3.1. Transient Moisture Variation and Drainage Mechanisms in Soil Columns with Non-Woven and Wicking Geotextiles

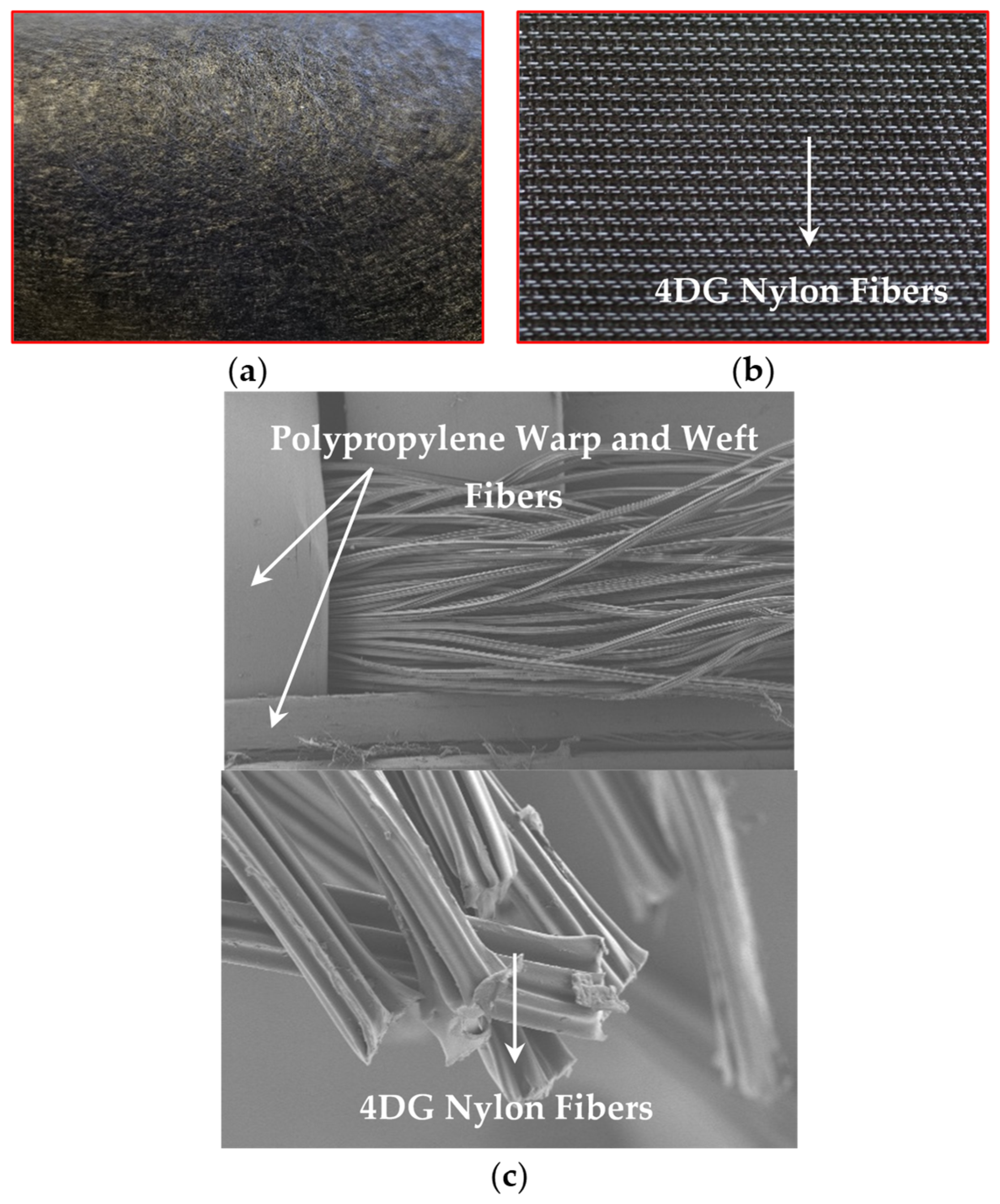

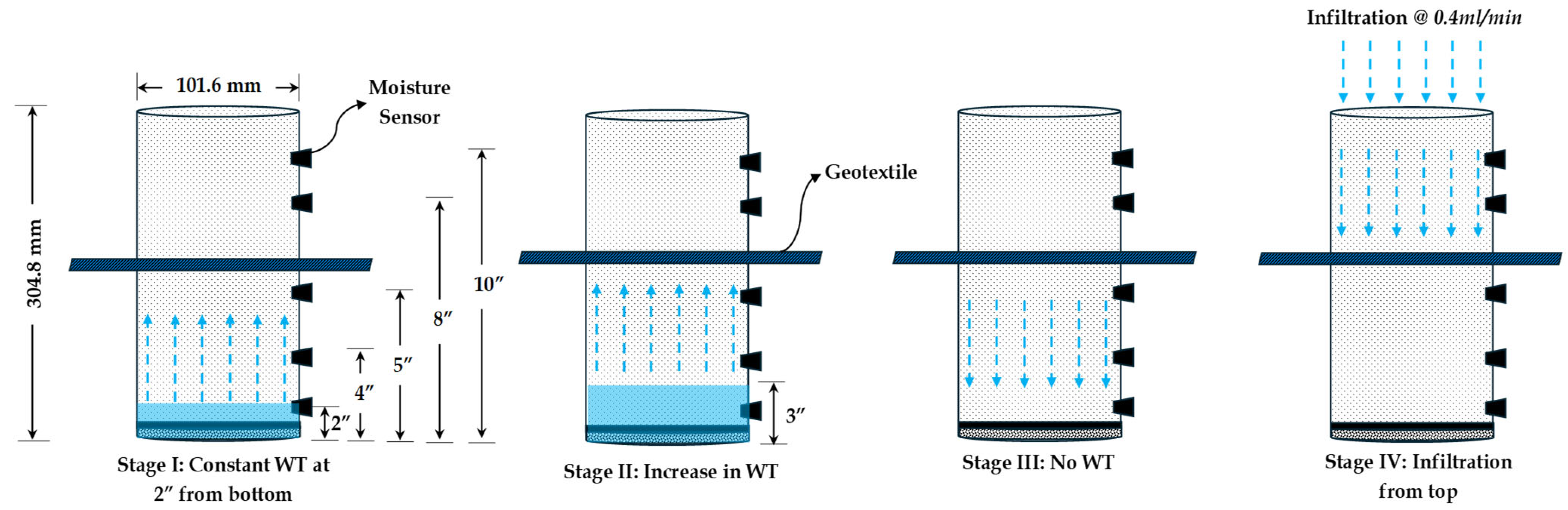

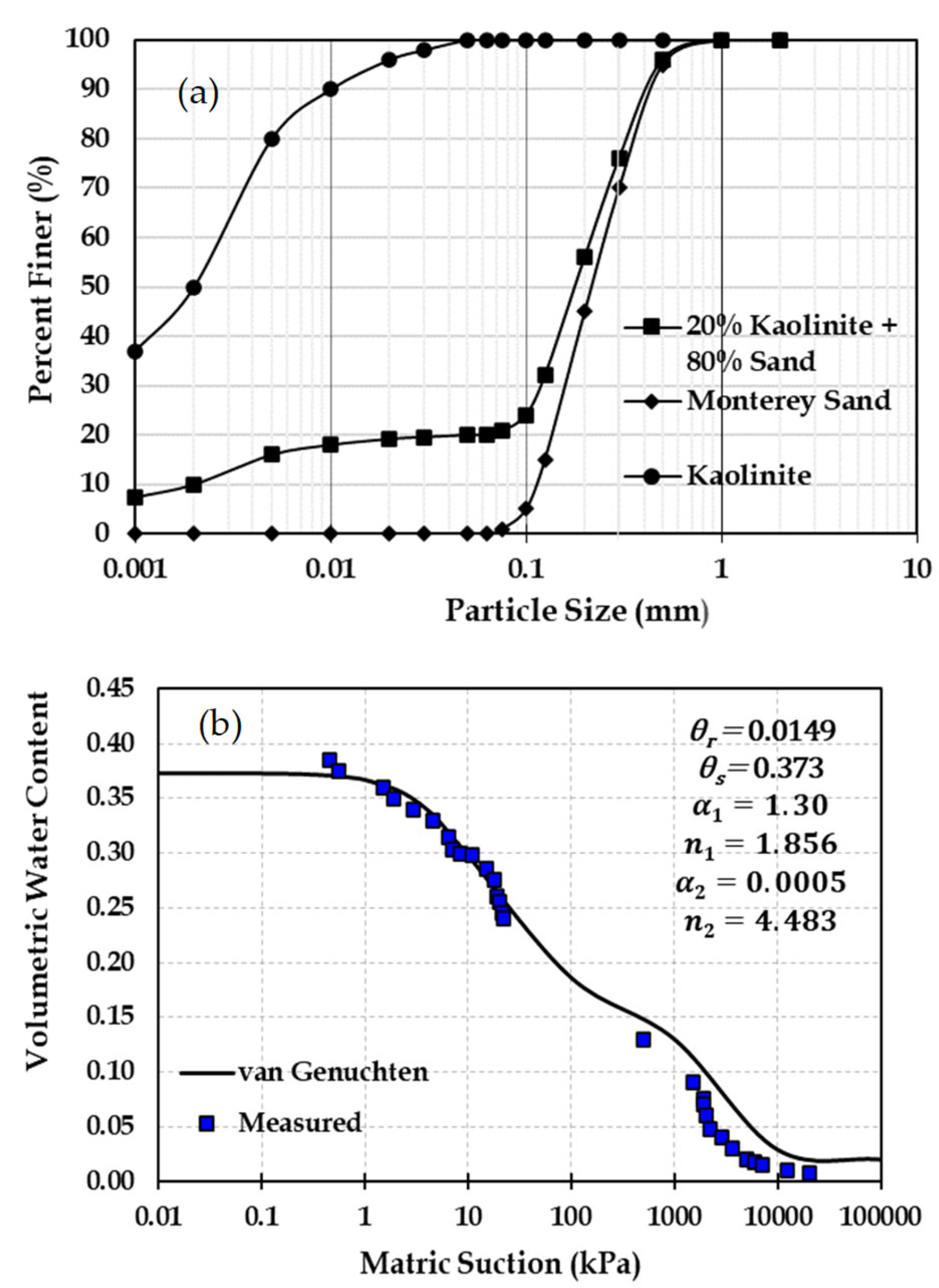

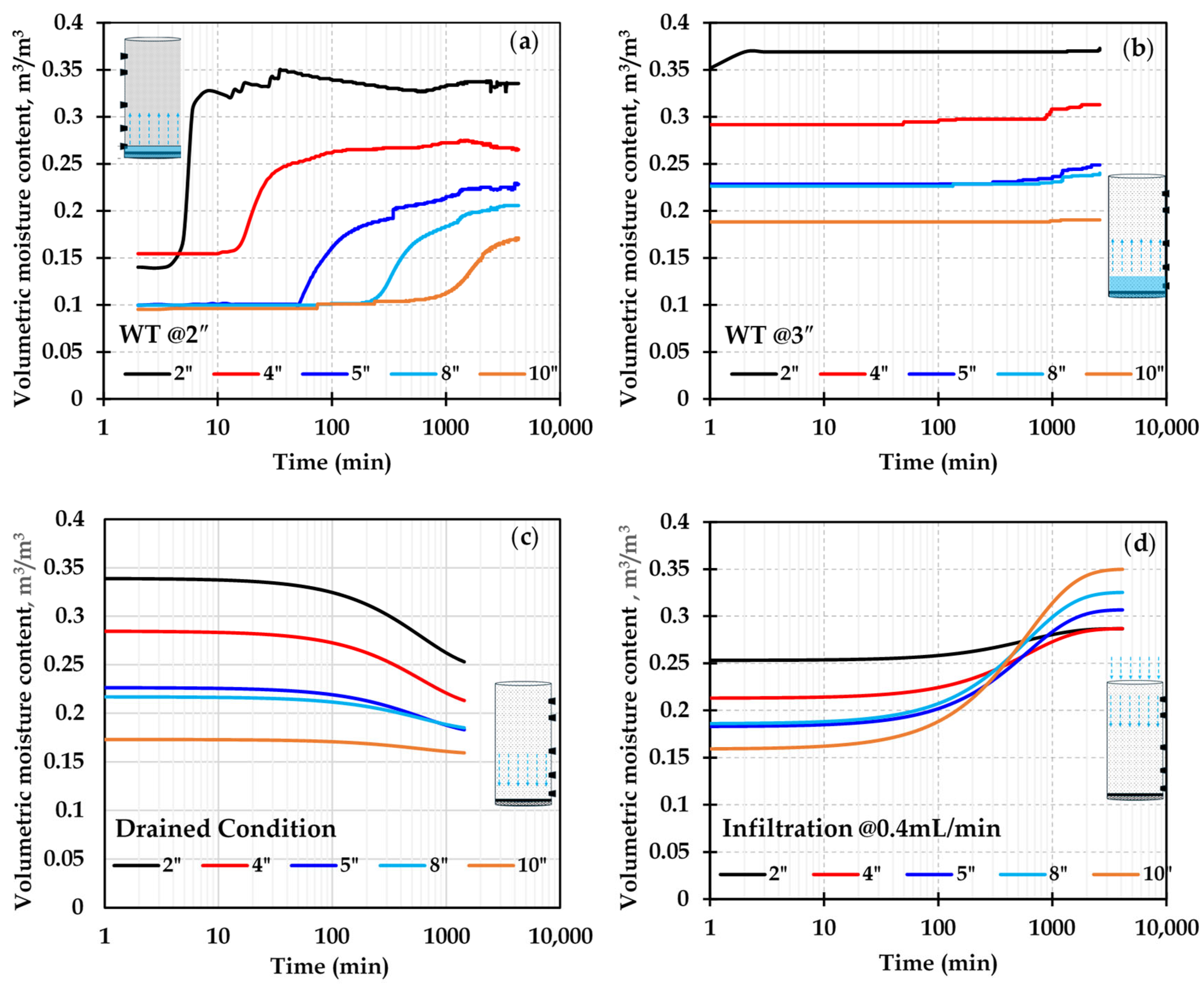

The variation of volumetric moisture content with time for the control column, the column with the non-woven geotextile, and the column with the ELD geotextile is presented in

Figure 4,

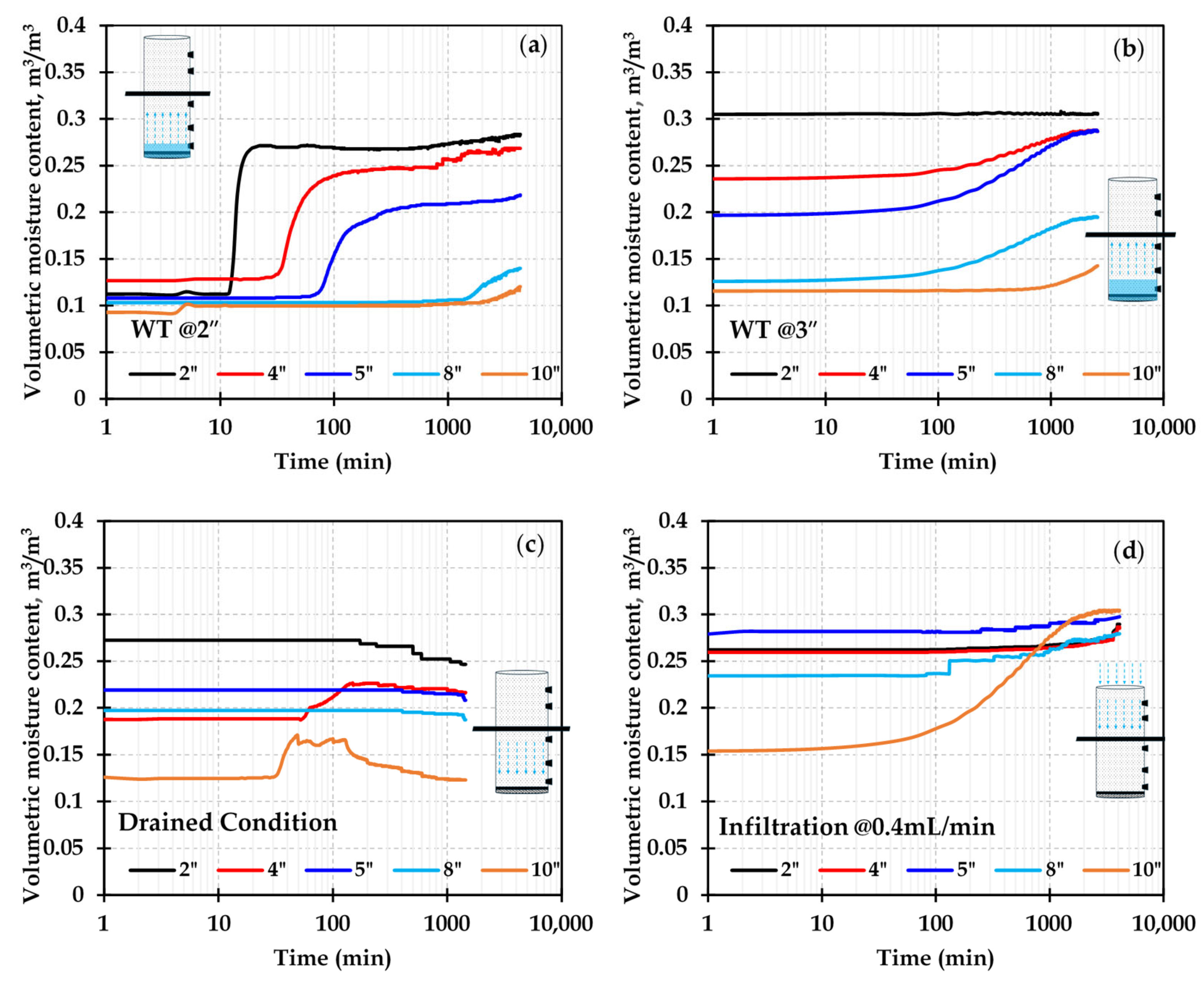

Figure 5 and

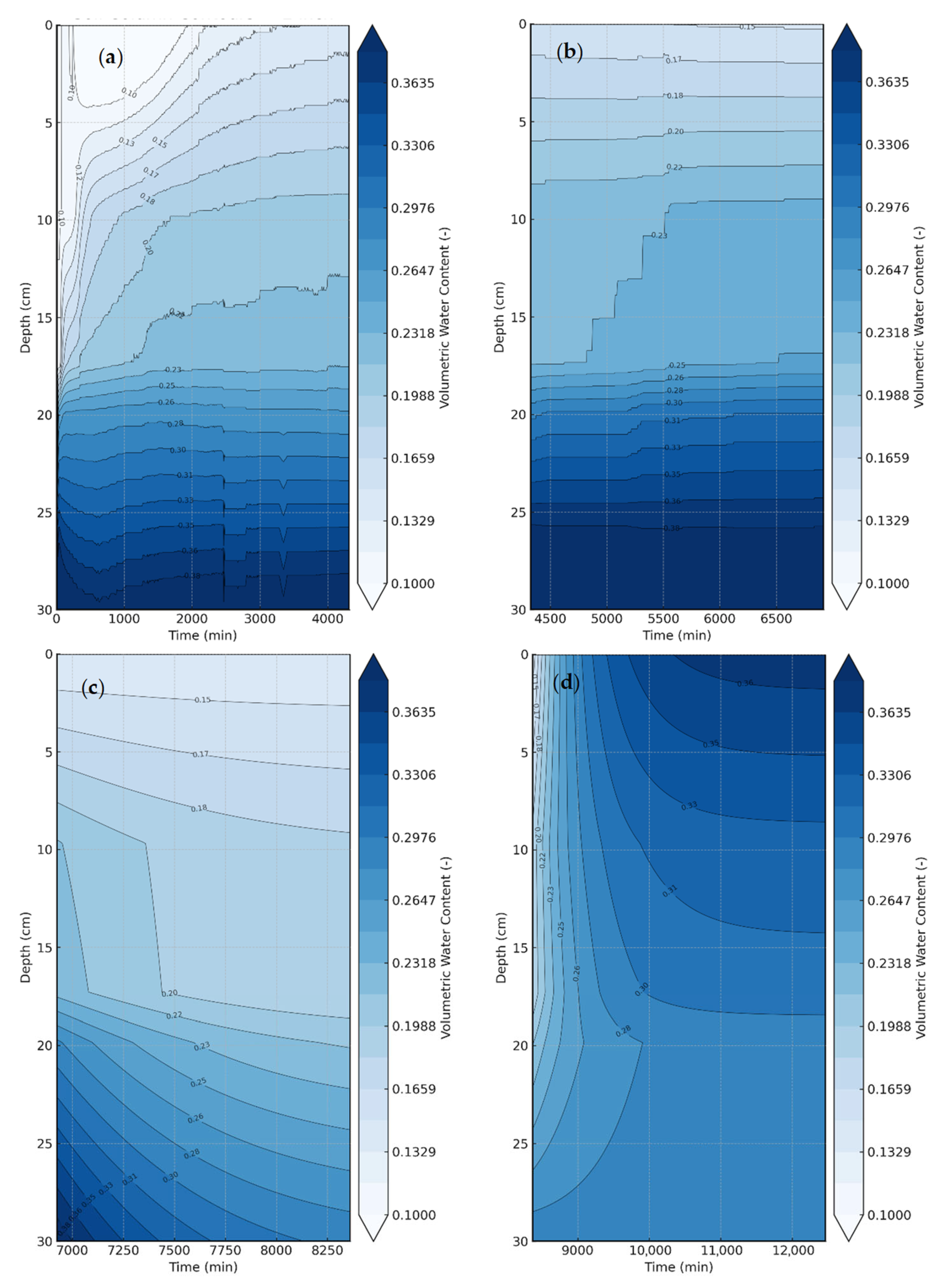

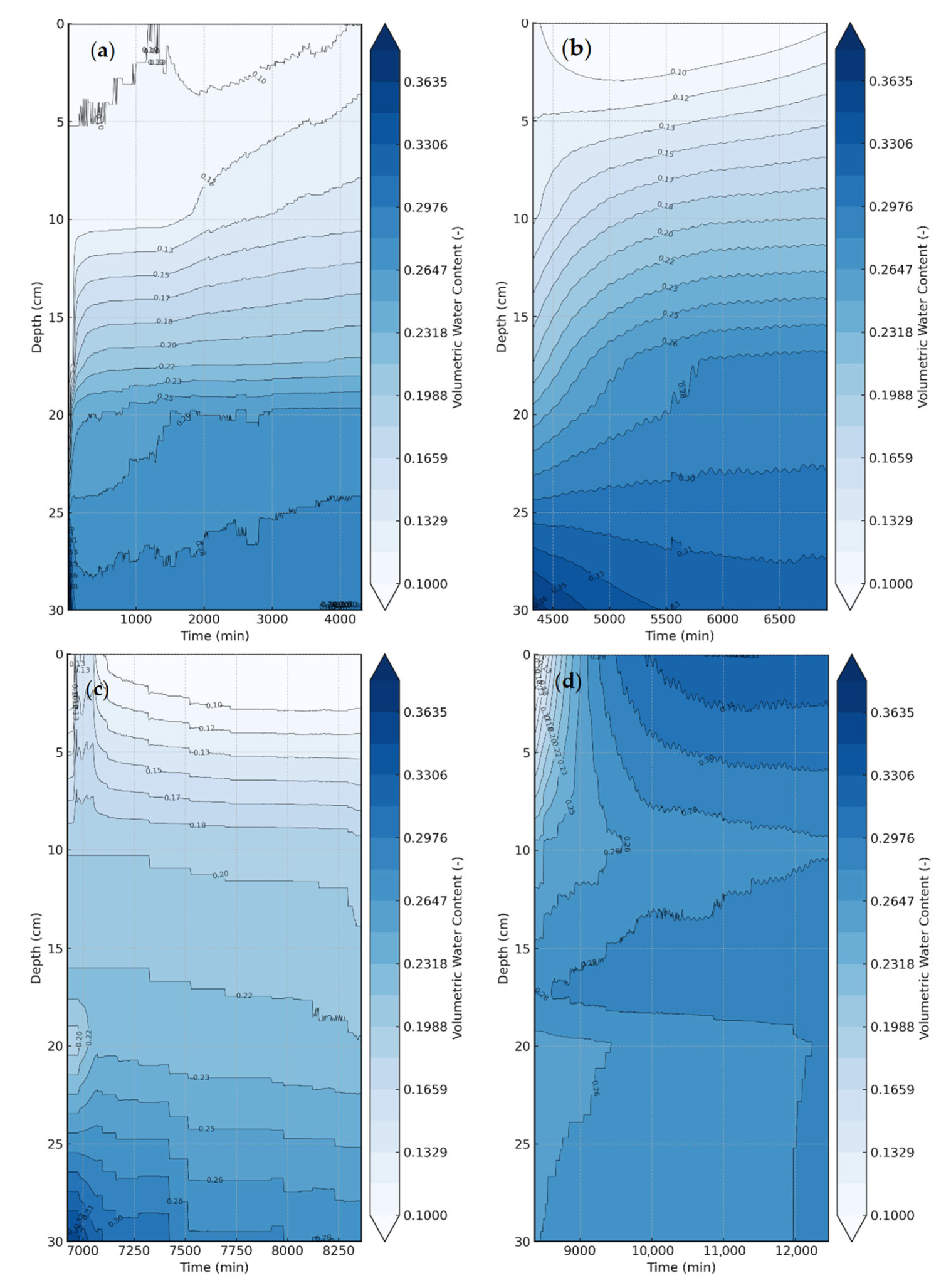

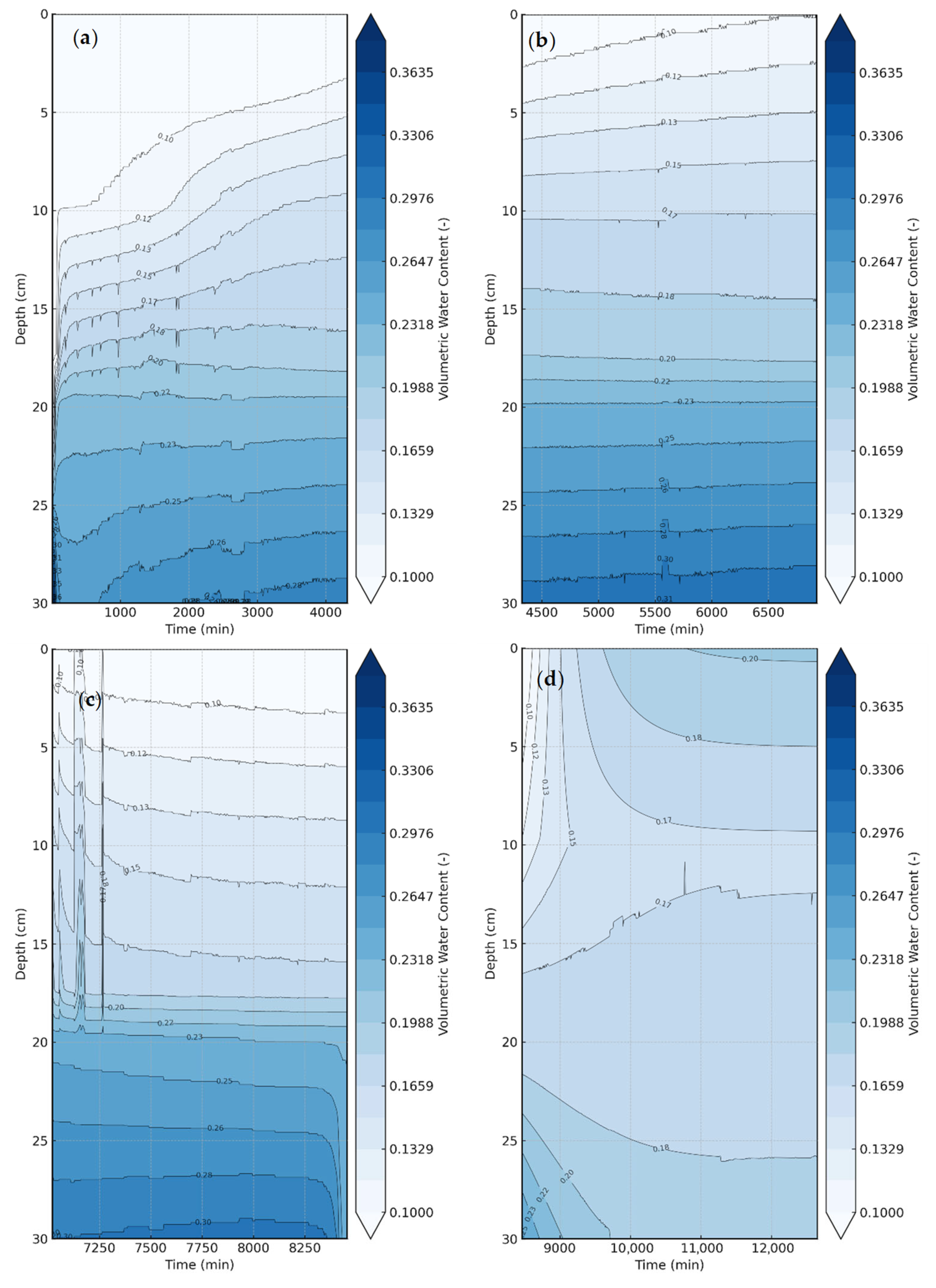

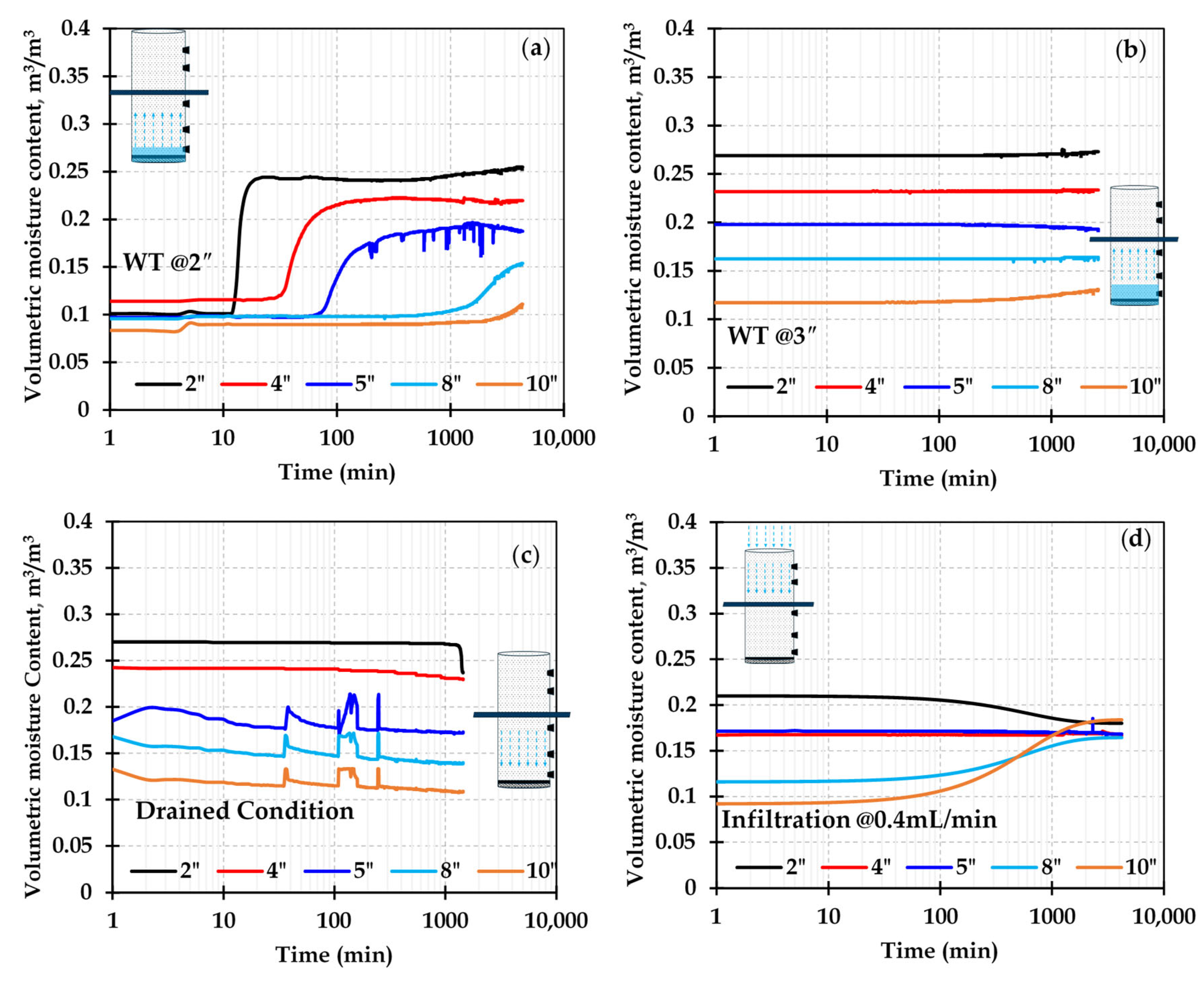

Figure 6. Furthermore, the contour plots of volumetric moisture distribution were generated from the measured time-series data using interpolated sensor readings throughout each hydraulic stage. The volumetric water content values obtained at different depths and discrete time intervals were processed using bilinear interpolation to estimate intermediate values across the entire 30 cm column domain. The resulting matrix was then contoured using a uniform color scale to represent the spatial and temporal evolution of moisture within the column. The upper and lower boundary conditions corresponded to the saturated and the dry surface, respectively. Each contour band thus represents a line of equal volumetric water content (θ), enabling visualization of the advancing and receding wetting fronts with time. The corresponding contour plots of volumetric moisture distribution with time and depth are shown in

Figure 7,

Figure 8 and

Figure 9. Together, these datasets provide a complete characterization of the transient hydraulic behavior of the soil–geotextile systems under sequential changes in boundary conditions. The time-series plots describe the dynamic evolution of volumetric moisture content at discrete depths, whereas the contour plots capture the spatial redistribution of wetting and drying fronts across the column. The combined interpretation of these data offers a mechanistic understanding of how geotextiles influence capillary continuity, water storage, and drainage efficiency within unsaturated soil profiles. These responses are representative of field subgrade environments, where seasonal fluctuations in groundwater table, infiltration, and evaporation cycles govern the hydraulic stability and long-term performance of pavement systems.

During the initial equilibrium stage with the water table at 2″, the control column exhibited a stable capillary rise profile consistent with the suction range typically observed in lightly compacted fine-grained subgrades under shallow groundwater conditions (

Figure 4a). The volumetric moisture content varied gradually from approximately 0.35–0.36 near the base to 0.16 near the surface, producing a smooth moisture gradient indicative of continuous liquid-phase connectivity. The corresponding contours (

Figure 7a) showed evenly spaced color bands, confirming uniform capillary rise and the absence of hydraulic impedance. Such a profile replicates field conditions following extended dry periods, where capillary rise from a shallow water table gradually restores subgrade moisture to equilibrium levels. In contrast, the column with the non-woven geotextile displayed a clear discontinuity in the moisture profile near the geotextile interface (≈15 cm depth) (

Figure 5a). The volumetric water content below the interface remained 25% higher than that above, indicating localized water accumulation. The contour plots showed a concentration of high-moisture immediately below the geotextile, confirming the onset of a capillary barrier effect (

Figure 8a). This was attributed to the relatively large pore openings of Mirafi N140 that prevented upward continuity of water films, creating a localized saturation zone. In the ELD geotextile column, however, the moisture distribution was comparatively uniform (

Figure 6a). Both the temporal and contour data showed no abrupt changes across the interface, reflecting effective capillary connectivity maintained by the hydrophilic 4DG fibers. This response demonstrates the lateral redistribution within the wicking fabric that minimized moisture accumulation. This behavior is analogous to the action of capillary-active layers in pavement systems, which regulate suction and control excessive moisture accumulation at the subgrade–subbase interface.

When the water table was raised by 1″, differences in the response among the three configurations became more pronounced. In the control column, the wetting front advanced upward by roughly 25 mm, and equilibrium was re-established within about 1500 min (

Figure 4b). The smooth upward progression of contours reflected unimpeded vertical flow, similar to transient water-table rises observed in natural subgrades following intense rainfall (

Figure 7b). The soil column with non-woven geotextile, however, exhibited a rapid increase in moisture content below the interface while maintaining near-constant values above it (

Figure 5b). This produced a horizontal band of high-moisture content visible in the contours, representing a localized moisture storage beneath the geotextile (

Figure 8b). The water storage increased by approximately 6 mm, corresponding to delayed breakthrough across the interface. Such behavior highlights field conditions in pavement sections where non-woven separator geotextiles temporarily trap water during rapid groundwater rise, causing elevated pore pressures and localized reductions in shear strength. The ELD geotextile, in contrast, showed a smaller net increase in storage and reached steady state within 1500 min, which accounts for three times faster than the non-woven system (

Figure 6b). The contours advanced upward smoothly without distortion, confirming uniform redistribution of water facilitated by capillary wicking and in-plane drainage (

Figure 9b). This lateral redistribution mechanism is similar to that occurring in geosynthetic drainage layers that quickly equilibrate pore-water pressures after rainfall events, thereby reducing differential softening in pavement subgrades.

During the drainage stage, the reservoir was removed to simulate a falling groundwater table, the control column exhibited a uniform and progressive decrease in volumetric moisture content, corresponding to gravity-driven flow typical of drying subgrades under recession conditions (

Figure 4c). In the non-woven column, however, drainage was impeded at the interface due to the difference in hydraulic conductivity between the soil and non-woven geotextile, causing water retention above the geotextile and a gradual rate of moisture reduction (

Figure 5c). The contours revealed persistent higher moisture zones above the geotextile even after prolonged drainage, illustrating poor desaturation and low drainage efficiency (

Figure 8c). Such delayed recovery replicates field conditions where trapped moisture persists at separator interfaces, preventing the re-establishment of suction and stiffness after wetting. In contrast, the ELD geotextile displayed a rapid and near-uniform decrease in moisture throughout the column (

Figure 6c). The contours descended evenly with minimal curvature, demonstrating simultaneous vertical and lateral drainage through the geotextile plane. This accelerated desaturation parallels the field performance of wicking geotextiles that enable faster drying of the pavement base–subgrade system following rainfall or groundwater recession, maintaining the subgrade within an optimal suction range and reducing the duration of low-stiffness conditions.

Under infiltration conditions, when water was introduced from the top at 0.4 mL/min, all columns exhibited a general increase in moisture, but the rate and distribution varied considerably. The control column displayed a gradual increase in moisture at all depths, and the contours showed evenly advancing wetting fronts, consistent with uniform infiltration through a homogeneous soil (

Figure 4d and

Figure 7d). The non-woven column, however, showed a rapid rise in moisture content near the surface, followed by delayed response at lower sensors, with pronounced contour gradients above the geotextile (

Figure 5d). This behavior indicates temporary ponding and slower percolation through the interface. The storage increases and steep gradients above the interface simulate the field response of pavement sections experiencing rainfall infiltration, where non-woven separators restrict downward drainage, leading to short-term moisture accumulation and subgrade weakening. The ELD geotextile displayed a markedly different behavior compared to the non-woven geotextile. Moisture increase was nearly synchronous across all depths, and the contours maintained parallel spacing, signifying uniform infiltration and rapid redistribution (

Figure 6d and

Figure 9d). A significant effect of ELD geotextiles was noticed around 2 inches of the soil-ELD geotextile interface. The total storage increase was limited, and as much of the infiltrating water was drained laterally along the wicking fibers. This efficient redistribution is similar to the capillary drainage mechanism observed in field pavements with horizontally wicking fabrics, where infiltrated water is quickly diverted toward the pavement edge drains, reducing ponding and moisture-induced degradation.

The combined interpretation of the time-series and contour data highlights the mechanistic distinctions among the three systems. The control column maintained hydraulic continuity dictated solely by the soil–water retention properties of the soil. The non-woven geotextile created a hydraulic discontinuity that restricted vertical flow, leading to excess water storage during wetting and residual moisture during drying. Such conditions would result in transient stiffness loss and increased rutting potential in pavement subgrades due to delayed drainage and localized saturation. The ELD geotextile, on the other hand, maintained hydraulic continuity and enhanced drainage by integrating capillary wicking with in-plane flow, resulting in balanced vertical and lateral flow. Quantitatively, the wicking geotextile reduced total moisture storage by approximately 25–30% and improved drainage efficiency by over 40% relative to the non-woven system. Spatially, the high moisture zone (θ > 0.25) contracted from 14 cm in the non-woven column to 8 cm in the ELD column, while the time to reach quasi-steady conditions decreased from about 7000 min to 2500 min. These improvements correspond to field benefits such as faster drainage recovery, lower pore pressures, and reduced seasonal moisture variation within the subgrade.

The laboratory findings correspond closely with the in situ pavement behavior. Conventional non-woven geotextiles can trap moisture and delay drainage under cyclic wetting, leading to temporary loss of stiffness. In contrast, ELD geotextiles facilitate capillary-driven lateral drainage, rapidly equilibrating porewater pressures and preventing localized water storage. This mechanism maintains uniform moisture and enhances pavement durability under variable hydrological conditions

Figure 7.

Moisture contour plots with time for the control column along different stages: (a) water table at 2″ from base, (b) water table at 3″ from base, (c) drained condition, (d) infiltration at the rate of 0.4 mL/min.

Figure 7.

Moisture contour plots with time for the control column along different stages: (a) water table at 2″ from base, (b) water table at 3″ from base, (c) drained condition, (d) infiltration at the rate of 0.4 mL/min.

Figure 8.

Moisture contour plots with time for the column with a non-woven textile along different stages: (a) water table at 2″ from base, (b) water table at 3″ from base, (c) drained condition, (d) infiltration at the rate of 0.4 mL/min.

Figure 8.

Moisture contour plots with time for the column with a non-woven textile along different stages: (a) water table at 2″ from base, (b) water table at 3″ from base, (c) drained condition, (d) infiltration at the rate of 0.4 mL/min.

Figure 9.

Moisture contour plots with time for the column with an ELD geotextile along different stages: (a) water table at 2″ from base, (b) water table at 3″ from base, (c) drained condition, (d) infiltration at the rate of 0.4 mL/min.

Figure 9.

Moisture contour plots with time for the column with an ELD geotextile along different stages: (a) water table at 2″ from base, (b) water table at 3″ from base, (c) drained condition, (d) infiltration at the rate of 0.4 mL/min.

3.2. Evolution of Moisture and Suction Profiles with Time

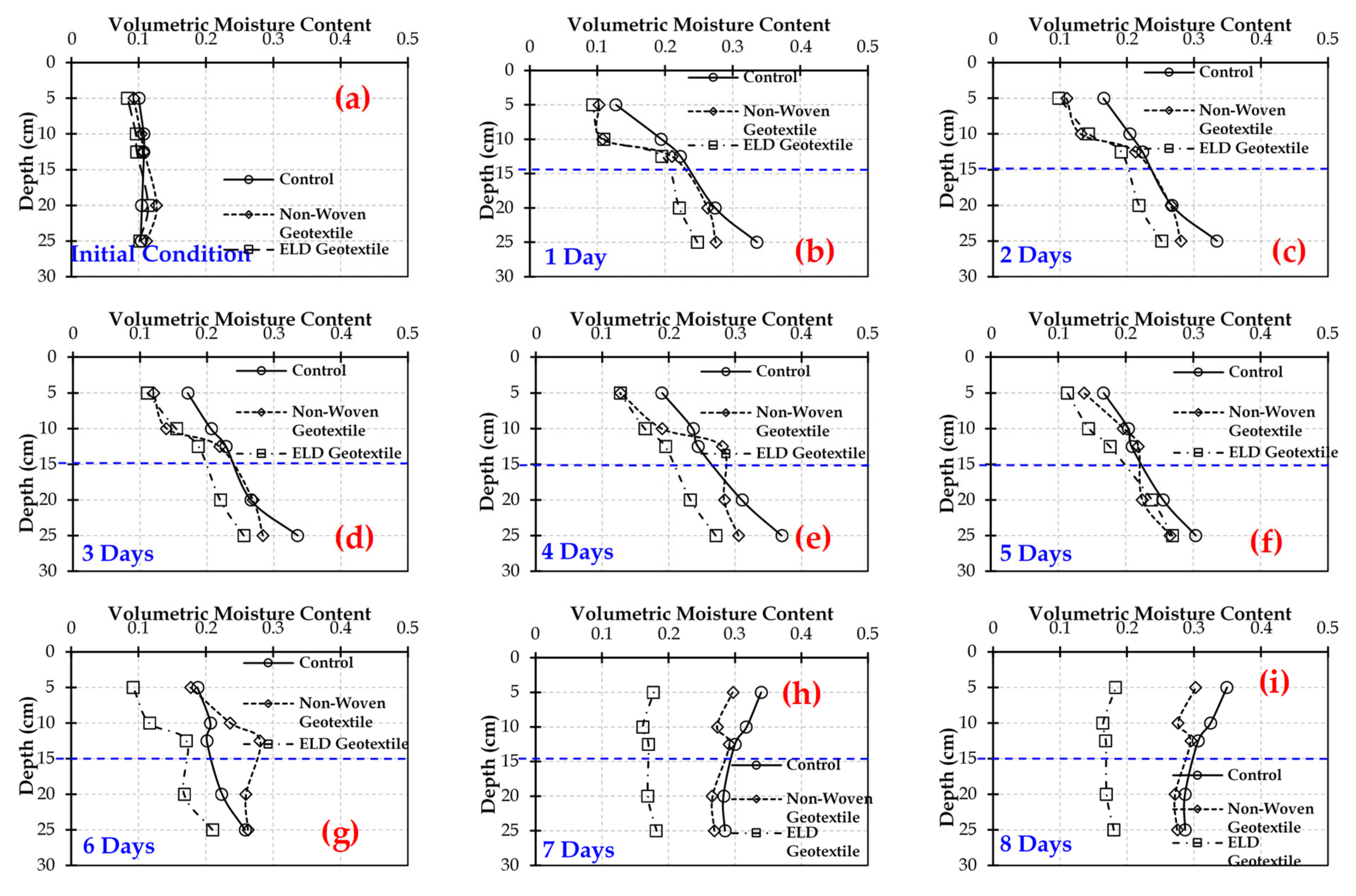

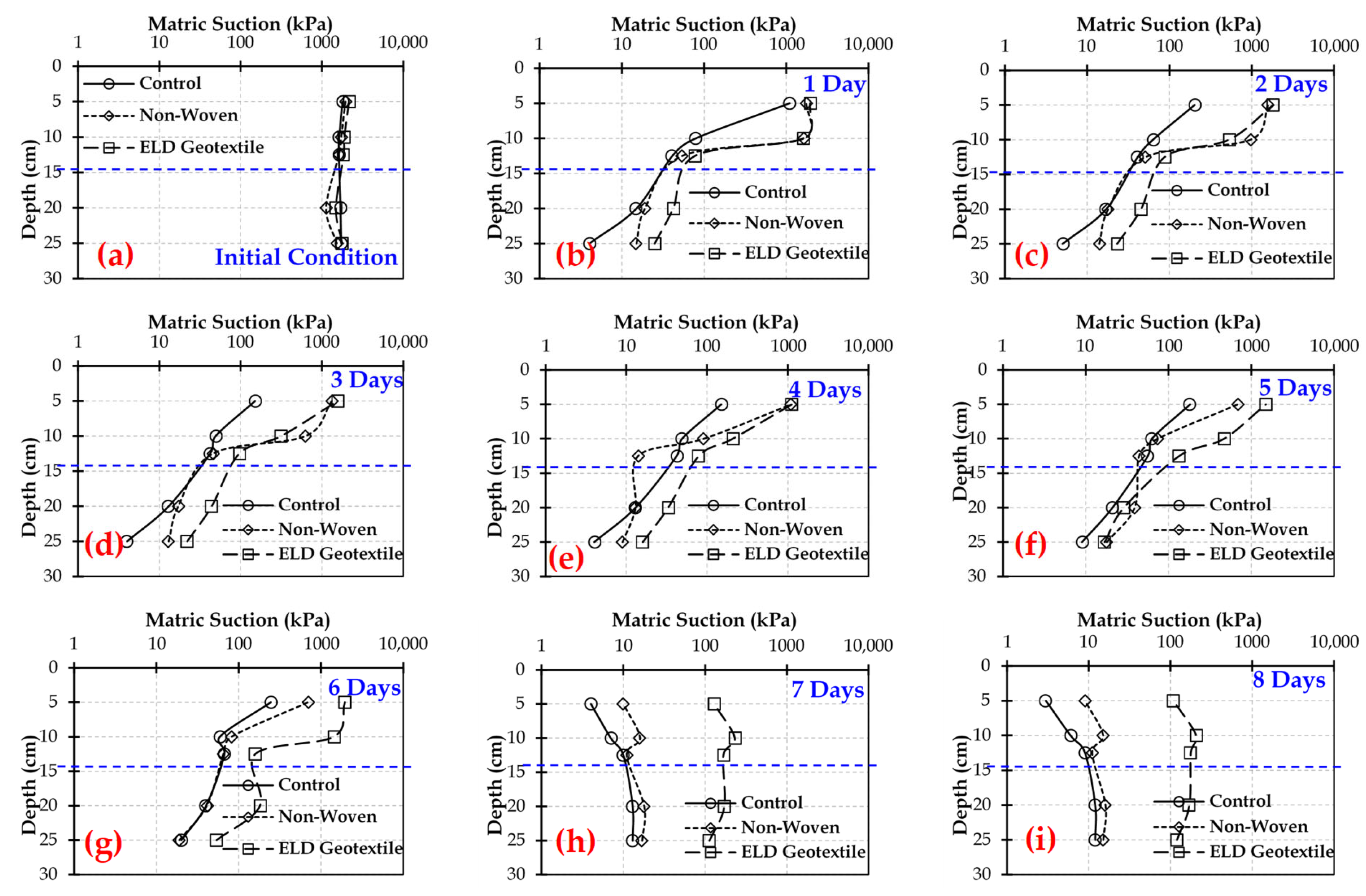

The daily variation of volumetric moisture content and matric suction with depth for the control column, the non-woven geotextile column, and the ELD geotextile column is presented in

Figure 10 and

Figure 11. These plots provide a day-by-day assessment of how the soil moisture and suction fields evolved throughout the nine-day testing sequence, comprehending the initial equilibrium, water table rise, drainage, and infiltration stages. The profiles facilitate understanding the redistribution mechanisms occurring within each soil–geotextile system, highlighting the influence of capillary continuity, interfacial flow impedance, and lateral drainage under changing hydraulic boundaries.

At the initial condition, all columns displayed similar moisture and suction distributions, with volumetric water contents ranging from approximately 0.10 near the surface to 0.35 near the base, corresponding to matric suctions of 1800–2500 kPa at the top and near-zero values at the lower boundary (

Figure 10a and

Figure 11a). Over the first three days, corresponding to the equilibrium and early rise in water table stages, the control column exhibited a uniform upward progression of the wetting front (

Figure 10a–e). The increase in volumetric water content with elevation was gradual and proportional, while the suction profiles showed a consistent reduction in suction near the base as the phreatic surface advanced upward (

Figure 11a–e). This trend demonstrates continuous hydraulic connectivity, similar to subgrades where shallow groundwater rises or infiltration from adjacent shoulders promotes uniform wetting of the lower layers.

Figure 10.

Variation in moisture profiles along depth for different soil columns.

Figure 10.

Variation in moisture profiles along depth for different soil columns.

Figure 11.

Variation in suction profiles along depth for different soil columns.

Figure 11.

Variation in suction profiles along depth for different soil columns.

In contrast, the non-woven geotextile column exhibited an early deviation from this behavior. Moisture profiles during Days 1–5 show a distinct inflection near the geotextile level (≈15 cm depth), where water content below the interface increased sharply to about 0.28–0.32, while the layer immediately above remained comparatively dry. The corresponding suction profiles show an abrupt jump at the same location, with suction above the geotextile remaining as high as 800–1000 kPa even after several days. This combination of high suction and low water content above the geotextile indicates the formation of a hydraulic break, resulting from the large pore openings and hydrophobic polymer surfaces of the non-woven fibers. Because the effective radius of the inter fiber pores is relatively large and the contact angle exceeds 90°, the capillary pressure required for upward flow could not be sustained, preventing continuity of the liquid phase. The ELD geotextile column displayed a markedly different evolution during the same period. The suction profiles confirmed a smoother gradient across depth, indicating maintained hydraulic connectivity. This is attributed to the hydrophilic 4DG nylon fibers within the Mirafi H2Ri, which sustain capillary films along their grooved surfaces and promote lateral transmission of water even under low suction gradients. The observed uniformity demonstrates that the wicking geotextile successfully redistributed the upward capillary flux laterally, preventing the formation of localized moisture zones. The 4DG nylon filaments, with deep longitudinal grooves, generate high capillary suction due to their extremely small effective radius and wetting surface (θ < 90°). These grooves rapidly absorb moisture films from adjacent soil pores, maintaining continuous menisci even under low saturation. As the water table was raised by 1″, the capillary fringe advanced upward, increasing the moisture content and lowering the matric suction in the surrounding soil. The increased saturation reduced soil suction to about 750 kPa. As the matric suction recovered quickly after the rise (See

Figure 10e), the effective stress in the subgrade remained stable, preventing strength loss typically observed in hydrophobic or non-wicking systems.

By day 6, during the drainage phase, distinct differences in hydraulic response became evident. The control column exhibited a moderate downward shift in the moisture profile, with moisture decreasing by approximately 0.03–0.05 at mid depths and the suction increasing gradually with height as gravitational drainage progressed. The non-woven geotextile column, however, retained high moisture content above the interface (θ ≈ 0.20–0.22) with negligible reduction over time, and the suction profiles showed a persistent discontinuity across the interface. The suction below the geotextile increased sharply, indicating air entry and partial desaturation, while the upper zone retained moisture pertaining to boundary effect zone, such conditions are analogous to hydraulic barriers persisting above separator geotextiles in the field during drying cycles. The ELD column, conversely, showed a rapid and uniform decrease in moisture content across depths. The suction gradient remained smooth and continuous, reflecting accelerated drainage through lateral flow paths. The rate of suction recovery in the ELD column was nearly twice that of the control and more than three times that of the non-woven column, confirming its superior drainage efficiency and suction restoration capability. This smooth suction recovery reduced the potential for differential settlement and maintained the soil’s structural integrity by preventing rapid collapse of suction and pore pressure imbalances.

During Days 7–8, corresponding to the infiltration stage, the control column showed a steady increase in moisture across depths, indicating typical downward percolation through the soil matrix. The non-woven column again exhibited moisture accumulation in the upper zone (θ > 0.35) with delayed response below the geotextile, while the suction profiles showed a decrease in suction near the surface but minimal change beneath the interface. This behavior demonstrates that the non-woven geotextile restricts downward infiltration, functioning temporarily as a hydraulic impedance layer. In contrast, the ELD geotextile column displayed a uniform moisture profile across all depths and nearly uniform suction reduction, suggesting that infiltrating water was efficiently transmitted laterally along the wicking fibers. Instead of accumulating above the fabric, water was redistributed along the geotextile toward the edges. Because the fabric boundaries were exposed to the atmosphere, a humidity gradient developed between the moist interior and the drier external air, promoting vapor diffusion and gradual drying at the open edges.

The combined evolution of moisture and suction profiles across the testing period reveals clear mechanistic distinctions among the three configurations. The control column maintained consistent capillary continuity, with storage and drainage governed solely by the soil’s water retention characteristics. The non-woven geotextile introduced a hydraulic discontinuity, leading to moisture retention above the interface and delayed drainage representing field conditions of transient softening and suction loss often recorded in subgrades incorporating non-woven separators under variable moisture conditions. The ELD geotextile conversely acted as a capillary active drainage layer that redistributed water more efficiently through its hydrophilic fiber network, thereby maintaining near continuous suction gradients and limiting moisture storage. Quantitatively, by the end of the test (Day 9), the mean volumetric moisture content in the upper 10 cm of the non-woven column was approximately 22% higher than the control and 36% higher than the ELD system, while the corresponding mean matric suction in the ELD column was about 1.8 times greater than that in the non-woven column, demonstrating its faster drainage and improved suction recovery.

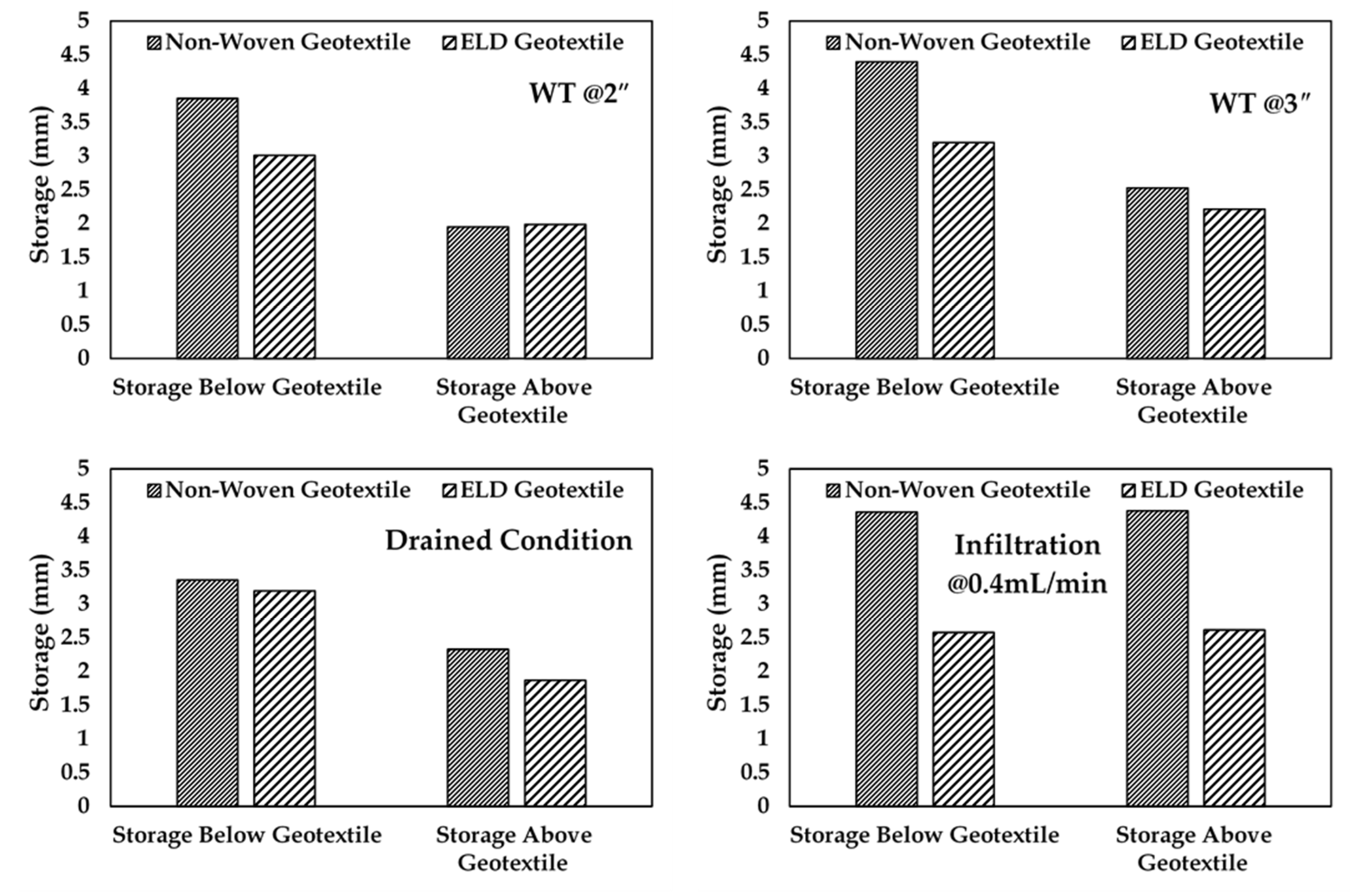

3.3. Water Storage Behavior of Soil–Geotextile Systems

The variation in water storage above and below the geotextile interface for the non-woven and ELD geotextile columns under different hydraulic boundary conditions is presented in

Figure 12. The results provide a quantitative basis for evaluating how each geotextile influences moisture accumulation, drainage, and redistribution across the soil–geotextile interface. The calculated storage represents the integrated change in volumetric water content over the depth intervals above and below the geotextile during each stage, serving as an indicator of both transient retention and drainage efficiency.

The moisture storage within the soil columns was determined following the formulation proposed by [

21], which represents the volumetric integration of water content change over the depth of the profile. For each test stage, the variation in volumetric water content measured by sensors at discrete depths was used to compute the incremental change in storage within each soil layer. The soil column was discretized by interpolating volumetric water content between adjacent sensor depths, and each interpolated interval was assigned a corresponding layer thickness based on the midpoint spacing. The total change in water storage between two-time steps, t

1 and t

2, was calculated as

where,

is the total change in water storage within the soil column (mm of water),

and

is volumetric water content (m

3/m

3) of the i-th layer at times t

1 and t

2, respectively,

is the thickness of the i-th soil layer or the vertical interval between adjacent sensors (mm), and

is the number of soil layers or measurement intervals considered above and below the geotextile interface.

Figure 12.

Comparison of moisture storage above and below non-woven and ELD geotextiles at different stages.

Figure 12.

Comparison of moisture storage above and below non-woven and ELD geotextiles at different stages.

The observed water storage patterns clearly illustrate the contrasting hydraulic coupling mechanisms between the soil and each geotextile type. The quantified storage fluctuated between about 4–5 mm below and 2–3 mm above the fabric, forming a cyclic build-up and release pattern typical of a capillary barrier. In the non-woven system, the hydrophobic fibers and large inter fiber pores created a high entry head and a sharp reduction in capillary conductivity at the soil–geotextile interface. This differentiation caused temporary moisture accumulation below the fabric until the local suction decreased enough to overcome the entry pressure, after which intermittent flow resumed. Such periodic flow produced cyclic variations in storage, reflecting a nonlinear water balance response with pronounced hysteresis during wetting and drying. The interface exhibited a cyclic moisture storage behavior, taking and releasing water as the hydraulic barrier developed and dissipated. Under field conditions, this behavior can lead localized saturation zones that reduces matric suction by 50–70%, and transient subgrade softening or loss of resilient modulus. In contrast, the ELD geotextile maintained nearly constant total storage throughout all stages (≈ 3 mm below and 2–3 mm above). exhibited strong hydraulic continuity and rapid equilibration across the interface. The 4DG fibers retained liquid films within their grooves even under negative pore pressures, ensuring continuous capillary contact with the surrounding soil and preventing air entry. As a result, the fabric acted as an extension of the unsaturated flow domain rather than a barrier, transmitting pressure and moisture changes almost instantaneously along its plane. Consequently, storage variations at the interface remained minimal (ΔS ≈ constant) despite changes in boundary conditions.

Furthermore, the response time was different in both the systems. The non-woven geotextile showed delayed equilibration after boundary shifts, with storage peaks lagging several hours behind imposed conditions, indicative of low interfacial diffusivity. Conversely, the ELD system responded within minutes, signifying higher flow and nearly instantaneous suction propagation. Hydromechanically, the ELD layer functioned as a capillary damping medium that moderated pore-pressure fluctuations and stabilized suction in the adjacent soil. This behavior is especially beneficial under cyclic infiltration or fluctuating groundwater levels, preventing repeated suction collapse and the associated reductions in small strain stiffness. The persistence of liquid films within the 4DG fiber grooves and inter yarn spaces preserves capillary continuity across contrasting materials, similar to the bridging behavior of menisci between soil particles during desaturation. Thus, the soil–geotextile composite acts as a single hydraulic continuum with smooth suction transitions rather than discrete zones separated by a hydraulic break. This integrated response reduces transient storage, limits hysteresis in the soil–water characteristic curve, and facilitates faster suction recovery after infiltration. These combined mechanisms emphasize superior ability of the ELD geotextile to stabilize moisture conditions and preserve the mechanical performance of pavement subgrades under variable climate and loading cycles.