The Effect of Replacement of Soybean Meal with Corn Dried Distillers Grains with Solubles (cDDGS) and Differentiation of Dietary Fat Sources on Pig Meat Quality and Fatty Acid Profile

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Ethical Approval

2.2. Animal Management, Diets, and Experimental Scheme

| Item | Group I (Control) SBM + RO | Group II cDDGS + RO | Group III cDDGS + BT | Group IV cDDGS + CO |

|---|---|---|---|---|

| Corn DDGS | ||||

| Barley | - | 200.0 | 200.0 | 200.0 |

| Wheat | 435.6 | 417.1 | 417.1 | 417.1 |

| Corn | 250.0 | 250.0 | 250.0 | 250.0 |

| Wheat bran | 50.0 | - | - | - |

| Soybean meal | 50.0 | - | - | - |

| Rapeseed oil | 160.0 | 80.0 | 80.0 | 80.0 |

| Beef tallow | 30.0 | 30.0 | - | - |

| Coconut oil | - | - | 30.0 | - |

| Vitamin-mineral premix * | - | - | - | 30.0 |

| NaCl | 5.0 | 5.0 | 5.0 | 5.0 |

| Calcium phosphate 1-Ca | 2.3 | 2.1 | 2.1 | 2.1 |

| Chalk | 1.7 | - | - | - |

| L-Lysine | 13.0 | 12.0 | 12.0 | 12.0 |

| DL-Methionine | 1.8 | 3.3 | 3.3 | 3.3 |

| L-Threonine | 0.3 | - | - | - |

| L-Tryptophan | 0.3 | 0.2 | 0.2 | 0.2 |

| - | 0.3 | 0.3 | 0.3 | |

| Content in 1 kg of feed mixture: | ||||

| ME ** (MJ/kg) | 13.4 | 13.4 | 13.3 | 13.4 |

| Dry matter (g/kg) | 880 | 883 | 881 | 883 |

| Crude protein (g/kg) | 162 | 165 | 164 | 164 |

| Crude fiber (g/kg) | 39 | 42 | 42 | 42 |

| Crude fat (g/kg) | 50 | 68 | 66 | 68 |

| Crude ash (g/kg) | 45 | 42 | 43 | 43 |

| Starch (g/kg) | 425 | 372 | 372 | 372 |

| Lys (g/kg) | 9.0 | 9.1 | 9.1 | 9.1 |

| Met + Cys (g/kg) | 5.8 | 5.9 | 5.9 | 5.9 |

| Tre (g/kg) | 5.8 | 5.9 | 5.8 | 5.8 |

| Trp (g/kg) | 1.9 | 1.9 | 1.9 | 1.9 |

| Phosphorus (g/kg) | 4.5 | 4.5 | 4.5 | 4.5 |

| Calcium (g/kg) | 7.6 | 7.6 | 7.6 | 7.6 |

2.3. Meat Sample Collection and Analysis

2.4. Statistical Analysis

3. Results

3.1. Fattening Results

3.2. Fatty Acids Profile of Meat

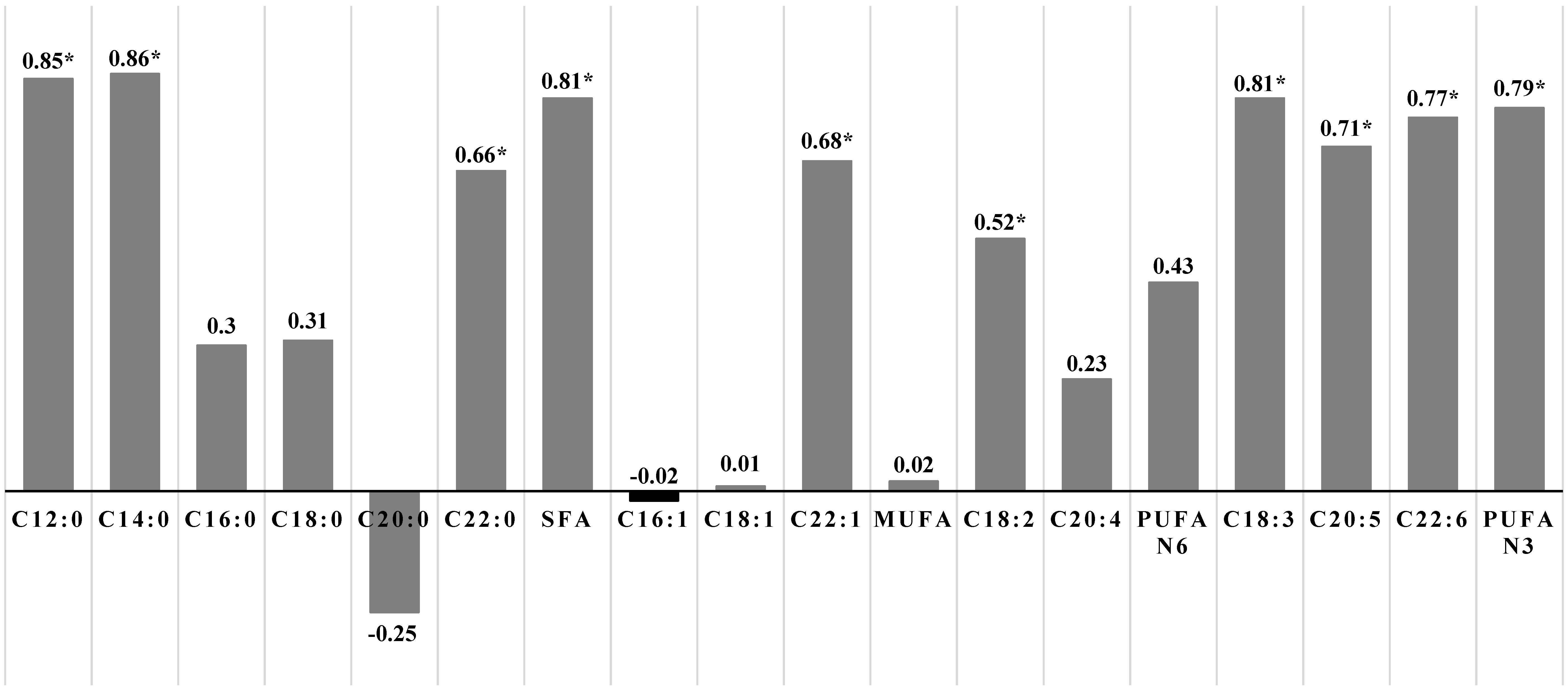

3.3. Correlations between Fatty Acid Content in the Diet and the Content of the Same Fatty Acids in Meat

3.4. Meat Quality Indices

3.5. Meat Shear Force and Texture Parameters

3.6. Meat Sensory Indices

3.7. Correlations between Groups of Fatty Acids in Meat and Meat Quality Traits

3.8. Correlations among the Chosen Quality Traits of Meat

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fearnside, P.M. Soybean cultivation as a threat to the environment in Brazil. Environ. Cons. 2001, 28, 23–38. [Google Scholar] [CrossRef]

- Brown, J.C.; Koeppe, M.; Coles, B.; Price, K.P. Soybean production and conversionof tropical forest in the Brazilian Amazon: The case of Vilhena, Rondônia. Ambio 2005, 34, 462–469. [Google Scholar] [CrossRef]

- Kaczmarek, P.; Korniewicz, D.; Lipiński, K.; Mazur-Kuśnirek, M. The effect of hydrothermally processed soybean-and rapeseed-based diets on performance, meat and carcass quality characteristics in growing-finishing pigs. Ann. Anim. Sci. 2019, 19, 1083–1097. [Google Scholar] [CrossRef]

- Milczarek, A.; Osek, M. Partial Replacement of Soybean with Low-Tannin Faba Bean Varieties (Albus or Amulet): Effects on Growth Traits, Slaughtering Parameters and Meat Quality of Puławska Pigs. Ann. Animal Sci. 2016, 16, 477–487. [Google Scholar] [CrossRef]

- Świątkiewicz, M.; Księżak, J.; Hanczakowska, E. The effect of feeding native faba bean seeds (Vicia faba L.) to sows and supplemented with enzymes to piglets and growing pigs. Ann. Anim. Sci. 2018, 18, 1007–1027. [Google Scholar] [CrossRef]

- Zaworska-Zakrzewska, A.; Kasprowicz-Potocka, M.; Wiśniewska, Z.; Rutkowski, A.; Hejdysz, M.; Kaczmarek, S.; Nowak, P.; Zmudzińska, A.; Banaszak, M. The chemical composition of domestic soybean seeds and the effects of partial substitution of soybean meal by raw soybean seeds in the diet on pigs’ growth performance and pork quality (m. longissimus lumborum). Ann. Anim. Sci. 2020, 20, 521–533. [Google Scholar] [CrossRef]

- Whitney, M.H.; Shurson, G.C.; Johnston, L.J.; Wulf, D.M.; Shanks, B.C. Growth performance and carcass characteristics of grower–finisher pigs fed high-quality corn distillers dried grain with solubles originating from a modern Midwestern ethanol plant. J. Anim. Sci. 2006, 84, 3356–3363. [Google Scholar] [CrossRef]

- Stein, H.H.; Shurson, G.C. Board-invited review: The use and application of distillers dried grains with solubles in swine diets. J. Anim. Sci. 2009, 87, 1292–1303. [Google Scholar] [CrossRef] [PubMed]

- Widmer, M.R.; McGinnis, L.M.; Wulf, D.M. Effects of feeding distillers dried grains with solubles, high protein distillers dried grains, and corn germ to growing–finishing pigs on pig performance, carcass quality, and the palatability of pork. J. Anim. Sci. 2008, 86, 1819–1831. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.S.; Shi, B.M.; Shan, A.S. Effects of dietary corn dried distillers grains with solubles and vitamin E on growth performance, meat quality, fatty acid profiles, and pork shelf life of finishing pigs. Livest. Sci. 2012, 149, 155–166. [Google Scholar] [CrossRef]

- Nuernberg, K.; Fischer, K.; Nuernberg, G.; Kuechenmeister, U.; Klosowska, D.; Eliminowska-Wenda, G.; Fiedler, I.; Ender, K. Effects of dietary olive and linseed oil on lipid composition, meat quality, sensory characteristics and muscle structure in pigs. Meat Sci. 2005, 70, 63–74. [Google Scholar] [CrossRef]

- Anjum, F.M.; Haider, M.F.; Khan, M.I.; Sohaib, M.; Arshad, M.S. Impact of extruded flaxseed meal supplemented diet on growth performance, oxidative stability and quality of broiler meat and meat products. Lipids Health Dis. 2013, 12, 1–12. [Google Scholar] [CrossRef]

- Wood, J.D.; Enser, M.; Fisher, A.V.; Nute, G.R.; Sheard, P.R.; Richardson, R.I.; Hughes, S.I.; Whittington, F.M. Fat deposition, fatty acid composition and meat quality: A review. Meat Sci. 2008, 78, 343–358. [Google Scholar] [CrossRef]

- Carr, S.N.; Rincker, P.J.; Killefer, J.; Baker, D.H.; Ellis, M.; McKeith, F.K. Effects of different cereal grains and ractopamine hydrochloride onperformance, carcass characteristics, and fat quality in late-finishing pigs. J. Anim. Sci. 2005, 83, 223–230. [Google Scholar] [CrossRef]

- Benz, J.M.; Tokach, M.D.; Dritz, S.S.; Nelssen, J.L.; DeRouchey, J.M.; Sulabo, R.C.; Goodband, R.D. Effects of choice white grease and soybean oil ongrowth performance, carcass characteristics, and carcass fat quality of growing-finishing pigs. J. Anim. Sci. 2011, 89, 404–413. [Google Scholar] [CrossRef]

- Benz, J.M.; Tokach, M.D.; Dritz, S.S.; Nelssen, J.L.; DeRouchey, J.M.; Sulabo, R.C.; Goodband, R.D. Effects of increasing choice white grease in corn-and sorghum-based diets on growth performance, carcass characteristics, and fat quality characteristics of finishing pigs. J. Anim. Sci. 2011, 89, 773–782. [Google Scholar] [CrossRef]

- Xu, G.; Baidoo, S.K.; Johnston, L.J.; Bibus, D.; Cannon, J.E.; Shurson, G.C. The effect of feeding diets containing corn distillers dried grains withsolubles, and withdrawal period of distillers dried grains with solubles, on growth performance and pork quality in grower-finisher pigs. J. Anim. Sci. 2010, 88, 1388–1397. [Google Scholar] [CrossRef]

- Wood, J.D.; Enser, M.; Whittington, F.M.; Moncrieff, C.B.; Kempster, A.J. Backfat composition in pigs: Differences between fat thickness groups and sexes. Livest. Prod. Sci. 1989, 22, 351–362. [Google Scholar] [CrossRef]

- Teye, G.A.; Wood, J.D.; Whittington, F.M.; Stewart, A.; Sheard, P.R. Influence of dietary oils and protein level on pork quality. 2. Effects on properties of fat and processing characteristics of bacon and frankfurter-style sausages. Meat Sci. 2006, 73, 166–177. [Google Scholar] [CrossRef]

- Cameron, N.D.; Enser, M.; Nute, G.R.; Whittington, F.M.; Penman, J.C.; Fisken, A.C.; Perry, M.A.; Wood, J.D. Genotype with nutrition interaction on fatty acid composition of intramuscular fat and the relationship with flavour of pig meat. Meat Sci. 2000, 55, 187–195. [Google Scholar] [CrossRef]

- Świątkiewicz, M.; Oczkowicz, M.; Ropka-Molik, K.; Hanczakowska, E. The effect of dietary fatty acid composition on adipose tissue quality and expression of genes related to lipid metabolism in porcine livers. Anim. Feed Sci. Technol. 2016, 216, 204–215. [Google Scholar] [CrossRef]

- Dierick, N.A.; Decuypere, J.A.; Molly, K.; Van Beek, E.; Vanderbeke, E. The combined use of triacylglycerols containing medium-chain fatty acids (MCFAs) and exogenous lipolytic enzymes as an alternative for nutritional antibiotics in piglet nutrition I. In vitro screening of the release of MCFAs from selected fat sources by selected exogenous lipolytic enzymes under simulated pig gastric conditions and their effects on the gut flora of piglets. Livest. Prod. Sci. 2002, 75, 129–142. [Google Scholar]

- Skřivanová, E.; Marounek, M.; Dlouhá, G.; Kaňka, J. Susceptibility of Clostridium perfringens to C2-C18 fatty acids. Lett. Appl. Microbiol. 2005, 41, 77–81. [Google Scholar] [CrossRef]

- National Research Council (NRC). Nutrient Requirements of Swine, 11th ed.; National Academies Press: Washington, DC, USA, 2012. [Google Scholar]

- Różycki, M.; Tyra, M. The Procedure of Pigs Fattening and Slaughter Value Estimation at Swine Performance Testing Stations; Report of pig breedingin Poland; National Research Institute of Animal Production: Krakow, Poland, 2010; Volume 28, pp. 93–112. [Google Scholar]

- Hoffmann, L.; Schiemann, R. Von der Kalorie zum Joule: Neue Grössenbeziehungen bei Messungen des Energieumsatzes und bei der Berechnung von Kennzahlen der energetischen Futterbewertung. Archiv. Tierer. 1980, 30, 733–742. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Folch, J.; Lees, M.; Sloane Stanley, G.H. A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Pikul, J.; Leszczynski, D.; Kummerow, F.A. Evaluation of three modified TBA methods for measuring lipid oxidation in chicken meat. J. Agric. Food Chem. 1989, 37, 1309–1315. [Google Scholar] [CrossRef]

- AOCS. Official Methods and Recommended Practices of the AOCS, 5th ed.; Journal of the American Oil Chemists’ Society: Champaign, IL, USA, 1998. [Google Scholar]

- MacDougall, D.B. Colour measurement of food. In Colour in Food; MacDougall, D.B., Ed.; CRC Press: Boca Raton, FL, USA, 2002; pp. 33–63. [Google Scholar]

- Grau, R.; Hamm, R. Eine einfache Methode zur Bestimmung der Wasserbindung im Fleisch. Naturwissenschaften 1952, 4, 295–297. [Google Scholar]

- Bertram, H.C.; Andersena, H.J.; Karlssona, A.H.; Horn, P.; Hedegaard, J.; Nřrgaard, L.; Balling, S. Engelsenb Prediction of technological quality (cooking loss and Napole Yield) of pork based on fresh meat characteristics. Meat Sci. 2003, 65, 707–712. [Google Scholar] [CrossRef]

- Baryłko-Pikielna, N. Zarys analizy sensorycznej żywności. In Wydawnictwo Naukowo-Techniczne; Warszawa, Poland, 1975; Available online: https://tezeusz.pl/barylko-pikielna-nina-zarys-analizy-sensorycznej-zywnosci-nina-barylko-pikielna (accessed on 29 April 2021).

- Harris, E.K.; Mellencamp, M.A.; Johnston, L.J.; Cox, R.B.; Shurson, G.C. Effect of time interval between the second Improvest® dose and slaughter and corn dried distillers grains with solubles feeding strategies on carcass composition, primal cutout, and pork quality of immunologically castrated pigs. Meat Sci. 2017, 127, 13–20. [Google Scholar] [CrossRef]

- Teye, G.A.; Sheard, P.R.; Whittington, F.M.; Nute, G.R.; Stewart, A.; Wood, J.D. Influence of dietary oils and protein level on pork quality. 1. Effects on muscle fatty acid composition, carcass, meat and eating quality. Meat Sci. 2006, 73, 157–165. [Google Scholar] [CrossRef]

- Apple, J.K.; Maxwell, C.V.; Galloway, D.L.; Hutchison, S.; Hamilton, C.R. Interactive effects of dietary fat source and slaughter weight in growing-finishing swine: I. Growth performance and longissimus muscle fatty acid composition1. J. Anim. Sci. 2009, 87, 1407–1422. [Google Scholar] [CrossRef]

- Kouba, M.; Enser, M.; Whittington, F.M.; Nute, G.R.; Wood, J.D. Effect of a high-linolenic acid diet on lipogenic activities, fatty acid composition and meat quality in the growing pig. J. Anim. Sci. 2003, 81, 1967–1979. [Google Scholar] [CrossRef]

- Calder, P.C. Functional roles of fatty acids and their effects on human health. J. Parenter. Enteral Nutr. 2015, 39 (Suppl. S1), 18S–32S. [Google Scholar] [CrossRef]

- Wood, J.D.; Richardson, R.I.; Nute, G.R.; Fisher, A.V.; Campo, M.M.; Kasapidou, E.; Sheard, P.R.; Enser, M. Effects of fatty acids on meat quality: A review. Meat Sci. 2003, 66, 21–32. [Google Scholar] [CrossRef]

- Fonti-Furnols, M.; Tous, N.; Esteve-Garcia, E.; Gispert, M. Do all the consumers accept marbling in the same way? The relationship between eating and visual acceptability of pork with different intramuscular fat content. Meat Sci. 2012, 91, 448–453. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Gong, H.; Cui, L.; Zhang, W.; Ma, J.; Chen, C.; Ai, H.; Xiao, S.; Huang, L.; et al. Genetic correlation of fatty acid composition with growth, carcass, fat deposition and meat quality traits based on GWAS data in six pig populations. Meat Sci. 2019, 150, 47–55. [Google Scholar] [CrossRef]

- Lee, S.D.; Jung, H.J.; Cho, K.C.; Park, J.C.; Kim, I.C.; Seong, P.N.; Song, J.M. Effects of corn dried distiller’s grains with solubles andenzyme premix supplements on growth performance, carcass characteristics and meat quality parameters infinishing pigs. Anim. Sci. J. 2011, 82, 461–467. [Google Scholar] [CrossRef]

- Averette Gatlin, L.; See, M.T.; Hansen, J.A.; Sutton, D.; Odle, J. The effects of dietary fat sources, levels, and feeding intervals on pork fatty acid composition. J. Anim. Sci. 2002, 80, 1606–1615. [Google Scholar] [CrossRef]

- Averette Gatlin, L.; See, M.T.; Hansen, J.A.; Odle, J. Hydrogenated dietary fat improves pork quality of pigs from two lean genotypes. J. Anim. Sci. 2003, 81, 1989–1997. [Google Scholar] [CrossRef]

- Riley, P.A.; Enser, M.; Nute, G.R.; Wood, J.D. Effects of dietary linseed on nutritional value and other quality aspects of pig muscle and adipose tissue. Anim. Sci. 2000, 71, 483–500. [Google Scholar] [CrossRef]

- Renerre, M. Oxidative processes and myoglobin. In Antioxidants in Muscle Foods; Deker, E., Faustman, C., Lopez-Bote, C.J., Eds.; John Wiley: New York, NY, USA, 2000; pp. 113–133. [Google Scholar]

| Item | Group I (Control) SBM + RO | Group II cDDGS + RO | Group III cDDGS + BT | Group IV cDDGS + CO | p Value | SEM |

|---|---|---|---|---|---|---|

| C8:0 caprylic | 0.08 | 0.06 | 0.09 | 0 | - | - |

| C10:0 capric | 0 | 0 | 0.27 | 0.65 | - | - |

| C12:0 lauric | 0.42 a | 0.35 a | 0.45 a | 1.01 b | 0.008 | 0.071 |

| C14:0 myristic | 1.36 a | 1.32 a | 1.41 a | 2.33 b | 0.005 | 0.111 |

| C16:0 palmitic | 20.60 b | 18.60 a | 21.46 b | 22.13 b | 0.003 | 0.402 |

| C16:1 n-7 palmitoleic | 2.36 | 2.39 | 2.37 | 2.42 | 0.993 | 0.068 |

| C18:0 stearic | 12.10 | 11.88 | 12.58 | 12.38 | 0.365 | 0.146 |

| C18:1 n-9 oleic | 35.35 | 37.14 | 36.81 | 35.80 | 0.641 | 0.535 |

| C18:2 n-6 linoleic | 16.75 ab | 18.12 b | 14.93 a | 14.02 a | 0.042 | 0.585 |

| ɤ C18:3 n-6 gama-linolenic | 0.16 | 0.13 | 0.15 | 0.13 | 0.501 | 0.008 |

| C18:3 n-3 alpha-linolenic | 1.34 c | 1.03 b | 0.66 a | 0.65 a | 0.001 | 0.074 |

| C20:0 arachidic | 0.32 | 0.28 | 0.33 | 0.36 | 0.551 | 0.019 |

| C20:4 n-6 arachidonic | 6.28 | 6.21 | 6.66 | 5.36 | 0.706 | 0.383 |

| C20:5 n-3 EPA | 0.54 b | 0.32 a | 0.22 a | 0.22 a | 0.005 | 0.041 |

| C22:0 behenic | 0.51 b | 0.34 a | 0.22 a | 0.33 a | 0.002 | 0.031 |

| C22:1 n-9 erucic | 0.22 b | 0.22 b | 0.09 a | 0.07 a | 0.003 | 0.021 |

| C22:6 n-3 DHA | 0.91 b | 0.50 a | 0.33 a | 0.21 a | 0.001 | 0.077 |

| SFA | 35.31 b | 32.83 a | 36.63 b | 39.20 c | 0.005 | 0.612 |

| UFA | 63.96 b | 66.05 c | 62.23 b | 58.86 a | 0.002 | 0.691 |

| MUFA | 37.94 | 39.74 | 39.28 | 38.28 | 0.674 | 0.562 |

| PUFA | 26.02 b | 26.31 b | 22.95 ab | 20.58 a | 0.042 | 0.919 |

| PUFA n-6 | 23.22 | 24.46 | 21.74 | 19.51 | 0.147 | 0.804 |

| PUFA n-3 | 2.80 c | 1.85 b | 1.21 a | 1.07 a | 0.001 | 0.176 |

| PUFA n-6/n-3 | 8.45 a | 13.25 b | 18.09 c | 18.38 c | 0.005 | 0.360 |

| PUFA:SFA ratio (P:S) | 0.74 b | 0.80 b | 0.63 ab | 0.52 a | 0.015 | 0.036 |

| Fat saturation index (S:P) | 0.53 ab | 0.48 a | 0.57 b | 0.63 c | 0.002 | 0.015 |

| Iodine value (IV) | 65.81 b | 68.79 b | 61.95 a | 59.44 a | 0.008 | 0.961 |

| Item | Group I (Control) SBM + RO | Group II cDDGS + RO | Group III cDDGS + BT | Group IV cDDGS + CO | p Value | SEM |

|---|---|---|---|---|---|---|

| Basic chemical analysis, g/kg: | ||||||

| - dry matter | 240.20 | 238.00 | 244.90 | 250.50 | 0.085 | 1.924 |

| - protein | 236.00 b | 228.00 a | 227.20 a | 233.70 b | 0.017 | 1.250 |

| - fat | 9.20 a | 10.50 ab | 15.90 b | 15.60 b | 0.045 | 1.149 |

| Oxidative stability after 4 months (−20 °C): | ||||||

| TBARS, mg/kg | 0.47 | 0.49 | 0.47 | 0.46 | 0.827 | 0.013 |

| Acidity: | ||||||

| - pH 45 min after slaughter | 6.48 | 6.38 | 6.36 | 6.35 | 0.337 | 0.028 |

| - pH after 24h (+4 °C) | 5.57 | 5.40 | 5.50 | 5.53 | 0.899 | 0.037 |

| - pH after 4 months (−20 °C) | 5.42 | 5.55 | 5.50 | 5.47 | 0.326 | 0.024 |

| Water holding capacity: | ||||||

| WHC index after 24h (+4 °C), cm2/g | 22.32 b | 21.80 ab | 18.80 a | 18.65 a | 0.038 | 0.603 |

| WHC index after 4 months (−20 °C), cm2/g | 15.73 | 15.15 | 13.99 | 13.78 | 0.352 | 0.440 |

| Drip loss during defrosting, % | 13.97 | 14.96 | 14.07 | 13.96 | 0.874 | 0.467 |

| Thermal (cooking) drip loss, % | 27.19 b | 24.53 a | 24.09 a | 24.63 a | 0.042 | 0.458 |

| Meat color after 24 h (+4 °C): | ||||||

| - lightness (L) | 52.02 | 52.24 | 51.72 | 51.77 | 0.564 | 0.564 |

| - saturation in red (a) | 17.29 | 16.45 | 16.03 | 16.46 | 0.060 | 0.178 |

| - saturation in yellow (b) | 2.35 | 2.21 | 2.13 | 2.36 | 0.808 | 0.091 |

| - color saturation (C) | 17.46 | 16.60 | 16.18 | 16.64 | 0.062 | 0.181 |

| Meat color after 4 months (−20 °C): | ||||||

| - brightness (L*) | 50.57 | 50.00 | 50.51 | 48.17 | 0.749 | 0.841 |

| - saturation in red (a*) | 17.52 | 17.14 | 16.80 | 16.91 | 0.304 | 0.146 |

| - saturation in yellow (b*) | 3.03 | 2.81 | 2.97 | 3.19 | 0.852 | 0.141 |

| - color saturation (C) | 17.80 | 17.38 | 17.08 | 17.21 | 0.299 | 0.142 |

| Color change during storage, ΔE (4 months −20 °C) | 1.77 | 2.74 | 2.22 | 2.05 | 0.287 | 0.181 |

| Item | Group I (Control) SBM + RO | Group II cDDGS + RO | Group III cDDGS + BT | Group IV cDDGS + CO | p Value | SEM |

|---|---|---|---|---|---|---|

| Shear force, N | 63.66 | 61.12 | 59.27 | 57.84 | 0.859 | 2.436 |

| Toughness, | 193.60 | 183.02 | 178.78 | 166.75 | 0.708 | 39.843 |

| Hardness | 9.44 | 7.36 | 6.35 | 6.51 | 0.264 | 0.631 |

| Springiness | 0.72 | 0.73 | 0.68 | 0.69 | 0.263 | 0.009 |

| Cohesiveness | 0.69 b | 0.68 b | 0.64 a | 0.63 a | 0.024 | 0.010 |

| Chewiness | 4.74 b | 3.80 ab | 2.66 a | 2.75 a | 0.047 | 0.339 |

| Resilience | 0.31 b | 0.32 b | 0.28 a | 0.27 a | 0.019 | 0.006 |

| Item | Group I (Control) SBM + RO | Group II cDDGS + RO | Group III cDDGS + BT | Group IV cDDGS + CO | p Value | SEM |

|---|---|---|---|---|---|---|

| Aroma | 4.68 | 4.80 | 4.89 | 4.76 | 0.165 | 0.032 |

| Taste | 4.78 | 4.82 | 4.89 | 4.82 | 0.750 | 0.033 |

| Tenderness | 4.50 a | 4.83 b | 4.87 b | 4.87 b | 0.027 | 0.040 |

| Juiciness | 4.53 a | 4.80 b | 4.89 b | 4.90 b | 0.037 | 0.039 |

| Meat Quality Traits | Fatty Acids in Meat | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Groups of Fatty Acids | The Most Abundant Fatty Acids | Iodine Value | ||||||||||||

| SFA | MUFA | PUFA | PUFAn-6 | PUFAn-3 | UFA | C16:1 | C18:1 | C18:2 | C18:3 | C16:0 | C18:0 | |||

| Texture parameters | Shear force | −0.34 | −0.18 | 0.41 ● | 0.38 | 0.36 | 0.38 | 0.02 | −0.20 | 0.41 ● | 0.37 | −0.21 | −0.38 | 0.41 ● |

| Toughness | −0.16 | −0.03 | 0.18 | 0.15 | 0.30 | 0.22 | 0.15 | −0.05 | 0.12 | 0.36 | −0.04 | −0.13 | 0.18 | |

| Hardness | 0.02 | −0.23 | 0.14 | 0.09 | 0.34 | 0.01 | −0.06 | −0.23 | 0.11 | 0.33 | 0.06 | 0.03 | 0.07 | |

| Springiness | −0.21 | −0.43 ● | 0.43 ● | 0.40 | 0.44 ● | 0.22 | −0.10 | −0.46 ● | 0.41 ● | 0.42 ● | −0.21 | −0.03 | 0.30 | |

| Cohesiveness | −0.48 ● | −0.33 | 0.54 ● | 0.48 ● | 0.62 ● | 0.45 ● | −0.30 | −0.33 | 0.58 ● | 0.55 ● | −0.58 ● | −0.07 | 0.56 ● | |

| Chewiness | −0.12 | −0.22 | 0.25 | 0.18 | 0.47 ● | 0.15 | −0.08 | −0.23 | 0.25 | 0.47 ● | −0.08 | −0.02 | 0.24 | |

| Resilience | −0.45 ● | −0.23 | 0.46 ● | 0.40 | 0.65 ● | 0.41 ● | −0.33 | −0.22 | 0.49 ● | 0.68 ● | −0.55 ● | −0.01 | 0.53 ● | |

| Organoleptic parameters | Aroma | 0.07 | 0.09 | −0.13 | −0.07 | −0.37 | −0.10 | 0.01 | 0.10 | −0.05 | −0.37 | 0.08 | 0.36 | −0.08 |

| Taste | 0.09 | −0.09 | −0.02 | 0.01 | −0.14 | −0.10 | −0.30 | −0.05 | −0.03 | −0.14 | 0.04 | 0.38 | −0.09 | |

| Tenderness | 0.18 | 0.37 | −0.44 ● | −0.33 | −0.77 ● | −0.28 | 0.01 | 0.41 ● | −0.35 | −0.69 ● | 0.05 | 0.37 | −0.33 | |

| Juiciness | 0.26 | 0.10 | −0.34 | −0.22 | −0.74 ● | −0.35 | −0.22 | 0.15 | −0.30 | −0.72 ● | 0.08 | 0.43 ● | −0.41 ● | |

| Moisture traits and fat content | Water holding capacity | −0.29 | 0.35 | −0.01 | −0.08 | 0.27 | 0.27 | 0.10 | 0.34 | −0.02 | 0.46 | −0.30 | −0.07 | 0.24 |

| Thermal drip loss | 0.07 | −0.04 | −0.01 | −0.12 | 0.50 ● | −0.04 | −0.07 | −0.04 | 0.05 | 0.54 | 0.15 | 0.07 | 0.14 | |

| Fat content | 0.69 ● | 0.33 | −0.73 ● | −0.70 ● | −0.61 ● | −0.68 ● | 0.39 | 0.33 | −0.54 ● | −0.56 ● | 0.73 ● | 0.43 ● | −0.52 ● | |

| Color traits | Lightness 24 h, L | 0.16 | 0.54 ● | −0.48 ● | −0.45 | −0.43 | −0.19 | 0.12 | 0.56 ● | −0.52 | −0.20 | 0.11 | 0.44 | −0.32 |

| Redness 24 h, a | −0.24 | −0.23 | 0.34 | 0.25 | 0.65 ● | 0.27 | −0.10 | −0.25 | 0.35 | 0.57 ● | −0.15 | −0.44 | 0.36 | |

| Yellowness 24 h, b | −0.12 | −0.30 | 0.33 | 0.31 | 0.19 | 0.19 | −0.42 | −0.27 | 0.05 | 0.19 | −0.15 | −0.21 | −0.05 | |

| Saturation 24 h, C | −0.24 | −0.25 | 0.35 | 0.26 | 0.65 ● | 0.28 | −0.09 | −0.27 | 0.35 | 0.57 ● | −0.15 | −0.44 | 0.35 | |

| Meat acidity | pH 45 min | 0.12 | 0.48 ● | −0.38 | −0.44 | 0.02 | −0.11 | 0.17 | 0.49 ● | −0.45 | 0.22 | 0.14 | 0.32 | −0.19 |

| pH 24 h | 0.17 | 0.27 | −0.25 | −0.27 | −0.06 | −0.11 | 0.19 | 0.27 | −0.33 | −0.02 | 0.07 | 0.17 | −0.22 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świątkiewicz, M.; Olszewska, A.; Grela, E.R.; Tyra, M. The Effect of Replacement of Soybean Meal with Corn Dried Distillers Grains with Solubles (cDDGS) and Differentiation of Dietary Fat Sources on Pig Meat Quality and Fatty Acid Profile. Animals 2021, 11, 1277. https://doi.org/10.3390/ani11051277

Świątkiewicz M, Olszewska A, Grela ER, Tyra M. The Effect of Replacement of Soybean Meal with Corn Dried Distillers Grains with Solubles (cDDGS) and Differentiation of Dietary Fat Sources on Pig Meat Quality and Fatty Acid Profile. Animals. 2021; 11(5):1277. https://doi.org/10.3390/ani11051277

Chicago/Turabian StyleŚwiątkiewicz, Małgorzata, Anna Olszewska, Eugeniusz R. Grela, and Mirosław Tyra. 2021. "The Effect of Replacement of Soybean Meal with Corn Dried Distillers Grains with Solubles (cDDGS) and Differentiation of Dietary Fat Sources on Pig Meat Quality and Fatty Acid Profile" Animals 11, no. 5: 1277. https://doi.org/10.3390/ani11051277

APA StyleŚwiątkiewicz, M., Olszewska, A., Grela, E. R., & Tyra, M. (2021). The Effect of Replacement of Soybean Meal with Corn Dried Distillers Grains with Solubles (cDDGS) and Differentiation of Dietary Fat Sources on Pig Meat Quality and Fatty Acid Profile. Animals, 11(5), 1277. https://doi.org/10.3390/ani11051277