3.1. Numerical Validation

During model testing, video recordings were captured in the visible section of the draft tube cone. Analysis of the footage confirmed the formation of a vortex rope within the draft tube. The right panel of

Figure 5a shows the vortex rope identified by the Omega method from the post-processed numerical simulation under the same operating condition.

Figure 5b,c present comparisons of the time-averaged axial and tangential velocity distributions in the draft tube, derived from both experimental measurements and numerical simulations. The strong agreement between the results highlights the accuracy of the simulation.

Figure 5d compares the external characteristic data obtained from simulations and experiments across various operating conditions. The deviations are within 2% for all cases, further validating the reliability of the numerical approach.

To eliminate the influence of the mean velocity, fluctuation coefficients for the tangential and axial velocities are defined as follows:

In the equations, Cma denotes the axial velocity fluctuation coefficient, Cua denotes the tangential velocity fluctuation coefficient, Vma is the mean axial velocity at the measurement point (m/s), and Vua is the mean tangential velocity at the measurement point (m/s).

Figure 6a,b show the time-domain scatter plots of

Cua and

Cma, respectively, obtained from numerical simulations. At the center of the draft tube (Rx/R

0 = 0.05 and 0.3), both

Cua and

Cma exhibit regular periodic fluctuation patterns. At Rx/R

0 = 0.7, the amplitude of

Cua fluctuations significantly decreases, while that of

Cma increases markedly, indicating that the tangential velocity tends to stabilize in this region, whereas the instability of the axial velocity is enhanced. Near the wall region (Rx/R

0 = 0.95), both

Cua and

Cma show varying degrees of increase, attributed to the destabilizing effect of wall friction on the local flow.

Figure 6c,d display the time-domain scatter plots of

Cua and

Cma measured experimentally. The LDV velocity data exhibit a distinctly discrete pattern, with instantaneous velocities approximately following a normal distribution centered on the steady-state velocity. This is due to the randomness inherent in the LDV system, which acquires velocity by detecting laser light scattered by tracer particles. When the number of samples is sufficiently large, the measured velocity distribution approximates a Gaussian profile.

At the center of the draft tube (Rx/R

0 = 0.05 and 0.3),

Cua appears more dispersed, while

Cma is more concentrated, indicating stronger tangential velocity fluctuations and relatively stable axial flow. At Rx/R

0 = 0.7, the dispersion of

Cua decreases noticeably, while

Cma becomes more scattered, suggesting a stabilization of tangential velocity and increased instability in axial flow—consistent with the trends shown in

Figure 6a,b. Near the wall (Rx/R

0 = 0.95), the dispersion of

Cua increases significantly, while that of

Cma increases slightly, further demonstrating that wall friction amplifies velocity fluctuations.

Additionally, the number of LDV samples for

Cua and

Cma is much higher in the near-wall region than in the center. This is because the higher flow velocity near the wall results in a higher concentration of tracer particles, which enhances the effective sampling rate of the LDV system. Comparing

Figure 6c,d, it is evident that, under the same sampling duration, the number of samples for

Cma is significantly greater than for

Cua. This is attributed to the dominance of axial flow in the draft tube under rated turbine conditions and the higher detection efficiency of the LDV optical system for the axial velocity component, leading to a higher effective sampling rate for

Cma.

Considering that the data obtained from the LDV flow measurement experiment are non-periodic discrete signals, while the data from numerical simulations are periodic and continuous, the same Fourier transform method cannot be applied for frequency-domain analysis. To quantitatively compare the degree of velocity fluctuation obtained from the experiment and simulation, the fluctuation coefficients of tangential and axial velocities are substituted into the root mean square formula to construct the fluctuation intensity of the velocity. The corresponding equations are as follows:

where

ICu represents the fluctuation intensity of the tangential velocity and

ICm represents the fluctuation intensity of the axial velocity.

As shown in

Figure 6e, the value of

ICm exhibits a nonlinear increasing trend from the center of the draft tube to Rx = 0.65, while

ICu shows a nonlinear decreasing trend over the same range, followed by a nonlinear increase from Rx = 0.65R_x = 0.65Rx = 0.65 to Rx = 0.95. The maximum values of

ICu and

ICm are 0.36 and 0.34, respectively. Meanwhile, the distribution trends of the predicted

ICu and

ICm values closely match the experimental results, indicating the reliability of the numerical simulations.

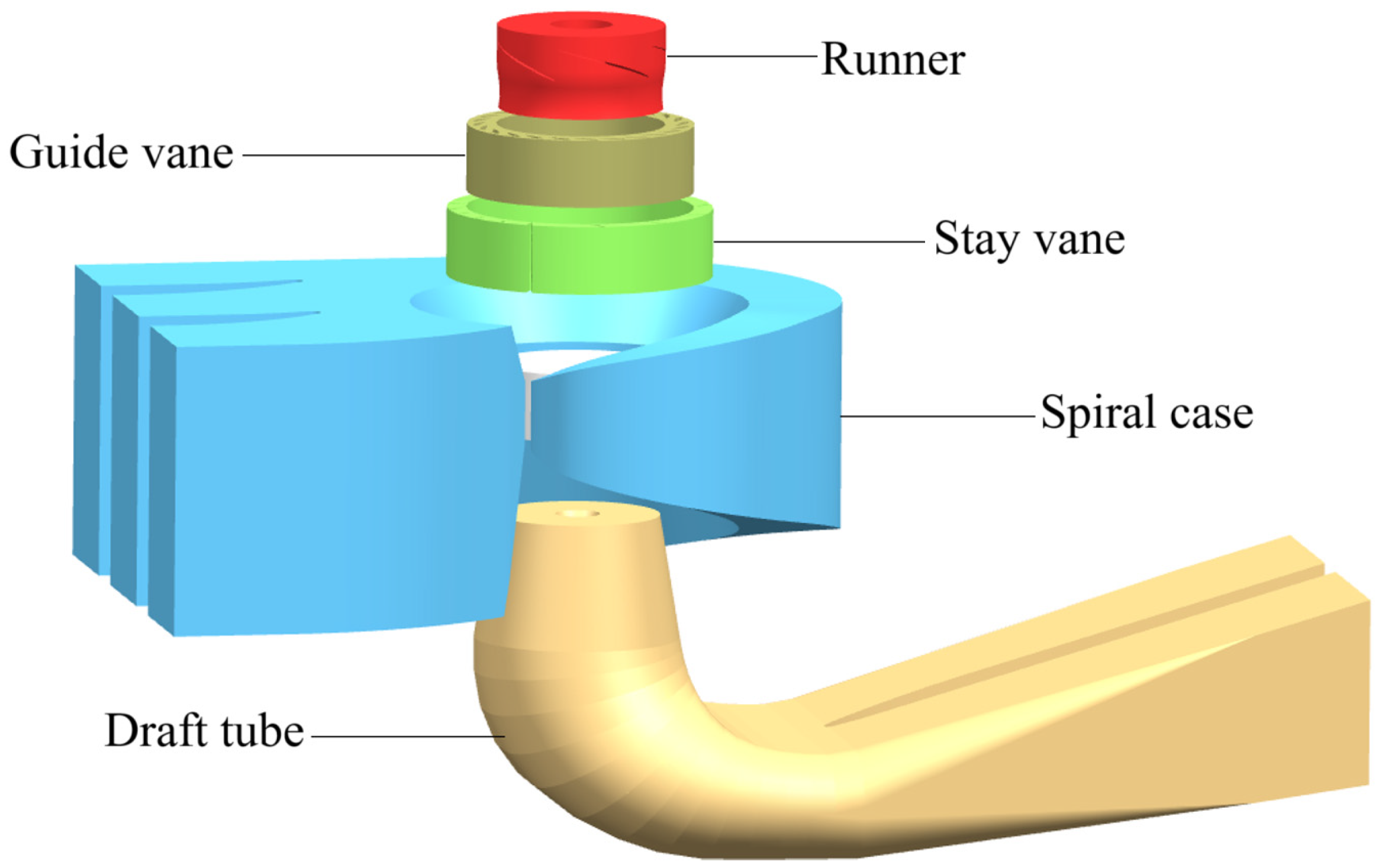

3.2. Analysis of Hydraulic Characteristics of the Draft Tube

After the water exchanges energy at the runner, it flows into the draft tube. As a critical energy recovery device, the draft tube of the turbine not only serves to smoothly guide the discharged flow from the runner downstream but also recovers residual energy from the flow. To investigate the influence of guide vane opening on the hydraulic performance of the turbine, it is essential to analyze the flow patterns within the draft tube. A total of 11 monitoring sections were selected across the conical section, elbow section, and diffuser section to observe flow characteristics and velocity distribution at different cross-sections, thereby identifying the influence patterns of guide vane openings.

Figure 7 presents a comparison of velocity vectors at various cross-sections of the draft tube under different guide vane openings for two head conditions. Observing the velocity distribution in the conical section, the flow velocity is relatively low at the center of the draft tube and increases progressively from the center towards the wall, showing a stable increasing trend. This pattern closely matches the velocity distribution observed in experiments. Overall, the velocity under high-head conditions is significantly greater than that under the rated head, as the higher flow rate leads to a higher relative velocity, which also contributes to increased flow instability. It can be seen from the figure that, with increasing guide vane opening, the area of high-velocity zones across sections from the elbow to the diffuser expands significantly, with this effect being particularly pronounced under high-head conditions.

According to

Figure 7, under small guide vane openings (i.e., conditions OP1 and OP4), energy losses result in lower outflow velocities near the hub, forming a large low-velocity zone in the center of the draft tube. Flow pulsations are evident, with a tendency for backflow. After leaving the flow passage, the fluid near the wall still exhibits tangential velocity similar to the inlet direction of the draft tube. Under the influence of inertia and gravity, the fluid flows diagonally downward along the wall, with the inclination angle gradually decreasing as the fluid moves downstream. A comparison of the two small-opening conditions reveals that the inflow under the maximum head increases compared to the rated head, and the low-velocity zone is significantly reduced; however, the overall flow characteristics remain chaotic and disordered.

At high-efficiency operating points (i.e., conditions OP2 and OP5), low-energy fluid exiting the flow passage is concentrated at the center of the conical section, where the central low-velocity zone expands progressively with the widening of the cone. As the flow passes through the elbow section, the velocity distribution becomes asymmetric, and the flow characteristics become more complex. In the diffuser section, velocity vectors across the sections are unevenly distributed. Under large guide vane openings, the increased flow rate leads to the outflow velocity being dominated by relative velocity. The inlet velocity within the draft tube is relatively uniform, but its direction forms a certain angle with the inlet surface. A distinct central low-velocity zone is present, which interacts with surrounding high-velocity flow to form vortices.

To further understand the flow characteristics within the draft tube, streamline patterns at the y = 0 cross-section were examined, as shown in

Figure 8. Analysis of flow patterns across different operating conditions and head levels reveals common features: low velocities at the center, higher velocities near the wall, and vortex formation in both flow regimes. Due to the unique structure of the draft tube, the flow velocity increases significantly after passing through the elbow section.

In the streamline plot for condition OP1, higher velocities can be observed near the wall (with peak values around 2.50 to 3.00 m/s), while the central region of the draft tube exhibits significant velocity decay (with some areas below 0.50 m/s), indicating a clear velocity gradient stratification. Local curvature of streamlines appears in the elbow section, likely due to flow inertia causing separation between high-speed flow near the wall and low-speed flow at the center, accompanied by localized backflow, which increases hydraulic losses. Small vortices can be observed near the inlet of the draft tube, while the downstream streamlines appear disordered. In comparison, under condition OP4, the overall flow velocity increases, vortices appear in the midsection of the conical part, and while backflow still occurs, the overall outflow is more stable.

Under high-efficiency operating conditions, the velocity distribution becomes more uniform, with streamlines smoothly diffusing along the wall surface. No significant low-velocity zones or backflow can be observed, indicating a higher efficiency in flow energy recovery. The draft tube vortex rope exhibits a helical shape with a significant velocity difference between its two sides—the low-velocity side typically located near the center and the high-velocity side near the draft tube wall. Compared to small guide vane openings, the overall flow pattern is slightly improved, and the backflow phenomenon is noticeably reduced. However, distinct vortex structures still appear in the conical section, with four vortices observed under condition OP5.

Examining the streamline diagrams for OP3 and OP6, it was found that the number of vortices increases compared to other conditions at the same head, with vortices extending into the elbow section. Under OP3, a clear low-velocity zone appears along the draft tube wall, accompanied by curved streamlines, indicating flow separation in this region.

In summary, it can be observed that changes in guide vane opening are closely related to the formation and evolution of vortices within the draft tube. Vortices generally appear in regions where there is a large velocity difference between two sides, suggesting that significant velocity gradients lead to pronounced pressure differences. Excessive tangential velocity induces convection, resulting in vortex formation. It was also noted that vortices mainly occur near the center of the conical section of the draft tube. To better understand the formation and distribution of vortices, the conical section of the draft tube was divided into planes, as shown in

Figure 9. DT1 represents the cross-section at the draft tube inlet, with subsequent sections taken at 100 mm intervals. DT3 corresponds to the end of the conical section.

Figure 10 presents the pressure distribution diagrams at various draft tube cross-sections under different operating conditions. It can be observed that the pressure gradually increases from section DT1 to DT3. In condition OP1, a distinct low-pressure zone appears at the center of section DT1, suggesting the possible presence of a vortex in this region. Additionally, five other low-pressure zones can be observed in DT1, corresponding to the number of runner blades, as this section is closest to the runner outlet and the flow is significantly influenced by the runner. The pressure distribution pattern in section DT2 is similar to that in DT1, with the low-pressure zones caused by the runner remaining largely unchanged in position, indicating the potential formation of a columnar vortex rope. However, the position of the central low-pressure zone shifts, suggesting that the central vortex rope is an eccentric helical vortex rope.

Section DT3 is predominantly characterized by high pressure, indicating that the helical vortex rope dissipates under OP1 conditions by this point. The pressure distribution patterns at each section under high-efficiency and high-flow conditions are generally consistent with those observed in OP1. However, it is evident from the figure that as the flow rate increases, the area of the central low-pressure zone also expands. At section DT3, near the draft tube wall, the low-pressure distribution becomes more pronounced with increasing guide vane opening. Due to boundary layer effects, the flow velocity near the wall is relatively low, making it easier for high-velocity fluid to interact and generate chaotic vortices that affect the overall flow pattern within the draft tube. Under OP3, which has the highest flow rate, the central low-pressure zone reaches its maximum area, and significant low-pressure regions can still be observed at DT3, indicating that the helical vortex rope extends continuously from the conical section to the elbow section of the draft tube.

In this study, the Q-criterion was employed for vortex identification.

Figure 11 shows the vorticity distribution under various operating conditions, where

Figure 11a presents a comparative diagram of the vortex rope and vorticity distribution for condition OP1. Observing the vortex rope distribution and vorticity contours at each cross-section for OP1, it is evident that a significant high-vorticity region appears at the center of section DT1, where the helical vortex rope originates. Notably, five additional regularly distributed high-vorticity zones are present within the section, corresponding precisely to the number of runner blades. This is primarily due to the proximity of this section to the runner outlet, where it is heavily influenced by periodic blade wake disturbances. These high-vorticity zones correspond to columnar vortex ropes, confirming the earlier hypothesis.

High vorticity can also be observed near the draft tube wall at DT1, where fluid flows downward along the wall under the influence of inertia and gravity. Due to boundary layer effects, vortices are generated in this region. Comparative analysis indicates that while section DT2 maintains a similar number of high-vorticity zones, the core high-vorticity regions exhibit a circumferential shift, reflecting the spatial evolution characteristics of the vortex rope. By DT3, the vorticity gradient changes significantly, with the overall flow field displaying low vorticity, indicating that the energy of the helical vortex rope has been fully dissipated in this region.

Compared to small guide vane openings, both high-efficiency and large-opening conditions exhibit a noticeable increase in the area of the central high-vorticity zone, along with significant enhancement in the volume and intensity of the helical vortex rope. The vorticity distribution at DT3 under these conditions shows that the vortex rope extends into the elbow section. Furthermore, the comparison reveals that as the guide vane opening increases, the higher outflow velocity reduces the influence of the boundary layer, leading to the gradual disappearance of the annular vortex rope near the draft tube wall.

Compared to the operating conditions at a head of 3 m, the vortex intensity under the 5 m head conditions shows a significant increase. Relative to OP1, the central high-vorticity region in OP4 exhibits notable expansion, with section DT5 still maintaining a high vorticity intensity (vorticity > 750 s−1). The pressure distribution characteristics in OP5 and OP6 differ markedly from those in other conditions, with a dual-vortex core structure appearing in the center of section DT1. The abnormal number and shape of vortex cores suggest the possible presence of a coupled double-helical vortex rope phenomenon. As the head increases, changes in the circulation distribution at the runner outlet lead to volumetric expansion and topological deformation of the central helical vortex rope.

Figure 12 illustrates the temporal evolution of vortex ropes under various operating conditions, where T

0 represents the initial moment and T denotes the time for one full rotation of the turbine. At a head of 3 m, the vortex rope under small guide vane openings is relatively slender, with a smaller eccentric angle. At the initial moment, a few random vortices are present near the draft tube inlet, which tend to interact with the draft tube wall, generating random pressure pulsations; these vortices gradually dissipate over time. Under OP2, the vortex rope volume increases compared to OP1, while the number of random vortices at the inlet decreases. In the large-guide vane opening condition, OP3, the vortex rope becomes larger and the number of random vortices increases.

Due to the rotational effect of the runner, the fluid acquires a tangential velocity similar to the direction of velocity at the flow passage outlet. Under the influence of inertia and gravity, the fluid flows downward along the wall and interacts with the stagnation zone at the center of the conical section of the draft tube, leading to vortex formation. Compared to OP1, the helical vortex rope in OP4 exhibits a larger volume and a greater eccentric angle. Under OP5 and OP6, double-helical vortex ropes appear, likely caused by increased blade loading under high-head conditions, where the intensified pressure difference between the suction and pressure sides of the blades induces secondary flows, generating counter-rotating vortex pairs. Additionally, the number of annular vortices near the draft tube wall significantly increases in these two conditions.

To analyze the pressure pulsation characteristics induced by the vortex rope in the draft tube of the Kaplan turbine under different operating conditions, OP1, OP2, OP3, and OP5 were selected based on the previous computational analysis. The distribution of monitoring surfaces and points is shown in

Figure 13, where the monitoring surfaces correspond to the previously defined DT1, DT2, and DT3 cross-sections. Taking the DT1 section as an example, the monitoring points are labeled dt101 to dt104, with similar naming conventions applied to the other sections.

For the pressure pulsations caused by the vortex rope, pressure data from four real-time monitoring points on each cross-section were extracted from the flow field calculations to obtain time-domain signals. These time-domain signals were processed using the 97% confidence method and subsequently subjected to the Fast Fourier Transform (FFT) to generate the frequency-domain spectra of the pressure pulsations.

Figure 14 shows the pressure pulsation frequency spectra of the draft tube under various operating conditions. The rotational frequency is non-dimensionalized, with the runner speed at 643.333 r/min, resulting in a rotational frequency of 643.333/60 = 10.722 Hz. The blade-passing frequency is five times the rotational frequency, which equals 53.611 Hz.

From

Figure 14, it can be observed that under all operating conditions, the pressure pulsation signals at each monitoring point are primarily low-frequency signals, followed by blade-passing frequency (BPF) signals. In OP1, aside from the low-frequency components, the dominant frequencies at monitoring points dt101 to dt104 are 5 times and 10 times the rotational frequency, corresponding to the blade-passing frequency and its second harmonic. This is due to the proximity of the DT1 section to the runner outlet, where the frequency signals are mainly caused by rotor–stator interaction at the interface between the runner and the draft tube.

At the DT2 section, the amplitude of the BPF signals significantly decreases. By the DT3 section, the BPF signals disappear entirely, leaving only low-frequency signals induced by the vortex rope. The pressure pulsation amplitude at points dt101 to dt104 shows a trend of decreasing first and then increasing, reaching a minimum at dt102 and a maximum at dt104. A similar pattern can be observed at DT2. However, at DT3, the minimum amplitude occurs at dt303.

For OP2, the BPF amplitudes at DT1 are significantly higher than the low-frequency components, with additional signals at two and three times the BPF. As the distance from the runner outlet increases, the BPF signals gradually weaken. This indicates that under OP2, the draft tube flow is less affected by the vortex rope, resulting in higher energy recovery efficiency. However, low-frequency pulsations induced by the vortex rope remain dominant at DT3. The pressure pulsation amplitude at monitoring points tends to increase with the distance from the runner outlet.

In OP3, compared to the other two conditions at the same head, the BPF amplitude is the lowest, with low-frequency signals dominating. These low-frequency components are more complex, likely originating from pulsations transmitted by blade channel vortices and other sources. Comparing the three conditions at the same head, OP2 exhibits the lowest pressure pulsation amplitude, while OP1 shows the highest. This aligns with previous analyses, indicating that the draft tube flow under OP3 is significantly affected by the helical vortex rope.

Analyzing the pressure pulsations in OP5 reveals that low-frequency signals remain dominant and are relatively chaotic, mainly influenced by the draft tube vortex rope. When the circulation at the runner outlet reaches a critical value, the vortex rope rotates in the opposite direction to the runner, causing expansion of the precessing vortex core diameter. This fluid–structure interaction can induce self-excited vibrations, leading to significant increases in pressure pulsation. The amplitude of pressure pulsations at each monitoring point increases with the distance from the runner outlet, reaching a maximum at DT3.

By analyzing

Figure 15 and

Figure 16 together, it can be observed that an eccentric vortex rope forms at the center of the draft tube, and as the guide vane opening increases, both the volume and the eccentric angle of the vortex rope increase accordingly. From the vorticity distribution diagrams, six high-vorticity regions are present at the draft tube inlet section. Excluding the central vortex rope, the other five high-vorticity zones are mainly influenced by the runner. Based on the position of the high-vorticity regions in section DT2, the vortex rope rotates clockwise, which is consistent with the rotational direction of the runner.

At section DT3, a central high-vorticity zone remains, and the number of scattered vortices significantly increases, particularly under large guide vane openings. Since DT3 marks the end of the draft tube’s conical section and the beginning of the elbow section, it can be inferred that these scattered vortices are largely due to structural influences of the draft tube. When the flow impacts the elbow wall, interactions with high-velocity fluid lead to vortex formation. Overall, the hydraulic behavior of the turbine at a blade angle of 6° follows a similar pattern to that observed at a blade angle of 0°.