Disturbance Observer-Based Robust Force Control for Tendon-Sheath Mechanisms

Abstract

1. Introduction

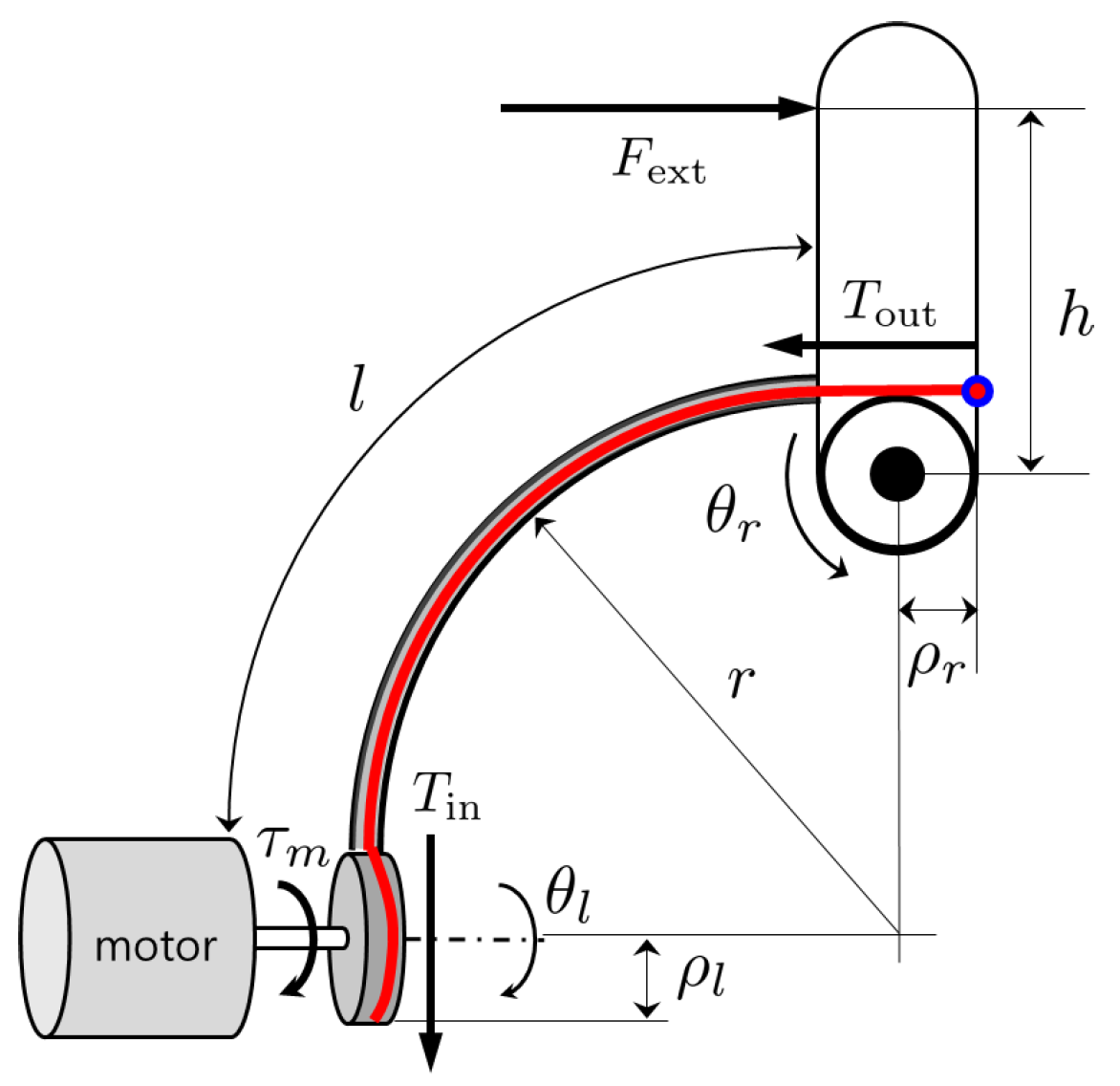

2. Motor-Driven Tendon-Sheath Mechanism

2.1. Motor-Driven Actuation of Tendon-Sheath Transmission Systems

2.2. Modeling Challenges and Uncertainties in Tendon-Sheath Transmission Systems

- (1)

- Friction: The friction model employed for the TSM in Appendix A incorporates only Coulomb friction while neglecting other critical components such as viscous damping and the spatially distributed, hysteretic characteristics of friction along the sheath. In particular, the friction coefficient in the tension force derivation (A6) is highly uncertain and difficult to measure accurately. Furthermore, both the local radius of curvature r and the direction indicator vary continuously along the tendon path, rendering it infeasible to determine their effective values in practice. These uncertainties contribute to significant variability in the lumped parameter defined in (A13), which is central to the nominal model (9), and introduce unmodeled friction dynamics that are not captured by the simplified model.

- (2)

- Stiffness: The effective stiffness in (A19) is a nonlinear function of and includes parameters that are likewise difficult to identify precisely in practical applications. As a result, the tendon elongation , which is determined by (6), becomes difficult to compute accurately. However, owing to its relatively small influence, the tendon elongation effect is neglected in deriving the final model from the angular relationship (5), and thus, it is not incorporated into the nominal model (9).

- (3)

- Backlash: As described in (A15), the distal tendon tension remains unchanged until the elongation exceeds the backlash threshold , even if the proximal input tension increases. Although this nonlinearity is represented in (6), it is omitted in the nominal model (9) under the assumption that the tendon operates outside the backlash region.

3. Disturbance Observer-Based Robust Force Control

3.1. Review on Disturbance Observer

- (1)

- The polynomial is stable for all .

- (2)

- The polynomial is stable for all .

- (1a)

- The nominal closed-loop system is stable.

- (1b)

- The plant is the minimum phase for all .

- (2)

- The polynomial is stable for all .

3.2. Application of Disturbance Observer to Tendon Transmission System and Design of Q-Filter

- (1)

- System structure of : The transfer function in (17) is a strictly proper first-order LTI system of relative degree one, which conforms to the admissible class defined in Assumption 1. In other words, the system has a fixed order and a relative degree , both of which are explicitly defined.

- (2)

- Coefficient bounds in : All coefficients , , and lie within known bounds due to physical constraints and manufacturing tolerances, although they are highly uncertain, and the corresponding bounds and may be relatively large. Additionally, the denominator’s leading coefficient is inherently positive, as dictated by the fundamental properties of inductance in electrical circuits. Similarly, the numerator’s leading coefficient is also positive, as each constituent parameter, namely, , , , , , , and h, is strictly positive by definition. This ensures that the leading coefficient conditions and in Assumption 1 are satisfied.

- (3)

- Minimum phase property of : Since contains no zeros, and hence no right-half plane zeros, it satisfies the minimum phase condition (1b) in Theorem 1.

- (4)

- Stabilizability of the nominal plant by an outer-loop controller : An outer-loop controller that stabilizes the nominal model can be readily designed to satisfy the nominal stability condition (1a) in Theorem 1. For instance, a simple proportional-integral (PI) controller of the formcan stabilize the first-order nominal plant , as the resulting closed-loop transfer function is given bywhich can easily be made a stable second-order system with appropriately chosen gains and .

4. Simulation Results

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Modeling of Tendon-Sheath Transmission Systems

References

- Jacobsen, S.C.; Wood, J.E.; Knutti, D.F.; Biggers, K.B. The UTAH/MIT dextrous hand: Work in progress. Int. J. Robot. Res. 1984, 3, 21–50. [Google Scholar] [CrossRef]

- Kang, B.B.; Choi, H.; Lee, H.; Cho, K.-J. Exo-Glove Poly II: A polymer-based soft wearable robot for the hand with a tendon-driven actuation system. Soft Robot. 2019, 6, 214–227. [Google Scholar] [CrossRef]

- Tran, P.; Jeong, S.; Lyu, F.; Herrin, K.; Bhatia, S.; Elliott, D.; Kozin, S.; Desai, J.P. FLEXotendon Glove-III: Voice-controlled soft robotic hand exoskeleton with novel fabrication method and admittance grasping control. IEEE/ASME Trans. Mechatron. 2022, 27, 3920–3931. [Google Scholar] [CrossRef]

- Yin, M.; Shang, D.; Xu, T.; Wu, X. Joint modeling and closed-loop control of a robotic hand driven by the tendon-sheath. IEEE Robot. Autom. Lett. 2021, 6, 7333–7340. [Google Scholar] [CrossRef]

- Palli, G.; Melchiorri, C. Model and control of tendon-sheath transmission systems. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation (ICRA), Orlando, FL, USA, 15–19 May 2006; pp. 988–993. [Google Scholar]

- Palli, G.; Borghesan, G.; Melchiorri, C. Tendon-based transmission systems for robotic devices: Models and control algorithms. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation (ICRA), Kobe, Japan, 12–17 May 2009; pp. 4063–4068. [Google Scholar]

- Palli, G.; Borghesan, G.; Melchiorri, C. Modeling, identification, and control of tendon-based actuation systems. IEEE Trans. Robot. 2011, 28, 277–290. [Google Scholar] [CrossRef]

- Kaneko, M.; Wada, M.; Maekawa, H.; Tanie, K. A new consideration on tendon-tension control system of robot hands. In Proceedings of the 1991 IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991; pp. 1028–1029. [Google Scholar]

- Kaneko, M.; Yamashita, T.; Tanie, K. Basic considerations on transmission characteristics for tendon drive robots. In Proceedings of the Fifth International Conference on Advanced Robotics: Robots in Unstructured Environments, Pisa, Italy, 19–22 June 1991; pp. 827–832. [Google Scholar]

- Wang, Z.; Sun, Z.; Phee, S.J. Modeling tendon-sheath mechanism with flexible configurations for robot control. Robotica 2013, 31, 1131–1142. [Google Scholar] [CrossRef]

- Dong, H.; Asadi, E.; Qiu, C.; Dai, J.; Chen, I.-M. Geometric design optimization of an under-actuated tendon-driven robotic gripper. Robot. Comput.-Integr. Manuf. 2018, 50, 80–89. [Google Scholar] [CrossRef]

- Palli, G.; Melchiorri, C. Optimal control of tendon-sheath transmission systems. IFAC Proc. Vol. 2006, 39, 73–78. [Google Scholar] [CrossRef]

- Palli, G.; Melchiorri, C. Velocity and disturbance observer for non-model based load and friction compensation. In Proceedings of the 10th IEEE International Workshop on Advanced Motion Control, Trento, Italy, 26–28 March 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 194–199. [Google Scholar]

- Yin, M.; Xu, Z.; Zhao, Z.; Wu, H. Mechanism and position tracking control of a robotic manipulator actuated by the tendon-sheath. J. Intell. Robot. Syst. 2020, 100, 849–862. [Google Scholar] [CrossRef]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.W.S.; Phee, S.J. Adaptive control for enhancing tracking performances of flexible tendon–sheath mechanism in natural orifice transluminal endoscopic surgery. Mechatronics 2015, 28, 67–78. [Google Scholar] [CrossRef]

- Wimböck, T.; Ott, C.; Albu-Schäffer, A.; Kugi, A.; Hirzinger, G. Impedance control for variable stiffness mechanisms with nonlinear joint coupling. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Nice, France, 22–26 September 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 3796–3803. [Google Scholar]

- Kobayashi, H.; Ozawa, R. Adaptive neural network control of tendon-driven mechanisms with elastic tendons. Automatica 2003, 39, 1509–1519. [Google Scholar] [CrossRef]

- Zhang, Y.; He, L.; Yan, B.; Chen, J.; Wu, C. Hierarchical sliding mode control for the trajectory tracking of a tendon-driven manipulator. J. Mech. Robot. 2023, 15, 061014. [Google Scholar] [CrossRef]

- Ohnishi, K. A new servo method in mechatronics. Trans. Jpn. Soc. Electr. Eng. D 1987, 177, 83–86. (In Japanese) [Google Scholar]

- Chen, W.-H.; Yang, J.; Guo, L.; Li, S. Disturbance-observer-based control and related methods—An overview. IEEE Trans. Ind. Electron. 2015, 63, 1083–1095. [Google Scholar] [CrossRef]

- Sariyildiz, E.; Oboe, R.; Ohnishi, K. Disturbance observer-based robust control and its applications: 35th anniversary overview. IEEE Trans. Ind. Electron. 2020, 67, 2042–2053. [Google Scholar] [CrossRef]

- Shim, H.; Park, G.; Joo, Y.; Back, J.; Jo, N.H. Yet another tutorial of disturbance observer: Robust stabilization and recovery of nominal performance. Control Theory Technol. 2016, 14, 237–249. [Google Scholar] [CrossRef]

- Shim, H.; Joo, Y.-J. State space analysis of disturbance observer and a robust stability condition. In Proceedings of the 46th IEEE Conference on Decision and Control, New Orleans, LA, USA, 12–14 December 2007; pp. 2193–2198. [Google Scholar]

- Shim, H.; Jo, N.H. An almost necessary and sufficient condition for robust stability of closed-loop systems with disturbance observer. Automatica 2009, 45, 296–299. [Google Scholar] [CrossRef]

- Sariyildiz, E.; Ohnishi, K. Analysis the robustness of control systems based on disturbance observer. Int. J. Control 2013, 86, 1733–1743. [Google Scholar] [CrossRef]

- Sariyildiz, E.; Ohnishi, K. A guide to design disturbance observer. J. Dyn. Syst. Meas. Control 2014, 136, 021011. [Google Scholar] [CrossRef]

- Iwasaki, M.; Shibata, T.; Matsui, N. Disturbance-observer-based nonlinear friction compensation in table drive system. IEEE/ASME Trans. Mechatron. 1999, 4, 3–8. [Google Scholar] [CrossRef]

- Chen, W.-H.; Ballance, D.J.; Gawthrop, P.J.; O’Reilly, J. A nonlinear disturbance observer for robotic manipulators. IEEE Trans. Ind. Electron. 2000, 47, 932–938. [Google Scholar] [CrossRef]

- Umeno, T.; Kaneko, T.; Hori, Y. Robust servosystem design with two degrees of freedom and its application to novel motion control of robot manipulators. IEEE Trans. Ind. Electron. 1993, 40, 473–485. [Google Scholar] [CrossRef]

- Ha, W.; Back, J. A disturbance observer-based robust tracking controller for uncertain robot manipulators. Int. J. Control. Autom. Syst. 2018, 16, 417–425. [Google Scholar] [CrossRef]

- Huang, W.-S.; Liu, C.-W.; Hsu, P.-L.; Yeh, S.-S. Precision control and compensation of servomotors and machine tools via the disturbance observer. IEEE Trans. Ind. Electron. 2009, 57, 420–429. [Google Scholar] [CrossRef]

- Joo, Y.; Park, G.; Back, J.; Shim, H. Embedding internal model in disturbance observer with robust stability. IEEE Trans. Autom. Control 2015, 61, 3128–3133. [Google Scholar] [CrossRef]

- Chang, H.; Song, D.; Lee, C.; Shim, H. Robust stability condition and simplified design of filter-embedded disturbance observer. Int. J. Control. Autom. Syst. 2024, 22, 3584–3594. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Yu, X. Sliding-mode control for systems with mismatched uncertainties via a disturbance observer. IEEE Trans. Ind. Electron. 2012, 60, 160–169. [Google Scholar] [CrossRef]

- Yin, M.; Wang, H.; Shang, D.; Li, M.; Xu, T.; Wu, X. Disturbance compensation control for humanoid robot hand driven by tendon-sheath based on disturbance observer. IEEE Trans. Autom. Sci. Eng. 2025, 22, 13387–13397. [Google Scholar] [CrossRef]

- Jiufang, P.; Jinshi, C. Research on sliding mode control of robot fingers driven by tendons based on nonlinear disturbance observer. Symmetry 2025, 17, 560. [Google Scholar] [CrossRef]

- Konyukhov, A.; Schweizerhof, K. Frictional interaction of a spiral rope and a cylinder–3D-generalization of the Euler-Eytelwein formula considering pitch. In Computational Contact Mechanics; Lecture Notes in Applied and Computational Mechanics; Springer: Berlin/Heidelberg, Germany, 2013; Volume 67, pp. 413–422. [Google Scholar]

- Dupont, P.; Hayward, V.; Armstrong, B.; Altpeter, F. Single state elastoplastic friction models. IEEE Trans. Autom. Control 2002, 47, 787–792. [Google Scholar] [CrossRef]

- Savkoor, A.R. Models of friction. In Handbook of Materials Behavior Models, Volume II Failures of Materials; Academic: Cambridge, MA, USA, 2001. [Google Scholar]

- Dahl, E.A. Solid friction damping of spacecraft oscillations. In Proceedings of the 1975 Guidance and Control Conference, Boston, MA, USA, 20–22 August 1975; pp. 1104:1–1104:13. [Google Scholar]

- Canudas de Wit, C.; Olsson, H.; Åström, K.J.; Lischinsky, P. A new model for control of systems with friction. IEEE Trans. Autom. Control 1995, 40, 419–425. [Google Scholar] [CrossRef]

- Franklin, G.F.; Powell, J.D.; Emami-Naeini, A.; Powell, J.D. Feedback Control of Dynamic Systems, 8th ed.; Pearson: London, UK, 2020. [Google Scholar]

- Ogata, K. Modern Control Engineering, 5th ed.; Pearson: London, UK, 2009. [Google Scholar]

- Lynch, K.M.; Park, F.C. Modern Robotics; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Welch, R.H.; Younkin, G.W. Why an increase in motor operating temperature doesn’t result in higher torque output. In Proceedings of the 38th IAS Annual Meeting on Conference Record of the Industry Applications Conference, Salt Lake City, UT, USA, 12–16 October 2003; pp. 870–874. [Google Scholar]

- Jo, N.H.; Jeon, C.; Shim, H. Noise reduction disturbance observer for disturbance attenuation and noise suppression. IEEE Trans. Ind. Electron. 2016, 64, 1381–1391. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| Motor torque constant | |

| Motor back electromotive force (EMF) constant | |

| Motor armature resistance | |

| Motor armature inductance | |

| Total gear ratio | |

| Motor efficiency | |

| Moment of inertia of motor’s rotor, including gear on rotor side | |

| Damping (or viscous friction) coefficient of motor’s rotor side | |

| Moment of inertia of motor’s load, including gear on load side | |

| Damping coefficient of motor’s load side | |

| Total moment of inertia of motor from the load side () | |

| Total damping coefficient of motor from the load side () | |

| Angular displacement of motor’s rotor () | |

| Angular displacement of motor’s load side after gearbox () | |

| Generated torque by motor () | |

| Torque transmitted to the load side from the rotor through the gearbox () | |

| Reaction torque transmitted from the load side to the motor rotor () | |

| Input voltage of motor | |

| Back EMF voltage induced by motor’s rotation () |

| Parameter | Description | Real Value | Nominal Value | Unit |

|---|---|---|---|---|

| E | Young’s modulus | |||

| A | Cross-sectional area | |||

| l | Free length of the tendon | |||

| r | Radius of the tendon route | |||

| f | Number of segments | 20 | 20 | − |

| m | Mass of one segment with length | |||

| k | Stiffness of one segment () | |||

| b | Damping coefficient | |||

| Rest stiffness in Dahl model | − | |||

| Friction coefficient in Coulomb model | − | |||

| Friction related parameter in (A13) | − | |||

| Pretension of single segment () | ||||

| Radius of the pulley on motor side | ||||

| Radius of the pulley on robot side | ||||

| h | Length of the robot link contact point |

| Parameter | Description | Real Value | Nominal Value | Unit |

|---|---|---|---|---|

| Motor torque constant | ||||

| Motor back EMF constant | ||||

| Motor armature resistance | 3 | |||

| Motor armature inductance | ||||

| Total gear ratio | 70 | 70 | − | |

| Motor efficiency | − | |||

| Total moment of inertia | ||||

| Total damping coefficient |

| Parameter | Description | Value |

|---|---|---|

| Proportional gain | ||

| Integral gain | 1000 | |

| Q-filter time constant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C. Disturbance Observer-Based Robust Force Control for Tendon-Sheath Mechanisms. Actuators 2025, 14, 320. https://doi.org/10.3390/act14070320

Lee C. Disturbance Observer-Based Robust Force Control for Tendon-Sheath Mechanisms. Actuators. 2025; 14(7):320. https://doi.org/10.3390/act14070320

Chicago/Turabian StyleLee, Chanhwa. 2025. "Disturbance Observer-Based Robust Force Control for Tendon-Sheath Mechanisms" Actuators 14, no. 7: 320. https://doi.org/10.3390/act14070320

APA StyleLee, C. (2025). Disturbance Observer-Based Robust Force Control for Tendon-Sheath Mechanisms. Actuators, 14(7), 320. https://doi.org/10.3390/act14070320