Abstract

Air temperature in the Northern Hemisphere has been progressively warming in the recent decades, and the ground temperatures have increased correspondingly. The air temperature increasing due to the climate change induces degradation of permafrost and frost heaving activation. The frost heaving forces cause unevenly distributed damaging displacement of foundations and thus poses problems to the development of Arctic regions. Frost-heave uplift forces can be reduced by protecting piles with an OSPT Reline (or Reline) polymer heat-shrinkable jacket. The interaction of heaving soil with a pile covered with the Reline jacket is modeled in laboratory to estimate the uplift force and the related shear strength of frozen soil along the soil-pile adfreeze surface at temperatures from −6 to −1 °C. The data are obtained for silty sand and silty clay soils and mortar (1:5 cement-sand mixture). The experiments show that frost-heave uplift forces on Reline-protected piles are 52% to 85% lower than on uncovered steel piles (steel grade 09G2S—analog to European steel grade S355JR), depending on soil type and temperature.

1. Introduction

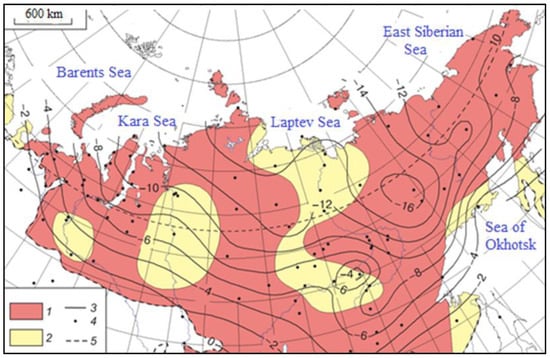

Climate warming has become obvious in the recent sixty or seventy years [1]. Since the 1990s, this effect has shown up in high climatic variability, with numerous anomalies. The magnitude of climate anomalies is commonly estimated by comparing air temperatures for a decade with the long-term climate norm, at three grades (Δtair): small (<0.7 °C), moderate (0.7 °C to 1.0 °C), and large (>1 °C) [2]. Mean annual air temperature variations for northern Russia over 2000–2010 are presented in a map (Figure 1) relative to the climate norm, which varies from −2 to −16 °C in the permafrost zone (contour lines in Figure 1). The map shows only moderate and large anomalies. The Russian permafrost regions mainly fall within the domain of large warming (>1 °C), while moderate warming (0.7 °C to 1.0 °C) is restricted to local areas in the European north, Central, and West and Central (Laptev Sea coast) Siberia, as well as in Primorye [3].

Figure 1.

Mean annual air temperature variations in northern Russia for 2000–2010. 1, 2 = large (1) and moderate (2) warming relative to climate norm (Δtair), >1 °C and 0.7 °C to 1.0 °C, respectively; 3 = climate norm contour lines; 4 = weather stations; 5 = southern limits of permafrost, after [3] Malkova et al. 2010.

The consequences of warming have been largely reported in the literature. Geocryological monitoring at reference stations shows that the air temperature increase since the late 1960s has affected the permafrost [1,3,4,5,6,7,8,9,10,11,12,13,14].

Ground warming was revealed, for instance, by temperature logging on an extended network of boreholes in northwestern Canada, in the Yukon basin [7]. On the global scale, permafrost temperature became 0.29 °C ± 0.12 °C higher on average, from 2007 to 2016. The warming trend in continuous permafrost is attributed to increasing air temperature in the Northern Hemisphere, whereas that in discontinuous permafrost is mainly due to greater snow depth at relatively stable air temperatures [11]. Permafrost warming has been aggravated by man-caused impacts on air temperatures well evident since the 1970s [15]. Anthropogenic activities, also, directly affect permafrost degradation. The results of special research in Mohe County (China) show that the permafrost table is much lower in the urban area because of the urban heat island, surface disturbance of construction, space heating in winter, etc. The permafrost table is 2.63–3.70 m on the edge of the urban area; the mean annual ground temperature is −1.0 to −1.33 °C. In the urban area, the maximum depth of permafrost has exceeded 15 m. The permafrost in the undisturbed area is 1.65–2.0 m and ground temperature is much lower at −2.75 °C [16].

The degrading permafrost loses its bearing capacity, which leads to damaging displacements of buildings and engineering structures [17,18]. Field observations from 1995 to 2007 revealed progressive active layer thickening [19], which continues to increase at 5 cm per year [20]. The mean annual temperature of the active layer was predicted to keep increasing in the future [21]. As the thaw depth increases, the surface area of the contact between the freezing ground and the foundations becomes larger, and the related processes in susceptible soils become ever more hazardous for the infrastructure. The frost heaving of freezing soils is one of such dangerous processes, which can lead to significant deformations of buildings and constructions. Currently, this process is widely studied by various specialists, and one of its directions is focused on the pile foundation stability to the effects of frost heaving forces.

Formation of ice lenses in the ground, or frost heaving, produces uplift forces that can act in tangential (shear) or normal planes, i.e., along the lateral surface or orthogonally to the foundation, respectively [22]. Pile foundations are commonly subject to shear forces that can reach considerable magnitudes and cause major damage to the infrastructure (Figure 2). These forces are caused by soil-pile adfreeze. In 2013–2014, frost heaving caused accidents to two new tanks of liquid natural gas, 20,000 m3 each, in the Zapolariye–Port Pur Pe pipeline system, as 10–15 cm cracks appeared in the cap of piles along the whole perimeter. The ground was stabilized by thermosyphons to −15 °C, till depths of 13–16 m, but the design took no account of the frost-heave uplift forces [23]. Another accident was reported in the same year [24] from the Urengoi area, where a pipeline segment rose 1.5 m above the ground for one year. In general, up to 1 billion USD is spent yearly for maintenance of pipeline structures and mitigation of damage associated with permafrost degradation [25]. One more example of deformation, other than in pipelines, comes from the Norilsk area where about 250 buildings and structures have been deformed for the recent decade out of which 40 houses had to be demolished [24,26].

Figure 2.

Piles affected by frost-heave uplift (gas field Zpolyarnoye, Western Siberia, Russia).

The frost heave hazard has been currently prevented by placing piles to greater or by layer-by-layer ground freezing [27]. The other method for frost jacking prevention is based on using specially designed piles: screw piles [28] and belled piles [29] of different configurations. An alternative approach is to coat the pile surface with various protective compounds (epoxy or polyurethane resin, zinc, etc.), which can reduce frost-heave uplift forces. One of the first anti-heave coatings for steel piles was developed in Russia in the 70th of the XX century during the construction of oil pipelines. Two of these include “BAM-4” and organic-silicone enamel “KO-1112” which reduce the uplift forces up to 50–60% and 25–40%, respectively. Nowadays these coatings are outdated and low-tech [30,31]. Most modern coatings are applied to piles in the factory conditions as enamel, and they have good adhesion to the material and a long service life. Despite the number of coatings used in practice, there are no published data about their efficiency for frost jacking reduction. An advantageous solution that differs from the existing coating methods is to protect piles with a heat-shrinkable ready-made jacket OSPT Reline designed at the Ural Plant for Polymer Technologies “MAYAK” (Ozyorsk, Chelyabinsk region, Russia). This coating is radically different from enamels and can be applied directly in field conditions before the pile is driven. Thus, the main objective of this experimental study was efficiency evaluation of the Reline jacket application for frost jacking reduction. The follows research objectives were formulated:

- -

- Experimental determination of the adfreeze strength for main types of soils (sand, silty clay, and mortar) with a pile coated by a Reline jacket at temperatures from −6 to −1 °C;

- -

- Determination of the adfreeze strength for the same soils and uncoated steel piles at the similar temperature conditions;

- -

- Analysis of the obtained results.

2. Materials and Methods

2.1. Model of Pile Foundation

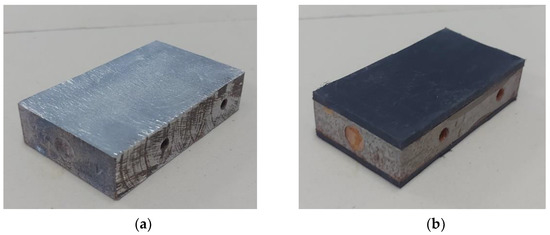

Piles were modeled by plates made of 09G2S steel (analog to European steel grade S355JR), which is used for piles in industry. The samples (Figure 3) were cut in the form of square parallelepipeds 80 × 50 × 20 (length, height, and width, respectively, in mm) and trimmed to surface roughness similar to that of hot-rolled pipe material. Roughness, which is an important parameter in the estimation of shear strength along the adfreeze surface and the related frost-heave uplift forces [32], was measured with a TIME TR 200 portable surface roughness tester. The measurements were applied to the working surfaces on both sides of the steel plates, at 5 points on each surface. The samples had an arithmetic mean roughness of Ra = 4.25 to 6.47 μm (4.61 μm on average) and a roughness height of Rz = 32.11 to 3951 μm (34.68 μm on average).

Figure 3.

Uncovered steel pile model (a) and steel pile model with a Reline jacket (b).

2.2. Reline Jacket

Reline is a heat-shrinkable jacket made of a complexly-modified polyolefin polymer composite, with an adhesive lining on the inner surface, which creates a solid and durable protection of piles.

Tests for estimating shear strength along the adfreeze surface of soil with Reline-covered piles were performed using specially designed jackets, 90 mm in diameter, in accordance with the size of the steel piles, and 2.1 mm thick on average (measured by a DeFelskoPositector 6000 coating thickness logger). The jackets were factory mounted on the steel plates, following a special technology. Thus, 18 samples of covered steel plates simulating piles were fabricated.

The steel plates in Reline jackets had an arithmetic mean roughness of Ra = 0.14 to 0.79 μm (0.32 μm on average) and a roughness height of Rz = 0.83 to 6.23 μm (1.95 μm on average).

2.3. Natural Soil Samples

Overdriven piles embedded into drilled holes of a smaller diameter adfreeze to the soil in a direct contact [31]. The soil samples were selected among soil types which are widespread in the Russian Arctic regions. They were silty sand, known to be frost-susceptible [22], and soft high-plasticity silty clay collected, respectively, from the Zapolyariye–Pur-Pe pipeline area and the East Messoyakha oil-gas-condensate field. The investigated samples had a moisture content corresponding to 80% of the water saturation, with parameters and particle size distribution as in Table 1 and Table 2, respectively.

Table 1.

Main soils parameters.

Table 2.

Particle size distribution of investigated soils.

2.4. Mortar (Cement-Sand Mixture)

Unlike the overdriven piles, bored precast piles are embedded into drilled holes of a larger diameter, and the space between the pile and the natural ground is backfilled with mortar (cement−sand mixture in a ratio 1:5). Thus, the precast piles contact the mortar rather than soil. Mortar was prepared by mixing carefully pre-dried silty sand with cement 500. The required amounts of sand–cement mixture were wetted successively. The mixture was compacted by rodding using a steel rod.

The plasticity of mortar was checked by cone tests, according to the cone penetration index (arithmetic mean of three measurements). The cone penetrated into the mortar to depths from 11.5 to 12.7 cm at moisture content from 19.5 to 23.5% and density from 1.92 to 2.03 g/cm3.

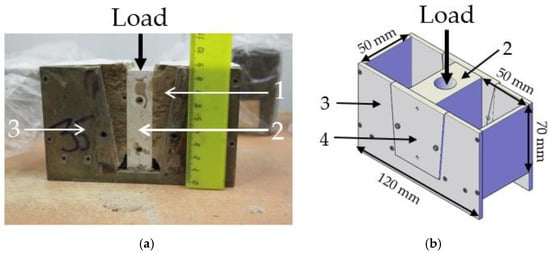

2.5. Samples Preparation

The shearing tests were performed on a system designed by V. Ermakov, which allows estimating adfreeze strength [31], and is especially convenient for coated piles. The design permits coating the tested model and increasing its size correspondingly without changing other units of the system. Furthermore, the larger surface area of the sample (70 cm2 instead of the 40 cm2 standard size) ensures better accuracy of adfreeze estimates in the region of low values. The system consists of a steel casing and a covered or uncovered pile model (Figure 4).

Figure 4.

Photo (a) and sketch (b) of Ermakov’s testing system. 1 = soil; 2 = pile model; 3 = box wall; 4 = pile’s holder.

Air-dried natural soil samples were saturated with water till specified moisture contents, and the obtained paste was compacted layer-by-layer in a sleeve. Density and moisture content were monitored while compacting and after the tests, respectively. The prepared samples were frozen to −15 °C, and then exposed to the specified run temperatures.

Mortar was poured into sleeves with the fixed pile samples. In natural conditions, backfilling warms up the soil around the mortar, and the temperature of the latter remains positive for a while afterwards. Therefore, pore water in the mortar remains unfrozen and is spent for its further hydration. Mortar is known [33,34] to hold positive temperature for at least one day (up to two or three days, according to different estimates). For this reason, the samples were kept at positive temperatures of 20 to 25 °C for 24 h, then frozen to −15 to −20 °C for mortar-pile adfreezing and then exposed to the specified run temperatures.

2.6. Shearing Tests

In Russia, methods for estimating uplift forces associated with frost heaving in soils were developed long ago [22,31,35]. The forces of this kind are equivalent to shear strength and arise when the pile walls adfreeze to the ambient soil or mortar. The frost-heave uplift forces mainly consist of adfreeze force (70−80%) and friction (20−30%) [22]. Thus, the tests focused on estimating adfreezing by a well-known method.

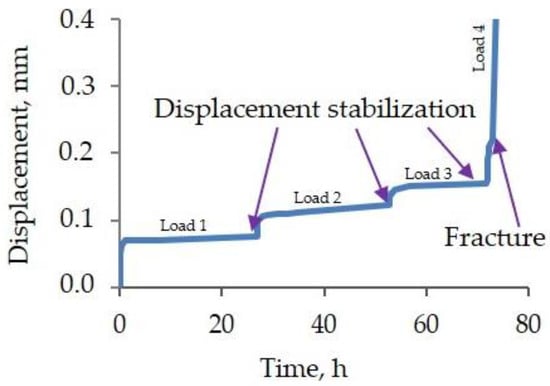

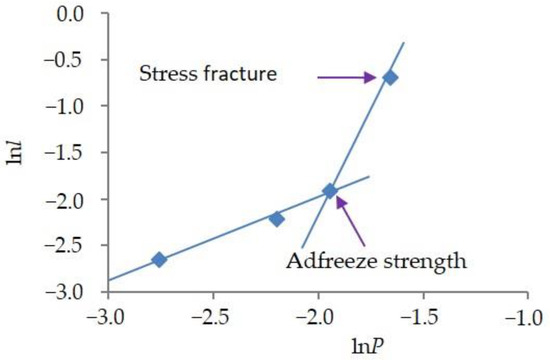

The testing was performed by incremental stepwise loading to determine shear strength along the adfreezing surface (Raf). The magnitude of load at the first and subsequent steps was chosen to provide at least four loading steps before fracture. Each step lasted till displacement stabilization, which was assumed to correspond to displacement increment of 0.01 mm for 12 h. Each following step began after complete stabilization of the previous step. The tests stopped when displacement progressed at an increasing rate, i.e., till fracture at the soil-pile contact. The shear strength along the adfreeze surface was determined as the highest shear stress at which displacement stabilized. The data were processed using creep curves (ε, mm, vs. t, h) (Figure 5) and log-log stress–displacement curves (shear stress vs. total displacement at the time of stabilization, lnτ vs. lnε) (Figure 6).

Figure 5.

Creep test under incremental stepwise load.

Figure 6.

Adfreeze strength in the loading force (P) vs. strain (l) plot. Axles are in the «ln» scale. Dotes are experimental data, lines are approximations.

3. Results

The efficiency of coating was tested at negative temperatures of −1, −2, and −6 °C corresponding to the temperature range of natural soils (current values to temperatures predicted with regard to climate warming). The tests provided estimates of shear strength along the adfreeze surface for covered (with Reline) and uncovered steel piles. The results (summarized in Table 3) are applicable to estimate the bearing capacity of soil for permafrost foundation designs, as well as the reduction of frost-heave uplift forces due to Reline jacket.

Table 3.

Shear strength along soil-pile adfreeze surface, for uncovered piles and piles with the Reline jacket.

For comparison, a series of tests was performed on uncovered plates, with roughness close to the roughness of real steel piles. The obtained shear strength values were considered as reference for further testing. Another series of tests was with samples in the Reline jacket.

4. Discussion

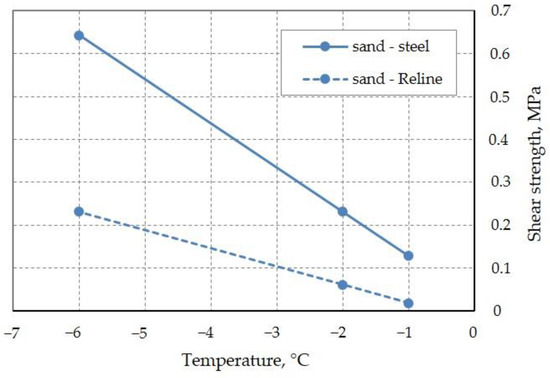

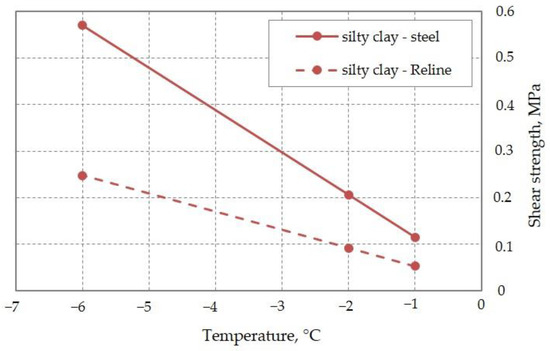

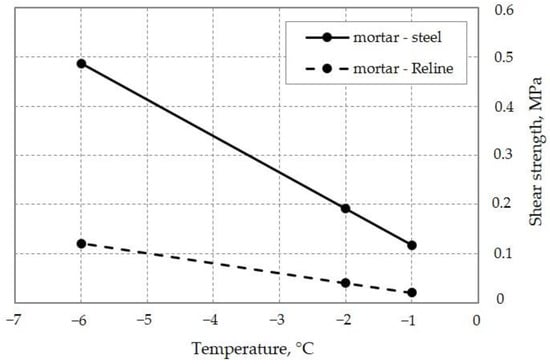

The testing results (Figure 7, Figure 8 and Figure 9) show that the soil-pile adfreeze strength becomes lower at higher temperatures, for all materials (soils and mortar), in both covered and uncovered samples. However, the difference is much smaller for the piles in the Reline jacket. The effect of Reline was estimated (in %) by comparing the results for covered and uncovered samples. The result for uncoated steel was taken as 100%. Then the relation of coated (in the Reline) and uncoated steel in % was calculated. The difference between them is the reduction of adfreeze strength. The obtained estimates were applicable to calculate the reduction of frost-heave uplift forces due to Reline, since they are mostly associated with adfreezing (Table 4). This approach can provide relative estimates despite large ranges of shear strength values for natural soils varying as a function of moisture content, density, mineralogy, and particle size of soils.

Figure 7.

Temperature dependence of shear strength: sand-steel and sand-Reline.

Figure 8.

Temperature dependence of shear strength: silty clay-steel and silty clay-Reline.

Figure 9.

Temperature dependence of shear strength: mortar-steel and mortar-Reline.

Table 4.

Reduction (%) of frost heave uplift forces under increasing temperatures.

Adreeze strength (uplift forces) for soil and foundation material are usually determined during geotechnical surveys. However, in practice, the decision about anti-heaving measures are usually made at the stage of construction designing, when engineering surveys are completed. The calculated reduction of frost heave uplift forces at various temperatures (Table 4) can be used for forecasting of pile foundation stability of real building or engineering construction based on adfreeze strength values (or frost-heave uplift forces) obtained earlier (for example, during geotechnical surveys).

Thus, the use of Reline provides significant reduction of adfreeze strength and related uplift forces: 62–85% for silty sand, 52–55% for silty clay, and 80–85% for mortar (1:5 cement-sand mixture). The poorer effect of Reline in the case of silty clay at the same roughness reduction (~93%) may be due to smaller particle sizes: on a rough surface, it is easier to displace fine-grained clayey soil than coarser sand. Since the size of sand particles is commensurate with the roughness height of uncovered piles, the roughness reduction causes a greater adfreezing effect on sand than on clay. Furthermore, the effect of coating in the case of sand soil varies with temperature: it increases from 62% to 85% upon warming from −6 to −1 °C, possibly, due to greater amounts of unfrozen pore water and related moisture increase (from 0.2 to 2%, or ten times). The water content increase in silty clay at the same warming conditions is much smaller: 3 to 6%, i.e., two times [36]. The reduction of uplift forces is the greatest in mortar (80–85%), irrespective of temperature. The reason is that mortar develops additional strong structural bonds (compared with fine-grained soil) and lacks unfrozen pore water, due to mineralogy (99% is quartz) and particle sizes of the sand (predominate fraction is 0.2–0.3 mm), since all unfrozen pore water is spent for cement hydration.

In comparison with other coatings noted in the literature [30], Reline is a modern and technologically advanced material. In addition, this coating can be applied not only at the factory, but also in the field conditions. Reline can be considered more effective for pile foundations for reducing uplift forces. It significantly outperforms organic-silicone enamel “KO-1112” for reducing uplift forces. The comparison Reline and “BAM-4” shows the similar results in clay soils but in sandy soils Reline is more effective. According to available papers and reports it is impossible to compare the efficiency of these coatings in contact with mortar due to the fact that there are no such investigations for “KO-1112” and “BAM-4”. Additionally, the authors of [30] do not indicate the temperature conditions of the experiments.

5. Conclusions

The use of Reline jacket reduces significantly (52 to 85%) the adfreeze strength and related frost-heave uplift forces on piles. The jacket is the most efficient for mortar (80–85%) and least efficient for silty clay (52–63%). In general, the reduction of uplift forces and its temperature dependence have several causes: changes in the roughness of protected pile surfaces; soil particle sizes; presence or absence of unfrozen pore water; temperature dependence of total moisture content at the account of unfrozen pore water.

Reline can successfully combat frost-heave uplift of foundations, for both overdriven and bored precast piles. This effect is especially important in the context of ongoing permafrost degradation under climate warming. Design solutions with due regard for the global change are indispensable for new construction projects in permafrost, in order to minimize deformation of foundations and structures associated with frost heaving and the ensuing accidents. The use of the Reline jacket can be an ideal solution for bored precast piles with grouting.

Author Contributions

Conceptualization, D.A., E.G. and A.A.; investigation, R.M. and O.K.; resources, D.A., V.B. and A.L.; data curation, E.G., V.B. and A.A.; writing—original draft preparation, E.G. and R.M.; writing—review and editing, E.G., A.A. and V.B.; supervision, D.A. and A.L.; project administration, A.A.; funding acquisition, D.A., V.B. and A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ural Plant for Polymer Technologies “MAYAK” (N° 268/8-18-20/SP).

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to the Ural Plant for Polymer Technologies “MAYAK” for research support. The authors would like to thank anonymous reviewers for valuable comments and recommendations.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Melnikov, V.P.; Osipov, V.I.; Brushkov, A.V.; Badina, S.V.; Sadurtdinov, M.R.; Drozdov, D.S.; Ananieva, G.V.; Zheleznyak, M.N.; Zhdaneev, O.V.; Ostarkov, N.A.; et al. Past and future of permafrost monitoring: Stability of Russian energetic infrastructure. Energies 2022, 15, 3190. [Google Scholar] [CrossRef]

- Pavlov, A.V.; Malkova, G.V. Modern Climate Change in the North of Russia; Geo: Novosibirsk, Russia, 2005; p. 54. (In Russian) [Google Scholar]

- Malkova, G.V.; Pavlov, A.V.; Skachkov, Y.B. Assessment of the stability of frozen strata under modern climate change. Earth’s Criosphere 2011, 4, 33–36. (In Russian) [Google Scholar]

- Skachkov, Y.B.; Skryabin, S.P.; Varlamov, S.P. Effect of modern climate change on permafrost in Central Yakutia. In Proceedings of the 3rd Conference of Geocryology Cryologists of Russia, Moscow, Russia, 1–3 June 2005; Moscow University Press: Moscow, Russia, 2005; Volume 2, pp. 146–152. (In Russian). [Google Scholar]

- Skachkov, Y.B.; Skriabin, P.N.; Varlamov, S.P. Results of 25 year-long monitoring of permafrost at the Chabyda hospital site (Central Yakutia). In Proceedings of the Conference Cryogenic Resources of Polar Regions, Salekhard City, Russia, 17–22 June 2007; TyumNGU: Salekhard, Russia, 2007; Volume 1, pp. 167–170. (In Russian). [Google Scholar]

- Malkova, G.V. Monitoring of the average annual temperature of rocks at the Bolvansky hospital. Earth’s Criosphere 2010, 3, 3–14. (In Russian) [Google Scholar]

- Smith, S.L.; Romanovsky, V.; Lewkowicz, A.; Burn, C.; Allard, M.; Clow, G.; Yoshikawa, K.; Throop, J. Thermal state of permafrost in North America: A contribution to the International Polar Year. Permafrost Periglac. Proc. 2010, 21, 117–135. [Google Scholar] [CrossRef] [Green Version]

- Vieira, G.; Bockheim, J.; Guglielmin, M.; Balks, M.; Abramov, A.; Boelhouwers, J.; Cannone, N.; Ganzert, L.; Gilichinsky, D.; Goryachkin, S.; et al. Thermal state of permafrost and active layer monitoring in the Antarctic: Advances during the International Polar Year 2007–2009. Permafrost Periglac. Processes 2010, 21, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Grosse, G.; Romanovsky, V.; Jorgenson, T.; Anthony, K.W.; Brown, J.; Overduin, P.P. Vulnerability and feedbacks of permafrost to climate change. Eos Trans. Am. Geophys. Union 2011, 92, 73–74. [Google Scholar] [CrossRef]

- Aalto, J.; Karjalainen, O.; Hjort, J.; Luoto, M. Statistical forecasting of current and future Circum-Arctic ground temperatures and active layer thickness. Geophys. Res. Lett. 2018, 45, 4889–4898. [Google Scholar] [CrossRef] [Green Version]

- Biskaborn, B.; Smith, S.H.; Noetzli, J.; Matthes, H.; Vieira, G.; Streletskiy, D.; Schoeneich, P.H.; Romanovsky, V.; Lewkowicz, A.; Abramov, A.; et al. Permafrost is warming at a global scale. Nat. Commun. 2019, 10, 264. [Google Scholar] [CrossRef] [Green Version]

- Alekseev, A.G.; Zorin, D.V. On changes in the temperature state of permafrost in the Taimyr region of the Krasnoyarsk territory. Foundations 2020, 2, 4–7. (In Russian) [Google Scholar]

- Daout, S.; Dini, B.; Haeberli, W.; Doin, M.-P.; Parsons, B. Ice loss in the Northeastern Tibetan Plateau permafrost as seen by 16 yr of ESA SAR missions. Earth Planet. Sci. Lett. 2020, 545, 116404. [Google Scholar] [CrossRef]

- Runge, A.; Nitze, I.; Grosse, G. Remote sensing annual dynamics of rapid permafrost thaw disturbances with LandTrendr. Remote Sens. Environ. 2022, 268, 112752. [Google Scholar] [CrossRef]

- Khrustalev, L.N.; Davydova, I.V. Forecast of climate warming and its accounting in assessing the reliability of the foundations of buildings on permafrost soils. Earth’s Criosphere 2007, 2, 68–75. (In Russian) [Google Scholar]

- Yu, W.B.; Guo, M.; Chen, L.; Lai, Y.M.; Yi, X.; Xu, L.L. Influence of urbanization on permafrost: A case study from Mohe County, northernmost China. Cryosphere Discuss. 2014, 8, 4327–4348. [Google Scholar] [CrossRef]

- Yurov, F.D.; Grebenets, V.I. Modern dynamics of engineering and geological conditions at Vankor and Zapolyarny oil and gas fields. In Prospects of Engineering Survey Development for Construction in Russia; Geomarketing: Moscow, Russia, 2017; pp. 239–246. (In Russian) [Google Scholar]

- Harris, S.; Brouchkov, A.; Cheng, G. Geocryology: Characteristics and Use of Frozen Ground and Permafrost Landforms; CRC Press: London, UK, 2018; 765p. [Google Scholar]

- Wu, Q.; Zhang, T. Changes in active layer thickness over the Qinghai Tibetan Plateau from 1995 to 2007. J. Geophys. Res. Atmos. 2010, 115, 1–12. [Google Scholar] [CrossRef]

- Solovyov, S.A.; Sushev, L.A.; Kochkin, A.A.; Solovyova, A.A. The problem of stability analysis for permafrost soils: Criterion of stability. Stroilestvo Rekonstr. 2021, 4, 3–15. (In Russian) [Google Scholar]

- Osipov, V.; Aksyutin, O.; Sergeev, D.; Tipenko, G.; Ishkov, A. Using the Data of geocryological monitoring and geocryological forecast for risk assessment and adaptation to climate change. Energies 2022, 15, 879. [Google Scholar] [CrossRef]

- Orlov, V.O.; Elgin, B.B.; Kim, V.K.H.; Filippov, V.D. Methods for estimation of tangent and normal forces of frost heaving in the field. In Transactions of N.M. Gersevanov NIIOSP; Production Experimental Workshops of VNIIIS Gosstroy of the USSR: Moscow, Russia, 1985; pp. 69–76. (In Russian) [Google Scholar]

- Kronik, Y.A. Analysis of accidents and safety of geotechnical systems in permafrost regions. In Proceedings of the 5th Conference of Geocryologists of Russia, Moscow, Russia, 14–17 June 2016; Plenary Presentations. Part 1. Engineering Geocryology. Part 2. Pipelines in Permafrost. Part 3. Seasonal and Cooling Systems in Permafrost. Part 4. Geophysical Studies of Permafrost during Construction. Universitetskaya Kniga, Lomonosov Moscow State University: Moscow, Russia, 2016; pp. 104–113. (In Russian). [Google Scholar]

- Anisimov, O.A. The main natural and socio-economic consequences of climate change in the areas of distribution of permafrost rocks: A forecast based on the synthesis of observations and modeling. Greenpeace 2010, 1, 14–15. [Google Scholar]

- Melnikov, V.P.; Osipov, V.I.; Brouchkov, A.V.; Falaleeva, A.A.; Badina, S.V.; Zheleznyak, M.N.; Sadurtdinov, M.R.; Ostrakov, N.A.; Drozdov, D.S.; Osokin, A.B.; et al. Climate warming and permafrost thaw in the Russian Arctic: Potential economic impacts on public infrastructure by 2050. Nat. Hazards 2022, 112, 231–251. [Google Scholar] [CrossRef]

- Anisimov, O.A.; Lavrov, S.A. Global warming and melting of permafrost: Risk assessment for production facilities of the fuel and energy complex. Tekhnologii V Topl. Energeticheskom Kompleks. 2004, 3, 78–83. (In Russian) [Google Scholar]

- Zhou, J.; Zhou, G.; Ma, W.; Wang, J.; Zhou, Y.; Ji, S.H. Experimental research on controlling frost heave of artificial frozen soil with intermission freezing method. J. China Univ. Min. Technol. 2006, 35, 708. [Google Scholar]

- Wang, T.; Liu, J.; Tian, Y.; Lv, P. Frost jacking characteristics of screw piles by model testing. Cold Reg. Sci. Technol. 2017, 138, 98–107. [Google Scholar] [CrossRef]

- Huang, X.; Sheng, Y.; Huang, L.; Peng, E.; Cao, W.; Zhang, X.; He, B. Experimental study on the anti-frost jacking ability of belled pile under unidirectional freezing condition. Adv. Eng. Sci. 2021, 53, 122–131. [Google Scholar] [CrossRef]

- Pchelintsev, A.M.; Levkovich, E.A. Recommendations for Reducing Uplift Forces of Frost Heave of Foundations Using Plastic Lubricants and Organic-Silicon Enamels; NIIOSP: Moscow, Russia, 1980; 36p. (In Russian) [Google Scholar]

- Pchelintsev, A.M. Laboratory studies of soil application to various surfaces. In NIIOSP Transactions; NIIOSP: Moscow, Russia, 1974; pp. 136–145. (In Russian) [Google Scholar]

- Andersland, O.B.; Ladanyi, B. Introduction to Frozen Ground Engineering; Springer: New York, NY, USA, 1994; 363p. [Google Scholar]

- Aksenov, V.I. Saline Frozen Soils of Arctic Shore as Foundation for Buildings; Vsyo o mire stroitelstva: Moscow, Russia, 2008; p. 340. (In Russian) [Google Scholar]

- Alekseev, A.G.; Sazonov, P.M.; Zorin, D.V.; Vinogradova, S.A. Application of pile foundations in structurally unstable soils. In Proceedings of the MATEC Web of Conferences, Yuzhno-Sakhalinsk, Russia, 4–7 July 2018; EDP Sciences: Yuzhno-Sakhalinsk, Russia, 2019; p. 05020. (In Russian). [Google Scholar] [CrossRef]

- Dalmatov, B.I. Effect of Frost Heaving on Foundations; Gosstroiizdat: Sankt-Peterburg, Russia; Moscow, Russia, 1957; p. 60. (In Russian) [Google Scholar]

- Chuvilin, E.M.; Bukhanov, B.A.; Mukhametdinova, A.Z.; Grechishcheva, E.S.; Sokolova, N.S.; Alekseev, A.G.; Istomin, V.A. Freezing point and unfrozen water contents of permafrost soils: Estimation by the water potential method. Cold Regions Sci. Technol. 2022, 196, 103448. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).