Semi-Active Vibration Controllers for Magnetorheological Fluid-Based Systems via Frequency Shaping †

Abstract

1. Introduction

2. Conventional Semi-Active Control

2.1. Background

2.2. Controller Design

3. Frequency-Shaped Semi-Active Control (FSSC)

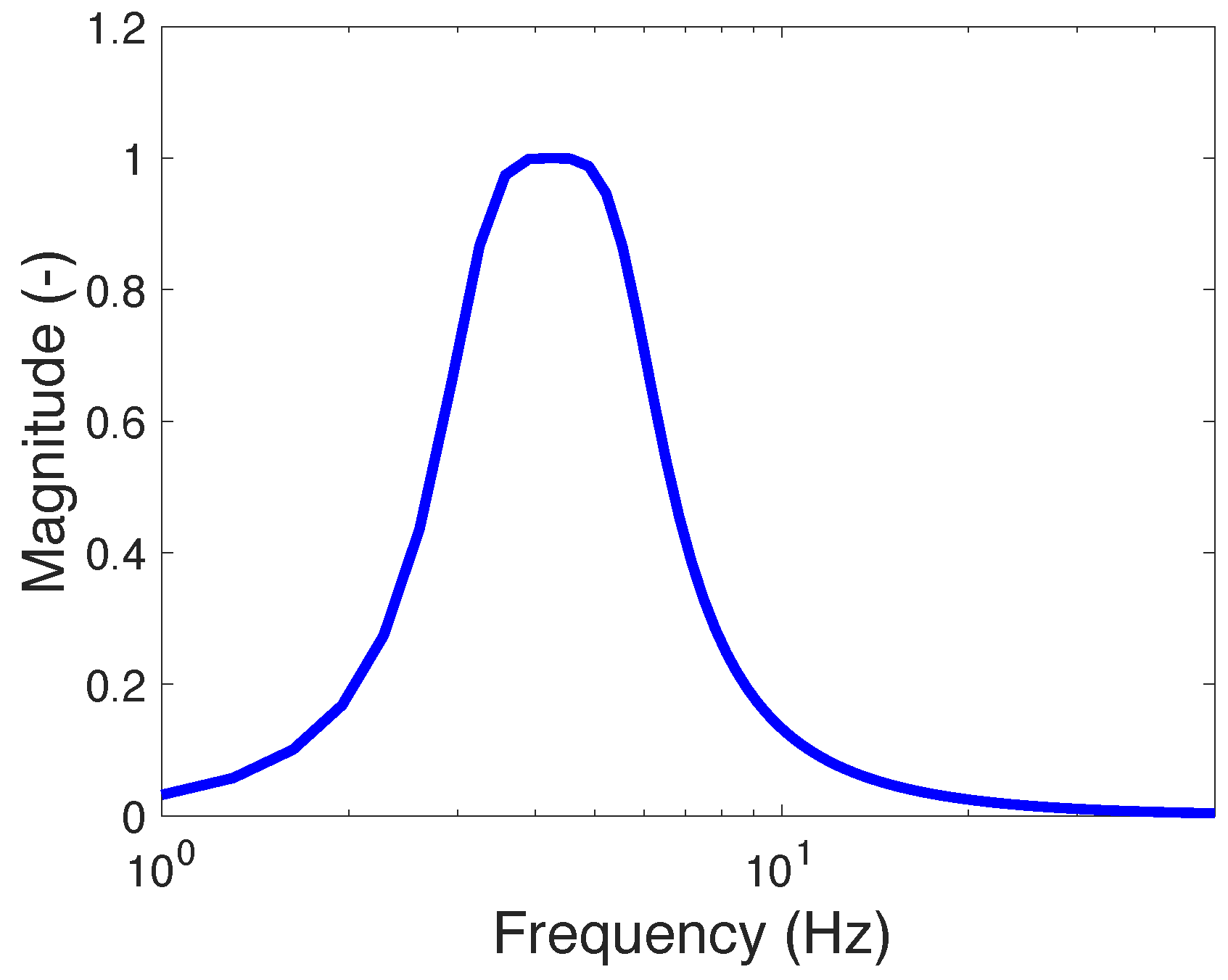

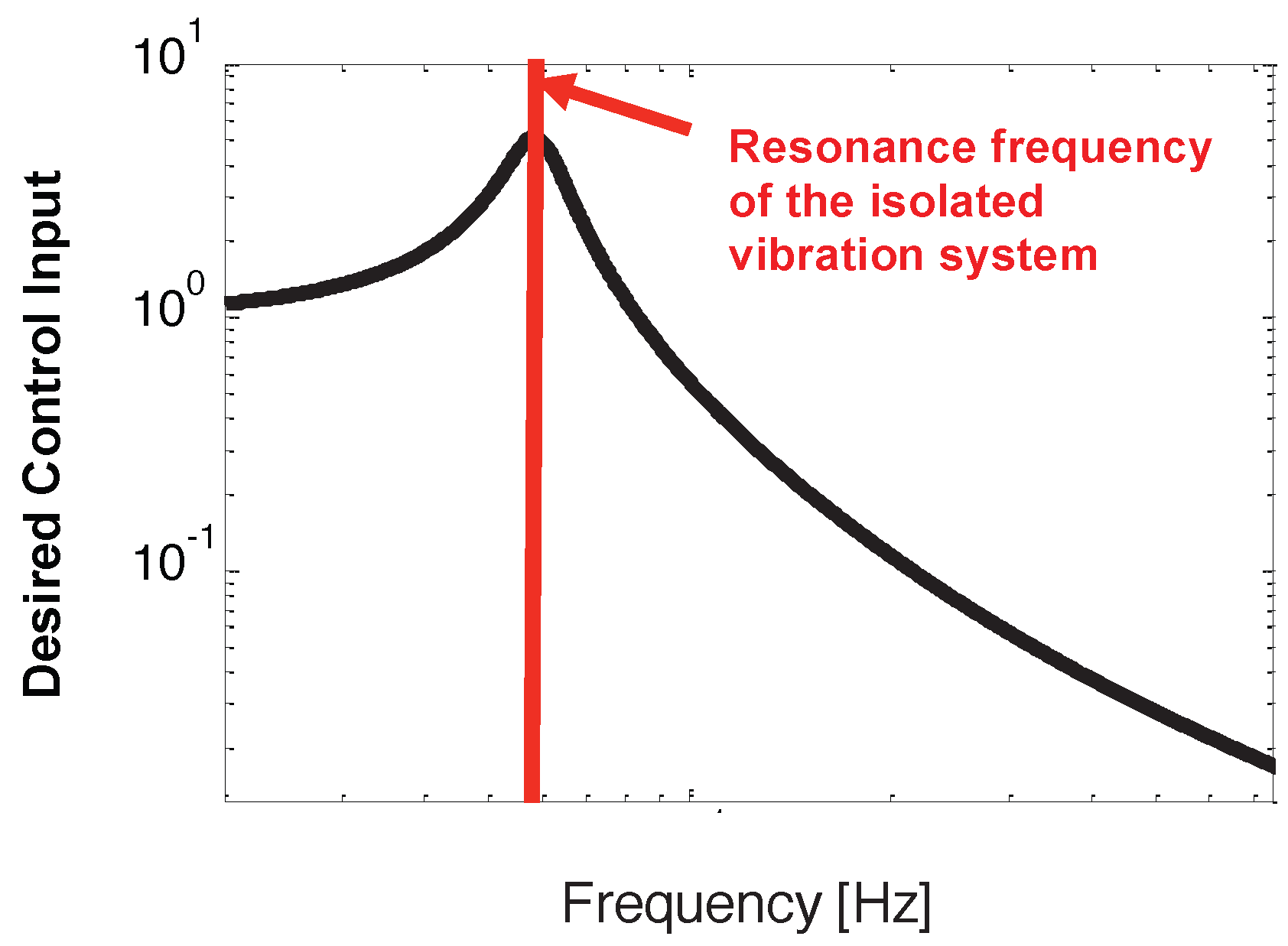

3.1. Band-Pass FSSC (BFSSC)

3.2. Narrow-Band FSSC (NFSSC)

4. Simulation Results

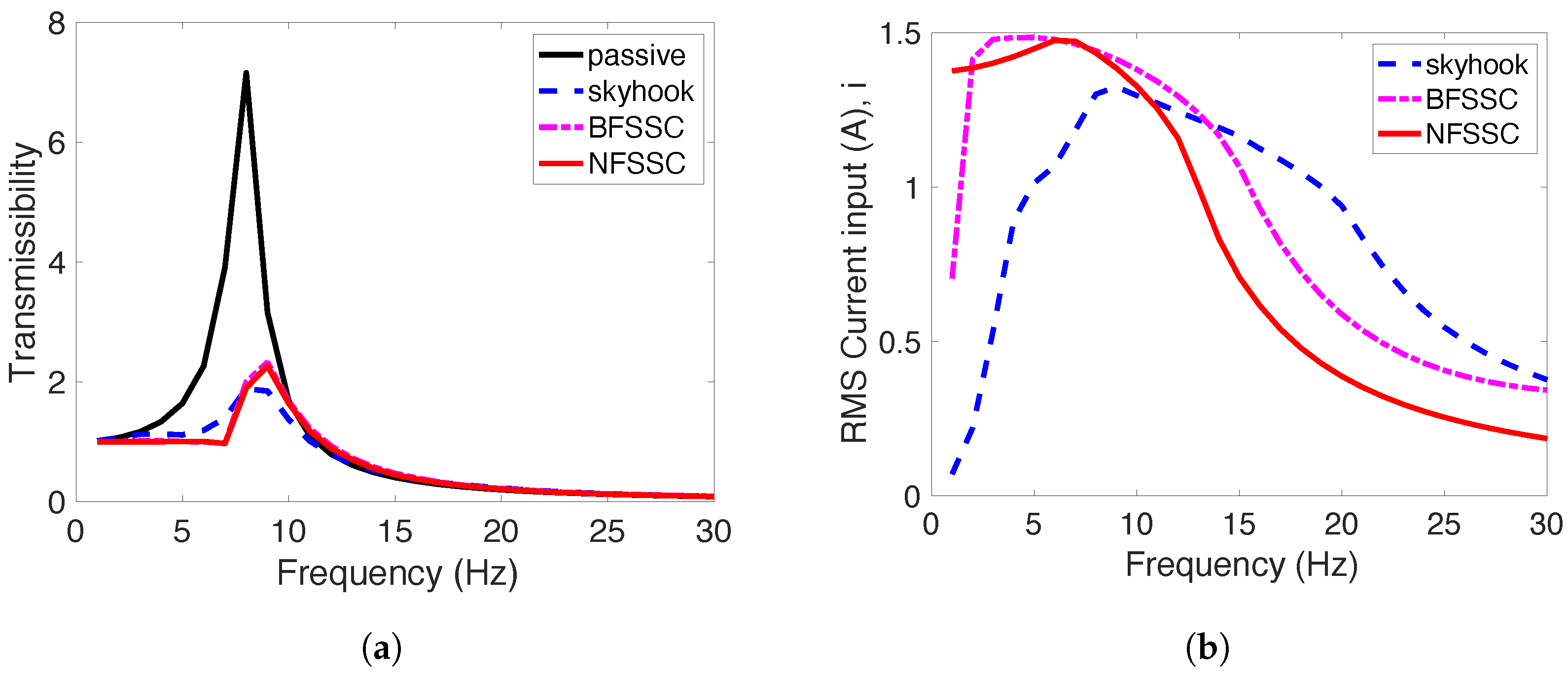

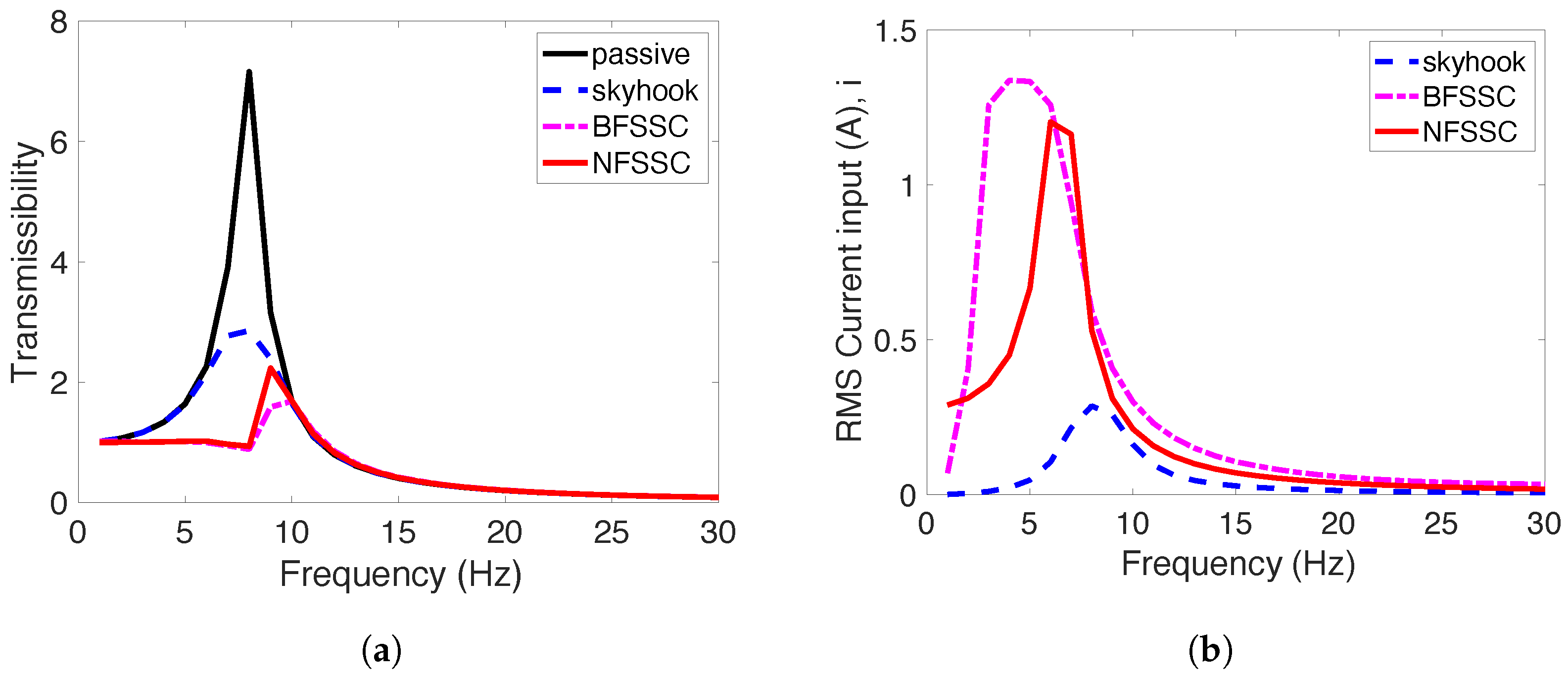

4.1. Steady-State Responses in the Frequency Domain

4.1.1. Performance Under Strong Excitation (±1.0 mm)

4.1.2. Performance Under Mild Excitation (±0.1 mm)

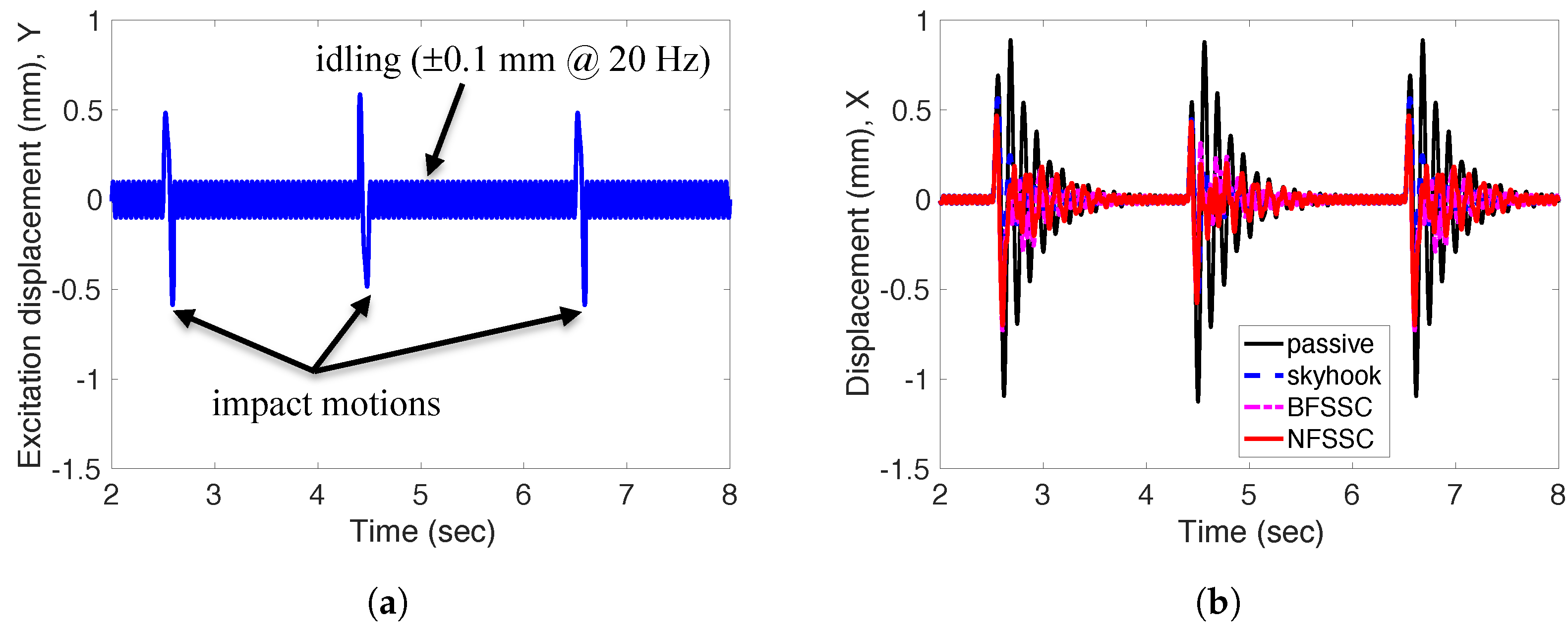

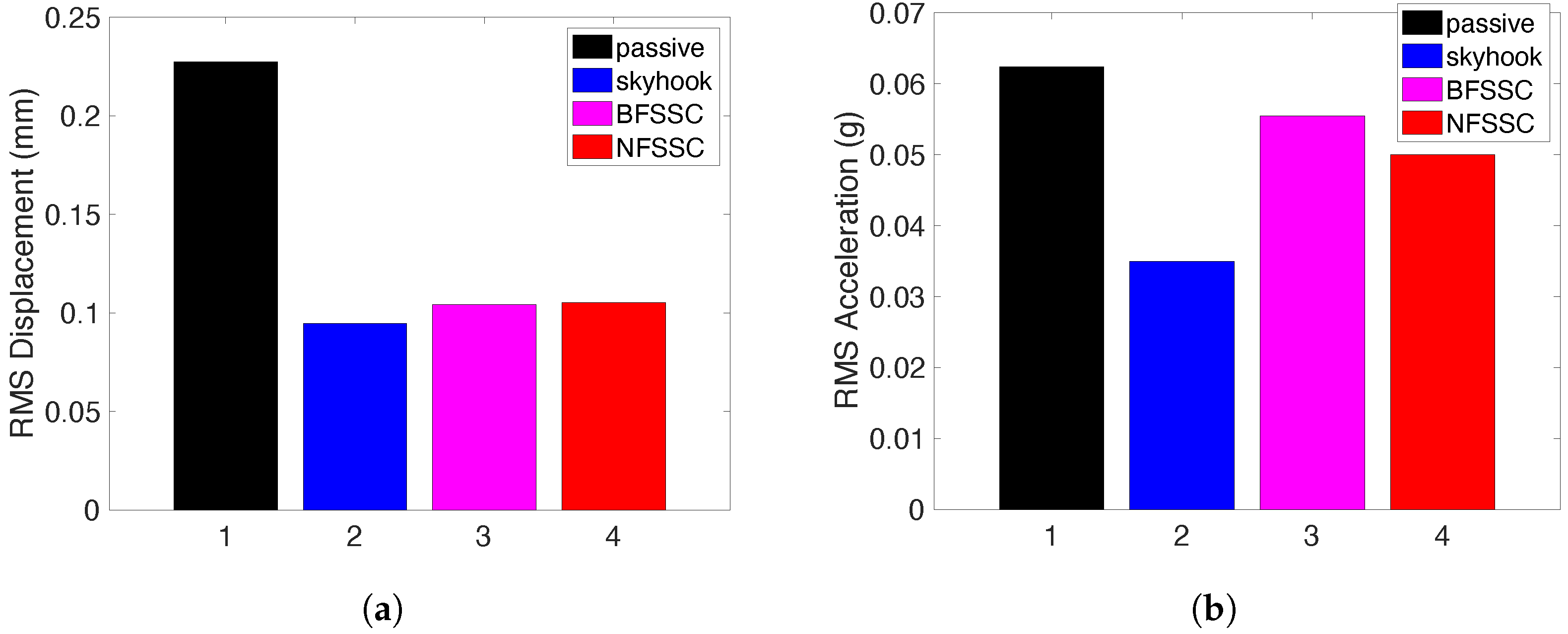

4.2. Transient Responses for MR Damper with 5 ms Time Constant

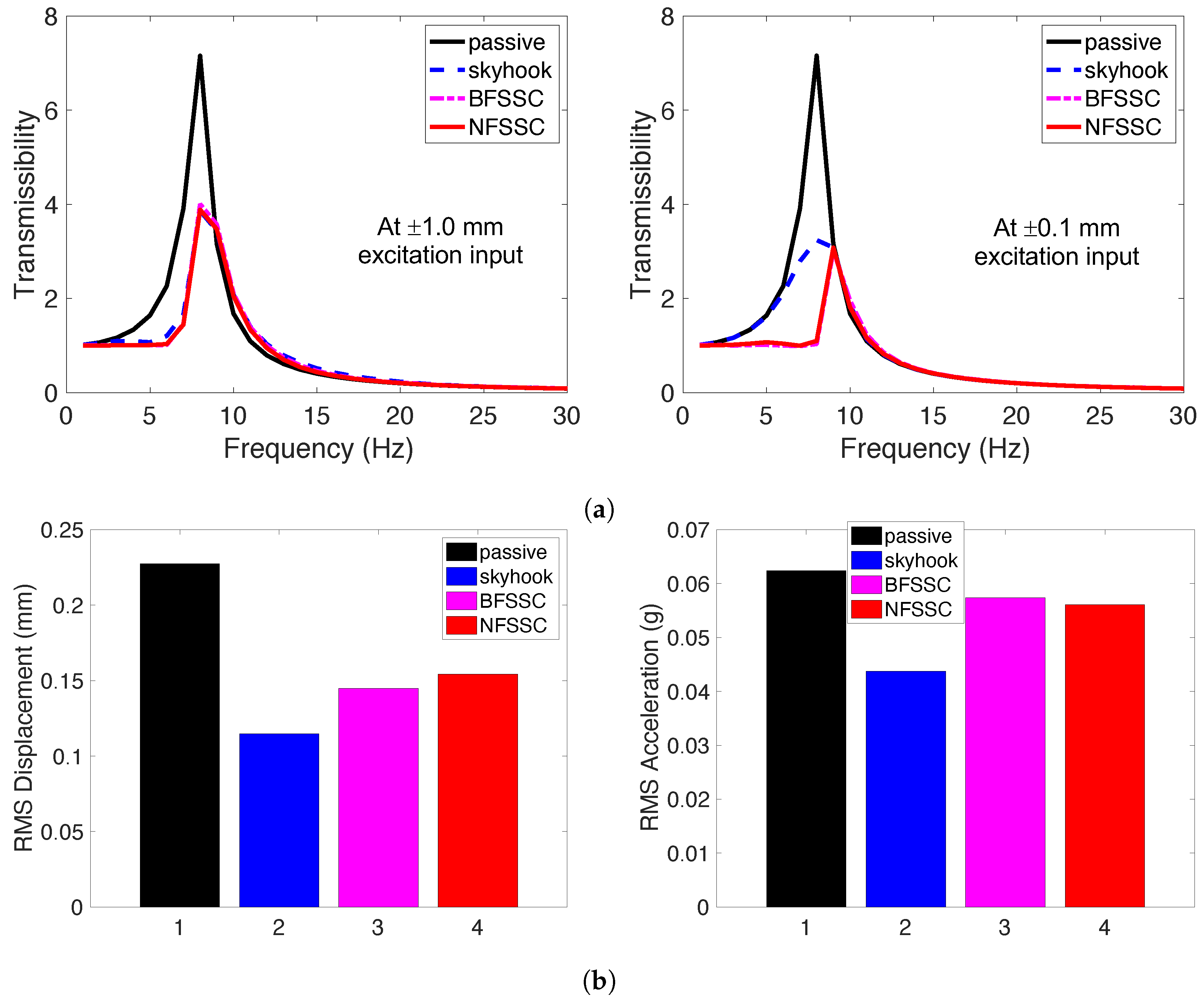

4.3. Responses for MR Damper with 20 ms Time Constant

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BFSSC | Band-pass Frequency Shaped Semi-Active Control |

| FFT | Fast Fourier Transform |

| FSSC | Frequency Shaped Semi-Active Control |

| LQR | Linear Quadratic Regulator |

| MR | Magnetorheological |

| NFSSC | Narrow-band Frequency Shaped Semi-Active Control |

| SDOF | Single-degree of Freedom |

| RMS | Root Mean Square |

References

- Jin, Z.; Yang, F.; Rui, X.; Jiang, M.; Wang, J. Design, Modeling, and Vibration Control of a Damper Based on Magnetorheological Fluid and Elastomer. Actuators 2024, 13, 241. [Google Scholar] [CrossRef]

- Yang, J.; Ezani, S.; Gong, N.; Deng, L.; Zhang, S.; Li, W. New Magnetorheological Engine Mount with Controllable Stiffness Characteristics Towards Improved Driving Stability and Ride Comfort. Smart Mater. Struct. 2022, 31, 125009. [Google Scholar] [CrossRef]

- Choi, Y.T.; Wereley, N.M.; Hiemenz, G.J. Three-Axis Vibration Isolation of a Full-Scale Magnetorheological Seat Suspension. Micromachines 2024, 15, 1417. [Google Scholar] [CrossRef]

- Mao, M.; Choi, Y.T.; Wereley, N.M.; Johnson, N.L. Influence of Biomechanical Compliance on Control Performance of a Magnetorheological Sliding Seat System. J. Intell. Mater. Syst. Struct. 2023, 24, 1983–1997. [Google Scholar] [CrossRef]

- Zhu, H.; Rui, X.; Yang, F.; Zhu, W.; Gu, J. Semi-Active Scissors-Seat Suspension with Magneto-Rheological Damper. Front. Mater. 2020, 7, 591283. [Google Scholar] [CrossRef]

- Park, Y.J.; Kang, B.H.; Choi, S.B. A New Rotary Magnetorheological Damper for a Semi-Active Suspension System of Low-Floor Vehicles. Actuators 2024, 13, 155. [Google Scholar] [CrossRef]

- Kumbhar, M.B.; Desavale, R.G.; Jagadeesha, T. Recent Advances in Magnetorheological Damping Systems for Automotive Technology. In Intelligent Manufacturing Systems in Industry 4.0; Deepak, B.B.V.L., Bahubalendruni, M.V.A.R., Parhi, D.R.K., Biswal, B.B., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2023; Chapter 12. [Google Scholar] [CrossRef]

- Choi, Y.T.; Yoo, B.; Park, J.; Pines, D.J.; Wereley, N.M. Design and Performance of a 3D-Printed Magnetorheological Fluid-based Adaptive Vibration Isolator. Front. Mater. 2023, 10, 1142590. [Google Scholar] [CrossRef]

- Deng, L.; Sun, S.; Wu, Q.; Gong, N.; Yang, J.; Zhang, S.; Du, H.; Li, W. A New Magnetorheological Quasi-Zero Stiffness Vibration Isolation System with Large Zero Stiffness Range and Highly Stable Characteristics. Nonlinear Dyn. 2023, 111, 18631–18653. [Google Scholar] [CrossRef]

- Choi, Y.T.; Wereley, N.M.; Hiemenz, G. Frequency Shaped Semi-Active Control For Magnetorheological Fluid-Based Vibration Control Systems. In Proceedings of the ASME Conference on Smart Materials, Adaptive Structures and Intelligent Systems (SMASIS), Snowbird, UT, USA, 16–18 September 2013; ASME: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Karnopp, D.; Crosby, M.J.; Harwood, R.A. Vibration Control Using Semi-Active Force Generators. J. Eng. Ind. 1974, 96, 619–626. [Google Scholar] [CrossRef]

- Choi, Y.T.; Wereley, N.M. Self-Powered Magnetorheological Dampers. ASME J. Vib. Acoust. 2009, 131, 044501. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, U. Development of a Control Algorithm for a Semi-Active Mid-Story Isolation System Using Reinforcement Learning. Appl. Sci. 2023, 13, 2053. [Google Scholar] [CrossRef]

- Lee, D.; Jin, S.; Lee, C. Deep Reinforcement Learning of Semi-Active Suspension Controller for Vehicle Ride Comfort. IEEE Trans. Veh. Technol. 2022, 72, 327–339. [Google Scholar] [CrossRef]

- Shih, M.H.; Sung, W.P. Parametric Study of Impulse Semi-Active Mass Damper with Developing Directional Active Joint. Arab. J. Sci. Eng. 2021, 46, 10711–10729. [Google Scholar] [CrossRef]

- Hiemenz, G.J.; Choi, Y.T.; Wereley, N.M. Semi-Active Control of Vertical Stroking Helicopter Crew Seat for Enhanced Crashworthiness. AIAA J. Aircr. 2007, 44, 1031–1034. [Google Scholar] [CrossRef]

- Choi, Y.T.; Wereley, N.M. Vibration Control of a Landing Gear System Featuring Electrorheological/Magnetorheological Fluids. AIAA J. Aircr. 2003, 40, 432–439. [Google Scholar] [CrossRef]

- Choi, S.B.; Choi, Y.T.; Park, D.W. A sliding mode control of a full-car electrorheological suspension system via hardware-in-the-loop simulation. ASME J. Dyn. Syst. Meas. Control 2000, 122, 114–121. [Google Scholar] [CrossRef]

- Lee, H.S.; Choi, S.B. Control and response characteristics of a magnetorheological fluid damper for passenger vehicles. J. Intell. Mater. Syst. Struct. 2000, 11, 80–87. [Google Scholar] [CrossRef]

- Spencer, B.F.; Dyke, S.J.; Sain, M.K.; Carlson, J.D. Phenomenological Model for Magnetorheological Dampers. J. Eng. Mech. 1997, 123, 230–238. [Google Scholar] [CrossRef]

- Thomson, W.T. Theory of Vibration with Applications; Prentice-Hall International Editions: Englewood Cliffs, NJ, USA, 1988. [Google Scholar]

- Elahinia, M.; Ciocanel, C.; Nguyen, T.M.; Wang, S. MR- and ER-Based Semiactive Engine Mounts: A Review. Smart Mater. Res. 2013, 2013, 831017. [Google Scholar] [CrossRef]

- Singh, R.; Kim, G.; Ravindra, P. Linear Analysis of Automotive Hydro-Mechanical Mount with Emphasis on Decoupler Characteristics. J. Sound Vib. 1992, 158, 219–243. [Google Scholar] [CrossRef]

- Flower, W.C. Understanding Hydraulic Mounts for Improved Vehicle Noise, Vibration and Ride Qualities; Technical Paper 850975; SAE: Warrendale, PA, USA, 1985. [Google Scholar] [CrossRef]

- Corcoran, P.E.; Ticks, G.H. Hydraulic Engine Mount Characteristics; Technical Paper 840407; SAE: Warrendale, PA, USA, 1984. [Google Scholar] [CrossRef]

- Holt, J.G.; Rao, M.D.; Blough, J.R.; Gruenberg, S.B. Time History-Based Excitation in the Dynamic Characterization of Automotive Elastomers. Proc. IMechE Part D J. Automob. Eng. 2007, 221, 271–284. [Google Scholar] [CrossRef]

- Graf, P.L.; Shoureshi, R. Modeling and Implementation of Semi-Active Hydraulic Mounts. ASME J. Dyn. Syst. Meas. Control 1988, 110, 422–429. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.T.; Wereley, N.M.; Hiemenz, G.J. Semi-Active Vibration Controllers for Magnetorheological Fluid-Based Systems via Frequency Shaping. Actuators 2025, 14, 425. https://doi.org/10.3390/act14090425

Choi YT, Wereley NM, Hiemenz GJ. Semi-Active Vibration Controllers for Magnetorheological Fluid-Based Systems via Frequency Shaping. Actuators. 2025; 14(9):425. https://doi.org/10.3390/act14090425

Chicago/Turabian StyleChoi, Young T., Norman M. Wereley, and Gregory J. Hiemenz. 2025. "Semi-Active Vibration Controllers for Magnetorheological Fluid-Based Systems via Frequency Shaping" Actuators 14, no. 9: 425. https://doi.org/10.3390/act14090425

APA StyleChoi, Y. T., Wereley, N. M., & Hiemenz, G. J. (2025). Semi-Active Vibration Controllers for Magnetorheological Fluid-Based Systems via Frequency Shaping. Actuators, 14(9), 425. https://doi.org/10.3390/act14090425