1. Introduction

Automated Milking Systems (AMSs) have become popular in Europe, Canada, and New Zealand in the last 30 years [

1,

2,

3]. However, the adoption and implementation vary based on regional practices and dairy farming characteristics. In Europe, Canada, and New Zealand, AMSs are commonly used in smaller- to medium-sized dairy herds (e.g., 80 cows on average), mainly in confinement housing [

1,

4]. Contrastingly, in New Zealand and Australia, AMSs are often employed in larger dairy herds (e.g., 390 cows), usually in pasture-based farms [

5].

The situation in the USA is quite distinct from these regions regarding dairy farming demographics, trends, and practices. In addition, the number of American dairy herds has decreased from 600,000 in the 80s to ~30,000, whereas the average herd size increased from 74 to 337 cows [

6]. Thus, this transition to larger dairy herds and various challenges related to the sustainability of the dairy sector, such as fluctuating milk prices, high feed costs, and limited margins for return on investment, might be some of the factors slowing the adoption of AMSs in the USA compared to Canada, Europe, and Oceania.

Recently, comprehensive AMS surveys were carried out in Canada and Australia, underscoring aspects such as housing, farm management, cow health, cow training, transition challenges, human–animal relationship, quality of life, labor management, and milk performance [

4,

5,

7,

8]. Albeit these surveys were very informative, they included local small herds (median of 77 to 85 lactating cows) or pasture-based systems that do not necessarily represent the USA demographic considering the adoption of an AMS. A limited number of surveys performed in the USA focused on a few specific topics, such as milk quality [

9], milking aspects [

9,

10,

11], transitioning concerns [

12], or adoption in specific states [

13,

14]. Piwczynski et al. [

15] highlighted that the average number of robots per herd in the USA is higher than in certain European countries (2.71 vs. 1.88). Therefore, many of the perceptions from previous surveys might not fully represent the demographics or directly apply to those large dairy operations in the USA adopting AMSs.

The global milking robot market is experiencing significant growth, estimated to reach USD 4.31 billion by 2027, with 7.2% coming from the USA [

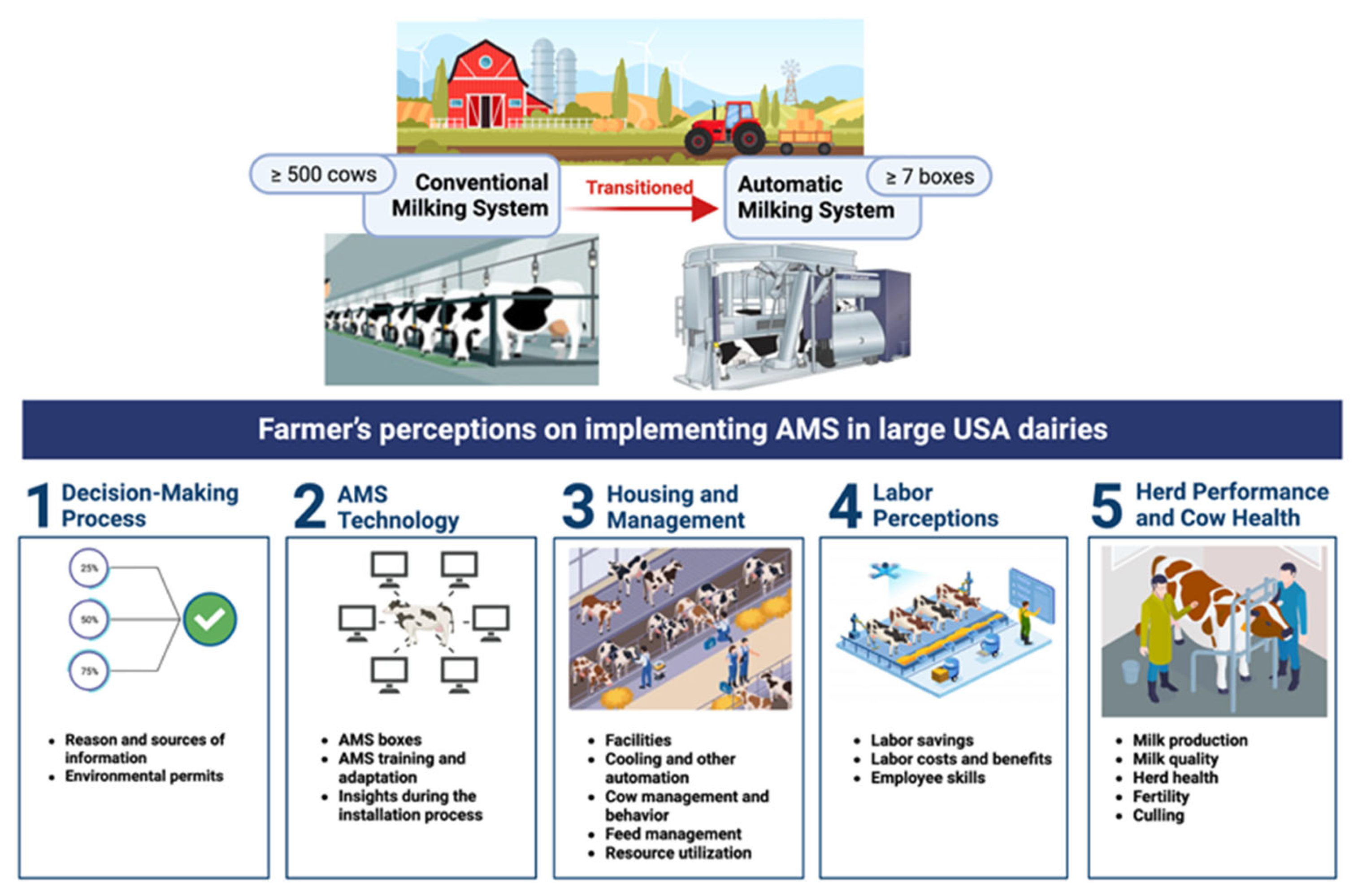

16] and larger herds potentially considering transitioning to an AMS. However, the literature has limited information on the challenges and perceptions of large dairy herd producers in the USA transitioning to an AMS. Therefore, this study was designed to specifically assess AMS adoption in large dairy herds within the USA framework and potentially highlight emerging challenges and trends in the dairy sector. This focus on large farms in the USA is vital, as they face unique challenges in adopting AMSs, a trend increasingly relevant due to their larger herd sizes and higher number of robots per farm compared to other regions. Our objectives were to explore perceptions and experiences of large dairy farms in the USA (≥7 AMS boxes) that transitioned to an AMS regarding the decision-making process, AMS technology, housing and management practices, labor, herd performance, and cow health (

Figure 1).

4. Discussion

Our study collected information about the perceptions of a sample of large dairy farmers in the USA who transitioned to an AMS. This includes insights into their decision-making process, AMS technology adopted, housing and management practices implemented, labor differences, herd performance, and cow health. These insights help to describe the landscape of large dairy herds adopting AMSs in the USA. However, it is crucial to emphasize that these are preliminary perceptions. To establish a more comprehensive and scientifically robust understanding, it is essential to verify or falsify these perceptions through systematic analysis of herd data. This follow-up study would provide empirical evidence to support or challenge the initial observations and experiences reported by the farmers, thereby contributing to a more nuanced and data-driven understanding of the impact of AMSs on large dairy farms.

Labor savings consistently emerged as the primary reason for adopting AMSs across global regions. Surveys from Europe and Canada additionally highlighted the aim to enhance dairy farming family lifestyles and quality of life [

7,

11,

19,

20], which was not an aspect indicated by the respondents in the current survey. Indeed, our survey revealed that even other aspects, such as cow welfare and herd performance, were perceived as more important reasons for AMS adoption. These differing top reasons can be likely attributed to each region’s farm structures and priorities. Canadian and European farms tend to be smaller and depend more on family labor. The respondents representing large USA herds adopting AMSs suggest a culture of this particular community that tends to list herd productivity and efficiency over their quality of life. Another potential explanation for the differences is the fact that the respondents in large dairy herds represent managers and part owners who do not perceive quality of life as a reason that aligns with their role.

Most producers relied on information from AMS suppliers and farmers familiar with AMSs, which aligns with findings from European and Canadian surveys [

7,

21,

22] underscoring that independent of the size of dairy herds and the particular characteristics of a region, AMS adopters rely on the AMS community as a main source to learn and decide about the adoption of the technology.

The present study also observed varied perceptions about AMS lifespan, salvage value, and plans for replacing boxes. The expected lifespan range was between 10 and 20 years, which is aligned with the manufacturer’s estimated lifespan (~13 years) [

23,

24]. Our survey found that a small proportion of respondents do not see salvage value for their boxes and expect to use them until the end of their lifespan without a plan for replacing them. Steeneveld et al. [

25] reported that other than higher capital costs, the use of an AMS rather than a CMS does not affect farm efficiency, but reliable estimates of AMS lifespan remain scarce. Therefore, future studies that rigorously assess AMS lifespan are needed to elucidate more accurate realistic expectations and overall AMS costs.

In line with previous studies [

3,

4], producers often preferred to construct new facilities for AMSs instead of retrofitting existing barns. These preferences persist even though our study reported costs were higher than upgrading current barns. Regarding changes in housing systems, most Canadian farms (47%) moved from tie stalls to free stalls, and in the present study, just 7% of farms changed from dry lots to free stalls. The housing shift being less prominent in the USA could be due to a major proportion of dairies already using free stalls, as highlighted in a mid-Atlantic region survey by [

13]. Furthermore, a study by [

14] in Idaho found that farms with free stalls were 60% more likely to adopt an AMS compared to those with different systems. A significant portion of farms kept the old parlor (58%) alongside the AMS, including farms that had completely switched the entire herd to an AMS. The primary reasons were to milk hospital and fresh cows, or those that did not adapt to the AMS. In addition, 37% did not plan to milk all their cows in the AMS, suggesting a continued use of both systems. Further studies are needed to understand why some farmers resist the full transition to AMSs, which would help identify the associated risks and opportunities in large herds.

Our survey found that the median number of cows per box in USA dairy farms (60 ± 3 cows/box) was higher than [

4] reported in a Canadian study (51 ± 9 cows/box). In our survey, 15% of farms operated over maximum capacity, and 27% focused on milk harvested per robot, which may account for the differences in the cows-per-box ratio. This result aligns with [

26]’s findings, which highlighted that a crucial part of the system’s profitability depends on the milk harvested by the robot each day, which in turn depends on the number of cows milked and the frequency of milkings per cow [

27]. On the other hand, comparing the times when the surveys were conducted, these differences can also be related to technological advances and a better understanding of system management for improved milk efficiency.

Regarding resource utilization, increases in water and energy consumption were perceived by 42% and 62% of the farms, respectively. Recently, a study was conducted in Germany [

28] to evaluate the impact of different technologies on the energy efficiency of AMSs. An AMS equipped with an electrical drive of the attachment arm showed strong advantages in the energetic efficiency of the whole milking process. However, the scarcity of research on AMS resource utilization and the impact on sustainability need to be further investigated, which was pointed out in a recent scoping review of our group [

29].

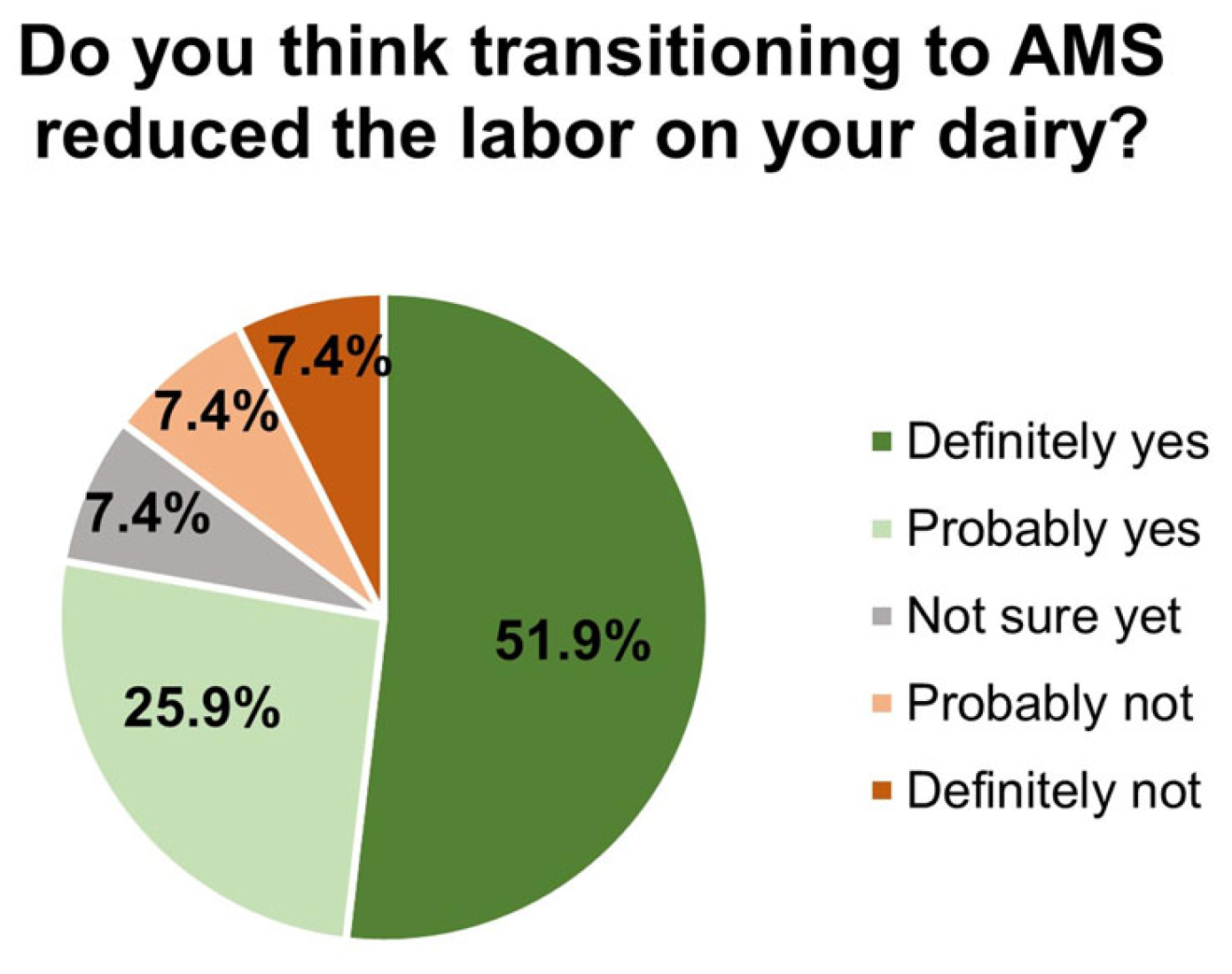

Consistent with previous surveys [

7,

19,

22], most farmers perceived a reduction in labor, with a large portion estimating decreases of more than 21%. Similarly, previous studies reported reductions of 18–19% [

30,

31] or over 29% [

32], while others found no change in labor use between CMS and AMS farms [

25,

33]. The variation could be attributed to individual farmer management skills, such as profitability or labor savings with AMS [

34].

In agreement with European and Canadian surveys [

7,

35], most farms implemented the free-flow traffic system. In the current study, cow welfare ranked as the second reason to adopt AMSs, followed by the possibility of enhancing herd performance. In the context of increasing farm intensification, public concern over animal welfare has grown, as noted by [

36]. An Australian study by [

5] found that transitioning from CMSs to AMSs led to farmers interacting less with their cows. However, cows in AMSs exhibited less fear around humans, showing shorter avoidance distances and reduced stress during close handling. Thus, adopting technologies like AMSs appears to enhance cow welfare, such as by minimizing milking wait times, which is a significant concern for many large dairy farmers.

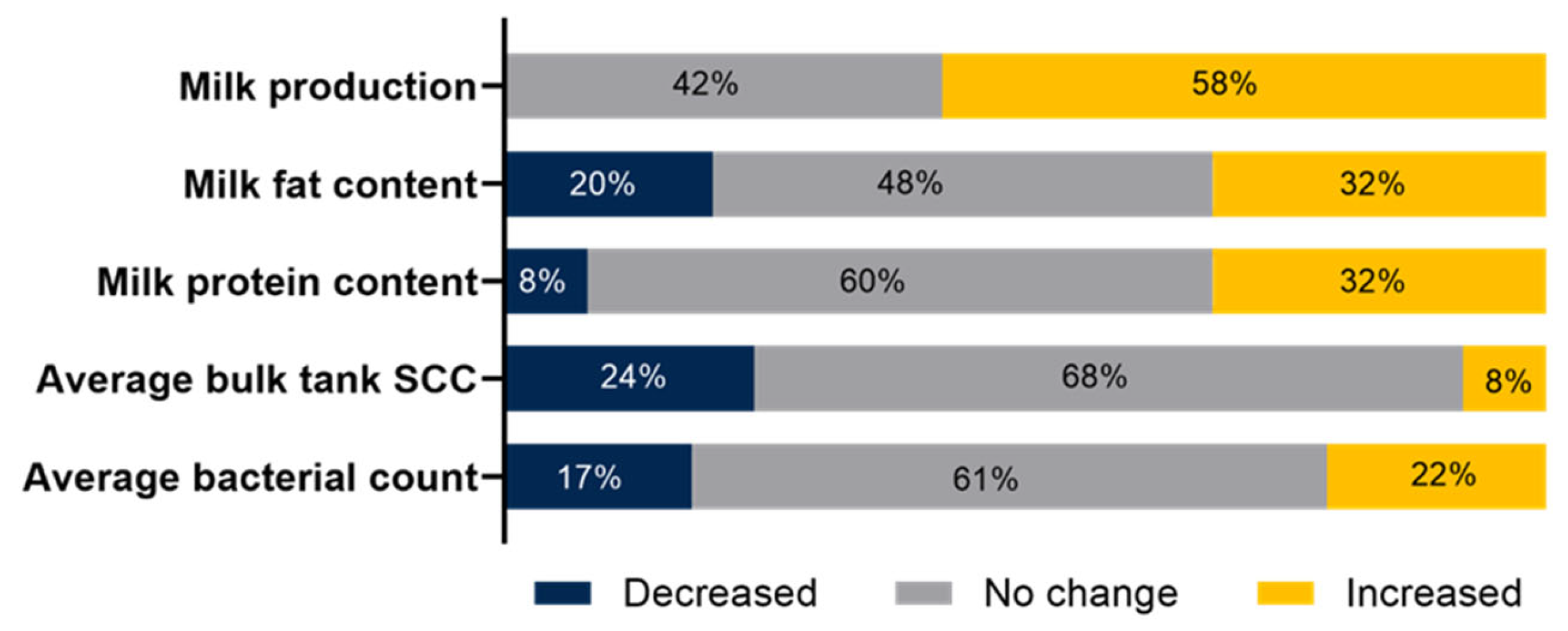

After adopting AMSs, many respondents noticed a rise in milk production (58%), with slight changes in milk components (32%) and unchanged levels of SCC and bacterial counts. The Canadian survey [

8] reported even more producers (82%) observing increased milk yields without changes in milk quality. However, it is noteworthy that misconceptions about perceived increased milk production have been reported previously. A recent Canadian survey [

37] showed that ~60% of dairy producers either misconceived or were unaware of the actual changes in their milk yield and SCC. Moreover, recent Canadian studies [

38,

39] associated milk production and quality in AMSs with herd-level housing factors and management practices rather than the AMS alone. Therefore, it is reasonable to surmise that future studies more rigorously isolating the relative impact of AMS adoption on milk production and quality are needed for large dairy herds representing the USA demographics captured by the current survey.

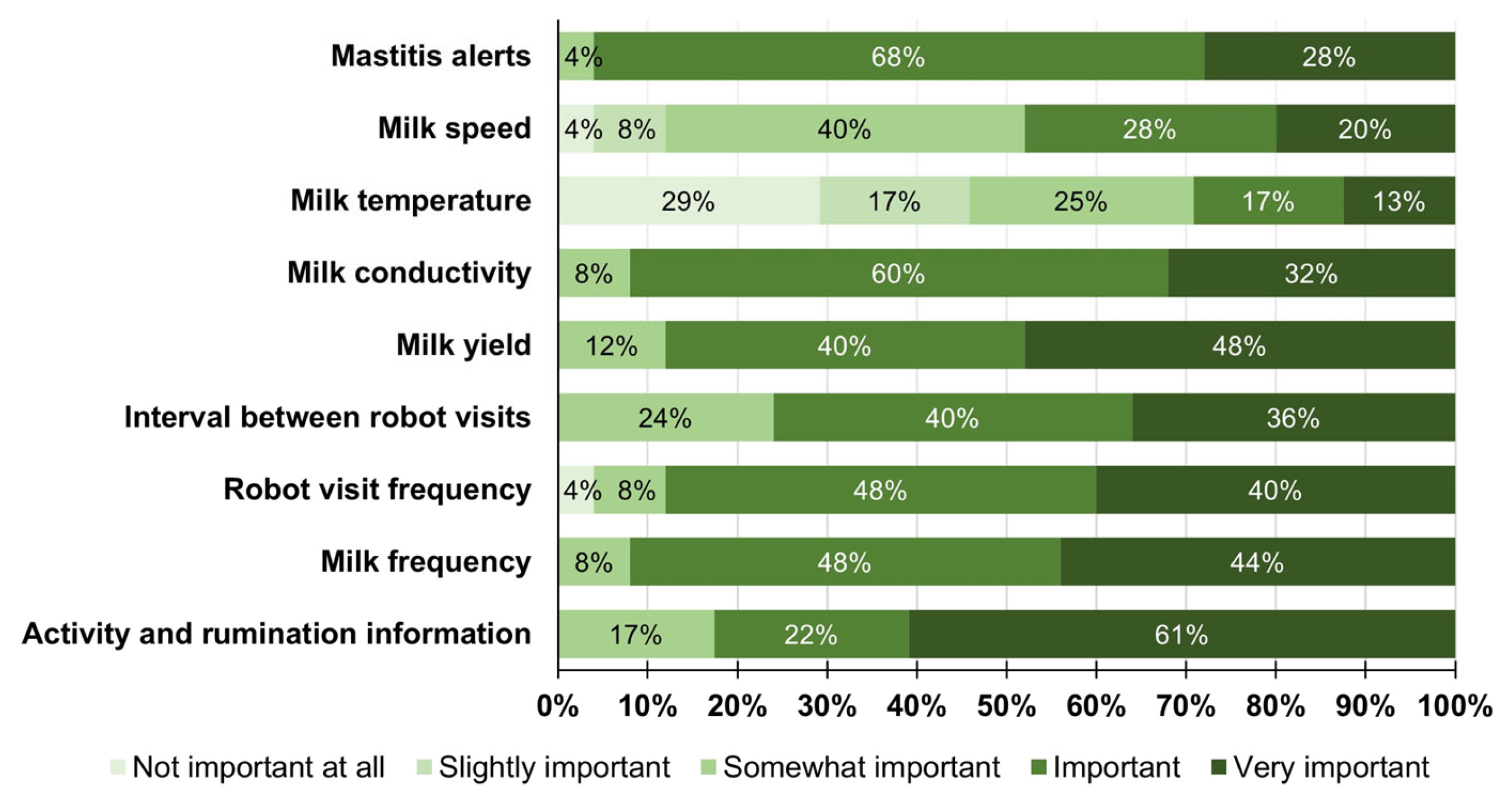

Similar to [

4], most respondents perceived that the AMS’s data made detecting sick cows easier, with clinical mastitis rates remaining stable or decreasing. Analogous to the Canadian survey, the current study revealed that the perception of lameness detection improved in most herds after AMS adoption, and the perceived incidence of lameness decreased. The similarity in trends observed by the survey suggests that AMSs, independent of their size, seem to facilitate routine assessment of cows that are behaving differently (e.g., cows not making their way to robots, lower activity, lower rumination, altered milk conductivity) or underperforming (e. g., decreased milk production).

Regarding pregnancy rates, as indicated by [

4], producers estimated improved reproductive performance and relied more on activity to breed cows. As discussed above, for perceptions regarding milk production, a robust assessment isolating the impact of AMS adoption from changes in reproductive programs is needed to represent an AMS’s impact on fertility outcomes fully.

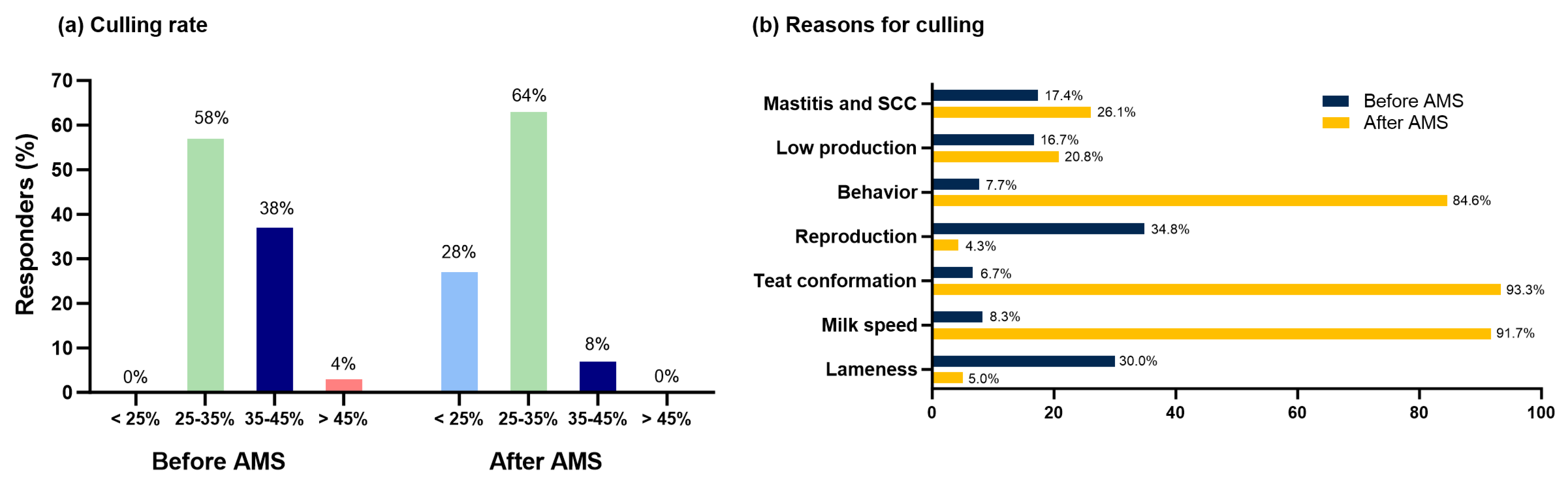

In our study, respondents believed the pattern of the culling rate changed after transitioning to an AMS, with an increase from 0% to 28% of respondents estimating a culling rate lower than 25%. These findings are not aligned with the previous survey, which indicated that perceptions of culling rates remained unchanged [

4]. An explanation for the potential differences is inaccuracies in the perceptions of our respondents or simply differences in genetics and behavior that allowed lower culling due to the udder conformation and adaptation to robots than reported in studies performed in Canada and Europe. As shown previously, our respondents indicated that behavior and udder conformation have overtaken reproduction as the primary reasons for culling cows [

4]. Research has shown that factors such as cow behavior and udder conformation can compromise the overall success of the AMS, with it being more economically viable to remove the problematic cows from the herd [

40]. Cow behaviors that consistently disrupt the system or require excessive manual intervention may influence the availability, frequency of milkings, and efficiency of the AMS [

40]. Cows with poor udder conformation posed challenges for teat cup attachment and were fetched twice as often as those without conformation problems [

40].

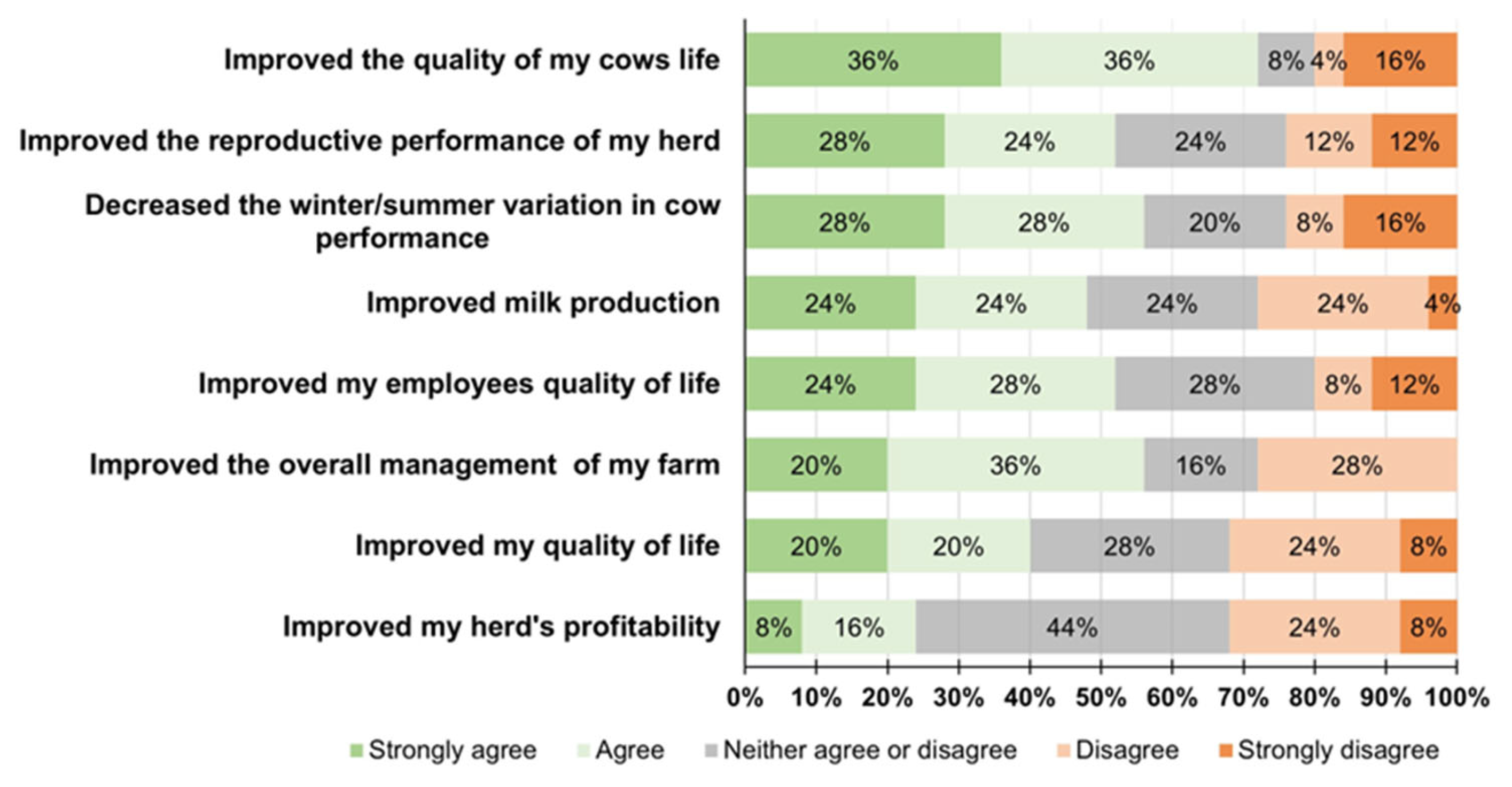

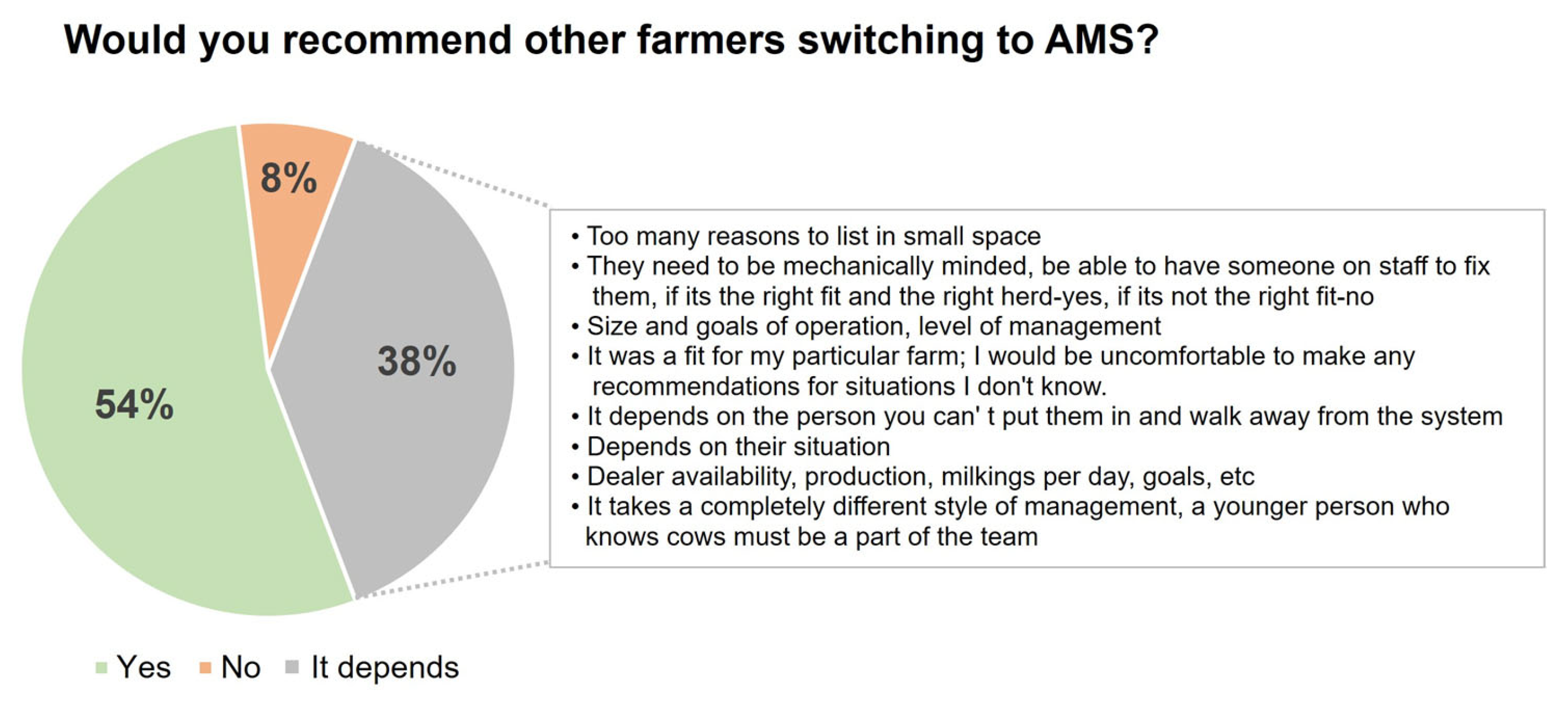

In general, most of the respondents had a positive perception of transitioning to an AMS and would recommend it to other farmers. This finding aligns with previous studies [

4,

31] that found that the AMS improves the quality of life for cows and employees and overall farm management. This finding agrees with [

7] that the quality of life for owners improved to a lesser extent on large AMS farms. The authors speculated that producers with larger herds would not score the statement “AMS has improved the quality of my life” as positively compared to smaller farm producers because they would not be able to reduce the number of employees to the same extent as smaller farms, which is corroborated by the findings of the present survey. On the other hand, in our study, we need to consider that one-third of respondents did not agree with the statements that AMS improved milk production, farmers’ quality of life, and herd profitability. This underscores the necessity for a more nuanced understanding of AMS adoption, considering individual farm contexts and broader socio-economic factors.

Finally, an improvement in herds’ profitability was not perceived by most of the respondents. The findings align with variable results reporting the estimated costs of AMSs. Higher initial and maintenance costs of AMSs in previous simulations and observational studies have suggested AMSs to be less profitable than CMSs [

13,

23]. However, [

41] found that larger AMS farms operating for over four years generate a higher gross farm income than newer and smaller ones. In our survey, the median number of years since AMS adoption was 4.4 years, but there were farms with adoption just over one year, which could have potentially influenced the profitability perceptions. In addition, advancements in AMS technology suggest that AMSs could be more profitable under certain circumstances such as increasing wages, higher milk production, and a longer equipment life span [

23,

42,

43]. As forecasted by these studies and accelerated by the COVID-19 pandemic, increased labor wages and labor shortages are already a reality for most farmers. Many studies like [

24] created simulation models on economic performance in different scenarios as tools for farmers to decide on AMS investment. However, updates in these models, including updated wages and inflation, need to be implemented to predict the risks of adopting AMSs more accurately.

Lastly, as in most surveys, the potential exists for misinterpretation of questions and recall bias (an issue of remembering accurately). In addition, [

4] mentioned that farmers who transitioned to AMSs might be affected by the cognitive justification in which a purchaser of an expensive product looks past any product faults to justify their purchase [

44]. Nonetheless, this survey focused on the perceptions of large dairy herd respondents transitioning to AMSs. The data presented here may benefit farmers thinking about transitioning to AMSs, future researchers seeking research directions, and extension educators/outreach personnel focusing on educational programs.