Study of Micro-Parameters of DEM Model on the Laboratory Experiment Results Obtained from Poorly Cemented Sandstone

Abstract

1. Introduction

2. Discrete Element Modelling

2.1. Bonded-Particle Model

2.2. Constitutive Relationships

2.3. Calibration

- Generate particles randomly with diameters in a specified range within a vessel bounded by frictionless walls.

- Adjust the system by allowing particles to move under zero friction.

- Apply low isotropic stress by modifying the diameters of all particles simultaneously.

- Modify the diameters of particles that have less than two contacts iteratively so that these particles have at least two contacts.

3. Experimental Test Results

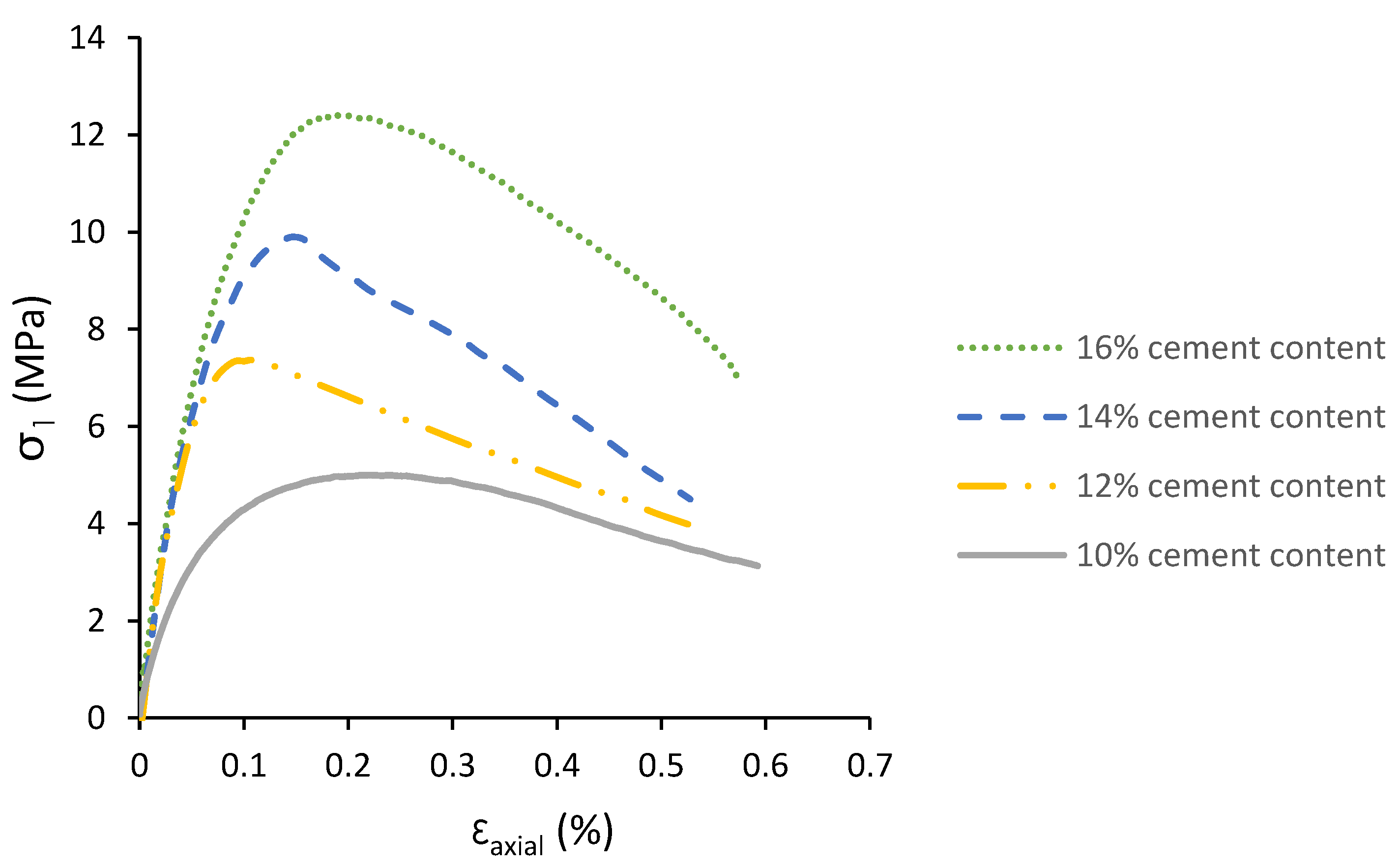

3.1. Cut-Off UCS

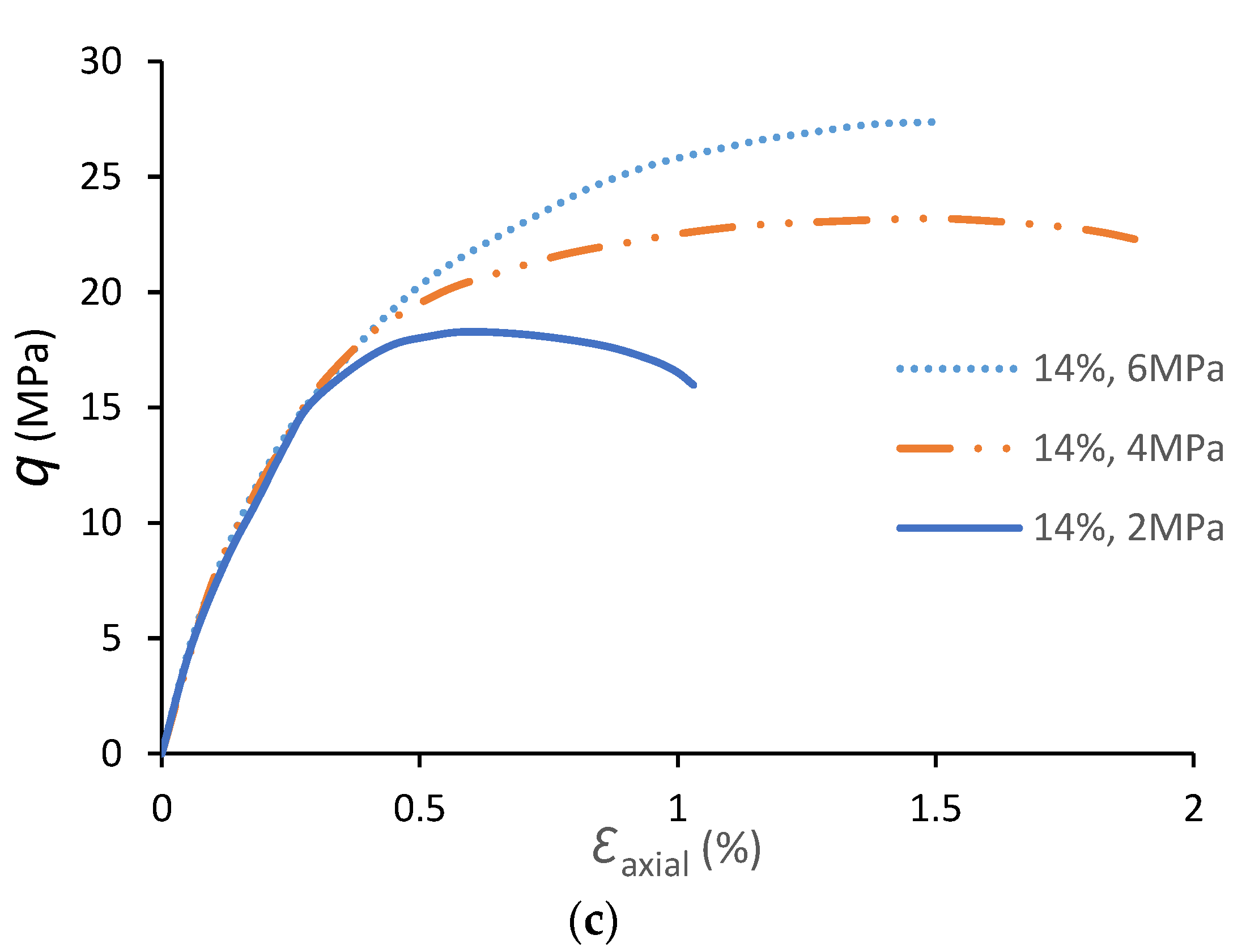

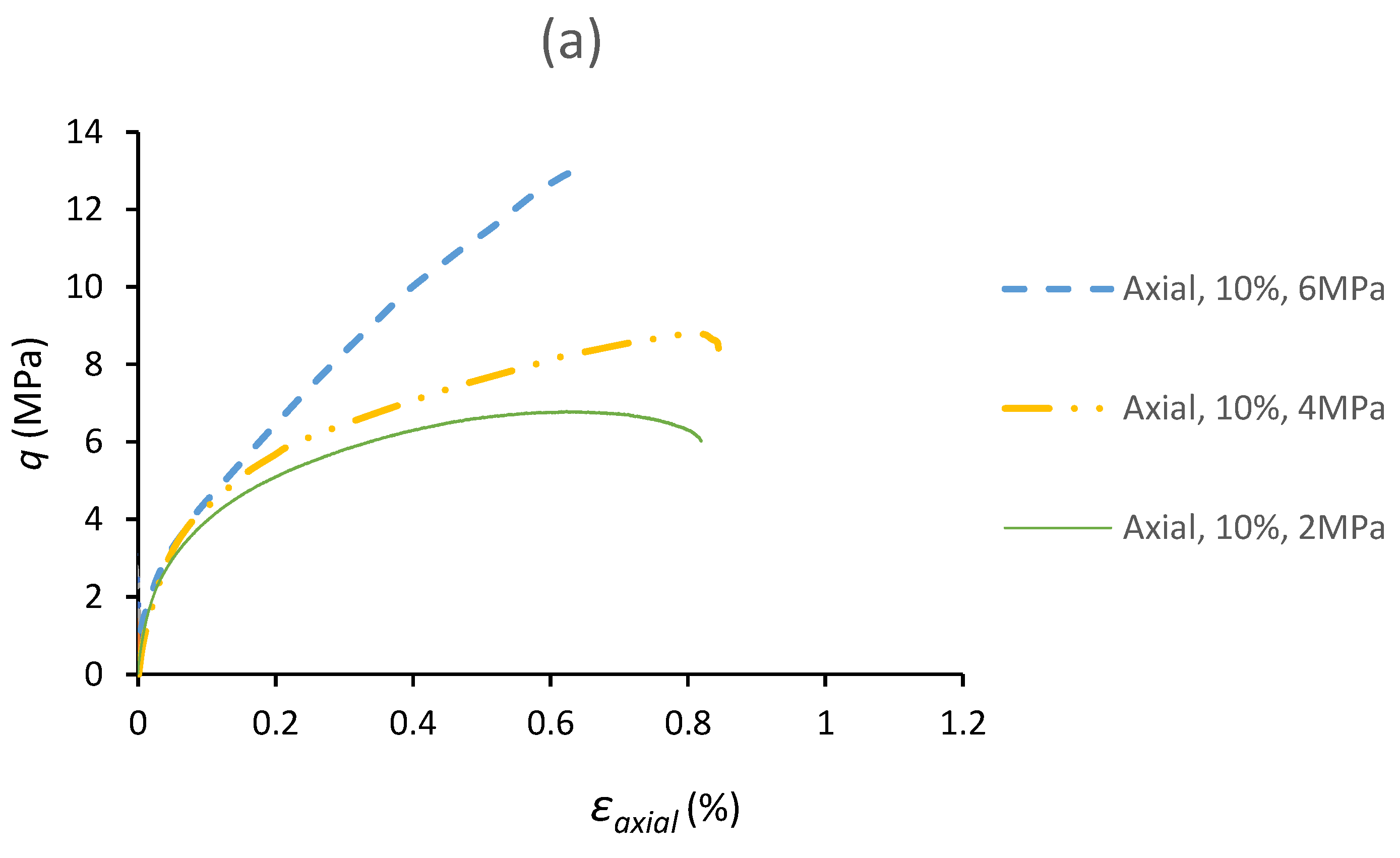

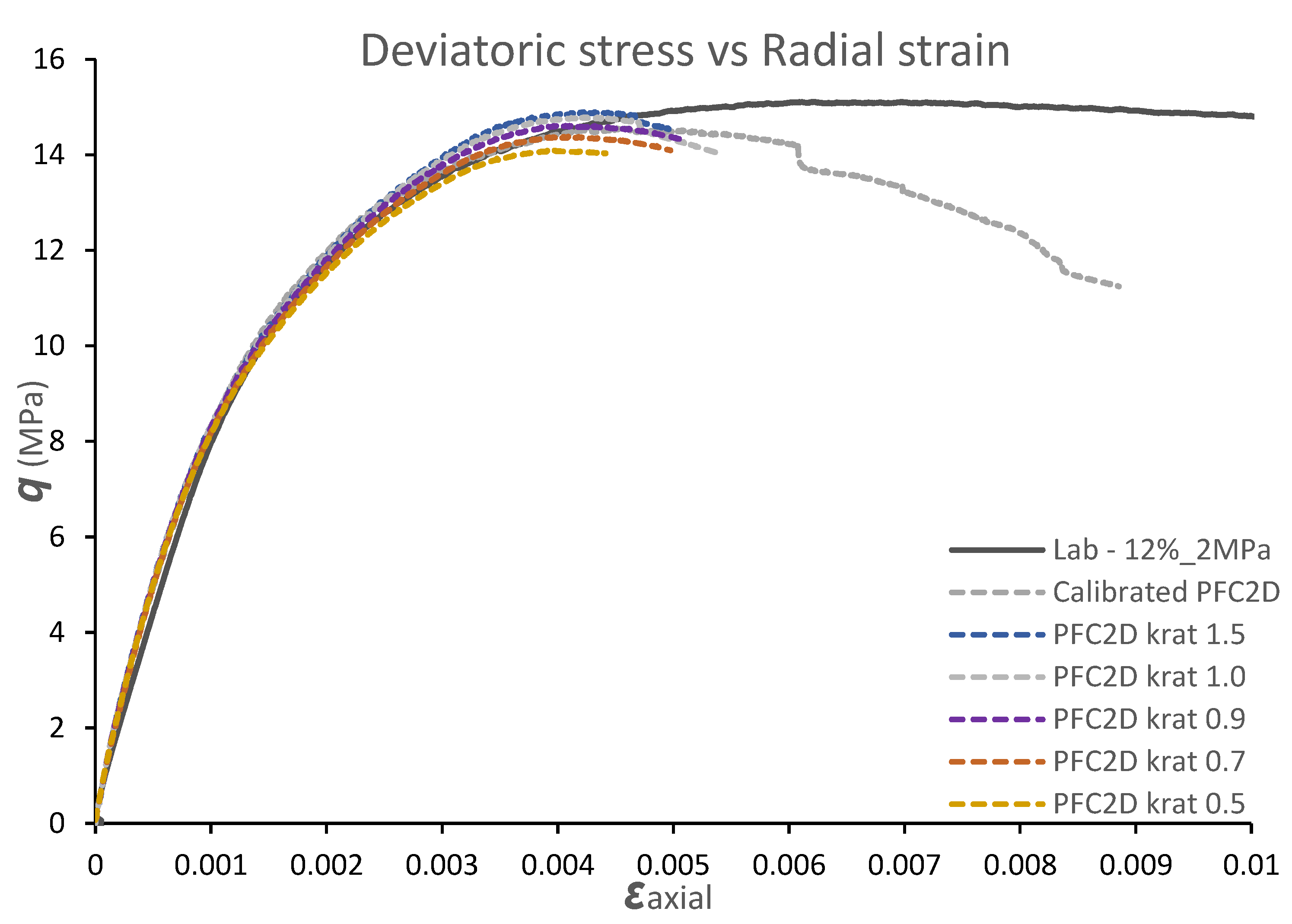

3.2. Triaxial Test Results on Solid Specimens

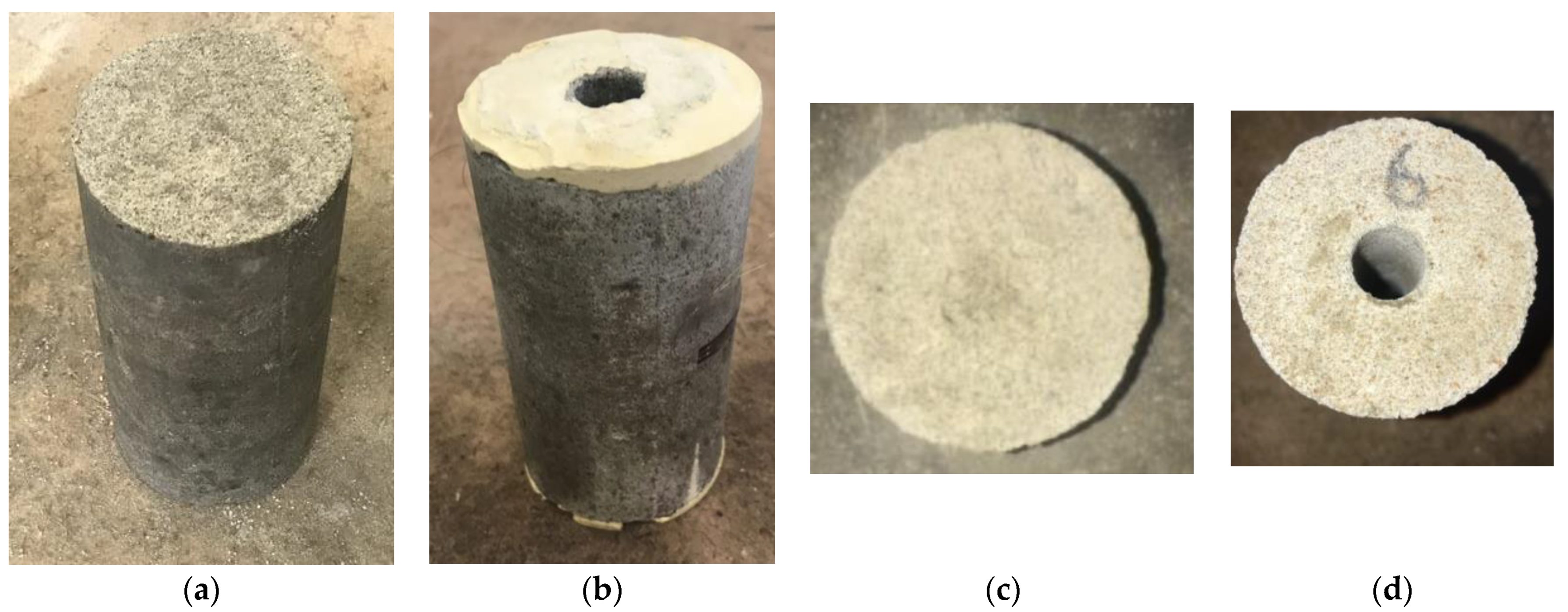

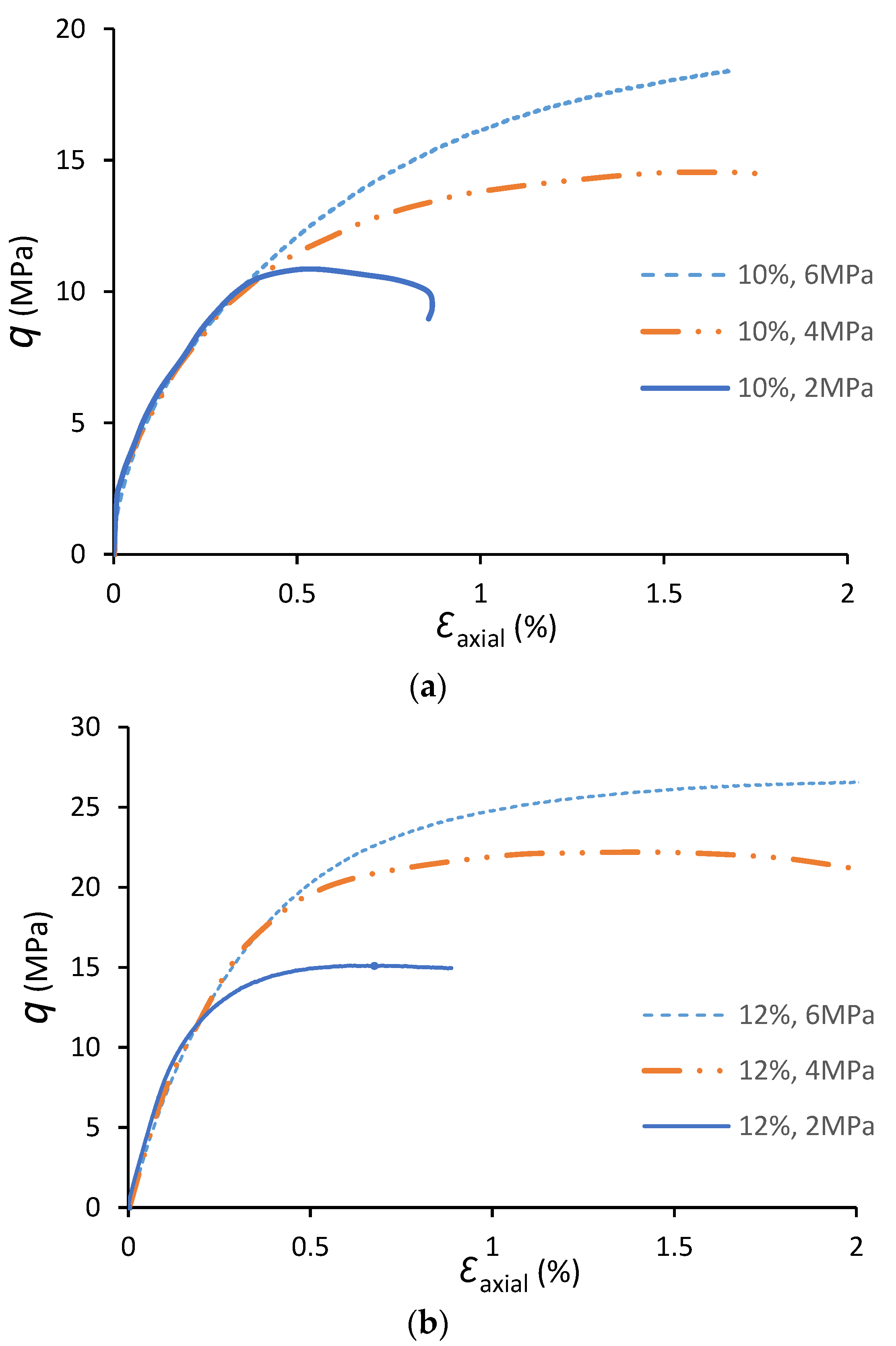

3.3. Triaxial Tests on Thick-Walled Hollow Cylinder Specimens

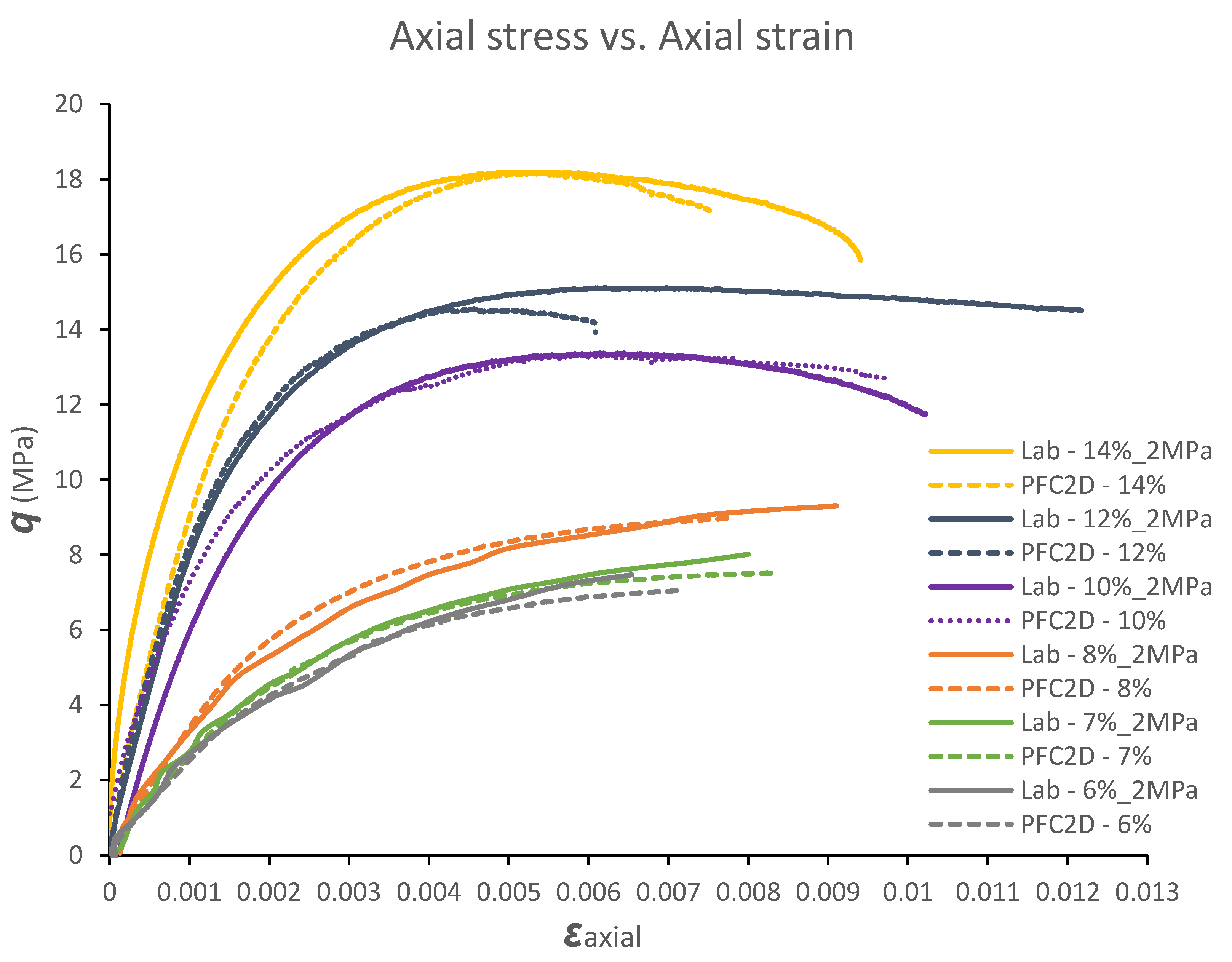

4. Numerical Simulation Results

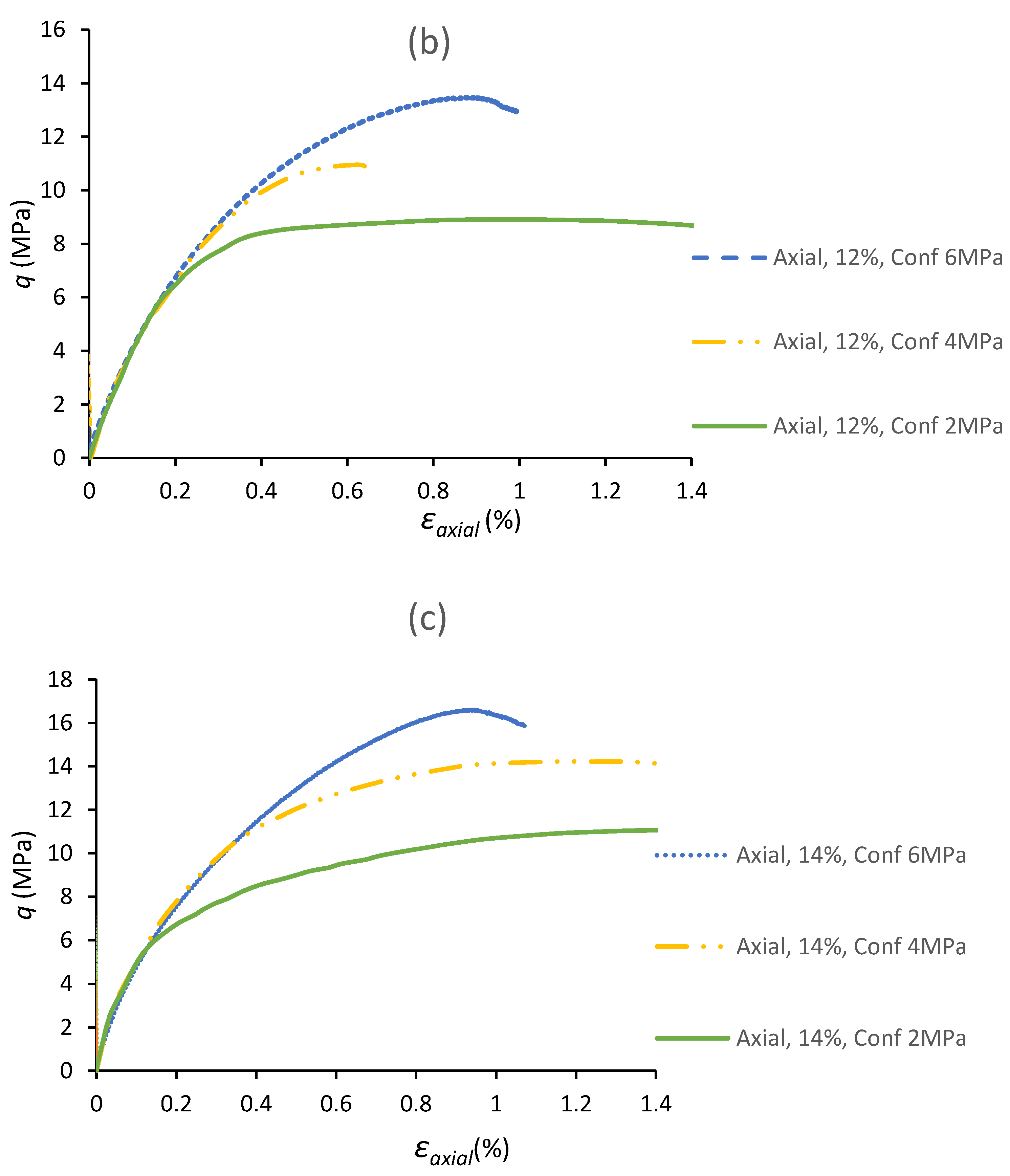

4.1. Stiffness Ratio

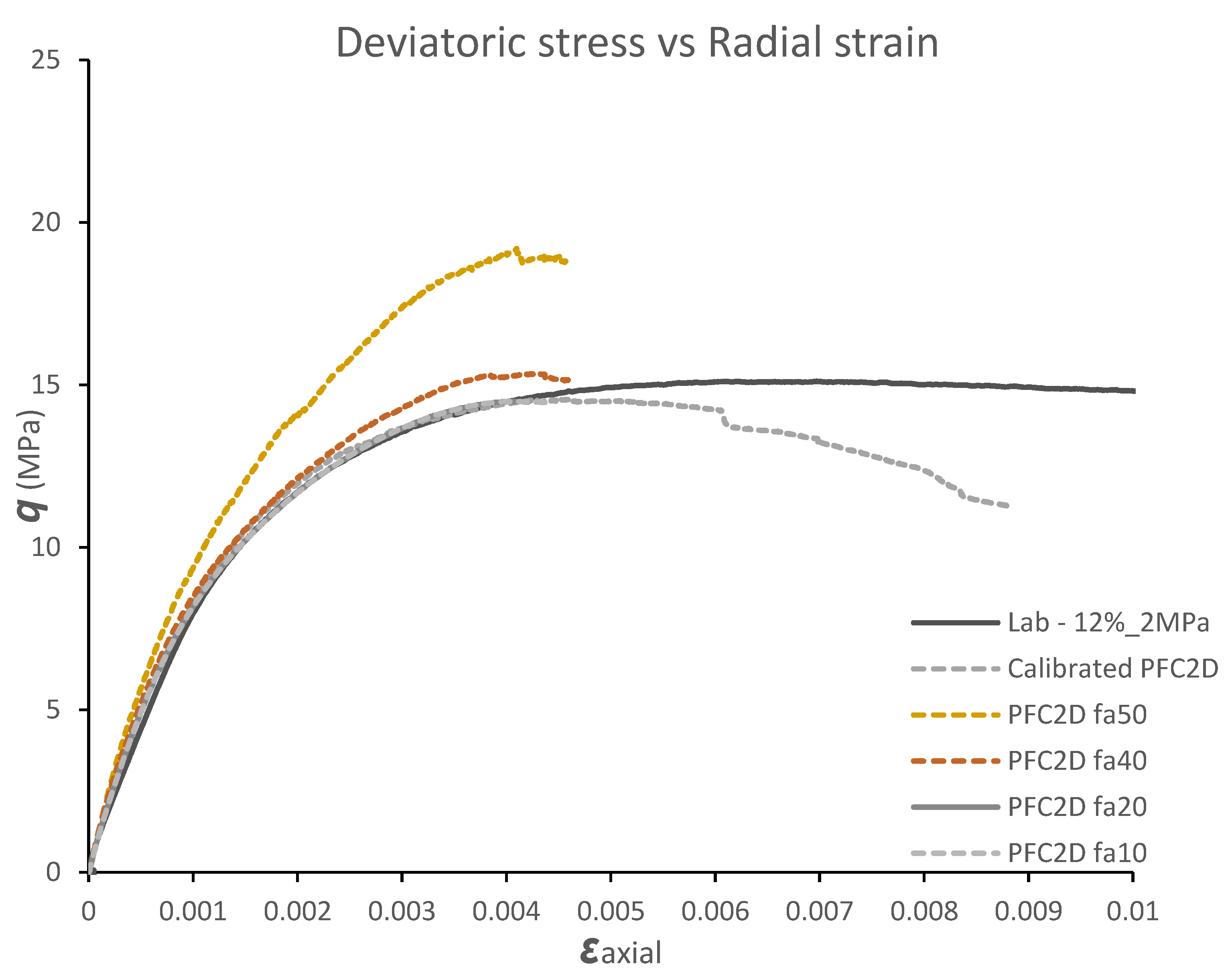

4.2. Friction Angle

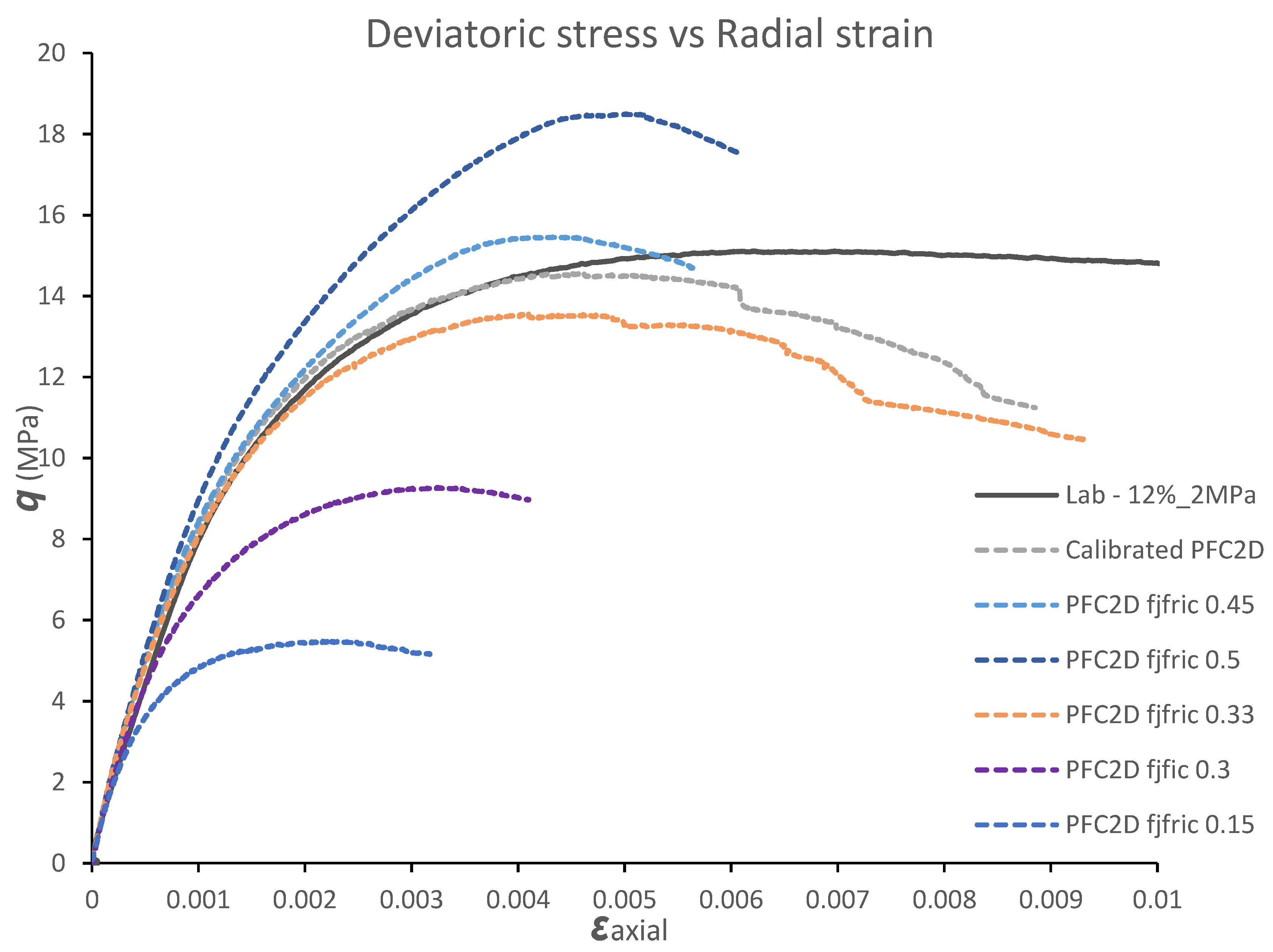

4.3. Friction Coefficient

4.4. Effective Modulus (E*)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hashemi, S.S.; Melkoumian, N.; Taheri, A.; Jaksa, M. The failure behaviour of poorly cemented sands at a borehole wall using laboratory tests. Int. J. Rock Mech. Min. Sci. 2015, 77, 348–357. [Google Scholar] [CrossRef]

- Fjar, E.; Holt, R.; Raaen, A.; Risnes, R.; Horsrud, P. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 309–310. [Google Scholar]

- Bianco, P.M.; Halleck. Mechanisms of arch instability and sand production in two-phase saturated poorly consolidated sandstones. In Proceedings of the SPE European Formation Damage Conference, Hague, The Netherlands, 21–22 May 2001. [Google Scholar]

- Al-Ajmi, A.; Zimmerman, R. Stability analysis of vertical boreholes using the Mogi–Coulomb failure criterion. Int. J. Rock Mech. Min. Sci. 2006, 43, 1200–1211. [Google Scholar] [CrossRef]

- Cundall, P.A. Distinct Element Models of Rock and Soil Structure. In Analytical and Computational Methods in Engineering Rock Mechanics; Brown, E.T., Ed.; Brown Allen and Unwin: London, UK, 1987; pp. 129–163. [Google Scholar]

- Hashemi, S.S.; Melkoumian, N. Effect of different stress path regimes on borehole instability in poorly cemented granular formations. J. Pet. Sci. Eng. 2016, 146, 30–49. [Google Scholar] [CrossRef]

- Potyondy, D.O. The bonded-particla model as a tool for rock mechanics research and application: Current trends and future directions. Geosyst. Eng. 2015, 18, 1–28. [Google Scholar] [CrossRef]

- Papanastasiou, P.C.; Vardoulakis, I.G. Numerical treatment of progressive localization in relation to borehole stability. Int. J. Numer. Anal. Methods Geomech. 1992, 16, 389–424. [Google Scholar] [CrossRef]

- Rahmati, H.; Nouri, A.; Chan, D.; Vaziri, H. Simulation of drilling-induced compaction bands using discrete element method. Int. J. Numer. Anal. Methods Geomech. 2014, 38, 37–50. [Google Scholar] [CrossRef]

- Duan, K.; Kwok, C.Y. Evolution of stress-induced borehole breakout in inherently anisotropic rock: Insights from discrete element modeling. J. Geophys. Res. Solid Earth 2016, 121, 2361–2381. [Google Scholar] [CrossRef]

- Lee, H.; Moon, T.; Haimson, B.C. Borehole breakouts induced in arkosic sandstones and a discrete element analysis. Rock Mech. Rock Eng. 2016, 49, 1369–1388. [Google Scholar] [CrossRef]

- Setiawan, N.B.; Zimmerman, R.W. Wellbore breakout prediction in transversely isotropic rocks using true-triaxial failure criteria. Int. J. Rock Mech. Min. Sci. 2018, 112, 313–322. [Google Scholar] [CrossRef]

- Li, X.; El Mohtar, C.S.; Gray, K. EModeling progressive breakouts in deviated wellbores. J. Pet. Sci. Eng. 2019, 175, 905–918. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Schöpfer, M.P.; Childs, C.; Walsh, J.J. Two-dimensional distinct element modeling of the structure and growth of normal faults in multilayer sequences: 1. Model calibration, boundary conditions, and selected results. J. Geophys. Res. Solid Earth 2007, 112. [Google Scholar] [CrossRef]

- Zhao, W.; Huang, R.; Yan, M. Mechanical and fracture behaviour of rock mass with parallel concentrated joints with different dip angle and number based on PFC simulation. Geomech. Eng. 2015, 8, 757–767. [Google Scholar] [CrossRef]

- Zhou, C.; Xu, C.; Karakus, M.; Shen, J. A systematic approach to the calibration of micro-parameters for the flat-jointed bonded particle model. Geomech. Eng. 2018, 16, 471–482. [Google Scholar]

- Duan, K.; Kwok, C.Y.; Pierce, M. Discrete element method modeling of inherently anisotropic rocks under uniaxial compression loading. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 1150–1183. [Google Scholar] [CrossRef]

- Fakhimi, A.; Villegas, T. Application of dimensional analysis in calibration of a discrete element model for rock deformation and fracture. Rock Mech. Rock Eng. 2007, 40, 193–211. [Google Scholar] [CrossRef]

- He, X.; Xu, C. Discrete element modelling of rock cutting: From ductile to brittle transition. Int. J. Numer. Anal. Methods Geomech. 2015, 39, 1331–1351. [Google Scholar] [CrossRef]

- Vesga, L.F.; Vallejo, L.E.; Lobo-Guerrero, S. DEM analysis of the crack propagation in brittle clays under uniaxial compression tests. Int. J. Numer. Anal. Methods Geomech. 2008, 32, 1405–1415. [Google Scholar] [CrossRef]

- Ning, J.; Liu, X.; Tan, Y.; Wang, J.; Tian, C. Relationship of box counting of fractured rock mass with Hoek-Brown parameters using particle flow simulation. Geomech. Eng. 2015, 9, 619–629. [Google Scholar] [CrossRef]

- Tian, W.L.; Yang, S.Q. Experimental and numerical study on the fracture coalescence behaviour of rock-like materials containing two non-coplanar filled fissures under uniaxial compression. Geomech. Eng. 2017, 12, 541–560. [Google Scholar] [CrossRef]

- Xu, W.J.; Li, C.Q.; Zhang, H.Y. DEM analyses of the mechanical behaviour of soil and soil-rock mixture via the 3D direct shear test. Geomech. Eng. 2015, 9, 815–827. [Google Scholar] [CrossRef]

- Cho, N.A.; Martin, C.D.; Sego, D.C. A clumped particle model for rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 997–1010. [Google Scholar] [CrossRef]

- Wu, S.; Xu, X. A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech. Rock Eng. 2016, 49, 1813–1830. [Google Scholar] [CrossRef]

- Khazaei, C.; Hazzard, J.; Chalaturnyk, R. Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput. Geotech. 2015, 67, 94–102. [Google Scholar] [CrossRef]

- Le, L.A.; Nguyen, G.D.; Bui, H.H.; Sheikh, A.H.; Kotousov, A.; Khanna, A. Modelling jointed rock mass as a continuum with an embedded cohesive-frictional model. Eng. Geol. 2017, 228, 107–120. [Google Scholar] [CrossRef]

- Le, L.A.; Nguyen, G.D.; Bui, H.H.; Sheikh, A.H.; Kotousov, A.; Khanna, A. Localised failure mechanism as the basis for constitutive modelling of geomaterials. Int. J. Eng. Sci. 2018, 133, 284–310. [Google Scholar] [CrossRef]

- Nguyen, N.H.T.; Bui, H.H.; Nguyen, G.D.; Kodikara, J. A cohesive damage-plasticity model for DEM and its application for numerical investigation of soft rock fracture properties. Int. J. Plast. 2017, 98, 175–196. [Google Scholar] [CrossRef]

- Nguyen, N.H.T.; Bui, H.H.; Nguyen, G.D.; Kodikara, J.; Arooran, S.; Jitsangiam, P. A thermodynamics-based cohesive model for discrete element modelling of fracture in cemented materials. Int. J. Solids Struct. 2017, 117, 159–176. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Sharrock, G.; Hebblewhite, B.K. Numerical direct shear tests to model the shear behaviour of rock joints. Comput. Geotech. 2013, 51, 101–115. [Google Scholar] [CrossRef]

- Gutiérrez, J.G.; Senent, S.; Melentijevic, S.; Jimenez, R. Distinct element method simulations of rock-concrete interfaces under different boundary conditions. Eng. Geol. 2018, 240, 123–139. [Google Scholar] [CrossRef]

- Koyama, T.; Jing, L. Effects of model scale and particle size on micro-mechanical properties and failure processes of rocks—A particle mechanics approach. Eng. Anal. Bound. Elem. 2007, 31, 458–472. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 2013, 38, 804–812. [Google Scholar] [CrossRef]

- Saidi, F.; Bernabe, Y.; Reuschle, T. The mechanical behaviour of synthetic, poorly consolidated granular rock under uniaxial compression. Tectonophysics 2003, 370, 105–120. [Google Scholar] [CrossRef]

- Heo, J.H.; Melkoumian, N.; Hashemi, S.S. Evaluating the Effect of Different Stress Path Regimes on Borehole Deformation Using Convergence Measuring Device. Geosciences 2022, 12, 317. [Google Scholar] [CrossRef]

- Bosio, J.J.; Kanji, M.A. Soft rocks of the Rio de la Plata Basin. In International Symposium on Indurated Soils and Soft Rocks; AGI: Naples, Italy, 1998; pp. 65–71. [Google Scholar]

- ISRM. Rock characterization, testing, and monitoring. ISRM suggested methods. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 109. [Google Scholar] [CrossRef]

- Kanji, M. Critical issues in soft rocks. J. Rock Mech. Geotech. Eng. 2014, 6, 186–195. [Google Scholar] [CrossRef]

- Baud, J.P.; Gambin, M. Classification of soils and rocks based on pressuremeter tests under high pressure. In Proceedings of the 15th European Conference on Soil Mechanics and Geotechnical Engineering, Athens, Greece, 11–15 September 2011; pp. 325–330. [Google Scholar]

- Liu, K.; Wu, B. Predicting Reservoir Rock Mechanical Properties Directly from Sedimentary Characterisation. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016. [Google Scholar]

- Bernabe, Y.; Fryer, D.; Hayes, J. The effect of cement on the strength of granular rocks. Geophys. Res. Lett. 1992, 19, 1511–1514. [Google Scholar] [CrossRef]

- Klein. An approach to the classification of weak rock for tunnel projects. In Proceedings of the Rapid Excavation and Tunneling Conference, San Diego, MA, USA, 6–12 October 2001. [Google Scholar]

- Huang, H. Discrete Element Modeling of Tool-Rock Interactio. Ph.D. Thesis, The University of Minnesota, Minneapolis, MN, USA, 1999. [Google Scholar]

- Yang, B.; Jiao, Y.; Lei, S. A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng. Comput. 2006, 23, 607–631. [Google Scholar] [CrossRef]

| Cement Content (%) | Uniaxial Compressive Strength (MPa) | Poisson’s Ratio (ν) | Bulk Density ρ () |

|---|---|---|---|

| 10 | 4.96 | 0.243 | 1792 |

| 12 | 7.34 | 0.237 | 1859 |

| 14 | 9.90 | 0.231 | 1913 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heo, J.H.; Hashemi, S.S.; Melkoumian, N. Study of Micro-Parameters of DEM Model on the Laboratory Experiment Results Obtained from Poorly Cemented Sandstone. Geosciences 2022, 12, 373. https://doi.org/10.3390/geosciences12100373

Heo JH, Hashemi SS, Melkoumian N. Study of Micro-Parameters of DEM Model on the Laboratory Experiment Results Obtained from Poorly Cemented Sandstone. Geosciences. 2022; 12(10):373. https://doi.org/10.3390/geosciences12100373

Chicago/Turabian StyleHeo, Jun Hyuk, Sam S. Hashemi, and Noune Melkoumian. 2022. "Study of Micro-Parameters of DEM Model on the Laboratory Experiment Results Obtained from Poorly Cemented Sandstone" Geosciences 12, no. 10: 373. https://doi.org/10.3390/geosciences12100373

APA StyleHeo, J. H., Hashemi, S. S., & Melkoumian, N. (2022). Study of Micro-Parameters of DEM Model on the Laboratory Experiment Results Obtained from Poorly Cemented Sandstone. Geosciences, 12(10), 373. https://doi.org/10.3390/geosciences12100373