Evaluation of Actual Ventilation Rates and Efficiency in Research-Scale Pig Houses Based on Ventilation Configurations

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

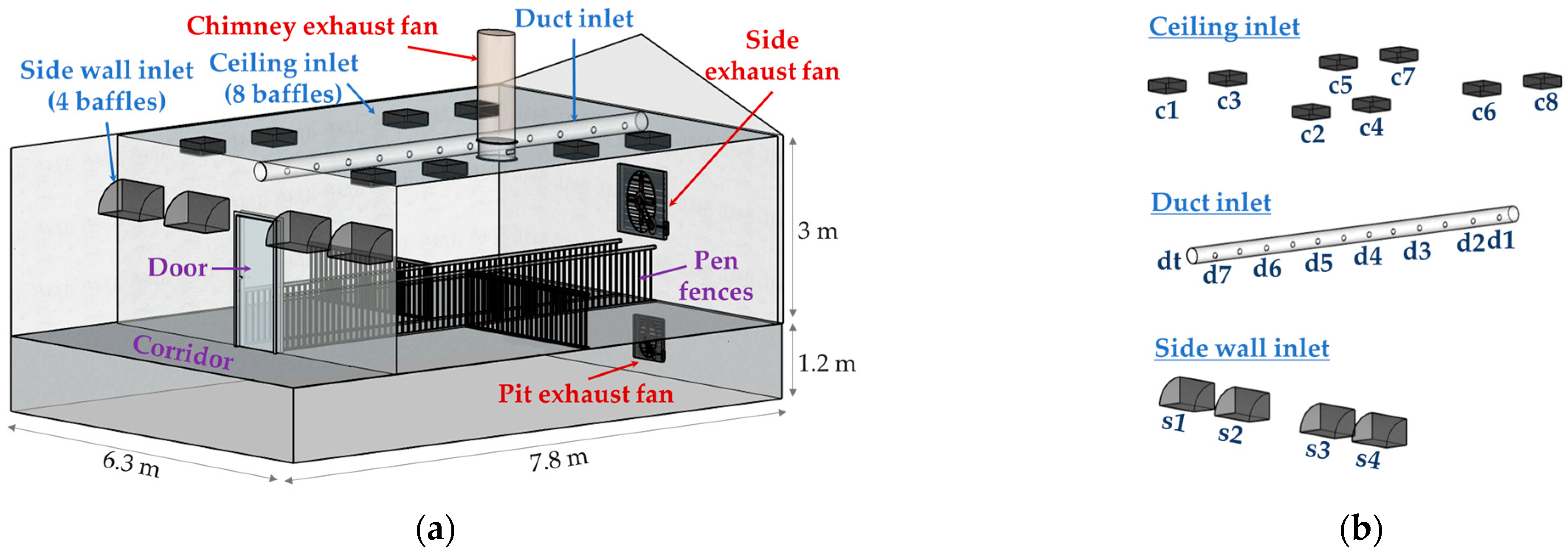

2.1. Experimental Pig Houses

2.2. Ventilation Configurations

2.2.1. Air Inlet Units

2.2.2. Exhaust Fan Units

2.3. Measurements

2.3.1. Ventilation Airflow Rates

2.3.2. Tracer Gas Decay Method

- (1)

- Start injecting CO2 gas and activate the mixing fans;

- (2)

- Stop the gas injection when the concentration of all gas analyzers reaches or exceeds 4500 ppm (the actual concentration is approximately 5000 ppm);

- (3)

- Stop the operation of the mixing fans when the concentration difference between the 14 gas analyzers at each point decreases to 10% (500 ppm). This indicates a uniform CO2 concentration throughout the pig room;

- (4)

- Allow time for the air currents to stabilize;

- (5)

- Perform the designated ventilation and stop the measurements when the concentration at all points reaches 1000 ppm.

2.4. Experimental Design and Analysis

3. Results

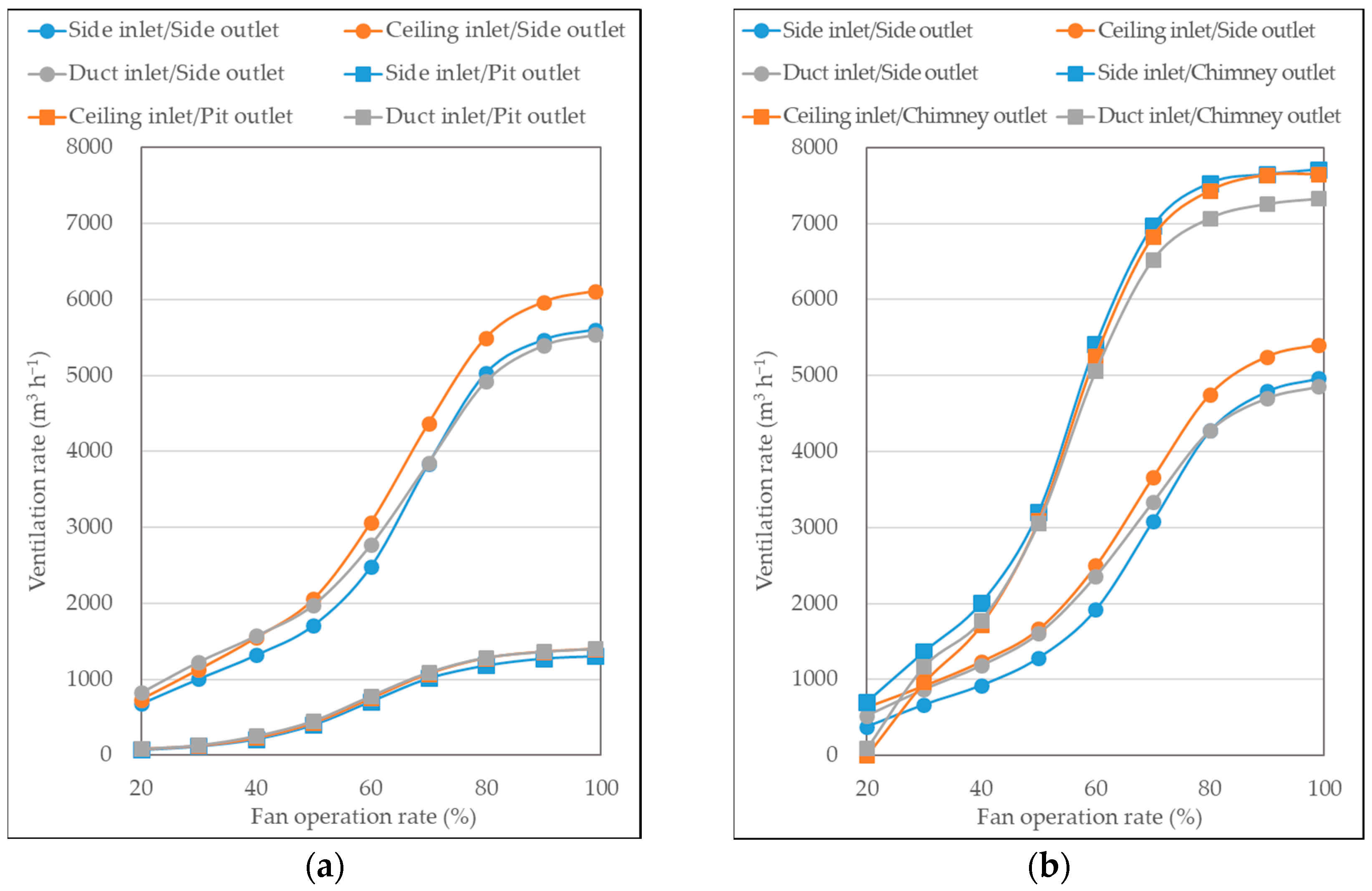

3.1. Ventilation Rates through Exhaust Fans and Inlet Openings

3.1.1. Actual Ventilation Rate

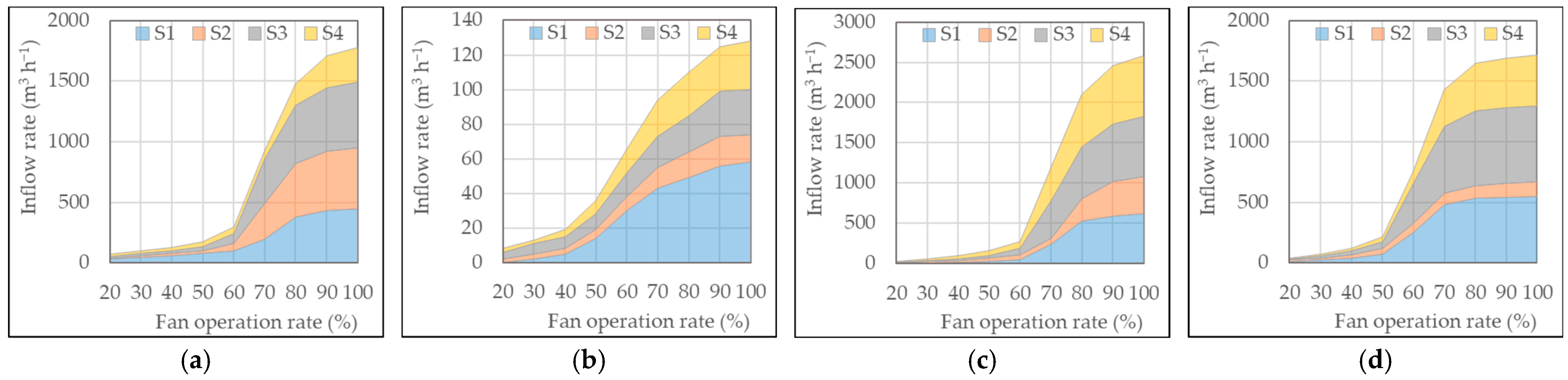

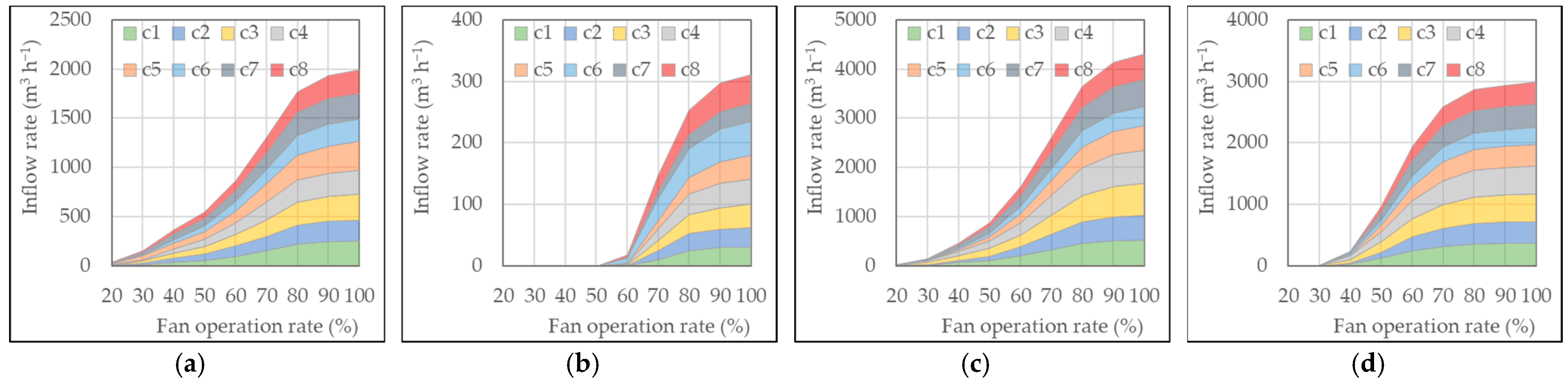

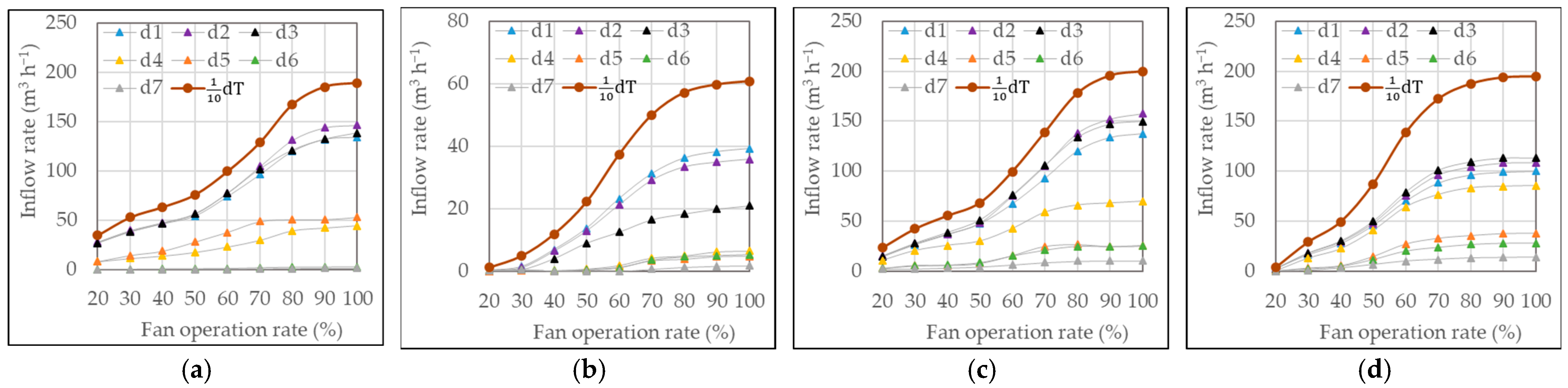

3.1.2. Inflow Rates through Inlet Openings

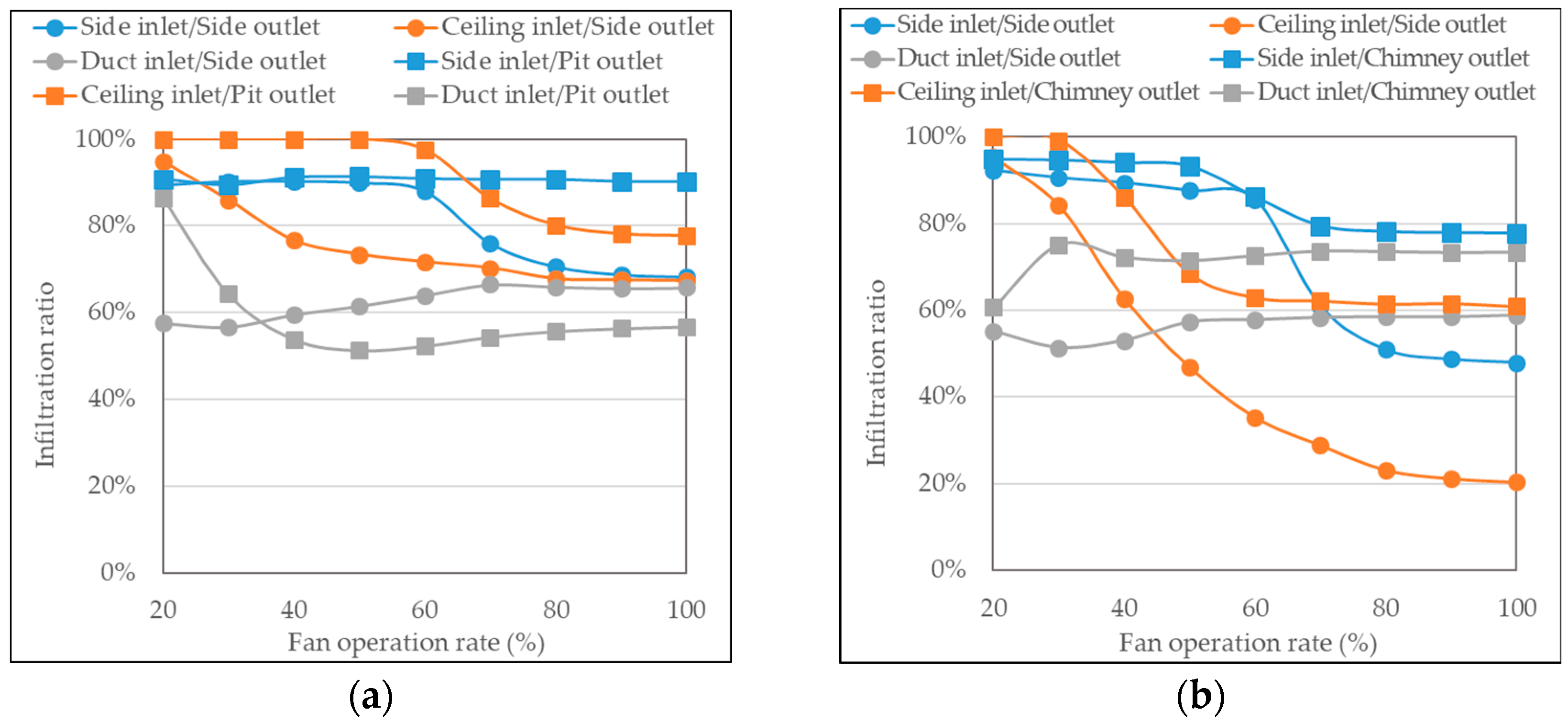

3.1.3. Infiltration Rate Estimation

3.2. Ventilation Effectiveness Using Tracer Gas Decay Method

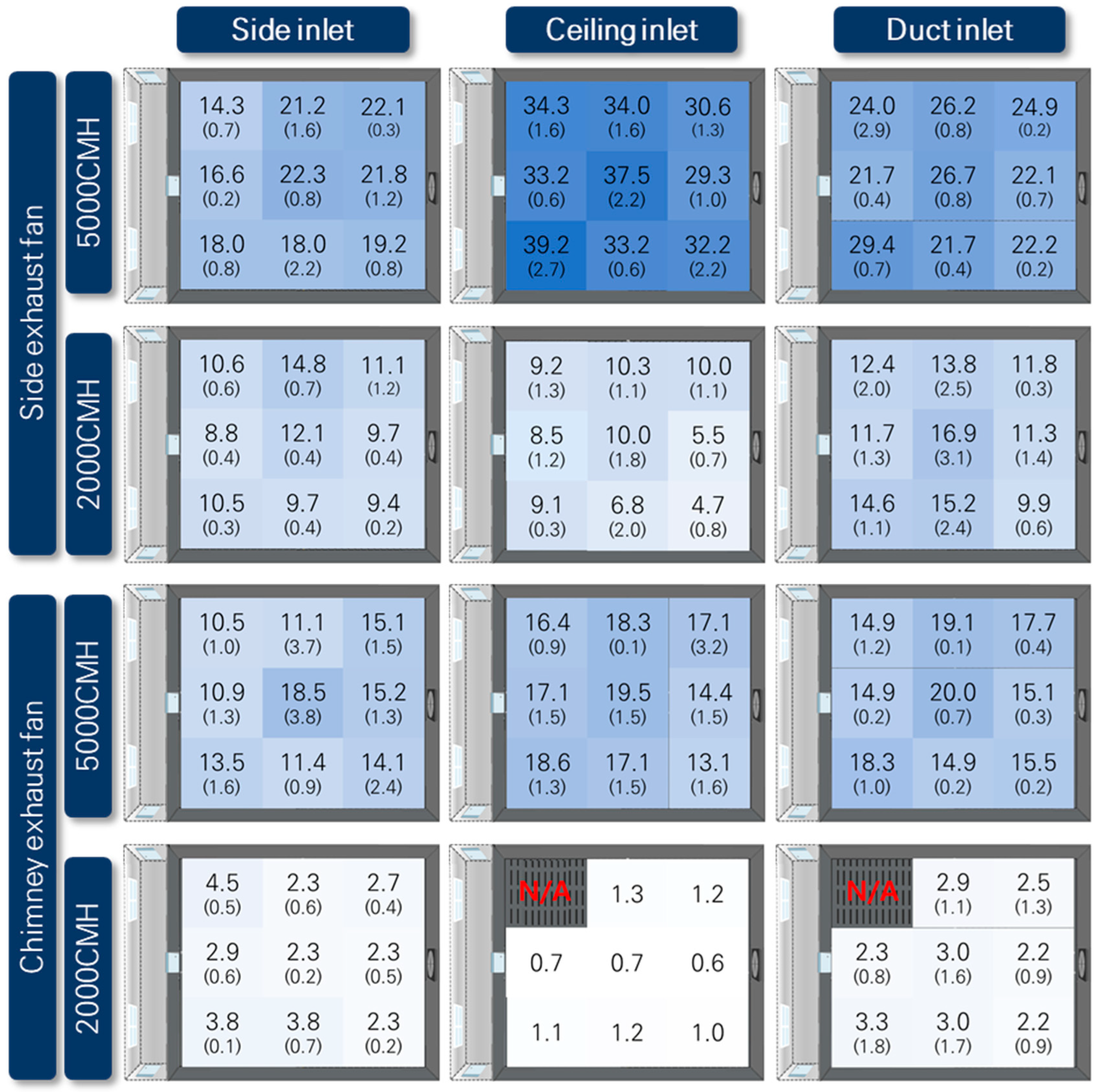

3.2.1. Distribution of Local ACH in Pig Activity Area

3.2.2. Comparison of Ventilation Effectiveness between Pig and Worker Activity Spaces

4. Conclusions

- (1)

- The maximum ventilation rates in pig room A and pig room B were measured as 6109 m3 h−1 and 7710 m3 h−1, respectively. The configurations that combined the side inlet/chimney outlet, ceiling inlet/side outlet, and duct inlet/pit outlet showed higher ventilation rates.

- (2)

- The measured maximum ventilation rates of the side, chimney, and pit exhaust fans in the experimental rooms were significantly lower (51.9%, 92.4%, and 33.6%, respectively) than the rates specified by the manufacturer. Therefore, relying on measured ventilation rates rather than fan operation rates is essential when using these pig facilities for research purposes.

- (3)

- The ceiling inlet was found to provide better airflow uniformity at individual inlet locations compared to the side inlet. The duct inlet had significant differences in airflow rates among individual holes along the length of the duct, with a substantial increase in the airflow near the exhaust fan.

- (4)

- The total inflow rates were much lower than the ventilation rates in both facilities. It was estimated that pig room A had infiltration rates ranging from 57% to 90% of the ventilation rate, while pig room B had infiltration rates ranging from 59% to 78%. High infiltration rates can reduce the influence of ventilation configurations and hinder ventilation effectiveness, highlighting the need for remedial actions.

- (5)

- The use of the side exhaust fan, which was closer to the pig activity space, resulted in higher ventilation effectiveness in the pig activity area compared to using the chimney exhaust fan. The use of the ceiling inlet, rather than the side inlet, not only improved ventilation effectiveness but also provided better spatial uniformity. In the case of using the side inlet, the jet effect of inflowing air through the baffle openings resulted in lower ventilation effectiveness in the pig area near the side inlet.

- (6)

- The ceiling inlet and side outlet combination exhibited the highest air exchange rates at a ventilation rate of 5000 m3 h−1. In general, the ventilation effectiveness significantly decreased when the ventilation rate was 2000 m3 h−1 compared to when it was 5000 m3 h−1 for all inlet and exhaust combinations.

- (7)

- In most combinations of inlet and exhaust configurations, the worker activity space exhibited higher air exchange rates than the pig activity space. However, in the small-scale facilities examined in this study, the difference was not substantial. Nevertheless, this difference could be more pronounced in ventilation configurations with lower effectiveness and facilities with higher infiltration ratios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tong, X.; Hong, S.-W.; Zhao, L. CFD modeling of airflow, thermal environment, and ammonia concentration distribution in a commercial manure-belt layer house with mixed ventilation systems. Comput. Electron. Agric. 2019, 162, 281–299. [Google Scholar] [CrossRef]

- Kwon, K.-S.; Lee, I.-B.; Ha, T. Identification of key factors for dust generation in a nursery pig house and evaluation of dust reduction efficiency using a CFD technique. Biosyst. Eng. 2016, 151, 28–52. [Google Scholar] [CrossRef]

- Mitloehner, F.M.; Calvo, M. Worker health and safety in concentrated animal feeding operations. J. Agric. Saf. Health 2008, 14, 163–187. [Google Scholar] [CrossRef] [PubMed]

- Calvet, S.; Cambra-López, M.; Blanes-Vidal, V.; Estellés, F.; Torres, A. Ventilation rates in mechanically-ventilated commercial poultry buildings in Southern Europe: Measurement system development and uncertainty analysis. Biosyst. Eng. 2010, 106, 423–432. [Google Scholar] [CrossRef]

- Casey, K.D.; Wheeler, E.F.; Gates, R.S.; Xin, H.; Topper, P.A.; Zajaczkowski, J.S.; Liang, Y.; Heber, A.J.; Jacobson, L.D. Quality assured measurements of livestock building emissions: Part 4. Building ventilation rate. In Proceedings of the Symposium on Air Quality Measurement Methods and Technology, San Francisco, CA, USA, 13–15 November 2002; pp. 13–15. [Google Scholar]

- Van Overbeke, P.; Pieters, J.G.; De Vogeleer, G.; Demeyer, P. Development of a reference method for airflow rate measurements through rectangular vents towards application in naturally ventilated animal houses: Part 1: Manual 2D approach. Comput. Electron. Agric. 2014, 106, 31–41. [Google Scholar] [CrossRef]

- Walker, I.S.; Wray, C.P. Evaluation of Flow Capture Techniques for Measuring HVAC Grille Airflows. 2002. Available online: https://escholarship.org/uc/item/0x45h4s0 (accessed on 15 May 2023).

- Norton, T.; Grant, J.; Fallon, R.; Sun, D.-W. Assessing the ventilation effectiveness of naturally ventilated livestock buildings under wind dominated conditions using computational fluid dynamics. Biosyst. Eng. 2009, 103, 78–99. [Google Scholar] [CrossRef]

- Rim, D.; Novoselac, A. Ventilation effectiveness as an indicator of occupant exposure to particles from indoor sources. Build. Environ. 2010, 45, 1214–1224. [Google Scholar] [CrossRef]

- Amai, H.; Novoselac, A. Experimental study on air change effectiveness in mixing ventilation. Build. Environ. 2016, 109, 101–111. [Google Scholar] [CrossRef]

- Fisk, W.J.; Faulkner, D.; Sullivan, D.; Bauman, F. Air change effectiveness and pollutant removal efficiency during adverse mixing conditions. Indoor Air 1997, 7, 55–63. [Google Scholar] [CrossRef]

- Krajčík, M.; Simone, A.; Olesen, B.W. Air distribution and ventilation effectiveness in an occupied room heated by warm air. Energy Build. 2012, 55, 94–101. [Google Scholar] [CrossRef]

- Kim, J.-G.; Lee, I.-B.; Kim, R.-W.; Yeo, U.-H.; Lee, S.-Y.; Jeong, D.-Y.; Decano, C. Analysis of local mean age and air supply effectiveness in a piglet house using the tracer gas decay method. Biosyst. Eng. 2022, 224, 49–67. [Google Scholar] [CrossRef]

- Kiwan, A.; Berg, W.; Fiedler, M.; Ammon, C.; Gläser, M.; Müller, H.-J.; Brunsch, R. Air exchange rate measurements in naturally ventilated dairy buildings using the tracer gas decay method with 85Kr, compared to CO2 mass balance and discharge coefficient methods. Biosyst. Eng. 2013, 116, 286–296. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Van Brecht, A.; Özcan, S.E.; Vranken, E.; Van Malcot, W.; Berckmans, D. Influence of sampling positions on accuracy of tracer gas measurements in ventilated spaces. Biosyst. Eng. 2009, 104, 216–223. [Google Scholar] [CrossRef]

- Samer, M.; Müller, H.-J.; Fiedler, M.; Ammon, C.; Gläser, M.; Berg, W.; Sanftleben, P.; Brunsch, R. Developing the 85Kr tracer gas technique for air exchange rate measurements in naturally ventilated animal buildings. Biosyst. Eng. 2011, 109, 276–287. [Google Scholar] [CrossRef]

- Seo, I.-H.; Lee, I.-B.; Moon, O.-K.; Kim, H.-T.; Hwang, H.-S.; Hong, S.-W.; Bitog, J.; Yoo, J.-I.; Kwon, K.-S.; Kim, Y.-H. Improvement of the ventilation system of a naturally ventilated broiler house in the cold season using computational simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Ding, L.; Lei, E.; Lyu, Y.; Yao, C.; Li, Q.; Huang, S.; Ma, W.; Yu, L.; Gao, R. Estimating the air exchange rates in naturally ventilated cattle houses using Bayesian-optimized GBDT. Int. J. Agric. Biol. Eng. 2023, 16, 73–80. [Google Scholar] [CrossRef]

- ISO 16000-8:2007; Indoor Air—Part 8: Determination of Local Mean Ages of Air in Buildings for Characterizing Ventilation Conditions. International Organization for Standardization: Geneva, Switzerland, 2007.

- Bowes, S.M.; Mason, E.G.; Corn, M. Confined space ventilation: Tracer gas analysis of mixing characteristics. Am. Ind. Hyg. Assoc. J. 1993, 54, 639–646. [Google Scholar] [CrossRef]

- Jadhav, H.T.; Hoff, S.J.; Harmon, J.D.; Jacobson, L.D.; Hetchler, B.P. Infiltration Characteristics of Swine Finishing and Gestation Buildings: Review and Quantification. In Proceedings of the 2015 ASABE International Meeting, New Orleans, LA, USA, 26–29 July 2015; p. 1. [Google Scholar]

- Zhang, Y.; Barber, E. Air leakage and ventilation effectiveness for confinement livestock housing. Trans. ASAE 1995, 38, 1501–1504. [Google Scholar] [CrossRef]

- Zhang, Y.; Barber, E.M. Infiltration Rates for a New Swine Building; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 1995. [Google Scholar]

- Jadhav, H.T.; Hoff, S.J.; Harmon, J.D.; Andersen, D.S. Swine finishing room air infiltration: Part 2. Infiltration as affected by room characteristics. Appl. Eng. Agric. 2018, 34, 735–745. [Google Scholar] [CrossRef]

| Conditions | Pig Room A | Pig Room B | |

|---|---|---|---|

| Air inlets | Side, Ceiling, Duct | ||

| Exhaust fans | Side, Pit 1 | Side Chimney | |

| Fan operation rates for measuring | Ventilation rate | 10, 20, 30, 40, 50, 60, 70, 80, 90, 100% | |

| ACH | Adjusted for ventilation rates of 2000 m3 h−1 and 5000 m3 h−1 | ||

| Conditions | Periods | Air Temperature (°C) | Humidity (%) | |||

|---|---|---|---|---|---|---|

| Experiments | Indoor | Outdoor | Indoor | Outdoor | ||

| Pig room A, VR 1 | 9–13 May 2022 | 19.2 | 18.8 | 69.0 | 59.0 | |

| Pig room A, ACH 2 | 16–20 May 2022 | 20.3 | 18.9 | 49.0 | 42.9 | |

| Pig room B, VR 1 | 11–22 July 2022 | 26.5 | 25.6 | 83.1 | 74.7 | |

| Pig room B, ACH 2 | 25–29 July 2022 | 28.5 | 28.3 | 74.6 | 71.9 | |

| Ventilation Rate Inlet Types | 2000 m3 h−1 | 5000 m3 h−1 | |||||

|---|---|---|---|---|---|---|---|

| Target Spaces | Side | Ceiling | Duct | Side | Ceiling | Duct | |

| Pigs | 4.5 ± 0.8 | 2.7 ± 0.5 | 2.6 ± 0.1 | 15.5 ± 1.0 | 21.1 ± 1.0 | 17.5 ± 1.1 | |

| Workers | 6.3 ± 2.0 | 8.4 ± 1.3 | 9.6 ± 2.3 | 21.1 ± 2.2 | 23.4 ± 2.8 | 19.8 ± 2.5 | |

| Ventilation Rate Inlet Types | 2000 m3 h−1 | 5000 m3 h−1 | |||||

|---|---|---|---|---|---|---|---|

| Target Spaces | Side | Ceiling | Duct | Side | Ceiling | Duct | |

| Pigs | 11.0 ± 0.5 | 8.4 ± 1.1 | 12.9 ± 1.5 | 18.8 ± 1.1 | 33.9 ± 1.7 | 24.7 ± 0.9 | |

| Workers | 10.1 ± 1.1 | 7.7 ± 1.8 | 10.2 ± 1.4 | 20.3 ± 4.7 | 32.0 ± 4.3 | 24.5 ± 2.7 | |

| Ventilation Rate Inlet Types | 2000 m3 h−1 | 5000 m3 h−1 | |||||

|---|---|---|---|---|---|---|---|

| Target Spaces | Side | Ceiling | Duct | Side | Ceiling | Duct | |

| Pigs | 3.1 ± 0.3 | 1.1 ± 1.1 | 2.8 ± 1.4 | 12.6 ± 1.7 | 16.8 ± 1.4 | 16.7 ± 0.5 | |

| Workers | 3.4 ± 0.7 | 1.8 ± 0.4 | 3.4 ± 1.0 | 16.1 ± 4.8 | 15.2 ± 1.6 | 17.2 ± 2.0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-y.; Choi, L.-y.; Park, J.; Daniel, K.F.; Hong, S.-w.; Kwon, K.; Hwang, O. Evaluation of Actual Ventilation Rates and Efficiency in Research-Scale Pig Houses Based on Ventilation Configurations. Animals 2023, 13, 2451. https://doi.org/10.3390/ani13152451

Lee S-y, Choi L-y, Park J, Daniel KF, Hong S-w, Kwon K, Hwang O. Evaluation of Actual Ventilation Rates and Efficiency in Research-Scale Pig Houses Based on Ventilation Configurations. Animals. 2023; 13(15):2451. https://doi.org/10.3390/ani13152451

Chicago/Turabian StyleLee, Se-yeon, Lak-yeong Choi, Jinseon Park, Kehinde Favour Daniel, Se-woon Hong, Kyeongseok Kwon, and Okhwa Hwang. 2023. "Evaluation of Actual Ventilation Rates and Efficiency in Research-Scale Pig Houses Based on Ventilation Configurations" Animals 13, no. 15: 2451. https://doi.org/10.3390/ani13152451

APA StyleLee, S.-y., Choi, L.-y., Park, J., Daniel, K. F., Hong, S.-w., Kwon, K., & Hwang, O. (2023). Evaluation of Actual Ventilation Rates and Efficiency in Research-Scale Pig Houses Based on Ventilation Configurations. Animals, 13(15), 2451. https://doi.org/10.3390/ani13152451