Mobile Poultry Processing Unit as a Resource for Small Poultry Farms: Planning and Economic Efficiency, Animal Welfare, Meat Quality and Sanitary Implications

Simple Summary

Abstract

1. Introduction

- Essential requirements of a MPPU

- Operation and economic efficiency

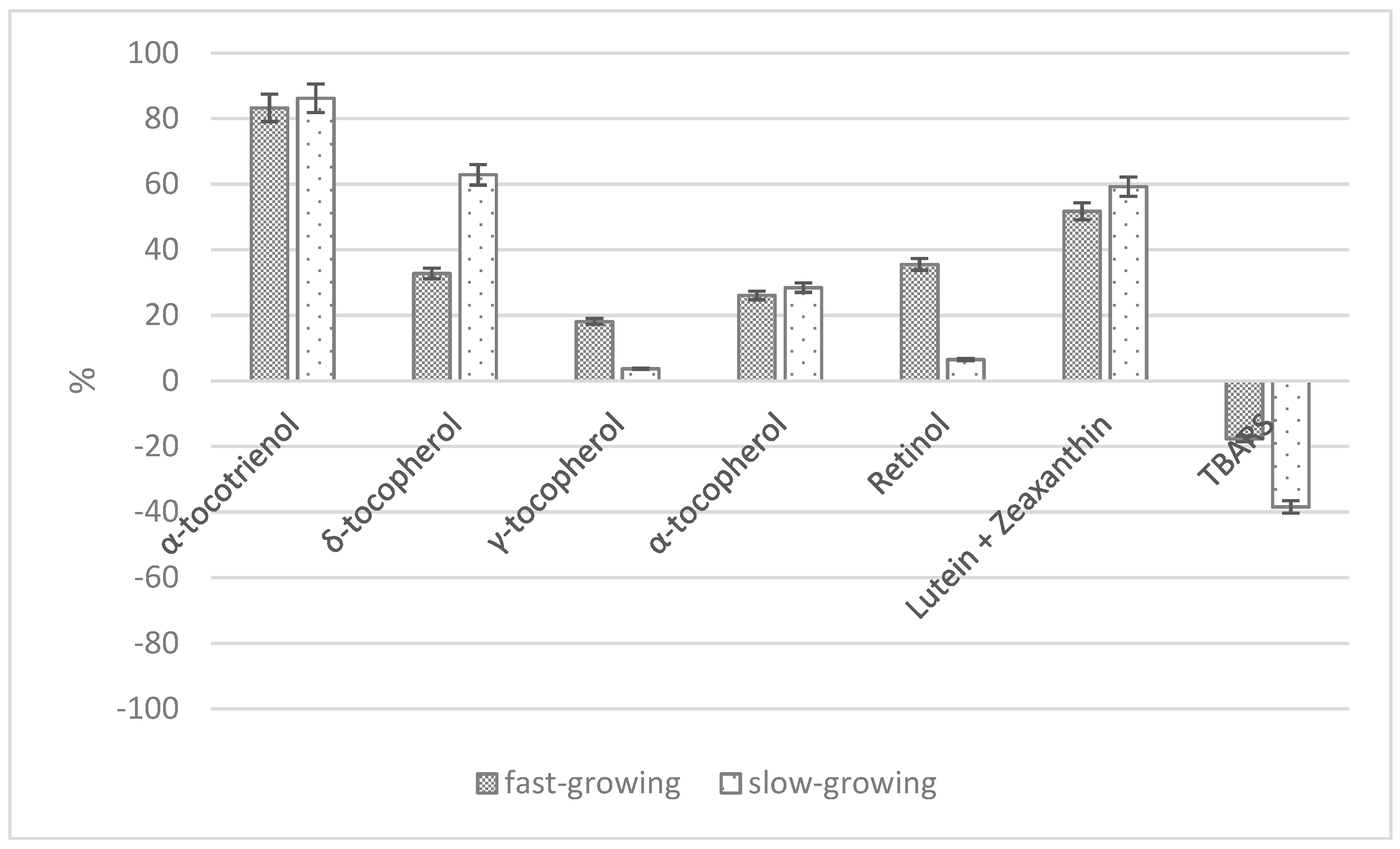

- Animal welfare aspects

- Qualitative and sanitary implications.

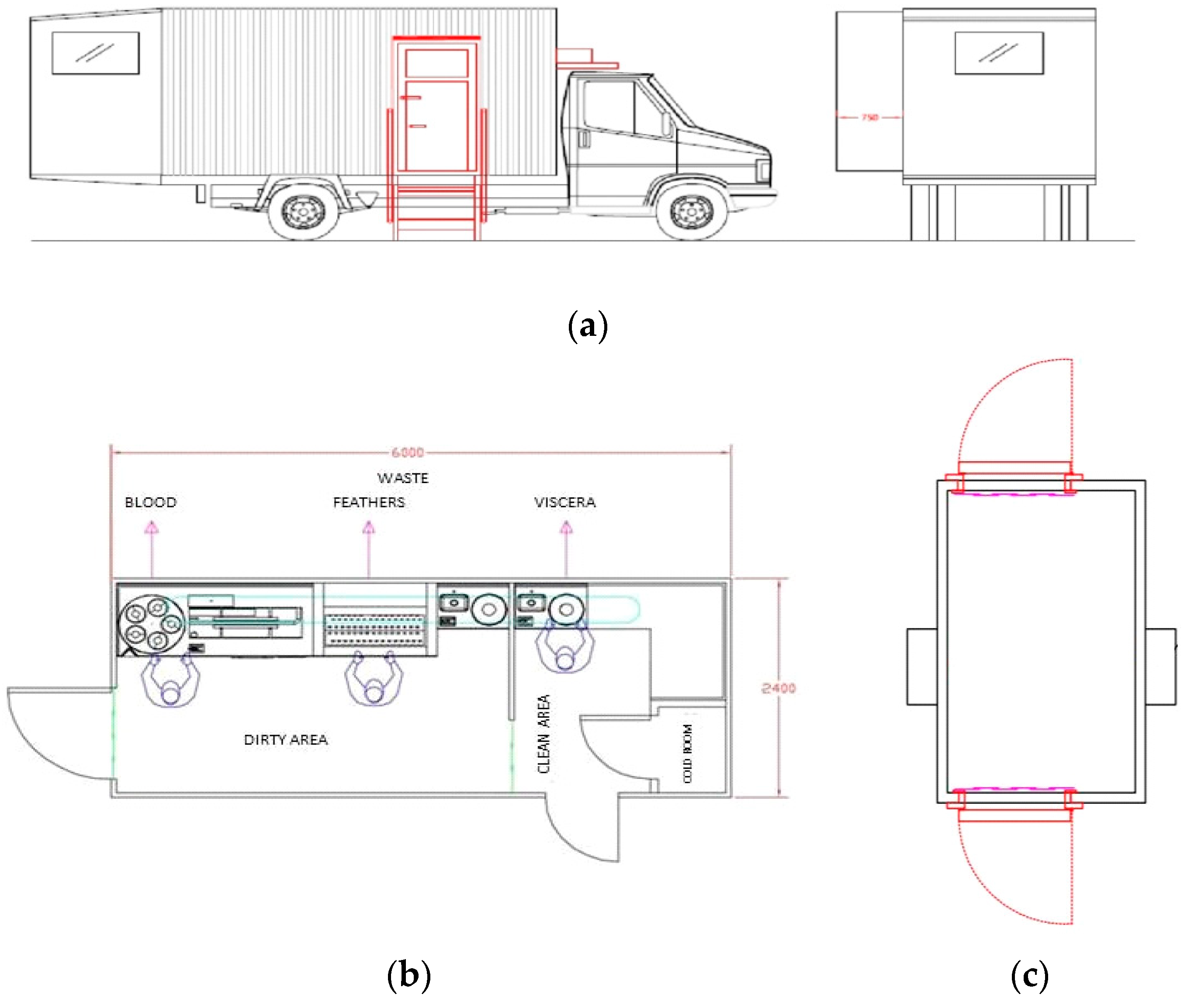

2. Essential Requirements: Planning and Layout

- The MPPU can be used on poultry farms producing less than 10,000 birds per year (EU State-Regions) [35];

- The meat processed in a MPPU can only be sold in neighbouring areas (the province where a MPPU is located and adjacent areas, within 50 Km of the province border) and this is not valid for all States of the EU;

- The buyer should be a retailer, that is, selling directly to the consumer.

3. A Case Study of MPPU in Italy

- -

- Dirty area;

- -

- Clean area; so at least two operators are needed, one for each area.

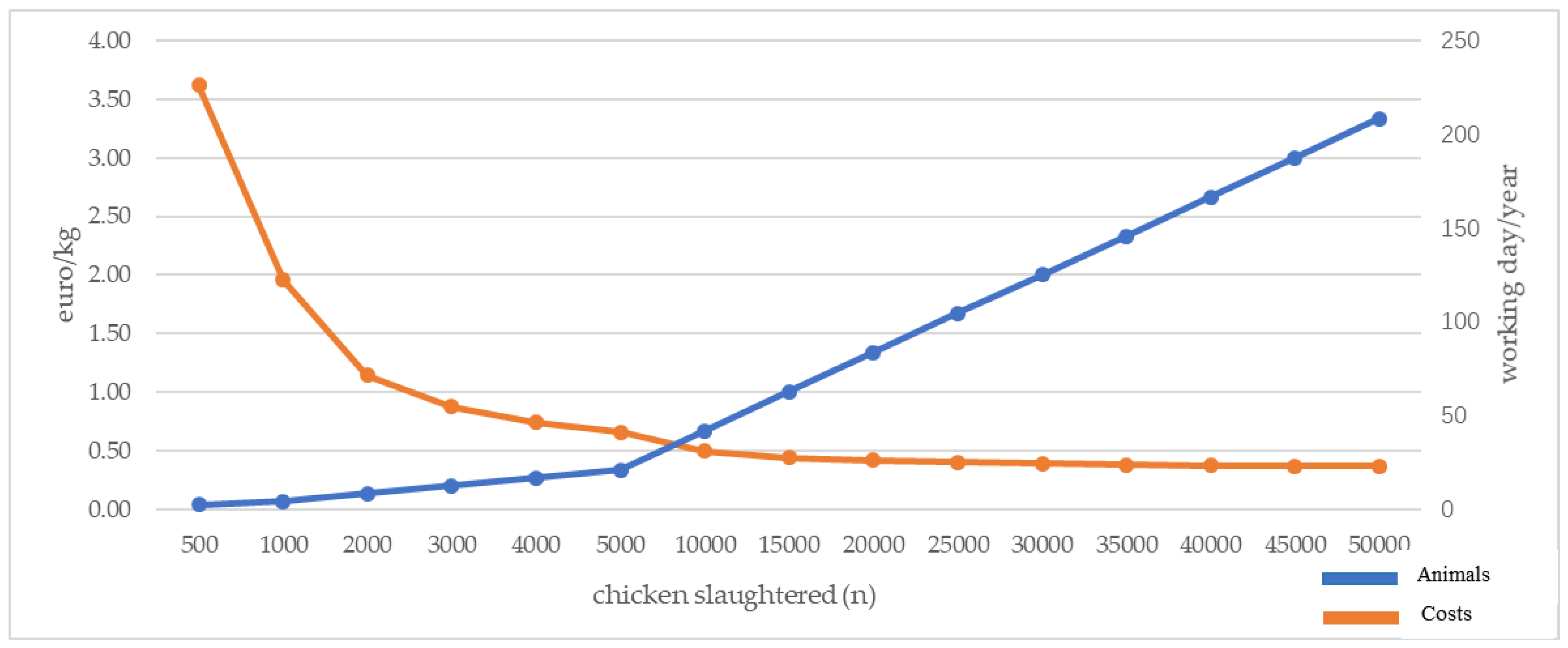

4. Operational and Economic Efficiency

- -

- transport of live animals by authorised vehicle €1–1.50/chicken (depending on the distance of the slaughterhouse from the farm);

- -

- slaughtering process 0.50 €/kg of live weight, therefore, an average of €1.50/chicken;

- -

- transport of carcass by refrigerated vehicle, €1.50/carcass.

5. Animal Welfare Aspects

6. Qualitative and Sanitary Implications

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Williams, A.G.; Audsley, E.; Sandars, D.L. Determining the Environmental Burdens and Resource Use in the Production of Agricultural and Horticultural Commodities; Main Report, Defra Research Project IS0205; Natural Resource Management Institute, Cranfield University: Bedford, UK, 2006. [Google Scholar]

- Siegel, P.B. Evolution of the modern broiler and feed efficiency. Ann. Rev. Anim. Biosci. 2014, 2, 375–385. [Google Scholar] [CrossRef] [PubMed]

- Corr, S.A.; Gentle, M.J.; Mc Corquodale, C.C.; Bennett, D. The effect of morphology on walking ability in the modern broiler: A gait analysis study. Anim. Welf. 2003, 12, 159–171. [Google Scholar]

- Petracci, M.; Soglia, F.; Berri, C. Muscle metabolism and meat quality abnormalities. In Poultry Quality Evaluation; Duxford, Woodhead Publishing: Sawston, CA, USA, 2017; pp. 51–75. [Google Scholar]

- Soglia, F.; Mudalal, S.; Babini, E.; Di Nunzio, M.; Mazzoni, M.; Sirri, F.; Cavani, C.; Petracci, M. Histology, composition, and quality traits of chicken Pectoralis major muscle affected by wooden breast abnormality. Poult. Sci. 2016, 95, 651–659. [Google Scholar] [CrossRef] [PubMed]

- Francham, R.; Ballou, J.D.; Briscoe, D.A. A Primer of Conservation Genetics; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Soleimani, A.F.; Zulkifli, I.; Omar, A.R.; Raha, A.R. Physiological responses of 3 chicken breeds to acute heat stress. Poult. Sci. 2011, 90, 1435–1440. [Google Scholar] [CrossRef] [PubMed]

- Muir, W.M.; Cheng, H.W.; Croney, C. Methods to address poultry robustness and welfare issues through breeding and associated ethical considerations. In Improving Animal Welfare through Genetic Selection; Rauw, W.M., Ed.; Frontiers in Genetics: Lausanne, Switzerland, 2014; pp. 407–420. [Google Scholar]

- Organic in Europee. Available online: http://www.ifoam-eu.org/sites/default/files/ifoameu_organic_in_europe_2016.pdf (accessed on 3 September 2017).

- Adams, D.C.; Salois, M.J. Local versus organic: A turn in consumer preferences and willingness to pay. Renew. Agric. Food Syst. 2010, 25, 331–341. [Google Scholar] [CrossRef]

- Castellini, C.; Mugnai, C.; Moscati, L.; Mattioli, S.; Guarino Amato, M.; CartoniMancinelli, A.; Dal Bosco, A. Adaptation to organic rearing system of eight different chicken genotypes: Behaviour, welfare and performance. Ital. J. Anim. Sci. 2016, 15, 37–46. [Google Scholar] [CrossRef]

- Dal Bosco, A.; Mugnai, C.; Rosati, A.; Paoletti, A.; Caporali, S.; Castellini, C. Effect of range enrichment on performance, behaviour and grass intake of organic chickens. J. Appl. Poult. Res. 2014, 23, 137–145. [Google Scholar] [CrossRef]

- Paolotti, L.; Boggia, A.; Castellini, C.; Rocchi, L.; Rosati, A. Combining livestock and tree crops to improve sustainability in agriculture: A case study using the Life Cycle Assessment (LCA) approach. J. Clean. Prod. 2016, 131, 351–363. [Google Scholar] [CrossRef]

- Ponte, P.I.P.; Rosado, C.M.C.; Crespo, J.P.; Mourão, J.L.; Miao, Z.H.; Glatz, P.C.; Ru, Y.J. Free-range poultry production: A review. Asian-Australas. J. Anim. Sci. 2004, 18, 1–20. [Google Scholar]

- Schutkowski, A.; Krämer, J.; Kluge, H.; Hirche, F.; Krombholz, A.; Theumer, T.; Stangl, G.I. UVB exposure of farm animals: Study on a food-based strategy to bridge the gap between current vitamin D intakes and dietary targets. PLoS ONE 2013, 8, e69418. [Google Scholar] [CrossRef]

- Dal Bosco, A.; Mugnai, C.; Ruggeri, S.; Mattioli, S.; Castellini, C. Fatty acid composition of meat and estimated indices of lipid metabolism in different poultry genotypes reared under organic system. Poult. Sci. 2012, 91, 2039–2045. [Google Scholar] [CrossRef] [PubMed]

- Woods, V.B.; Fearon, A.M. Dietary sources of unsaturated fatty acids for animals and their transfer into meat, milk and eggs: A review. Livest. Sci. 2009, 126, 1–20. [Google Scholar] [CrossRef]

- Dal Bosco, A.; Mugnai, C.; Mattioli, S.; Rosati, A.; Ruggeri, S.; Ranucci, D.; Castellini, C. Transfer of bioactive compounds from pasture to meat in organic free-range chickens. Poult. Sci. 2016, 95, 2465–2471. [Google Scholar] [CrossRef] [PubMed]

- Gordon, S.H.; Charles, D.R. Niche and Organic Chicken Products; University Press: Nottingham, UK, 2002. [Google Scholar]

- Ponte, P.I.; Mendes, I.; Quaresma, M.; Aguiar, M.N.; Lemos, J.P.; Ferreira, L.M.; Soares, M.A.; Alfaia, C.M.; Prates, J.A.; Fontes, C.M. Cholesterol levels and sensory characteristics of meat from broilers consuming moderate to high levels of alfalfa. Poult. Sci. 2008, 83, 810–814. [Google Scholar] [CrossRef] [PubMed]

- Zeltner, E.; Maurer, V. Welfare of organic poultry. In Proceedings of the 8th Poultry Welfare Symposium, Cervia, Italy, 18–22 May 2009; pp. 104–112. [Google Scholar]

- Sossidou, E.N.; Rose, S.P.; Hall, N.W.; Tserveni-Goussi, A. Effects of composted vegetable waste as soil medium in free-range laying hens’ production systems on birds’ behaviour, soil structure, grass cover and nematode population. Arch. Geflügel. 2010, 74, 81–87. [Google Scholar]

- Sossidou, E.N.; Dal Bosco, A.; Castellini, C.; Grashorn, M.A. Effects of pasture management on poultry welfare and meat quality in organic poultry production systems. World’s Poult. Sci. J. 2015, 71, 375–384. [Google Scholar] [CrossRef]

- Castellini, C.; Mugnai, C.; Dal Bosco, A. Meat quality of three chicken genotypes reared according to the organic system. Ital. J. Food Sci. 2002, 4, 401–412. [Google Scholar]

- Castellini, C.; Dal Bosco, A.; Mugnai, C.; Bernardini, M. Performance and behaviour of chickens with different growing rate reared according to the organic system. Ital. J. Anim. Sci. 2002, 1, 291–300. [Google Scholar] [CrossRef]

- Dal Bosco, A.; Mugnai, C.; Sirri, F.; Zamparini, C.; Castellini, C. Assessment of a global positioning system to evaluate activities of organic chickens at pasture. J. Appl. Poult. Res. 2010, 19, 213–218. [Google Scholar] [CrossRef]

- Ropkin, K.; Beck, A.J. Using HACCP to control organic chemical hazards in food wholesale, distribution, storage and retail. Trends Food Sci. Technol. 2003, 14, 374–379. [Google Scholar] [CrossRef]

- Raynolds, L.T. The globalization of organic agro-food networks. World Dev. 2004, 32, 725–731. [Google Scholar] [CrossRef]

- Van Der Ploeg, J.; Jingzhong, Y.; Schneider, S. Rural development through the construction of new, nested, markets: Comparative perspectives from China, Brazil and the European Union. J. Peas. Stud. 2012, 39, 133–173. [Google Scholar] [CrossRef]

- Sonnino, R.; Marsden, T. Beyond the divide: Rethinking relationships between alternative and conventional food networks in Europe. J. Econ. Geogr. 2004, 6, 181–187. [Google Scholar] [CrossRef]

- Kirwan, J. The interpersonal world of direct marketing: Examining conventions of quality at UK farmers’ market. J. Rural Stud. 2006, 22, 301–307. [Google Scholar] [CrossRef]

- Higgins, V.; Dibden, J.; Cocklin, C. Building alternative agri-food networks: Certification, embeddedness and agri-environmental governance. J. Rural Stud. 2008, 24, 15–20. [Google Scholar] [CrossRef]

- O’Bryan, C.A.; Crandall, P.G.; Davis, M.L.; Kostadini, G.; Gibson, WK.; Alali, W.Q.; Jaroni, D.; Ricke, S.C.; Marcy, J.A. Mobile poultry processing units: A safe and cost-effective poultry processing option for the small-scale farmer in the United States. World’s Poult. Sci. J. 2004, 70, 787–802. [Google Scholar] [CrossRef]

- Angioloni, A.; Kostandini, G.; Alali, W.Q.; O’Bryan, C.O. Economic feasibility of mobile processing units for small-scale pasture poultry farmers. Renew. Agric. Food Syst. 2015, 1, 1–15. [Google Scholar] [CrossRef]

- Ministero delle infrastrutture e dei trasporti. Available online: http://www.gazzettaufficiale.it/eli/gu/2010/03/19/65/so/55/sg/pdf (accessed on 6 November 2018).

- Ali, S.; Kang, G.; Seon-Tea, J. A Review: Influences of pre-slaughter stress on poultry meat quality. Asian Australas. J. Anim. Sci. 2008, 21, 6–12. [Google Scholar] [CrossRef]

- Mitchell, M.A.; Kettlewell, P.J. Physiological stress and welfare of broiler chickens in transit: Solutions not problems! Poult. Sci. 1998, 77, 1803–1814. [Google Scholar] [CrossRef]

- Yalcin, S.; Ozkan, S.; Oktay, G.; Cabuk, M.; Erbayraktar, Z.; Bilgili, S.F. Age-related effects of catching, crating, and transportation at different seasons on core body temperature and physiological blood parameters in broilers. J. Appl. Poult. Res. 2004, 13, 549–560. [Google Scholar] [CrossRef]

- Nijdam, E.; Delezie, E.; Lambooij, E.; Nabuurs, M.J.; Decuypere, E.; Stegeman, J.A. Feed withdrawal of broilers before transport changes plasma hormone and metabolite concentrations. Poult. Sci. 2005, 84, 1146–1152. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yue, H.Y.; Zhang, H.J.; Xu, L.; Wu, S.G.; Yan, H.J.; Gong, Y.S.; Qi, G.H. Transport stress in broilers: I. Blood metabolism, glycolytic potential, and meat quality. Poult. Sci. 2009, 88, 2033–2041. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yue, H.Y.; Wu, S.G.; Xu, L.; Zhang, H.J.; Yan, H.J.; Cao, Y.L.; Gong, Y.S.; Qi, G.H. Transport stress in broilers. II. Superoxide production, adenosine phosphate concentrations, and mRNA levels of avian uncoupling protein, avian adenine nucleotide translocator, and avian peroxisome proliferator-activated receptor-c coactivator-1a in skeletal muscles. Poult. Sci. 2010, 89, 393–400. [Google Scholar]

- Debut, M.; Berri, C.; Baeza, M.; Sellier, N.; Arnould, N.; Guemene, N.; Jehl, N.; Boutten, B.; Jego, Y.; Beaumont, C.; et al. Variation of chicken technological meat quality in relation to genotype and preslaughter stress conditions. Poult. Sci. 2003, 82, 1829–1838. [Google Scholar] [CrossRef] [PubMed]

- Berri, C.; Debut, M.; Santé-Lhoutellier, V.; Arnould, C.; Boutten, B.; Sellier, N.; Baéza, E.; Jehl, N.; Jego, Y.; Duclos, M.J.; et al. Variations in chicken breast meat quality: Implications of struggle and muscle glycogen content at death. Br. Poult. Sci. 2005, 82, 572–579. [Google Scholar] [CrossRef] [PubMed]

- Rimoldi, S.; Lasagna, E.; Sarti, F.M.; Marelli, S.P.; Cozzi, M.C.; Bernardini, G.; Terova, G. Expression profile of six stress-related genes and productive performances of fast and slow growing broiler strains reared under heat stress conditions. Meta Gene 2005, 6, 17–25. [Google Scholar] [CrossRef]

- Le Bihan-Duval, E.; Millet, N.; Remignon, H. Broiler meat quality: Effect of selection for increased carcass quality and estimates of genetic parameters. Poult. Sci. 1999, 78, 822–826. [Google Scholar] [CrossRef]

- Berri, C.; Le Bihan-Duval, E.; Debut, M.; Santé-Lhoutellier, V.; Baéza, E.; Gigaud, V.; Jégo, E.; Duclos, M.J. Consequence of hypertrophy on characteristics of pectoralis major muscle and breast meat quality of broiler chickens. J. Anim. Sci. 2007, 85, 2005–2011. [Google Scholar] [CrossRef]

- CartoniMancinelli, A.; Mugnai, C.; Castellini, C.; Mattioli, S.; Moscati, L.; Piottoli, L.; Guarino Amato, M.; Doretti, M.; Dal Bosco, A.; Cordovani, E.; et al. Effect of transport length and genotype on some welfare parameters and carcass contamination of free-range reared chickens. Ital. J. Anim. Sci. 2018, 17, 557–564. [Google Scholar] [CrossRef]

- Kannan, G.; Heath, J.L.; Wabeck, C.J.; Souza, M.C.P.; Howe, J.C.; Mench, J.A. Effects of crating and transport on stress and meat quality characteristics in broilers. Poult. Sci. 1997, 76, 523–529. [Google Scholar] [CrossRef]

- Schwartzkopf-Genswein, K.S.; Faucitano, L.; Dadgar, V.; Shand, P.; González, L.A.; Crowe, T.G. Road transport of cattle, swine and poultry in North America and its impact on animal welfare, carcass and meat quality: A review. Meat Sci. 2012, 92, 227–243. [Google Scholar] [CrossRef] [PubMed]

- Dadgar, S.; Lee, E.S.; Leer, T.L.V.; Crowe, T.G.; Classen, H.L.; Shand, P.J. Effect of acute cold exposure, age, sex, and lairage on broiler breast meat quality. Poult. Sci. 2011, 90, 444–457. [Google Scholar] [CrossRef] [PubMed]

- Castellini, C.; Mattioli, S.; Piottoli, L.; CartoniMancinelli, A.; Ranucci, D.; Branciari, R.; Guarino Amato, M.; Dal Bosco, A. Effect of transport length on in vivo oxidative status and breast meat characteristics in outdoor-reared chicken genotypes. Ital. J. Anim. Sci. 2016, 15, 191–199. [Google Scholar] [CrossRef]

- Humphrey, T. Are happy chickens safer chickens? Poultry welfare and disease susceptibility. Br. Poult. Sci. 2006, 47, 379–391. [Google Scholar] [CrossRef] [PubMed]

- Cogan, T.A.; Thomas, A.O.; Rees, L.E.; Taylor, A.H.; Jepson, M.A.; Williams, P.H.; Ketley, J.; Humphrey, T.J. Norepinephrine increases the pathogenic potential of Campylobacter jejuni. Gut 2007, 56, 1060–1065. [Google Scholar] [CrossRef] [PubMed]

- Hue, O.; Le Bouquin, S.; Laisney, M.J.; Allain, V.; Lalande, F.; Petetin, I.; Santolini, J. Prevalence of and risk factors for Campylobacter spp. contamination of broiler chicken carcasses at the slaughterhouse. Food Microbiol. 2010, 27, 992–999. [Google Scholar] [CrossRef] [PubMed]

- Hansson, I.; Ederoth, M.; Andersson, L.; Olsson, E. Transmission of Campylobacter spp. to chickens during transport to slaughter. J. Appl. Microbiol. 2005, 99, 1149–1157. [Google Scholar] [CrossRef] [PubMed]

- Hinojosa, C.A.; Caldwell, D.J.; Byrd, J.A.; Ross, M.A.; Stringfellow, K.D.; Fowlkes, E.J.; Farnell, M.B. Use of a foaming disinfectant and cleaner to reduce aerobic bacteria on poultry transport coops. J. Appl. Poult. Res. 2015, 24, 364–370. [Google Scholar] [CrossRef]

- Posch, J.; Feierl, G.; Wuest, G.; Sixl, W.; Schmidt, S.; Haas, D.; Reinthaler, F.F.; Marth, E. Transmission of Campylobacter spp. in a poultry slaughterhouse and genetic characterization of the isolates by pulsed-field gel electrophoresis. Br. Poult. Sci. 2006, 47, 286–293. [Google Scholar] [CrossRef]

- Allen, V.M.; Bull, S.A.; Corry, J.E.; Domingue, G.; Jorgensen, F.; Frost, G.A.; Whyte, R.; Gonzalez, A. Campylobacter spp. contamination of chicken carcasses during processing in relation to flock colonization. Int. J. Food Microbiol. 2007, 113, 54–61. [Google Scholar] [CrossRef]

- Northcutt, J.K.; Berrang, M.E. Influence of a chicken transport cage-washing system on wastewater characteristics and bacteria recovery from cage flooring. J. Appl. Poult. Res. 2006, 15, 457–463. [Google Scholar] [CrossRef]

- Newell, D.G.; Elvers, K.T.; Dofper, D.; Hansson, I.; Jones, P.; James, S.; Pearson, D. A critical review of biosecurity-based interventions and strategies to reduce Campylobacter on the poultry farm. Appl. Environ. Microbiol. 2009, AEM-01090. [Google Scholar] [CrossRef]

- Russa, A.D.; Bouma, A.; Vernooij, J.C.M.; Jacobs-Reitsma, W.; Stegeman, J.A. No association between partial depopulation and Campylobacter spp. colonization of Dutch broiler flocks. Lett. Appl. Microbiol. 2005, 41, 280–285. [Google Scholar] [CrossRef] [PubMed]

- Trimble, L.M.; Alali, W.Q.; Gibson, K.E.; Ricke, S.C.; Crandall, P.; Jaroni, D.; Berrang, M. Salmonella and Campylobacter prevalence and concentration on pasture-raised broilers processed on-farm, in a Mobile Processing Unit, and at small USDA-inspected facilities. Food Control 2013, 34, 177–182. [Google Scholar] [CrossRef]

- Li, K.; Lemonakis, L.; Glover, B.; Moritz, J.; Shen, C. Impact of built-up-litter and commercial antimicrobials on Salmonella and Campylobacter contamination of broiler carcasses processed at a pilot Mobile Poultry-Processing Unit. Front. Vet. Sci. 2017, 4, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Ranucci, D.; Castellini, C.; Branciari, R.; Miraglia, D.; Cives, I. Development of legislation on mobile slaughterhouse for rural poultry meat production. In Proceedings of the 2015 SISVET Congress, Perugia, Italy, 15 June 2015; pp. 15–18. [Google Scholar]

- Guerin, M.T.; Sir, C.; Sargeant, J.M.; Waddell, L.; o’Connor, A.M.; Wills, R.W.; Byrd, J.A. The change in prevalence of Campylobacter on chicken carcasses during processing: A systematic review. Poult. Sci. 2010, 89, 1070–1084. [Google Scholar] [CrossRef] [PubMed]

- Fanatico, A.C. Small-Scale Poultry Processing. National Center for Appropriate Technology. May 2003. Available online: http://www.attra.ncat.org (accessed on 23 August 2018).

- Mead, G.; Lammerding, A.M.; Cox, N.A.; Doyle, M.P.; Humbert, F.; Kulikovskiy, A. Scientific and technical factors affecting the setting of Salmonella criteria for raw poultry: A global perspective. J. Food Prot. 2010, 73, 1566–1590. [Google Scholar] [CrossRef]

| Aspects Considered | MPPU | Conventional Slaughtherhouse | ||

|---|---|---|---|---|

| Pros | Cons | Pros | Cons | |

| Essential Requirements | Small truck easily handled | Need of a site for slaughtering in the farm (H2o, electricity, etc.) | ||

| There are numerical and geographic restrictions | No numerical and geographic restrictions | |||

| Operational and Economic Efficiency | Sharing the MPPU by farmers allows to reduce the processing cost | Low number of birds processed/hour | High number of birds processed/hour | High unitary cost for transporting live animals (farm–slaughterhouse) |

| Possible use of a refrigerated trailer for the delivery of slaughtered carcasses | Cost for transporting carcasses (farm-market) | |||

| Public funds can partially cover MPPU purchase | No public funds for the purchase | |||

| Animal Welfare | No chicken transport and reduction of pre-slaughter stress | Transport negatively affects animal welfare | ||

| Qualitative and Sanitary Implications | Safeguarding the quality of meat (low stress) | Good Manufacturing Practices (GMP)for welfare respectful handling and limited time crating | Pre-slaughter stress negatively affects meat quality: change in colour, shelf-life, nutritional parameters | |

| Low risk of cross contaminations (one flock per day) | Cross contamination due to the processing of different batches of flocks per day Reduction of hygienic/safety condition of meat due to the pre-slaughter stress. | |||

| Reducing carcass contamination due to crating and transport | Difficult in biosafety management (specific for pastured poultry production) Higher age of the birds (Campylobacter) | Proper biosafety measures at flock level | GMP for handling, crating and transport (particularly from different flocks in the same day) | |

| No decontamination strategy applicable (not allowed in European Union) | Possibility of decontamination strategies of the carcass (water bath chilling) | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cartoni Mancinelli, A.; Dal Bosco, A.; Mattioli, S.; Ranucci, D.; Castellini, C. Mobile Poultry Processing Unit as a Resource for Small Poultry Farms: Planning and Economic Efficiency, Animal Welfare, Meat Quality and Sanitary Implications. Animals 2018, 8, 229. https://doi.org/10.3390/ani8120229

Cartoni Mancinelli A, Dal Bosco A, Mattioli S, Ranucci D, Castellini C. Mobile Poultry Processing Unit as a Resource for Small Poultry Farms: Planning and Economic Efficiency, Animal Welfare, Meat Quality and Sanitary Implications. Animals. 2018; 8(12):229. https://doi.org/10.3390/ani8120229

Chicago/Turabian StyleCartoni Mancinelli, Alice, Alessandro Dal Bosco, Simona Mattioli, David Ranucci, and Cesare Castellini. 2018. "Mobile Poultry Processing Unit as a Resource for Small Poultry Farms: Planning and Economic Efficiency, Animal Welfare, Meat Quality and Sanitary Implications" Animals 8, no. 12: 229. https://doi.org/10.3390/ani8120229

APA StyleCartoni Mancinelli, A., Dal Bosco, A., Mattioli, S., Ranucci, D., & Castellini, C. (2018). Mobile Poultry Processing Unit as a Resource for Small Poultry Farms: Planning and Economic Efficiency, Animal Welfare, Meat Quality and Sanitary Implications. Animals, 8(12), 229. https://doi.org/10.3390/ani8120229