Measurement of Methane and Ammonia Emissions from Compost-Bedded Pack Systems in Dairy Barns: Tilling Effect and Seasonal Variations

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Barn Management

2.2. Animal Management

2.3. Environmental Parameters

2.4. Sample and Data Collection

2.4.1. Static Emission

2.4.2. Dynamic Emission

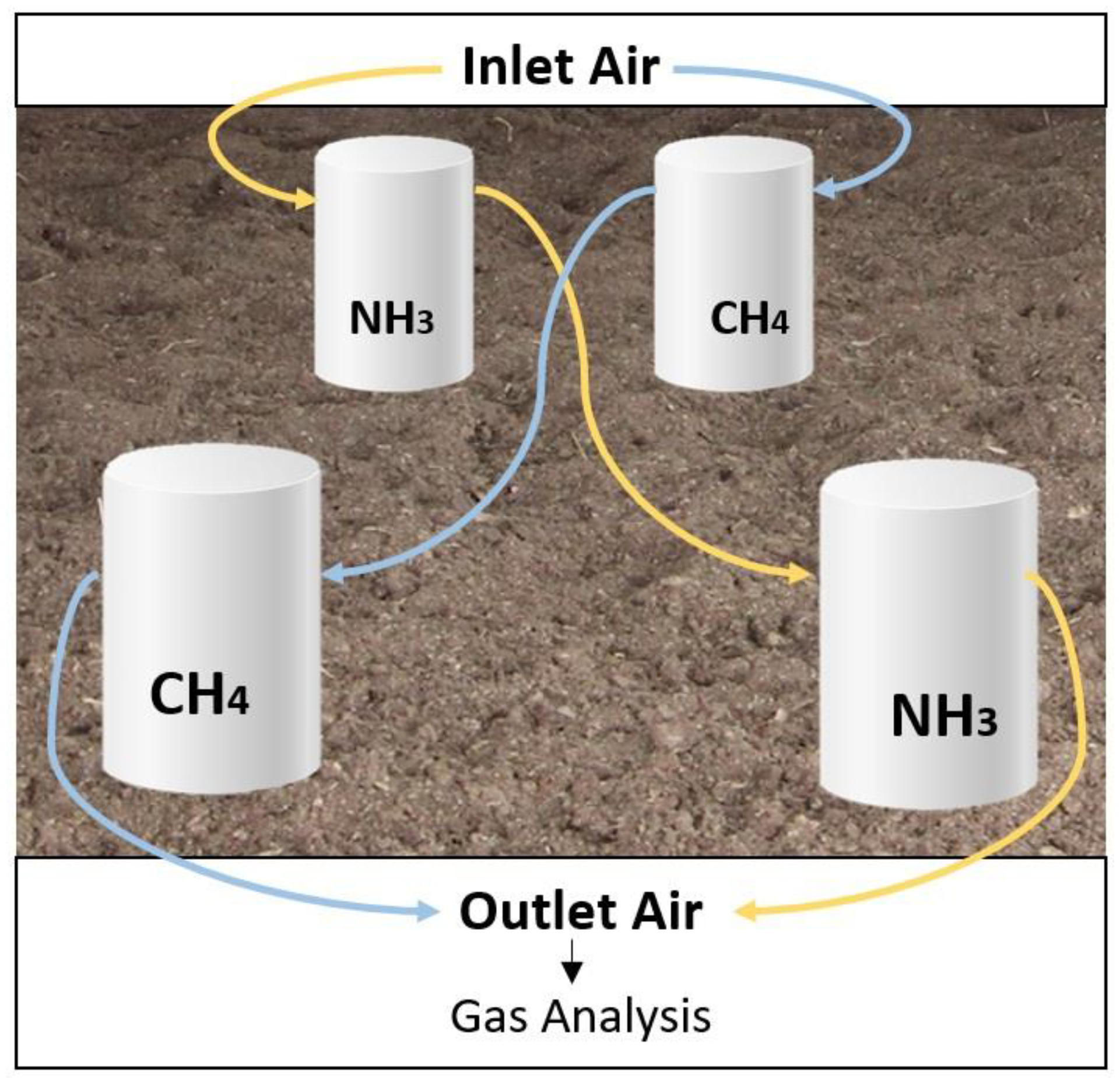

2.5. Air Sampling Protocol

2.5.1. Methane

2.5.2. Ammonia

2.6. Sample Analysis

2.6.1. Methane

2.6.2. Ammonia

2.7. Emission Calculation

2.7.1. Static-Phase Calculations

- i.

- Methane

- ii.

- Ammonia

2.7.2. Dynamic Emission Calculations

- i.

- Methane

- ii.

- Ammonia

2.8. Statistical Analysis

3. Results

Gaseous Emissions

4. Discussion

4.1. Methodological Approach

4.2. Phase-Related Emissions

4.3. CBP Emission: CH4

4.4. CBP Emission: NH3

4.5. Season-related Emissions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gerber, P.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J. Tackling Climate Change through Livestock: A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; ISBN 9789251079201. [Google Scholar]

- Rojas-Downing, M.M.; Nejadhashemi, A.P.; Harrigan, T.; Woznicki, S.A. Climate Change and Livestock: Impacts, Adaptation, and Mitigation. Clim. Risk Manag. 2017, 16, 145–163. [Google Scholar] [CrossRef]

- Kumari, S.; Hiloidhari, M.; Narayan, S.; Pal Dahiya, R. Methane Emission Assessment from Indian Livestock and Its Role in Climate Change Using Climate Metrics. In Climate Change and Agriculture; IntechOpen: London, UK, 2019. [Google Scholar]

- Montes, F.; Meinen, R.; Dell, C.; Rotz, A.; Hristov, A.N.; Oh, J.; Waghorn, G.; Gerber, P.J.; Henderson, B.; Makkar, H.P.S.; et al. Mitigation of Methane and Nitrous Oxide Emissions from Animal Operations: II. A Review of Manure Management Mitigation Options. J. Anim. Sci. 2013, 91, 5070–5094. [Google Scholar] [CrossRef] [PubMed]

- European Environment Agency. Agriculture—Ammonia Emission Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agriculture_-_ammonia_emission_statistics&oldid=257567 (accessed on 23 November 2020).

- Demmers, T.G.M.; Phillips, V.R.; Short, L.S.; Burgess, L.R.; Hoxey, R.P.; Wathes, C.M. Validation of Ventilation Rate Measurement Methods and the Ammonia Emission from Naturally Ventilated Dairy and Beef Buildings in the United Kingdom. J. Agric. Eng. Res. 2001, 79, 107–116. [Google Scholar] [CrossRef]

- Vranken, E.; Claes, S.; Hendriks, J.; Darius, P.; Berckmans, D. Intermittent Measurements to Determine Ammonia Emissions from Livestock Buildings. Biosyst. Eng. 2004, 88, 351–358. [Google Scholar] [CrossRef]

- Jeppsson, K.H. Diurnal Variation in Ammonia, Carbon Dioxide and Water Vapour Emission from an Uninsulated, Deep Litter Building for Growing/Finishing Pigs. Biosyst. Eng. 2002, 81, 213–223. [Google Scholar] [CrossRef]

- Balcells, J.; Fuertes, E.; Seradj, A.; Maynegre, J.; Villalba, D.; de la Fuente, G. Study of Nitrogen Fluxes across Conventional Solid Floor Cubicle and Compost-Bedded Pack Housing Systems in Dairy Cattle Barns Located in the Mediterranean Area: Effects of Seasonal Variation. J. Dairy Sci. 2020, 103, 10882–10897. [Google Scholar] [CrossRef]

- Fuertes, E.; Seradj, A.R.; Maynegre, J.; Villalba, D.; de la Fuente, G.; Balcells, J. Annual Nitrogen Balance from Dairy Barns, Comparison between Cubicle and Compost-Bedded Pack Housing Systems in the Northeast of Spain. Animals 2021, 11, 2136. [Google Scholar] [CrossRef]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Bewley, J.M. Compost Bedded Pack Dairy Barn Management, Performance, and Producer Satisfaction Compost Bedded Pack Dairy Barn Management, Performance, and Producer Satisfaction. J. Dairy Sci. 2013, 96, 8060–8074. [Google Scholar] [CrossRef]

- Klaas, I.C.; Bjerg, B.; Friedmann, S.; Bar, D. Cultivated Barns for Dairy Cows. Dan. Vet. 2010, 93, 20–29. [Google Scholar]

- Biasato, I.; D’Angelo, A.; Bertone, I.; Odore, R.; Bellino, C.; D’angelo, A. Compost Bedded-Pack Barn as an Alternative Housing System for Dairy Cattle in Italy: Effects on Animal Health and Welfare and Milk and Milk Product Quality. Ital. J. Anim. Sci. 2019, 18, 1142–1153. [Google Scholar] [CrossRef]

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited Review: Compost-Bedded Pack Barns for Dairy Cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef] [PubMed]

- Poteko, J.; Zähner, M.; Schrade, S. Effects of Housing System, Floor Type and Temperature on Ammonia and Methane Emissions from Dairy Farming: A Meta-Analysis. Biosyst. Eng. 2019, 182, 16–28. [Google Scholar] [CrossRef]

- Seipelt, F. Quantifizierung Und Bewertung Gasförmiger Emissionen Aus Frei Gelüfteten Milchviehställen Mit TraufFirst-Lüftung; Diss. Univ. Vdimeg-Schriftenr: Göttingen, Germany, 1999; Volume 336. [Google Scholar]

- Snell, H.G.J.; Seipelt, F.; Van Den Weghe, H.F.A. Ventilation Rates and Gaseous Emissions from Naturally Ventilated Dairy Houses. Biosyst. Eng. 2003, 86, 67–73. [Google Scholar] [CrossRef]

- Mohn, J.; Zeyer, K.; Keck, M.; Keller, M.; Zähner, M.; Poteko, J.; Emmenegger, L.; Schrade, S. A Dual Tracer Ratio Method for Comparative Emission Measurements in an Experimental Dairy Housing. Atmos. Environ. 2018, 179, 12–22. [Google Scholar] [CrossRef]

- Kittas, C.; Boulard, T.; Mermier, M.; Papadakis, G. Wind Induced Air Exchange Rates in a Greenhouse Tunnel with Continuous Side Openings. J. Agric. Eng. Res. 1996, 65, 37–49. [Google Scholar] [CrossRef]

- Barber, E.M.; Ogilvie, J.R. Incomplete Mixing in Ventilated Airspaces. Part Ii. Scale Model Study. Can. Agric. Eng. 1982, 26, 189–196. [Google Scholar]

- van Dooren, H.J.; Galama, P.J.; Smits, M.C.J.; Ouweltjes, W.; Driehuis, F.; Bokma, S. Bodemsvoorvrijloopstallen; Report 411; Wageningen UR Livestock Research: Lelystad, The Netherlands, 2011. [Google Scholar]

- Seradj, A.R.; Balcells, J.; Morazan, H.; Alvarez-Rodriguez, J.; Babot, D.; De la Fuente, G. The Impact of Reducing Dietary Crude Protein and Increasing Total Dietary Fiber on Hindgut Fermentation, the Methanogen Community and Gas Emission in Growing Pigs. Anim. Feed Sci. Technol. 2018, 245, 54–56. [Google Scholar] [CrossRef]

- FEFRIC. Control Lleter de La Raça Frisona a Catalunya; Federació Frisona de Catalunya: New York, NY, USA, 2018. [Google Scholar]

- Agricultural and Food Research Council Agricultural and Food Research Council. Energy and Protein Requirements of Ruminants. In An Advisory Manual Prepared by the Agricultural Food and Research Council Technical Committee on Responses to Nutrients; CAB International: Wallingford, UK, 1993. [Google Scholar]

- Morazán, H.; Seradj, A.R.; Contreras, D.; Medina, I.; Álvarez-Rodríguez, J.; Babot, D.; Balcells, J. Quantification of CH4, NH3 and N2O Emission from Growing-Finishing Pigs: The Effect of Protein and Fibre Levels in Their Ration. XV Jorn. Sobre Prod. Anim. 2013, 2013, 109–111. [Google Scholar]

- Goldman, F.H.; Jacobs, M.B. Chemical Methods in Industrial Hygiene. Available online: https://www.researchgate.net/publication/31674648_Chemical_methods_in_industrial_hygiene_FH_Goldman_MB_Jacobs (accessed on 17 September 2019).

- Ndegwa, P.M.; Vaddella, V.K.; Hristov, A.N.; Joo, H.S. Measuring Concentrations of Ammonia in Ambient Air or Exhaust Air Stream Using Acid Traps. J. Environ. Qual. 2009, 38, 647–653. [Google Scholar] [CrossRef]

- Holland, E.A.; Robertson, G.P.; Greenberg, J.; Groffman, P.M.; Boone, R.D.; Gosz, J.R. Soil CO2, N2O, and CH4 Exchange. In Standard Soil Methods for Long-Term Ecological Research; Oxford University Press: New York, NY, USA, 1999; pp. 185–201. [Google Scholar]

- AOAC International. Official Methods of Analysis of Association of Official Analytical Chemists, 18th ed.; AOAC International: Washington, DC, USA, 2010. [Google Scholar]

- Aarnink, A.J.A.; Verstegen, M.W.A. Nutrition, Key Factor to Reduce Environmental Load from Pig Production. Livest. Sci. 2007, 109, 194–203. [Google Scholar] [CrossRef]

- Chadwick, D.; Sommer, S.; Thorman, R.; Fangueiro, D.; Cardenas, L.; Amon, B.; Misselbrook, T. Manure Management: Implications for Greenhouse Gas Emissions. Anim. Feed Sci. Technol. 2011, 166–167, 514–531. [Google Scholar] [CrossRef]

- Petersen, S.O.; Blanchard, M.; Chadwick, D.; Del Prado, A.; Edouard, N.; Mosquera, J.; Sommer, S.G. Manure Management for Greenhouse Gas Mitigation. Animal 2013, 7, 266–282. [Google Scholar] [CrossRef] [PubMed]

- Wolf, K. A Portable Sensor for Measuring Gas Emissions from Dairy Compost Bedded Pack Barns; University of Kentucky: Lexington, KY, USA, 2017. [Google Scholar]

- Montes, F.; Rotz, C.A.; Chaoui, H. Process Modeling of Ammonia Volatilization from Ammonium Solution and Manure Surfaces: A Review with Recommended Models. Trans. ASABE 2009, 52, 1707–1719. [Google Scholar] [CrossRef]

- Pratt, C.; Redding, M.; Hill, J.; Jensen, P.D. Does Manure Management Affect the Latent Greenhouse Gas Emitting Potential of Livestock Manures? Waste Manag. 2015, 46, 568–576. [Google Scholar] [CrossRef]

- Amon, B.; Amon, T.; Boxberger, J.; Alt, C. Emissions of NH3, N2O and CH4 from Dairy Cows Housed in a Farmyard Manure Tying Stall (Housing, Manure Storage, Manure Spreading). Nutr. Cycl. Agroecosyst. 2001, 60, 103–113. [Google Scholar] [CrossRef]

- Owen, J.J.; Silver, W.L. Greenhouse Gas Emissions from Dairy Manure Management: A Review of Field-Based Studies. Glob. Chang. Biol. 2015, 21, 550–565. [Google Scholar] [CrossRef]

- Leytem, A.B.; Dungan, R.S.; Bjorneberg, D.L.; Koehn, A.C. Emissions of Ammonia, Methane, Carbon Dioxide, and Nitrous Oxide from Dairy Cattle Housing and Manure Management Systems. J. Environ. Qual. 2011, 40, 1383–1394. [Google Scholar] [CrossRef] [PubMed]

- van Dooren, H.J.C.; Galama, P.J.; Blanken, K. On Farm Development of Bedded Pack Dairy Barns in The Netherlands: Gaseous Emissions Bedding (No. 710); Wageningen Livestock Research: Wageningen, The Netherlands, 2016. [Google Scholar]

- De La Fuente, G.; Yañez-Ruiz, D.R.; Seradj, A.R.; Balcells, J.; Belanche, A. Methanogenesis in Animals with Foregut and Hindgut Fermentation: A Review. Anim. Prod. Sci. 2019, 59, 2109–2122. [Google Scholar] [CrossRef]

- Cárdenas, A.; Ammon, C.; Schumacher, B.; Stinner, W.; Herrmann, C.; Schneider, M.; Weinrich, S.; Fischer, P.; Amon, T.; Amon, B. Methane Emissions from the Storage of Liquid Dairy Manure: Influences of Season, Temperature and Storage Duration. Waste Manag. 2021, 121, 393–402. [Google Scholar] [CrossRef]

- Im, S.; Petersen, S.O.; Lee, D.; Kim, D.H. Effects of Storage Temperature on CH4 Emissions from Cattle Manure and Subsequent Biogas Production Potential. Waste Manag. 2020, 101, 35–43. [Google Scholar] [CrossRef]

- Dalby, F.R.; Hafner, S.D.; Petersen, S.O.; VanderZaag, A.C.; Habtewold, J.; Dunfield, K.; Chantigny, M.H.; Sommer, S.G. Understanding Methane Emission from Stored Animal Manure: A Review to Guide Model Development. J. Environ. Qual. 2021, 50, 817–835. [Google Scholar] [CrossRef] [PubMed]

- Petersen, S.O.; Sommer, S.G. Ammonia and Nitrous Oxide Interactions: Roles of Manure Organic Matter Management. Anim. Feed Sci. Technol. 2011, 166–167, 503–513. [Google Scholar] [CrossRef]

| Barna nº | Geographic Coordinates | Floor Type and Manure Handing System | Length, m | Width, m | Feed Alley, m | Emission Surface, m2 | m2 per cow |

|---|---|---|---|---|---|---|---|

| 1 | 41°34′29.8″ N 0°27′07.0″ E | Daily bed cultivation, bed emptying up to 6 month, daily mechanical cleaning of the feed alley (2/day), and no bedding material | 50 | 20.80 × 1 b | 4.0 × 1 | 1040 | 10.4 |

| 2 | 41°42′46.3″ N 0°46′44.7″ E | Daily bed cultivation, bed emptying up to 6 month, daily mechanical cleaning of the feed alley (3/day), and no bedding material | 140 | 21.50 × 2 | 4.0 × 2 | 6020 | 12.4 |

| 3 | 41°42′33.5″ N 0°54′45.2″ E | Daily bed cultivation, bed emptying up to 6 month, daily mechanical cleaning of the feed alley (1/day), and no bedding material | 84 | 11.45 × 3 | 5.0 × 3 | 2885 | 12.3 |

| Barn nº | Barn 1 | Barn 2 | Barn 3 | Season | Barns | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Season | W | S | W | S | W | S | p-Value | SEM | p-Value | SEM |

| Climatic condition | ||||||||||

| Temperature [ºC] | 7.1 | 38.5 | 6.2 | 36.7 | 5.5 | 33.9 | <0.01 | 1.00 | 0.9 | 15.06 |

| Wind [km/h higher rate] | 43.3 | 42.7 | 16.6 | 15.7 | 17.7 | 16.9 | 0.9 | 8.76 | <0.01 | 0.38 |

| Humidity [%] | 71.0 | 40 | 81.7 | 53.2 | 72.7 | 58.2 | 0.02 | 4.49 | 0.8 | 12.85 |

| Herd structure and performance | ||||||||||

| Cows, nº | 110 | 100 | 480 | 483 | 241 | 236 | 0.9 | 110.22 | <0.01 | 3.34 |

| Mean lactation, nº | 2.3 | 2.2 | 2.2 | 2.2 | 2. 2 | 2. 2 | 0.4 | 0.02 | 0.5 | 0.03 |

| Parturition interval, days | 450 | 442 | 412 | 434 | 445 | 437 | 0.9 | 8.58 | 0.2 | 7.14 |

| DMI [kg/day] | 23.8 | 26.2 | 24.7 | 25.9 | 24.2 | 25.8 | 0.04 | 0.21 | 0.9 | 0.91 |

| Milk yield [kg/day] | 35.1 | 31.1 | 34.2 | 36.9 | 33.9 | 34.6 | 0.9 | 1.21 | 0.5 | 1.41 |

| Barn nº | Barn 1 | Barn 2 | Barn 3 | |||

|---|---|---|---|---|---|---|

| Ingredients [kg Fresh Matter/day] | W | S | W | S | W | S |

| Corn silage | 21.00 | 22.00 | 12.00 | 26.00 | 14.00 | 25.00 |

| Barley silage | 5.00 | 6.88 | 12.00 | 9.37 | ||

| Cottonseeds | 2.00 | 1.65 | ||||

| Corn ears | 8.02 | 7.24 | ||||

| Alfalfa hay | 2.50 | 2.00 | 3.00 | 3.70 | 4.00 | |

| Barley straw | 1.00 | 0.70 | 0.80 | 0.80 | 1.13 | |

| Soybean hulls | 1.03 | 1.00 | ||||

| Brewers grains | 8.00 | 5.00 | 3.00 | 5.00 | ||

| Corn grain | 5.00 | 3.50 | 7.15 | 3.18 | ||

| Barley grain | 2.50 | 2.50 | ||||

| Soybean meal | 2.46 | 2.14 | 3.40 | 3.50 | 2.87 | 3.73 |

| Rapeseed meal | 2.00 | 2.50 | 1.70 | 2.00 | 1.53 | 1.50 |

| Bypass fat | 0.30 | 0.30 | 0.24 | 0.35 | ||

| Molasses | 0.10 | 0.10 | 1.5 | |||

| Sodium bicarbonate | 0.20 | 0.20 | 0.27 | 0.30 | 0.04 | 0.04 |

| Palmitic acid | 0.15 | 0.2 | 0.34 | 0.35 | ||

| Minerals and vitamins | 0.35 | 0.35 | 0.47 | 0.47 | 0.43 | 0.55 |

| Total fresh matter | 48.28 | 47.11 | 46.00 | 48.10 | 34.42 | 46.72 |

| Chemical composition [g/kg DM] | ||||||

| Dry matter [g/kg fresh matter] | 480.9 | 488.2 | 525.6 | 535.0 | 668.4 | 496.0 |

| CP | 165.0 | 165.0 | 170.1 | 169.8 | 170.0 | 168.1 |

| NDF | 384.3 | 334.8 | 321.3 | 313.2 | 330.3 | 313.3 |

| ADF | 215.8 | 198.2 | 197.8 | 187.2 | 215.0 | 180.0 |

| NFC | 331.6 | 378.7 | 384.5 | 390.9 | 380.1 | 391.7 |

| Gaseous Emission (g m−2 Day−1) | SE | DE | Total Emission | Phase Effect | |

|---|---|---|---|---|---|

| SEM | p-Value | ||||

| CH4 | |||||

| Winter | 0.004 | 0.99 | 1.00 | 0.09 | <0.001 |

| Summer | 0.09 | 4.65 | 4.74 | 0.283 | 0.03 |

| NH3 | |||||

| Winter | 0.39 | 1.46 | 1.86 | 0.075 | 0.01 |

| Summer | 1.13 | 2.95 | 4.08 | 0.233 | 0.30 |

| Compost-Bedded Pack Emission [g Animal−1 Day−1] | Gaseous Emission | SEM | ||

|---|---|---|---|---|

| NH3 | CH4 | NH3 | CH4 | |

| Winter | 20.9 | 11.31 | 4.13 | 2.85 |

| Summer | 50.2 | 58.5 | 22.2 | 27.0 |

| SEM | 22.56 | 27.15 | - | - |

| p-Value | 0.57 | 0.14 | - | - |

| [g milk−1 day−1] | ||||

| Winter | 0.61 | 0.33 | 0.12 | 0.08 |

| Summer | 1.41 | 1.64 | 0.61 | 0.73 |

| SEM | 0.62 | 0.74 | - | - |

| p-Value | 0.44 | 0.08 | - | - |

| Compost Bed Pack [g g N intake−1 day−1] | ||||

| Winter | 0.03 | 0.01 | 0.006 | 0.004 |

| Summer | 0.08 | 0.09 | 0.03 | 0.04 |

| SEM | 0.03 | 0.04 | - | - |

| p-Value | 0.61 | 0.12 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuertes, E.; Balcells, J.; Maynegre, J.; de la Fuente, G.; Sarri, L.; Seradj, A.R. Measurement of Methane and Ammonia Emissions from Compost-Bedded Pack Systems in Dairy Barns: Tilling Effect and Seasonal Variations. Animals 2023, 13, 1871. https://doi.org/10.3390/ani13111871

Fuertes E, Balcells J, Maynegre J, de la Fuente G, Sarri L, Seradj AR. Measurement of Methane and Ammonia Emissions from Compost-Bedded Pack Systems in Dairy Barns: Tilling Effect and Seasonal Variations. Animals. 2023; 13(11):1871. https://doi.org/10.3390/ani13111871

Chicago/Turabian StyleFuertes, Esperanza, Joaquim Balcells, Jordi Maynegre, Gabriel de la Fuente, Laura Sarri, and Ahmad Reza Seradj. 2023. "Measurement of Methane and Ammonia Emissions from Compost-Bedded Pack Systems in Dairy Barns: Tilling Effect and Seasonal Variations" Animals 13, no. 11: 1871. https://doi.org/10.3390/ani13111871

APA StyleFuertes, E., Balcells, J., Maynegre, J., de la Fuente, G., Sarri, L., & Seradj, A. R. (2023). Measurement of Methane and Ammonia Emissions from Compost-Bedded Pack Systems in Dairy Barns: Tilling Effect and Seasonal Variations. Animals, 13(11), 1871. https://doi.org/10.3390/ani13111871