Abstract

Geomembranes are used worldwide as basin liners in tailings ponds to decrease the permeability of the foundation and prevent further transportation of harmful contaminants and contaminated water. However, leakage into the environment and damage to the geomembrane have been reported. This paper reviews available literature and recommendations on geomembrane structures for use as a basal liner in tailings ponds, and presents a framework to achieve early involvement and an integrated approach to geomembrane structure design. Cohesive planning guidelines or legislative directions for such structures are currently lacking in many countries, which often means that the structure guidelines for groundwater protection or landfill are applied when designing tailings storage facilities (TSF). Basin structure is generally unique to each mine but, based on the literature, in the majority of cases the structure has a single-composite liner. The type of liner system used depends mainly on the material to be used on top of the structure, local hydraulic pressure gradient, and climate conditions. More practical information and scientific knowledge on the use of base liners in various cases are needed. A sustainable approach could be risk-based design, where the life cycle of the basin is taken into consideration. To this end, this paper proposes geomembrane-lined tailings pond to be assessed as a stakeholder. Emphasis on this, early enough, can ensure critical factors for tailings ponds to be considered from the outset in the design of mines and reduces the environmental footprint of the mining industry. More holistic project management and early involvement and integration are recommended to improve construction quality during the entire life cycle of the pond. In the long term, use of dry stacking or other alternative methods should be encouraged, despite the higher costs for operators.

1. Introduction

The use of geosynthetics in industrial applications has become common since the 1970s [1]. There is huge potential to use these in different mine-related applications, e.g., as geomembranes, plastic pipes, geotextiles, geosynthetic clay liners (GCLs) and reinforcements. The first major mining application was for lining process ponds and as partly impermeable basal structures for solar ponds at the Tenneco Minerals mines in Utah, USA, and at a Sociedada Quimica y Minera mine in Northern Chile at the beginning of the 1970s [2]. By the late 1970s, geomembranes were in general use in the basal structures of heap leach pads, but they have only become widely been used in the basal liner structures of tailings ponds and waste rock dumps during the past 20 years [2,3,4,5].

Impoundment of tailings generally poses one of the most significant environmental risks associated with mines [6], with the risk closely linked to the type and quality of tailings. Since each mine is unique, the physical and chemical quality of the tailings varies. Typical tailings can be of the same consistency as fine sand, loamy sand, or sandy loam, and they may contain chemical residues from mineral separation or from the coagulants and flocculants used in water separation, e.g., [7]. The particle properties differ from those of natural soils because the grains in tailings are jagged in shape, while natural loam grains are rounded. High angularity, grading characteristics and loose depositional state of tailings have direct effects on increasing compressibility compared with natural soils [8], but also on susceptibility of liquefaction of tailings [9,10].

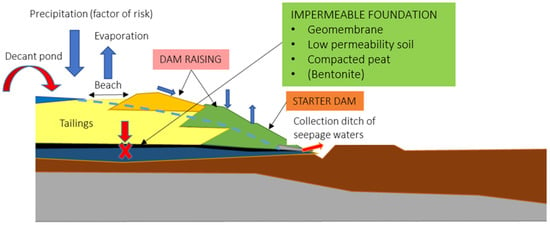

In conventional disposal systems, tailings are dumped in ponds as a slurry with a solids content of 20–40% by weight relative to the total weight [11]. In a typical case, the tailings ponds are located within peatland areas, in valleys, or on hillsides worldwide. The objective is to utilize natural soil layers with low water permeability (such as peat and glacial till) and local soil formations to reduce the risk of pollution to the environment. The mode of operation of these ponds is seepage of water from the ponds and its collection in a nearby ditch or other drainage structure. One of the greatest environmental challenges arises with tailings that create an acid environment [12,13]. Acid is formed through the oxidization of minerals containing sulfur (e.g., pyrite) and can have significant effects on surface waters and groundwater in the mine surroundings, where screening, recovering and treating these waters may be difficult and expensive [12]. Because releases of acidic mine drainage (AMD) into the environment are not desirable, control of the water within stored tailings is essential. The first priority is to prevent formation of AMD but in many cases an impermeable basal layer may need to be constructed (Figure 1).

Figure 1.

A conventional way of disposing of mine tailings, as a slurry in a tailings pond. In some cases, regulations demand use of a geomembrane liner at the pond base to achieve low permeability and keep seepage waters away from the surrounding environment during the active phase of disposal.

Because awareness of environmental impacts has increased and the legislation on basal structures has generally become stricter, in some cases an artificial liner in the foundation design is required to prevent seepage of water from tailings ponds. Positive effects of lining systems with low water permeability in landfill structures have been reported and have affected the requirements regarding foundations in mining areas in Europe [11,14,15]. The functionality of basal linings has been widely studied [16,17,18,19,20,21,22,23,24] and both national and international design guidelines (e.g., European Council Directive 1999/31/EC, Government Decree on Landfills 331/2013) are available for landfill basal structures. In the mining industry, however, the legislation regarding basal liners structure is less cohesive and requirements vary between different countries. In Europe mine wastes are regulated under Directive 2006/21/EC. Otherwise, there are country-specific laws and guidelines, which poses challenges for the mining sector since mining companies are typically international.

While basal structures of tailings ponds have been improved, problems relating to harmful seepage waters have not been entirely solved. In recent years, leakages have occurred even through geomembrane-lined basal structures meeting the new requirements for mining operations. For example, at the Talvivaara mine in Finland, which was opened in 2008, leakages were detected in 2008, 2010, 2012 and 2013, at the Kittilä mine in Finland, also opened in 2008, leakage was reported in 2015, and at Kokoya Gold Mine, Liberia, opened in 2014, the latest liner failure was reported in 2017 [25,26,27].

Typically, development and planning of industrial projects follows an “the over-the-wall” approach, where design proceeds step by step. Plans are drawn within different design disciplines and given to the next designer or customer in the ”chain” until the plans are complete [28]. This practice leads to sub-optimization, as different phases, design areas and stakeholders strive to optimize only their own view and performance [29]. A more holistic approach to tailings ponds project management is clearly needed to utilize the accumulated knowledge. It is particularly important for geomembrane design to be considered and integrated at an early stage, because its importance for the overall solution costs and life cycle costs.

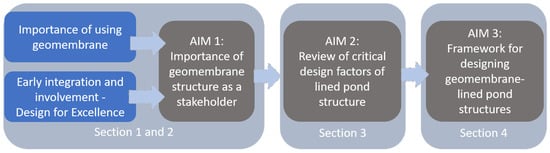

In this paper, we review geomembranes already used in basal structures in the mining industry worldwide, with the main aim of identifying design requirements, guidelines, or recommendations for the use of geomembrane structures. First, we review the literature on how widely geomembrane liner structure are used in mines and their intended purpose, and on how to achieve early involvement and integration of geomembrane structure design in the planning process. We then outline the structural requirements for geomembranes and for the structures above and below geomembranes, and possible restrictions on the use of geomembrane structures (such as water storage, the disposal technique used, and the material to be dumped on top of the geomembrane). Finally, we present a framework for design for geomembrane structures and discuss limitations and prospects of geomembrane-lined tailings ponds. Figure 2 illustrates the research process.

Figure 2.

Flowchart of the work performed in this study.

2. Use of Geomembranes in Basal Structures and Need for Early Integration and Involvement

2.1. Quantifications of Geomembranes Used in Pond Basal Structures Worldwide

The most common application for geomembrane basal structures is probably heap leaching, at least in the United States and South America [30]. Rowe et al. [31] studied 92 different heap leaching projects in 15 countries (Argentina, Brazil, Chile, Columbia, Philippines, Ghana, Indonesia, Mexico, Namibia, Nigeria, Peru, Poland, Turkey, the United States, and Uzbekistan). Published studies on the application of geomembranes in tailings ponds are fewer. The largest single application in Europe may be the tailings pond at the Lisheen Mine in Ireland [32]. Some corporations, e.g., Alcoa World Alumina [33], have published guidelines, including a recommendation on use of geomembranes for the disposal of bauxite tailings generated in aluminum works on purpose-built disposal sites. According to the literature and reports, various examples of planned or built geomembrane-lined tailings storage facilities can be found around the world (Table 1).

Table 1.

Use of geomembranes in tailings storage facility (TSF) ponds around the world.

The list in Table 1 gives some indication of the geomembrane liners used worldwide. There may be other cases of use, but none were found in the present review for e.g., Sweden or Canada, which are located in regions characterized by snow and a cold climate (Figure 3). However, information is available on the use of geomembrane structures in dams generally in Canada [41].

Figure 3.

World map depicting current use of geomembranes in heap leaching and in the basal structures of tailings ponds around the world, as estimated from scientific publications and conference presentations.

2.2. Special Circumstances to Consider in Design of Tailings Impoundments

In the mining industry, geomembranes and other geosynthetic products used in basal structures face harsh conditions that are not comparable to those in other industrial applications or landfill constructions [30,42,43]. These conditions include unusual process conditions, such as high pressure (up to over 3 MPa) directed at the geomembrane, high or low temperatures, air injection, and use of different chemicals. In addition, mines are often located in geographically and climatically extreme or remote areas, such as cold, dry, sunny, or rainy areas or on high ground, making selection of materials and installation techniques challenging. The operating conditions can cause additional stress on materials, which may lead to faster wear and weakening of material properties [43]. These harsh conditions drastically differentiate the disposal sites in mines from the disposal sites for municipal waste. According to Garrick et al. [42], the most significant differences between facilities for disposal of tailings and those for municipal waste disposal are:

- The hydraulic conductivity of tailings can range from 10−6 to 10−10 m/s and can vary both vertically and horizontally. However, tailings commonly have low hydraulic conductivity (less than 5 × 10−8 m/s), so the consolidated tailings can control the seepage rate.

- Analytical approaches to leakage calculations are unsuitable when a large tailings pond is located in a valley, as the groundwater level beneath the geomembrane varies locally. This, combined with restrictions on fluid migration above the geomembrane due to the low hydraulic conductivity of the tailings, makes seepage flow problems complicated.

- If a drainage system is not installed above the geomembrane, the effluent accumulating in the pond may create a high-pressure head above the geomembrane. On municipal waste disposal sites, a drainage system normally exists.

- The chemistry of the tailings effluent may increase the hydraulic conductivity of geosynthetic clay liners (GCLs) [44]. Hornsey et al. [14] point out that other stress factors can also affect the functionality of GCLs, e.g., traffic stress or excessive temperatures.

- Temperatures are typically lower in tailings ponds than at municipal waste sites. This may slow the rate of geomembrane degradation, but degradation will still occur over time. Little information is currently available because of suspicions that high sulfate content and very high salinity can reduce the durability of geomembranes [14].

- Municipal waste sites use protective textiles, but in tailings disposal or heap leaching these are not always used, as they generate significant extra costs [45].

2.3. Early Involvement and Integration Enabling Excellence in Design

Traditional design and construction in tailings ponds projects are typically carried out in linear order, where design and construction proceeds step by step. However, the early phases of the design stage provide the best possibilities to influence the plans and ultimate project success, in the present case in terms of the quality and efficiency of geomembranes in tailings ponds. It applies on both; on contributing to the project aims and solutions, but also reducing the total cost and environmental effects of the project in the later phases of its life cycle. [46,47,48]

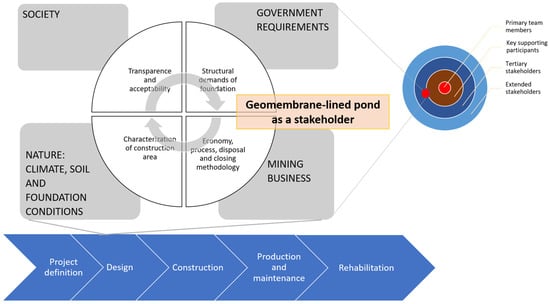

One of the primary difficulties in project management arises from who to involve and how to involve them. Stakeholder management has several methodologies for identification, analysis, and prioritization of key stakeholders. Early influencing requires project management to identify and involve key stakeholders at the beginning of the project, enabling them to make an early contribution [49]. In the present analysis of the importance of geomembranes in basal structures in the mining industry, we consider geomembrane-lined tailings pond as an important stakeholder for early involvement and integration.

Design for Excellence (DfX) is a widely used logic on early involvement and integration. It has been applied for decades in the manufacturing industry, especially in the context of product development projects. DfX is a structured approach for systematic assessment of early product development and functional integration. In DfX, the X stands for an area of design, aspect, or a stakeholder, such as manufacturing, environment, maintenance, supply chain, cost, and so on [46,47,50]. In other words, X can be any aspect considered critical for the project. The basic logic of DfX is that “X” sets requirements, guidelines, and recommendations for design and development. For example, sourcing (design for sourcing) aims for material harmonization and outlines which materials and suppliers are on the list of recommended materials [50]. The present study analyzes “design for geomembrane structures”.

In complex industrial projects, it is crucial to analyze the stakeholders according to the project’s specific areas and aims. One way to analyze the importance of project stakeholders is to consider the salience of the identified stakeholders [51]. In addition to salience, it is vital to evaluate the stakeholders’ roles within the project and ensure that different disciplines (stakeholders) work concurrently in collaboration. The overall aim is to integrate all stakeholders and balance their needs and requirements at an early stage. The idea is to involve disciplines or stakeholders in the same process and consider all life cycle issues affecting the project [52,53]. At present, there may be a risk of the opposite, i.e., a tendency to rush into the details of the design without a proper understanding of the premises. Therefore, a systematic approach is required for organizing the entire design process. This systematic approach must describe stakeholder identification, classification, and management. The project must be organized and controlled by a project management team or project core group with a comprehensive understanding of the project and with the power to steer and manage the project.

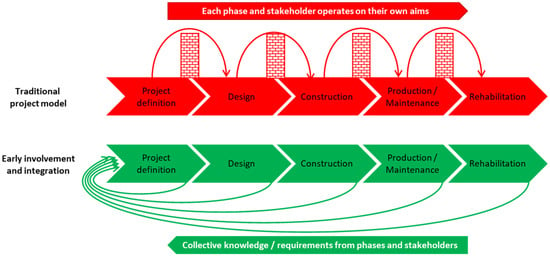

Figure 4 depicts the main differences between the traditional way of organizing complex planning, design, and delivery projects and collaborative arrangements enabling early involvement and integration. Again, one of the greatest challenges is to identify, analyze, and prioritize the most important areas, phases, or stakeholders to be involved and integrated [54]. One way of prioritization is the salience model developed by Mitchell et al. [51] and the impact/probability-matrix created by Olander [55]. Using the salience model, Aapaoja and Haapasalo [54] proposes the following classes to rank the importance of the requirements: (1) Primary team members (the project core group), (2) key supporting participants, (3) tertiary stakeholders, and (4) extended stakeholders.

Figure 4.

Ideological differences between traditional linear project delivery and collaborative project delivery implementing integration and early stakeholder involvement, modified from [28].

The specific value of early stakeholder involvement arises from the possibility to influence project success during the early project stages, because decisions made early reduce unnecessary changes during later development stages and even the total life-cycle costs [46,47]. According to Dowlatshahi [56] and van Valkenburg et al. [57] early stakeholder involvement results in the following benefits:

- (i)

- A lower likelihood of developing poor designs.

- (ii)

- A higher likelihood of more effective design, improved construction operations, and less waste.

- (iii)

- Higher customer satisfaction regarding the product’s function and usage.

- (iv)

- The more stakeholders know about actual usage of the products by customers or end-users, the more efficient stakeholder operations can be in terms of meeting buyers’ needs and purposes.

- (v)

- The more stakeholders know about the exact objectives of the design specifications, the more stakeholders are able to meet or revise those specifications by adjusting their capabilities.

- (vi)

- Scope is created for creative solutions and intensive exchange of ideas.

- (vii)

- Procedures are synchronized and run in phases.

2.4. The Importance of Geomembrane-Lined Tailings Pond as a Stakeholder

Based on the above (Section 2.1, Section 2.2 and Section 2.3), the importance of geomembrane-lined tailings pond as a stakeholder arises from its major role in reducing the environmental footprint of the mining industry. First, the usage of geomembrane-lined basal structures is known worldwide, but all the structures described in the literature are more or less unique. Second, although landfill construction protocols set detailed instructions and design guidelines for geomembrane-lined structures under landfills, mine tailings exert different stresses on the basal structure compared with landfills. Therefore, the exact same construction or design guidelines cannot be used. Third, the climate characteristics pose challenges in design and construction to which attention must be paid. In traditional linear construction project model, participants and stakeholders do not work together at a sufficiently early stage. Many different experts are needed to solve the challenges and balance requirements for success in the demanding construction project. Thus, it is justified to use an advanced project management method like DfX for handling holistic plans to achieve the best available structure.

3. Review of Existing Design Criteria for Tailings Pond Structures

3.1. Basics of Tailings Pond Design

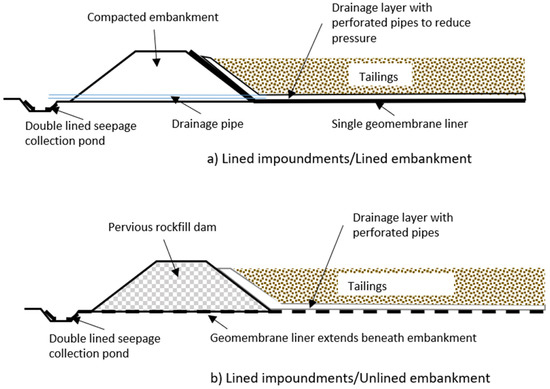

Designing sustainable tailing ponds requires modeling of seepage water routes, both during operation and on closure of the mine. Initial plans are made on the basis of the original mine design and, as reliable data on more parameters become available, modeling calculation are updated [42]. The most important factors to be considered are the stability of the dam and the foundation and drainage structures [4]. The most common structures for tailings ponds are: (1) a structure where the geomembrane liner reaches the top of the dam and (2) a structure where the liner is located underneath the dam and reaches the collection pond for seepage water (Figure 5) [4]. In the latter case, the drainage layer is above the geomembrane liner, in order to lower the hydraulic pressure caused by capillary water above the geomembrane and to minimize leakage through the geomembrane [4]. The drainage structure decreases the hydraulic pressure and improves the strength and stability of the tailings.

Figure 5.

Conceptual models of lined tailings storage facilities with underdrains, modified from [4].

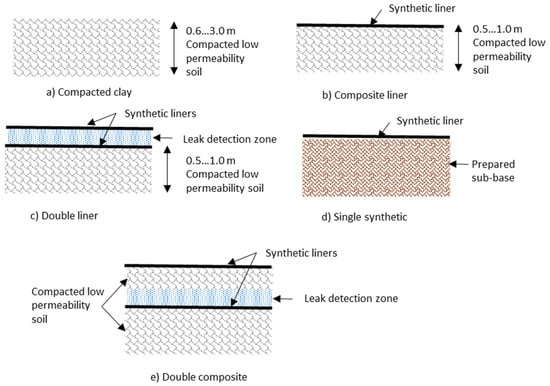

However, the structures shown in Figure 5 do not take into consideration the layers beneath the geomembrane liner. In 2001, the United States Environmental Protection Agency (US EPA) issued instructions for the basal structure if low water permeability is required (Figure 6). The modified basal structure can be constructed according to one of five different design types: (a) compacted clay without geomembrane, (b) a composite solution featuring geomembrane and a layer of compacted soil with low hydraulic conductivity, (c) two geomembrane liners with a leak detection layer, (d) a single geomembrane liner with an underliner layer, and e) a double composite liner structure with two geomembrane liners and a layer with good hydraulic conductivity properties in between for the detection of leaks, as well as compacted layers with low water permeability [58].

Figure 6.

Example of different liner systems (a) compacted clay, (b) composite liner, (c) double liner, (d) single synthetic, and (e) double composite specified for use in the United States if low hydraulic conductivity is required, modified from [58,59].

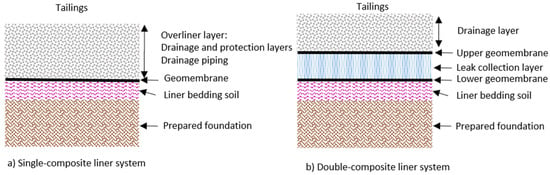

In addition to the above, the tension and pressure caused by the load and consolidation of the foundation, as well as the stress caused by the chemistry of the seepage water, need to be taken into account in the design [5]. The water on top of the geomembrane, leak detection/collection of leakage water, and loading and unloading of tailings can damage the geomembrane. This can be avoided using a single-composite structure where both underliner and overliner structures are adapted [60] (Figure 7). This structure is specially designed for ponds where the tailings are dumped as slurry [5]. The foundation structure underneath the pond has to be connected to the surrounding dam structure and the function of both structures has to be carefully checked [4,61]. Actions performed during operation, such as raising of the dam, closure of the pond and post-monitoring activities, need to be taken into consideration.

Figure 7.

(a) A typical single-composite liner system used in tailings storage facilities (TSF) according to Lupo, modified from [60], and (b) an advanced solution rarely used in TSF, but more common in heap leaching, modified from [43].

3.2. Choice of Geomembrane

Geomembranes used in basal structures are typically made from one of the following materials: linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), polyvinyl chloride (PVC), polypropylene (PP), ethylene propylene diene monomer (EPDM), and ethylene interpolymer alloy (EIA). When choosing geomembrane type, key properties that need to be considered are chemical resistance of the geomembrane, tensile strength, temperature resistance, installation conditions, cost, and previous experiences of its use (Table 2). Bituminous geomembrane (BGM) has been used in the basal structures of tailings ponds in some cases, e.g., [36], but there are no scientific papers describing experiences of this material [30]. However, experiences of its use in other applications, such as dams and channels, have been reported [62,63]. According to Cunning et al. [63], one of the advantages of BGM is that the choice of the underliner material becomes less critical. Additionally, the material’s resistance to low temperatures is good and installation is easier, as it can be done at any time of the year. Other benefits of BGM are high resistance to stress and great resistance to damage [64].

Table 2.

Advantages and disadvantages of typically used geomembranes according to Scheirs [65] and Fourie et al. [30], complemented with data on the properties of bituminous geomembrane (BGM) [63,64].

Selection of an appropriate geomembrane requires a clear understanding of the combined operation of the geomembrane liner and the underliner and overliner layers, as well as the relevant normal and shear loads [66]. Based on practical experiences, Lupo and Morrison [43] developed a selection chart to facilitate determination of a suitable geomembrane material (only for HDPE and LLDPE) and its strength (Table 3). The chart takes into consideration the foundation conditions (the bearing capacity of the subsoil), the underliner and overliner materials, geomembrane thickness, and the load directed at the geomembrane.

Table 3.

General guide to selecting an appropriate linear low-density (LLDPE) or high-density (HDPE) polyethylene geomembrane, modified from [30,43]. Other types of geomembranes described by Fourie et al. [30] that could also be suitable are not included.

Table 3 only includes LLDPE and HDPE and not other possible geomembrane materials. The strength and puncture resistance of the geomembrane can be determined in laboratory tests simulating the on-site conditions [31,45]. The thickness of the geomembrane must be considered; and the recommendation is to use HDPE or LLDPE geomembranes with a minimum thickness of 1.5 mm in all heap leach pads, while for dynamic heaps the recommended geomembrane thickness is no less than 2.0 mm [45]. Other geomembrane materials have not been examined scientifically but, may be as suitable or even better [5], and properties of existing geomembranes are continually being improved.

3.3. Foundation, Underliner and Overliner Material

Geomembranes are known to be damaged during both construction and use [19,67], placing emphasis on the importance of the underliner layer. The soil underneath the geomembrane has to be well-prepared subsoil or a constructed layer. When the underlying subsoil does not generate tension or stretching due to consolidation that might be critical to the proper functioning of the structure, the foundations can be regarded as stable [43].

Any geomembrane strain causing consolidation needs to be assessed. Consolidation of the foundation, i.e., the underliner structure, caused by the pond is usually first estimated by calculation, and these calculations are then used to assess the behavior of the geomembrane. A strain of 4–8% can be permitted for HDPE and 8–12% for LLDPE [22], although the permissible strain should always be verified with the material supplier. It is worth noting that the consolidation in question is large-scale and that local situations, such as tension caused by point loads, are not taken into consideration.

Lupo and Morrison [43] propose requirements for the underliner material. The material should be soil containing fines with maximum particle size no more than 38 mm, particles of different sizes should be evenly distributed, plasticity should be over 15, and the saturated hydraulic conductivity should be 1 × 10−8 m/s or less. The benefits of having the geomembrane directly in contact with an underlying layer of soil with low hydraulic conductivity have been stated in several publications, e.g., [62,68]. The conditions at the site need to be taken into consideration to control the construction costs. If the natural hydraulic conductivity on-site is too high, bentonite can be used to reduce the seepage rate [44]. The amount of bentonite used in soil improvement typically varies between 3 and 8% of dry weight, but the appropriate percentage has to be determined separately in each case [43]. Hydrated bentonite liners can also be used, but due to high loads and the compressibility and internal shear strength of the liners, it is important to verify the stability of the solution [44].

The above applies to the selection of material when the subsoil or underliner material is non-cohesive soil [43,66]. In cases where cohesive material (e.g., clay) or organic matter (e.g., peat) is left at the bottom of the pond, it is important to perform the same field and laboratory tests as for a foundation with good bearing capacity [32,43]. This is because these soils may not only be compressible, but may also yield and compact over time due to creeping or natural degradation. Reinforcement nets, materials intended for under-soil filling, and concrete structures can be used to reduce the strain on the geomembrane liner [41].

The importance of the overliner is sometimes ignored during design, and only the geomembrane material and the hydraulic conductivity of the underliner layer are considered. For example, Rowe et al. [31] tested the impact of the underliner material on the puncture resistance of the geomembrane and noted that when the strain rose to 13–14%, the underliner material no longer mattered. In fact, the overliner material was suspected to have a greater impact.

Because the overliner layer protecting the geomembrane may have several purposes, it can be composed of one or several separate layers. In double-composite structures, for example, the overliner layer provides protection and also functions as a leak detection layer [30]. However, the most important task of the overliner material is to protect the geomembrane liner from the stress caused by the materials above it. The protective material can be sand, gravel and loam or, in some cases, even soil containing clay [43]. As long as its stability is not at risk, the protective layer can also contain geotextiles. The thickness of the layer can vary, depending on the load to the geomembrane, from under 1 m to up to 5 m if heavy vehicles drive on it [31].

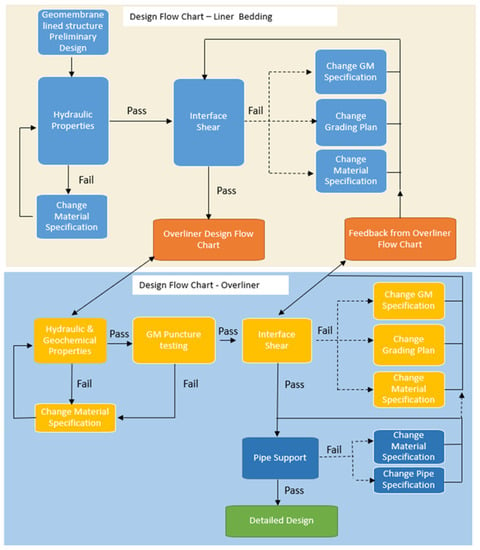

The drainage layer is usually part of the protective layer and generally consists of a natural material, such as sand or gravel [43]. The hydraulic conductivity of the drainage layer has to be high to maintain a steady flow and preventing clogging of the drainage layer. Moreover, the layer has to be sufficiently strong to take the load placed on it without disintegration [30]. The drainage layer can also contain pipes, and these pipes have to withstand the conditions in the pond. Problems due to pipes collapsing or becoming blocked have been reported [60,69]. Lupo [5] discusses factors affecting selection of underliner and overliner materials, as summarized in Figure 8. Overall, the entire liner system has to be considered when choosing the materials for the foundation. If design tests indicate that the structure will not function properly with the selected materials, other materials need to be considered (Figure 8).

Figure 8.

Logic chart for the design of liner bedding and overliner for a basal liner system (GM = geomembrane) modified from [5].

3.4. Other Boundary Conditions for the Use of Geomembranes

3.4.1. Quality Assurance

Quality assurance is an important component of success when lining a pond with geomembrane. Construction quality assurance (CQA) is expensive and, because of the high costs, several quality assurances levels have been established. These are generally divided into three groups: poor or low, good or average, and excellent or high [19,58]. The CQA protocol covers material testing, geomembrane installation control activities, testing of the geomembrane seams, and searches and detection of leakages using electronic methods, among others.

Quality assurance activities largely revolve around testing the integrity of the geomembrane seams, even though these seldom fail [19]. The greatest risk has been found to be in installation of the protective layer on top of the geomembrane liner. To avoid construction-related damage when the pond is in use, quality assurance activities should focus more on the detection of leaks. In the USA, geomembrane integrity methods are described in ASTM D6747 standard, which is also applied in Europe as there are no equivalent standards available [70]. Electrical leak location technologies (ELL) are technologies available for monitoring leakages in the geomembrane lined structures and several standardized methods are available [71,72,73,74,75,76]. The sensors measure changes in the resistivity or dielectric property of the soil, which can indicate leakage processes [77,78]. The monitoring of covered geomembrane structures requires specific methods where grip pattern is installed throughout the survey area, described more closely, e.g., by Gilson-Beck [77]. According to Gilson-Beck [77], covered geomembrane structures should be inspected after material placement to avoid later environmental consequences and ELL methods could be adopted as a common method of locating holes during construction, e.g., seam testing in CQA process. The advantages gained with the installation of continuous ELL monitoring to the basal structure of a tailings pond, however, needs further studies. Lupo and Morrison [43] list the most important points to be taken into consideration in quality assurance as:

- Documentation: examination of the underliner soil, the quality of the examinations, compaction activities and the hydraulic conductivity of the underliner material.

- Monitoring geomembrane installation: avoidance of damage during installation, testing of geomembrane quality, monitoring of the success of installation activities.

- Monitoring drainage layer installation: suitability of the material, compliance with the required layer thickness, special attention to the sensitivity to damage of the underliner layer.

- Climate: consideration of rainfall, snowfall, wind, changes in temperature and UV radiation, to ensure that the geomembrane is installed without construction-induced problems occurring during use.

3.4.2. Effects of Damages on Seepage Rates

Accurate estimation of the surface level of seepage water at dam structures is extremely important, making it one of the basic elements in the design of tailings ponds or similar types of dams. Geomembrane liners are increasingly being used in pond basal structures, and other calculations should also be performed. These include modeling seepage routes and rates, and estimating the ability to prevent or minimize leakage throughout the life cycle of the mine. Analytical methods are usually used in calculation of the specifics [79], while numerical modeling is used in assessing the behavior of the entire pond or the movement of seepage waters [80,81,82]. Analytical calculations are based on the theory of fluid movement in pipe systems (Bernoulli equation) and the flow of a fluid through a porous medium (Darcy’s law). Many studies have also developed empirical formulae for leakage calculations in various composite solutions [81,83,84,85,86,87]. Sufficient modeling accuracy can often be achieved by 2D examination, but 3D modeling is required when, e.g., modeling groundwater head beneath the facility of valley fill [42].

Garrick et al. [42] and La Touche and Garrick [80] calculated the seepage rates from tailings ponds and compared different scenarios. Their calculations and modeling results showed that when the quality assurance level is excellent, loss of seepage waters into the environment can be limited efficiently through composite structures (geomembrane and bentonite liners) [42,80]. According to Garrick et al. [42], the performance of HDPE liners is extremely sensitive to defect occurrence rates, and is thus highly dependent on liner manufacturing and construction quality. Their calculations indicated that a single HDPE liner requires construction to the highest CQA standards to be of significant benefit in reducing the seepage rates of a tailings pond and that, even when the CQA standard is ”good”, the liner can have higher hydraulic conductivity (>1 × 10−8 m/s) than the tailings on top of it [42].

3.4.3. Stability

Stability issues are important to consider when designing foundation and structures during the lifecycle of a tailings pond. Failures of tailings ponds have caused several environmental and human disaster in recent history, e.g., in 2014 at Mount Polley mine in Canada and in 2018 at Córrego de Feijão mine in Brazil. There are no existing limit or reference values for the safety factors for stability of structures to facilitate calculation in all scenarios, but some general guidelines have been formulated [10,45]:

- Changes in shear strength, cohesion, friction angle and hydraulic conditions: these may vary in different parts of the pond, causing segregation.

- Raising the dams: considering the construction method carefully beforehand, especially the upstream construction method, is critical in stability analyses.

- Various biological and chemical reactions take place and may increase the amount of fine material, filter saturation, blocking of filters, etc.

- Loose and grainy material can liquefy and lose its stability, e.g., under earthquake or dynamic load.

Normally, impoundment of tailings demands huge earth dam structures, and those dams are typically raised during production. Tailings dams can be raised by three options: upstream, downstream and centerline. A starter dam is typically constructed as a normal earth dam, using natural materials, but dam raisings involves use of tailings. It is economically sound to raise the dam using the upstream method, to decrease the material and space requirements, but in terms of stability issues the upstream method is the most challenging option [88]. Concerns arise because of poor management, using tailings and mining waste residues, and having raisings located above the stacking. Dam failure mechanisms have been described [88,89]. The selected method may increase the risks of liquefaction of tailings, a phenomenon which is poorly described, making risk estimations difficult [83,90,91]. Foundation properties also affect the failure risk of dams, e.g., due to the drainage arrangements, and special attention has to be paid to estimating the stability of tailings ponds in every step of the life cycle [88].

3.4.4. Closure

Tailings ponds usually require a closure plan [92,93]. The basal structure of the pond may affect the design and costs of closure, as well as the available closure methods. If the aim is to build a compact surface over the pond, it must be possible to reduce the hydraulic pressure in the pond and to remove all free water. This can be challenging if drainage solutions are not considered when designing the geomembrane-sealed pond. Dewatering of tailings is also challenging but, according to Bourgès-Gastaud et al. [94] new innovative cost-efficient drainage possibilities for harsh dewatering cases would be helped by using electrokinetic geocomposite. The function of a compact surface is, above all, to prevent long-term environmental impacts and formation of AMD. AMD develops when water flows over or through sulfur-bearing materials, forming solutions of net acidity. The only way to stop its formation is to prevent sulfur tailings coming into contact with oxygen. Depending on the closure method, harmful AMD can be neutralized or seepage containing the acid can be collected. The closure costs may be high, and the mining operator should be prepared for these expenses [93]. Increasingly stricter laws have been developed to improve the technologies used, e.g., thickening tailings and paste [6,30]. In a good design, various alternatives are considered and compared from the perspective of the entire life span of the mine [95,96].

3.5. Critical Design Factors of Geomembrane Lined Pond

Based on our review of critical factors for design (Section 3.1, Section 3.2, Section 3.3, Section 3.4.1, Section 3.4.2, Section 3.4.3 and Section 3.4.4), use of at least the single-composite liner structure or, in very harsh conditions, the double-composite liner structure is recommended. The single-composite liner structure secures functionality with the geomembrane layer, but also with a sufficiently thick and compacted natural mineral soil layer. The single-composite liner and soil layers work together, so that if one fails the other stabilizes and prevents uncontrolled water flow from the base of the pond. Therefore, attention has to be paid to modeling of seepage water routes and the stability of the dams and foundation. Selection of a suitable geomembrane is also important, as is taking into account the properties of the layers below and above the geomembrane liner. Quality assurance of construction plays a major role in achieving an undamaged and well-functioning structure. In the final phase of the project the tailings pond will be rehabilitated, and the design needs to take into account also the closing arrangements already at the beginning of the tailings pond planning process.

4. Discussion

According to the literature and reports examined, geomembranes are widely used in basal structures of mine basins all over the world. The mining industry has a large environmental footprint and one option to decrease the impacts is to introduce mandatory non-permeability basins. If legislation or other regulations are intended to promote the use of geomembrane liners to reduce seepage through the basal structure, more cohesive construction instructions are needed. In European countries, the construction of landfill sites is regulated through legislation, and the structural requirements, such as layer thicknesses and hydraulic conductivity, are specified. If constructors of landfill structures deviate from the structural guidelines for landfill sites, they must prove that the protection level of the alternative structure is at least on the same level, e.g., [97]. Similar requirements do not exist for structures used in mine tailings ponds. The majority of the existing structures are qualitative, and layer thickness and material requirements are not specified. Therefore, the required level of protection is often unclear. Because boundary limits for design are normally lacking, one option could be a risk-based approach, e.g., [98,99,100,101]. In the design phase, the relevant authorities could set a limit (e.g., mg/L or mg/kg) on the amount of harmful contaminants that the mine operator is allowed to release to the environment. Based on the limit, designers could then calculate the required basal liner structures and dimensions. Possible seepage rates and contaminant concentrations should be analyzed in different scenarios and accumulation of contaminants in nearby surroundings (soil, groundwater, surface water) should be calculated and compared against permit limits considering the whole life cycle of the pond.

There are certain major differences between construction of basal liners for tailings ponds and e.g., for heap leach pads. In heap leaching, the use of geomembranes is justified and even necessary to ensure that metals are recovered as efficiently as possible. Geomembranes are needed to maximize economic efficiency and to prevent transportation of the solution containing metals into the environment. The collection of waters from tailings ponds, on the other hand, does not necessarily increase the efficiency of the process or production. The construction of basal structures and adoption of more complex structures in tailings ponds generate significant extra costs. The leaks that have been detected to date indicate that the structures have to be designed with care and consideration. The reality is that a basal structure lined with a geomembrane will leak at some point in the life cycle of the structure. Leak location technologies could be used to locate failures, although in tailings pond cases, emptying the pond in active phase is challenging and failure repairing is difficult. In heap leach pad cases, the technology would serve more advantages and improve leakage detection and repairing. However, Joshi and Mcleod [102] found that leakages through the geomembrane in tailings ponds are much smaller than in typical landfill and heap leach geomembrane liner systems. The intended use of the tailings pond has a significant effect on the design of the basal structures. Therefore, changes in the primary purpose of use after construction may create problems if these changes have not been taken into consideration during design. If the selected and constructed basal structures have not been designed for the alternative use, this can have dramatic consequences, e.g., failures.

One of the most significant problems in creating better solutions for the basal structures of mine tailings ponds is that relatively little information has been published on the foundation structures of such ponds. More research is needed, for example on the functionality of geomembrane liners and the underliner and overliner soil, and on related solutions and how the combined operation of natural soil and artificial liners can be optimized through the use of a constructed layer of natural soil or bentonite liners. Some studies, e.g., [14,23,44,81,103] have expressed concerns about the long-term behavior of clay liners and layers, which are not believed to be as reliable in composite structures as the calculations suggest. Changes in the behavior of clay in the long run cannot be taken into account in calculations, e.g., channels, fissures, or other weaknesses that allow leakage may form. Rowe et al. [31] tested the functionality of underliner with geomembrane and concluded that further studies are needed on the compatibility of the underliner and overliner materials with the geomembrane, since the maximum allowable strain of 6%, which is generally acceptable for geomembrane liners (HDPE), was exceeded in every test. Brachman et al. [104] performed similar tests on HDPE geomembrane and concluded that if the geomembrane is not covered with protective textiles and a layer of loamy sand, the risk of puncturing is significant. To improve the safety and functionality of future structures, it is therefore important to collect relevant information on successful solutions and to learn from mistakes.

Early involvement and integration can improve the whole design and construction process enabling management of the most critical areas of design, early enough. By identifying geomembrane-lined tailings pond as a stakeholder with a critical impact on the whole mine, decreases the life cycle costs, improves sustainability and quality of the entire mine. Figure 9 shows major factors affecting the sustainable disposal of tailings, in a framework focusing on the possibilities of influencing the successful project and aiming to prevent conflicts arising later in the process. The key supporting perspectives, from our review, are identified as the mining business, governments requirements, nature, and society (Figure 9). These perspectives were identified from the literature, because international guidelines are lacking, and thus attention must be paid to national instructions and conditions (government requirements). A successful project has to be environmentally sustainable, society’s requirements must be heard, and feedback obtained from society needs to be taken seriously. As previously discussed, mines are unique, detailed guidelines are lacking worldwide, and local conditions and material availability differ. Together, these factors form an important part of the framework (nature). Finally, the mining business itself sets the frame for the whole construction process (mining business). Here we outline important perspectives based on earlier research results, but the actual stakeholders and the classifications are project specific, so must identified for each project [see 54]. Based on research on project management, see [47], it is not sufficient to state simply that tailings ponds are important. Rather, practical tools and methods are needed, especially in complex projects, to enable positive impacts on the final design. Through applying “design for tailings ponds” as a method, or considering “geomembrane-lined tailings pond as a stakeholder” it can be ensured that critical factors for tailings ponds are considered from the outset in the design of mines.

Figure 9.

A framework for identified geomembrane-lined tailings pond as a stakeholder in early involvement and integration process. The key supporting perspectives are identified as i) mining business, ii) governments requirements, iii) nature, and iv) society, which all include several details to be noticed in every phase of mining.

Ultimately, the selection of disposal methodology is one more option to alleviate the risk of seepage through the basal structure. To promote the use of more modern disposal technologies, e.g., paste or dry stacking, more experience is needed, especially on the suitability of the method in cold climate regions. Alakangas et al. [105] reviewed the paste technique and noted that the geotechnical and rheological properties of suitable pastes are well-defined and documented, but that difficulties can arise under cold climate conditions. Snow and ice, together with freezing and thawing cycles, can cause problems, e.g., for pipes, deposition, slopes, and stability, but can also have a positive effect, e.g., by accelerating consolidation [105,106]. Nevertheless, scientific studies are needed on the functionality and usability of the paste technique in cold climates, and the risks need to be identified and resolved. The presence of snow and ice also affects other disposal methods and makes design, construction, operation and monitoring more challenging.

5. Conclusions

Geomembranes are widely used in the mining industry to prevent or reduce the harmful effects caused by seepage of leachates. Within the past two decades, use of geomembranes has increased sharply, as their installation as a basal liner in tailings storage basins is often required by stringent legislation and as there have been positive experiences of their use in landfill site construction. However, few case studies describing geomembrane-lined tailings ponds have been performed worldwide. Previous studies present basic examples and design criteria for well-functioning basal liners, but practice has proven to be more complex. The most common structures used are a single-composite liner system comprising a prepared foundation, low permeability soil layer (clay or GCL), geomembrane, and drainage layer; and a double-composite liner system, where there is a secondary geomembrane and a leak collection layer. More research should be targeted at identifying suitable underliner and overliner material. Challenges to the use of geomembranes arise due to the large area to be covered, as circumstances differ, and the costs may be relatively high. Installation of geomembrane in cold climate conditions poses particular challenges, with the timing of installation playing an important role. Good practices, design criteria and user experience are lacking. Better process management is needed, and one solution could offer early involvement and integration. By including geomembrane-lined tailings ponds as a stakeholder in mine development projects, the importance of pond design is recognized. The framework presented in this paper can help prevent conflicts among other stakeholders and avoid structurally weak designs. Overall, future attention should be focused on legislation, site selection, quality of design, weather demands, material properties and their compatibility, construction quality assurance, monitoring, closure procedures, and finally project management.

Based on the evidence available to date, geomembrane structures can considerably reduce the amount of seepage water lost through lined basal structures in comparison with naturally low permeability soil structures. For tailings ponds, there are already more modern disposal methods to consider, such as thickened tailings, paste, or dry dumping, which have the major advantage of reducing the amount of seepage water. However, in many cases these alternatives are non-viable because of higher initial or operating costs or lack of operating experience. A main conclusion of this review is that the mining industry needs guidelines and recommendations on design and construction of geomembrane-lined basal structures. To improve the function of these structures, more specific knowledge is needed from practical use and from precise scientific studies. To avoid future problems, positive and negative experiences should be reported in the literature and detailed knowledge of successful working structures, and of failures, should be shared openly.

Author Contributions

Conceptualization A.T., A.-K.R. and P.M.R., methodology A.T., H.H., validation, formal analysis, resources, data curation, writing—original draft preparation, visualization, project administration, funding acquisition, A.T.; writing—review and editing, A.-K.R., P.M.R., A.R., H.H. and supervision K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded and supported by Ministry of the Environment of Finland, The Centres for Economic Development, Transport and the Environment Kainuu, K. H Renlunds foundation and Tauno Tönning foundation.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

References

- Thenepalli, T.; Chilakala, R.; Habte, L.; Tuan, L.Q.; Kim, C.S. A brief note on the heap leaching technologies for the recovery of valuable metals. Sustainability 2019, 11, 3347. [Google Scholar] [CrossRef]

- Breitenbach, A.J.; Smith, M.E. Overview of geomembrane history in the mining industry. In Proceedings of the 8th bi-annual meeting of the International Geosynthetics Society, Yokohama, Japan, 18–22 September 2006. [Google Scholar]

- Addis, P. Lining of the Return Water Dam at the Onverwacht Tailings Storage Facility. In Proceedings of the Tailings and Mine Waste, Vancouver, BC, Canada, 1 July 2011. [Google Scholar]

- Davies, M.; Lighthall, P.; Rice, S.; Martin, T. Design of Tailings Dams and Impoundments. In Proceedings of the 2002 SME Annual Meeting, Phoenix, AZ, USA, 25–27 February 2002. [Google Scholar]

- Lupo, J.F. Liner system design for heap leach pads. Geotext. Geomembr. 2010, 28, 163–173. [Google Scholar] [CrossRef]

- Wang, C.; Harbottle, D.; Liu, Q.; Xu, Z. Current state of fine mineral tailings treatment: A critical review on theory and practice. Min. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Jewell, R.J.; Fourie, A.B. (Eds.) Paste and Thickened Tailings—A Guide, 3rd ed.; Australian Centre for Geomechanics: Perth, Australia, 2015; p. 356. [Google Scholar]

- Vick, S.G. Planning, Design, and Analysis of Tailings Dams; BiTech: Vancouver, BC, Canada, 1990. [Google Scholar]

- Yang, J.; Wei, L.M. Collapse of loose sand with the addition of fines: The role of particle shape. Géotechnique 2012, 62, 1111–1125. [Google Scholar] [CrossRef]

- Davies, M.; McRoberts, E.; Martin, T. Static Liquefaction of Tailings—Fundamentals and Case Histories. Available online: http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.561.3723 (accessed on 21 November 2020).

- European Commission. Management of Tailings and Waste-Rock in Mining Activities. Reference Documents on Best Available Techniques. 2009. Available online: http://www7.nau.edu/itep/main/HazSubMap/docs/CoalMining/ManagementOfTailingsAndWasteRockInMiningActvities.pdf (accessed on 21 November 2020).

- Kuyucak, N. Acid mine drainage prevention and control options. C. Bull. 2002, 1060, 96–102. [Google Scholar]

- Lange, K.; Rowe, R.K.; Jamieson, H. The potential role of geosynthetic clay liners in mine water treatment systems. Geotext. Geomembr. 2010, 28, 199–205. [Google Scholar] [CrossRef]

- Hornsey, W.P.; Scheirs, J.; Gates, W.P.; Bouazza, A. The impact of mining solutions/liquors on geosynthetics. Geotext. Geomembr. 2010, 28, 191–198. [Google Scholar] [CrossRef]

- Garbarino, E.; Orveillon, G.; Saveyn HBarthe, P.; Eder, P. Best Available Techniques (BAT) Reference Document for the Management of Waste from Extractive Industries; In accordance with Directive 2006/21/EC.; EUR 28963 EN.; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-77178-1. [Google Scholar]

- Touze-Foltz, N.; Bannour, H.; Barral, C.; Stoltz, G. A review of the performance of geosynthetics for environmental. Geotext. Geomembr. 2016, 44, 656–672. [Google Scholar] [CrossRef]

- Bouazza, A.; Zornberg, J.G.; Adam, D. Geosynthetics in waste containment facilities: Recent advances. In Proceedings of the International Conference on Geosynthetics, Nice, France, 22–27 September 2002; pp. 445–507. [Google Scholar]

- Daniel, D.E. Case histories compacted clay liners and covers for waste disposal facilities. In Proceedings of the Third International Conference on Case Histories in Geotechnical Engineering, St. Louis, MO, USA, 1–9 June 1993; pp. 1407–1425. [Google Scholar]

- Darilek, G.T.; Laine, D.L. Costs and Benefits of Geomembrane Liner Installation CQA. In Proceedings of the Geosynthetics Conference Proceedings, Portland, OR, USA, 12–14 February 2001; pp. 65–75. [Google Scholar]

- Jingjing, F. Leakage Performance of the GM + CCL Liner System for the MSW Landfill. Sci. World J. 2014, 2014, 9. [Google Scholar] [CrossRef][Green Version]

- Lupo, J.F.; Morrison, K.F. Innovative Geosynthetic Liner Design Approaches and Construction in the Mining Industry. In Proceedings of the ASCE Geo-Frontiers, Austin, TX, USA, 24–26 January 2005; p. 16. [Google Scholar] [CrossRef]

- Peggs, I.D.; Schmucker, B.; Carey, P. Assessment of Maximum Allowable Strains in Polyethylene and Polypropylene Geomembranes. In Proceedings of the Geo-Frontiers 2005 Congress, Austin, TX, USA, 24–26 January 2005. [Google Scholar]

- Podgorney, R.K.; Bennett, J.E. Evaluating the Long-Term Performance of Geosynthetic Clay Liners Exposed to Freeze-Thaw. J. Geotech. Geoenvironmental Eng. 2006, 132, 265–268. [Google Scholar] [CrossRef]

- Stepniewski, W.; Widomski, M.K.; Horn, R. Hydraulic Conductivity and Landfill Construction. In Developments in Hydraulic Conductivity Research; Dikinya, O., Ed.; Intech: Rijeka, Croatia, 2011; pp. 249–270. [Google Scholar]

- Finland Times. Leakage in Kittilä Gold Mine Termed Serious. FTimes—STT Report. 2015. Available online: http://www.finlandtimes.fi/business/2015/10/31/21896/Leakage-in-Kittil%C3%A4-gold-mine-termed-serious (accessed on 13 January 2021).

- Safety Investigation Authority. Ympäristöonnettomuus Talvivaaran Kaivoksella Marraskuussa 2012 (Environmental Accident at the Talvivaara Mine in November 2012, Abstract in English). The investigation report Y2012-03. 2014. Available online: https://www.turvallisuustutkinta.fi/material/attachments/otkes/tutkintaselostukset/fi/muutonnettomuudet/2012/k2wFN7MMJ/Y2012-03_Tutkintaselostus.pdf (accessed on 13 January 2021).

- Harmon, W.Q. EPA Provides Updates on MNG Gold Mine Incident (News). 2017. Available online: https://www.liberianobserver.com/news/epa-provides-updates-on-mng-gold-mine-incident/ (accessed on 15 January 2021).

- Aapaoja, A.; Haapasalo, H.; Söderström, P. Early Stakeholder Involvement in the Project Definition Phase: Case Renovation. Int. Sch. Res. Not. 2013, 2013, 1–14. [Google Scholar] [CrossRef]

- Matthews, O.; Howell, G.A. Integrated project delivery an example of relational contracting. Lean Constr. J. 2005, 2, 46–61. [Google Scholar]

- Fourie, A.B.; Bouazza, A.; Lupo, J. Improving the performance of mining infrastructure through the judicious use of geosynthetics. In Proceedings of the 9th International Conference on Geosynthetics, Guarujá, Brazil, 23–27 May 2010. [Google Scholar]

- Rowe, R.K.; Brachman RW, I.; Irfan, H.; Smith, M.E.; Thiel, R. Effect of underliner on geomembrane strains in heap leach applications. Geotext. Geomembr. 2013, 40, 37–47. [Google Scholar] [CrossRef]

- Dillon, M.; White, R.; Power, D. Tailings storage at Lisheen Mine, Ireland. Miner. Eng. 2004, 17, 123–130. [Google Scholar] [CrossRef]

- Alcoa World Alumina. Application Guide—Geosynthetic Clay liners (GCLs) for Residue Disposal Areas (AWA); Report; Alcoa: Anglesea, Australia, 2009. [Google Scholar]

- Hillgrove Copper Pty Ltd. Program. for Environment Protection and Rehabilitation—Life of Mine. Report. Available online: https://www.miningdataonline.com/reports/Kanmantoo_Program%20for%20environment%20protection%20and%20rehabilitation_Oct2016.pdf (accessed on 15 January 2021).

- SRK Consulting. Technical Report for the Yaramoko Gold Mine, Burkina Faso. Report. Available online: https://www.miningnewsfeed.com/reports/Yaramoko_Technical_Report_12202017.pdf (accessed on 21 November 2020).

- Jouttijärvi, T.; Kallio, A.; Kauppi, S.; Kauppila, P.; Komulainen, H.; Laasonen, J.; Laine-Ylijoki, J.; Leppänen, M.; Reinikainen, J.; Wahlström, M. Kaivosten Stressitestit 2013; Report; Välisalo, T., Ed.; Ympäristöministeriö: Helsinki, Finland, 2014; Available online: http://hdl.handle.net/10138/42780 (accessed on 15 January 2021).

- Avesoro Holdings. Kokoya Gold Mine, Rebublic of Liberia. Presentation of Kokoya Gold Mine. 2017. Available online: https://avesoroholdings.com/wp-content/uploads/2017/09/Avesoro_Holdings_Kokoya_Sept_2017.pdf (accessed on 15 January 2021).

- Cole, J.; Walls, J.; Collins, R. Husab Tailings Storage Facility Containment Design. In Proceedings of the Geosynthetics Mining Solutions, Vancouver, BC, Canada, 8−11 September 2014. [Google Scholar]

- Akcil, A. Cyanide control in tailings pond: Ovacik gold mine. In Proceedings of the SWEMP Conference, Palermo, Italy, 28 July–1 August 2002; pp. 437–441. [Google Scholar]

- Cetco. Mine Tailings Storage Facility Bottom Liner System. Project case study. 2012. Available online: https://www.mineralstech.com/docs/default-source/performance-materials-documents/cetco/environmental-products/case-studies/cs_barrickgoldstrike2012_am_en_201709_v3.pdf?sfvrsn=47798a91_16 (accessed on 15 January 2021).

- ICOLD. Geomembrane Sealing Systems for Dams, Design Principles and Review of Experience; Bulletin 135; ICOLD: Paris, France, 2010. [Google Scholar]

- Garrick, H.; Digges La Touche, G.; Plimmer, B.; Hybert, D. Assessing the hydraulic performance of tailings management facilities. In Proceedings of the 17th Extractive Industry Geology Conference, Fife, Scotland, 11–14 June 2014. [Google Scholar]

- Lupo, J.F.; Morrison, K.F. Geosynthetic design and construction approaches in the mining industry. Geotext. Geomembr. 2007, 25, 96–108. [Google Scholar] [CrossRef]

- Shackelford, C.D.; Sevick, G.W.; Eykholt, G.R. Hydraulic conductivity of geosynthetic clay liners to tailings impoundment solutions. Geotext. Geomembr. 2009, 28, 149–162. [Google Scholar] [CrossRef]

- Thiel, R.; Smith, M.E. State of The Practice Review of Heap Leach Pad Design Issues. Geotext. Geomembr. 2004, 22, 555–568. [Google Scholar] [CrossRef]

- Möttönen, M.; Härkonen, J.; Belt, P.; Haapasalo, H.; Similä, J. Managerial view on design for manufacturing. Ind. Manag. Data Syst. 2009, 109, 859–872. [Google Scholar] [CrossRef]

- Lehto, J.; Härkönen, J.; Haapasalo, H.; Belt, P.; Möttönen, M.; Kuvaja, P. Benefits of DfX in Requirements Engineering. Technol. Invest. 2011, 2, 27–37. [Google Scholar] [CrossRef]

- Aapaoja, A.; Herrala, M.; Pekuri, A.; Haapasalo, H. The characteristics of and cornerstones for creating integrated teams. Int. J. Manag. Proj. Bus. 2013, 6, 695–713. [Google Scholar] [CrossRef]

- Lahdenperä, P. Making sense of the multi-party contractual arrangements of project partnering, project alliancing and integrated project delivery. Constr. Manag. Econ. 2012, 30, 57–79. [Google Scholar] [CrossRef]

- Bralla, J.G. Design for Excellence, 1st ed.; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Mitchell, R.K.; Agle, B.R.; Wood, D.J. Towards a Theory of Stakeholder Identification and Salience: Defining the Principle of Who and What Really Counts. Acad. Manag. Rev. 1997, 22, 853–886. [Google Scholar] [CrossRef]

- Kamara, J.M.; Anumba, C.J.; Evbuomwan, N.F.O. Establishing and processing client requirements—A key aspect of concurrent engineering in construction. Eng. Constr. Archit. Manag. 2000, 7, 15–28. [Google Scholar] [CrossRef]

- Anumba, C.J.; Baugh, C.; Khalfan, M.M.A. Organisational structures to support concurrent engineering in construction. Ind. Manag. Data Syst. 2002, 102, 260–270. [Google Scholar] [CrossRef]

- Aapaoja, A.; Haapasalo, H. A Framework for Stakeholder Identification and Classification in Construction Projects. Open J. Bus. Manag. 2014, 2, 43–55. [Google Scholar] [CrossRef]

- Olander, S. Stakeholder impact analysis in construction project management. Constr. Manag. Econ. 2007, 25, 277–287. [Google Scholar] [CrossRef]

- Dowlatshahi, S. Implementing early supplier involvement: A conceptual framework. Int. J. Oper. Prod. Manag. 1998, 18, 143–167. [Google Scholar] [CrossRef]

- Valkenburg, M.; van Lenferink, S.; Nijsten, R.; Arts, J. Early contractor involvement: A new strategy for “buying the best” in infrastructure development in the Netherlands. In Proceedings of the 3rd International Public Procurement Conference Proceedings, Amsterdam, The Netherlands, 28–30 August 2008. [Google Scholar]

- U.S. Environmental Protection Agency. Part. IV Protecting Ground Water Chapter 7: Section B Designing and Installing Liners Technical Considerations for New Surface Impoundments, Landfills, and Waste Piles Contents; US Environment Protection Agency publication SW-846; U.S. Environmental Protection Agency: Washington, DC, USA, 2001. Available online: https://www.epa.gov/sites/production/files/2016-03/documents/industrial-waste-guide.pdf (accessed on 15 January 2021).

- Workman, J.P.; Keeble, R.L. Design and Construction of Liner Systems. In Sanitary Landfilling: Process, Technology and Environmental Impact; Christensen, T.H., Ed.; Academic Press: New York, NY, USA, 1989; Chapter 5.1; pp. 301–309. [Google Scholar]

- Lupo, J.F. Liner system design for tailings impoundments and heap leach pads. In Proceedings of the Tailings and Mine Waste, Fort Collins, CO, USA, 18 October 2008. [Google Scholar]

- Chou, A.; Rowe, K.; Brachman, R. Erosion of Silty Sand Tailings through a Geomembrane Defect under Filter Incompatible Conditions. Can. Geotech. J. 2018, 55, 1564–1576. [Google Scholar] [CrossRef]

- Bannour, H.; Barral, C.; Touze-Foltz, N. Flow rate in composite liners including GCLs and a bituminous geomembrane. In Proceedings of the 3rd International Conference on Geotechnical Engineering, Hamamet, Tunisia, 21–23 February 2013; p. 11. [Google Scholar]

- Cunning, J.; Isidoro, A.; Eldridge, T.; Reinson, J. Dam Construction at Diavik using Bituminous Geomembrane Liners. In Proceedings of the 61st Canadian Geotechnical Conference, Edmonton, AB, Canada, 21–24 September 2008; pp. 933–939. [Google Scholar]

- Breul, B.; Reinson, J.; Eldreidge, T.; Stenson, G.; Harman, A. Bituminous geomembrane in extremely cold conditions. In Proceedings of the 8th International Conference on Geosynthetics, Yokohama, Japan, 18–22 September 2006. [Google Scholar]

- Scheirs, J. A Guide to Polymeric Geomembranes, A Practical Approach, 1st ed.; Wiley & Sons Ltd.: Hoboken, NJ, USA, 2009; 596p, ISBN 978-0-470-51920-2. [Google Scholar]

- Touze-Foltz Nathalie Lupo, J.; Barroso, M. Geoenvironmental Applications of Geosynthetics. In Proceedings of the 4th European Geosynthetics Conference, Edinburgh, UK, 7–10 September 2008; pp. 1–98. [Google Scholar]

- Giroud, J.P. Leakage Control using Geomembrane Liners. Soils Rocks 2016, 39, 213–235. [Google Scholar]

- Weber, C.T.; Zornberg, G.J. Leakage through Liners under High Hydraulic Heads. In Proceedings of the Geosynthetics Research and Development in Progress, Eighteenth Geosynthetic Research Institute Conference (GRI-18), Austin, TX, USA, 24–26 January 2005. [Google Scholar]

- Khalaj, O.; Azizian, M.; Darabi, N.J.; Tafreshi, S.N.M.; Jirková, H. The role of expanded polystyrene and geocell in enhancing the behavior of buried HDPE pipes under trench loading using numerical analyses. Geosciences 2020, 10, 251. [Google Scholar] [CrossRef]

- Hruby, V.; Barrie, S. Geomembrane integrity surveys—Difference between us an EU concepts. In Proceedings of the Sixteenth International Waste Management and Landfill Symposium, Santa Margherita di Pula, Italy, 2–6 October 2017. [Google Scholar]

- ASTM D6747-15. Standard Guide for Selection of Techniques for Electrical Leak Location of Leaks in Geomembranes; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- ASTM D7002-16. Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Water Puddle Method; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- ASTM D7007-16. Standard Practices for Electrical Methods for Locating Leaks in Geomembranes Covered with Water or Earthen Materials. ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- ASTM D7240-18. Standard Practice for Electrical Leak Location Using Geomembranes with an Insulating Layer in Intimate Contact with a Conductive Layer via Electrical Capacitance Technique (Conductive-Backed Geomembrane Spark Test.); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar] [CrossRef]

- ASTM D7703-16. Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Water Lance Method; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- ASTM D7953-20. Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Arc Testing Method; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- Gilson-Beck, A. Controlling leakage through installed geomembranes using electrical leak location. Geotext. Geomembr. 2019, 47, 697–710. [Google Scholar] [CrossRef]

- Guan, S.P.; Yu, Z.H.; Zhong, S. Leak marking scheme for construction quality testing of geomembrane liners in Landfills. Int. J. Environ. Res. 2014, 8, 447–452. [Google Scholar] [CrossRef]

- Beck, P.E.; Smith, M.; Sample, K. Design considerations for the use of geomembranes for phosphate tailing impoundments. In Proceedings of the 3rd International Conference on the Valorization of Phosphates and Phosphorus Compounds, Marrakesh, Morocco, 18–20 March 2009. [Google Scholar]

- La Touche, G.D.; Garrick, H. Hydraulic performance of liners in tailings management and heap leach facilities. In Proceedings of the International Mine Water Association Symposium, Bunbury, Australia, 30 September–4 October 2012; pp. 371–378. [Google Scholar]

- Rowe, R.K. Short- and long-term leakage through composite liners. In The 7th Arthur Casagrande Lecture, 14th Pan-American Conference on Soil Mechanics and Geotechnical Engineering; NRC Research Press: Ottawa, ON, Canada. [CrossRef]

- Beck-Broichsitter, S.; Gerke, H.H.; Horn, R. Assessment of leachate production from a municipal solid-waste landfill through water-balance modeling. Geosciences 2018, 8, 372. [Google Scholar] [CrossRef]

- Barroso, M.; Touze-Foltz, N.; von Maubeuge, K.; Pierson, P. Laboratory investigation of flow rate through composite liners consisting of a geomembrane, a GCL and a soil liner. Geotext. Geomembr. 2006, 24, 139–155. [Google Scholar] [CrossRef]

- Giroud, J.P. Equations for Calculating the Rate of Liquid Migration Through Composite Liners Due to Geomembrane Defects. Geosynth. Int. 1997, 4, 335–348. [Google Scholar] [CrossRef]

- Giroud, J.P.; King, T.D.; Sanglerat, T.R.; Hadj-Hamou, T.; Khire, M.V. Rate of Liquid Migration Through Defects in a Geomembrane Placed on a Semi-Permeable Medium. Geosynth. Int. 1997, 4, 349–372. [Google Scholar] [CrossRef]

- Rowe, R.K.; Booker, J. Theoretical Solutions for Calculating Leakage through Composite liner Systems; Geotechnical Research Centre Report. GEOT-18–98; Department of Civil & Environmental Engineering, Faculty of Engineering Science, University of Western Ontario: London, ON, USA, 1998. [Google Scholar]

- Touze-Foltz, N.; Giroud, J.P. Empirical Equations for Calculating the Rate of Liquid Flow through Composite Liners Due to Geomembrane Defects. Geosynth. Int. 2003, 10, 215–233. [Google Scholar] [CrossRef]

- Lyu, Z.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J. A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Adv. Civ. Eng. 2019, 2019, 18. [Google Scholar] [CrossRef]

- Rico, M.; Benito, G.; Salgueiro, A.R.; Díez-Herrero, A.; Pereira, H.G. Reported tailings dam failures. A review of the European incidents in the worldwide context. J. Hazard. Mater. 2008, 152, 846–852. [Google Scholar] [CrossRef] [PubMed]

- Robertson, P.K. Evaluation of flow liquefaction and liquefied strength using the cone penetration test. J. Geotech. Geoenvironmental Eng. 2010, 136, 842–853. [Google Scholar] [CrossRef]

- Shuttle, D.A.; Cunning, J. Discussion: Liquefaction Potential of Silts from CPTu. Can. Geotech. J. 2008, 45, 142–145. [Google Scholar] [CrossRef]

- 2016. Available online: http://en.gtk.fi/research/program/greenmining/closedure.html, (accessed on 15 January 2021).

- The Mining Association of Canada. A Guide to the Management of Tailings Facilities, 2nd ed. Available online: https://mining.ca/wp-content/uploads/2019/02/GuidetotheManagementofTailingsFacilities2011.pdf (accessed on 15 January 2021).

- Bourgès-Gastaud, S.; Stoltz, G.; Dolez, P.; Blond, É.; Touze-Foltz, N. Laboratory device to characterize electrokinetic geocomposites for fluid fine tailings dewatering. Can. Geotech. J. 2015, 52, 505–514. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef]

- Boger, D. Rheology of Slurries and Environmental Impacts in the Mining Industry. Annu. Rev. Chem. Biomol. Eng. 2013, 239–257. [Google Scholar] [CrossRef] [PubMed]

- Simon, F.-G.; Müller, W. Standard and alternative landfill capping design in Germany. Environ. Sci. Policy 2004, 7. [Google Scholar] [CrossRef]

- Butt, T.E.; Lockley, E.; Oduyemi, K.O.K. Risk assessment of landfill disposal sites—State of the art. Waste Manag. 2008, 28, 952–964. [Google Scholar] [CrossRef] [PubMed]

- Butt, T.E.; Gouda, H.M.; Baloch, M.I.; Paul, P.; Javadi, A.A.; Alam, A. Literature review of baseline study for risk analysis—The landfill leachate case. Environ. Int. 2014, 63, 149–162. [Google Scholar] [CrossRef] [PubMed]

- Høyer, A.S.; Klint KE, S.; Fiandaca, G.; Maurya, P.K.; Christiansen, A.V.; Balbarini, N.; Bjerg, P.L.; Hansen, T.B.; Møller, I. Development of a high-resolution 3D geological model for landfill leachate risk assessment. Eng. Geol. 2019, 249, 45–59. [Google Scholar] [CrossRef]

- Arjwech, R.; Somchat, K.; Pondthai, P.; Everett, M.; Schulmeister, M.; Saengchomphu, S. Assessment of geological, hydrogeological and geotechnical characteristics of a proposed waste disposal site: A case study in Khon Kaen, Thailand. Geosciences 2020, 10, 109. [Google Scholar] [CrossRef]

- Joshi, P.; McLeod, H. Effectiveness of Geomembrane Liners in Minimizing Seepage in Tailings Storage Facilities: New Knowledge. In Proceedings of the 26th International Congress on Large Dams, Vienna, Austria, 1–7 July 2018; International Commission on Large Dams: Vienna, Austria, 2018. [Google Scholar]

- Beck-Broichsitter, S.; Gerke, H.H.; Horn, R. Effect of compaction on soil physical properties of differently textured landfill liner materials. Geosciences 2019, 9, 1. [Google Scholar] [CrossRef]

- Brachman, R.W.I.; Rowe, R.K.; Irfan, H.; Gudina, S. High-Pressure Puncture Testing of HDPE Geomembranes. In Proceedings of the 2011 Pan-Am CGS Geotechnical Conference, Toronto, ON, Canada, 2–6 October 2011. [Google Scholar]

- Alakangas, L.; Dagli, D.; Knutsson, S. Literature Review on Potential Geochemical and Geotechnical Effects of Adopting Paste Technology under Cold Climate Conditions; Lulea University of Technology Division of Mining and Geotechnical Engineering: Lulea, Sweden, 2013; pp. 1–34. [Google Scholar]

- Knutsson, R.; Viklander, P.; Knutsson, S. Stability considerations for thickened tailings due to freezing and thawing. In Proceedings of the Paste 2016, 19th International Seminar on Paste and Thickened Tailings, Santiago, Chile, 5–8 July 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).