, Solanum lycopersicum, Nicotiana tabacum, Lolium perenne, Pisum sativum, Vicia faba, Phaseolus coccineus, Hordeum vulgare, Avena sativa, Beta vulgaris, Daucus carota, Allium ampeloprasum, Mentha spicate, Cucumis melo, Spinacia oleracea, Brassica oleracea var. italica, Brassica oleracea var. gemmifera, Brassica oleracea gongylodes group, Brassica hirta, Brassica oleracea var. botrytis, Brassica rapa subsp. rapa, Brassica rapa subsp. chinensis, Salvia splendens, Brassica hirta, Raphanus raphanistrum, Brassica oleracea var. sabellica, Brassica oleracea borecole, Cardamine hirsuta, Nasturtium officinale, Eruca sativa, Lepidium sativum and Cardamine hirsuta.

2.3. Soil Preparation

Li occurs in most soils in small quantities and was present in the soils used in these experiments. All soil used in these experiments was a commercially obtained top soil, consisting of a sieved dark brown/black rich clay loam soil with a high humus content. Ten 1 g soil samples from our bulk soil supply were characterised for Li content. Soil samples were thermally acid digested in aqua regia (HCl and HNO3) at a ratio of 1:1 for 2 h, filtered and then analysed for their Li content using FES. The Li concentration measured in soil samples was 20.9 mg/kg SD = 8.2 mg/kg ranging from 9 to 34 mg/kg. Soil was dried and then sieved (4 mm) for pot experiments. Approximately 2 kg of soil was transferred to polyethylene pots (15 cm diameter and 15 cm depth). All plants in these trials were grown in a large greenhouse maintained at a relative humidity of 69.5% (day/night) and an air temperature of 26 ± 3 °C. Soils used in these experiments was artificially spiked with Li. Li as LiCl was made up in deionised water at each concentration of Li required (i.e., of 0, 20, 50, 100, 150, 200, 300, 400, 500 and 1000 mg/kg). Each plant species tested required 100 pots (i.e., 10 pots at each concentration). 10 pots required around 20 kg of soil. Groups of 20 kg of soil were saturated with a specific Li solution, mixed allowed to dry and then the process repeated until testing of the soil for Li concentration showed that the soil was ±5 mg/kg the desired concentration. These soils were then transferred to pots. All pots for each trial were treated this way. This method of ‘spiking’ the soil with Li was adapted from other works [81].

2.4. Plant Trials

Initial plant trials consisted of 100 plants of each of the 5 species (Brassica napus, Brassica oleracea var. capitata, Helianthus annuus, Solanum lycopersicum and Cardamine hirsuta) planted in Li amended soils. Plants were grown in soils amended with Li at levels of 20, 50, 100, 150, 200, 300, 400, 500 and 1000 mg/kg with 10 control plants grown in untreated soil. 10 plants were grown (one plant per pot) at each concentration, totalling 10 groups of 10 plants for each of the 5 species (N = 500 initial plants, N = 500 pots). Plants were grown for approximately 4 months to maturity and then harvested. The plants were watered on alternate days and fertilised once a week with nutrients in the form of Miracle grow® a commercially available water soluble all-purpose plant food. The study was conducted in a screened greenhouse at the Institute of Technology Carlow, Ireland. TomtechHC80 environmentally controlled research greenhouse facility, available from TOMTECH, Lincolnshire, England. Screens provided thermal protection at night and shading during the day. Plants were grown with a cycle of 16 h light and 8 h dark each day, with a constant light phase temperature of 26 °C (±3 °C) and dark phase temperature of 24 °C (±3 °C). The lighting system consisted of 18,400 watt lighting luminaries which supplemented natural daylight if insufficient. Light intensity threshold was set to 10 KL. Three of the original species progressed to chelator-induced accumulation trials Brassica napus, Brassica oleracea var. capitate (referred to herein after as Brassica oleracea) and Helianthus annuus. One hundred plants of each of the 3 species (N = 300) were planted in Li amended soil as before with 10 plants (one plant per pot) in each group. The plants were grown to maturity (circa, 4 months) then treated with EDTA in trial 1 and EDDS in trial 2 bidaily for 1 week prior to harvesting. In most induced metal accumulation experiments chelating agents are generally added to the soil at concentrations between 0.001 M and 0.02 M [35]. In these experiments EDTA and EDDS were added to the soil at a concentration of 0.05 M in aliquots of 100 mL during regular watering times [82]. The chelate concentration used was large to offset the co-complexation of other metals present in the soil with stronger chelating stability constants than Li. For example, the stability constant for Li-EDTA is 2.79 while the constant for Fe-EDTA is 25.1 and Ca-EDTA is 10.65, both of which typically have high concentrations in soil and compete for EDTA. At this high level of chelate addition the co-complexation of other more toxic elements from the soil used to the plants such as lead (Pb) is a real danger and was also considered as a contributing factor to plant mortality in this study. Another possible contributing factor to plant mortality included the toxic effect of salinity caused by the addition of large amounts of LiCl to the plants at high concentrations. The chosen chelate concentration also served to maintain the pH of the soil solution low enough for the Li to exist as ions.

2.5. Sample Preparation and Analysis

Plants were harvested and washed with deionised water. The leaves from each plant were separated from the rest of the plant, and then dried in a forced air oven (WiseVen® Am Bildacker 16, 97877 Wertheim, Germany) at 60 ± 1 °C to a constant weight overnight. One g of leaf material from each plant was grinded and then acid digested. A reliable, conventional digestion method was used to digest all plant leaf samples. The method involved the pre-digestion of samples (overnight) in a mixture of HNO3 and H2O2 at a ratio of 4:1. Further digestion took place in an open vessel, heated on a hot plate (WiseStir® Am Bildacker 16, 97877 Wertheim, Germany) in the same mix at the same ratio for approximately 30 to 40 min until the plant material was brought into solution. This method cannot be said to constitute a complete digestion of materials but was internally consistent being replicated with all samples in the study. The digest was then filtered first using Whatman® (800 Centennial Avenue, Building 1, Piscataway, NJ 08854-3911, USA) grade 1 filter paper and then using a 0.45 µm syringe filter. The filtrate was brought to a constant volume of 100 mL in a volumetric flask with deionised water i.e., giving a dilution factor of 1/100 when analysed. The FES (Flame Emission Spectroscopy) instrument used was a Sherwood 410 Flame Photometer using a mixture of natural gas and air, operating at a temperature of 1700 to 1800 °C, suitable for Li, Na and K analysis. Li is routinely analysed by FES. Limit of Detection (LOD) for FES analysis was 0.13 mg/L while limit of quantification (LOQ) was 0.44 mg/L. After every 20 samples, the instrument was recalibrated using blank samples and working standards. Typical readings obtained from blank samples were 0.0001 to 0.0003 mg/L of Li. Li in plants and animals interacts with K and Na [69]. In this study we determined the K and Na content in all plants both as internal consistency standards and to investigate their intrinsic concentration. The accuracy of Li determinations using FES (670.8 nm) are not affected by the presence of K and Na which have intense spectrum lines at 589 and 767 nm respectively [83].

2.6. Data Analysis

Statistical analysis was carried out using SPSS® (Statistical Package for the Social Sciences, version 23.0, IBM Corp, Armonk, NY, USA) and Microsoft Excel® (2016 MSO 16.0.8625.2121). Where significant differences were found, a post-hoc t-test was used to identify significant differences between sample means. A p-value of 0.05 was considered significant. Bonferroni corrections were used as appropriate.

3. Discussion and Results

3.1. Germination Trials

The results from the general germination trials were used as a means of selecting suitable plant species for the plant trials. In all cases, as the concentration of Li increased the germination rate decreased. Of the original 34 species, nine had total germination rates above 90%, germinating in deionised water along with increasing Li concentrations. These nine species were selected to continue to further germination trials, Brassica napus, Brassica oleracea var. capitate, Helianthus annuus, Solanum lycopersicum, Brassica hirta, Brassica rapa subsp. chinensis, Raphanus raphanistrum, Lepidium sativum and Cardamine hirsuta. These germination trials were carried out as before but included the addition of EDTA and EDDS along with Li. In the presence of EDTA germination was poor with only three species showing germination rates above 10%. In the presence of EDDS four species had germination rates above 90% and the other five above 55%. Based on the results of these trials, five species were selected to continue to plant trials, Brassica napus, Brassica oleracea var. capitate, Helianthus annuus, Solanum lycopersicum, and Cardamine hirsuta.

3.2. Plant Pot Trials

Three main pot trials were carried out using the selected plant species. In each trial the soil of each group was amended with increasing concentrations of Li, to identify any potential natural Li accumulators among the five species. Trial 2 was carried out to assess the effect EDTA doping on the amounts of Li taken into the plants. Trial 3 was used to assess the effect doping the soil with EDDS on the uptake of Li into the plants, using the same parameters as in trial 2.

3.3. Trial 1, Li Amended Soil

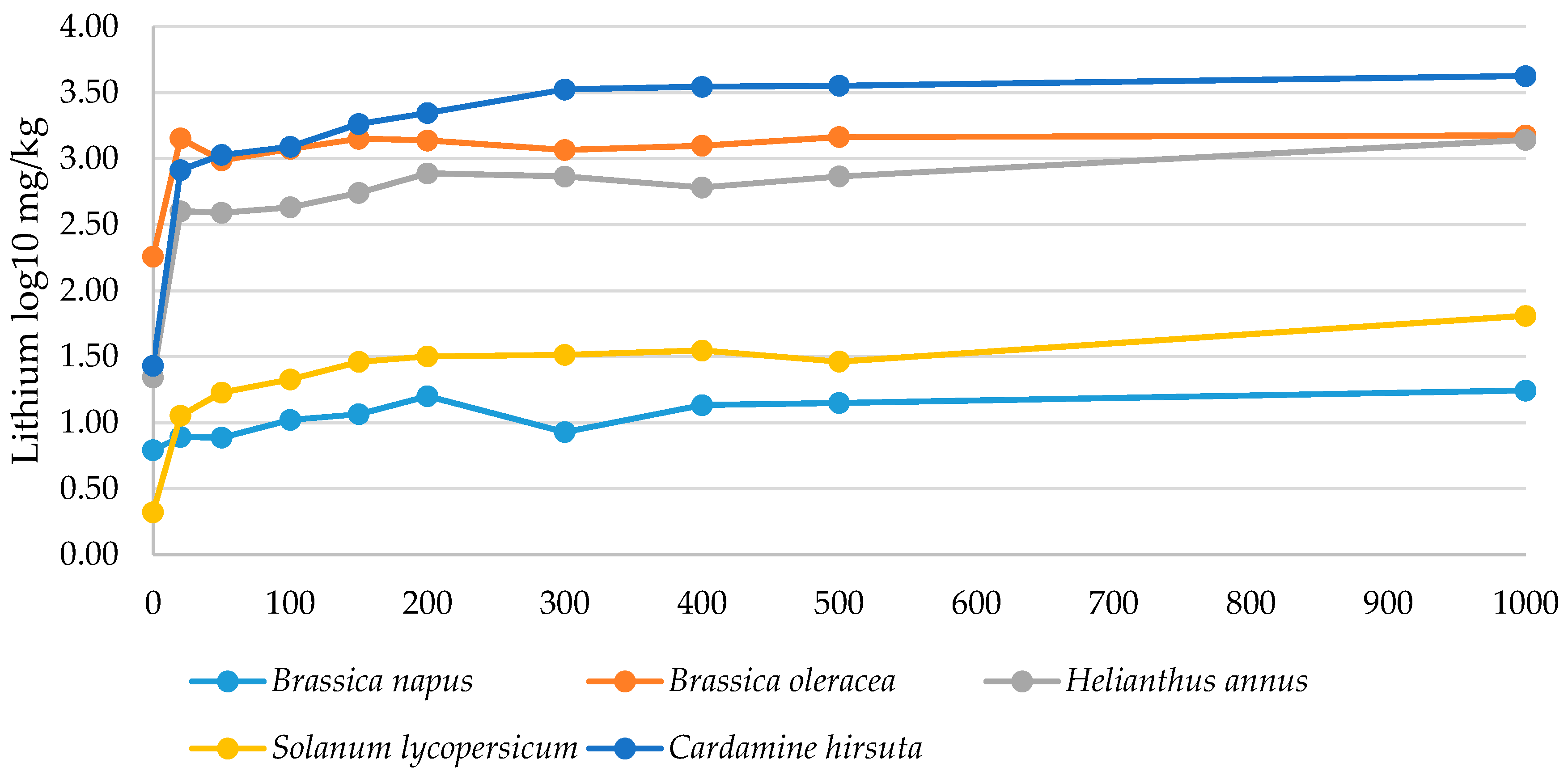

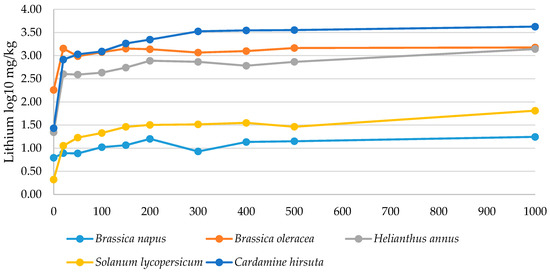

The purpose of this trial was to determine if there were any natural Li accumulator plants among our five selected species, Brassica napus, Brassica oleracea, Helianthus annuus, Solanum lycopersicum, and Cardamine hirsuta. N = 100 plants of each of the five species were planted in individual pots at the start of trial 1 e.g., 10 plants as a control in untreated soil, 10 plants in soil at 20 mg/kg Li, 10 plants in soil at 50 mg/kg Li and so on to 1000 mg/kg Li. (Table 3).: Figure 1 lists the amounts of Li recorded in the leaves of 10 plants from each species at each of the nine different Li soil amendment levels and at control level. Figure 2 shows the distribution of levels of the concentration of Li in leaves for the five species.

Table 3.

Li concentrations in leaves of 5 plant species at each level of Li soil amendment in mg/kg and plant dry matter yields in grams. (Con = Control group) (starting, n = 10 plants per group) (Total number of plants at end of trial 1 = 468).

Figure 1.

Li concentrations in leaves of 5 species (Brassica napus, Brassica oleracea, Helianthus annuus, Solanum lycopersicum, and Cardamine hirsuta). Y-axis, logarithmic transformed mg/kg Li data. X-axis, Li soil amendments, (N = 468 plants) (Units = mg/kg).

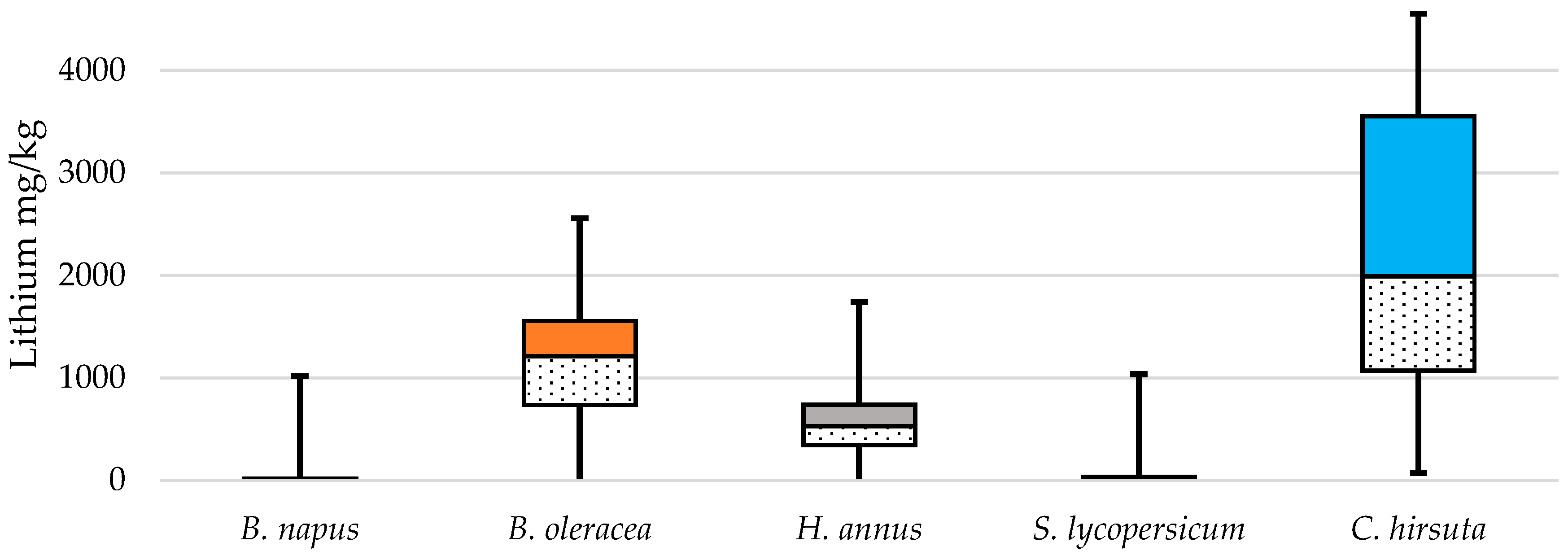

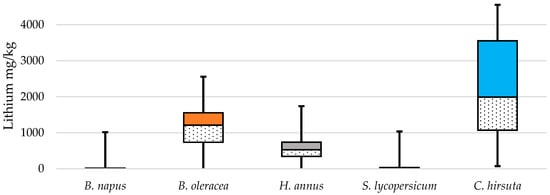

Figure 2.

Li concentration in leaves of the 5 species (Brassica napus, Brassica oleracea, Helianthus annuus, Solanum lycopersicum, and Cardamine hirsuta.) (Units = mg/kg).

Brassica oleracea, Helianthus annuus and Cardamine hirsuta showed a considerable increase in their Li content from the control group up to the 1000 mg/kg Li doped soil group. Brassica oleracea and Helianthus annuus showed variable Li levels (Figure 3) and maximum levels of 1496, SD = 691 and 601, SD = 354 mg/kg respectively. The data from these two species suggested that they were natural Li accumulators, which could absorb Li from soil and accumulate the metal in substantial amounts in their tissues. This accumulation also seems to have had a negligible effect on the health of the plants which had a mortality rate of just 5% in Brassica oleracea and Helianthus annuus (five plants of each). A strong linear association between the Li content in the plants and Li content amended to the soil was evident, Brassica oleracea at a coefficient of determination (r2) = 0.927 and Helianthus annuus at r2 = 0.953. These two species were selected to progress to further trials. There was an increase of around 150 mg/kg Li from group to group in Brassica oleracea and Helianthus annuus. Cardamine hirsuta showed increases of around 460 mg/kg Li between treatments, with maximum level of 4997, SD = 339 mg/kg. Even though Cardamine hirsuta accumulated the highest concentrations of Li among the five species tested, the size of the plant (i.e., it is a low yielding crop) means that the species could never be used successfully in any agro-mining project which require substantial amounts of biomass to justify the process economically. Although, the exceptional high growth rate of this species could potentially make it a viable venture, this is unlikely as the harvesting frequencies would need to be increased thereby increasing costs. Cardamine hirsuta also displayed the highest level of plant mortality among the five species tested i.e., >20% in trial 1 (i.e., 22 plants), because of these facts Cardamine hirsuta did not progress to further trials. Brassica napus and Solanum lycopersicum showed Li maximum levels of = 11.3, SD = 3.9 and = 120, SD = 32.4 mg/kg respectively. Both species had a strong positive linear association between Li in the plant and Li amended to the soil, Brassica napus at r = 0.68 and Solanum lycopersicum at r = 0.85. There were no plant mortalities observed in trial 1 for Brassica napus and Solanum lycopersicum the plants appeared to have a high tolerance to Li. The low concentrations of Li present in the leaves of both species should have determined that they did not progress to further trials. However. Because of the possibilities provided by Brassica napus such as oil and biodiesel production the plant was selected to continue to further trials. Solanum lycopersicum did not progress to further trials.

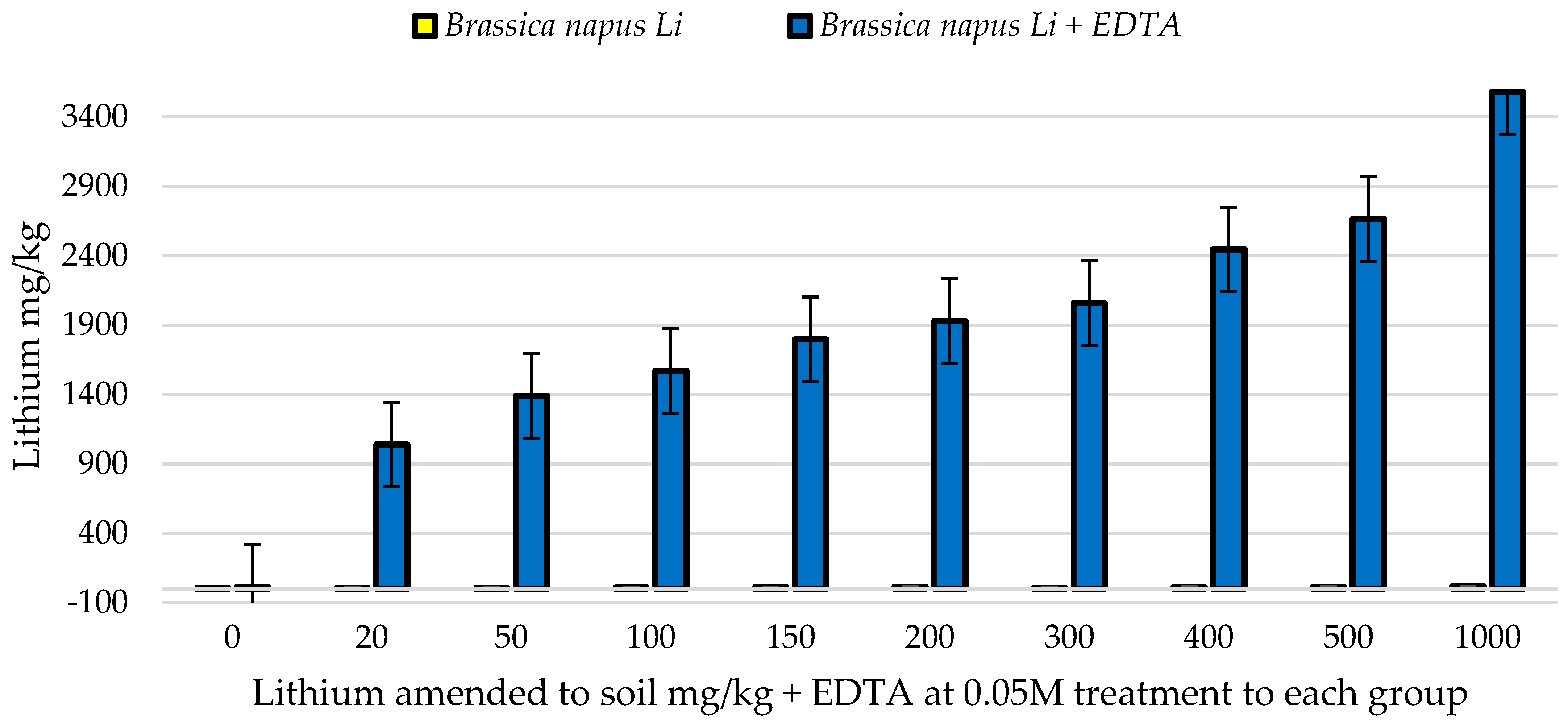

Figure 3.

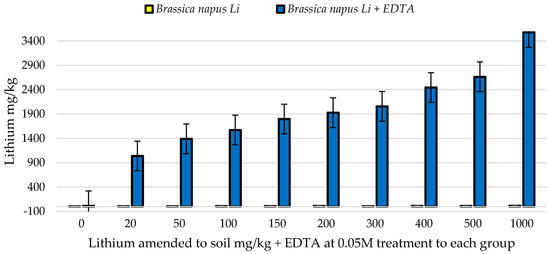

Li concentration in leaves of Brassica napus from trial 1 (no chelator) and Brassica napus from trial 2 (EDTA treatments at 0.05 M). X-axis, concentration of Li amended to the soil. (Units = mg/kg).

3.4. Trial 2, Li Amended Soil, EDTA Treatment

These trials were carried out using the plants Brassica napus, Brassica oleracea and Helianthus annuus (N = 300 new plants). The purpose of trial 2 was to assess the effect EDTA doping had on the amounts of Li taken into the plants. Trials were carried out as before using the same Li soil amendment protocol and the same number of plants in each group. The only difference between the trials was that one week prior to harvesting (i.e., around 3.5 months) EDTA at 0.05M was added to the soil along with their normal watering (i.e., approximately 100 mL of 0.05M EDTA solution in deionised water). Giving approximately 2.5 mmol EDTA/kg. Figure 3, Figure 4 and Figure 5 illustrate the differences in the amount of Li absorbed by Brassica napus, Brassica oleracea and Helianthus annuus in trial 1 (i.e., only Li amendments) and trial 2 (Li and EDTA amendments).

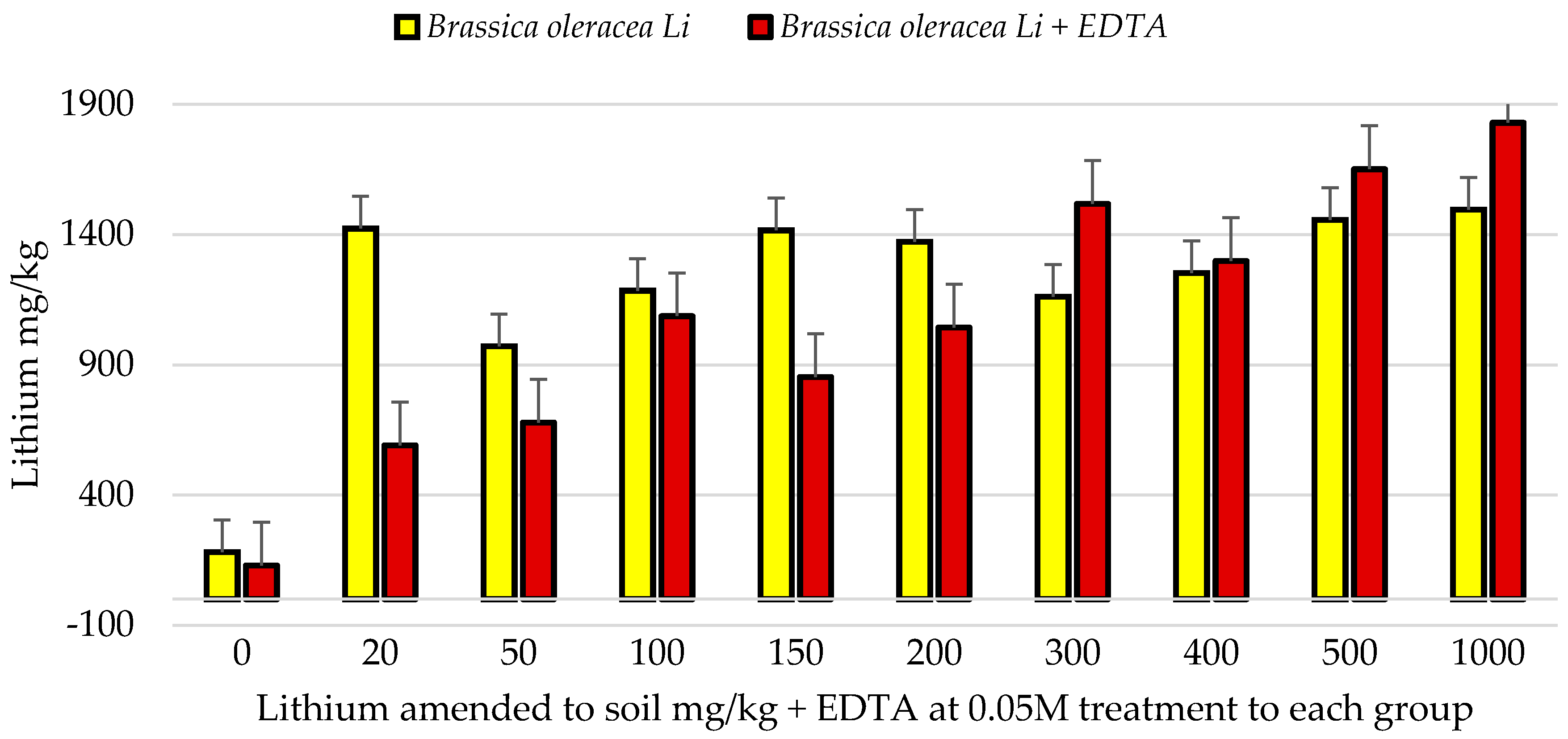

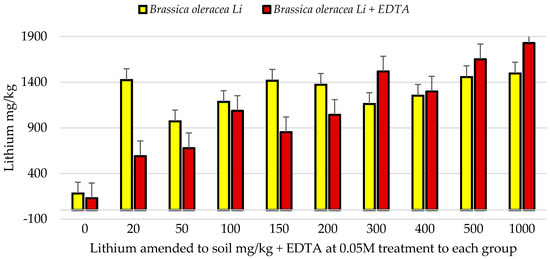

Figure 4.

Li concentration in leaves of Brassica oleracea from trial 1 (no chelator) and Brassica oleracea from trial 2 (EDTA treatments at 0.05M). X-axis, concentration of Li amended to the soil. (Units = mg/kg).

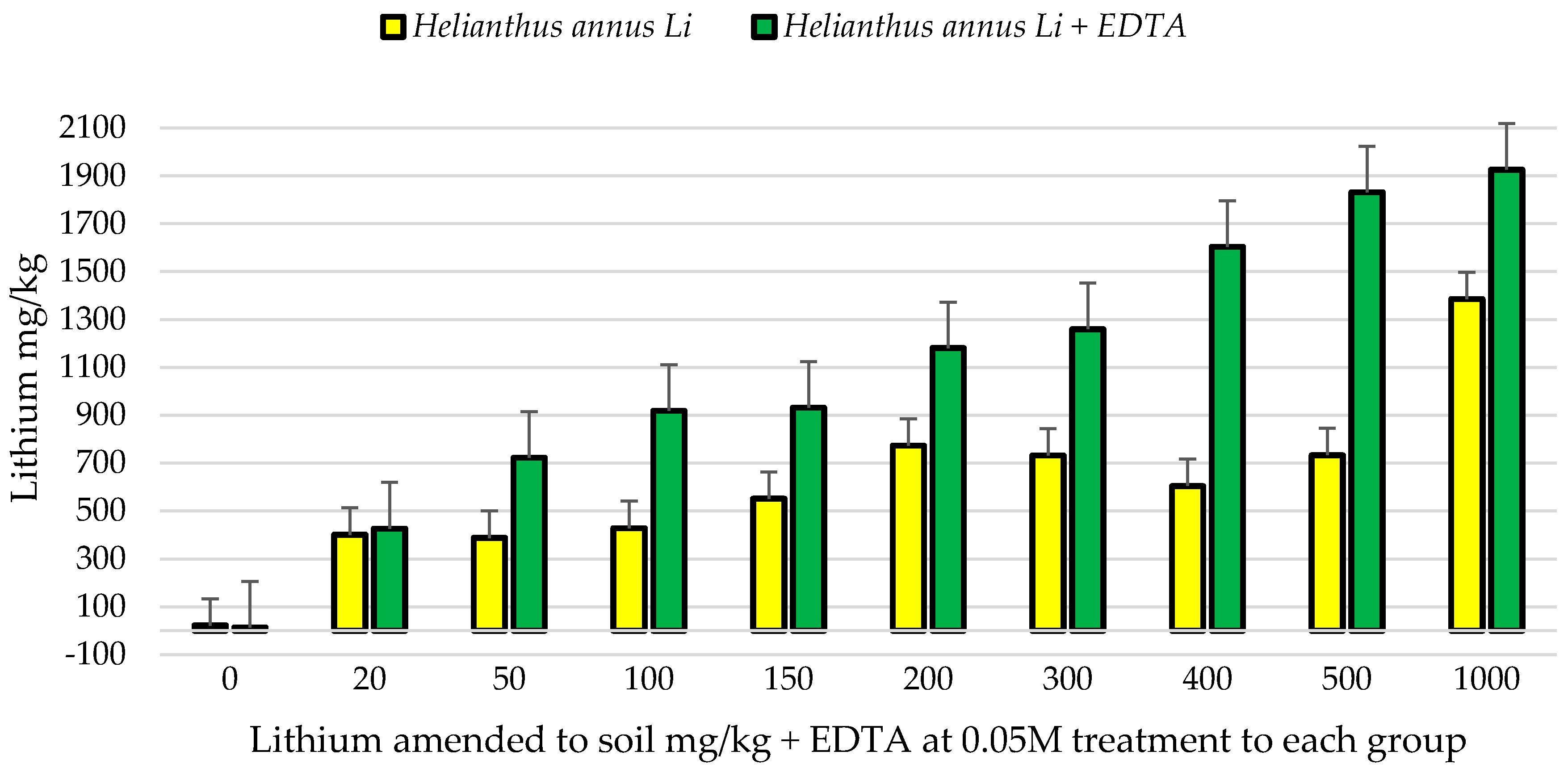

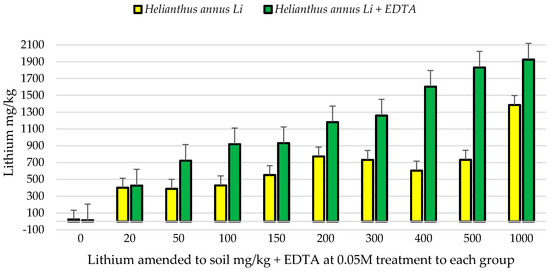

Figure 5.

Li concentration in leaves of Helianthus annuus from trial 1 (no chelator) and Helianthus annuus from trial 2 (EDTA treatments at 0.05M). X-axis, concentration of Li amended to soil. (Units in mg/kg).

There was an increase in the amount of Li found in the EDTA treated Brassica napus plants in trial 2 compared to trial 1. No plant mortalities were observed in trial 2 for Brassica napus. There was an increase in the amount of Li in Brassica napus by around 300 mg/kg, from group to group Brassica oleracea by around 180 mg/kg from one soil treatment to the next and Helianthus annuus by around 210 mg/kg. These figures for Brassica oleracea and Helianthus annuus were only slightly larger than the previous figures reached in trial 1 (i.e., Brassica oleracea trial 1 = 150 mg/kg, Helianthus annuus trial 1 = 150 mg/kg) while Brassica napus at an increase of 1.3 mg/kg in trial 1 from group to group showed a considerable increase. Brassica napus reached a maximum Li level of 1849, SD = 914 mg/kg in trial 2, comparable to the same figures in trial 1 at 11.3, SD = 3.9 mg/kg. Brassica oleracea reached an maximum Li level of 1830, SD = 625 mg/kg in trial 2. When compared to the same figures from trial 1 of 1496, SD = 691 mg/kg there was a slight increase of around 300 mg/kg. Plant mortalities in Brassica oleracea were >25% (26 plants) after the addition of EDTA. Helianthus annuus reached a maximum Li level of 1081, SD = 609 mg/kg in trial 2. When compared to the same figures from trial 1 of 601, SD = 354 mg/kg there was a slight increase of around 300 to 400 mg/kg. Plant mortalities for Helianthus annuus were also close to 25% (24 plants) after the addition of EDTA. A positive linear association between Li content in the plants and Li content amended to the soil was observed in all 3 species in trial 2, Brassica napus at r2 = 0.80, Brassica oleracea at r2 = 0.71 and Helianthus annuus at r2 = 0.73.

3.5. Trial 3, Li Amended Soil, EDDS Treatment

Li was amended to the soil in trial 3 in the same manner as in trial 1 and 2 (i.e., 20, 50, 100, 150, 200, 300, 400, 500, 1000 mg/kg Li with a control group). In trial 3 EDDS was used as the chelating agent the exact same way as EDTA was used in trial 2 (i.e., EDDS at 0.05M added to the mature plants 1 week prior to harvesting). Figure 6, Figure 7 and Figure 8 illustrate the differences in the amount of Li absorbed by Brassica napus, Brassica oleracea and Helianthus annuus in trial 1 (i.e., only Li amendments) and trial 3 (Li and EDDS amendments).

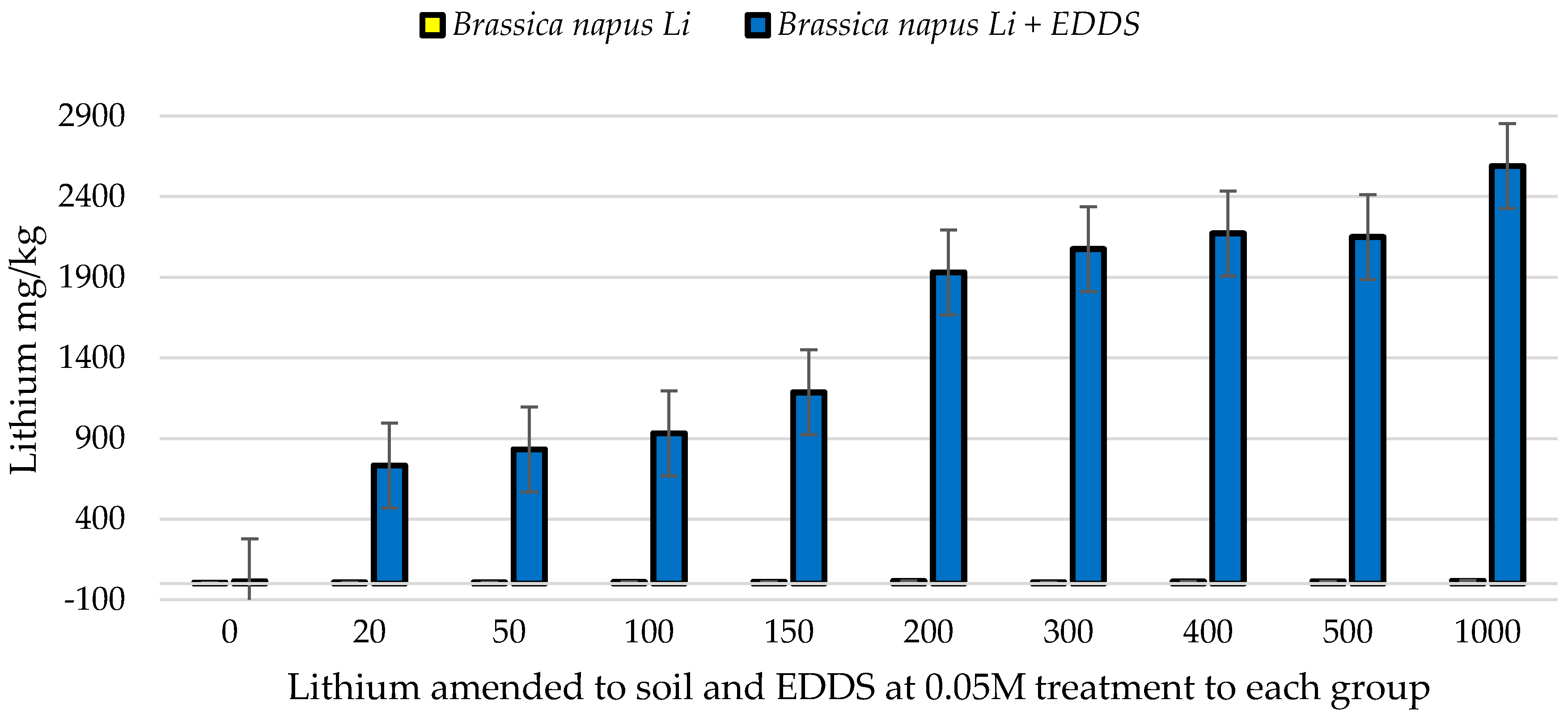

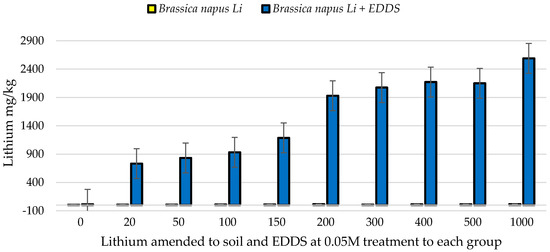

Figure 6.

Li concentration in leaves of Brassica napus from trial 1 (No chelator) and Brassica napus from trial 3 (EDDS treatments at 0.05M) X-axis, concentration of Li amended to the soil. (Units in mg/kg).

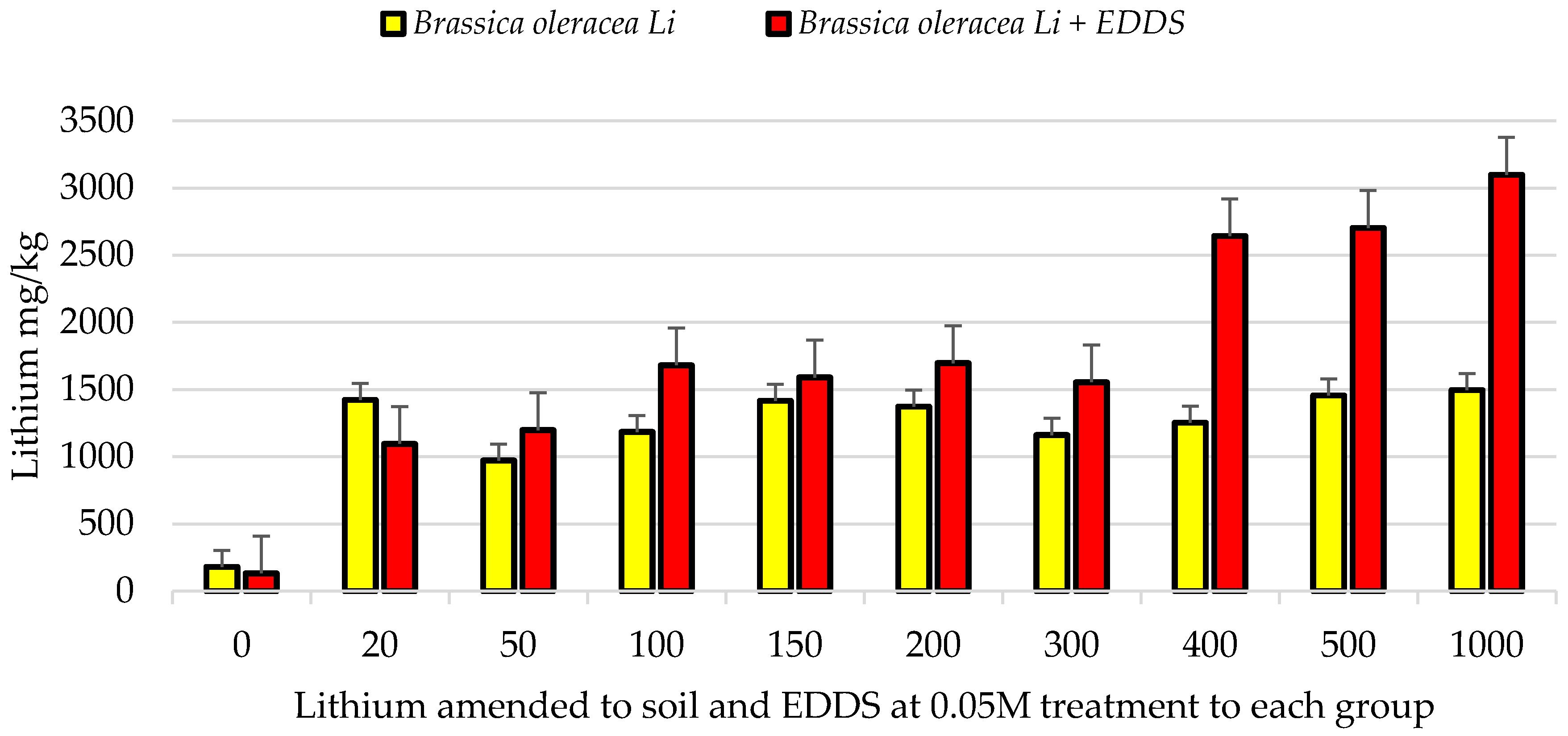

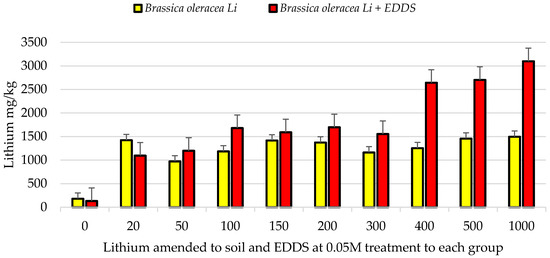

Figure 7.

Li concentration in leaves of Brassica oleracea from trial 1 (No chelator) and Brassica oleracea from trial 3 (EDDS treatments at 0.05M) X-axis, concentration of Li amended to the soil. (Units in mg/kg).

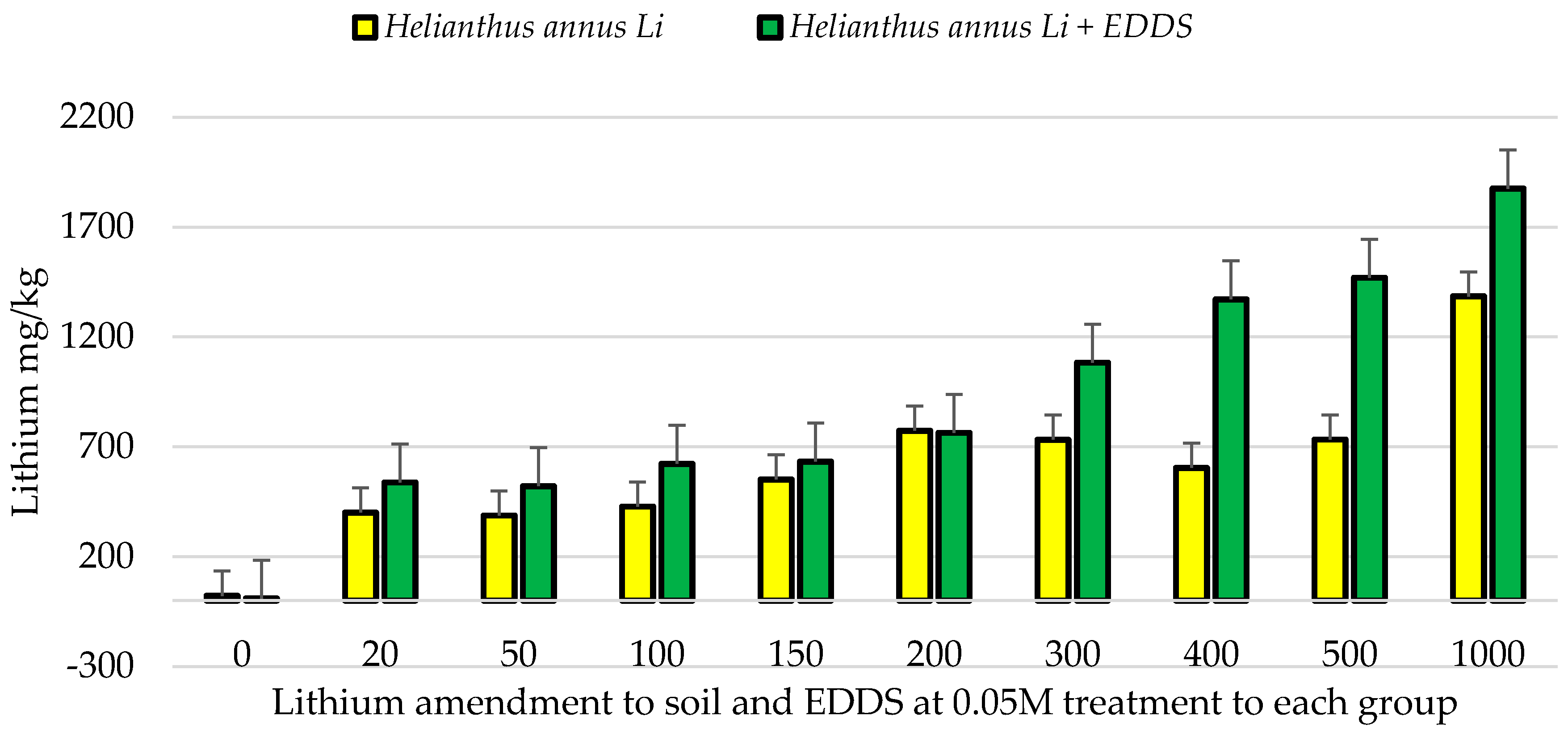

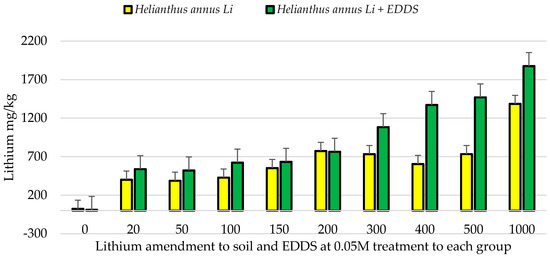

Figure 8.

Li concentration in leaves of Helianthus annuus from trial 1 (no chelator) and Helianthus annuus from trial 3 (EDDS treatments at 0.05M) X-axis, concentration of Li amended to the soil (Units in mg/kg).

Brassica napus showed maximum Li levels of = 1461, SD = 301. There was an increase in the amount of Li in the Brassica napus plants in trial 3 (EDDS) by around 300 mg/k from group to group compared to data from trial 1 of 1.3 mg/kg. Brassica oleracea showed maximum Li levels of = 1739, SD = 878 and an increase of around 330 between groups compared to trial 1 at 150 mg/kg. Helianthus annuus showed maximum Li levels of = 889, SD = 554 and an increase of around 210 between groups compared to trial 1 data at 150 mg/kg (Table 4). Plant mortalities in trial 3 were low >5% for each species (i.e., Brassica napus = 1, Brassica oleracea = 6 and Helianthus annuus = 4). Table 4 lists the and maximum Li levels measured in the leaves of each plant species in trial 1, 2 and 3 at the highest Li amendment. A positive linear association between Li content in the plants and Li content amended to the soil was observed in all 3 species in trial 3, Brassica napus, r2 = 0.73 at Brassica oleracea, at r2 = 0.73 from and Helianthus annuus at r2 = 0.86.

Table 4.

maximum Li levels, standard deviations and maximum levels of Li in plants from all 3 trials (units in mg/kg).

An analysis of variance (ANOVA) was conducted on the Li values from each plant species to test the null hypothesis that there was no significant difference between all Li data within the groups of each plant. Brassica napus at (F (2,27) = 17.36, p = 1.42−5) rejected the null hypothesis. Post hoc t-tests showed at (t-stat = −8.08, df = 9, p-value = 2.02 × 10−5) a significant difference between trial 1 and 2 and at (t-stat = −5.5, df = 9, p-value = 0.00018) a significant difference between trial 1 and 3. An ANOVA analysis performed on Brassica oleracea data at (F (2,27) = 3.19, p = 3.35) failed to reject the null hypothesis. Post hoc testing revealed at (t-stat = 1.01, df = 9, p-value = 0.169) these was no statistical difference between trial 1 and 2 and at (t-stat = −2.68, df = 9, p-value = 0.012) showed only a marginally significant difference between trial 1 and trial 3 data. The same ANOVA analysis and null hypothesis was carried out on the Helianthus annuus Li data from each trial. At (F (2,27) = 2.17, p = 0.133) it also failed to reject the null hypothesis. Subsequent t-tests at (t-stat = −4.26, df = 9, p-value = 0.001) between trial 1 and 2 data and at (t-stat = −3.14, df = 9, p-value = 0.005) between trial 1 and 3 showed that there was only a marginally significant difference between the groups. Brassica napus despite not been a natural Li accumulator performed significantly better when it came to Li accumulation when both chelating agents were applied, EDTA treated plants showing a marginally higher level that EDDS treated plants. Although Brassica oleracea and Helianthus annuus accumulated large amounts of Li in trial 1, the addition of chelating agents did not increase the amount of Li accumulated by any significant difference. As part of this work both K and Na were measured along with Li in all samples taken from all plant species. A multiple regression analysis was carried out to assess whether there was any association between Li, Na and K levels. The following was observed in trial 1: Brassica napus, Li/Na, r2 = 0.58, Li/K, r2 = −0.1, Brassica oleracea, Li/Na, r2 = −0.15, Li/K, r2 = 0.23, Helianthus annuus, Li/Na, r2 = −0.70, Li/K, r2 = −0.25, Cardamine hirsuta, Li/Na, r2 = 0.53, Li/K, r2 = 0.33. No significant correlations were observed, only weak negative and positive associations were present. An analysis was also performed on data from trials 2 and 3, no significant correlations were observed.

4. Conclusions

Agro-mining as a mining technology has not yet being widely implemented. The process takes time compared to conventional mining which produces more immediate results. Mining companies are not yet eager to invest in any commercial scale application of the technology. The main economic considerations of any agro-mining project include; global metal prices, energy recovery and agronomic costs. These factors can determine whether a project is feasible or not [8]. Other considerations such as plant biomass, climate, growth rates and whether the process is introducing an invasive species to an area are also important. In general, hyperaccumulators have a lower biomass than regular plants and are mostly endemic to ultrabasic soils. Induced plant metal accumulation uses endemic crops that have a high biomass. The key value for agro-mining is the amount of metal extracted per hectare multiplied by the value of the metal [84]. Studies have been carried out on hundreds of plant species and their suitability for agro-mining different metals [14,77]. The data from some of these studies are listed below in Table 5.

Table 5.

List of metal yields reached during agro-mining research.

The experiments presented here are the first examining Li-accumulation in plants with the intention of agro-mining Li. The data shows that EDDS performed as well as EDTA at inducing Li accumulation in these trials. EDDS’s biodegradability in comparison to EDTA’s persistence and performance in these trials make it an ideal candidate for chelate induced agro-mining of Li. The highest concentrations of Li recorded in this study using EDDS as a chelating agent was observed in the plants Brassica napus (2590 mg/kg) and Brassica oleracea (3091 mg/kg). Li prices are at an all-time high and the price is expected to increase in the coming years, having increased massively since the early 21st century from $1590 per metric ton in 2002 to $9100 in 2017 [85]. Brassica napus crops have a yield of around 1.3 tons/ha fresh weight. The moisture content of fresh cut Brassica napus is around 13%, so 1.3 tons yields around 1.1 tons dry plant matter, and 1.1 tons of plant matter should contain approximately 0.26 kg of Li worth around $23.7/ha. A conservative estimate of a crop yield of Brassica oleracea is approximately 50 tons/ha fresh weight. The moisture content of cabbage is commonly >90% so a crop of 50 tons should produce around five tons of dry plant matter. Grown under the conditions set out in this work, five tons of dry plant matter should contain approximately 1.55 kg of Li worth around $141.05/ha. When dried, the leaves of these two Brassica plants are prone to crumbling resulting in a loss of plant matter before transportation. Instead the fresh plant matter could be transported (increasing costs) and used to recover energy (fermentation) before being processed for Lithium. The true potential of agro-mining is still unknown, the technology, despite been around for the last four decades still needs to prove its economic significance. Large-scale agro-mining operations are needed to work through real word challenges and provide “real-life” evidence of profitability [3]. If agro-mining could be combined with other technologies such as forestry, there could be more of an economic incentive for companies to invest in the technology [86]. Genetic modification could also be the future of the technology [23]. The optimising of agronomic practices, such as irrigation and fertilization will increase the efficiency of the agro.mining process [86]. A Li metal agro-mining industry may be wishful thinking right now. However, as suitable rich ore deposits become scarcer in the future, agro-mining may become a more feasible approach and industry may be willing to adopt the technology.

Acknowledgments

This study was carried out at EnviroCORE, Department of Science and Health, Institute of Technology Carlow, Ireland. We acknowledge support from the Institute of Technology Carlow President’s Research Fellowship Programme fund and the Development and Research Postgraduate fund. This work was also supported by the Government of Ireland Postgraduate Scholarship Scheme 2016 in conjunction with the Environmental Protection Agency of Ireland. Project ID: GOIPG/2016/703.

Author Contributions

Laurence Kavanagh conceived and designed the experiments. Laurence Kavanagh acquired the samples, performed the experiments and analysed data. Laurence Kavanagh, Andrew Lloyd and John Cleary interpreted the data. Jerome Keohane and Guiomar Garcia-Cabellos contributed reagents/materials/analysis tools to the work. Laurence Kavanagh wrote the paper. Andrew Lloyd, Guiomar Garcia-Cabellos, Jerome Keohane and John Cleary contributed toward drafting the article and revising it critically.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Chaney, R.L. Plant uptake of inorganic waste constituents. In Land Treatment of Hazardous Wastes; Parr, J.F., Marsh, P.B., Kla, J.M., Eds.; Noyes Data Corp.: Park Ridge, NJ, USA, 1983; pp. 50–76. [Google Scholar]

- Sheoran, V.; Sheoran, A.S.; Poonia, P. Agromining: A review. Miner. Eng. 2009, 22, 1007–1019. [Google Scholar] [CrossRef]

- Van Der Ent, A.; Baker, A.J.; Reeves, R.D.; Chaney, R.L.; Anderson, C.W.; Meech, J.A.; Erskine, P.D.; Simonnot, M.O.; Vaughan, J.; Morel, J.L.; et al. Agromining: Farming for metals in the future? Environ. Sci. Technol. 2009, 49, 4773–4780. [Google Scholar] [CrossRef] [PubMed]

- Garbisu, C.; Alkorta, I. Phytoextraction: A cost-effective plant-based technology for the removal of metals from the environment. Bioresour. Technol. 2009, 77, 229–236. [Google Scholar] [CrossRef]

- Brooks, R.R.; Robinson, B.H. The potential use of hyperaccumulators and other plants for agromining. In Plants that Hyperaccumulate Heavy Metals: Their Role in Archaeology, Microbiology, Mineral Exploration, Agromining and Phytoremediation; CAB International: Wallingford, UK, 1998; pp. 327–356. [Google Scholar]

- Robinson, B.H.; Anderson, C.W.N.; Dickinson, N.M. Phytoextraction: Where’s the action? J. Geochem. Explor. 2015, 151, 34–40. [Google Scholar] [CrossRef]

- Sheoran, V.; Sheoran, A.S.; Poonia, P. Agromining of gold: A review. J. Geochem. Explor. 2013, 128, 42–50. [Google Scholar] [CrossRef]

- Robinson, B. Agromining: Growing a crop of metal. Biologist 1999, 46, 201–205. [Google Scholar]

- Phytoremediation and Agromining in Manitoba: Preliminary Observation from an Orientation Survey at the Central Manitoba (Au) Minesite (NTS 52L/13). Report of Activities. Available online: http://manitoba.ca/iem/geo/field/roa00pdfs/00gs-28.pdf (accessed on 5 February 2018).

- Timofeeva, S.S.; Ulrikh, D.V.; Timofeev, S.S. Agromining Perspectives in Rehabilitation of Mining and Industrial Areas of South Ural; InIOP Conference Series. Earth Environ. Sci. 2017, 66, 012030. [Google Scholar]

- Reeves, R.D.; Baker, A.J. Metal accumulating plants. In Phytoremediation of Toxic Metals Using Plants to Clean Up the Environment; Raskin, I., Ensley, B.D., Eds.; John Wiley & Sons Inc.: New York, NY, USA, 2000. [Google Scholar]

- Sachs, J. Manual of Experimental Physiology of Plants. Investigations on the General Living Conditions of the Plants and the Functions of Their Organs; Wilhelm Engelmann: Leipzig, Germany, 1865; p. 514. [Google Scholar]

- Assunção, A.G.; Schat, H.; Aarts, M.G. Thlaspi caerulescens, an attractive model species to study heavy metal hyperaccumulation in plants. New Phytol. 2003, 159, 351–360. [Google Scholar] [CrossRef]

- Brooks, R.R.; Chambers, M.F.; Nicks, L.J.; Robinson, B.H. Agromining. Trends Plant Sci. 1998, 3, 359–362. [Google Scholar] [CrossRef]

- Verbruggen, N.; Hermans, C.; Schat, H. Molecular mechanisms of metal hyperaccumulation in plants. New Phytol. 2009, 181, 759–776. [Google Scholar] [CrossRef] [PubMed]

- Jaffré, T.; Brooks, R.R.; Lee, J.; Reeves, R.D. Sebertia acuminata: A hyperaccumulator of nickel from New Caledonia. Science 1976, 193, 579–580. [Google Scholar] [CrossRef] [PubMed]

- Baker, A.J.M.; McGrath, S.P.; Sidoli, C.M.D.; Reeves, R.D. The possibility of in situ heavy metal decontamination of polluted soils using crops of metal-accumulating plants. Resour. Conserv. Recycl. 1994, 11, 41–49. [Google Scholar] [CrossRef]

- Pollard, A.J.; Reeves, R.D.; Baker, A.J. Facultative hyperaccumulation of heavy metals and metalloids. Plant Sci. 2014, 217, 8–17. [Google Scholar] [CrossRef] [PubMed]

- Rascio, N.; Navari-Izzo, F. Heavy metal hyperaccumulating plants: How and why do they do it? And what makes them so interesting? Plant Sci. 2011, 180, 169–181. [Google Scholar] [CrossRef] [PubMed]

- Sarma, H. Metal hyperaccumulation in plants: A review focusing on phytoremediation technology. J. Environ. Sci. Technol. 2011, 4, 118–138. [Google Scholar] [CrossRef]

- Baker, A.J.M.; Reeves, R.D.; Hajar, A.S.M. Heavy metal accumulation and tolerance in British populations of the metallophyte Thlaspi caerulescens J. & C. Presl (Brassicaceae). New Phytol. 1994, 127, 61–68. [Google Scholar]

- Wang, H.B.; Wong, M.H.; Lan, C.Y.; Baker, A.J.M.; Qin, Y.R.; Shu, W.S.; Chen, G.Z.; Ye, Z.H. Uptake and accumulation of arsenic by 11 Pteris taxa from southern China. Environ. Pollut. 2007, 145, 225–233. [Google Scholar] [CrossRef] [PubMed]

- Dodson, J.R.; Hunt, A.J.; Parker, H.L.; Yang, Y.; Clark, J.H. Elemental sustainability: Towards the total recovery of scarce metals. Chem. Eng. Process. Process Intensif. 2012, 51, 69–78. [Google Scholar] [CrossRef]

- Morrison, R.S.; Brooks, R.R.; Reeves, R.D.; Malaisse, F. Copper and cobalt uptake by metallophytes from Zaïre. Plant Soil 1979, 53, 535–539. [Google Scholar] [CrossRef]

- Blaylock, M.J.; Salt, D.E.; Dushenkov, S.; Zakharova, O.; Gussman, C.; Kapulnik, Y.; Ensley, B.D.; Raskin, I. Enhanced accumulation of Pb in Indian mustard by soil-applied chelating agents. Environ. Sci. Technol. 1997, 31, 860–865. [Google Scholar] [CrossRef]

- Freeman, J.L.; Zhang, L.H.; Marcus, M.A.; Fakra, S.; McGrath, S.P.; Pilon-Smits, E.A. Spatial imaging, speciation, and quantification of selenium in the hyperaccumulator plants Astragalus bisulcatus and Stanleya pinnata. Plant Physiol. 2006, 142, 124–134. [Google Scholar] [CrossRef] [PubMed]

- Anderson, C.W.N.; Brooks, R.R.; Chiarucci, A.; Lacoste, C.J.; Leblanc, M.; Robinson, B.H.; Simcock, R.; Stewart, R.B. Agromining for nickel, thallium and gold. J. Geochem. Explor. 1999, 67, 407–415. [Google Scholar] [CrossRef]

- Huang, J.W.; Blaylock, M.J.; Kapulnik, Y.; Ensley, B.D. Phytoremediation of uranium-contaminated soils: Role of organic acids in triggering uranium hyperaccumulation in plants. Environ. Sci. Technol. 1998, 32, 2004–2008. [Google Scholar] [CrossRef]

- Elektorowicz, M.; Keropian, Z. Lithium, Vanadium and Chromium Uptake Ability of Brassica juncea from Lithium Mine Tailings. Int. J. Phytoremediat. 2015, 17, 521–528. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.T.; Qiu, R.L.; Zeng, X.W.; Ying, R.R.; Yu, F.M.; Zhou, X.Y. Lead, zinc, cadmium hyperaccumulation and growth stimulation in Arabis paniculata Franch. Environ. Exp. Bot. 2009, 66, 126–134. [Google Scholar] [CrossRef]

- Ernst, W.H. Evolution of metal tolerance in higher plants. For. Snow Landsc. Res. 2006, 80, 251–274. [Google Scholar]

- Krämer, U. Metal hyperaccumulation in plants. Annu. Rev. Plant Biol. 2010, 61, 517–534. [Google Scholar] [CrossRef] [PubMed]

- Salt, D.E.; Blaylock, M.; Kumar, N.P.; Dushenkov, V.; Ensley, B.D.; Chet, I.; Raskin, I. Phytoremediation: A novel strategy for the removal of toxic metals from the environment using plants. Nat. Biotechnol. 1995, 13, 468–474. [Google Scholar] [CrossRef]

- Norvell, W.A. Comparison of chelating agents as extractants for metals in diverse soil materials. Soil Sci. Soc. Am. J. 1984, 48, 1285–1292. [Google Scholar] [CrossRef]

- Nowack, B.; Schulin, R.; Robinson, B.H. Critical assessment of chelant-enhanced metal phytoextraction. Environ. Sci. Technol. 2006, 40, 5225–5232. [Google Scholar] [CrossRef] [PubMed]

- Peters, R.W. Chelant extraction of heavy metals from contaminated soils. J. Hazard. Mater. 1999, 66, 151–210. [Google Scholar] [CrossRef]

- Kołodyńska, D. Chelating agents of a new generation as an alternative to conventional chelators for heavy metal ions removal from different waste waters. In Expanding Iszzsues in Desalination; InTech: Rijeka, Croatia, 2011. [Google Scholar] [CrossRef]

- Nörtemann, B. Biodegradation of Chelating Agents: EDTA, DTPA, PDTA, NTA, and EDDS. In Biogeochemistry of Chelating Agents; Nowack, B., VanBriesen, J.M., Eds.; American Chemical Society: Washington, DC, USA, 2005. [Google Scholar]

- Satroutdinov, A.D.; Chistyakova, T.I.; Dedyukhina, E.G.; Minkevich, I.G. Microbial degradation of EDTA: New EDTA-degrading bacterial strains. In Biogeochemistry of Chelating Agents; American Chemical Society: Washington, DC, USA, 2005; pp. 171–182. [Google Scholar]

- Nowack, B. Environmental chemistry of aminopolycarboxylate chelating agents. Environ. Sci. Technol. 2002, 36, 4009–4016. [Google Scholar] [CrossRef] [PubMed]

- Bucheli-Witschel, M.; Egli, T. Environmental fate and microbial degradation of aminopolycarboxylic acids. FEMS Microbiol. Rev. 2001, 25, 69–106. [Google Scholar] [CrossRef] [PubMed]

- Van Herwijnen, R.; van Fleuren, R.H.L.J. Environmental Risk Limits for EDTA. National Environmental Quality Standards for Substances Netherlands; Report 601782028/2009; RIVM: Bilthoven, The Netherlands, 2009. [Google Scholar]

- Tandy, S.; Bossart, K.; Mueller, R.; Ritschel, J.; Hauser, L.; Schulin, R.; Nowack, B. Extraction of heavy metals from soils using biodegradable chelating agents. Environ. Sci. Technol. 2004, 38, 937–944. [Google Scholar] [CrossRef] [PubMed]

- Schowanek, D.; Feijtel, T.C.; Perkins, C.M.; Hartman, F.A.; Federle, T.W.; Larson, R.J. Biodegradation of [S, S], [R, R] and mixed stereoisomers of ethylenediaminedisuccinic acid (EDDS), a transition metal chelator. Chemosphere 1997, 34, 2375–2391. [Google Scholar] [CrossRef]

- Hyvönen, H. Studies on Metal Complex Formation of Environmentally Friendly Aminopolycarboxylate Chelating Agents. Ph.D. Thesis, University of Helsinki, Helsinki, Finland, 2008. [Google Scholar]

- Takahashi, R.; Fujimoto, N.; Suzuki, M.; Endo, T. Biodegradabilities of ethylenediamine-N, N′-disuccinic acid (EDDS) and other chelating agents. Biosci. Biotechnol. Biochem. 1997, 61, 1957–1959. [Google Scholar] [CrossRef] [PubMed]

- Meers, E.; Tack, F.M.G.; Verloo, M.G. Degradability of ethylenediaminedisuccinic acid (EDDS) in metal contaminated soils: Implications for its use soil remediation. Chemosphere 2008, 70, 358–363. [Google Scholar] [CrossRef] [PubMed]

- Metsärinne, S.; Tuhkanen, T.; Aksela, R. Photodegradation of ethylenediaminetetraacetic acid (EDTA) and ethylenediamine disuccinic acid (EDDS) within natural UV radiation range. Chemosphere 2001, 45, 949–955. [Google Scholar] [CrossRef]

- Turan, M.; Esringu, A. Phytoremediation based on canola (Brassica napus L.) and Indian mustard (Brassica juncea L.) planted on spiked soil by aliquot amount of Cd, Cu, Pb, and Zn. Plant Soil Environ. 2007, 53, 7. [Google Scholar]

- Kos, B.; Greman, H.; Lestan, D. Phytoextraction of lead, zinc and cadmium from soil by selected plants. Plant Soil Environ. 2003, 49, 548–553. [Google Scholar]

- Pereira, B.F.F.; Abreu, C.A.D.; Herpin, U.; Abreu, M.F.D.; Berton, R.S. Phytoremediation of lead by jack beans on a Rhodic Hapludox amended with EDTA. Sci. Agricola 2010, 67, 308–318. [Google Scholar] [CrossRef]

- Seth, C.S.; Misra, V.; Singh, R.R.; Zolla, L. EDTA-enhanced lead phytoremediation in sunflower (Helianthus annuus L.) hydroponic culture. Plant Soil 2011, 347, 231. [Google Scholar] [CrossRef]

- Pinto, I.S.; Neto, I.F.; Soares, H.M. Biodegradable chelating agents for industrial, domestic, and agricultural applications, a review. Environ. Sci. Pollut. Res. 2014, 21, 11893–11906. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Shen, Z.; Li, X. Enhanced phytoextraction of Cu, Pb, Zn and Cd with EDTA and EDDS. Chemosphere 2005, 59, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Tandy, S.; Schulin, R.; Nowack, B. Uptake of metals during chelant-assisted phytoextraction with EDDS related to the solubilized metal concentration. Environ. Sci. Technol. 2006, 40, 2753–2758. [Google Scholar] [CrossRef] [PubMed]

- Hauser, L.; Tandy, S.; Schulin, R.; Nowack, B. Column extraction of heavy metals from soils using the biodegradable chelating agent EDDS. Environ. Sci. Technol. 2005, 39, 6819–6824. [Google Scholar] [CrossRef] [PubMed]

- Grčman, H.; Vodnik, D.; Velikonja-Bolta, Š.; Leštan, D. Ethylenediaminedissuccinate as a new chelate for environmentally safe enhanced lead phytoextraction. J. Environ. Qual. 2003, 32, 500–506. [Google Scholar] [CrossRef] [PubMed]

- Fine, P.; Paresh, R.; Beriozkin, A.; Hass, A. Chelant-enhanced heavy metal uptake by Eucalyptus trees under controlled deficit irrigation. Sci. Total Environ. 2014, 493, 995–1005. [Google Scholar] [CrossRef] [PubMed]

- Shilev, S.; Naydenov, M.; Tahsin, N.; Sancho, E.D.; Benlloch, M.; Vancheva, V.; Sapundjieva, K.; Kuzmanova, J. Effect of easily biodegradable amendments on heavy metal solubilization and accumulation in technical crops—A field trial. J. Environ. Eng. Landsc. Manag. 2007, 15, 237–242. [Google Scholar]

- Cao, A.; Carucci, A.; Lai, T.; La Colla, P.; Tamburini, E. Effect of biodegradable chelating agents on heavy metals phytoextraction with Mirabilis jalapa and on its associated bacteria. Eur. J. Soil Biol. 2007, 43, 200–206. [Google Scholar] [CrossRef]

- Lenntech. Lithium (Li) and Water: Reaction Mechanisms, Environmental Impact and Health Effects. 2017. Available online: https://www.lenntech.com/periodic/elements/li.htm (accessed on 2 November 2017).

- Schrauzer, G.N. Lithium: Occurrence, dietary intakes, nutritional essentiality. J. Am. Coll. Nutr. 2002, 21, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Wallace, A.; Romney, E.M.; Cha, J.W.; Chaudhry, F.M. Lithium toxicity in plants. Commun. Soil Sci. Plant Anal. 1977, 8, 773–780. [Google Scholar] [CrossRef]

- Kabata-Pendias, A.; Pendias, H. Source Trace Elements in Soil and Plants, 3rd ed.; CRC Press: Boca Raton, FL, USA, 1984; p. 116. [Google Scholar]

- Shahzad, B.; Tanveer, M.; Hassan, W.; Shah, A.N.; Anjum, S.A.; Cheema, S.A.; Ali, I. Lithium toxicity in plants: Reasons, mechanisms and remediation possibilities—A review. Plant Physiol. Biochem. 2016, 107, 104–115. [Google Scholar] [CrossRef] [PubMed]

- Ammari, T.G.; Al-Zu’bi, Y.; Abu-Baker, S.; Dababneh, B.; Tahboub, A. The occurrence of lithium in the environment of the Jordan Valley and its transfer into the food chain. Environ. Geochem. Health 2011, 33, 427–437. [Google Scholar] [CrossRef] [PubMed]

- Aral, H.; Vecchio-Sadus, A. Toxicity of lithium to humans and the environment—A literature review. Ecotoxicol. Environ. Saf. 2008, 70, 349–356. [Google Scholar] [CrossRef] [PubMed]

- Magalhaes, J.R.; Wilcox, G.E.; Rocha, A.N.F.; Silva, F.L.I.M. Research on lithium-phytological metabolism and recovery of hypo-lithium. Pesqui. Agrospecu. Bras. 1990, 25, 1781–1787. [Google Scholar]

- Kent, N.L. Absorption, translocation and ultimate fate of lithium in the wheat plant. New Phytol. 1994, 40, 291–298. [Google Scholar] [CrossRef]

- Hawrylak-Nowak, B.; Kalinowska, M.; Szymańska, M. A study on selected physiological parameters of plants grown under lithium supplementation. Biol. Trace Elem. Res. 2012, 149, 425–430. [Google Scholar] [CrossRef] [PubMed]

- McStay, N.G.; Rogers, H.H.; Anderson, C.E. Effects of lithium on Phaseolus vulgaris L. Sci. Total Environ. 1980, 16, 185–191. [Google Scholar] [CrossRef]

- Bingham, F.T.; Page, A.L.; Bradford, G.R. Tolerance of plants to lithium. Soil Sci. 1964, 98, 4–8. [Google Scholar] [CrossRef]

- Li, X.; Gao, P.; Gjetvaj, B.; Westcott, N.; Gruber, M.Y. Analysis of the metabolome and transcriptome of Brassica carinata seedlings after lithium chloride exposure. Plant Sci. 2009, 177, 68–80. [Google Scholar] [CrossRef]

- Cannon, H.L.; Harms, T.F.; Hamilton, J.C. Lithium in Unconsolidated Sediments and Plants of the Basin and Range Province, Southern California and Nevada 1975, (No. 918); United States Government Printing Office: Washington, DC, USA, 1975.

- Jiang, L.; Wang, L.; Mu, S.Y.; Tian, C.Y. Apocynum venetum: A newly found lithium accumulator. Flora Morphol. Distrib. Funct. Ecol. Plants 2014, 209, 285–289. [Google Scholar] [CrossRef]

- Tölgyesi, G. Distribution of lithium in Hungarian soils and plants. Lithium 1983, 4, 39–44. [Google Scholar]

- Saeidnia, S.; Abdollahi, M. Concerns on the growing use of lithium: The pros and cons. Iran. Red Crescent Med. J. 2013, 15, 629–632. [Google Scholar] [CrossRef] [PubMed]

- Anderson, C.E. Lithium in Plants. In Lithium and Cell Physiology; Springer: New York, NY, USA, 1990; pp. 25–46. [Google Scholar]

- Schwertfeger, D.M.; Hendershot, W.H. Spike/leach procedure to prepare soil samples for trace metal ecotoxicity testing: Method development using copper. Commun. Soil Sci. Plant Anal. 2013, 44, 1570–1587. [Google Scholar] [CrossRef]

- Wuana, R.A.; Okieimen, F.E.; Imborvungu, J.A. Removal of heavy metals from a contaminated soil using organic chelating acids. Int. J. Environ. Sci. Technol. 2010, 7, 485–496. [Google Scholar] [CrossRef]

- Strange, E.E. Determination of Lithium in Magnesium Alloy by Flame Photometer. Anal. Chem. 1953, 25, 650–651. [Google Scholar] [CrossRef]

- Robinson, B.; Fernández, J.E.; Madejón, P.; Marañón, T.; Murillo, J.M.; Green, S.; Clothier, B. Phytoextraction: An assessment of biogeochemical and economic viability. Plant Soil 2003, 249, 117–125. [Google Scholar] [CrossRef]

- Keeling, S.M.; Stewart, R.B.; Anderson, C.W.N.; Robinson, B.H. Nickel and cobalt phytoextraction by the hyperaccumulator Berkheya coddii: Implications for polymetallic agromining and phytoremediation. Int. J. Phytoremediat. 2003, 5, 235–244. [Google Scholar] [CrossRef] [PubMed]

- Bani, A.; Echevarria, G.; Sulçe, S.; Morel, J.L. Improving the agronomy of Alyssum murale for extensive agromining: A five-year field study. Int. J. Phytoremediat. 2015, 17, 117–127. [Google Scholar] [CrossRef] [PubMed]

- Metallary. Lithium Price. 2017. Available online: https://www.metalary.com/lithium-price (accessed on 7 November 2017).

- Van Der Ent, A.; Baker, A.J.; Reeves, R.D.; Pollard, A.J.; Schat, H. Hyperaccumulators of metal and metalloid trace elements: Facts and fiction. Plant Soil 2013, 362, 319–334. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).