A State Estimation of Dynamic Parameters of Electric Drive Articulated Vehicles Based on the Forgetting Factor of Unscented Kalman Filter with Singular Value Decomposition

Abstract

1. Introduction

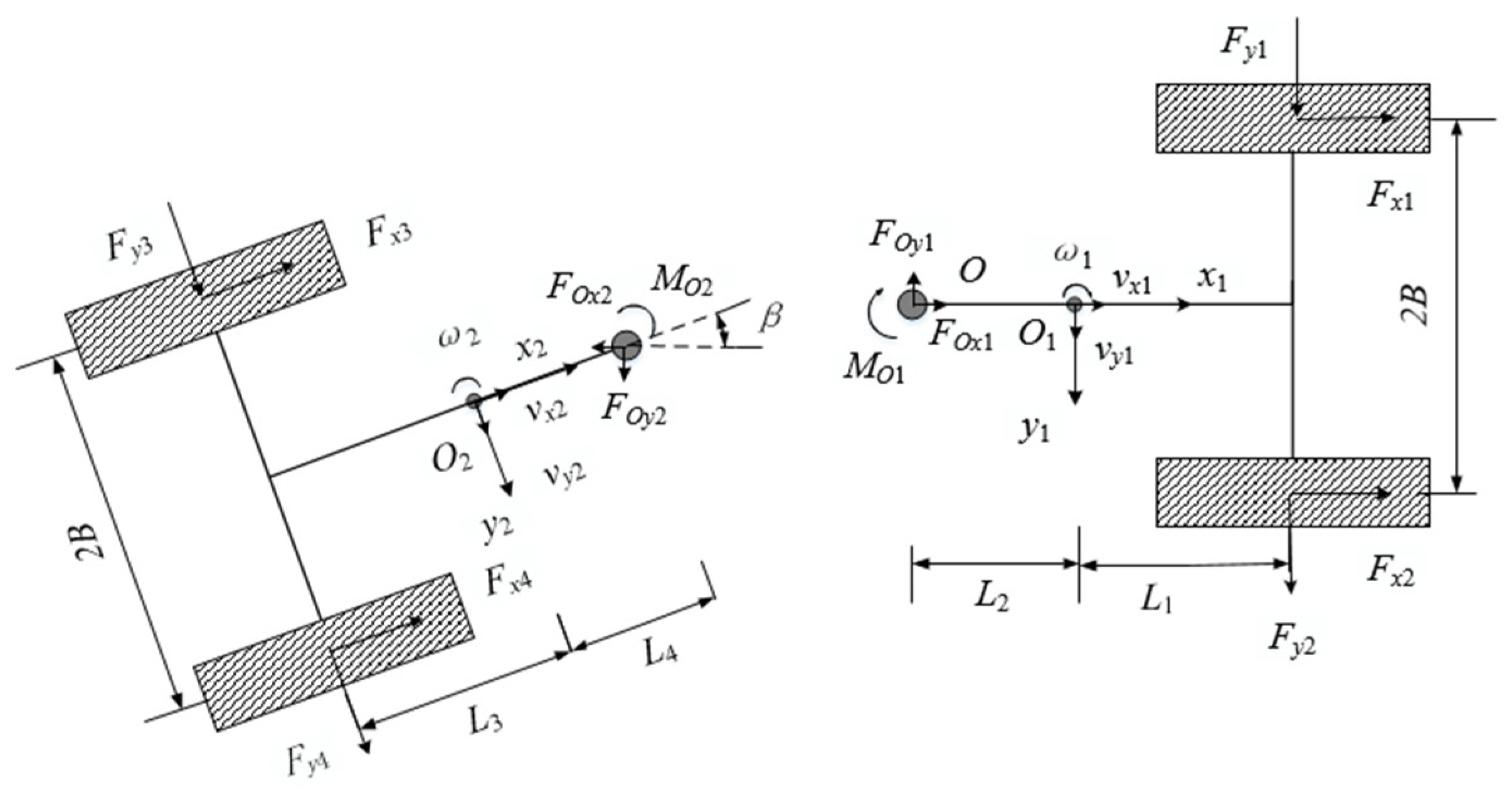

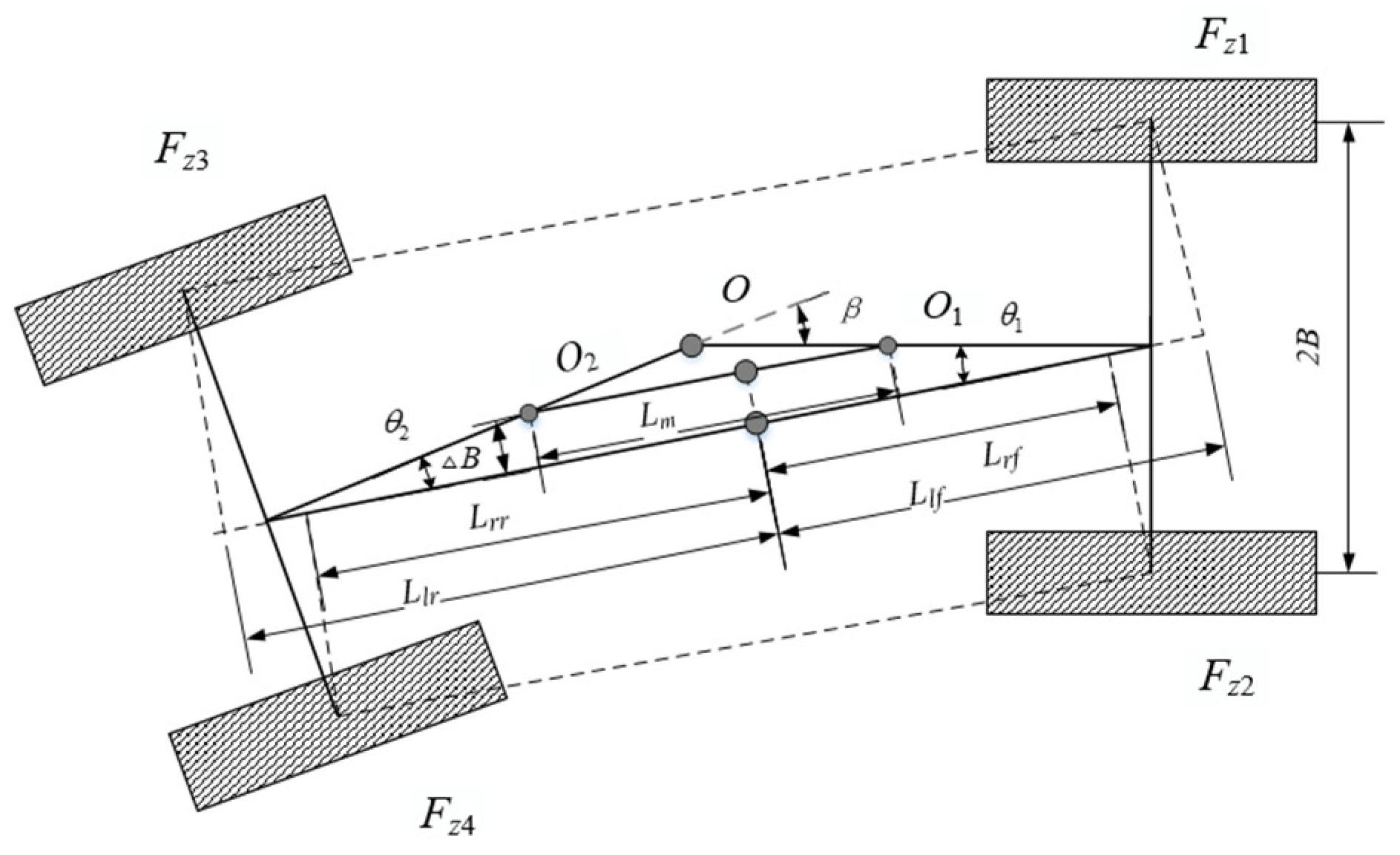

2. Nonlinear Dynamics Modeling of Articulated Vehicles

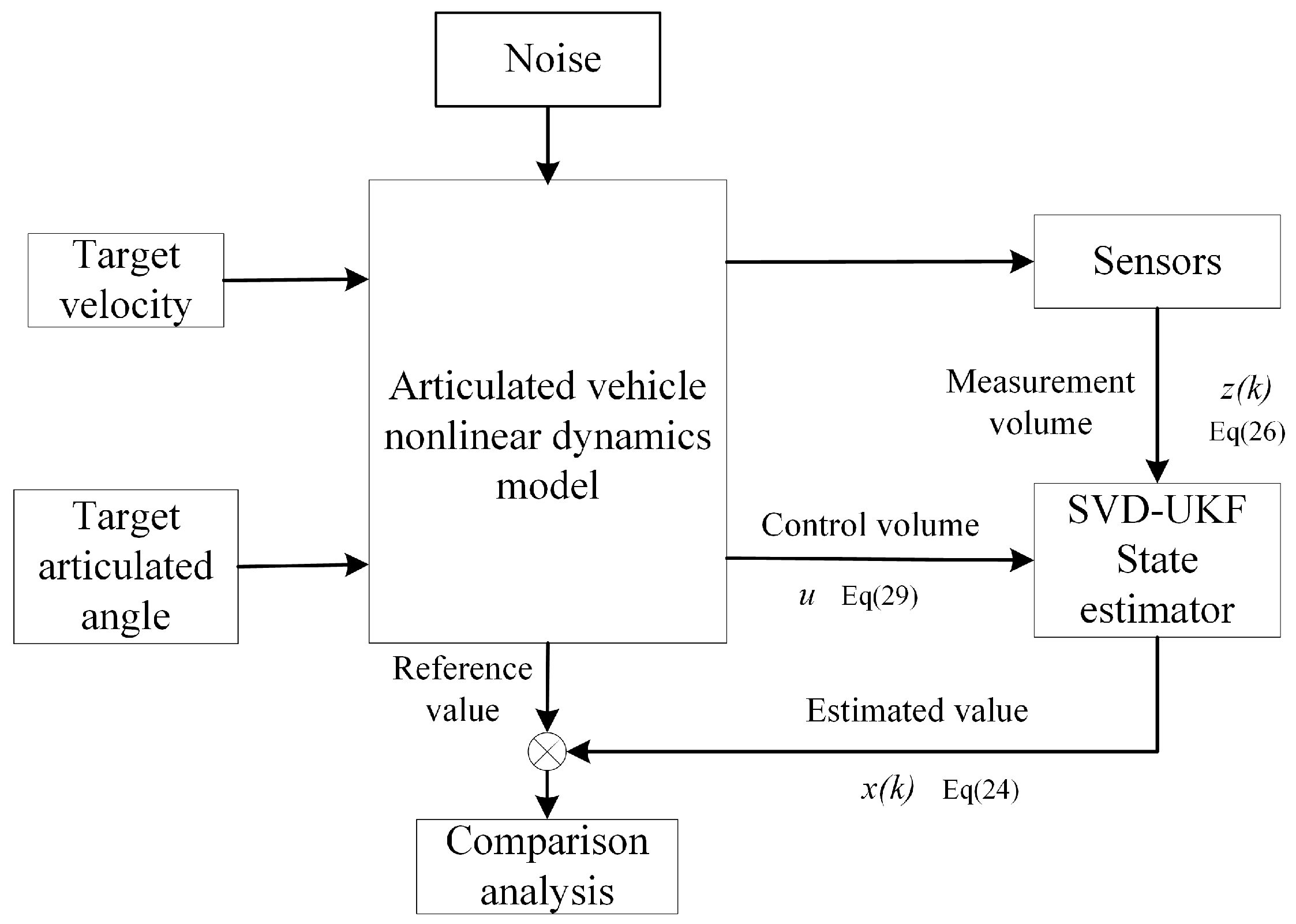

3. Adaptive Forgetting Factor SVD-UKF Articulated Vehicle Dynamics Parameter Estimation

3.1. Adaptive Forgetting Factor SVD-UKF(ASVD-UKF)

3.2. System State Equations and Observation Equations

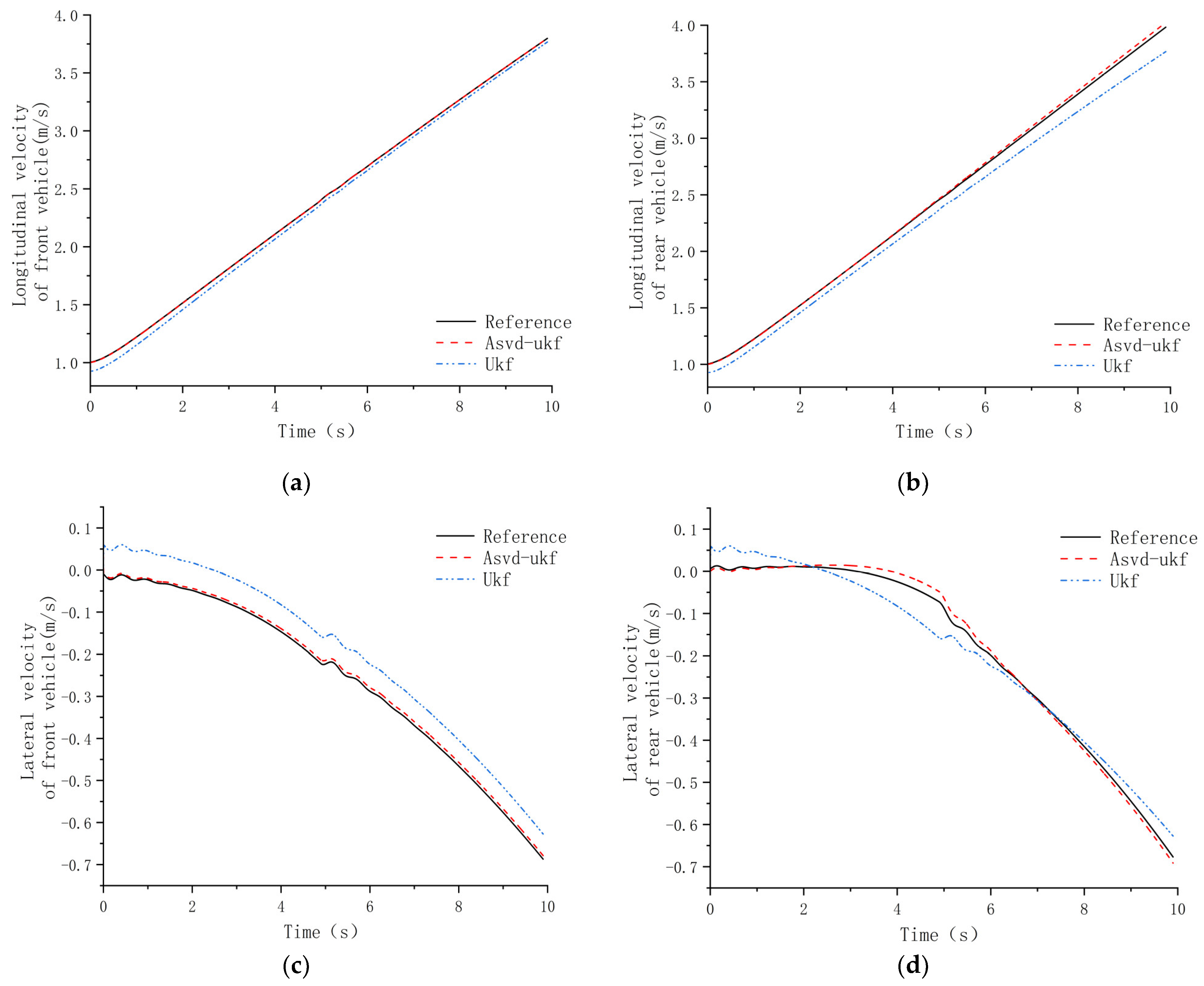

4. Simulation Analysis

4.1. Simulation Settings

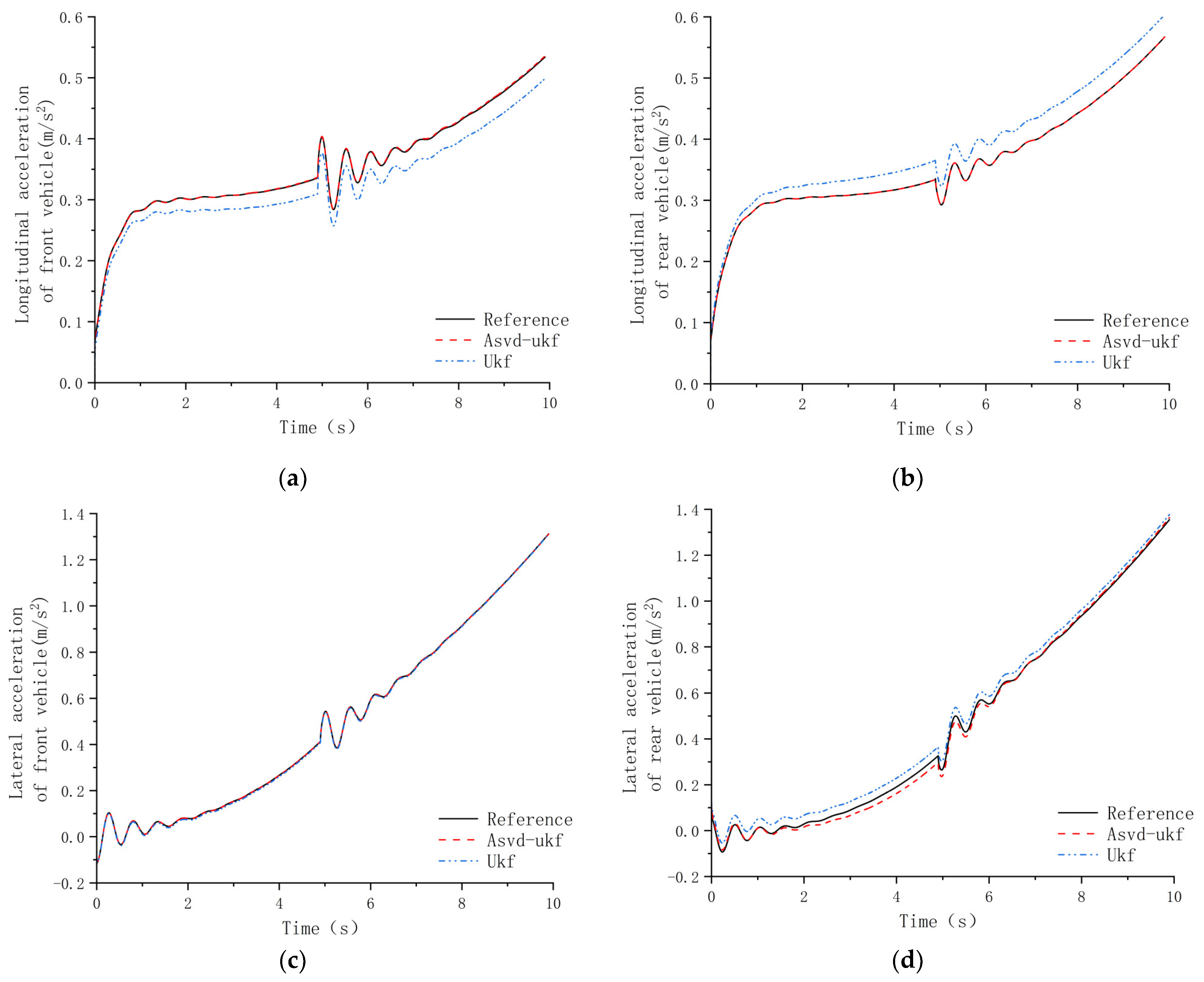

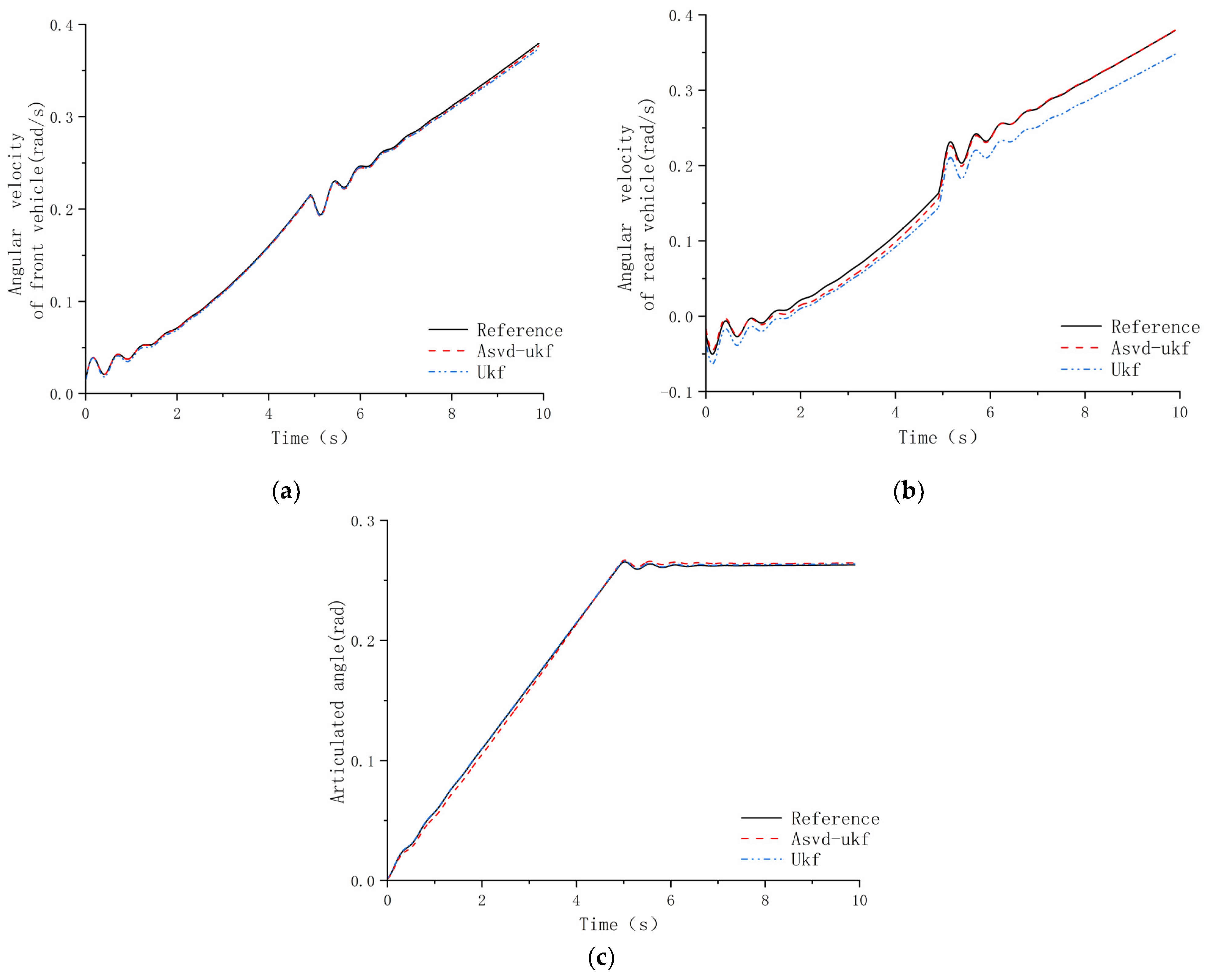

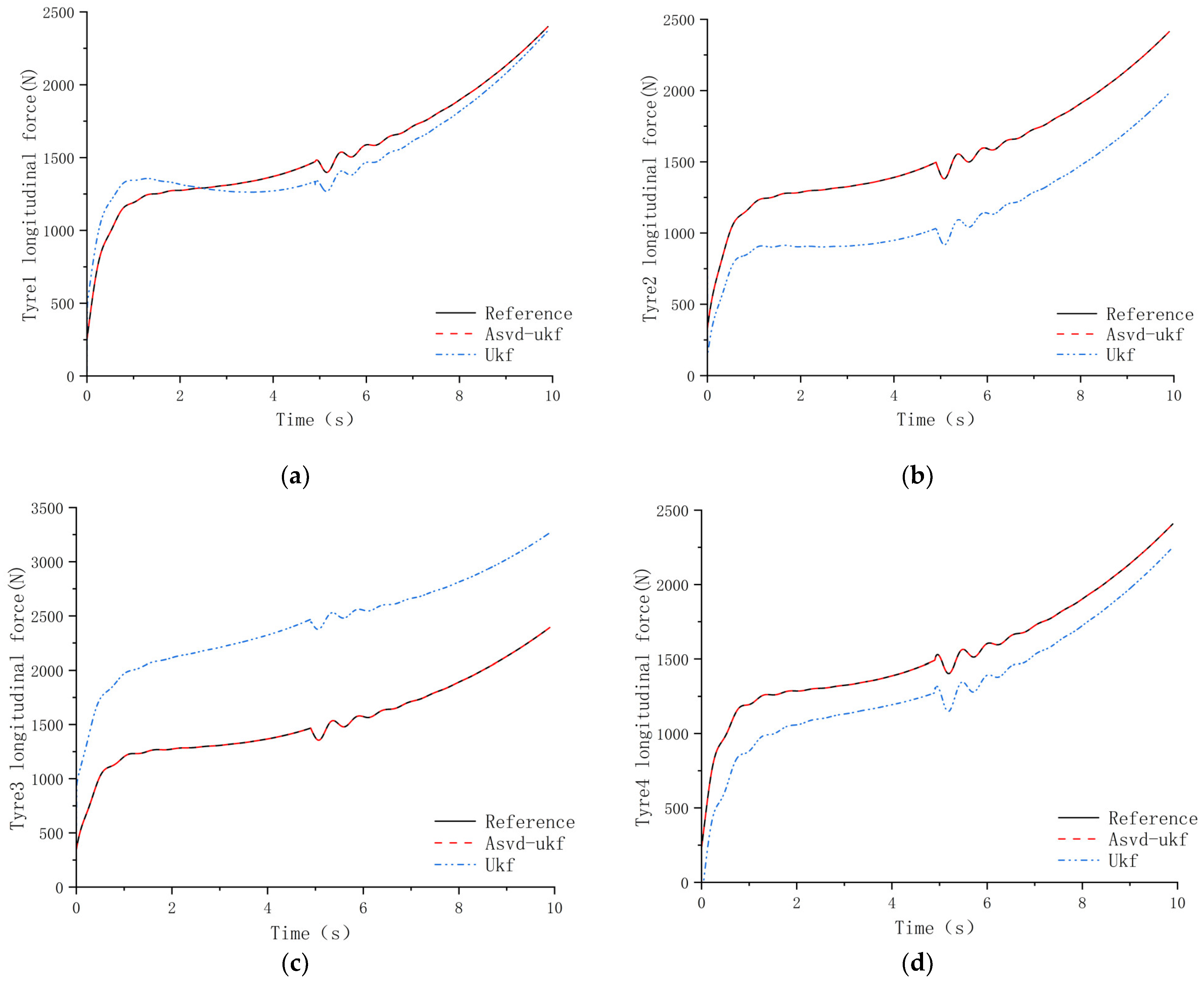

4.2. Analysis of Simulation Results

5. Experimental Verification

5.1. Distributed Electric Drive Principle Prototype Vehicle and Test Program

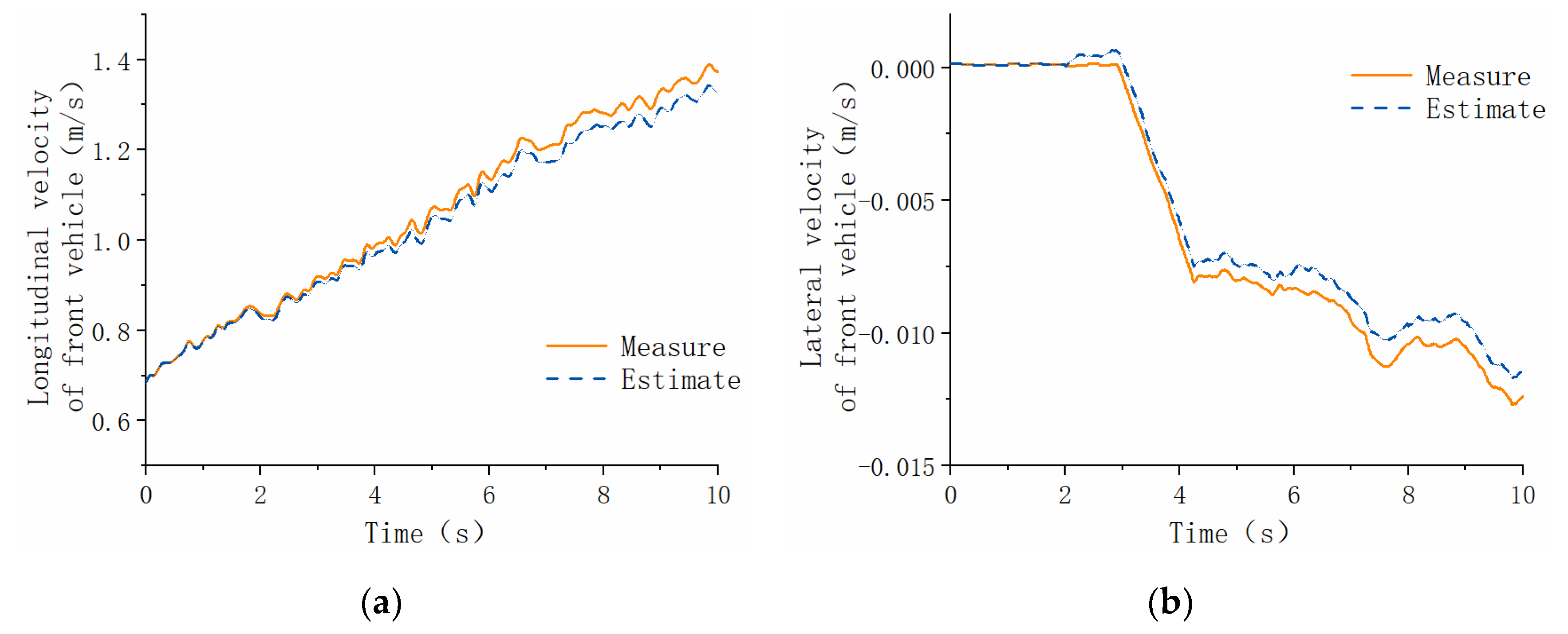

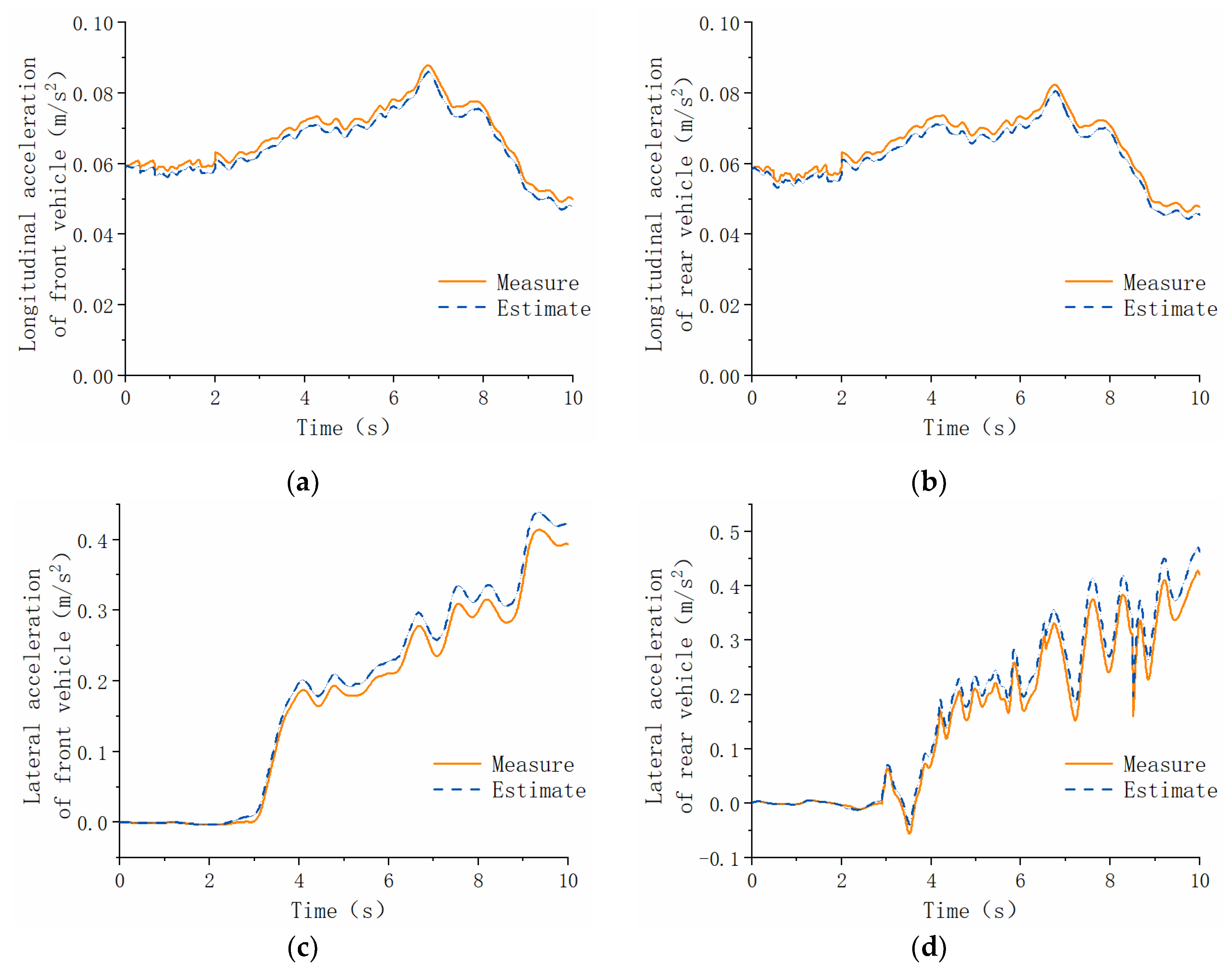

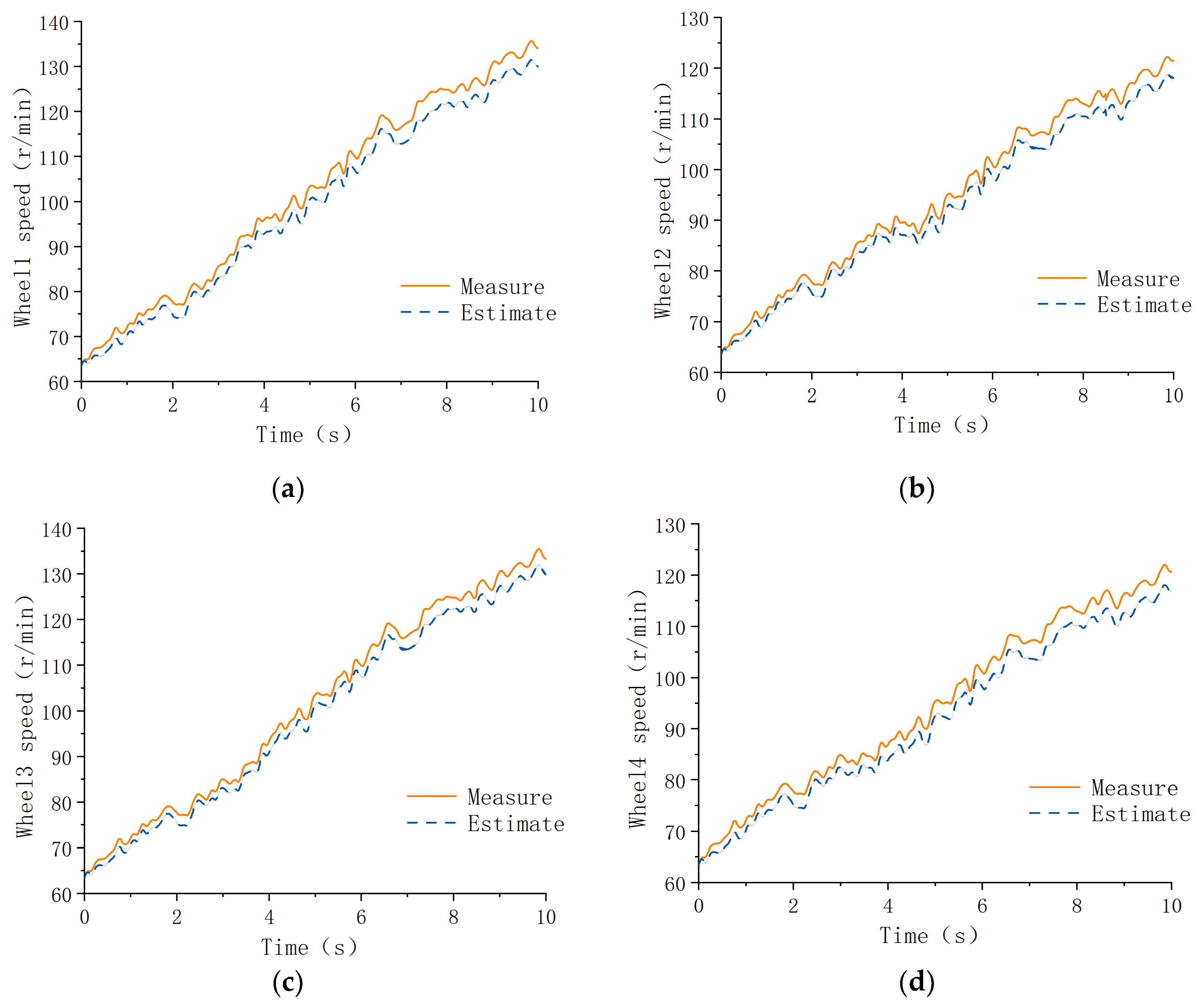

5.2. Analysis of Test Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Front vehicle body coordinate system | |

| Rear vehicle body coordinate system | |

| Longitudinal velocity of front vehicle body | |

| Longitudinal velocity of rear vehicle body | |

| Lateral velocity of front vehicle body | |

| Lateral velocity of front vehicle body | |

| Angular velocity of z-axis of front vehicle body | |

| Angular velocity of z-axis of rear vehicle body | |

| Distance from center of front vehicle gravity to front axles | |

| Distance from articulated point to center of front vehicle gravity | |

| Distance from center of rear vehicle gravity to front axles | |

| Distance from articulated point to center of rear vehicle gravity | |

| Vertical tire force | |

| Longitudinal tire stiffness | |

| Lateral tire stiffness | |

| Swing angle | |

| Vehicle rotational inertia of -axis of front vehicle body | |

| Vehicle rotational inertia of -axis of rear vehicle body | |

| Longitudinal tire force | |

| Lateral tire force | |

| Torque of steering mechanism on front vehicle body | |

| Torque of steering mechanism on rear vehicle body | |

| Mass of front vehicle body | |

| Mass of rear vehicle body | |

| Longitudinal force of steering mechanism on front vehicle body | |

| Longitudinal force of steering mechanism on rear vehicle body | |

| Lateral force of steering mechanism on front vehicle body | |

| Lateral force of steering mechanism on rear vehicle body | |

| Friction coefficient | |

| Distance between hinge points of hydraulic cylinder rod and articulated point | |

| Distance between hinge points of hydraulic cylinder seat and articulated point | |

| Initial angle of hydraulic cylinder | |

| Sti | Tire slip rate ) |

| Tire slip angle | |

| Wheel drive torque |

Appendix A

Related Calculation for Vehicle Dynamics Model

Appendix B

Appendix C

References

- Gao, L.; Dong, Y.; Zhao, J. Dynamic Modeling and Characteristic Analysis of Articulated Steering Vehicles. Appl. Sci. 2023, 13, 5099. [Google Scholar] [CrossRef]

- Azad, N.L.; Khajepour, A.; Mcphee, J. A survey of stability enhancement strategies for articulated steer vehicles. Int. J. Heavy Veh. Syst. 2009, 16, 26. [Google Scholar] [CrossRef]

- Guo, H.; Cao, D.; Chen, H.; Lv, C.; Wang, H.; Yang, S. Vehicle Dynamic State Estimation: State of the Art Schemes and Perspectives. IEEE-CAA J. Autom. Sin. 2018, 5, 418–431. [Google Scholar] [CrossRef]

- Hong, S.; Lee, C.; Borrelli, F.; Hedrick, J.K. A Novel Approach for Vehicle Inertial Parameter Identification Using a Dual Kalman Filter. IEEE Trans. Intell. Transp. Syst. 2015, 16, 151–161. [Google Scholar] [CrossRef]

- Mosconi, L.; Farroni, F.; Sakhnevych, A.; Timpone, F.; Gerbino, F.S. Adaptive vehicle dynamics state estimator for onboard automotive applications and performance analysis. Veh. Syst. Dyn. 2023, 61, 3244–3268. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.; Zhang, L.; Cao, D.; Dorrell, D.G. A Vehicle Rollover Evaluation System Based on Enabling State and Parameter Estimation. IEEE Trans. Ind. Inform. 2021, 17, 4003–4013. [Google Scholar] [CrossRef]

- Rezaei, O.; Moghaddam, H.A.; Papari, B. A fast sliding-mode-based estimation of state-of-charge for Lithium-ion batteries for electric vehicle applications. J. Energy Storage 2022, 45, 103484. [Google Scholar] [CrossRef]

- Yang, C.; Zhu, Q.; Liu, Q.; Chen, X. An unscented Kalman filter based velocity estimation method for articulated steering vehicle using a novel dynamic model. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2023, 237, 389–405. [Google Scholar] [CrossRef]

- Tan, C.; Cai, Y.; Wang, H.; Sun, X.; Chen, L. Vehicle State Estimation Combining Physics-Informed Neural Network and Unscented Kalman Filtering on Manifolds. Sensors 2023, 23, 6665. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Lv, C. Dynamic State Estimation for the Advanced Brake System of Electric Vehicles by Using Deep Recurrent Neural Networks. IEEE Trans. Ind. Electron. 2020, 67, 9536–9547. [Google Scholar] [CrossRef]

- Heidfeld, H.; Schünemann, M.; Kasper, R. UKF-based State and tire slip estimation for a 4WD electric vehicle. Veh. Syst. Dyn. 2020, 58, 1479–1496. [Google Scholar] [CrossRef]

- Hashemi, E.; Khosravani, S.; Khajepour, A.; Kasaiezadeh, A.; Chen, S.-K.; Litkouhi, B. Longitudinal vehicle state estimation using nonlinear and parameter-varying observers. Mechatronics 2017, 43, 28–39. [Google Scholar] [CrossRef]

- Jin, X.; Yin, G.; Chen, N. Advanced Estimation Techniques for Vehicle System Dynamic State: A Survey. Sensors 2019, 19, 4289. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi Jeyed, H.; Ghaffari, A. Nonlinear estimator design based on extended Kalman filter approach for state estimation of articulated heavy vehicle. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2019, 233, 254–265. [Google Scholar] [CrossRef]

- Ziaukas, Z.; Wielitzka, M.; Ortmaier, T.; Kobler, J.-P. Simultaneous Estimation of Steering and Articulation Angle in a Truck-Semitrailer Combination Solely Based on Trailer Signals. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 2509–2514. [Google Scholar] [CrossRef]

- Ehlers, S.F.G.; Sourkounis, P.; Ziaukas, Z.; Kobler, J.-P.; Jacob, H.-G. Optimized Tuning of an EKF for State and Parameter Estimation in a Semitrailer. In Proceedings of the International Symposium on Advanced Vehicle Control, Kanagawa, Japan, 12–16 September 2022; Kanagawa Institute of Technology: Atsugi, Japan, 2024. [Google Scholar]

- Wenwei, W.; Yifan, Z.; Wei, Z.; Cheng, L. Yaw Stability Control Strategy of Multi-wheel Independent Electric Articulated Bus. J. Mech. Eng. 2020, 56, 161. [Google Scholar] [CrossRef]

- Gao, L.; Ma, F.; Jin, C. A Model-Based Method for Estimating the Attitude of Underground Articulated Vehicles. Sensors 2019, 19, 5245. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Cheng, X.; Zhang, H.; Gong, X. Estimation of Center of Gravity Position for Distributed Driving Electric Vehicles Based on Combined H∞-EKF Method. Energy Procedia 2016, 88, 970–977. [Google Scholar] [CrossRef][Green Version]

- Yang, Z.; Wang, J.; Han, Y. A Novel Real-Time Center of Gravity Estimation Method for Wheel Loaders with Front/Rear-Axle-Independent Electric Driving. J. Control Sci. Eng. 2021, 2021, 6621060. [Google Scholar] [CrossRef]

- Gao, G.; Wang, J.; Ma, T.; Liu, W.; Lei, T. Multistage Estimators for the Distributed Drive Articulated Steering Vehicle. Math. Probl. Eng. 2020, 2020, 5921285. [Google Scholar] [CrossRef]

- Lei, T.; Gu, X.; Zhang, K.; Li, X.; Wang, J. PSO-Based Variable Parameter Linear Quadratic Regulator for Articulated Vehicles Snaking Oscillation Yaw Motion Control. Actuators 2022, 11, 337. [Google Scholar] [CrossRef]

- Dugoff, H.; Fancher, P.S.; Segel, L. Tire Performance Characteristics Affecting Vehicle Response to Steering and Braking Control Inputs; National Academy of Sciences: Washington, DC, USA, 1969. [Google Scholar]

| Name | Quantity | Location | Measured Parameters |

|---|---|---|---|

| IMU | 2 | front and rear bodies | (Equation (26)) |

| drive torque | 4 | 4 hub motors | (Equation (29)) |

| steering torque | 1 | steering system | (Equation (29)) |

| wheel speed | 4 | 4 hub motors | (Equation (26)) |

| articulated angle | 1 | steering system | |

| RTK | 1 | front body | (Equation (24)) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, T.; Hou, M.; Li, L.; Cao, H. A State Estimation of Dynamic Parameters of Electric Drive Articulated Vehicles Based on the Forgetting Factor of Unscented Kalman Filter with Singular Value Decomposition. Actuators 2025, 14, 31. https://doi.org/10.3390/act14010031

Lei T, Hou M, Li L, Cao H. A State Estimation of Dynamic Parameters of Electric Drive Articulated Vehicles Based on the Forgetting Factor of Unscented Kalman Filter with Singular Value Decomposition. Actuators. 2025; 14(1):31. https://doi.org/10.3390/act14010031

Chicago/Turabian StyleLei, Tianlong, Mingming Hou, Liaoyuan Li, and Haohua Cao. 2025. "A State Estimation of Dynamic Parameters of Electric Drive Articulated Vehicles Based on the Forgetting Factor of Unscented Kalman Filter with Singular Value Decomposition" Actuators 14, no. 1: 31. https://doi.org/10.3390/act14010031

APA StyleLei, T., Hou, M., Li, L., & Cao, H. (2025). A State Estimation of Dynamic Parameters of Electric Drive Articulated Vehicles Based on the Forgetting Factor of Unscented Kalman Filter with Singular Value Decomposition. Actuators, 14(1), 31. https://doi.org/10.3390/act14010031