Egg Quality, Yolk Fatty Acid Profiles from Laying Hens Housed in Conventional Cage and Cage-Free Production Systems in the Andean Tropics

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Population and Sample Collection

2.2. Egg Quality Measurement

2.3. Yolk Fatty Acid Analysis

2.4. Yolk Protein Analysis

2.5. Salmonella Flock Status

2.6. Statistical Analysis

3. Results

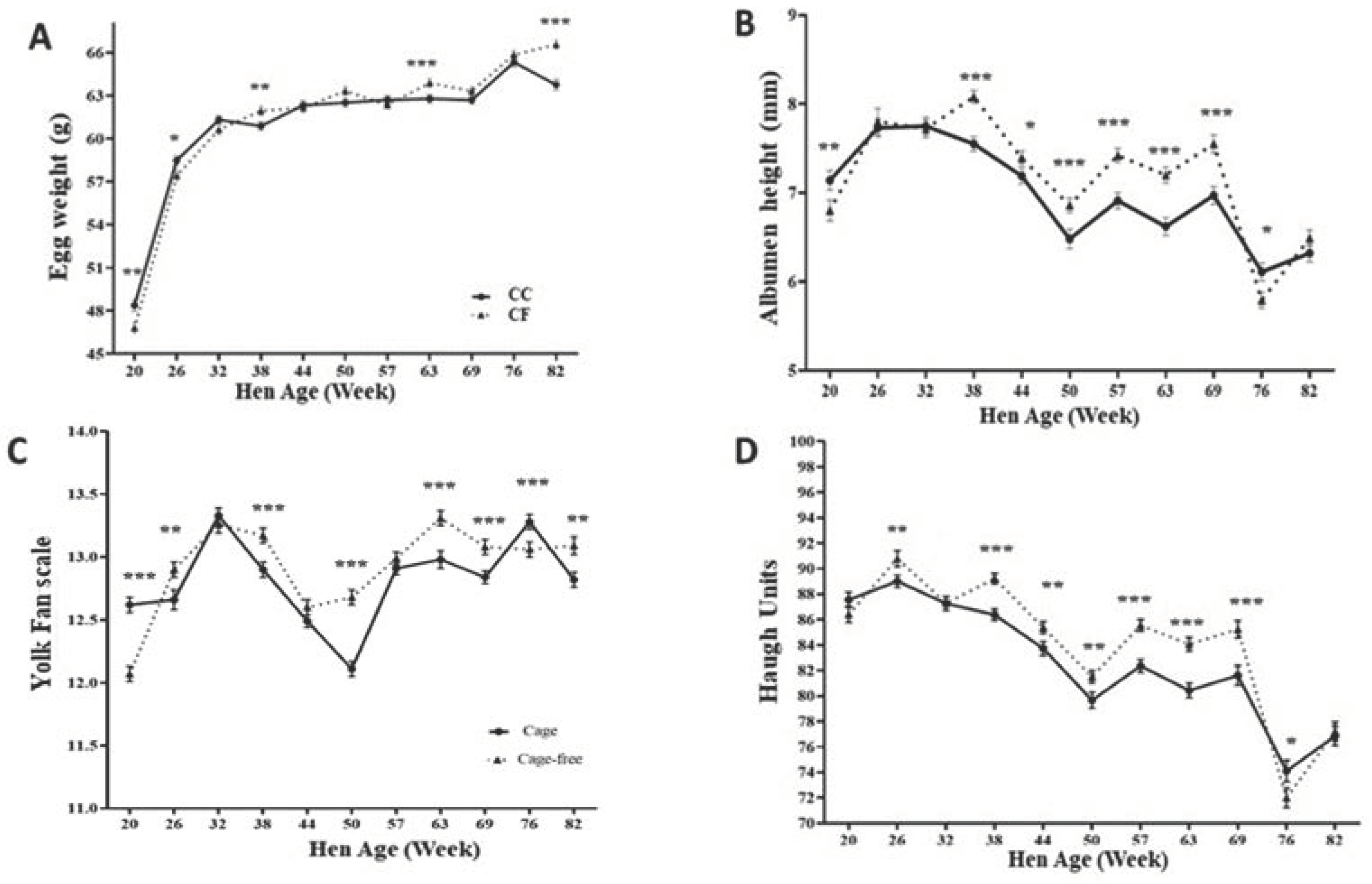

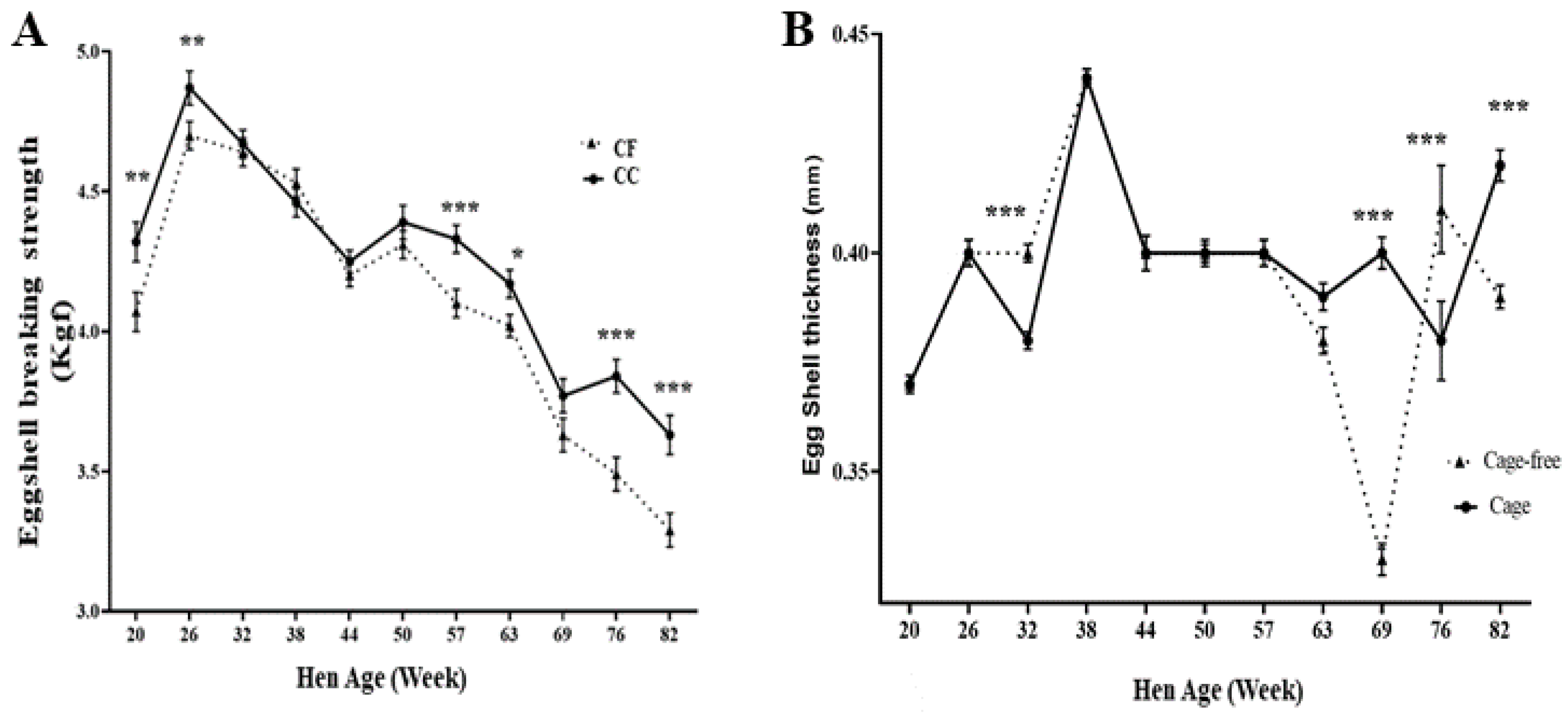

3.1. Egg Quality

3.1.1. Egg Weight

3.1.2. Internal Quality

3.1.3. External Quality

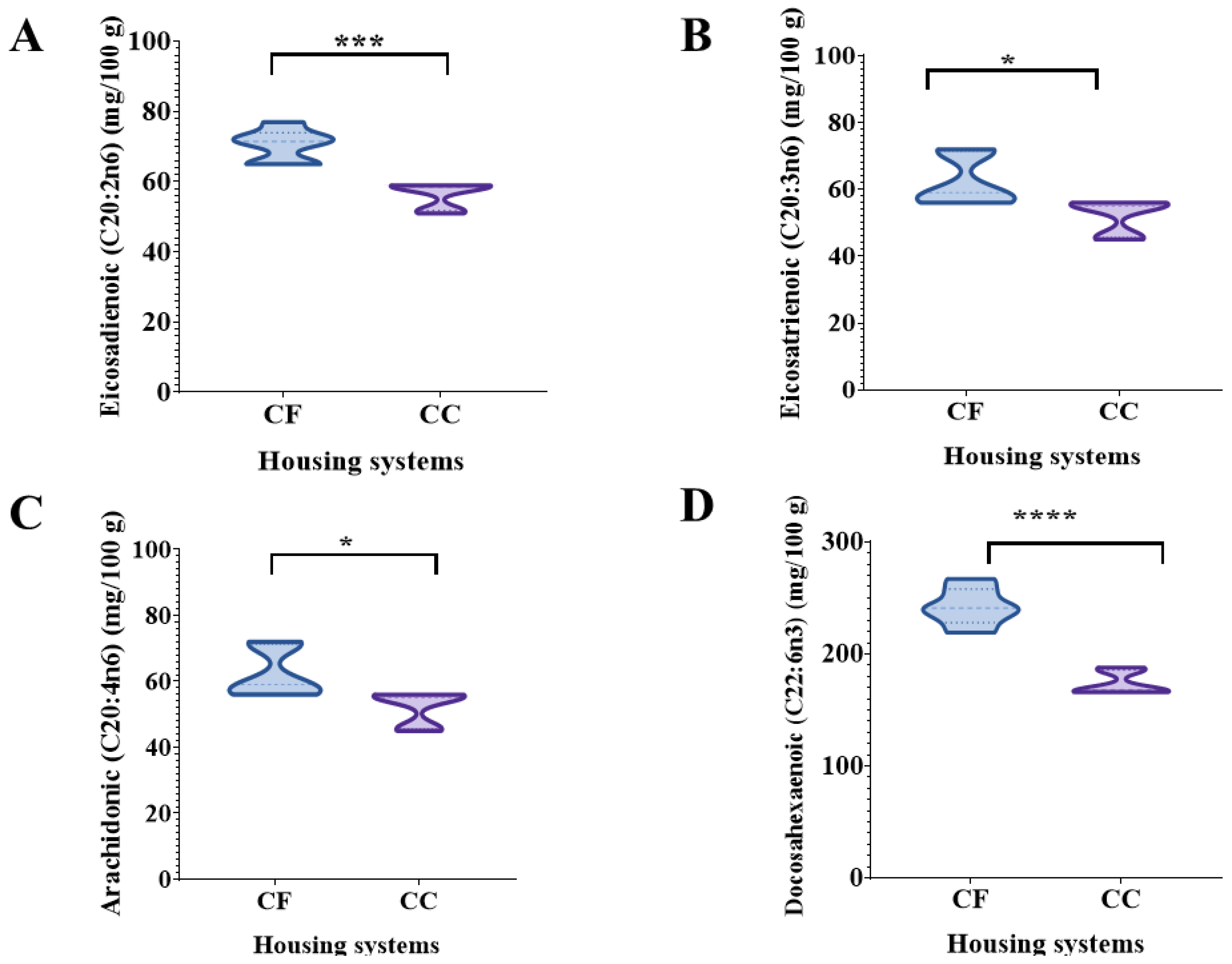

3.2. Yolk Fatty Acid Analysis

3.3. Yolk Protein Analysis

3.4. Salmonella Status

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Molnár, S.; Szőllősi, L. Sustainability and quality aspects of different table egg production systems: A literature review. Sustainability 2020, 12, 7884. [Google Scholar] [CrossRef]

- Mottet, A.; Tempio, G. Global poultry production: Current state and future outlook and challenges. World’s Poult. Sci. J. 2017, 73, 245–256. [Google Scholar] [CrossRef]

- Castro, F.L.S.; Chai, L.; Arango, J.; Owens, C.M.; Smith, P.A.; Reichelt, S.; DuBois, C.; Menconi, A. Poultry industry paradigms: Connecting the dots. J. Appl. Poult. Res. 2023, 32, 100310. [Google Scholar] [CrossRef]

- Gonzalez-Mora, A.F.; Rousseau, A.N.; Larios, A.D.; Godbout, S.; Fournel, S. Assessing environmental control strategies in cage-free aviary housing systems: Egg production analysis and random forest modeling. Comput. Electron. Agric. 2022, 196, 106854. [Google Scholar] [CrossRef]

- Sosnówka-Czajka, E.; Herbut, E.; Skomorucha, I. Effect of different housing systems on productivity and welfare of laying hens. Ann. Anim. Sci. 2010, 10, 349–360. [Google Scholar]

- Jones, D.R.; Cox, N.A.; Guard, J.; Fedorka-Cray, P.J.; Buhr, R.J.; Gast, R.K.; Abdo, Z.; Rigsby, L.L.; Plumblee, J.R.; Karcher, D.M.; et al. Microbiological impact of three commercial laying hen housing systems. Poult. Sci. 2015, 94, 544–551. [Google Scholar] [CrossRef] [PubMed]

- English, M.M. The chemical composition of free-range and conventionally-farmed eggs available to Canadians in rural Nova Scotia. PeerJ 2021, 9, e11357. [Google Scholar] [CrossRef] [PubMed]

- Janczak, A.M.; Riber, A.B. Review of rearing-related factors affecting the welfare of laying hens. Poult. Sci. 2015, 94, 1454–1469. [Google Scholar] [CrossRef]

- Løtvedt, P.; Fallahshahroudi, A.; Bektic, L.; Altimiras, J.; Jensen, P. Chicken domestication changes the expression of stress-related genes in brain, pituitary and adrenals. Neurobiol. Stress 2017, 7, 113–121. [Google Scholar] [CrossRef]

- Henchion, M.; Moloney, A.P.; Hyland, J.; Zimmermann, J.; McCarthy, S. Trends for meat, milk, and egg consumption for the next decades and the role played by livestock systems in the global production of proteins. Animal 2021, 15, 100287. [Google Scholar] [CrossRef]

- Zhu, L.; Liao, R.; Wu, N.; Zhu, G.; Tu, Y.; Yang, C. Integrating miRNA and mRNA expression profiles in plasma of laying hens associated with heat stress. Mol. Biol. Rep. 2019, 46, 2779–2789. [Google Scholar] [CrossRef] [PubMed]

- Rozenboim, I.; Tako, E.; Gal-Garber, O.; Proudman, J.A.; Uni, Z. The effect of heat stress on ovarian function of laying hens. Poult. Sci. 2007, 86, 1760–1765. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.H.; Lee, Y.K.; Lee, S.D.; Kim, S.H.; Lee, S.R.; Lee, H.G.; Lee, K.W. Changes in production parameters, egg qualities, fecal volatile fatty acids, nutrient digestibility, and plasma parameters in laying hens exposed to ambient temperature. Front. Vet. Sci. 2020, 7, 412. [Google Scholar] [CrossRef] [PubMed]

- Barrett, N.W.; Rowland, K.; Schmidt, C.J.; Lamont, S.J.; Rothschild, M.F.; Ashwell, C.M.; Persia, M.E. Effects of acute and chronic heat stress on the performance, egg quality, body temperature, and blood gas parameters of laying hens. Poult. Sci. 2019, 98, 6684–6692. [Google Scholar] [CrossRef] [PubMed]

- da Silva Pires, P.G.; Bavaresco, C.; Prato, B.S.; Wirth, M.L.; de Oliveira Moraes, P. The relationship between egg quality and hen housing systems systematic review. Livest. Sci. 2021, 250, 104597. [Google Scholar] [CrossRef]

- Samiullah, S.; Omar, A.S.; Roberts, J.; Chousalkar, K. Effect of production system and flock age on eggshell and egg internal quality measurements. Poult. Sci. 2017, 96, 246–258. [Google Scholar] [CrossRef]

- Dikmen, B.Y.; Ipek, A.Y.D.I.N.; Şahan, Ü.; Petek, M.E.T.I.N.; Sözcü, A. Egg production and welfare of laying hens kept in different housing systems (conventional, enriched cage, and free range). Poult. Sci. 2016, 95, 1564–1572. [Google Scholar] [CrossRef]

- Philippe, F.X.; Mahmoudi, Y.; Cinq-Mars, D.; Lefrançois, M.; Moula, N.; Palacios, J.; Pelletier, F.; Godbout, S. Comparison of egg production, quality and composition in three production systems for laying hens. Livest. Sci. 2020, 232, 103917. [Google Scholar] [CrossRef]

- Haugh, R.R. The Haugh unit for measuring egg quality. United States Egg Poult. Mag. 1937, 43, 552–555. [Google Scholar]

- ISO 12966-1: 2014; Animal and Vegetable Fats and Oils—Gas Chromatography of Fatty Acid Methyl esters—Part 1: Guidelines on Modern Gas Chromatography of Fatty Acid Methyl esters. ISO: Geneva, Switzerland, 2014.

- ISO 12966-2: 2017; Animal and Vegetable Fats and Oils—Gas Chromatography of Fatty Acid Methyl Esters—Part 2: Preparation of Methyl Esters of Fatty Acids. ISO: Geneva, Switzerland, 2017.

- Mooijman, K.A. The new ISO 6579-1: A real horizontal standard for detection of Salmonella, at last! Food Microbiol. 2018, 71, 2–7. [Google Scholar] [CrossRef]

- Mikoleit, M.L. WHO Global Foodborne Infections Network. A WHO Network Building Capacity to Detect, Control, and Prevent Foodborne and Other Enteric Infections from Farm to Table” Laboratory Protocol: “Isolation of Salmonella and Shigella from Faecal Specimens”; Enteric Diseases laboratory branch, Centers for Disease Control and Prevention: Atlanta, GA, USA, 2010. [Google Scholar]

- Yenice, G.; Kaynar, O.; Ileriturk, M.; Hira, F.; Hayirli, A. Quality of eggs in different production systems. Czech J. Food Sci. 2016, 34, 370–376. [Google Scholar] [CrossRef]

- Alig, B.N.; Malheiros, R.D.; Anderson, K.E. Evaluation of Physical Egg Quality Parameters of Commercial Brown Laying Hens Housed in Five Production Systems. Animals 2023, 13, 716. [Google Scholar] [CrossRef] [PubMed]

- Schuck-Paim, C.; Negro-Calduch, E.; Alonso, W.J. Laying hen mortality in different indoor housing systems: A meta-analysis of data from commercial farms in 16 countries. Sci. Rep. 2021, 11, 3052. [Google Scholar] [CrossRef] [PubMed]

- Sinclair, M.; Lee, N.Y.; Hötzel, M.J.; de Luna, M.C.T.; Sharma, A.; Idris, M.; Islam, M.A.; Iyasere, O.S.; Navarro, G.; Ahmed, A.A.; et al. Consumer attitudes towards egg production systems and hen welfare across the world. Front. Anim. Sci. 2022, 3, 995430. [Google Scholar] [CrossRef]

- de Luna, M.C.T.; Yang, Q.; Agus, A.; Ito, S.; Idrus, Z.; Iman, R.H.; Jattuchai, J.; Lane, E.; Nuggehalli, J.; Hartcher, K.; et al. Cage egg producers’ perspectives on the adoption of cage-free systems in China, Japan, Indonesia, Malaysia, Philippines, and Thailand. Front. Vet. Sci. 2022, 9, 1038362. [Google Scholar] [CrossRef] [PubMed]

- Racevičiūtė-Stupelienė, A.; Vilienė, V.; Bliznikas, S.; Šašytė, V.; Nutautaitė, M. The relationship between different laying hen housing systems in Lithuania and egg production quality and chemical composition. Cogent Food Agric. 2023, 9, 2211432. [Google Scholar] [CrossRef]

- Roberts, J.R.; Chousalkar, K.K. Effect of production system and flock age on egg quality and total bacterial load in commercial laying hens. J. Appl. Poult. Res. 2014, 23, 59–70. [Google Scholar]

- Soler Castillo, R.; Mínguez Balaguer, C.; Ibanez Sanchis, C.; Bueso Rodenas, J. Egg size and quality of hens housed in three different group sizes. J. Appl. Anim. Res. 2022, 50, 598–602. [Google Scholar] [CrossRef]

- Şekeroğlu, A.; Duman, M.; Tahtalı, Y.; Yıldırım, A.; Eleroğlu, H. Effect of cage tier and age on performance, egg quality and stress parameters of laying hens. S. Afr. J. Anim. Sci. 2014, 44, 288–297. [Google Scholar] [CrossRef]

- Kucukkoyuncu, E.; Okur, A.A.; Tahtabiçen, E.; Korkmaz, F.; Samli, H.E. Comparing the quality of free range and battery cage eggs. Eur. Poult. Sci./Arch. Für Für Geflügelkunde 2017, 81, 1. [Google Scholar] [CrossRef]

- Sokołowicz, Z.; Krawczyk, J.; Dykiel, M. Effect of alternative housing system and hen genotype on egg quality characteristics. Emir. J. Food Agric. 2018, 30, 695–703. [Google Scholar] [CrossRef]

- Speake, B.K.; Murray, A.M.B.; Noble, R.C. Transport and transformations of yolk lipids during the development of the avian embryo. Prog. Lipid Res. 1998, 37, 1–32. [Google Scholar] [CrossRef] [PubMed]

- Marelli, S.P.; Madeddu, M.; Mangiagalli, M.G.; Cerolini, S.; Zaniboni, L. Egg Production Systems, Open Space Allowance and Their Effects on Physical Parameters and Fatty Acid Profile in Commercial Eggs. Animals 2021, 11, 265. [Google Scholar] [CrossRef] [PubMed]

- Lordelo, M.; Fernandes, E.; Bessa, R.J.B.; Alves, S.P. Quality of eggs from different laying hen production systems, from indigenous breeds and specialty eggs. Poult. Sci. 2017, 96, 1485–1491. [Google Scholar] [CrossRef]

- Whelan, J.; Fritsche, K. Linoleic acid. Adv. Nutr. 2013, 4, 311–312. [Google Scholar] [CrossRef]

- Orczewska-Dudek, S.; Pietras, M.; Puchała, M.; Nowak, J. Camelina sativa oil and camelina cake as sources of polyunsaturated fatty acids in the diets of laying hens: Effect on hen performance, fatty acid profile of yolk lipids, and egg sensory quality. Ann. Anim. Sci. 2020, 20, 1365–1377. [Google Scholar] [CrossRef]

- Tomaszewska, E.; Muszyński, S.; Arczewska-Włosek, A.; Domaradzki, P.; Pyz-Łukasik, R.; Donaldson, J.; Świątkiewicz, S. Cholesterol Content, Fatty Acid Profile and Health Lipid Indices in the Egg Yolk of Eggs from Hens at the End of the Laying Cycle, Following Alpha-Ketoglutarate Supplementation. Foods 2021, 10, 596. [Google Scholar] [CrossRef]

- Hidalgo, A.; Rossi, M.; Clerici, F.; Ratti, S. A market study on the quality characteristics of eggs from different housing systems. Food Chem. 2008, 106, 1031–1038. [Google Scholar] [CrossRef]

- Mika, A.; Van Treuren, W.; González, A.; Herrera, J.J.; Knight, R.; Fleshner, M. Exercise is more effective at altering gut microbial composition and producing stable changes in lean mass in juvenile versus adult male F344 rats. PLoS ONE 2015, 10, e0125889. [Google Scholar] [CrossRef]

- Kawamura, N.; Yokoyama, R.; Takaya, M.; Ono, R.; Goto, T. The combined effect of feed and housing system affects the free amino acid content of egg yolk and albumen in brown layer chickens. J. Poult. Sci. 2023, 60, 2023007. [Google Scholar] [CrossRef]

- EFSA Panel on Biological Hazards (EFSA BIOHAZ Panel); Koutsoumanis, K.; Allende, A.; Alvarez-Ordóñez, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; Herman, L.; Hilbert, F.; Lindqvist, R.; et al. Salmonella control in poultry flocks and its public health impact. EFSA J. 2019, 17, e05596. [Google Scholar]

- Sharma, M.K.; McDaniel, C.D.; Kiess, A.S.; Loar II, R.E.; Adhikari, P. Effect of housing environment and hen strain on egg production and egg quality as well as cloacal and eggshell microbiology in laying hens. Poult. Sci. 2022, 101, 101595. [Google Scholar] [CrossRef] [PubMed]

- Mollenhorst, H.; Van Woudenbergh, C.J.; Bokkers, E.G.M.; De Boer, I.J.M. Risk factors for Salmonella enteritidis infections in laying hens. Poult. Sci. 2005, 84, 1308–1313. [Google Scholar] [CrossRef] [PubMed]

| Diet Composition | Peaking | Layer 2 | Layer 3 | Layer 4 | Layer 5 |

|---|---|---|---|---|---|

| Crude protein (g/day) | 17 | 16.7 | 16 | 15.5 | 15 |

| Metabolizable energy (kcal/bird/day) | 320 | 325 | 310 | 305 | 305 |

| Lysine (mg/day) | 830 | 810 | 790 | 770 | 750 |

| Methionine (mg/day) | 415 | 405 | 395 | 385 | 375 |

| Methionine + cysteine (mg/day) | 746 | 728 | 710 | 692 | 673 |

| Threonine (mg/day) | 574 | 560 | 546 | 532 | 518 |

| Ca (g/day) | 3.8 | 4.00 | 4.2 | 4.4 | 4.6 |

| P (mg/day) | 438 | 419 | 384 | 355 | 331 |

| P (digestible) (mg/day) | 396 | 376 | 347 | 321 | 300 |

| Na (mg/day) | 180 | 180 | 180 | 180 | 180 |

| Cl (mg/day) | 180 | 180 | 180 | 180 | 180 |

| Feed Intake Mean (g/day) | p-Value | Body Weight (g) | p-Value | |||

|---|---|---|---|---|---|---|

| Age/Hens | CC | CF | CC | CF | ||

| (Weeks) | ||||||

| 20 | 100.1 ± 1.7 | 98.7 ± 0.4 | 0.0701 | 1822 ± 5.84 | 1690 ± 4.6 | <0.0001 |

| 26 | 113.5 ± 0.0 | 120.2 ± 0.1 | <0.0001 | 1961 ± 5.64 | 1812 ± 4.3 | <0.0001 |

| 32 | 114 ± 0.0 | 119.3 ± 0.1 | <0.0001 | 1979 ± 6.13 | 1870 ± 4.3 | <0.0001 |

| 38 | 111.6 ± 0.1 | 119.1 ± 0.3 | <0.0001 | 1929 ± 6.0 | 1868 ± 4.7 | <0.0001 |

| 44 | 112.1 ± 0.0 | 120.3 ± 0.2 | <0.0001 | 1921 ± 5.7 | 1890 ± 4.4 | <0.0001 |

| 50 | 112.7 ± 0.0 | 118.6 ± 0.0 | <0.0001 | 1962 ± 6.6 | 1864 ± 5.0 | <0.0001 |

| 57 | 113.4 ± 0.0 | 114.8 ± 0.9 | >0.9999 | 1954 ± 7.2 | 1846 ± 5.3 | <0.0001 |

| 64 | 114 ± 0.0 | 117.6 ± 1.1 | 0.0565 | 1973 ± 6.2 | 1925 ± 4.8 | <0.0001 |

| 69 | 112.1 ± 0.0 | 118.9 ± 0.5 | <0.0001 | 1976 ± 7.0 | 1918 ± 4.7 | <0.0001 |

| 76 | 105.8 ± 0.0 | 113.5 ± 2.0 | 0.0182 | 2029 ± 7.2 | 1926 ± 5.8 | <0.0001 |

| 82 | 111.1 ± 0.1 | 114.9 ± 0.6 | 0.0023 | 1996 ± 6.8 | 1931 ± 7.3 | <0.0001 |

| Fatty Acid | Week | CF | CC | p-Value | |

|---|---|---|---|---|---|

| Pentadecanoic acid | C15:0 | 34 | 18.83 ± 0.4 | 14.83 ± 0.4 | <0.0001 |

| Palmitic acid | C16:0 | 34 | 7326.5 ± 175.8 | 6829 ± 121.5 | 0.0422 |

| Linoleic acid | C18:2n6c | 34 | 4766 ± 28.6 | 3909.83 ± 159.5 | 0.0032 |

| g-Linolenic acid | C18:3n6 | 34 | 5.33 ± 0.2 | 4 ± 0.0 | 0.0015 |

| Linolenic acid | C18:3n3 | 34 | 106.33 ± 1.4 | 80.33 ± 2.3 | <0.0001 |

| Eicosenoic acid | C20:1n9 | 34 | 78.83 ± 3.6 | 68.83 ± 1.4 | 0.0297 |

| Eicosadienoic acid | C20:2n6 | 34 | 70.5 ± 1.9 | 56.33 ± 1.5 | 0.0002 |

| Eicosatrienoic acid | C20:3n6 | 34 | 62.17 ± 3.01 | 52.17 ± 2.1 | 0.218 |

| Arachidonic acid | C20:4n6 | 34 | 738.17 ± 31.7 | 594 ± 16.1 | 0.0023 |

| Docosahexaenoic acid | C22:6n3 | 34 | 242.33 ± 6.9 | 173.5 ± 4.1 | <0.0001 |

| Lignoceric acid | C24:0 | 34 | 6.83 ± 0.47 | 5.5.0 ± 0.2 | 0.0299 |

| Lauric acid | C12:0 | 64 | 13.17 ± 0.3 | 6.33 ± 0.2 | <0.0001 |

| Myristic acid | C14:0 | 64 | 166.5 ± 3.5 | 135.67 ± 2.3 | <0.0001 |

| Palmitic acid | C16:0 | 64 | 6932.5 ± 68.6 | 7141.17 ± 30.1 | 0.0194 |

| Palmitoleic acid | C16:1 | 64 | 619.7 ± 20.1 | 785.8 ± 9.3 | <0.0001 |

| Heptadecanoic acid | C17:0 | 64 | 58.33 ± 1.02 | 51.5 ± 0.3 | <0.0001 |

| Stearic acid | C18:00 | 64 | 2345 ± 13.8 | 2438 ± 36.5 | 0.039 |

| Oleic acid | C18: 1n9c | 64 | 11,579 ± 100.9 | 12,136 ± 111.0 | 0.004 |

| Linoleic acid | C18:2n6c | 64 | 5990.83 ± 89.3 | 5373.33 ± 43.7 | 0.0001 |

| Eicosenoic acid | C20:1n9 | 64 | 78.33 ± 1.2 | 73.5 ± 1.4 | 0.0283 |

| Eicosatrienoic acid | C20:3n6 | 64 | 61 ± 1.7 | 56 ± 0.3 | 0.0037 |

| Lauric acid | C12:0 | 82 | 7.17 ± 0.0 | 8.67 ± 0.2 | 0.0024 |

| Heptadecanoic acid | 17:00 | 82 | 48.50 ± 1.3 | 55.5 ± 1.8 | 0.012 |

| Nervonic acid | C24:1 | 82 | 10.17 ± 0.5 | 12.83 ± 0.6 | 0.0081 |

| Hen Age | Production System | p-Value | |

|---|---|---|---|

| (Week) | CF | CC | |

| 34 | 13.80 ± 0.3 | 13.22 ± 0.0 | 0.368 |

| 64 | 14.69 ± 0.3 | 15.84 ± 0.3 | 0.1017 |

| 82 | 14.55 ± 0.2 | 13.87 ± 0.06 | 0.0346 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Hernández, R.; Rondón-Barragán, I.S.; Oviedo-Rondón, E.O. Egg Quality, Yolk Fatty Acid Profiles from Laying Hens Housed in Conventional Cage and Cage-Free Production Systems in the Andean Tropics. Animals 2024, 14, 168. https://doi.org/10.3390/ani14010168

Rodríguez-Hernández R, Rondón-Barragán IS, Oviedo-Rondón EO. Egg Quality, Yolk Fatty Acid Profiles from Laying Hens Housed in Conventional Cage and Cage-Free Production Systems in the Andean Tropics. Animals. 2024; 14(1):168. https://doi.org/10.3390/ani14010168

Chicago/Turabian StyleRodríguez-Hernández, Roy, Iang Schroniltgen Rondón-Barragán, and Edgar O. Oviedo-Rondón. 2024. "Egg Quality, Yolk Fatty Acid Profiles from Laying Hens Housed in Conventional Cage and Cage-Free Production Systems in the Andean Tropics" Animals 14, no. 1: 168. https://doi.org/10.3390/ani14010168

APA StyleRodríguez-Hernández, R., Rondón-Barragán, I. S., & Oviedo-Rondón, E. O. (2024). Egg Quality, Yolk Fatty Acid Profiles from Laying Hens Housed in Conventional Cage and Cage-Free Production Systems in the Andean Tropics. Animals, 14(1), 168. https://doi.org/10.3390/ani14010168