Analytical Approach of a Pure Flow Mode Serpentine Path Rotary Magnetorheological Damper

Abstract

1. Introduction

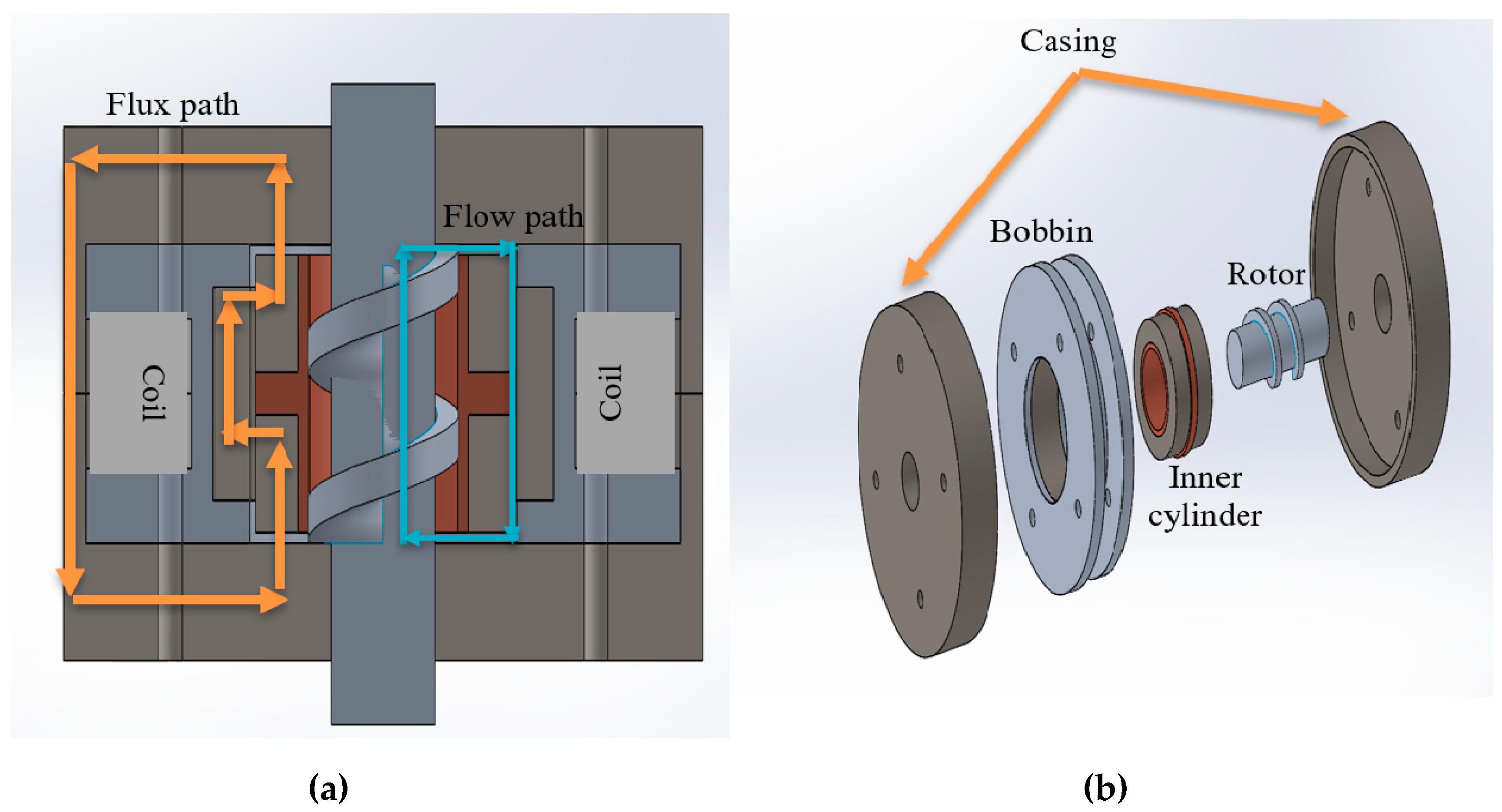

2. Design of a Flow-Mode Serpentine Path Rotary MR Damper

2.1. Structural Design

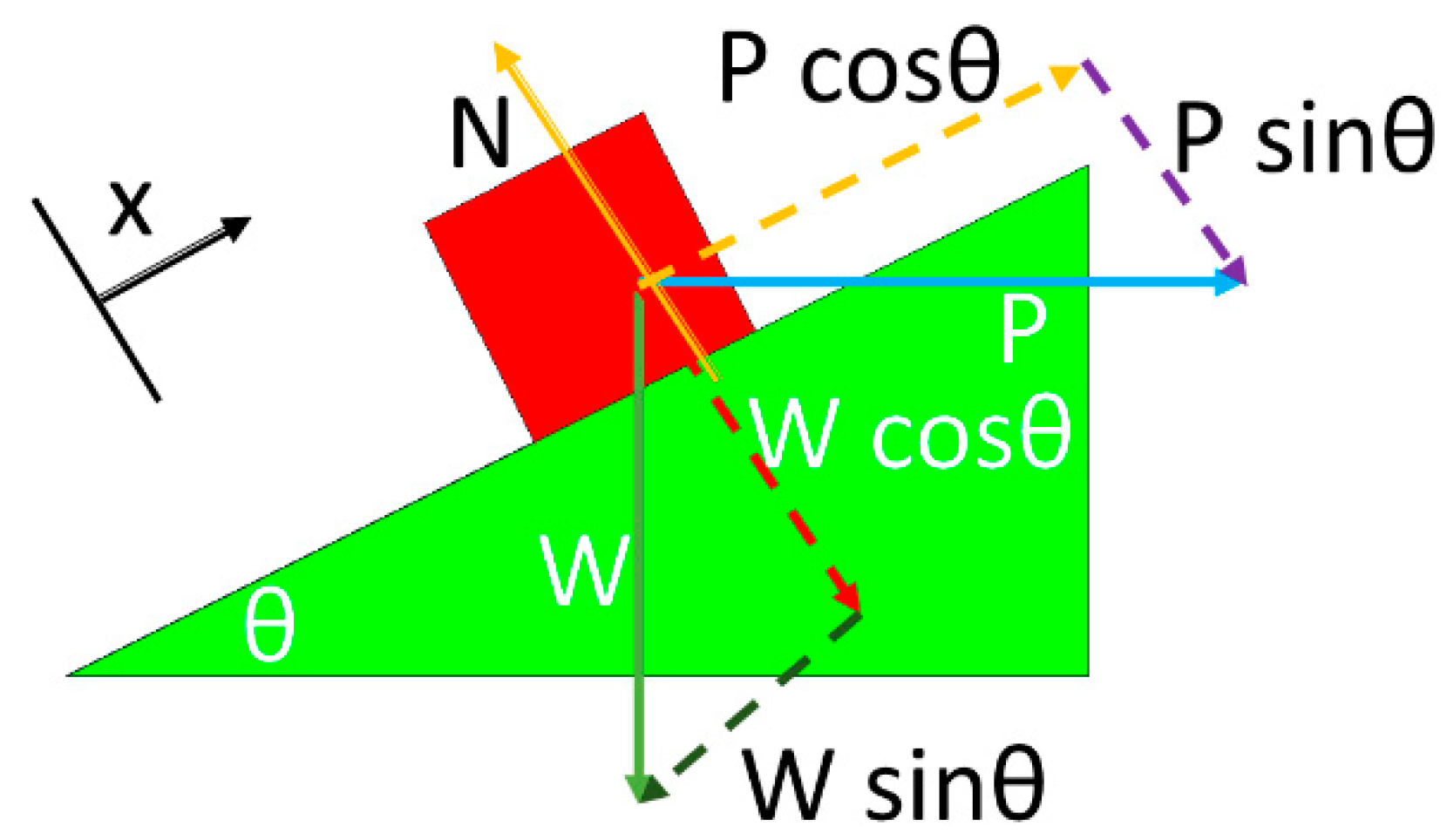

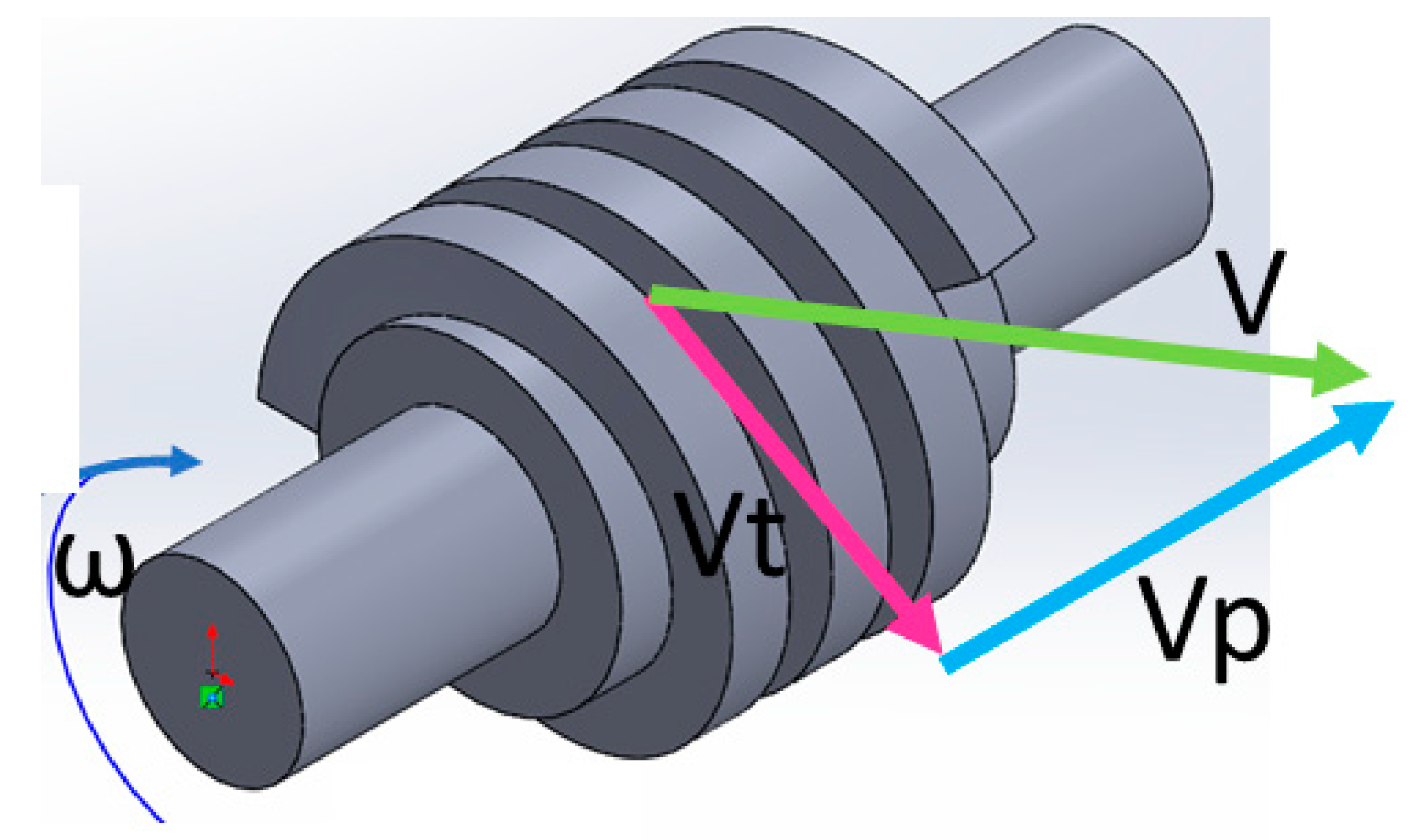

2.2. Torque Analysis

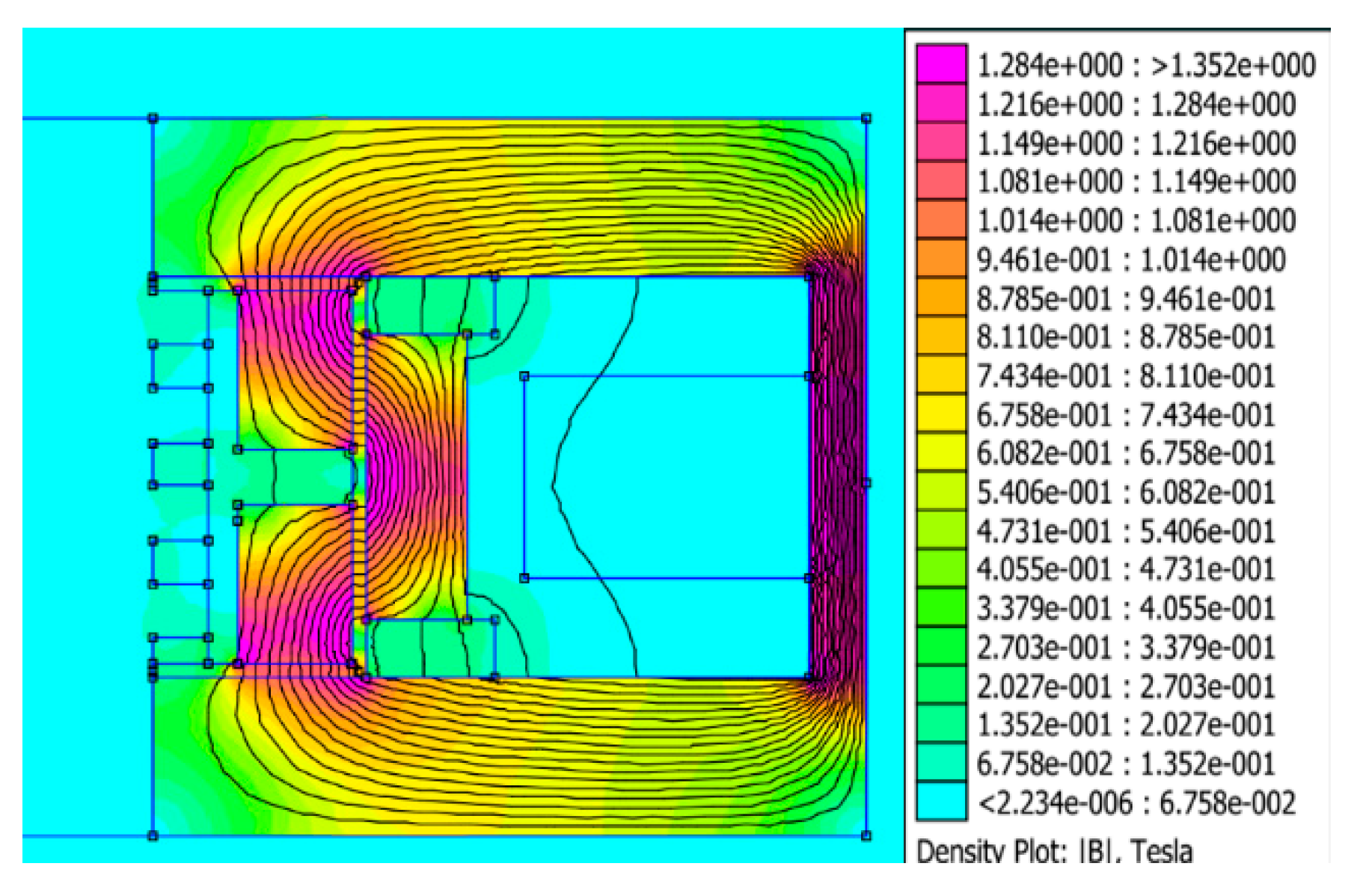

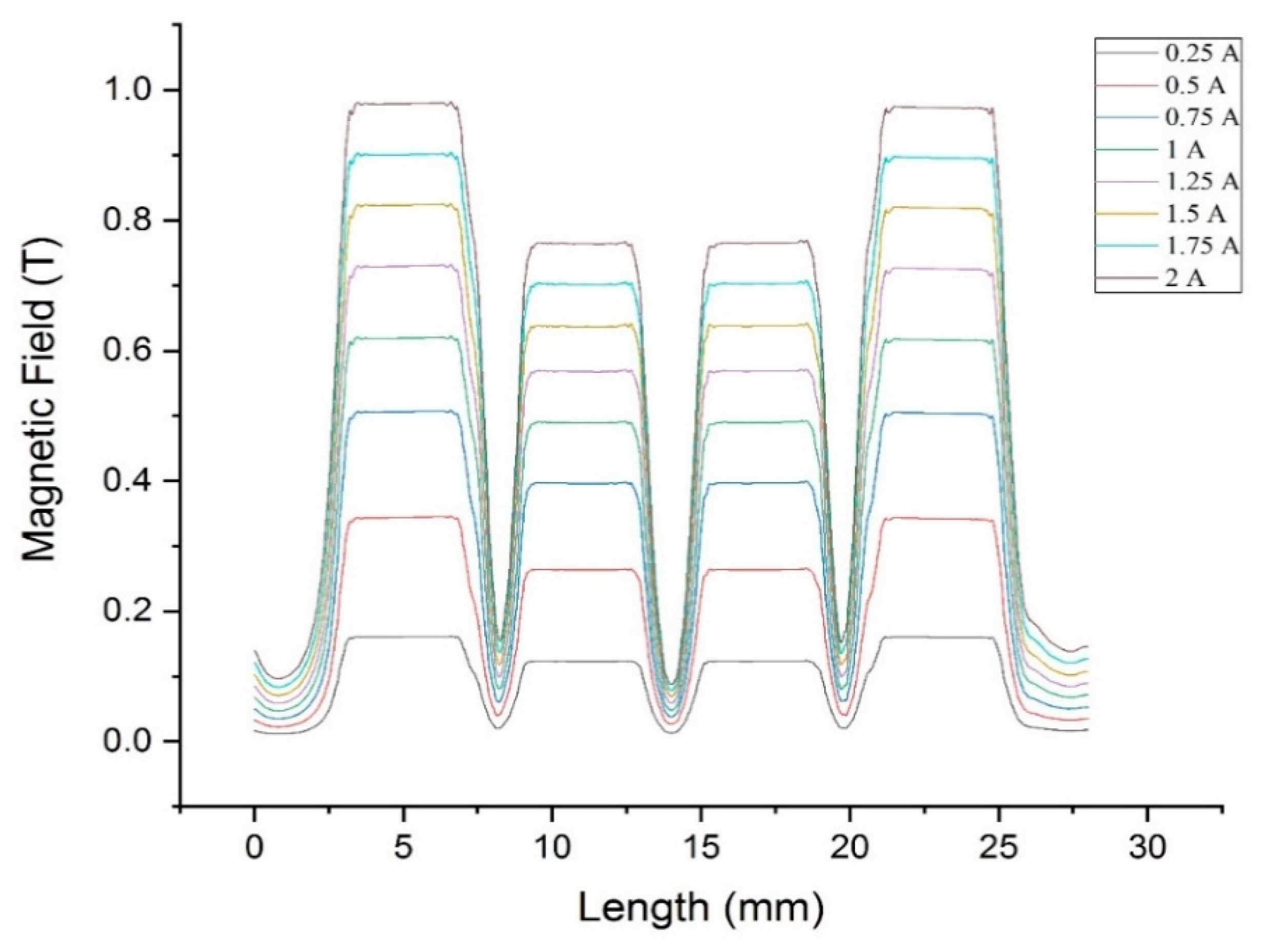

3. Magnetic Field Analysis

4. Performance Prediction

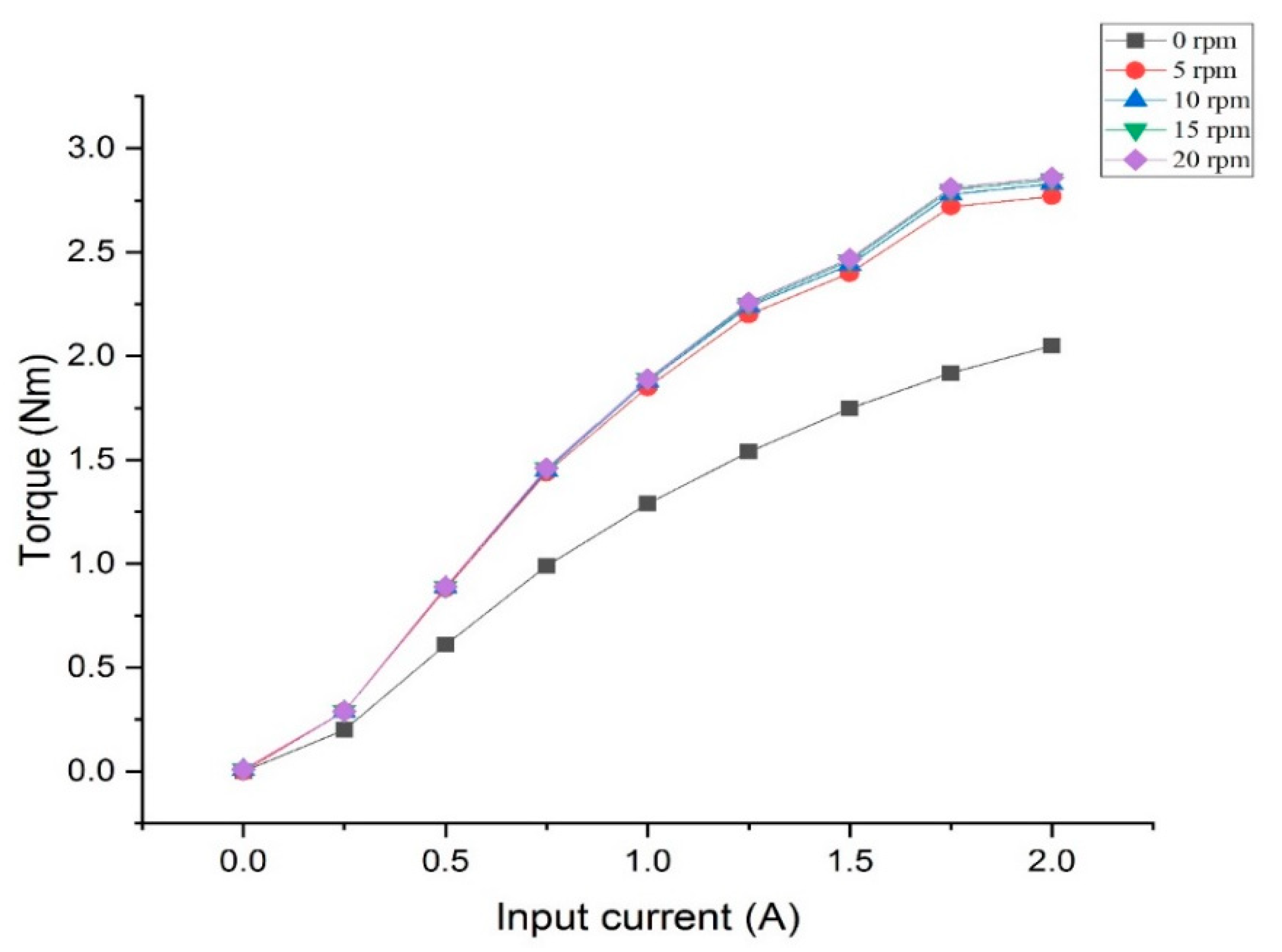

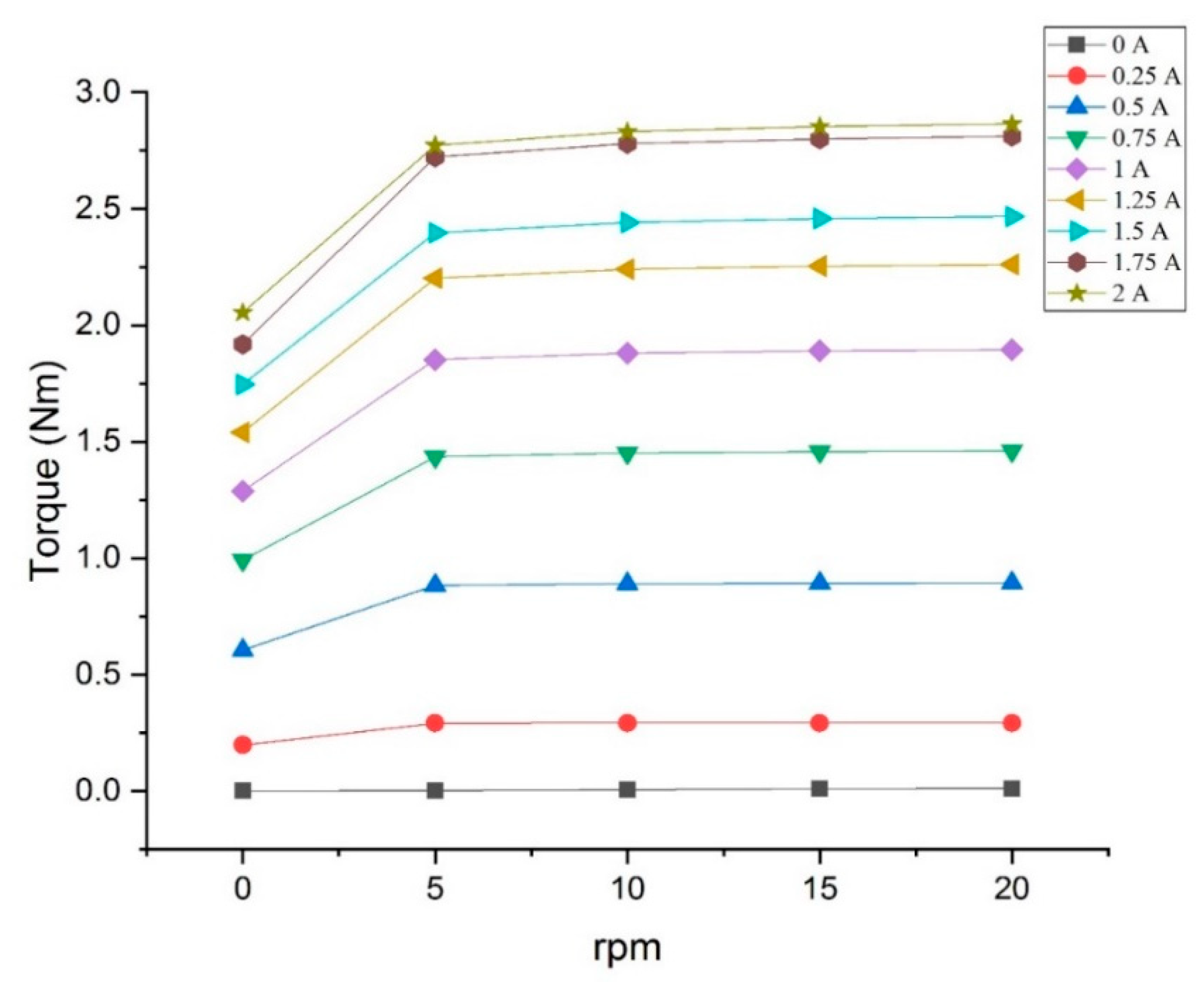

4.1. Damping Torque Prediction

4.2. Torque Density Prediction

5. Discussion

6. Conclusions

- The results of FEMM simulation indicate that the configuration of the magnetic conductive material and non-magnetic conductive material of the proposed rotary MR damper could bend the magnetic flux into a serpentine path configuration. It was successful in turning the annular channel into an active region. The activated annular channel would lead to a higher pressure drop and output damping torque.

- FEMM simulation shows that the average magnetic field can reach 0.82 and 0.67 T in radial and annular channels, respectively, at 2 A of current variation. It shows that the serpentine path will lead to a higher output damping torque, because the yield stress of MRF-132 at a magnetic field of 0.67 T is 38.16 kPa.

- The proposed rotary MR damper has a more compact structure than the other rotary MR dampers compared. The analytical approach of the proposed rotary MR damper reveals a torque of 2.86 and a torque density of 4.05 × 104 N/m2.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| R | MRF channel radius |

| Shear stress | |

| Viscosity | |

| Angular speed | |

| Outer radius of radial channel | |

| Inner radius of radial channel | |

| Q | Flowrate |

| Vp | Pitch velocity |

| Lp | Pitch |

| Θ | Screw helical angle |

| Ap | Cross section |

| L | Annular channel length |

| d | Width of channel |

| ΔP | Pressure drop |

| Viscous pressure drop | |

| Yield pressure drop | |

| c | constants |

References

- Ubaidillah; Sutrisno, J.; Purwanto, A.; Mazlan, S.A. Recent progress on magnetorheological solids: Materials, fabrication, testing, and applications. Adv. Eng. Mater. 2015, 17, 563–597. [Google Scholar] [CrossRef]

- Choi, H.J.; Mazlan, S.A.; Imaduddin, F. Fabrication and viscoelastic characteristics of waste tire rubber based magnetorheological elastomer. Smart Mater. Struct. 2016, 25, 115026. [Google Scholar]

- Ahmad Khairi, M.H.; Mazlan, S.A.; Ubaidillah; Ku Ahmad, K.Z.; Choi, S.B.; Abdul Aziz, S.A.; Yunus, N.A. The field-dependent complex modulus of magnetorheological elastomers consisting of sucrose acetate isobutyrate ester. J. Intell. Mater. Syst. Struct. 2017, 28, 1993–2004. [Google Scholar] [CrossRef]

- Kumbhar, B.K.; Patil, S.R.; Sawant, S.M. Synthesis and characterization of magneto-rheological (MR) fluids for MR brake application. Eng. Sci. Technol. Int. J. 2015, 18, 432–438. [Google Scholar] [CrossRef]

- Ahamed, R.; Choi, S.B.; Ferdaus, M.M. A state of art on magneto-rheological materials and their potential applications. J. Intell. Mater. Syst. Struct. 2018, 29, 2051–2095. [Google Scholar] [CrossRef]

- Hema Latha, K.; Usha Sri, P.; Seetharamaiah, N. Design and Manufacturing Aspects of Magneto-rheological Fluid (MRF) Clutch. Mater. Today Proc. 2017, 4, 1525–1534. [Google Scholar] [CrossRef]

- Gadekar, P.; Kanthale, V.S.; Khaire, N.D. Study of Magnetorheological Fluid and its Applications. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 7, 271–275. [Google Scholar]

- Avraam, T.M. MR-Fluid Brake Design and Its Application to a Portable Muscular Rehabilitation Device. Ph.D. Thesis, Université Libre de Bruxelles, Brussels, Belgium, 2009. [Google Scholar]

- Imaduddin, F.; Mazlan, S.A.; Zamzuri, H. A design and modelling review of rotary magnetorheological damper. Mater. Des. 2013, 51, 575–591. [Google Scholar] [CrossRef]

- Imaduddin, F.; Nizam, M.; Mazlan, S.A. Response of a magnetorheological brake under inertial loads. Int. J. Electr. Eng. Inform. 2015, 7, 308–322. [Google Scholar]

- Hudha, K.; Jamaluddin, H. Simulation and experimental evaluation on a skyhook policy-based fuzzy logic control for semi-active suspension system. Int. J. Struct. Eng. 2011, 2, 243–272. [Google Scholar]

- Chen, S.; Yang, J. Probing slip differential heat of magnetorheological fluids subjected to shear mode operation and its effect on the structure. Materials 2019, 12, 1860. [Google Scholar] [CrossRef] [PubMed]

- Tak, R.S.S.; Kumar, H.; Chandramohan, S.; Srinivasan, S. Design of twin-rod flow mode magneto rheological damper for prosthetic knee application. AIP Conf. Proc. 2019, 2200, 020045. [Google Scholar]

- Meng, F.; Zhou, J.; Jin, C.; Ji, W. Modeling and experimental verification of a squeeze mode magnetorheological damper using a novel hysteresis model. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5253–5263. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, J. Modeling and Control of a Shear-Valve Mode MR Damper for Semiactive Vehicle Suspension. Math. Probl. Eng. 2019, 2019, 2568185. [Google Scholar] [CrossRef]

- Tu, J.; Li, Z.; Zhang, J.; Gao, K.; Liao, J.; Gao, J. Development, test, and mechanical model of the leak-proof magnetorheological damper. Front. Mater. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Yu, J.; Dong, X.; Wang, X.; Li, J.; Li, B. Design, modeling, and control of a magnetorheological rotary damper for scissor seat suspension. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 1–15. [Google Scholar] [CrossRef]

- Nabaei, V.; Chandrawati, R.; Heidari, H. Magnetic biosensors: Modelling and simulation. Biosens. Bioelectron. 2018, 103, 69–86. [Google Scholar] [CrossRef]

- Seid, S.; Chandramohan, S.; Sujatha, S. Optimal design of an MR damper valve for prosthetic knee application. J. Mech. Sci. Technol. 2018, 32, 2959–2965. [Google Scholar] [CrossRef]

- Daniel, C.; Hemalatha, G.; Sarala, L.; Tensing, D.; Manoharan, S.S. Magnetorheological fluid with nano Fe3O4 for performance enhancement of MR damper for seismic resistance of steel structures. Key Eng. Mater. 2018, 763, 975–982. [Google Scholar] [CrossRef]

- Yu, J.; Dong, X.; Wang, W. Prototype and test of a novel rotary magnetorheological damper based on helical flow. Smart Mater. Struct. 2016, 25, 25006. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, F.; Zhang, C.; Chen, C.; Wang, D. Recent Advances in Intelligent Manufacturing; Springer: Singapore, 2018; Volume 923, ISBN 978-981-13-2395-9. [Google Scholar]

- Wei, M.; Rui, X.; Zhu, W.; Yang, F.; Gu, L.; Zhu, H. Design, modelling and testing of a novel high-torque magnetorheological damper. Smart Mater. Struct. 2020, 29. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, J.Q.; Yang, Y.; Wei, Y.Q. Analysis and design of a cylindrical magneto-rheological fluid brake. J. Mater. Process. Technol. 2002, 129, 559–562. [Google Scholar] [CrossRef]

- Li, W.H.; Du, H. Design and experimental evaluation of a magnetorheological brake. Int. J. Adv. Manuf. Technol. 2003, 21, 508–515. [Google Scholar] [CrossRef]

- Senkal, D.; Gurocak, H. Serpentine flux path for high torque MRF brakes in haptics applications. Mechatronics 2010, 20, 377–383. [Google Scholar] [CrossRef]

- Idris, M.H.; Imaduddin, F.; Mazlan, S.A.; Choi, S.B. A concentric design of a bypass magnetorheological fluid damper with a serpentine flux valve. Actuators 2020, 9, 16. [Google Scholar] [CrossRef]

- Hidayatullah, F.H.; Purnomo, E.D.; Tjahjana, D.D.D.P.; Wiranto, I.B. Design and simulation of a combined serpentine T-shape magnetorheological brake. Indones. J. Electr. Eng. Comput. Sci. 2019, 13, 1221–1227. [Google Scholar] [CrossRef]

- Patel, Y.H.; Patel, D. Geometrical Optimization of Magnetorheological Fluid Based Rotary Damper. Int. J. Pure Appl. Math. 2018, 119, 1991–1999. [Google Scholar]

- Wang, M.; Chen, Z.; Wereley, N.M. Magnetorheological damper design to improve vibration mitigation under a volume constraint. Smart Mater. Struct. 2019, 28, 114003. [Google Scholar] [CrossRef]

- Wang, J.; Zhan, J.; Wang, Y.; Hu, L. Correction of Constitutive Equation for Magnetorheological Fluid Torque Servo Control. In Proceedings of the 2019 IEEE 9th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Suzhou, China, 29 July–2 August 2019; pp. 335–340. [Google Scholar]

| Property | Value |

|---|---|

| Appearance | Dark grey liquid |

| Viscosity, Pa·s | 0.112 |

| Density, | 2.95–3.15 |

| Solid contain by weight, % | 80.98 |

| Flashpoint, | >150 |

| Operational temperature, | −40 to +130 |

| Part | Type | Material |

|---|---|---|

| Casing | Magnetic | Mild Steel |

| Non-Magnetic Bobbin | Non-Magnetic | Aluminium |

| Magnetic Bobbin | Magnetic | Mild Steel |

| Magnetic Inner Cylinder | Magnetic | Mild Steel |

| Non- Magnetic Inner Cylinder | Non-Magnetic | Copper |

| Rotor | Non-Magnetic | Aluminium |

| Parameter | Symbol | Value |

|---|---|---|

| Inner radius of screw | Rp | 5 mm |

| Outer radius of screw | Rd | 7 mm |

| Radius of annular channel | R | 12 mm |

| Length of annular channel | L | 14 mm |

| Helical angle of screw | θ | 45° |

| Width of MRF gap | d | 0.5 |

| Parameter | Flow Mode MRB Serpentine Flux (a) | Yu (2016) [21] | Senkal (2010) [26] | Hidayatullah (2019) [28] |

|---|---|---|---|---|

| Max. T (Nm) | 2.86 | 80 | 10.9 | 2.1 |

| T off state (Nm) | 0.01 | 26 | <0,1 | <0.1 |

| Volume (m3) | 7 × 10−5 | 1.9 × 10−3 | 2.9 × 10−4 | 7.3 × 10−5 |

| T/V (x104 N/m2) | 4.05 | 4.1 | 3.8 | 2.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Satria, R.R.; U. Ubaidillah; Imaduddin, F. Analytical Approach of a Pure Flow Mode Serpentine Path Rotary Magnetorheological Damper. Actuators 2020, 9, 56. https://doi.org/10.3390/act9030056

Satria RR, U. Ubaidillah, Imaduddin F. Analytical Approach of a Pure Flow Mode Serpentine Path Rotary Magnetorheological Damper. Actuators. 2020; 9(3):56. https://doi.org/10.3390/act9030056

Chicago/Turabian StyleSatria, Rivananda Rama, U. Ubaidillah, and Fitrian Imaduddin. 2020. "Analytical Approach of a Pure Flow Mode Serpentine Path Rotary Magnetorheological Damper" Actuators 9, no. 3: 56. https://doi.org/10.3390/act9030056

APA StyleSatria, R. R., U. Ubaidillah, & Imaduddin, F. (2020). Analytical Approach of a Pure Flow Mode Serpentine Path Rotary Magnetorheological Damper. Actuators, 9(3), 56. https://doi.org/10.3390/act9030056