Crushed and River-Origin Sands Used as Aggregates in Repair Mortars

Abstract

:1. Introduction

2. Experimental Work

3. Results

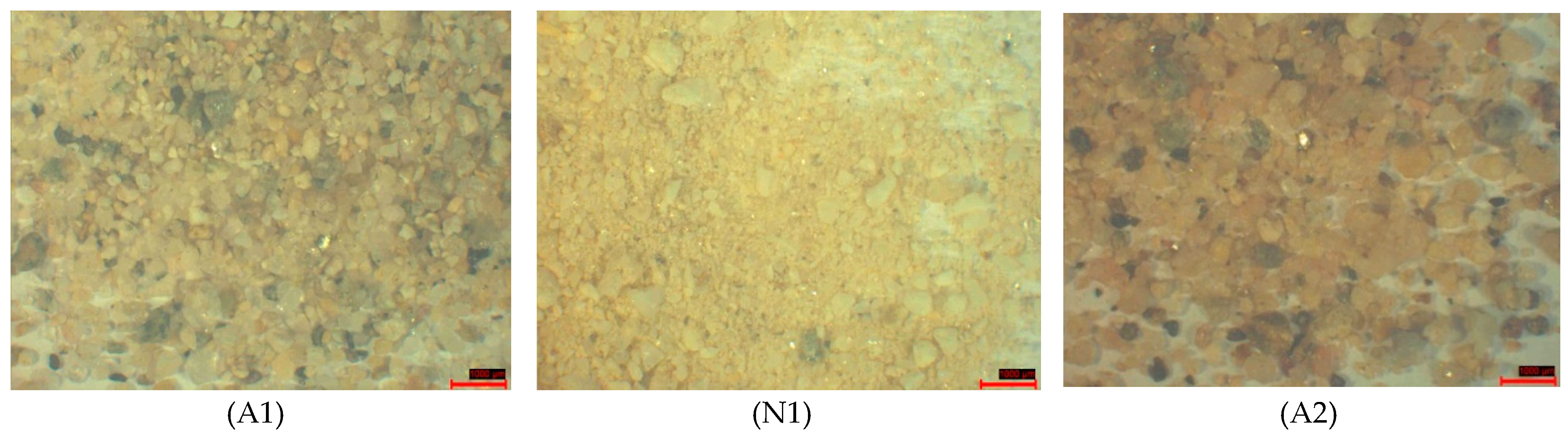

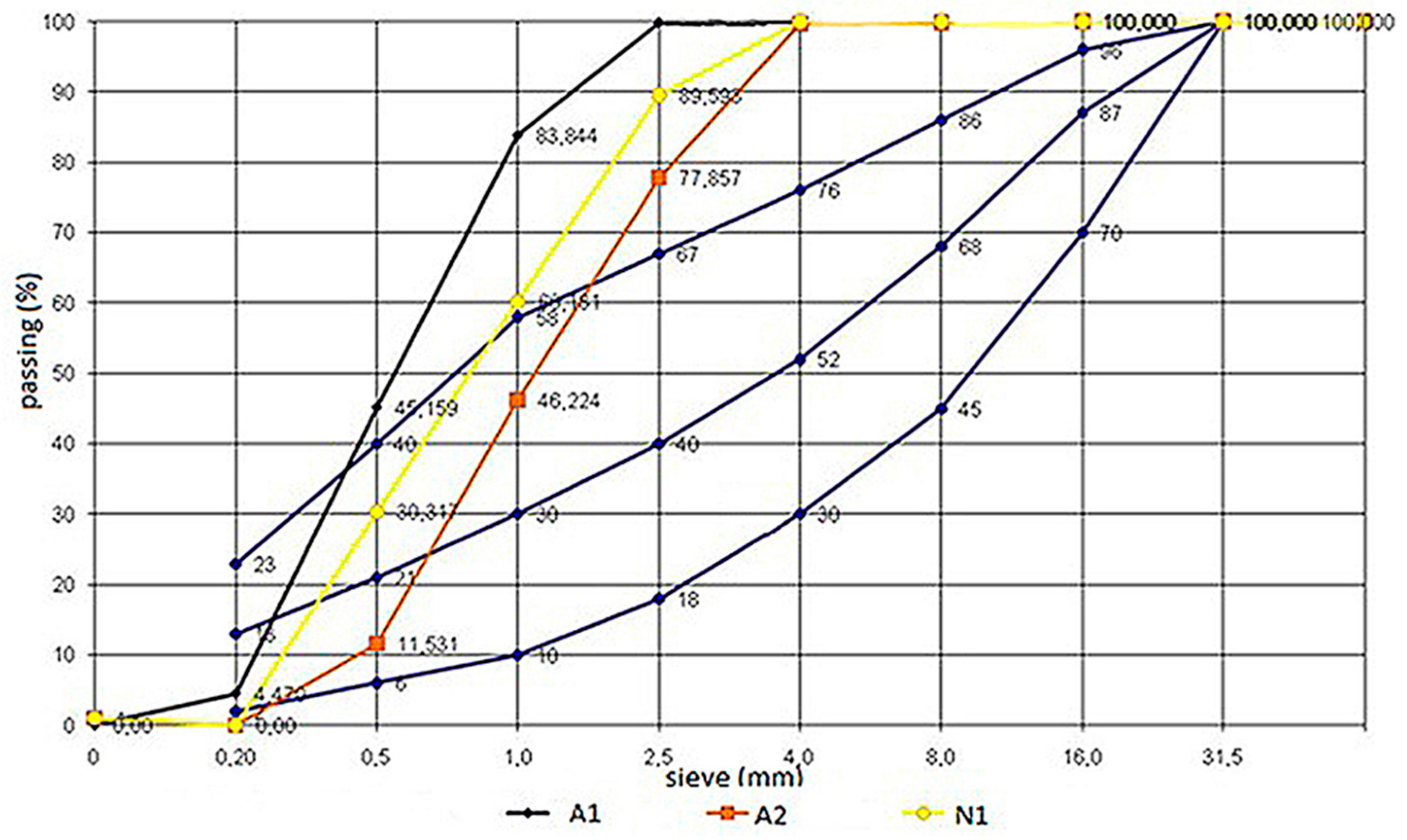

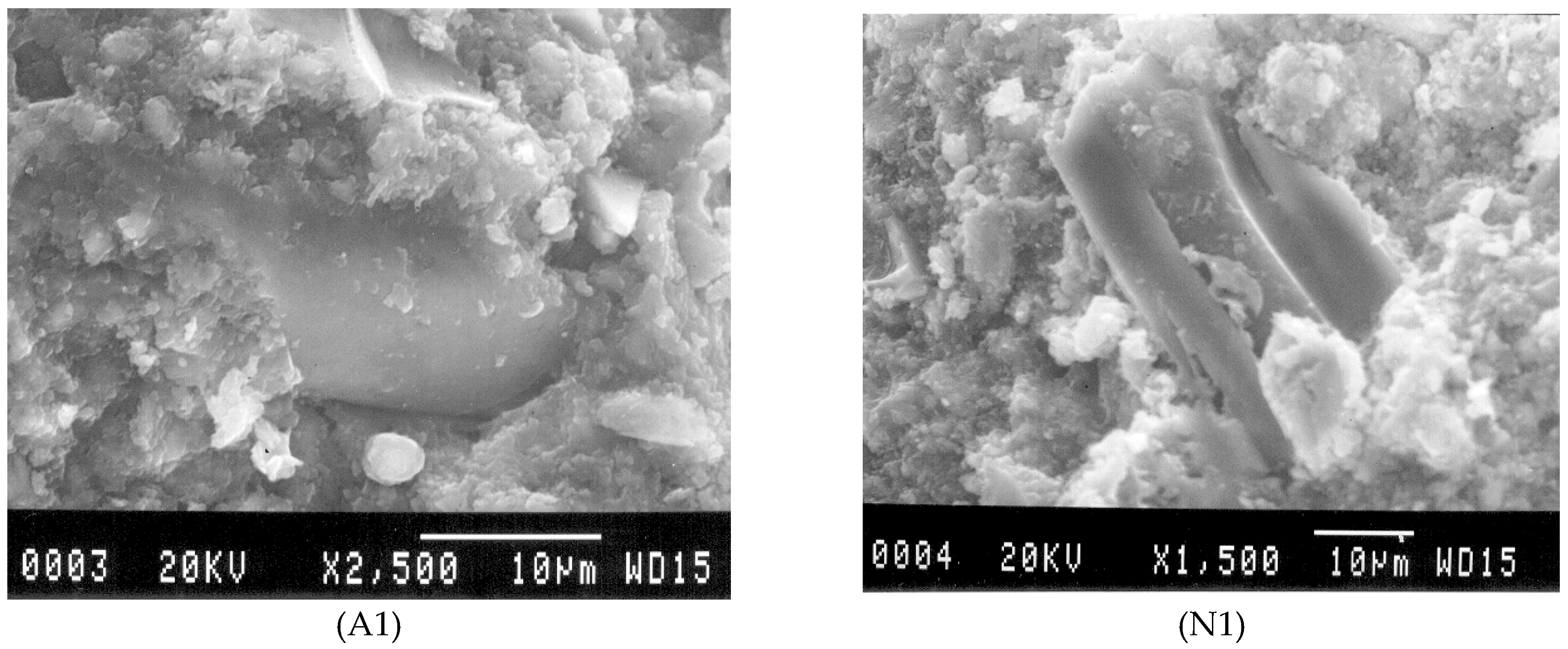

3.1. Tests on Sands

3.2. Mortar Production

3.3. Discussion

4. Conclusions

Conflicts of Interest

References

- Jackson, N.; Dhir, R.K. Concrete—aggregate. In Civil Engineering Materials, 5th ed.; Jackson, N., Dhir, R.K., Eds.; Macmillan: Basingstoke, UK, 1996; pp. 179–181. [Google Scholar]

- Stefanidou, M.; Papayianni, I. The role of aggregates on the structure and properties of lime mortars. Cem. Concr. Compos. 2005, 27, 914–919. [Google Scholar] [CrossRef]

- Tasong, W.A.; Lynsdale, C.J.; Cripps, J.C. Aggregate-cement paste interface: Influence of aggregate physical properties. Cem. Concr. Res. 1998, 28, 1453–1465. [Google Scholar] [CrossRef]

- Neville, A.M. Admixtures. In Properties of Concrete Longman, 4th ed.; Prentice Hall Pearson Education: Washington, DC, USA, 1995; pp. 244–248. [Google Scholar]

- Hobbs, D.W. Influence of aggregate restraint on the shrinkage of concrete. J. Proc. 1974, 71, 445–450. [Google Scholar]

- Kwan, A.K.; Fung, W.W. Packing density measurement and modeling of fine aggregate and mortar. Cem. Concr. Compos. 2009, 31, 349–357. [Google Scholar] [CrossRef]

- Gonçalves, J.P.; Tavares, L.M.; Toledo Filho, R.D.; Fairbairn, E.M.R.; Cunha, E.R. Comparison of natural and manufactured fine aggregates in cement mortars. Cem. Concr. Res. 2007, 37, 924–932. [Google Scholar] [CrossRef]

- Pavia, S.; Toomey, B. Influence of the aggregate quality on the physical properties of natural feebly-hydraulic lime mortars. Mater. Struct. 2008, 41, 559–569. [Google Scholar] [CrossRef]

- Mahaut, F.; Mok, S.; Chateau, X.; Roussel, N.; Ovarlez, G. Effect of coarse particle volume fraction on the yield stress and thixotropy of cementitious materials. Cem. Concr. Res. 2008, 38, 1276–1285. [Google Scholar] [CrossRef]

- Westerholm, M.; Lagerblad, B.; Forssberg, E. Rheological properties of micromortars containing fines from manufactured aggregates. Mater. Struct. 2007, 40, 615–625. [Google Scholar] [CrossRef]

- Westerholm, M.; Lagerblad, B.; Silfwerbrand, J.; Forssberg, E. Influence of fine aggregate characteristics on the rheological properties of mortars. Cem. Concr. Compos. 2008, 30, 274–282. [Google Scholar] [CrossRef]

- Mehta, P.K. Microstructure of Concrete. In Concrete, Structure, Properties and Materials; Hall, W.J., Ed.; Prentice Hall: Washington, DC, USA, 1986; pp. 44–50. [Google Scholar]

- Pettifer, K. A Petrographic Investigation of Ancient Mortars and Concretes; NOTE No. N44/86, April 1986; Building Research Establishment: Watford, UK, 1986. [Google Scholar]

- Bugini, R.; Salvatori, A.; Capannesi, G.; Sedda, A.F.; D’Agostini, C.; Giuiani, C.F. Investigation of the characteristics and properties of “cocciopesto” from the ancient roman period. In Proceedings of the 1993 RILEM Congress on Conservation of Stone and Other Materials, Paris, France, 29 June–1 July 1993; pp. 386–393.

- Baronio, G.; Binda, L.; Lombardini, N. The role of brick pebbles and dust in conglomerates based on hydrated lime and crushed bricks. Constr. Build. Mater. 1997, 11, 33–40. [Google Scholar] [CrossRef]

- Lanas, J.; Alvarez-Galindo, J.I. Masonry repair lime based mortars: Factors affecting the mechanical behavior. Cem. Concr. Res. 2003, 33, 1867–1876. [Google Scholar] [CrossRef]

- Martin, R. Les Belles Letres; Palladius Traite D’ Agriculture Livre I. Societe D’Edition 1976; Bibliothèque Nationale: Paris, France, 1976. (In French) [Google Scholar]

- Cox, M.R.; Budhu, M. A practical approach to grain shape quantification. Eng. Geol. 2008, 96, 1–16. [Google Scholar] [CrossRef]

- Hong, L.; Gu, X.; Lin, F. Influence of aggregate surface roughness on mechanical properties. Constr. Build. Mater. 2014, 65, 338–349. [Google Scholar] [CrossRef]

- De Schutter, G.; Poppe, A.-M. Quantification of the water demand of sand in mortar. Constr. Build. Mater. 2004, 18, 517–521. [Google Scholar] [CrossRef]

| - | Natural Absorption (%) | App. Specific Gravity (g/cm3) | S.E. | Sphericity |

|---|---|---|---|---|

| Α1 | 0.70 | 2.36 | 98.0 | 0.825 |

| Α2 | 1.46 | 2.35 | 90.5 | 0.791 |

| Ν1 | 1.09 | 2.34 | 75.0 | 0.723 |

| - | Cl− | NO− | SO42− |

|---|---|---|---|

| Α1 | <0.01 | - | <0.01 |

| Α2 | <0.01 | - | 0.04 |

| Ν1 | <0.01 | - | 0.01 |

| - | Flexure (MPa) | Compressive (MPa) | Εdyn (ΜPa) | Porosity (%) | Workability (cm) |

|---|---|---|---|---|---|

| Α1 | 0.05 | 0.57 | 407.04 | 36.02 | 15.7 |

| Α2 | 0.05 | 0.56 | 387.8 | 35.95 | 15.5 |

| Ν1 | 0.42 | 0.94 | 1586.4 | 35.02 | 14.8 |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stefanidou, M. Crushed and River-Origin Sands Used as Aggregates in Repair Mortars. Geosciences 2016, 6, 23. https://doi.org/10.3390/geosciences6020023

Stefanidou M. Crushed and River-Origin Sands Used as Aggregates in Repair Mortars. Geosciences. 2016; 6(2):23. https://doi.org/10.3390/geosciences6020023

Chicago/Turabian StyleStefanidou, Maria. 2016. "Crushed and River-Origin Sands Used as Aggregates in Repair Mortars" Geosciences 6, no. 2: 23. https://doi.org/10.3390/geosciences6020023

APA StyleStefanidou, M. (2016). Crushed and River-Origin Sands Used as Aggregates in Repair Mortars. Geosciences, 6(2), 23. https://doi.org/10.3390/geosciences6020023