Influence of Slaughter Weight and Sex on Growth Performance, Carcass Characteristics and Ham Traits of Heavy Pigs Fed Ad-Libitum

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Pig Housing, Rearing and Slaughtering

2.2. Diets and Feeding

2.3. Slaughter and Evaluation of Carcass and Green Ham Traits

2.4. Statistical Analysis

3. Results

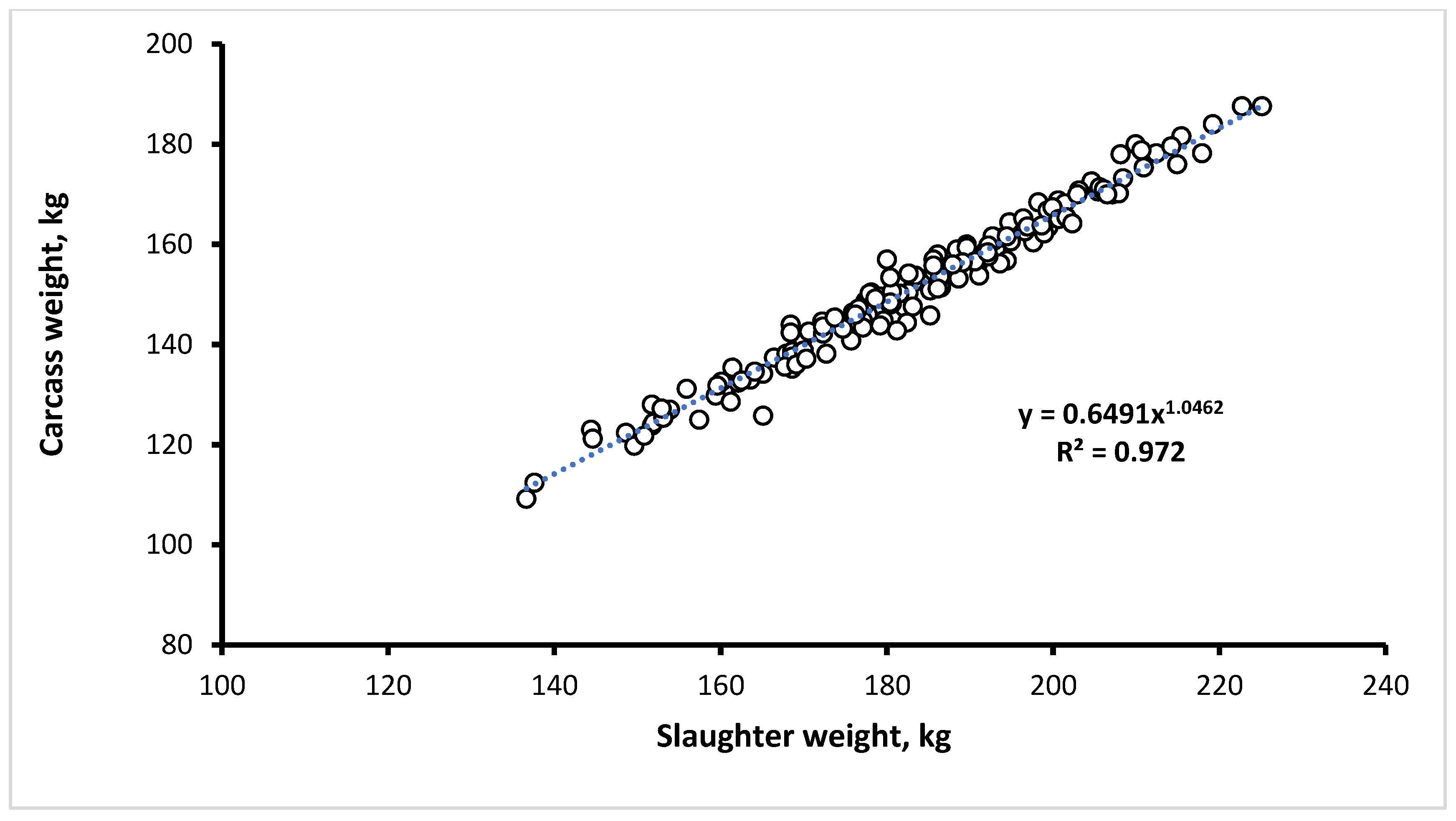

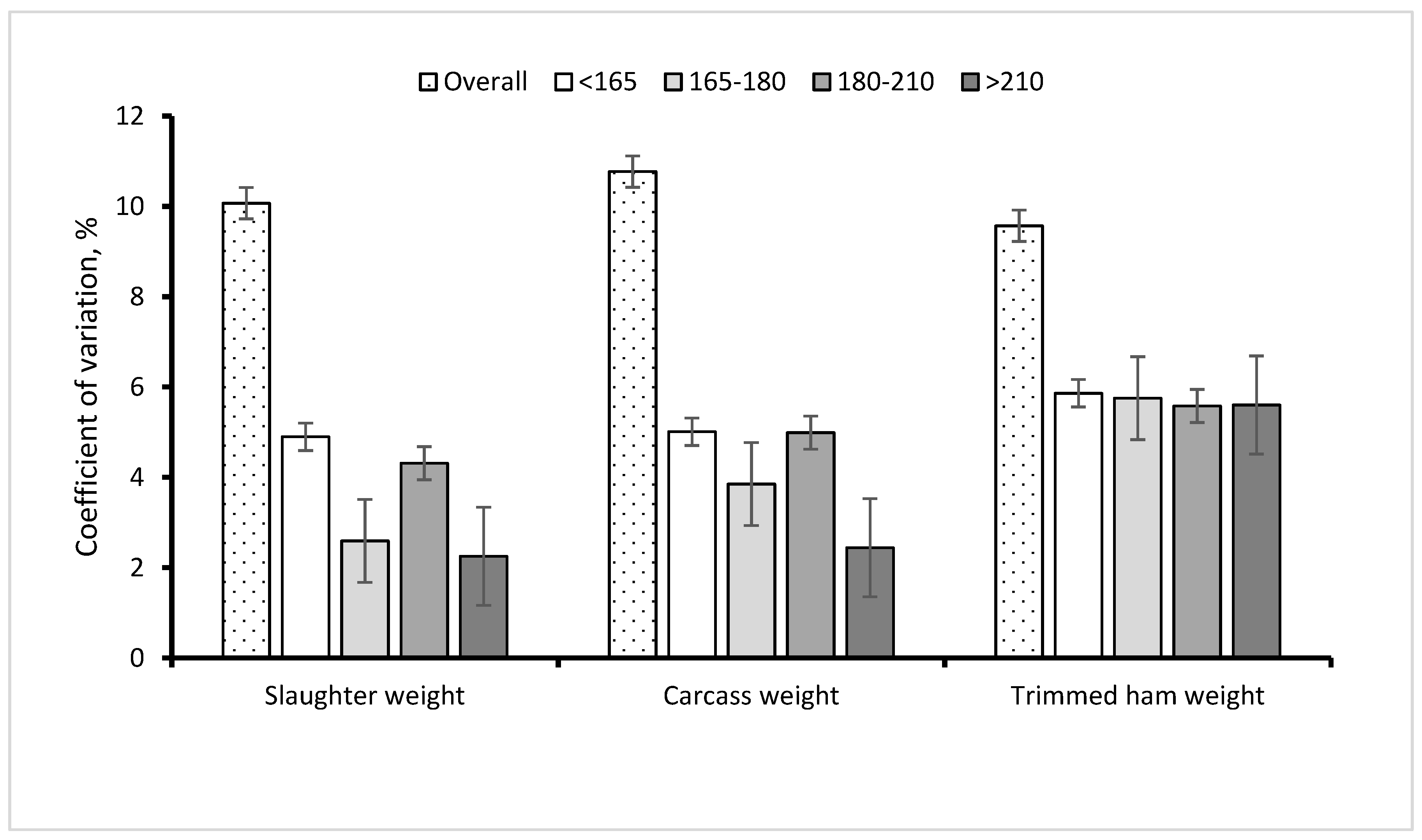

3.1. Growth Performance and Main Carcass Characteristics

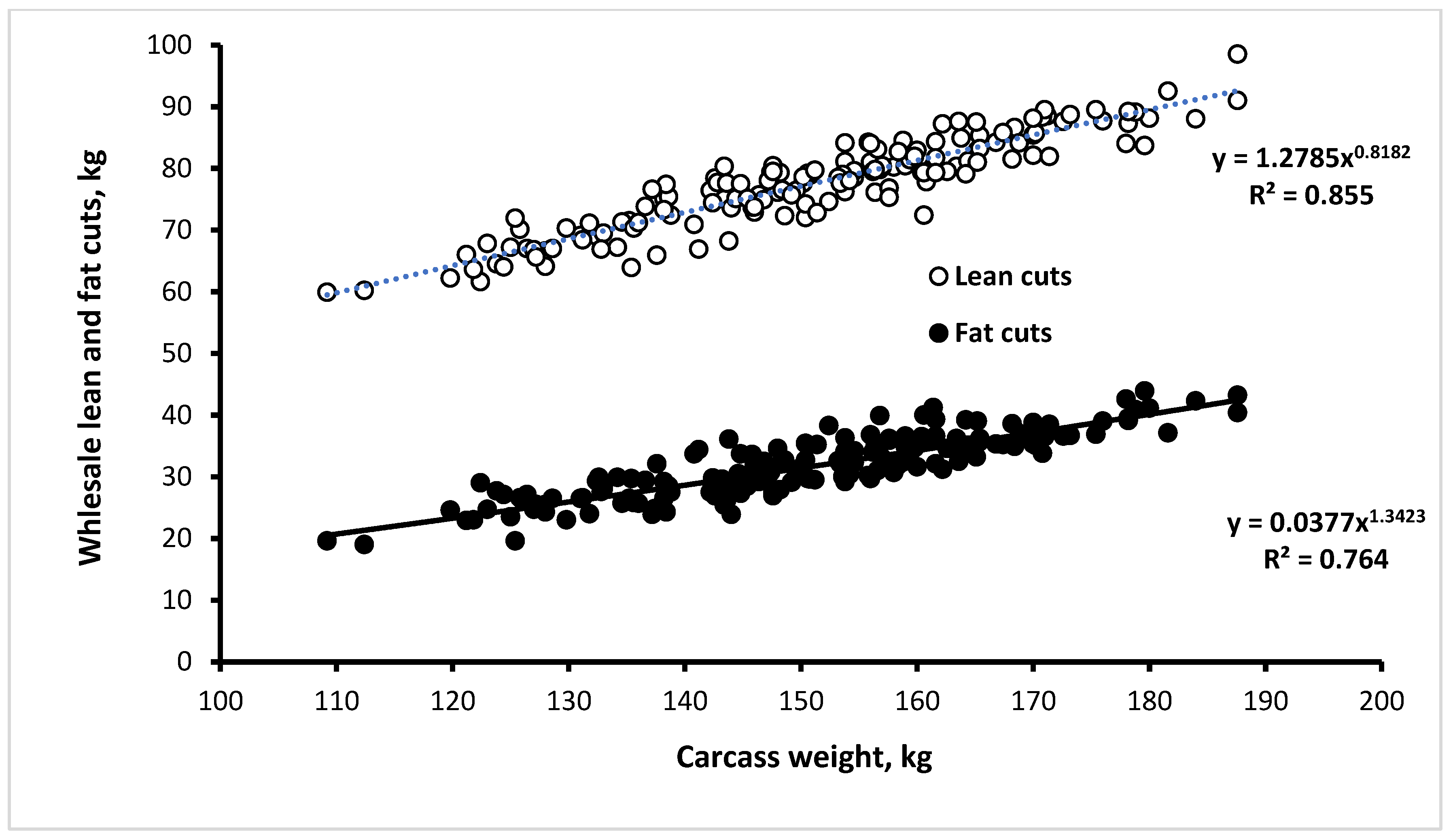

3.2. Wholesale Cuts Weights and Proportions

3.3. Green and Trimmed Ham Characteristics

4. Discussion

4.1. Growth Performance and Feed Efficiency

4.2. Carcass Traits

4.3. Commercial Cuts

4.4. Ham Traits

4.5. Sex Effects

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, F.; Vierck, K.R.; DeRouchey, J.M.; O’Quinn, T.G.; Tokach, M.D.; Goodband, R.D.; Dritz, S.S.; Woodworth, J.C. A review of heavy weight market pigs: Status of knowledge and future needs assessment. Transl. Anim. Sci. 2017, 1, 1–15. [Google Scholar] [CrossRef]

- Cisneros, F.; Ellis, M.; McKeith, F.; McCaw, J.; Fernando, R. Influence of slaughter weight on growth and carcass characteristics, commercial cutting and curing yields, and meat quality of barrows and gilts from two genotypes. J. Anim. Sci. 1996, 74, 925–933. [Google Scholar] [CrossRef]

- Latorre, M.A.; Lázaro, R.; Valencia, D.G.; Medel, P.; Mateos, G.G. The effects of gender and slaughter weight on the growth performance, carcass traits, and meat quality characteristics of heavy pigs. J. Anim. Sci. 2004, 82, 526–533. [Google Scholar] [CrossRef] [PubMed]

- Ramos, A.M.; Glenn, K.L.; Serenius, T.V.; Stalder, K.J.; Rothschild, M.F. Genetic markers for the production of US country hams. J. Anim. Breed. Genet. 2008, 125, 248–257. [Google Scholar] [CrossRef] [PubMed]

- Malgwi, I.H.; Gallo, L.; Halas, V.; Bonfatti, V.; Carc, G.; Sasso, C.P.; Carnier, P.; Schiavon, S. The Implications of Changing Age and Weight at Slaughter of Heavy Pigs on Carcass and Green Ham Quality Traits. Animals 2021, 11, 2447. [Google Scholar] [CrossRef] [PubMed]

- EEC. Prosciutto di Parma. Protected Designation of Origin. General Rules, Dossier Pursuant to Article 4 of Council Regulation (EEC) No. 2081/92 of 14 July 1992. Off. J. Eur. Communities 1992, L208, 9–14. [Google Scholar]

- Gallo, L.; Dalla Bona, M.; Cecchinato, A.; Schiavon, S. Effect of growth rate on live performance, carcass and green thigh traits of finishing Italian heavy pigs. Ital. J. Anim. Sci. 2017, 16, 652–658. [Google Scholar] [CrossRef]

- INEQ (Istituto Nord-Est Qualità). Dossier 2014. Report on the Control Activity in the Year 2014. Section 3. Protected Denomination Origin and Protected Geographic Indication, Products and Productions; Istituto Nord-Est Qualità: San Daniele del Friuli, Udine, Italy, 2015. [Google Scholar]

- Lebret, B. Effects of feeding and rearing systems on growth, carcass composition and meat quality in pigs. Animal 2008, 2, 1548–1558. [Google Scholar] [CrossRef]

- Gallo, L.; Dalla Montà, G.; Carraro, L.; Cecchinato, A.; Carnier, P.; Schiavon, S. Carcass quality and uniformity of heavy pigs fed restrictive diets with progressive reductions in crude protein and indispensable amino acids. Livest. Sci. 2015, 172, 50–58. [Google Scholar] [CrossRef]

- Correa, J.A.; Faucitano, L.; Laforest, L.P.; Rivest, J.; Marcoux, M.; Gariépy, C. Effects of slaughter weight on carcass composition and meat quality in pigs of two different growth rates. Meat Sci. 2006, 72, 91–99. [Google Scholar] [CrossRef]

- Van den Broeke, A.; Leen, F.; Aluwé, M.; Van Meensel, J.; Millet, S. The effect of sex and slaughter weight on performance, carcass quality and gross margin, assessed on three commercial pig farms. Animal 2020, 14, 1546–1554. [Google Scholar] [CrossRef] [PubMed]

- Čandek-Potokar, M.; Žlender, B.; Lefaucheur, L.; Bonneau, M. Effects of age and/or weight at slaughter on longissimus dorsi muscle: Biochemical traits and sensory quality in pigs. Meat Sci. 1998, 48, 287–300. [Google Scholar] [CrossRef]

- Ferguson, N.S.; Gous, R.M.; Emman, G.C. Preferred components for the construction of a new simulation model of growth, feed intake and nutrient requirements of growing pigs. S. Afr. J. Anim. Sci. 1994, 24, 10–17. [Google Scholar]

- Kyriazakis, I.; Whittemore, C.T. (Eds.) Whittemore’s Science and Practice of Pig Production; Blackwell Publishing: Oxford, UK, 2006; p. 417. [Google Scholar] [CrossRef]

- Rostellato, R.; Sartori, C.; Bonfatti, V.; Chiarot, G.; Carnier, P. Direct and social genetic effects on body weight at 270 days and carcass and ham quality traits in heavy pigs. J. Anim. Sci. 2015, 93, 1–10. [Google Scholar] [CrossRef]

- Bonfatti, V.; Carnier, P. Prediction of dry-cured ham weight loss and prospects of use in a pig breeding program. Animal 2020, 14, 1128–1138. [Google Scholar] [CrossRef] [PubMed]

- Carcò, G.; Schiavon, S.; Casiraghi, E.; Grassi, S.; Sturaro, E.; Dalla Bona, M.; Novelli, E.; Gallo, L. Influence of dietary protein content on the chemico-physical profile of dry-cured hams produced by pigs of two breeds. Sci. Rep. 2019, 9, 1–12. [Google Scholar] [CrossRef]

- NRC. Nutrient Requirements of Swine, 11th ed.; National Academy Press: Washington, DC, USA, 2012; p. 278. [Google Scholar]

- Schiavon, S.; Bona, M.D.; Carcò, G.; Carraro, L.; Bunger, L.; Gallo, L. Effects of feed allowance and indispensable amino acid reduction on feed intake, growth performance and carcass characteristics of growing pigs. PLoS ONE 2018, 13, e0195645. [Google Scholar] [CrossRef]

- European Commission. Commission implementing decision of 24 January 2014 authorising methods for grading pig carcases in Italy [notified under document C (2014) 279]. Off. J. Eur. Union 2014, L23. [Google Scholar]

- European Commission. Corrigendum to commission implementing decision 2014/38/EU of 24 January 2014 authorising methods for grading pig carcases in Italy (Official Journal of the European Union L23 of 28 January 2014). Off. J. Eur. Union 2014, L54. [Google Scholar]

- Barducci, R.S.; Zhou, Z.Y.; Wormsbecher, L.; Roehrig, C.; Tulpan, D.; Bohrer, B.M. The relationship of pork carcass weight and leanness parameters in the Ontario commercial pork industry. Transl. Anim. Sci. 2021, 4, 331–338. [Google Scholar] [CrossRef]

- Schiavon, S.; Carraro, L.; Dalla Bona, M.; Cesaro, G.; Carnier, P.; Tagliapietra, F.; Sturaro, E.; Galassi, G.; Malagutti, L.; Trevisi, E.; et al. Growth performance, and carcass and raw ham quality of crossbred heavy pigs from four genetic groups fed low protein diets for dry-cured ham production. Anim. Feed Sci. Technol. 2015, 208, 170–181. [Google Scholar] [CrossRef]

- NPPC. Pork Composition and Quality Assessment Procedures; Berg, E.P., Ed.; National Pork Producers Council: Des Moines, IA, USA, 2000; pp. 1–42. [Google Scholar]

- Magistrelli, D.; Galassi, G.; Crovetto, G.M.; Rosi, F. Influenza della somministrazione di elevate quantità di polpe di bietola essiccate su parametri endocrino/metabolici, rilievi al macello e qualità del prosciutto nel suino pesante italiano. Ital. J. Anim. Sci. 2009, 8, 37–49. [Google Scholar] [CrossRef]

- Čandek-Potokar, M.; Škrlep, M. Factors in pig production that impact the quality of dry-cured ham: A review. Animal 2012, 6, 327–338. [Google Scholar] [CrossRef]

- Bosi, P.; Russo, V. The production of the heavy pig for high quality processed products. Ital. J. Anim. Sci. 2004, 3, 309–321. [Google Scholar] [CrossRef]

- Latorre, M.A.; García-Belenguer, E.; Ariño, L. The effects of sex and slaughter weight on growth performance and carcass traits of pigs intended for dry-cured ham from Teruel (Spain). J. Anim. Sci. 2008, 86, 1933–1942. [Google Scholar] [CrossRef] [PubMed]

- Fabro, C.; Sgorlon, S.; Guiatti, D.; Stefanon, B.; Susmel, P. Productive response of Duroc x Large white and commercial Hybrid x Large white crosses fed high and low protein diets. Ital. J. Anim. Sci. 2013, 12, 507–512. [Google Scholar] [CrossRef]

- Galassi, G.; Colombini, S.; Malagutti, L.; Crovetto, G.M.; Rapetti, L. Effects of high fibre and low protein diets on performance, digestibility, nitrogen excretion and ammonia emission in the heavy pig. Anim. Feed Sci. Technol. 2010, 161, 140–148. [Google Scholar] [CrossRef]

- Lo Fiego, D.P.; Santoro, P.; Macchioni, P.; De Leonibus, E. Influence of genetic type, live weight at slaughter and carcass fatness on fatty acid composition of subcutaneous adipose tissue of raw ham in the heavy pig. Meat Sci. 2005, 69, 107–114. [Google Scholar] [CrossRef]

- Corino, C.; Musella, M.; Pastorelli, G.; Rossi, R.; Paolone, K.; Costanza, L.; Manchisi, A.; Maiorano, G. Influences of dietary conjugated linoleic acid (CLA) and total lysine content on growth, carcass characteristics and meat quality of heavy pigs. Meat Sci. 2008, 79, 307–316. [Google Scholar] [CrossRef]

- Fisher, A.V.; Green, D.M.; Whittemore, C.T.; Wood, J.D.; Schofield, C.P. Growth of carcass components and its relation with conformation in pigs of three types. Meat Sci. 2003, 65, 639–650. [Google Scholar] [CrossRef]

- Latorre, M.A.; Medel, P.; Fuentetaja, A.; Lázaro, R.; Mateos, G.G. Effect of gender, terminal sire line and age at slaughter on performance, carcass characteristics and meat quality of heavy pigs. Anim. Sci. 2003, 77, 33–45. [Google Scholar] [CrossRef]

- Minelli, G.; Macchioni, P.; Ielo, M.C.; Santoro, P.; lo Fiego, D.P. Effects of dietary level of pantothenic acid and sex on carcass, meat quality traits and fatty acid composition of thigh subcutaneous adipose tissue in Italian heavy pigs. Ital. J. Anim. Sci. 2013, 12, 329–336. [Google Scholar] [CrossRef][Green Version]

- Zappaterra, M.; Zambonelli, P.; Schivazappa, C.; Simoncini, N.; Virgili, R.; Stefanon, B.; Davoli, R. Investigating the features of PDO green hams during salting: Insights for new markers and genomic regions in commercial hybrid pigs. Animals 2021, 11, 68. [Google Scholar] [CrossRef] [PubMed]

- Čandek-Potokar, M.; Monin, G.; Žlender, B. Pork quality, processing, and sensory characteristics of dry-cured hams as influenced by Duroc crossing and sex. J. Anim. Sci. 2002, 80, 988–996. [Google Scholar] [CrossRef] [PubMed]

- Cecchinato, A.; Schiavon, S.; Tagliapietra, F.; Gallo, L. Relationships between in vivo Measurements of Backfat Thickness and Several Carcass and Ham Traits in Heavy Pigs. Agric. Conspec. Sci. 2013, 78, 255–258. [Google Scholar]

- Rodríguez-Sánchez, J.A.; Calvo, S.; Suárez-Beloch, J.; Latorre, M.A. Effect of pig slaughter weight on chemical and sensory characteristics of teruel dry-cured ham. Ital. J. Food Sci. 2014, 26, 420–426. [Google Scholar]

- Lo Fiego, D.P.; Comellini, M.; Ielo, M.C.; Ulrici, A.; Volpelli, L.A.; Tassone, F.; Costa, N. Preliminary investigation of the use of digital image analysis for raw ham evaluation. Ital. J. Anim. Sci. 2007, 6, 693–695. [Google Scholar] [CrossRef]

- Laureati, M.; Buratti, S.; Giovanelli, G.; Corazzin, M.; Lo Fiego, D.P.; Pagliarini, E. Characterization and differentiation of Italian Parma, San Daniele and Toscano dry-cured hams: A multi-disciplinary approach. Meat Sci. 2014, 96, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Gallo, L.; Dalla Montà, G.; Carraro, L.; Cecchinato, A.; Carnier, P.; Schiavon, S. Growth performance of heavy pigs fed restrictively diets with decreasing crude protein and indispensable amino acids content. Livest. Sci. 2014, 161, 130–138. [Google Scholar] [CrossRef]

- Quiniou, N.; Courboulay, V.; Salaün, Y.; Chevillon, P. Impact of the non-castration of male pigs on growth performance and behaviour- comparison with barrows and gilts. In Proceedings of the 61st Annual Meeting of the European Association for Animal Production, Heraklion, Greece, 23–27 August 2010; pp. 1–7. [Google Scholar]

- Auspurger, N.R.; Ellis, M.; Hamilton, D.N.; Wolter, B.F.; Beverly, J.L.; Wilson, E.R. The effect of sire line on the feeding patterns of grow-finish pigs. Appl. Anim. Behav. Sci. 2002, 75, 103–114. [Google Scholar] [CrossRef]

| Ingredient | Early Finishing (90 to 120 kg Body Weight) | Late Finishing (120 kg Body Weight upwards) |

|---|---|---|

| Corn grain | 361.8 | 398.9 |

| Wheat grain | 240.0 | 238.0 |

| Barley grain | 100.0 | 100.0 |

| Soybean meal 48% (solv. ex.) | 196.0 | 143.0 |

| Wheat bran | 26.5 | 7.5 |

| Wheat middlings | - | 40.0 |

| Cane molasses | 20.0 | 22.5 |

| Lard | 20.0 | 20.0 |

| Dried sugar beet pulp | - | - |

| Calcium carbonate | 15.0 | 13.0 |

| Dicalcium phosphate | 4.5 | 2.0 |

| Sodium chloride | 3.0 | 3.0 |

| Sodium bicarbonate | 2.5 | 2.5 |

| Vitamin and mineral premix a | 2.0 | 2.0 |

| Grapeseed meal | 7.0 | 7.0 |

| Choline, liquid, 75% b | 0.5 | 0.3 |

| L-Lysine c | 1.0 | 0.3 |

| DL-Methionine d | 0.2 | 0.1 |

| L-Thryptophan, 49% e | - | - |

| Class of Slaughter Weight (SWC), kg | Sex | Sex × SWC | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Items | <165 | 165 to 180 | 180 to 210 | >210 | SEM 1 | p-Linear2 | Gilts | Barrows | SEM 1 | p | p |

| Pigs, n. | 26 | 41 | 82 | 10 | - | - | 72 | 87 | - | - | - |

| 230 d-old pigs, n. | 23 | 29 | 24 | 1 | - | - | 32 | 45 | - | - | - |

| 258 d-old pigs, n. | 3 | 12 | 58 | 9 | - | - | 40 | 42 | - | - | - |

| Average age at slaughter, d | 235 | 238 | 249 | 262 | - | - | 246 | 244 | - | - | - |

| Live performances: | |||||||||||

| Initial body weight | 86.0 | 95.4 | 97.7 | 105.0 | 3.4 | <0.001 | 95.3 | 96.7 | 6.3 | 0.48 | 0.85 |

| Slaughter weight (SW), kg | 153.8 | 172.7 | 193.1 | 214.6 | 3.2 | <0.001 | 182.9 | 184.3 | 5.7 | 0.027 | 0.94 |

| Feed intake, g/d | 2880 | 3130 | 3412 | 3835 | 130 | <0.001 | 3287 | 3342 | 241 | 0.45 | 0.64 |

| Average daily gain, g/d | 821 | 874 | 959 | 1074 | 50 | <0.001 | 944 | 920 | 96 | 0.42 | 0.18 |

| Gain: feed | 0.283 | 0.279 | 0.280 | 0.279 | 0.009 | 0.72 | 0.286 | 0.275 | 0.018 | 0.043 | 0.21 |

| Post mortem performances: | |||||||||||

| Carcass weight, kg | 125.9 | 142.0 | 159.8 | 178.1 | 2.9 | <0.001 | 150.3 | 152.6 | 5.4 | 0.16 | 0.97 |

| Carcass yield, % | 81.8 | 82.2 | 82.7 | 83.0 | 0.60 | 0.043 | 82.1 | 82.8 | 1.1 | 0.039 | 0.31 |

| Carcass backfat depth 3, mm | 36.2 | 40.6 | 46.3 | 50.4 | 2.3 | <0.001 | 42.4 | 44.3 | 4.2 | 0.13 | 0.30 |

| Lean meat g/kg | 51.7 | 49.6 | 46.6 | 42.8 | 1.7 | <0.001 | 48.0 | 47.4 | 3.1 | 0.53 | 0.023 |

| Wholesale cuts weight, kg: | |||||||||||

| Total cuts 4 | 91.3 | 103.1 | 115.7 | 128.0 | 2.1 | <0.001 | 108.9 | 110.2 | 3.8 | 0.25 | 0.73 |

| Primal lean cuts | 66.2 | 74.2 | 81.3 | 88.5 | 1.6 | <0.001 | 77.7 | 77.5 | 3.0 | 0.84 | 0.62 |

| Primal fat cuts | 25.1 | 28.9 | 34.4 | 39.4 | 1.3 | <0.001 | 31.2 | 32.7 | 2.5 | 0.043 | 0.89 |

| Wholesale cuts yield, g/kg: | |||||||||||

| Total cuts 4 | 725 | 727 | 724 | 718 | 5.1 | 0.15 | 725 | 722 | 9.5 | 0.40 | 0.48 |

| Lean cuts | 526 | 523 | 509 | 497 | 7.6 | <0.001 | 519 | 509 | 14.3 | 0.026 | 0.58 |

| Fat cuts | 199 | 204 | 215 | 221 | 7.3 | 0.001 | 206 | 213 | 13.7 | 0.08 | 0.64 |

| Class of Slaughter Weight (SWC), kg | Sex | Sex × SWC | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Items | <165 | 165 to 180 | 180 to 210 | >210 | SEM 1 | p-Linear2 | Gilts | Barrows | SEM 1 | p | p |

| Wholesale cuts, kg: | |||||||||||

| Loins and ribs | 19.1 | 21.4 | 22.9 | 24.8 | 5.9 | <0.001 | 22.4 | 21.8 | 1.1 | 0.06 | 0.98 |

| Shoulders | 16.7 | 18.6 | 20.5 | 22.3 | 0.5 | <0.001 | 19.4 | 19.6 | 1.0 | 0.44 | 0.42 |

| Green hams | 30.5 | 34.1 | 37.9 | 41.4 | 0.8 | <0.001 | 35.9 | 36.1 | 1.5 | 0.64 | 0.48 |

| Trimmed hams 3 | 24.8 | 27.8 | 30.4 | 32.9 | 0.7 | <0.001 | 29.0 | 29.0 | 1.2 | 0.89 | 0.43 |

| Trimming loss 3 | 5.7 | 6.3 | 7.5 | 8.5 | 0.3 | <0.001 | 6.9 | 7.1 | 0.6 | 0.37 | 0.93 |

| Backfat | 15.7 | 18.0 | 21.0 | 24.4 | 0.7 | <0.001 | 19.7 | 19.9 | 1.3 | 0.66 | 0.94 |

| Belly | 9.4 | 10.9 | 13.4 | 15.0 | 0.8 | <0.001 | 11.5 | 12.9 | 1.5 | 0.005 | 0.50 |

| Wholesale Cut Yields, g/kg Carcass: | |||||||||||

| Loins and ribs | 152 | 151 | 143 | 140 | 3.7 | <0.001 | 150 | 143 | 6.9 | 0.003 | 0.99 |

| Shoulders | 133 | 131 | 128 | 125 | 2.7 | 0.010 | 130 | 129 | 5.6 | 0.72 | 0.59 |

| Green hams | 242 | 240 | 237 | 232 | 3.5 | 0.003 | 239 | 237 | 6.5 | 0.16 | 0.26 |

| Trimmed legs | 197 | 196 | 190 | 184 | 3.3 | <0.001 | 194 | 190 | 6.1 | 0.11 | 0.33 |

| Ham trimming loss 3 | 44.9 | 44.3 | 47.1 | 47.5 | 1.9 | 0.09 | 45.9 | 46.1 | 3.6 | 0.83 | 0.91 |

| Backfat | 124 | 127 | 131 | 137 | 3.8 | <0.001 | 131 | 129 | 6.7 | 0.61 | 0.88 |

| Belly | 75 | 77 | 84 | 84 | 5.3 | 0.04 | 75.6 | 84.0 | 9.9 | 0.006 | 0.22 |

| Class of Slaughter Weight (SWC), kg | Sex | Sex × SWC | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Items | <165 | 165 to 180 | 180 to 210 | >210 | SEM 1 | p-Linear2 | Gilts | Barrows | SEM 1 | p | p |

| Trimmed ham, kg | |||||||||||

| slaughter house (SH) | 12.3 | 13.8 | 15.1 | 16.4 | 0.3 | <0.001 | 14.4 | 14.4 | 0.6 | 0.96 | 0.44 |

| ham factory (HF) 3 | 11.9 | 13.2 | 14.4 | 15.7 | 0.3 | <0.001 | 13.8 | 13.8 | 0.6 | 0.86 | 0.65 |

| losses at the HF 3, kg | 0.44 | 0.58 | 0.68 | 0.70 | 0.07 | <0.001 | 0.58 | 0.62 | 0.14 | 0.33 | 0.21 |

| losses at the HF 3, g/kg | 35.6 | 42.0 | 44.5 | 43.2 | 0.49 | 0.11 | 40.1 | 42.5 | 0.93 | 0.41 | 0.39 |

| Green ham quality traits: | |||||||||||

| Round shape 4 | 1.35 | 1.58 | 1.95 | 2.57 | 0.40 | 0.002 | 2.04 | 1.68 | 0.76 | 0.12 | 0.20 |

| Veining 5 | 1.73 | 1.64 | 1.43 | 1.12 | 0.41 | 0.12 | 1.40 | 1.57 | 0.76 | 0.45 | 0.95 |

| Haemorrhage 6 | 0.15 | 0.37 | 0.25 | 0.50 | 0.22 | 0.23 | 0.46 | 0.17 | 0.46 | 0.037 | 0.12 |

| Visible marbling 7 | 0.84 | 0.90 | 0.73 | 0.73 | 0.33 | 0.65 | 0.56 | 1.04 | 0.61 | 0.011 | 0.14 |

| Meat colour 8 | −0.63 | −0.69 | −0.64 | −0.56 | 0.61 | 0.88 | −0.81 | −0.44 | 1.14 | 0.29 | 0.28 |

| Fat cover score 9 | 0.20 | 0.41 | 1.09 | 1.20 | 0.69 | 0.09 | 0.71 | 0.74 | 1.28 | 0.94 | 0.52 |

| Subcutaneous fat, mm | |||||||||||

| P1 position 10 | 29.5 | 30.6 | 34.1 | 32.6 | 3.1 | 0.20 | 30.6 | 32.7 | 5.9 | 0.23 | 0.92 |

| P2 position 11 | 6.6 | 6.4 | 7.0 | 7.7 | 0.4 | 0.005 | 7.05 | 6.83 | 0.8 | 0.39 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malgwi, I.H.; Giannuzzi, D.; Gallo, L.; Halas, V.; Carnier, P.; Schiavon, S. Influence of Slaughter Weight and Sex on Growth Performance, Carcass Characteristics and Ham Traits of Heavy Pigs Fed Ad-Libitum. Animals 2022, 12, 215. https://doi.org/10.3390/ani12020215

Malgwi IH, Giannuzzi D, Gallo L, Halas V, Carnier P, Schiavon S. Influence of Slaughter Weight and Sex on Growth Performance, Carcass Characteristics and Ham Traits of Heavy Pigs Fed Ad-Libitum. Animals. 2022; 12(2):215. https://doi.org/10.3390/ani12020215

Chicago/Turabian StyleMalgwi, Isaac Hyeladi, Diana Giannuzzi, Luigi Gallo, Veronika Halas, Paolo Carnier, and Stefano Schiavon. 2022. "Influence of Slaughter Weight and Sex on Growth Performance, Carcass Characteristics and Ham Traits of Heavy Pigs Fed Ad-Libitum" Animals 12, no. 2: 215. https://doi.org/10.3390/ani12020215

APA StyleMalgwi, I. H., Giannuzzi, D., Gallo, L., Halas, V., Carnier, P., & Schiavon, S. (2022). Influence of Slaughter Weight and Sex on Growth Performance, Carcass Characteristics and Ham Traits of Heavy Pigs Fed Ad-Libitum. Animals, 12(2), 215. https://doi.org/10.3390/ani12020215