Abstract

Ionic electromechanically active polymers (IEAP) are laminar composites that can be considered attractive candidates for soft actuators. Their outstanding properties such as low operating voltage, easy miniaturization, and noiseless operation are, however, marred by issues related to the repeatability in the production and operation of these materials. Implementing closed-loop control for IEAP actuators is a viable option for overcoming these issues. Since IEAP laminates also behave as mechanoelectrical sensors, it is advantageous to combine the actuating and sensing functionalities of a single device to create a so-called self-sensing actuator. This review article systematizes the state of the art in producing self-sensing ionic polymer actuators. The IEAPs discussed in this paper are conducting (or conjugated) polymers actuators (CPA), ionic polymer-metal composite (IPMC), and carbonaceous polymer laminates.

1. Introduction

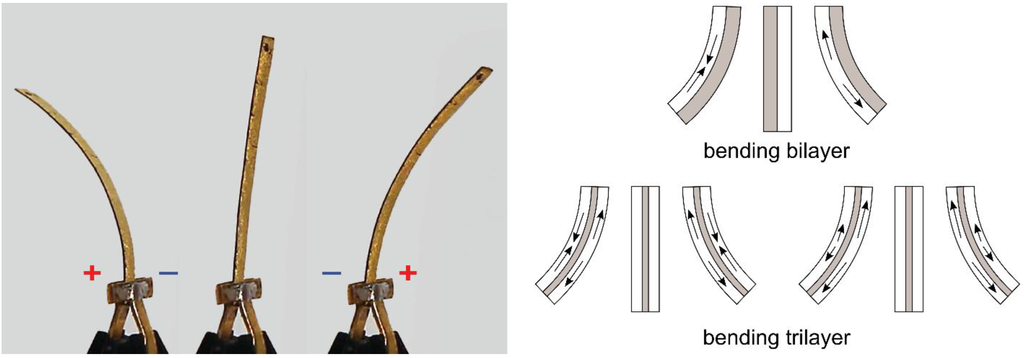

Since electromechanically active polymers (EAP) exhibit mechanical deformation when subjected to electric stimulus [1] they are considered advantageous for creating various types of actuators. More specifically, ionic EAPs (IEAPs) are one of the main types of EAPs that can be used to create small and soft actuators that operate under very low voltage (typically 1–3 V). A common IEAP is a laminar structure that bends when voltage is applied to it in a cantilever configuration (Figure 1) [1,2,3,4,5,6,7], though many other motion patterns (e.g., linear [8], twisting [9], and spiral [10]) are attainable.

Figure 1.

Bending ionic electromechanically active polymer (IEAP) actuator.

Analogously to the well-known bimetals, the bending of IEAPs is a result of the difference of small-scale strains generated within the individual layers of the laminar structure [11]. In a cantilever configuration, these relatively small longitudinal strains translate into a fairly large-scale bending (Figure 1). Even though different IEAPs exhibit visually similar responses, the specific mechanisms for generating the strains are often different and depend on the composition of these materials [1,2,3,4,5,6,7]. At a general level, it can be stated that the longitudinal strain difference is a result of volumetric changes of select layers due to electrically-induced migration of mobile ions within the soft laminar structure [1,2,3,4,5,6,7].

IEAPs stand out as strong candidates for actuators in a wide ranges of applications including but not limited to biomimetic robotics [12,13,14,15,16], varifocal optics [17,18,19], haptic displays [20,21], space technology [22,23], microfluidic systems [24,25,26], and biology-on-chip devices [27]. The large number of possible application areas can be attributed to the unique properties of these actuators, such as softness, silent operation, fairly simple structure that allows easy miniaturization, adjustable actuation trajectories, ability to function in liquid environments, and optionally metal-free composition, to name a few. Furthermore, a number of these materials are also known to function as sensors for detecting motion [28,29,30], curvature [31,32], humidity [33,34], or other ambient parameters [35].

On the downside, the electromechanical response of IEAPs is also known to be dependent on ambient parameters such as humidity and temperature [34,36]. Issues of repeatability can emerge due to viscoelastic creep that depends both on the temperature of the environment as well as the heating induced by the actuator’s driving signal [37,38,39,40]. The performance of IEAP actuators has been reported to change both because of repeated work-cycles as well as the spontaneous deterioration [23,41]. Furthermore, several types of IEAPs suffer from so-called back-relaxation: a process where after initial bending, the actuator moves towards its starting position even though a constant voltage is applied [42,43,44,45]. Therefore, a closed-loop control (i.e., exact positioning using a feedback signal) of an IEAP device is required.

However, say a soft actuator is downscaled for micro applications or placed in liquid environments, the feedback sensor must operate under similar conditions. Since typically video cameras or laser distance meters are used for acquiring feedback signal, the use of external sensors can limit the applicability of IEAP actuators. One solution would be to combine the IEAP’s own ability to sense motion and/or curvature with their actuation property, thus creating a so-called self-sensing actuator.

This review article systematizes the advancements towards fully self-sensing ionic polymer devices, i.e., the research related to utilizing simultaneously the actuating and sensing properties of IEAP materials. The next section introduces the general approaches for designing self-sensing polymer actuators and, thus, specifies the scope of this review article. Section 3, Section 4 and Section 5 describe the self-sensing actuator systems implementing the main three IEAP types: conducting polymer actuators (CPA) [2,3], ionic-polymer metal composites (IPMC) [4], and carbonaceous polymer laminates [5,6,7]. Section 6 provides a brief overview of alternatives to the self-sensing approach.

2. Self-Sensing Actuator

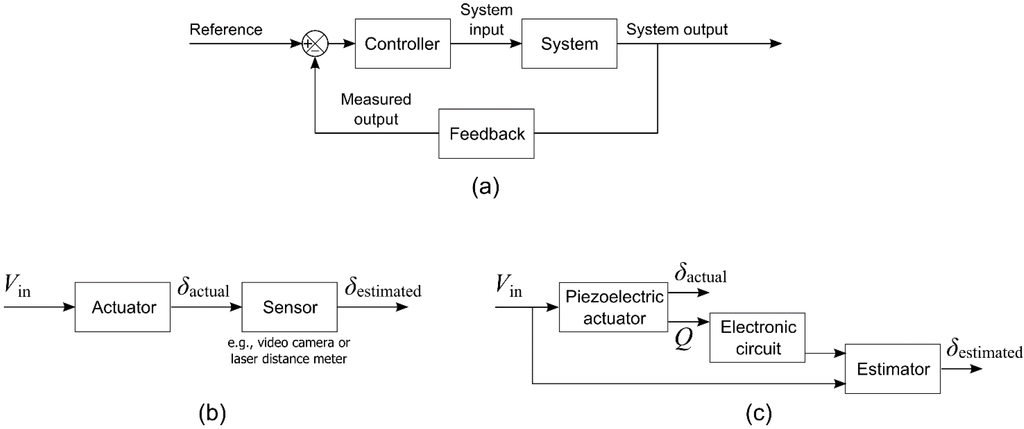

In the classical control theory, a closed-loop controller refers to a setup where a certain target output (e.g., displacement or torque) of a dynamic system (e.g., electromechanical actuator) is achieved by feeding the present output of the system back to modify its input (Figure 2a). While a conventional closed-loop control of an actuator utilizes an external sensor to directly measure the system output (Figure 2b), a so-called self-sensing system estimates the output from the actuator itself. Thus, a self-sensing actuator exploits its actuation and sensory functionality simultaneously. Figure 2c depicts an example of self-sensing piezoelectric system that uses the electric charge to implicitly estimate the displacement δ of an actuator.

Figure 2.

(a) Description of a closed-loop control system; (b) conventional sensor-based systems for estimating displacement δ of an actuator; (c) example of self-sensing estimation of displacement δ based on the charge Q of a piezoelectric actuator (subplot (c) adapted and redrawn from [46]).

A significant milestone for smart material actuators was established in 1992 when Dosch et al. introduced a self-sensing piezoelectric actuator that used specially designed electronic circuits for estimating the position and velocity from electric charge [47]. The validity of this self-sensing system was demonstrated in a closed-loop configuration that actively suppressed the vibration in a cantilever beam [47]. Ever since there has been a steady drive to improve self-sensing piezoelectric systems [46,48] and to implement self-sensing for other types of smart actuators including electroactive polymers [49,50,51], shape-memory alloys [52], and magnetostrictive materials [53].

In the case of ionic polymer materials, the basis for the self-sensing signal is typically a particular electrical parameter that has been shown to correlate with the mechanical behavior (e.g., amplitude or rate of bending) of the actuator. This electrical parameter can be, for example, the current generated between the electrodes of an IEAP due to external manipulation [28,29,30] or the deformation-dependent impedance (including capacitance and resistance) [31,32] of the multilayer IEAP or its parts. After accurately locating and describing such mechanoelectrical correlation, curvature or force of the IEAP actuator can be estimated by measuring this electrical parameter, thus yielding a feedback signal for the closed-loop control. The term self-sensing has, however, no strict definition and thus multiple interpretations exist. In the current review, self-sensing refers to a system where the same piece of material is simultaneously used for actuation and sensing.

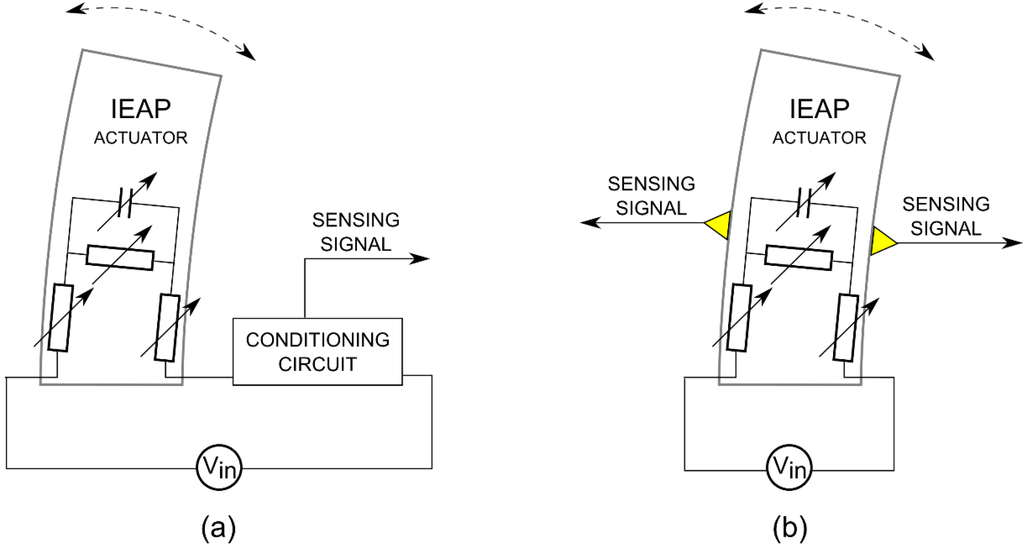

Figure 3.

Self-sensing IEAP systems based on deformation-dependent internal parameters.

Due to the high level of integration in self-sensing actuator systems, the extraction of viable feedback signal requires a complex mathematical modelling and electronic signal processing unit [54]. To this day, decoupling sensing and actuating operations remain as the biggest challenge, especially for the self-sensing ionic polymer actuators reviewed herein. The wide range of methods used to measure and extract relevant sensing signal in self-sensing electroactive polymer actuator systems can be categorized into three general approaches as follows.

- (1)

- Using external circuit to detect relevant sensing data from the input voltage/current (Figure 3a) (see e.g., [51,55,56]).

- (2)

- (3)

- Actuator is driven with a special signal that has been modified for sensing purposes (this method is typically combined with the previous two methods (see e.g., [49,59,60]).

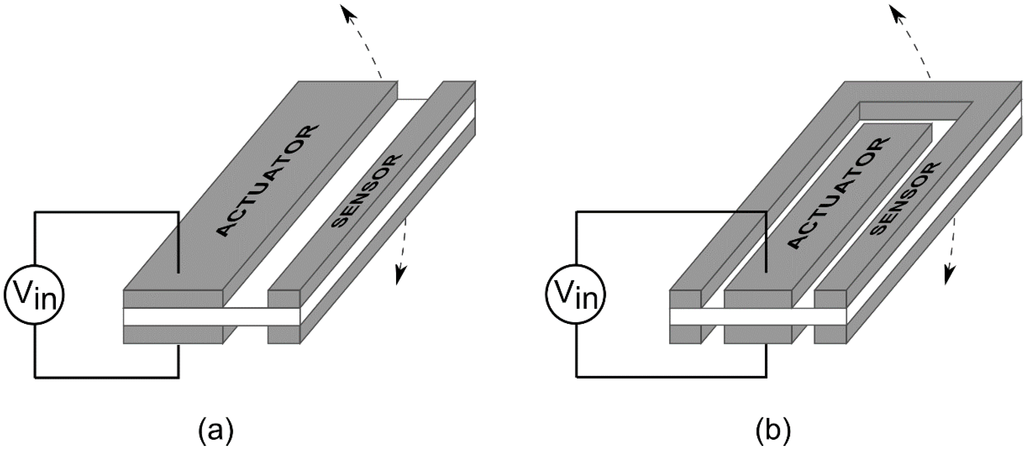

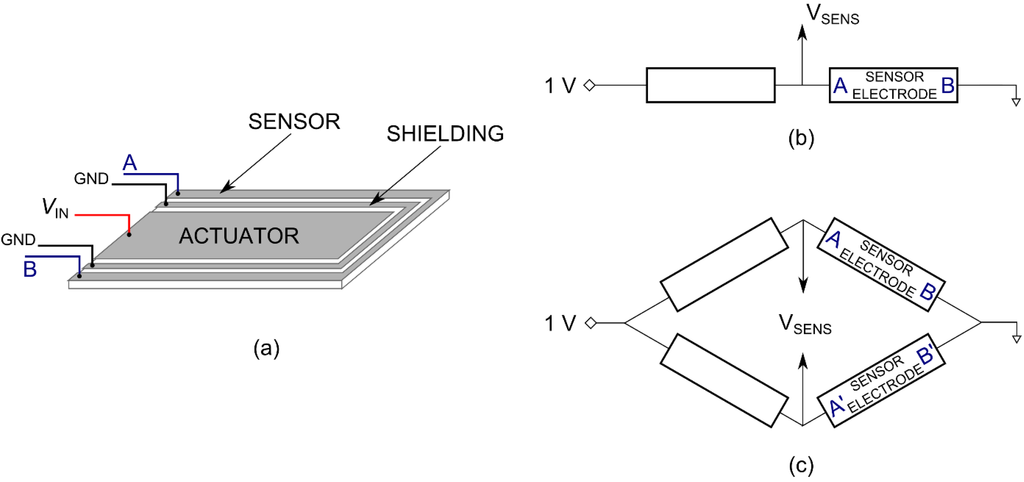

Another approach for creating a self-sensing system is to divide the EAP actuator into electrically insulated but physically intact sections (i.e., patterning the electrode layers) so that one section is used only as sensor while the other is responsible for actuating the whole structure (Figure 4).

Figure 4.

Self-sensing IEAP systems with patterned electrodes.

There are several smart systems which consist of an IEAP actuator mechanically coupled with a separate piece of sensor material to provide the feedback signal. Examples of such configurations include IPMC actuators linked side-by-side with IPMC sensors [61,62,63] and IPMC actuators stacked with other IPMCs [64], piezoelectric sensors [65,66] or resistive strain gages [67]. From the perspective of potential applications, such mechanically well-coupled systems provide similar functionality to self-sensing and, hence, they are—although not considered in the scope of this review article—briefly outlined in Section 6.

3. Conducting Polymer Actuators

3.1. Conducting Polymer Actuator and Sensor

Bending conducting polymer actuators are usually bi- or trilayer structures that are composed of a single electromechanically inert layer coated by a conducting polymer (e.g., polypyrrole or PEDOT) electrode on one or both sides. The strain difference responsible for bending is generated by reversible electrochemical reactions within the conducting polymer layer. When the conducting polymer electrode layer is oxidized or reduced, mobile ions enter or exit this layer causing volumetric change [2,3]. For operation, the CPA is either placed in an electrolyte solution or contains electrolyte (such as ionic liquid). Dissimilarly to other ionic polymer actuators of this article, CPAs are considered faradaic devices as their working mechanism is based on electrochemical redox reactions [3].

Trilayer CPAs can also be utilized as mechanoelectrical transducers that generate electrical signal between the electrodes when the laminate is subjected to external bending deformation [30]. The phenomenon is explained by the flux of mobile ions due to externally caused stresses within the polymer [30,68,69]. Since the flow of ions subsides under a steady state, the CPA sensor cannot be used to detect absolute deformation.

3.2. Self-Sensing CPA

Instead of implementing the previously described sensing functionality, the leading self-sensing CPA systems make use of their faradaic nature. Namely, a full concept of self-awareness has been developed based on what Otero et al. refer to as the reformulated Le Chatelier principle: “any chemical or physical perturbation of the chemical reaction rate driving the device actuation shifts the reaction energy to fit the new imposed energetic requirements” [56]. In other words, when a CPA is driven with a constant current (i.e., at a constant electrochemical reaction rate), the potential compensates any physical or chemical perturbations, thereby acting as a sensor signal able to detect the rate of movement [70], trailing weight [71,72], temperature [73] and electrolyte concentration [35]. A comprehensive review on the physical and chemical awareness of conducting polymer actuators has been recently published by Otero et al. [56].

In order to realize the closed-loop position control of a CPA, a self-sensing design exploiting the motion-induced signal generated between the electrodes of the trilayer structure has also been proposed [74]. This self-sensing system would adopt the patterned electrode design depicted in Figure 4a where the sensor and actuator parts are electrically insulated but physically linked by the inert polymer backbone. A theoretical concept for such a self-sensing CPA system is provided in [74].

4. Ionic Polymer-Metal Composite Actuators

4.1. IPMC as Actuator and Sensor

Ionic polymer-metal composite is a type of IEAP where an ionic membrane (e.g., Nafion) is plated by thin noble metal (e.g., platinum or gold) electrodes, thus forming a soft capacitor-like trilayer structure [1,4]. To balance the electric charge of the ionic polymer membrane, the IPMC contains mobile ions. Until the emergence of room temperature ionic liquids as the electrolytes for the so-called dry actuators, IPMCs were mainly operated in deionized water. When a voltage is applied to the metal electrodes of an IPMC, it causes directional motion of mobile cations together with water molecules. The excess of cations and water near the negatively charged electrode causes swelling which results in bending toward the positive electrode. It is a general understanding that the magnitude of bending deformation is strongly related to the charge accumulated by the electrical double-layers emerging at the boundary of metal electrodes [75,76].

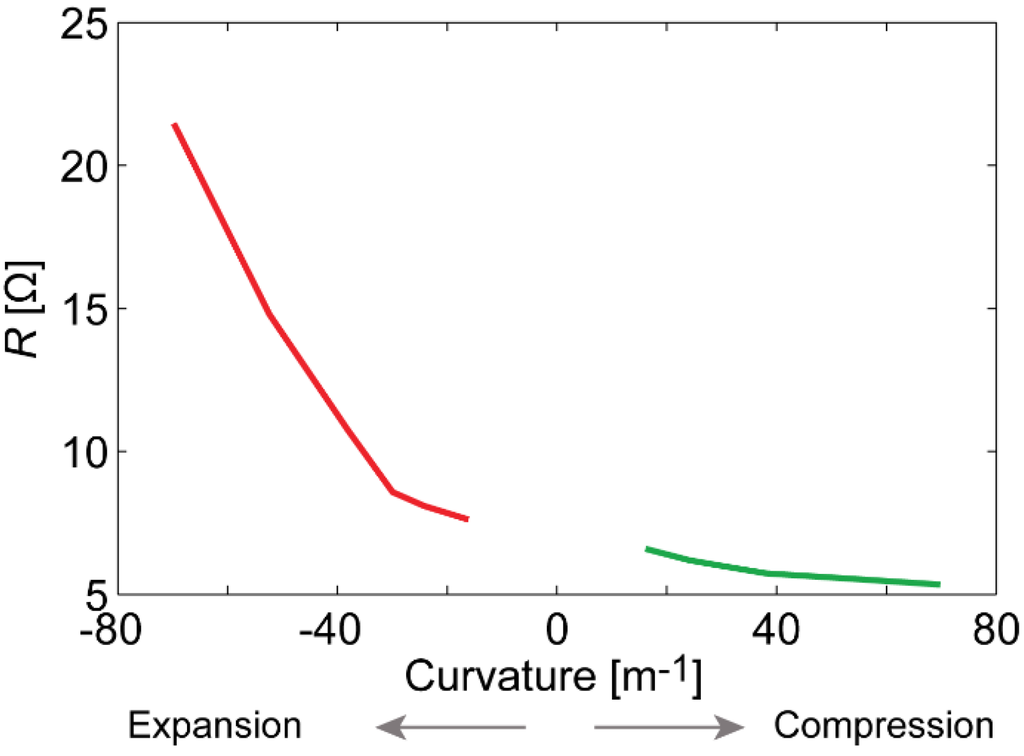

IPMCs can also be used as sensors detecting motion and deformation. When externally manipulated, a small (in the order of few millivolts) amplitude electrical signal is generated between the electrodes of IPMC. Competing theories attribute this phenomenon to a mechanically-induced ionic motion and thus, at a steady deformation state the electrical signal dissipates [28,77,78]. While such a direct transduction from mechanical to electrical energy is advantageous for vibration detection and energy harvesting, it is impractical for position sensing, especially for systems where actuator remains bent for a longer period of time. On the other hand, the electrode resistances of an IPMC depend on its curvature so that the resistance of convex electrode increases while that of a concave electrode decreases (Figure 5 and Figure 6a) [31]. As seen in Figure 5, the change in resistance is asymmetric exhibiting larger variation in the case of electrode expansion (convex side) than that of electrode compression (concave side). Even though active input is required for measuring the resistance of the electrode, the sensing signal is easily detectable and can be used to estimate actuator position in a steady state [31,57].

Figure 5.

Example of the relation between the curvature and the electrode resistance of an IPMC with platinum electrodes.

4.2. Self-Sensing IPMC

In order to create self-sensing IPMC, it is necessary to measure at least one of the sensing signals during the work-cycle of the actuator, i.e., while driving voltage is applied. Since the amplitude of sensing signal generated between the electrodes is very small in comparison to the actuation voltage, the electrical noise or cross-talk becomes a critical issue. Estimating the position of the actuator from electrode resistance will allow more prominent sensing effect but it poses the challenge of measuring the resistance of an electrically active system.

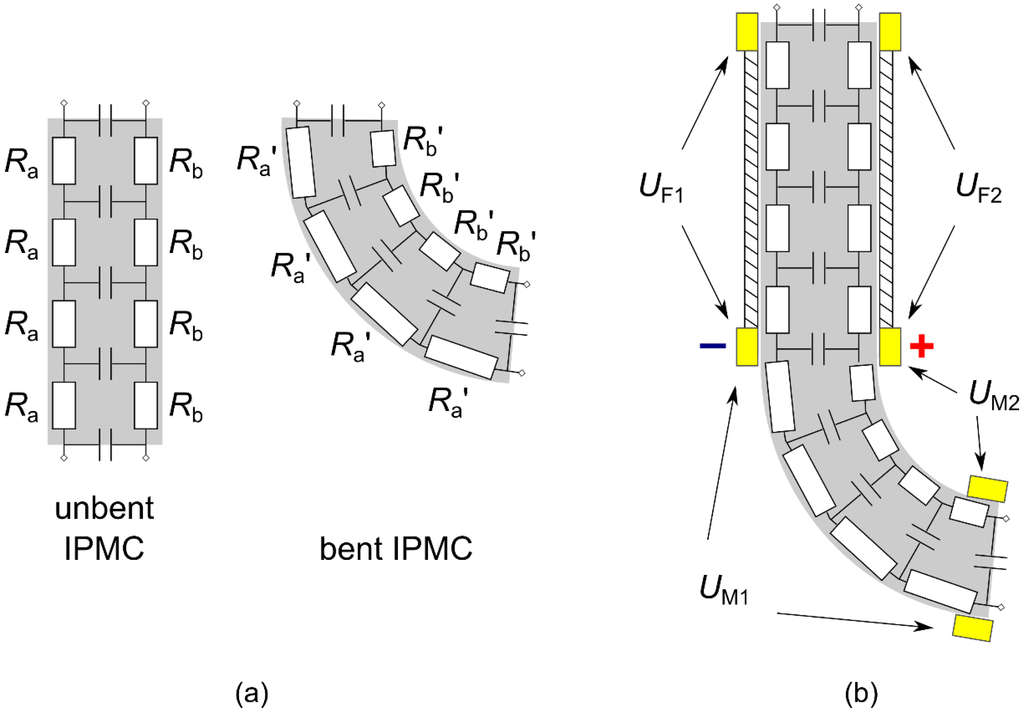

Punning et al. proposed regarding IPMC as a transmission line with an equivalent circuit containing curvature-dependent resistors (Figure 6a) [57]. By attaching additional wiring to the moving tip of the actuator, it is possible to directly measure the voltage drop along each electrode of the IPMC [31,57]. Although these voltage drops contain information about the alteration of resistance, they are dominated by the charging of the IPMC transmission line. In order to separate the component describing only the alteration of resistance, half of the IPMC sheet was mechanically fixed between rigid plates (Figure 6b). When the driving voltage is applied in the middle section of such an IPMC system, the deformation dependent resistors of the fixed half remain constant and thus the signals (UF1 and UF2 in Figure 6b) act as references for the moving part (UM1 and UM2 in Figure 6b) with varying electrode resistances. Even though by referencing UM to UF the self-sensing actuator can distinguish between several externally imposed deformations and completely unobstructed bending [57] (Figure 7), the differential sensing signal is still distorted by some noise. The source of this noise may be the inhomogeneity of the material (i.e., fixed and moving halves are not identical) or the dynamic behavior of other components in the transmission line model of the IPMC.

Figure 6.

(a) Equivalent circuit of IPMC undergoing bending. (b) Equivalent circuit of self-sensing IPMC actuator proposed by Punning et al. [57].

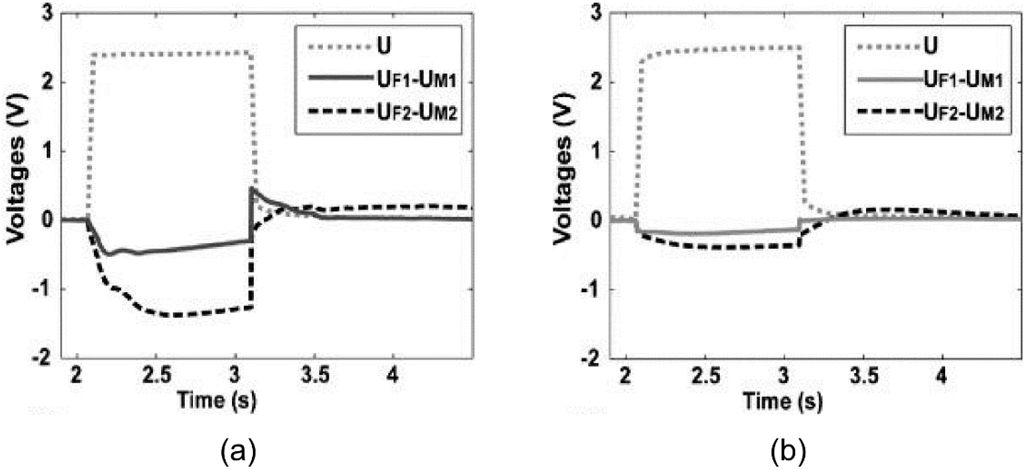

Figure 7.

(a) Difference of voltage drops when the self-sensing actuator is bending to the left by input voltage. (b) The driving voltage of the self-sensing actuator causes bending to the left, but the actuator is obstructed by an external force. U denotes the driving signal and UF1, UF2, UM1, UM2 are explained in Figure 6b. Reprinted from [57], Copyright 2007, with permission from Elsevier.

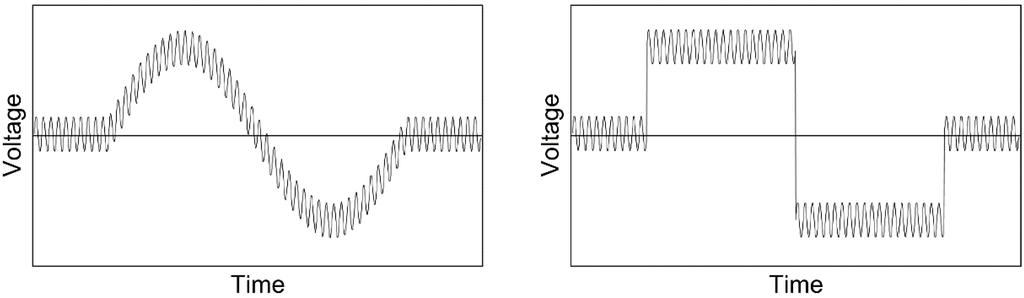

In order to specifically measure the alteration of resistance with the voltage drops UM and UF, Fang et al. added a small amplitude high-frequency (1 kHz) sinusoidal signal to the driving voltage of the self-sensing actuator depicted in Figure 6b [60]. Examples of such composite driving signals are illustrated in Figure 8. The frequency of the added signal is chosen well outside the electromechanical bandwidth of the IPMC actuator. With an appropriate high-pass filter the high-frequency component of the differential signal UM–UF can be separated and its amplitude is proportional to the actuator’s bending deformation [60]. While noise-related issues were not completely overcome, a proof-of-concept for an active guide-wire system with a self-sensing IPMC was demonstrated [60].

Figure 8.

Composite input voltages where a high-frequency component for sensing the resistance is added to the low-frequency driving signal.

A nonlinear black-box model using a theory of neural networks [58,79,80] and a physics-based model adopting an electrical equivalent circuit with dynamic components [81,82] have been developed to estimate the bending deflection from the combination of voltages measured at the fixed and moving parts in Figure 6b. A closed-loop control of the IPMC actuator was realized by using the estimated self-sensing signal together with quantitative feedback theory (QFT) [82]. Although relatively good estimation of the tip displacement of a freely bending part is attained, it is unclear whether the modeling in [58,79,80,81,82] is also capable of detecting external obstructions and back-relaxation.

The hereinabove described studies indicate that as long as the dynamics of IPMC are not fully understood, it is an ongoing challenge to create a robust self-sensing system based on measuring electrode signals of the actuator. On the other hand, it is possible to pattern the electrodes of a single piece of IPMC in a way that different sections are created for actuator and sensor (Figure 4). When sufficient insulation is obtained, the actuator and sensor parts can be regarded as two electrically independent devices that have very good mechanical coupling due to the shared polymer backbone.

Since patterning is also implemented for creating multi-degree-of-freedom actuators, a number of methods for segmenting IPMC electrodes have been developed, see e.g., [9,83,84,85]. Many of the patterning methods, such as machining, laser ablation, and inkjet printing are scalable to mass production and may be considered technologically less complex in comparison to integrating a separate sensor with an ionic actuator (as discussed in Section 6).

Patterning actuator and sensor electrodes in parallel (Figure 4a) is advantageous for using the IPMC sensor in the generative mode, i.e., the electric signal is measured between the opposite electrodes of the sensing element [86,87,88,89]. However, the adjacent electrode segments exhibit both capacitive and resistive coupling [87,88], causing significant cross-talk from actuator segment to sensor. Nakadoi et al. estimated that merely 0.3% of the amplitude of the signal acquired from the adjacent sensor represents the information about bending deformation [87]. Nevertheless, the level of noise reduces with every additional electrode created between the actuating and sensing segments [88].

Even though the sensor segment depicted in Figure 4a can also be used for sensing deformation via the variation of electrode resistance, it is more practical to place the sensor segment around the actuator as depicted in Figure 4b [90]. Such configuration allows the measurement of resistance without any additional wiring to the moving tip and as the length of sensing electrode is more than doubled, sensitivity is enhanced. In order to overcome the issues of cross-talk, the following two methods can be implemented concurrently or individually [90,91].

- (1)

- Creating of a shielding electrode between the sensor and actuator (Figure 9a) which is connected to the system ground.

- (2)

- Connecting the opposite sensor electrodes in a bridge configuration and, thus, cancelling out the common mode noise in the sensing signal (Figure 9c).

Figure 9.

(a) Self-sensing IPMC with patterned electrodes and methods for acquiring sensing signal by using (b) voltage divider or (c) bridge circuits. A’ and B’ denote the sensing electrode on the opposite side that is not visible in subplot (a).

The self-sensing IPMC system with coincident patterning (depicted in Figure 9a) on both electrode layers manages to overcome several of the technical issues plaguing its predecessors. The cross-talk from actuator to sensor can be successfully suppressed by the two previously listed methods [90]. Moreover, as the electrode resistance depends on the mechanical deformation, this system can be used to detect the constant position over extended time, external obstructions, and possibly back-relaxation [85,90,91]. The sensing electrodes can be modeled as strain gages to estimate bending deformation from the change of resistance [85].

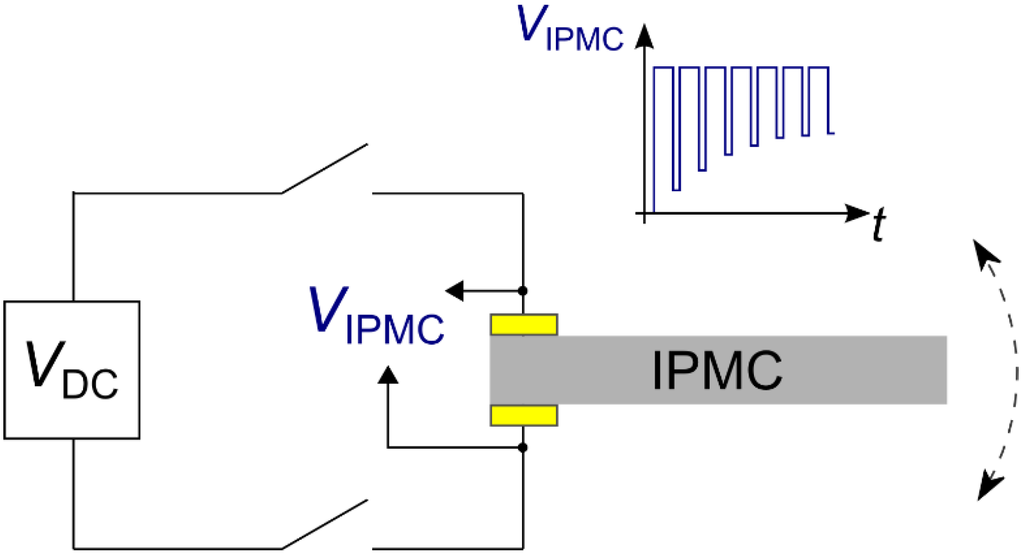

Similarly to piezoelectric actuators, the accumulated charge may be used to estimate displacement of self-sensing IPMC actuators [55]. However, the charging curve depends heavily on ambient conditions such as humidity [55,92] and it is negligibly influenced by the actual deformation of IPMC (e.g., external obstruction or back-relaxation may not be explicitly recognized). Therefore, this approach can only be implemented in a fixed electromechanical bandwidth and controlled environment where the function for displacement δ = f (Q) is invertible so that charge Q = f−1 (δ). When the previous criteria are met, closed-loop control of a self-sensing IPMC is obtained by measuring and integrating the current flowing through the actuator [55]. Furthermore, Ko et al. showed that the charge can be measured directly from the electrodes of IPMC when a pulse-width-modulated (PWM) signal is used to drive the actuator in a free run mode, i.e., during the low state of the PWM signal the IPMC is disconnected completely from the power supply or connected to a high impedance source (Figure 10) [93]. The latter setup is advantageous due to its straightforward design as there exists a wide range of commercially available microchips to generate suitable PWM signals.

Figure 10.

Self-sensing IPMC proposed by Ko et al. [93].

5. Carbonaceous Polymer Actuators

5.1. Carbonaceous Polymer Composites as Actuators and Sensors

Ionic polymer actuators with electrode layers that contain some particular allotrope of carbon (e.g., nanotubes, graphene, and carbide-derived carbon) are the newest of the three main categories of IEAPs [5,6,7]. Due to the wide selection of carbons used for creating the electrodes of these actuators, no uniform naming convention has been agreed upon. Nevertheless, the general structure of these materials is similar to trilayer IPMCs and CPAs with the exception that the conductivity of electrode layers comes from carbon particles [5,6,7]. In order to obtain soft and uniform electrode films these carbon particles may be mixed together with suitable ionic liquid and polymer [6].

The detailed working mechanism of carbonaceous polymer actuator is a subject of ongoing dispute and may actually vary depending on the exact composition of electrodes [5]. However, the use of porous carbons is related to their high specific area that accommodates the formation of large electric-double layers and, thus, the bending is attributed to the ion-transport-induced volumetric difference of opposite electrodes [5,6,7].

The amount of research about the sensing functionality of carbonaceous polymer laminates is rather modest but, so far, all the familiar sensing phenomena—generating signal in response to externally-induced motion [29,94,95] and curvature-dependent alteration of electrode resistance [32,96]—have been reported for at least actuators incorporating carbon nanotubes or carbide-derived carbon in their electrodes.

5.2. Self-Sensing Carbonaceous Polymer Actuator

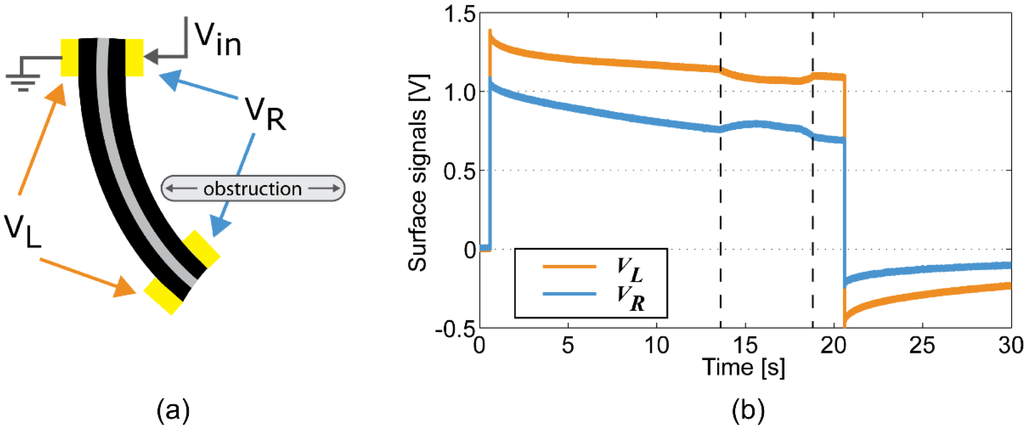

As the majority of carbonaceous polymer actuators are considered non-faradaic devices, the research involving their possible self-sensing properties is largely inspired by the concepts implemented for IPMCs. By measuring voltage drops along the bending carbide-derived-carbon-based actuator, it is possible to detect collision with external obstruction (Figure 11) [32]. Similarly to IPMCs, it has been observed that such a system is able to distinguish between free and obstructed bending [32,97] but transient position estimation is challenging until the working mechanisms of the actuator are fully understood.

Figure 11.

(a) Measurement setup for acquiring voltage drops during the work-cycle of a carbide-derived-carbon-based actuator; (b) voltage drops along the electrodes of this actuator, free movement of the actuator was obstructed at the 14th second of the experiment. Figure is adapted from [32].

Tanaka et al. produced a self-sensing system by patterning the electrode layers of a bucky-gel actuator so that the actuator and sensor are placed in parallel (see Figure 4a) [96]. By using the sensor part of the system in the generative mode, the cross-talk signal was compensated by modeling it as a linear time-invariant system. The obtained self-sensing data was successfully utilized as a feedback signal for self-excited actuation of the whole device. Furthermore, sensing based on the electrode resistance was also experimentally studied for the same system that consists of an actuator and sensor side-by-side. After testing three different bridge configurations, it was concluded that the differential measurement scheme depicted in Figure 9c yields the best results for both position sensing and noise suppression.

For an IEAP containing carbide-derived carbon, the electrodes were patterned in accordance to the design where sensor is positioned around the actuator segment and shielded by intermediate electrode [98] (see also Figure 9a). The sensing electrode worked well for detecting externally induced deformations but as the passive segments constituted roughly 75% of the whole system, the overall actuation remained relatively small [98].

Analogously to IPMC systems, Tamagawa et al. showed that the closed-loop control of a Nafion-based IEAP with electrodes containing multi-walled carbon nanotubes is possible under conditions where charge unequivocally determines the bending curvature of such an actuator [99]. However, the issues and limitations related to this type of self-sensing system are similar to those raised in Section 4.

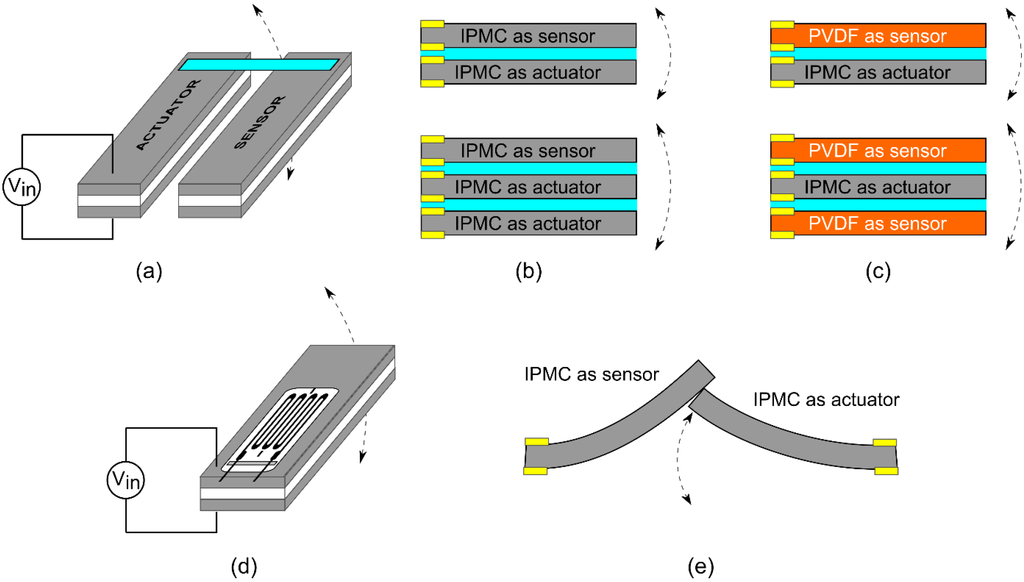

6. Alternatives to Self-Sensing: Mechanically Coupled Integrated Sensing

As noted in Section 2, there are many mechanically well-integrated systems that incorporate ionic polymer materials and offer similar functionality to self-sensing actuators. This section aims to highlight some key concepts in obtaining compact systems that utilize or could potentially utilize closed-loop control of an ionic polymer actuator. The following is by no means an exhaustive reference of such studies, rather it gives additional insight to the previously described self-sensing systems as somewhat similar designs and corresponding issues are discussed. Figure 12 depicts the diversity of integrated actuator-sensor systems using ionic polymer actuators.

Figure 12.

Mechanically coupled integrated sensing for ionic polymer actuators. (a) Actuator and sensor placed in parallel while linked by a non-conductive rigid clamp. (b) Multilayer ionic stacked actuator-sensor systems. (c) IPMC actuator stacked with PVDF that acts as a piezoelectric sensor. (d) Strain gage attached to a bending ionic actuator. (e) Sensor system for detecting softness of a colliding object.

Firstly, there are many studies where actuator and sensor of the same ionic polymer transducer are placed in parallel and linked rigidly to ensure that sensor bends together with the actuator (Figure 12a) [61,62,63,100]. In this setup, the sensor is used in the mode where electrical signal is generated between its electrodes due to the motion of actuator. Closed-loop control of the system using two separate pieces of IPMCs has been implemented with very good accuracy [62,63].

Akle et al. proposed to stack multiple IPMCs on top of each other. Individual IPMC layers are isolated by separate non-conductive films and can thus be electrically connected in parallel or series [64,101]. Moreover, the role of individual IPMCs can be altered based on the requirements of the intended application. Figure 12b depicts a configuration where one IPMC layer behaves as sensor and other as actuator. By varying the number of layers and the ratio of sensors and actuators in the stack (Figure 12b), it is possible to adjust the force and displacement or the sensitivity of the whole device. Since IPMC sensing signal is several orders of magnitude lower than that of a piezoelectric sensor, Chen et al. proposed to stack IPMC actuator with a PVDF sensor (Figure 12c) [65,66]. Both of these systems (Figure 12b,c) suffer from the cross-talk between the actuator and sensor layers and exhibit reduced actuation performance due to passive sensing and insulating layers.

Strain gages are widely used to detect accurate small-scale motion and thus there are many commercially available solutions that already come in lightweight and well-insulated configurations. Research about bonding a small strain gage to the surface of ionic polymer actuator (Figure 12d) shows promising results for estimating bending strain [102,103] and realizing closed-loop control [67].

An interesting integrated actuator-sensor system where an actively oscillating actuator dislocates an ionic sensor as depicted in Figure 12e has also been proposed [104]. Such system can be used for tactile probe as the amplitude of sensing signal varies depending on the presence and softness of external body. By detecting the shift in mechanical resonance frequency it is possible to use this system for identifying changes in ambient conditions.

7. Discussion and Conclusions

In this review article, advancements in creating self-sensing ionic polymer actuators have been presented. The term self-sensing refers to a system where a same piece of IEAP material is acting simultaneously as actuator and sensor so that the sensing signal can be utilized for closed-loop control of the device. The motivation for creating self-sensing IEAP devices is to achieve their closed-loop control in a highly compact way, whilst not limiting the applicability of soft ionic polymer actuators. As the research regarding the development and understanding of IEAP is still an ongoing effort, designing a self-sensing IEAP requires a combination of interdisciplinary skills, e.g., understanding of chemical and physical modelling in addition to very good knowledge of control theory.

While recent developments concerning fully self-sensing IEAP actuators show some very promising results, several challenges still lie ahead. For instance, although a comprehensive theory of self-awareness based on the electrochemical nature of conducting polymer actuators has been devised and experimentally validated [56], it has not yet been successfully implemented for controlling these actuators. Recently, a closed-loop control of self-sensing IPMC which uses the voltage drops along the bending electrodes as the feedback signal has been demonstrated [82]. However, the limitations of this approach need to be studied further as several issues related to decoupling the sensing information from driving signals persist. Initial results for achieving closed-loop control of a self-sensing carbonaceous polymer actuator have also been obtained. A so-called self-driven actuation, which takes only the direction of motion as input, has been realized for a self-sensing bucky-gel actuator with patterned electrodes [96].

Despite there already being many scientific papers where a satisfactory closed-loop control of IEAP actuator is obtained by using external sensors (e.g., [105,106,107]), the amount of studies achieving it in a self-sensing system is relatively low. This is likely because many of the proposed self-sensing IEAP systems still suffer from issues related to noise or these issues have been resolved quite recently. Moreover, one has to consider that the research dedicated to self-sensing IEAPs is relatively young as majority of papers published on the topic are from the past 10 years. However, given that methods such as the patterning of IEAP electrodes provide a good quality feedback signal, development of completely self-sensing closed-loop control seems to be the only logical next step. Since pattering the electrode layers yields a single-piece IEAP device that is analogous to the mechanically coupled systems (Section 6), adoption of similar control methods (e.g., [62,63,67]) can be considered very promising.

Acknowledgments

Andres Punning and Alvo Aabloo would like to acknowledge the support of institutional research funding IUT (IUT20-24) of the Estonian Ministry of Education and Research.

Author Contributions

Karl Kruusamäe reviewed the related journal and conference papers, summarized the literature, and prepared the manuscript; Andres Punning helped collecting the relevant references and assisted in writing the manuscript; Kinji Asaka and Alvo Aabloo planned the study, commented on the overall review, and provided critical input. All the authors approved the final version of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bar-Cohen, Y. Electroactive polymer (EAP) actuators as artificial muscles: Reality, potential, and challenges, 2nd ed.; SPIE Press: Bellingham, WA, USA, 2004. [Google Scholar]

- Smela, E. Conjugated Polymer Actuators for Biomedical Applications. Adv. Mater. 2003, 15, 481–494. [Google Scholar] [CrossRef]

- Otero, T.F.; Martinez, J.G.; Arias-Pardilla, J. Biomimetic electrochemistry from conducting polymers. A review: Artificial muscles, smart membranes, smart drug delivery and computer/neuron interfaces. Electrochim. Acta 2012, 84, 112–128. [Google Scholar]

- Jo, C.; Pugal, D.; Oh, I.-K.; Kim, K.J.; Asaka, K. Recent advances in ionic polymer–metal composite actuators and their modeling and applications. Prog. Polym. Sci. 2013, 38, 1037–1066. [Google Scholar] [CrossRef]

- Kosidlo, U.; Omastová, M.; Micusík, M.; Ćirić-Marjanović, G.; Randriamahazaka, H.; Wallmersperger, T.; Aabloo, A.; Kolaric, I.; Bauernhansl, T. Nanocarbon based ionic actuators—A review. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Asaka, K.; Mukai, K.; Sugino, T.; Kiyohara, K. Ionic electroactive polymer actuators based on nano-carbon electrodes. Polym. Int. 2013, 62, 1263–1270. [Google Scholar] [CrossRef]

- Kong, L.; Chen, W. Carbon Nanotube and Graphene-based Bioinspired Electrochemical Actuators. Adv. Mater. 2014, 26, 1025–1043. [Google Scholar] [CrossRef] [PubMed]

- Torop, J.; Arulepp, M.; Leis, J.; Punning, A.; Johanson, U.; Palmre, V.; Aabloo, A. Nanoporous Carbide-Derived Carbon Material-Based Linear Actuators. Materials 2009, 3, 9–25. [Google Scholar] [CrossRef]

- Kim, K.J.; Pugal, D.; Leang, K.K. A Twistable Ionic Polymer-Metal Composite Artificial Muscle for Marine Applications. Mar. Technol. Soc. J. 2011, 45, 83–98. [Google Scholar] [CrossRef]

- Li, S.-L.; Kim, W.-Y.; Cheng, T.-H.; Oh, I.-K. A helical ionic polymer–metal composite actuator for radius control of biomedical active stents. Smart Mater. Struct. 2011, 20. [Google Scholar] [CrossRef]

- Punning, A.; Vunder, V.; Must, I.; Johanson, U.; Anbarjafari, G.; Aabloo, A. In situ scanning electron microscopy study of strains of ionic electroactive polymer actuators. J. Intell. Mater. Syst. Struct. under review.

- Punning, A.; Anton, M.; Kruusmaa, M.; Aabloo, A. A Biologically Inspired Ray-like Underwater Robot with Electroactive Polymer Pectoral Fins. In Proceedings of the IEEE Confrence on Mechatronics and Robotics 2004, Aachen, Germany, 13–15 September 2004; Volume 2, pp. 241–245.

- Sareh, S.; Rossiter, J.; Conn, A.; Drescher, K.; Goldstein, R.E. Swimming like algae: Biomimetic soft artificial cilia. J. R. Soc. Interface 2013, 10. [Google Scholar] [CrossRef] [PubMed]

- Yeom, S.-W.; Oh, I.-K. A biomimetic jellyfish robot based on ionic polymer metal composite actuators. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- Must, I.; Kaasik, F.; Põldsalu, I.; Mihkels, L.; Johanson, U.; Punning, A.; Aabloo, A. Ionic and Capacitive Artificial Muscle for Biomimetic Soft Robotics. Adv. Eng. Mater. 2015, 17, 84–94. [Google Scholar] [CrossRef]

- Firouzeh, A.; Ozmaeian, M.; Alasty, A.; Iraji zad, A. An IPMC-made deformable-ring-like robot. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- Vunder, V.; Punning, A.; Aabloo, A. Variable-focal lens using electroactive polymer actuator. Proc. SPIE 2011, 7977. [Google Scholar] [CrossRef]

- Lee, H.-K.; Choi, N.-J.; Jung, S.; Park, K.-H.; Jung, H.; Shim, J.-K.; Ryu, J.-W.; Kim, J. Electroactive Polymer Actuator for Lens-Drive Unit in Auto-Focus Compact Camera Module. ETRI J. 2009, 31, 695–702. [Google Scholar] [CrossRef]

- Ikushima, K.; John, S.; Ono, A.; Nagamitsu, S. PEDOT/PSS bending actuators for autofocus micro lens applications. Synth. Met. 2010, 160, 1877–1883. [Google Scholar] [CrossRef]

- Fukuda, K.; Sekitani, T.; Zschieschang, U.; Klauk, H.; Kuribara, K.; Yokota, T.; Sugino, T.; Asaka, K.; Ikeda, M.; Kuwabara, H.; et al. A 4 V Operation, Flexible Braille Display Using Organic Transistors, Carbon Nanotube Actuators, and Organic Static Random-Access Memory. Adv. Funct. Mater. 2011, 21, 4019–4027. [Google Scholar]

- Kato, Y.; Sekitani, T.; Takamiya, M.; Doi, M.; Asaka, K.; Sakurai, T.; Someya, T. Sheet-Type Braille Displays by Integrating Organic Field-Effect Transistors and Polymeric Actuators. IEEE Trans. Electron Devices 2007, 54, 202–209. [Google Scholar] [CrossRef]

- Krishen, K. Space applications for ionic polymer-metal composite sensors, actuators, and artificial muscles. Acta Astronaut. 2009, 64, 1160–1166. [Google Scholar] [CrossRef]

- Punning, A.; Kim, K.J.; Palmre, V.; Vidal, F.; Plesse, C.; Festin, N.; Maziz, A.; Asaka, K.; Sugino, T.; Alici, G.; et al. Ionic electroactive polymer artificial muscles in space applications. Sci. Rep. 2014, 4. [Google Scholar] [CrossRef]

- Ghamsari, A.K.; Zegeye, E.; Jin, Y.; Woldesenbet, E. Application of bucky gel in fabrication of a low-voltage rapid microvalve for flow regulation. ACS Appl. Mater. Interfaces 2013, 5, 5408–5412. [Google Scholar] [CrossRef] [PubMed]

- Addinall, R.; Sugino, T.; Neuhaus, R.; Kosidlo, U.; Tonner, F.; Glanz, C.; Kolaric, I.; Bauernhansl, T.; Asaka, K. Integration of CNT-based actuators for bio-medical applications—Example printed circuit board CNT actuator pipette. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besançon, France, 8–11 July 2014; pp. 1436–1441.

- Sareh, S.; Rossiter, J. Kirigami artificial muscles with complex biologically inspired morphologies. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Jager, E.W.H.; Immerstrand, C.; Peterson, K.H.; Magnusson, K.-E.; Lundström, I.; Inganäs, O. The Cell Clinic: Closable Microvials for Single Cell Studies. Biomed. Microdevices 2002, 4, 177–187. [Google Scholar] [CrossRef]

- Pugal, D.; Jung, K.; Aabloo, A.; Kim, K.J. Ionic polymer-metal composite mechanoelectrical transduction: Review and perspectives. Polym. Int. 2010, 59, 279–289. [Google Scholar] [CrossRef]

- Must, I.; Kaasik, F.; Põldsalu, I.; Johanson, U.; Punning, A.; Aabloo, A. A carbide-derived carbon laminate used as a mechanoelectrical sensor. Carbon 2012, 50, 535–541. [Google Scholar] [CrossRef]

- Wu, Y.; Alici, G.; Madden, J.D.W.; Spinks, G.M.; Wallace, G.G. Soft Mechanical Sensors through Reverse Actuation in Polypyrrole. Adv. Funct. Mater. 2007, 17, 3216–3222. [Google Scholar] [CrossRef]

- Punning, A.; Kruusmaa, M.; Aabloo, A. Surface resistance experiments with IPMC sensors and actuators. Sens. Actuators A Phys. 2007, 133, 200–209. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Punning, A.; Aabloo, A. Electrical Model of a Carbon-Polymer Composite (CPC) Collision Detector. Sensors 2012, 12, 1950–1966. [Google Scholar] [CrossRef] [PubMed]

- Must, I.; Johanson, U.; Kaasik, F.; Põldsalu, I.; Punning, A.; Aabloo, A. Charging a supercapacitor-like laminate with ambient moisture: from a humidity sensor to an energy harvester. Phys. Chem. Chem. Phys. 2013, 15, 9605–9614. [Google Scholar] [CrossRef] [PubMed]

- Must, I.; Vunder, V.; Kaasik, F.; Põldsalu, I.; Johanson, U.; Punning, A.; Aabloo, A. Ionic liquid-based actuators working in air: The effect of ambient humidity. Sens. Actuators B Chem. 2014, 202, 114–122. [Google Scholar] [CrossRef]

- Martinez, J.G.; Otero, T.F. Biomimetic dual sensing-actuators: theoretical description. Sensing electrolyte concentration and driving current. J. Phys. Chem. B 2012, 116, 9223–9230. [Google Scholar]

- Brunetto, P.; Fortuna, L.; Giannone, P.; Graziani, S.; Strazzeri, S. Static and Dynamic Characterization of the Temperature and Humidity Influence on IPMC Actuators. IEEE Trans. Instrum. Meas. 2010, 59, 893–908. [Google Scholar] [CrossRef]

- Ghamsari, A.K.; Jin, Y.; Woldesenbet, E. Mechanical characterization of bucky gel morphing nanocomposite for actuating/sensing applications. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Mukai, K.; Sugino, T.; Asaka, K. Impact of viscoelastic properties on bucky-gel actuator performance. J. Intell. Mater. Syst. Struct. 2014, 25, 2235–2245. [Google Scholar] [CrossRef]

- Di Pasquale, G.; Graziani, S.; Messina, F.G.; Pollicino, A.; Puglisi, R.; Umana, E. An investigation of the structure–property relationships in ionic polymer polymer composites (IP2Cs) manufactured by polymerization in situ of PEDOT/PSS on Nafion®117. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Mukai, K.; Sugino, T.; Asaka, K. Electroactive Shape-Fixing of Bucky-Gel Actuator. IEEE/ASME Trans. Mechatron. 2014. [Google Scholar] [CrossRef]

- Punning, A.; Must, I.; Põldsalu, I.; Vunder, V.; Temmer, R.; Kruusamäe, K.; Kaasik, F.; Torop, J.; Rinne, P.; Lulla, T.; et al. Lifetime measurements of ionic electroactive polymer actuators. J. Intell. Mater. Syst. Struct. 2014, 25, 2267–2275. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Lin, J.; Wang, D.; Jain, V.; Montazami, R.; Heflin, J.R.; Li, J.; Madsen, L.; Zhang, Q.M. Ion transport and storage of ionic liquids in ionic polymer conductor network composites. Appl. Phys. Lett. 2010, 96. [Google Scholar] [CrossRef]

- Vunder, V.; Punning, A.; Aabloo, A. Mechanical interpretation of back-relaxation of ionic electroactive polymer actuators. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- Zhu, Z.; Asaka, K.; Chang, L.; Takagi, K.; Chen, H. Multiphysics of ionic polymer–metal composite actuator. J. Appl. Phys. 2013, 114. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Mukai, K.; Sugino, T.; Asaka, K. Mechanical behaviour of bending bucky-gel actuators and its representation. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Rakotondrabe, M.; Ivan, I.A.; Khadraoui, S.; Lutz, P.; Chaillet, N. Simultaneous Displacement/Force Self-Sensing in Piezoelectric Actuators and Applications to Robust Control. IEEE/ASME Trans. Mechatron. 2015, 20, 519–531. [Google Scholar] [CrossRef]

- Dosch, J.J.; Inman, D.J.; Garcia, E. A Self-Sensing Piezoelectric Actuator for Collocated Control. J. Intell. Mater. Syst. Struct. 1992, 3, 166–185. [Google Scholar] [CrossRef]

- Anderson, E.H.; Hagood, N.W. Simultaneous Piezoelectric Sensing/Actuation: Analysis and Application to Controlled Structures. J. Sound Vib. 1994, 174, 617–639. [Google Scholar] [CrossRef]

- Jung, K.; Kim, K.J.; Choi, H.R. A self-sensing dielectric elastomer actuator. Sens. Actuators A Phys. 2008, 143, 343–351. [Google Scholar] [CrossRef]

- Rosset, S.; O’Brien, B.M.; Gisby, T.; Xu, D.; Shea, H.R.; Anderson, I.A. Self-sensing dielectric elastomer actuators in closed-loop operation. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Gisby, T.A.; O’Brien, B.M.; Anderson, I.A. Self sensing feedback for dielectric elastomer actuators. Appl. Phys. Lett. 2013, 102. [Google Scholar] [CrossRef]

- Lan, C.-C.; Lin, C.-M.; Fan, C.-H. A Self-Sensing Microgripper Module with Wide Handling Ranges. IEEE/ASME Trans. Mechatron. 2011, 16, 141–150. [Google Scholar] [CrossRef]

- Pratt, J.; Flatau, A.B. Development and Analysis of a Self-Sensing Magnetostrictive Actuator Design. J. Intell. Mater. Syst. Struct. 1995, 6, 639–648. [Google Scholar] [CrossRef]

- Janocha, H. Adaptronics and Smart Structures, 2nd, rev. ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Sasaki, M.; Lin, W.; Tamagawa, H.; Ito, S.; Kikuchi, K. Self-Sensing Control of Nafion-Based Ionic Polymer-Metal Composite (IPMC) Actuator in the Extremely Low Humidity Environment. Actuators 2013, 2, 74–85. [Google Scholar] [CrossRef]

- Otero, T.F.; Martinez, J.G. Physical and chemical awareness from sensing polymeric artificial muscles. Experiments and modeling. Prog. Polym. Sci. 2014. [Google Scholar] [CrossRef]

- Punning, A.; Kruusmaa, M.; Aabloo, A. A self-sensing ion conducting polymer metal composite (IPMC) actuator. Sens. Actuators A Phys. 2007, 136, 656–664. [Google Scholar] [CrossRef]

- Truong, D.Q.; Ahn, K.K.; Nam, D.N.C.; Yoon, J.I. Identification of a nonlinear black-box model for a self-sensing polymer metal composite actuator. Smart Mater. Struct. 2010, 19. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Punning, A.; Kruusmaa, M.; Aabloo, A. Dynamical variation of the impedances of IPMC. Proc. SPIE 2009, 7287. [Google Scholar] [CrossRef]

- Fang, B.-K.; Lin, C.-C.K.; Ju, M.-S. Development of sensing/actuating ionic polymer–metal composite (IPMC) for active guide-wire system. Sens. Actuator A Phys. 2010, 158, 1–9. [Google Scholar] [CrossRef]

- Bonomo, C.; Fortuna, L.; Giannone, P.; Graziani, S. A sensor-actuator integrated system based on IPMCs [ionic polymer metal composites]. In Proceedings of IEEE Sensors 2004, Vienna, Austria, 24–27 October 2004; pp. 489–492.

- Yamakita, M.; Sera, A.; Kamamichi, N.; Asaka, K. Integrated Design of an Ionic Polymer–Metal Composite Actuator/Sensor. Adv. Robot. 2008, 22, 913–928. [Google Scholar] [CrossRef]

- Hunt, A.; Chen, Z.; Tan, X.; Kruusmaa, M. Feedback Control of a Coupled IPMC (Ionic Polymer-Metal Composite) Sensor-Actuator. In Proceedings of the ASME 2009 Dynamic Systems and Control Conference, Hollywood, CA, USA, 12–14 October 2009; pp. 485–491.

- Akle, B.J.; Leo, D.J. Multilayer ionic polymer transducer. Proc. SPIE 2003, 5051, 214–225. [Google Scholar]

- Chen, Z.; Shen, Y.; Xi, N.; Tan, X. Integrated sensing for ionic polymer–metal composite actuators using PVDF thin films. Smart Mater. Struct. 2007, 16, S262–S271. [Google Scholar] [CrossRef]

- Chen, Z.; Kwon, K.-Y.; Tan, X. Integrated IPMC/PVDF sensory actuator and its validation in feedback control. Sens. Actuators. A Phys. 2008, 144, 231–241. [Google Scholar] [CrossRef]

- Leang, K.K.; Shan, Y.; Song, S.; Kim, K.J. Integrated Sensing for IPMC Actuators Using Strain Gages for Underwater Applications. IEEE/ASME Trans. Mechatron. 2012, 17, 345–355. [Google Scholar] [CrossRef]

- Alici, G.; Spinks, G.M.; Madden, J.D.; Wu, Y.; Wallace, G.G. Response Characterization of Electroactive Polymers as Mechanical Sensors. IEEE/ASME Trans. Mechatron. 2008, 13, 187–196. [Google Scholar] [CrossRef]

- John, S.W.; Alici, G.; Spinks, G.M.; Madden, J.D.; Wallace, G.G. Towards fully optimized conducting polymer bending sensors: The effect of geometry. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- Otero, T.F.; Cortes, M.T. Artificial muscle: Movement and position control. Chem. Commun. 2004. [Google Scholar] [CrossRef]

- Otero, T.F.; Cortés, M.T. Artificial Muscles with Tactile Sensitivity. Adv. Mater. 2003, 15, 279–282. [Google Scholar] [CrossRef]

- Martinez, J.G.; Otero, T.F. Mechanical awareness from sensing artificial muscles: Experiments and modeling. Sens. Actuator B Chem. 2014, 195, 365–372. [Google Scholar] [CrossRef]

- Otero, T.F.; Sanchez, J.J.; Martinez, J.G. Biomimetic dual sensing-actuators based on conducting polymers. Galvanostatic theoretical model for actuators sensing temperature. J. Phys. Chem. B 2012, 116, 5279–5290. [Google Scholar]

- John, S.W.; Alici, G.; Cook, C.D. Towards the position control of conducting polymer trilayer bending actuators with integrated feedback sensor. In Proceedings of the 2009 IEEE/ASME International Conference Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 65–70.

- Nemat-Nasser, S. Micromechanics of actuation of ionic polymer-metal composites. J. Appl. Phys. 2002, 92. [Google Scholar] [CrossRef]

- Akle, B.J.; Leo, D.J.; Hickner, M.A.; McGrath, J.E. Correlation of capacitance and actuation in ionomeric polymer transducers. J. Mater. Sci. 2005, 40, 3715–3724. [Google Scholar] [CrossRef]

- Kocer, B.; Weiland, L.M. Experimental investigation of the streaming potential hypothesis for ionic polymer transducers in sensing. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Aureli, M.; Porfiri, M. Nonlinear sensing of ionic polymer metal composites. Contin. Mech. Thermodyn. 2013, 25, 273–310. [Google Scholar] [CrossRef]

- Truong, D.Q.; Ahn, K.K. Design and Verification of a Non-linear Black-Box Model for Ionic Polymer Metal Composite Actuators. J. Intell. Mater. Syst. Struct. 2011, 22, 253–269. [Google Scholar] [CrossRef]

- Truong, D.Q.; Ahn, K.K. Modeling of an ionic polymer metal composite actuator based on an extended Kalman filter trained neural network. Smart Mater. Struct. 2014. [Google Scholar] [CrossRef]

- Nam, D.N.C.; Ahn, K.K. Analysis and experiment on a self-sensing ionic polymer–metal composite actuator. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Nam, D.N.C.; Ahn, K.K. Modeling and control of a self-sensing polymer metal composite actuator. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Jeon, J.-H.; Yeom, S.-W.; Oh, I.-K. Fabrication and actuation of ionic polymer metal composites patterned by combining electroplating with electroless plating. Compos. Part A Appl. Sci. Manuf. 2008, 39, 588–596. [Google Scholar] [CrossRef]

- Rossiter, J.; Mukai, T. Electrostatic and thermal segmentation of multi-segment IPMC sensor-actuators. Proc. SPIE 2011, 7976. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Brunetto, P.; Punning, A.; Kodu, M.; Jaaniso, R.; Graziani, S.; Fortuna, L.; Aabloo, A. Electromechanical model for a self-sensing ionic polymer–metal composite actuating device with patterned surface electrodes. Smart Mater. Struct. 2011, 20. [Google Scholar] [CrossRef]

- Konyo, M.; Konishi, Y.; Tadokoro, S.; Kishima, T. Development of velocity sensor using ionic polymer–metal composites. Proc. SPIE 2004, 5385, 307–318. [Google Scholar]

- Nakadoi, H.; Sera, A.; Yamakita, M.; Asaka, K.; Luo, Z.-W.; Ito, K. Integrated actuator-sensor system on patterned IPMC film: Consideration of electoric interference. In Proceedings of the 4th IEEE International Conference on Mechatronics, Kumamoto, Japan, 8–10 May 2007; pp. 1–6.

- Kamamichi, N.; Stoimenov, B.; Mukai, T.; Asaka, K. A Sensor-Actuator Integrated System with a Patterned IPMC—the interference of actuation to the sensing signal—. In Proceedings of the 7th Meeting of the System Integration Division SICE, Sapporo, Japan, 14–17 December 2006; pp. 175–176.

- Nishida, G.; Sugiura, M.; Yamakita, M.; Maschke, B.; Ikeura, R. Multi-Input Multi-Output Integrated Ionic Polymer-Metal Composite for Energy Controls. Micromachines 2012, 3, 126–136. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Brunetto, P.; Graziani, S.; Punning, A.; Di Pasquale, G.; Aabloo, A. Self-sensing ionic polymer-metal composite actuating device with patterned surface electrodes. Polym. Int. 2010, 59, 300–304. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Brunetto, P.; Graziani, S.; Fortuna, L.; Kodu, M.; Jaaniso, R.; Punning, A.; Aabloo, A. Experiments with self-sensing IPMC actuating device. Proc. SPIE 2010, 7642. [Google Scholar] [CrossRef]

- Zhu, Z.; Chang, L.; Asaka, K.; Wang, Y.; Chen, H.; Zhao, H.; Li, D. Comparative experimental investigation on the actuation mechanisms of ionic polymer–metal composites with different backbones and water contents. J. Appl. Phys. 2014, 115. [Google Scholar] [CrossRef]

- Ko, B.G.; Kwon, H.C.; Lee, S.J. A Self-Sensing Method for IPMC Actuator. Adv. Sci. Technol. 2008, 56, 111–115. [Google Scholar] [CrossRef]

- Kamamichi, N.; Yamakita, M.; Asaka, K.; Luo, Z.; Mukai, T. Sensor Property of a Novel EAP Device with Ionic-liquid-based Bucky Gel. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007; pp. 221–224.

- Must, I.; Anton, M.; Viidalepp, E.; Põldsalu, I.; Punning, A.; Aabloo, A. Mechanoelectrical impedance of a carbide-derived carbon-based laminate motion sensor at large bending deflections. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Tanaka, K.; Sugiura, M.; Yamakita, M.; Kamamichi, N.; Mukai, T. Integrated Actuator-Sensor System of Bucky Gel Device. In Proceedings of SICE Annual Conference 2010, Taipei, Taiwan, 18–21 August 2010; Volume 4, pp. 2472–2478.

- Kruusamäe, K.; Punning, A.; Aabloo, A. Self-sensing properties of carbon-polymer composite (CPC) actuators. Proc. SPIE 2011, 7976. [Google Scholar] [CrossRef]

- Kruusamäe, K.; Kaasik, F.; Punning, A.; Aabloo, A. Self-sensing ionic electromechanically active actuator with patterned carbon electrodes. Proc. SPIE 2013, 8687. [Google Scholar] [CrossRef]

- Tamagawa, H.; Lin, W.; Kikuchi, K.; Sasaki, M. Bending control of Nafion-based electroactive polymer actuator coated with multi-walled carbon nanotubes. Sens. Actuators B Chem. 2011, 156, 375–382. [Google Scholar] [CrossRef]

- Festin, N.; Plesse, C.; Chevrot, C.; Teyssié, D.; Josselin, L.; Pirim, P.; Vidal, F. Actuation and Sensing properties of Electroactive Polymer Whiskers. Procedia Comput. Sci. 2011, 7, S4–S7. [Google Scholar] [CrossRef]

- Akle, B.; Leo, D.J. Electromechanical transduction in multilayer ionic transducers. Smart Mater. Struct. 2004, 13, 1081–1089. [Google Scholar] [CrossRef]

- Bohn, C.; Sadki, S.; Brennan, A.B.; Reynolds, J.R. In Situ Electrochemical Strain Gage Monitoring of Actuation in Conducting Polymers. J. Electrochem. Soc. 2002, 149, E281–E285. [Google Scholar] [CrossRef]

- Feng, G.-H.; Huang, W.-L. A self-strain feedback tuning-fork-shaped ionic polymer metal composite clamping actuator with soft matter elasticity-detecting capability for biomedical applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 45, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Bonomo, C.; Brunetto, P.; Fortuna, L.; Giannone, P.; Graziani, S.; Strazzeri, S. A tactile sensor for biomedical applications based on IPMCs. IEEE Sens. J. 2008, 8, 1486–1493. [Google Scholar] [CrossRef]

- Richardson, R.C.; Levesley, M.C.; Brown, M.D.; Hawkes, J.A.; Watterson, K.; Walker, P.G. Control of ionic polymer metal composites. IEEE/ASME Trans. Mechatron. 2003, 8, 245–253. [Google Scholar] [CrossRef]

- Vunder, V.; Itik, M.; Põldsalu, I.; Punning, A.; Aabloo, A. Inversion-based control of ionic polymer–metal composite actuators with nanoporous carbon-based electrodes. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Druitt, C.M.; Alici, G. Intelligent control of electroactive polymer actuators based on fuzzy and neurofuzzy methodologies. IEEE/ASME Trans. Mechatron. 2014, 19, 1951–1962. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).