A Hybrid Electromagnetic and Tendon-Driven Actuator for Minimally Invasive Surgery

Abstract

1. Introduction

2. Materials and Methods

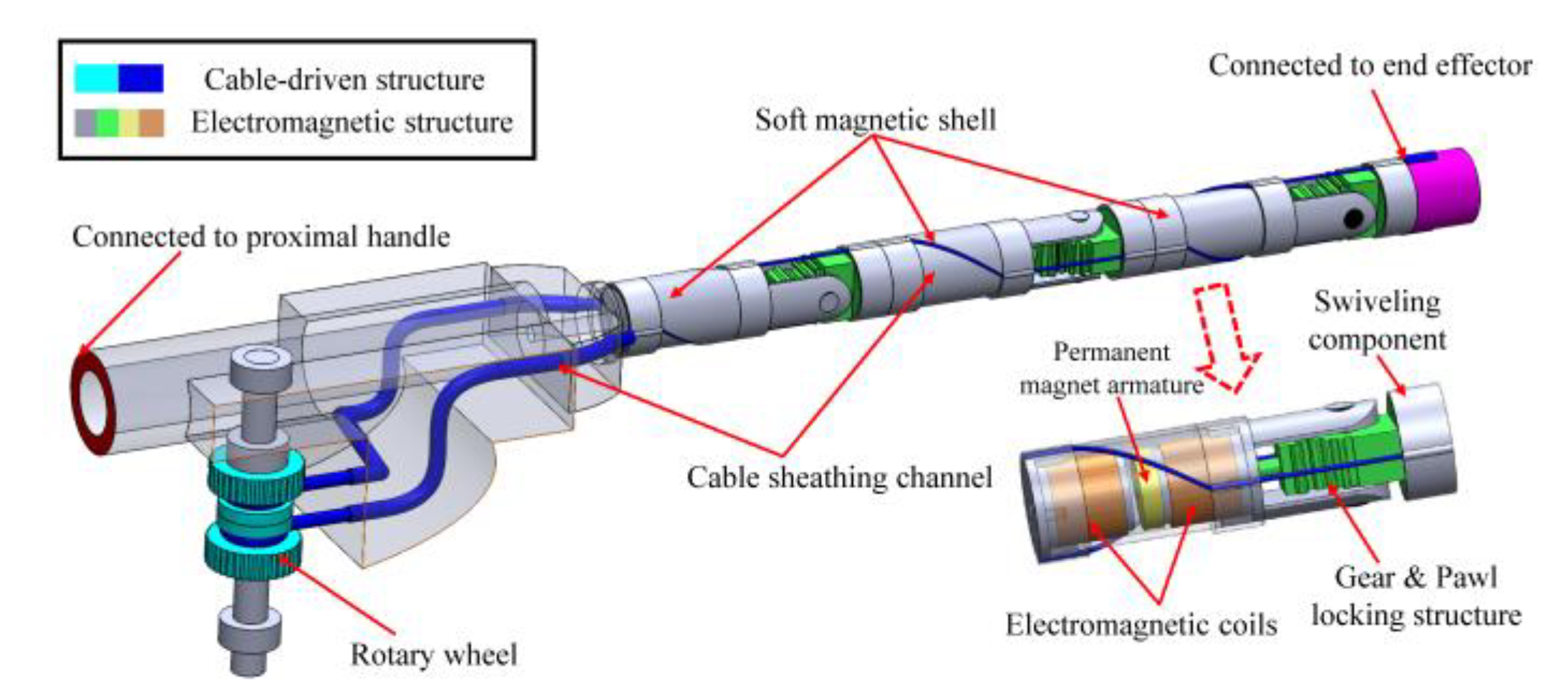

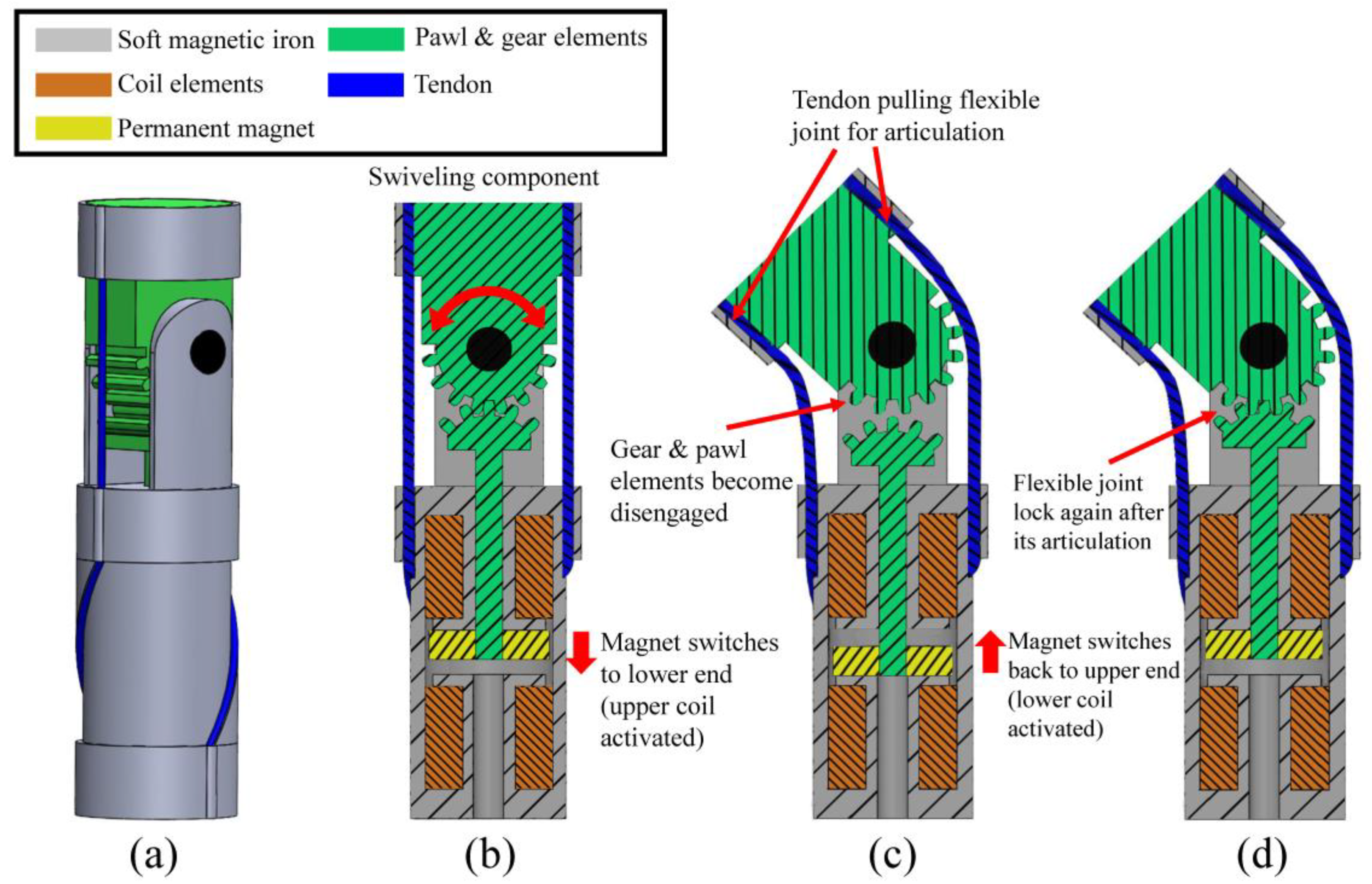

2.1. Design of the Hybrid Electromagnetic and Tendon-Driven Actuator for MIS

2.2. Kinematic Analysis of the Hybrid Electromagnetic and Tendon-Driven Actuator

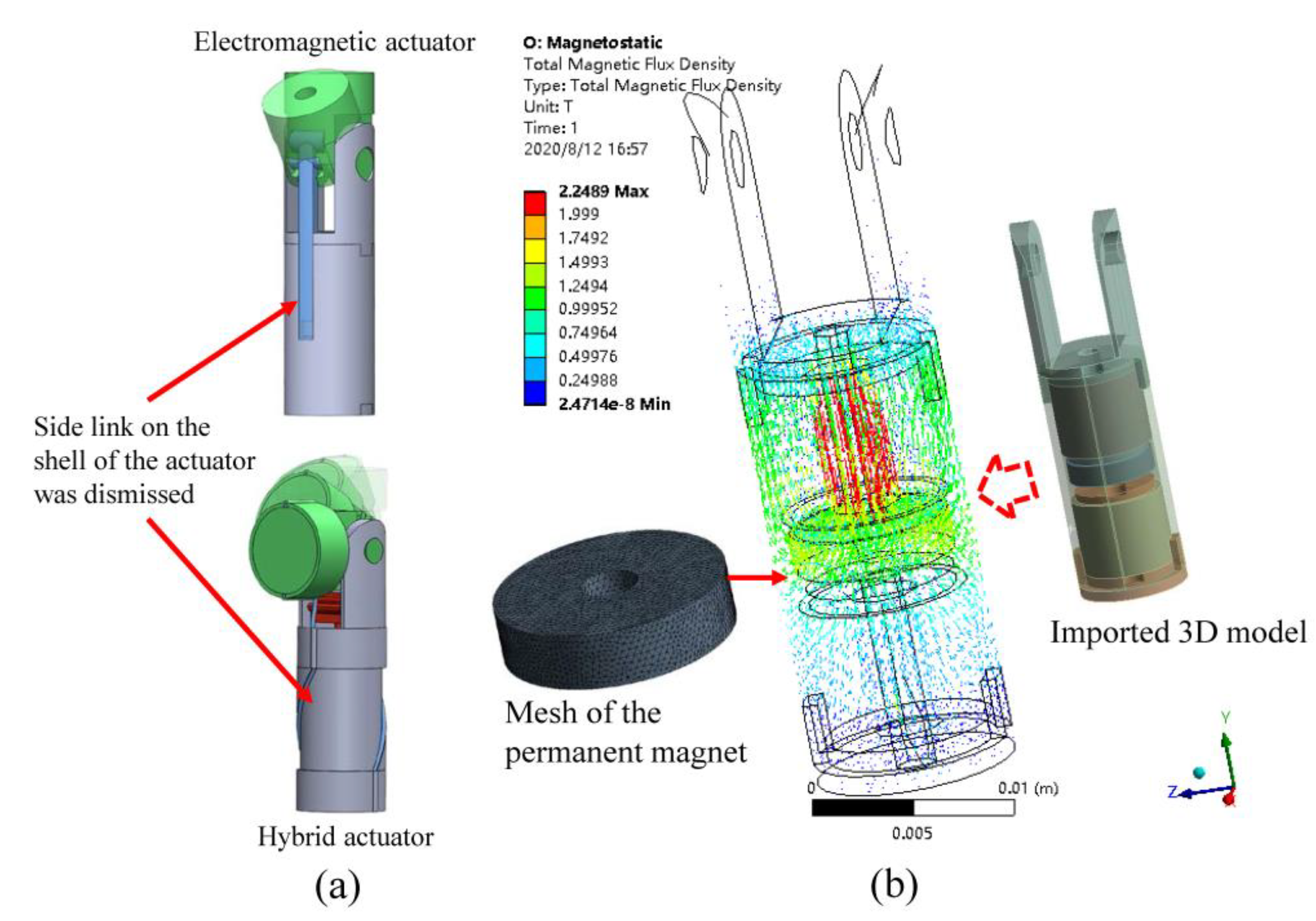

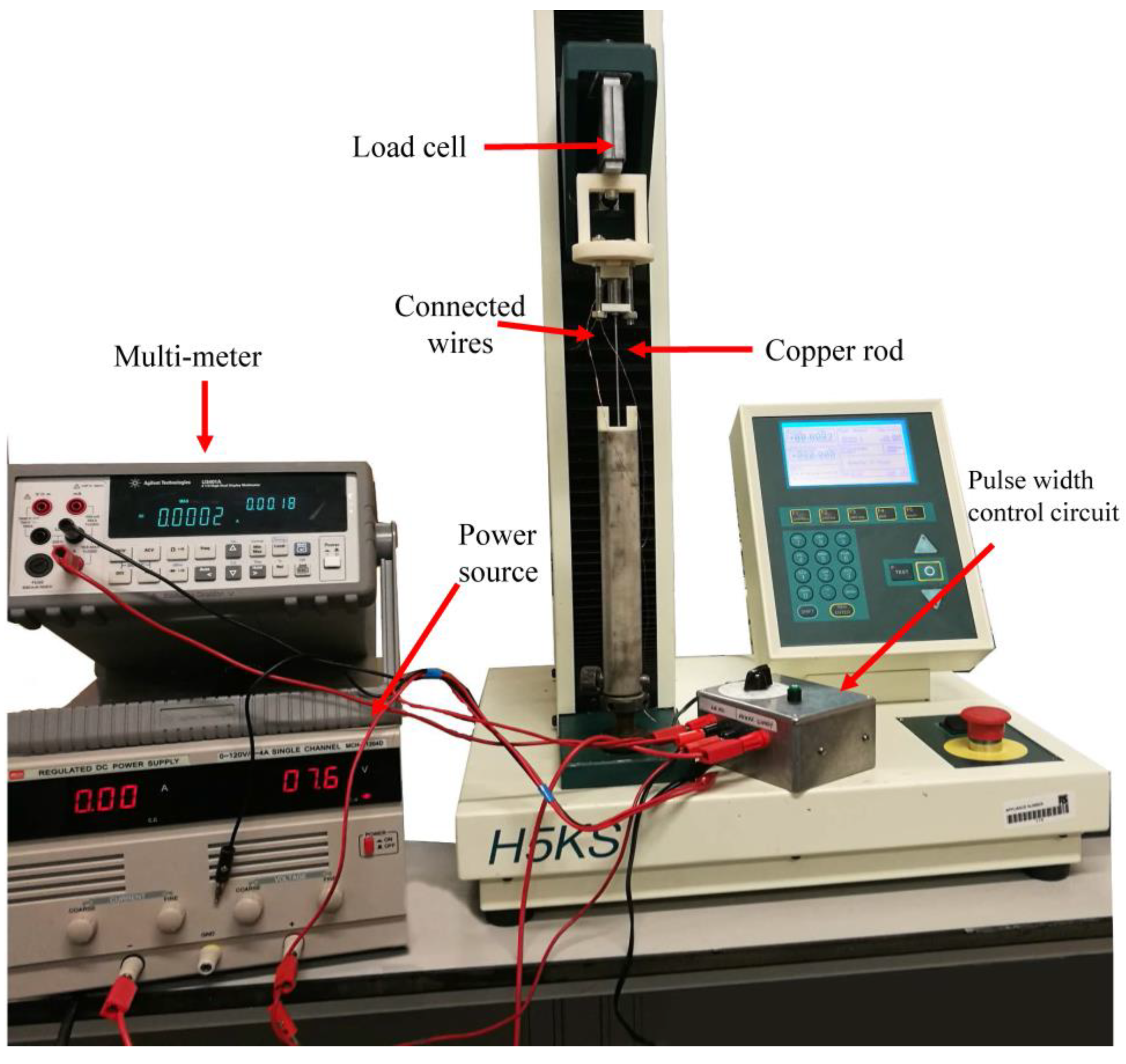

2.3. Numerical and Experimental Evaluation of the Actuator Performance

3. Results and Discussion

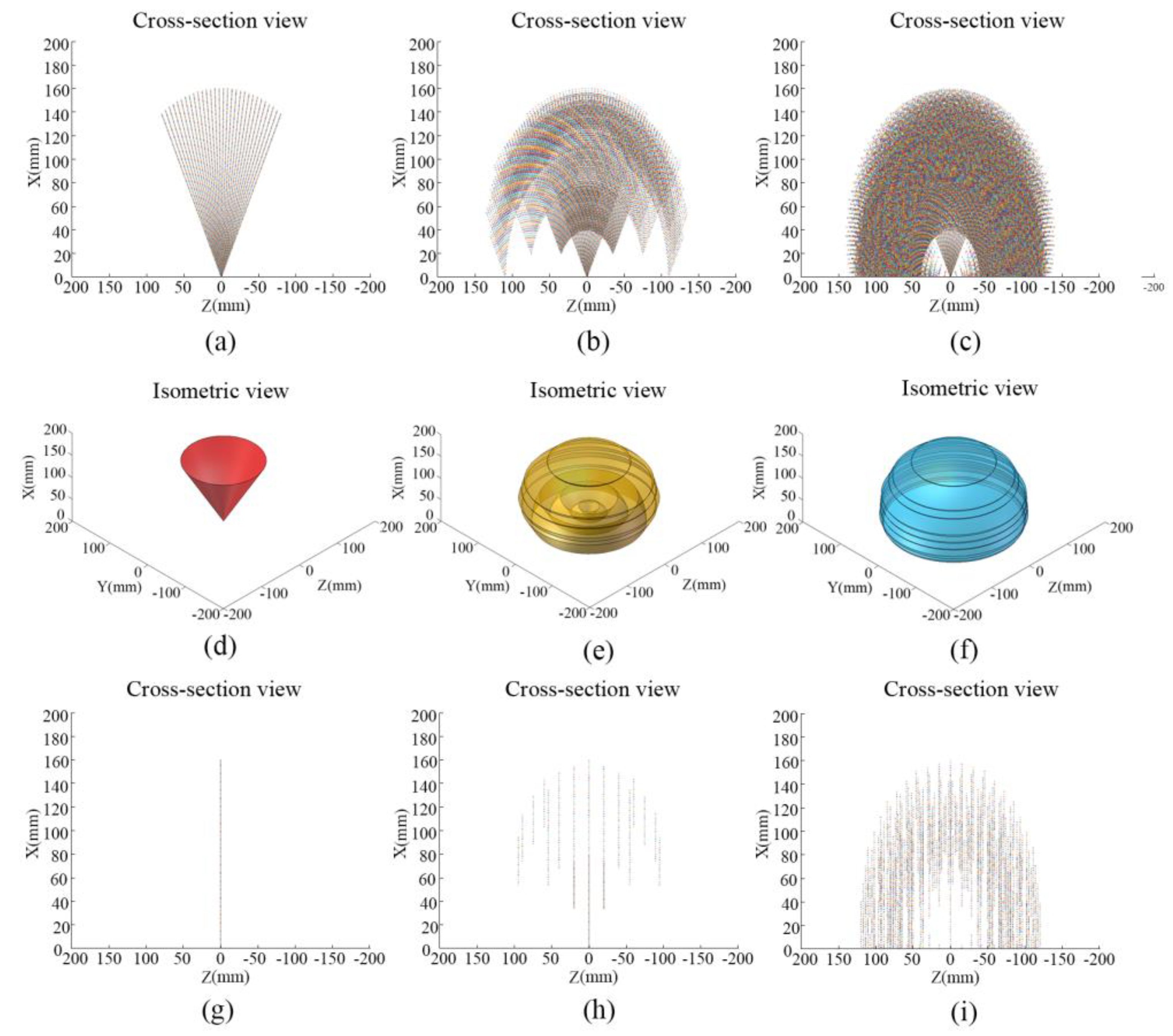

3.1. Workspace of the Developed Hybrid Electromagnetic and Tendon-Driven Actuator

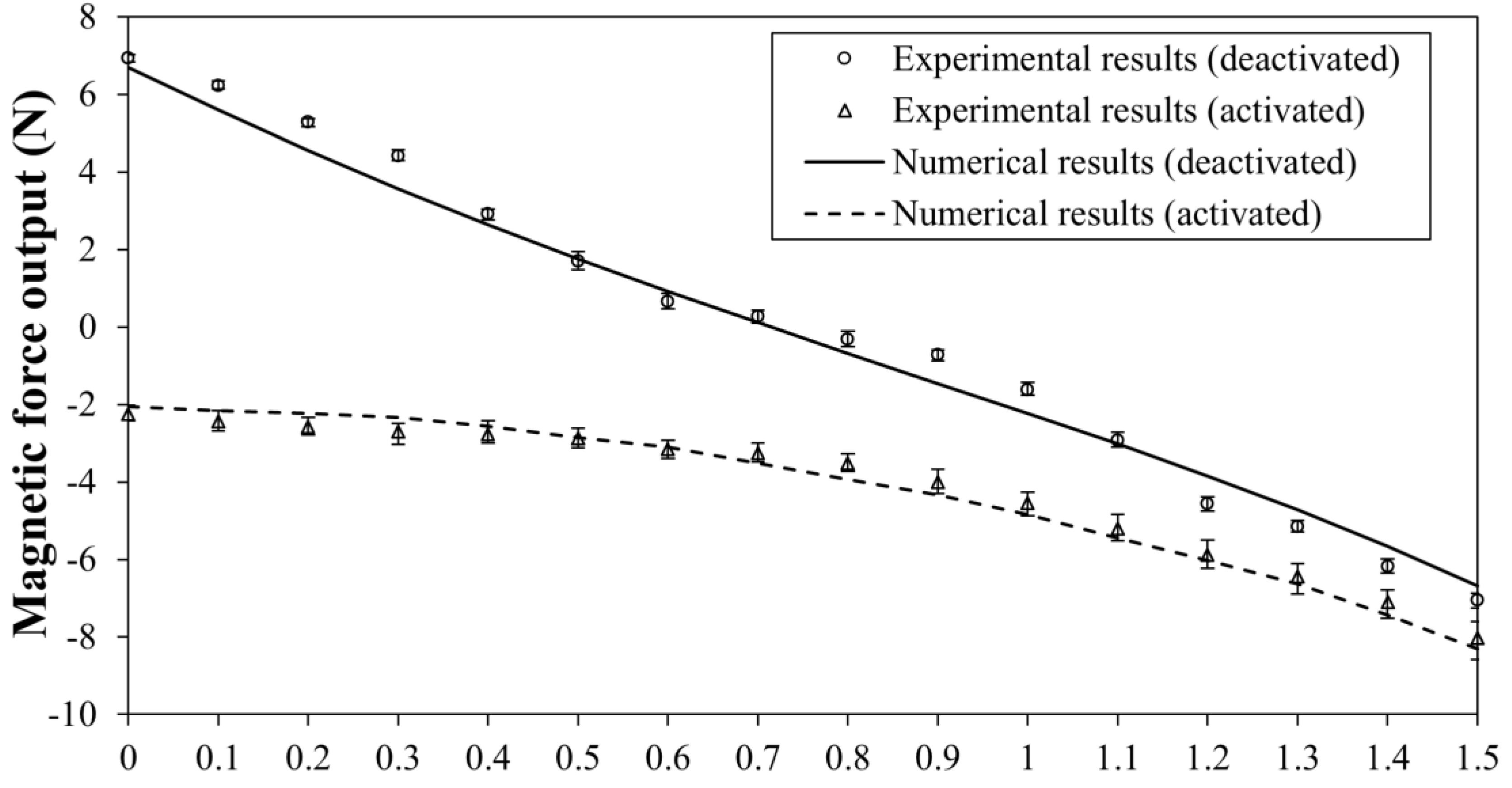

3.2. Force Output of the Electromagnetic Structure

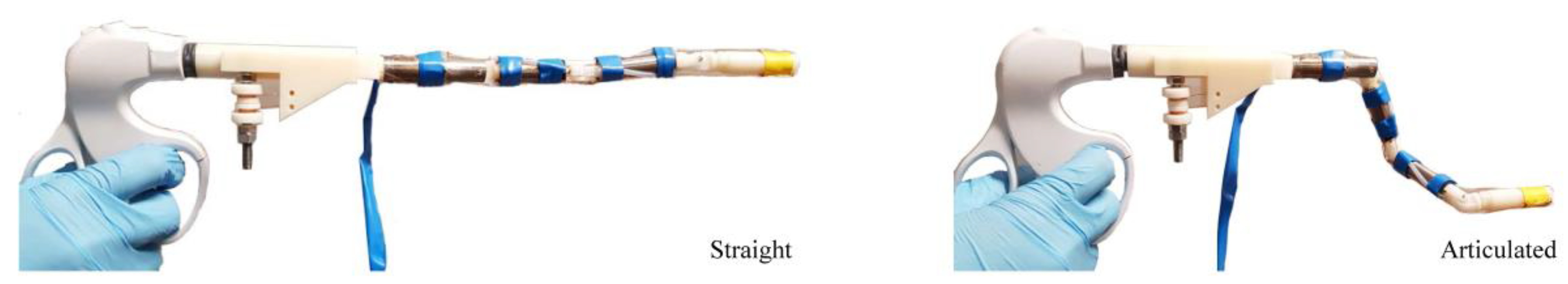

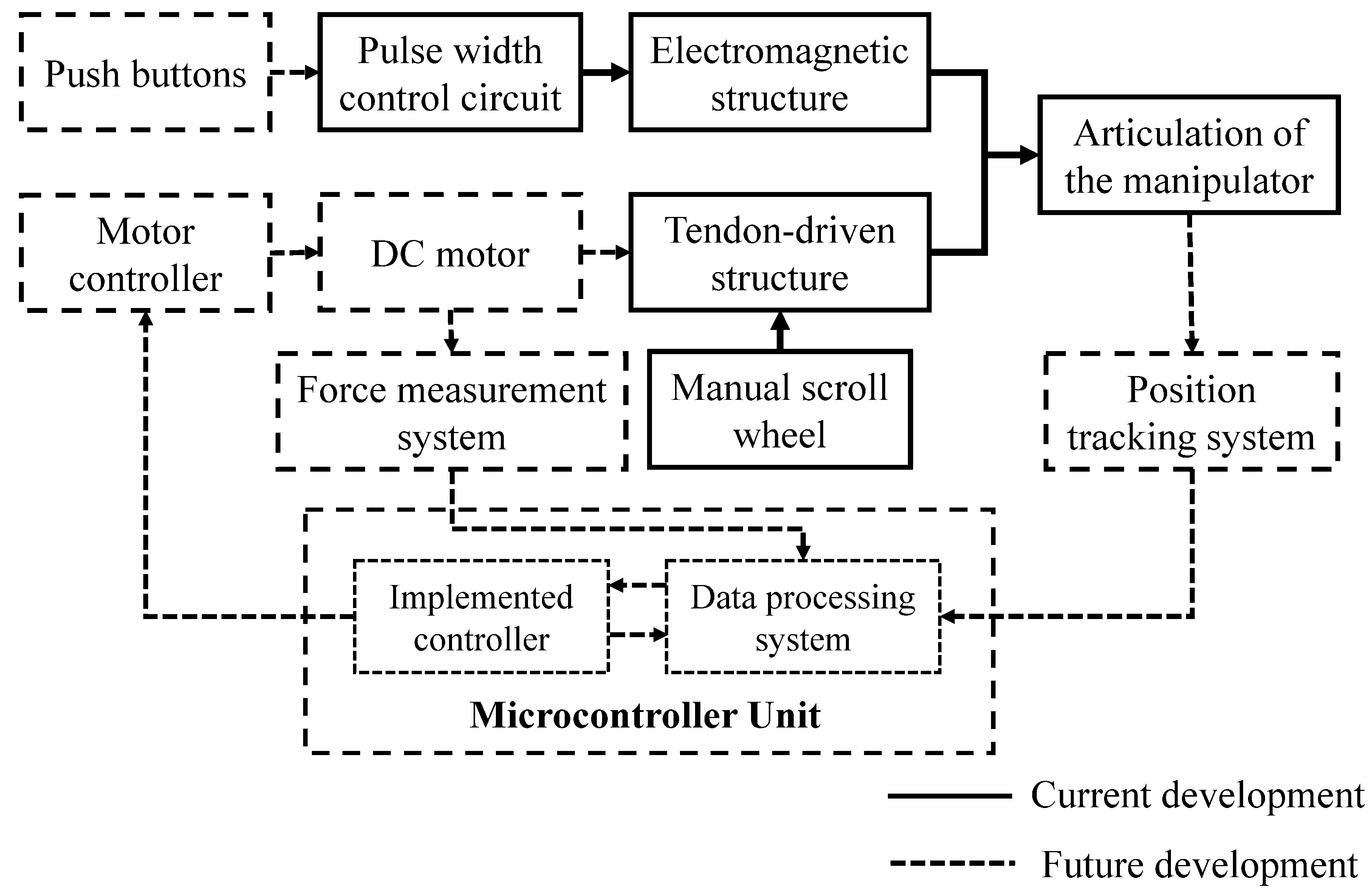

3.3. Prototype of the Developed Actuator

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jaffray, B. Minimally invasive surgery. Arch. Dis. Child. 2005, 90, 537–542. [Google Scholar] [CrossRef] [PubMed]

- Peter, S.D.S.; Holcomb, G.W., III. History of minimally invasive surgery. In Atlas of Pediatric Laparoscopy and Thoracoscopy; Saunders: Lodon, UK, 2008. [Google Scholar]

- Alevizos, L.; Brinkman, W.; Fingerhut, A.; Jakimowicz, J.; Leandros, E. Novice Surgeons Versus Experienced Surgeons in Laparoendoscopic Single-Site (LESS) Surgery: A Comparison of Performances in a Surgical Simulator. World J. Surg. 2012, 36, 939–944. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-H. Single port laparoscopic surgery: Mission completed or more evolution to come? Ann. Laparosc. Endosc. Surg. 2017, 2, 79. [Google Scholar] [CrossRef]

- Li, Z.; Wu, L.; Ren, H.; Yu, H. Kinematic comparison of surgical tendon-driven manipulators and concentric tube manipulators. Mech. Mach. Theory 2017, 107, 148–165. [Google Scholar] [CrossRef]

- Anderson, P.L.; Lathrop, R.; Herrell, S.D.; Webster, R.J. Comparing a Mechanical Analogue with the Da Vinci User Interface: Suturing at Challenging Angles. IEEE Robot. Autom. Lett. 2016, 1, 1060–1065. [Google Scholar] [CrossRef] [PubMed]

- Simaan, N.; Yasin, R.M.; Wang, L. Medical technologies and challenges of robot-assisted minimally invasive intervention and diagnostics. Annu. Rev. Control Robot. Auton. Syst. 2018, 1, 465–490. [Google Scholar] [CrossRef]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.S.; Phee, S.J. Adaptive Control of Position Compensation for Cable-Conduit Mechanisms Used in Flexible Surgical Robots. In Proceedings of the 11th International Conference on Informatics in Control, Campeche, Mexico, 29 September–3 October 2014; pp. 110–117. [Google Scholar]

- Le, H.M.; Do, T.N.; Phee, S.J. A survey on actuators-driven surgical robots. Sens. Actuators A Phys. 2016, 247, 323–354. [Google Scholar] [CrossRef]

- Minor, M.; Mukherjee, R. A dexterous manipulator for minimally invasive surgery. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999. [Google Scholar]

- Giataganas, P.; Evangeliou, N.; Koveos, Y.; Kelasidi, E.; Tzes, A. Design and experimental evaluation of an innovative SMA-based tendon-driven redundant endoscopic robotic surgical tool. In Proceedings of the 19th Mediterranean Conference on Control & Automation (MED), Corfu, Greece, 20–23 June 2011; pp. 1071–1075. [Google Scholar]

- Cianchetti, M.; Ranzani, T.; Gerboni, G.; De Falco, I.; Laschi, C.; Menciassi, A.; De Falco, I. STIFF-FLOP surgical manipulator: Mechanical design and experimental characterization of the single module. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 3576–3581. [Google Scholar]

- Plooij, M.; Mathijssen, G.; Cherelle, P.; Lefeber, D.; VanderBorght, B. Lock Your Robot: A Review of Locking Devices in Robotics. IEEE Robot. Autom. Mag. 2015, 22, 106–117. [Google Scholar] [CrossRef]

- Wang, H.; El Wahed, A.K. Development of a Novel Latching-Type Electromagnetic Actuator for Applications in Minimally Invasive Surgery. Actuators 2020, 9, 41. [Google Scholar] [CrossRef]

- Tennant Metallurgical Group Ltd. Chesterfield, United Kingdom. Electromagnetic Test on Cast 80626. Available online: http://www.tenmet.co.uk/ (accessed on 18 April 2020).

- Hartenberg, R.S.; Denavit, J. A kinematic notation for lower pair mechanisms based on matrices. J. Appl. Mech. 1955, 77, 215–221. [Google Scholar]

- Soper, N.J.; Swanström, L.L.; Eubanks, S. (Eds.) Mastery of Endoscopic and Laparoscopic Surgery; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2008. [Google Scholar]

- Lum, M.J.H.; Rosén, J.; Sinanan, M.N.; Hannaford, B. Kinematic optimization of a spherical mechanism for a minimally invasive surgical robot. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; Volume 1, pp. 829–834. [Google Scholar]

- Li, Y.; Chen, Y.; Yang, Y.; Wei, Y. Passive Particle Jamming and Its Stiffening of Soft Robotic Grippers. IEEE Trans. Robot. 2017, 33, 446–455. [Google Scholar] [CrossRef]

- Brancadoro, M.; Manti, M.; Grani, F.; Tognarelli, S.; Menciassi, A.; Cianchetti, M. Toward a Variable Stiffness Surgical Manipulator Based on Fiber Jamming Transition. Front. Robot. AI 2019, 6, 12. [Google Scholar] [CrossRef]

- Chern, B.S.M.; Lakhotia, S.; Khoo, C.K.; Siow, A.Y.M. Single incision laparoscopic surgery in gynecology: Evolution, current trends, and future perspectives. Gynecol. Minim. Invasive Ther. 2012, 1, 9–18. [Google Scholar] [CrossRef]

- Romanelli, J.R.; Earle, D.B. Single-port laparoscopic surgery: An overview. Surg. Endosc. 2009, 23, 1419–1427. [Google Scholar] [CrossRef] [PubMed]

- Allemann, P.; Leroy, J.; Asakuma, M.; Al Abeidi, F.; Dallemagne, B.; Marescaux, J. Robotics May Overcome Technical Limitations of Single-Trocar Surgery. Arch. Surg. 2010, 145, 267–271. [Google Scholar] [CrossRef] [PubMed]

- Shang, J.; Noonan, D.; Payne, C.; Clark, J.; Sodergren, M.; Darzi, A.; Yang, G.-Z. An articulated universal joint based flexible access robot for minimally invasive surgery. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1147–1152. [Google Scholar]

| Outer diameter | 11 mm |

| Height | 40 mm |

| Angulation | −90°–90° |

| Activated voltage | ~31.5 V |

| Weight | ~25 g |

| Current pulse width | 0.1 s |

| Shell material | Low-carbon magnetic iron (MAXIMAG ®) [15] |

| Permanent magnet | Neodymium N52 |

| N-Surgical System | i-Joint | αi (°) | ai (mm) | di (mm) | θi (°) |

|---|---|---|---|---|---|

| 1-Hybrid electromagnetic and tendon-driven actuator | 0 | 0–360 | 0–40 | 0 | −30–30 |

| 1 | 90 | 40 | 0 | −90–90 | |

| 2 | 90 | 40 | 0 | −90–90 | |

| 3 | 90 | 40 | 0 | −90–90 | |

| 2-Electromagnetic actuator [14] | 0 | 0–360 | 0–40 | 0 | −30–30 |

| 1 | 90 | 40 | 0 | 0, 30 | |

| 2 | 90 | 40 | 0 | 0, 30 | |

| 3 | 90 | 40 | 0 | 0, 30 | |

| 3-Conventional MIS tools [17,18] | 0 | 0–360 | 0–160 | 0 | −30–30 |

| Element type | Ansys SOLID 117 (pyramid shape) |

| Element length | 0.2–2 mm |

| Principle of magnetic force calculation | Surface integral methods |

| Applied current | 6.7 A |

| Coil current density | 8 × 104 kA/m2 |

| Coil electric conductivity | 6 × 107 S/m |

| Coercive force of magnet | 796 kA/m |

| Actuator Type | Length (mm) | Outer Diameter (mm) | Angulation (°) | Power Unit | Response Speed |

|---|---|---|---|---|---|

| Electromagnetic [14] | 31 | 10 | 30 | Small | Quick |

| Tendon-driven [24] | 35 | 12.5 | 45 | Moderate | Quick |

| Pneumatic [12] | 50 | 35 | 120 | Bulky | Moderate |

| Hybrid electromagnetic and tendon-driven | 40 | 11 | 180 | Small | Quick |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Cui, S.; Wang, Y.; Song, C. A Hybrid Electromagnetic and Tendon-Driven Actuator for Minimally Invasive Surgery. Actuators 2020, 9, 92. https://doi.org/10.3390/act9030092

Wang H, Cui S, Wang Y, Song C. A Hybrid Electromagnetic and Tendon-Driven Actuator for Minimally Invasive Surgery. Actuators. 2020; 9(3):92. https://doi.org/10.3390/act9030092

Chicago/Turabian StyleWang, HaoChen, SaiHui Cui, Yao Wang, and ChengLi Song. 2020. "A Hybrid Electromagnetic and Tendon-Driven Actuator for Minimally Invasive Surgery" Actuators 9, no. 3: 92. https://doi.org/10.3390/act9030092

APA StyleWang, H., Cui, S., Wang, Y., & Song, C. (2020). A Hybrid Electromagnetic and Tendon-Driven Actuator for Minimally Invasive Surgery. Actuators, 9(3), 92. https://doi.org/10.3390/act9030092