Research on Output Characteristics of a Non-Contact Piezoelectric Actuator’s Micro-Displacement Amplifying Mechanism

Abstract

1. Introduction

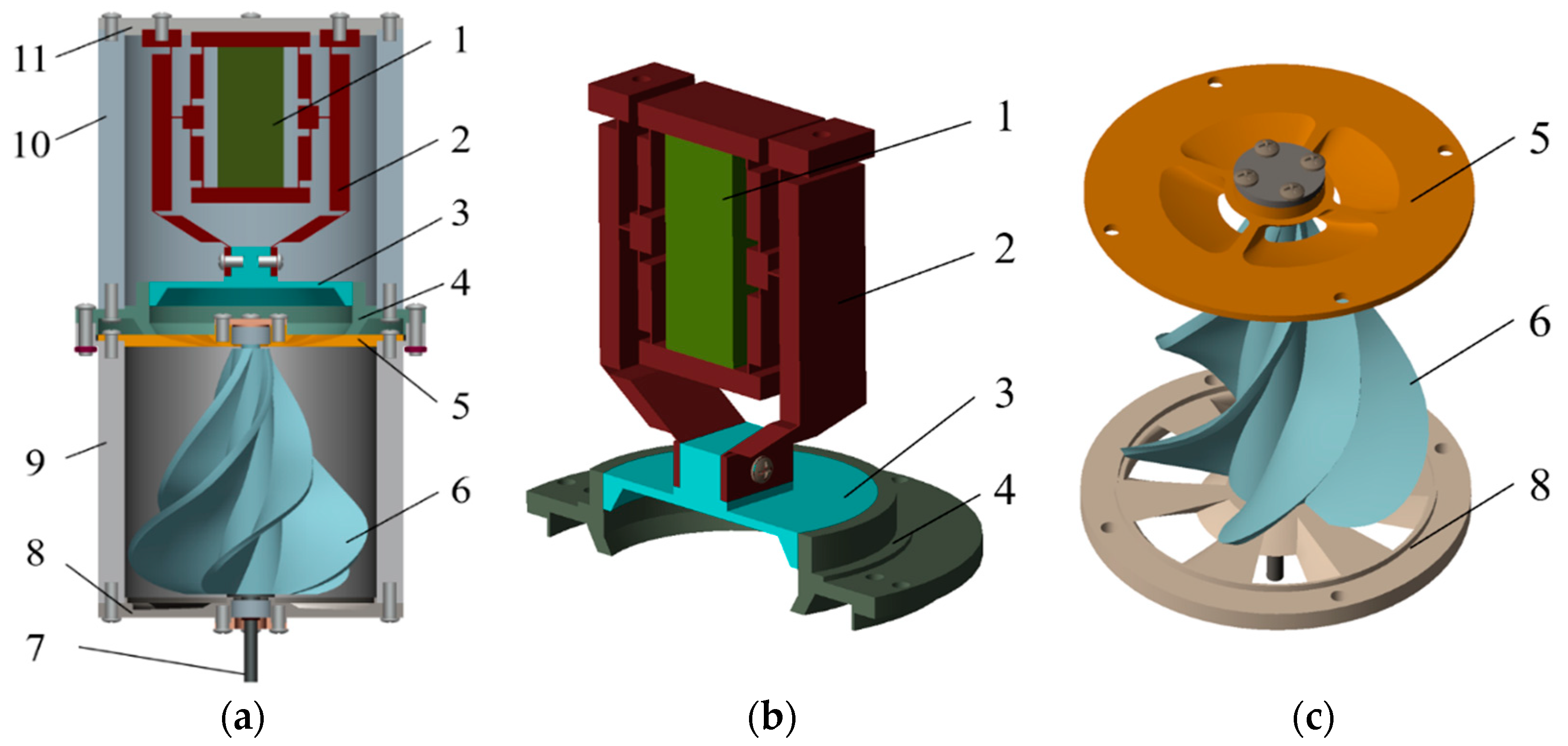

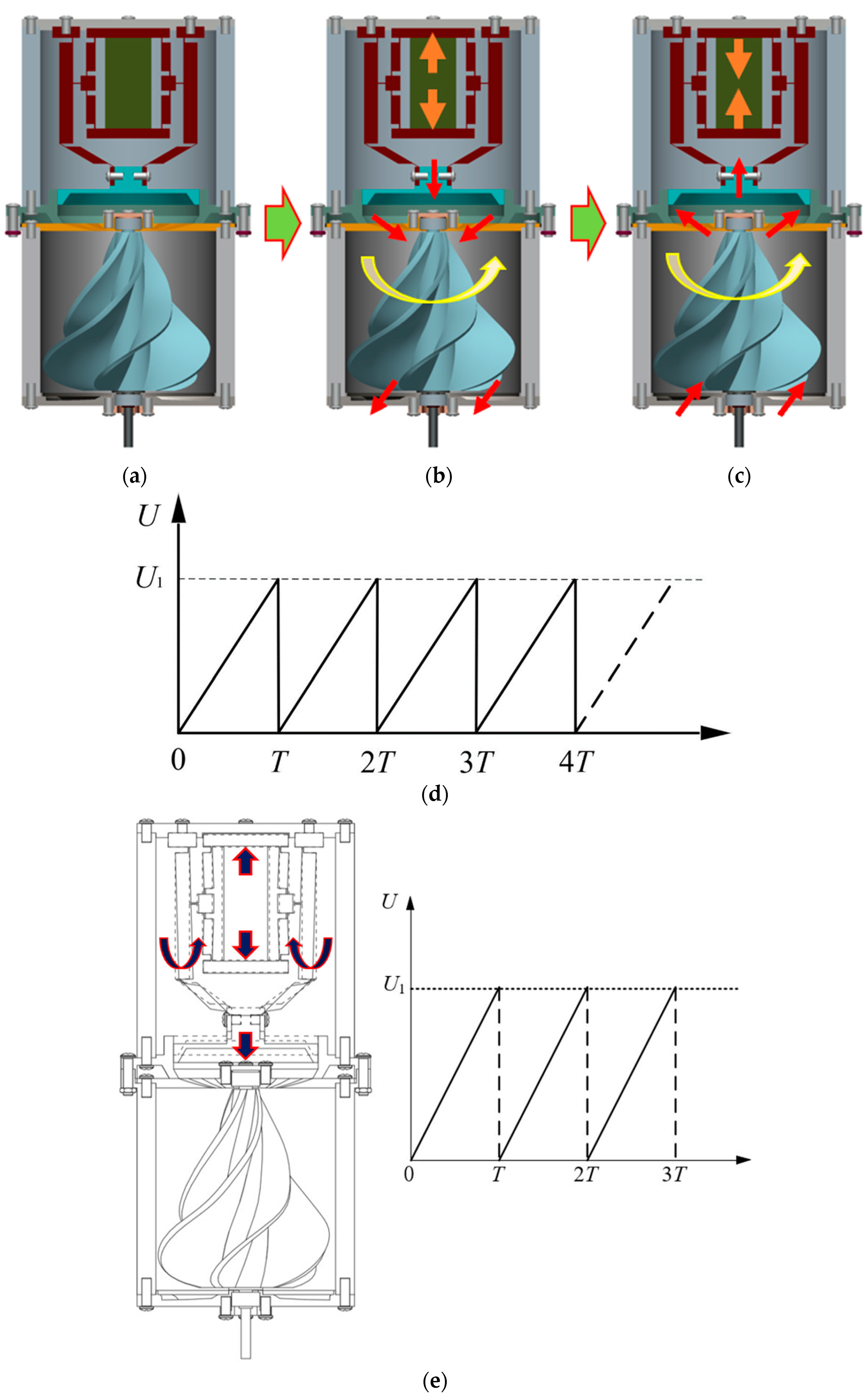

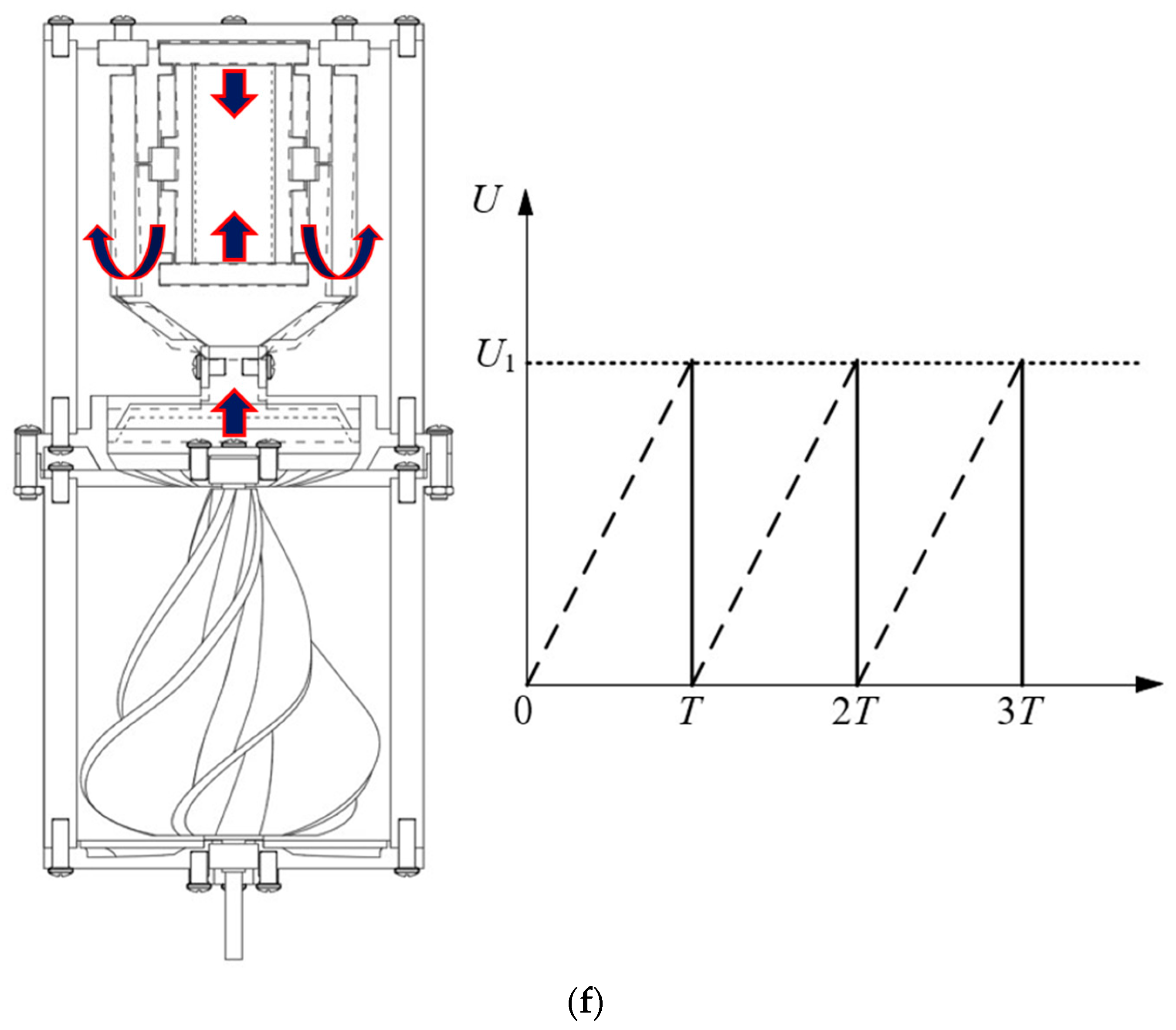

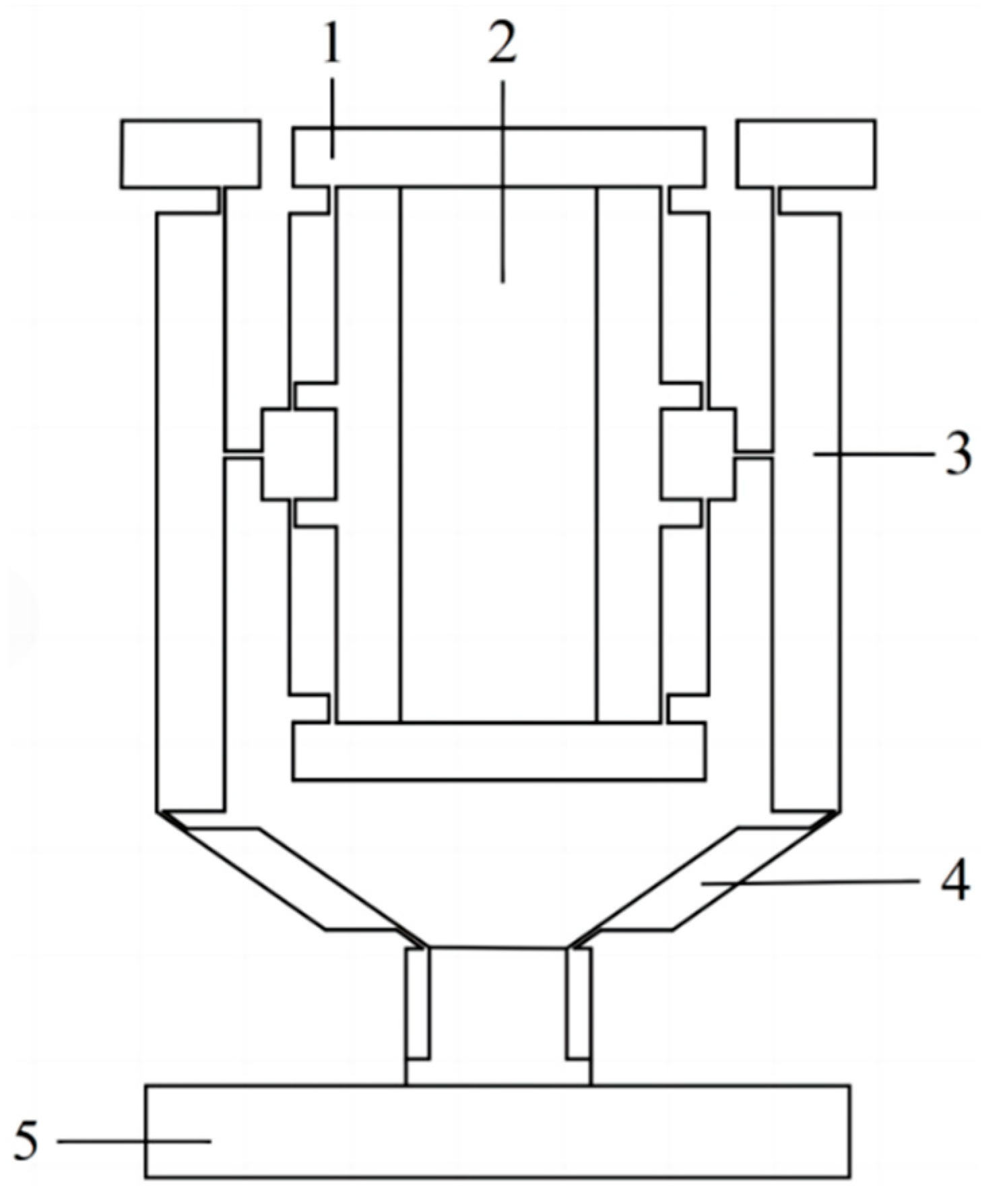

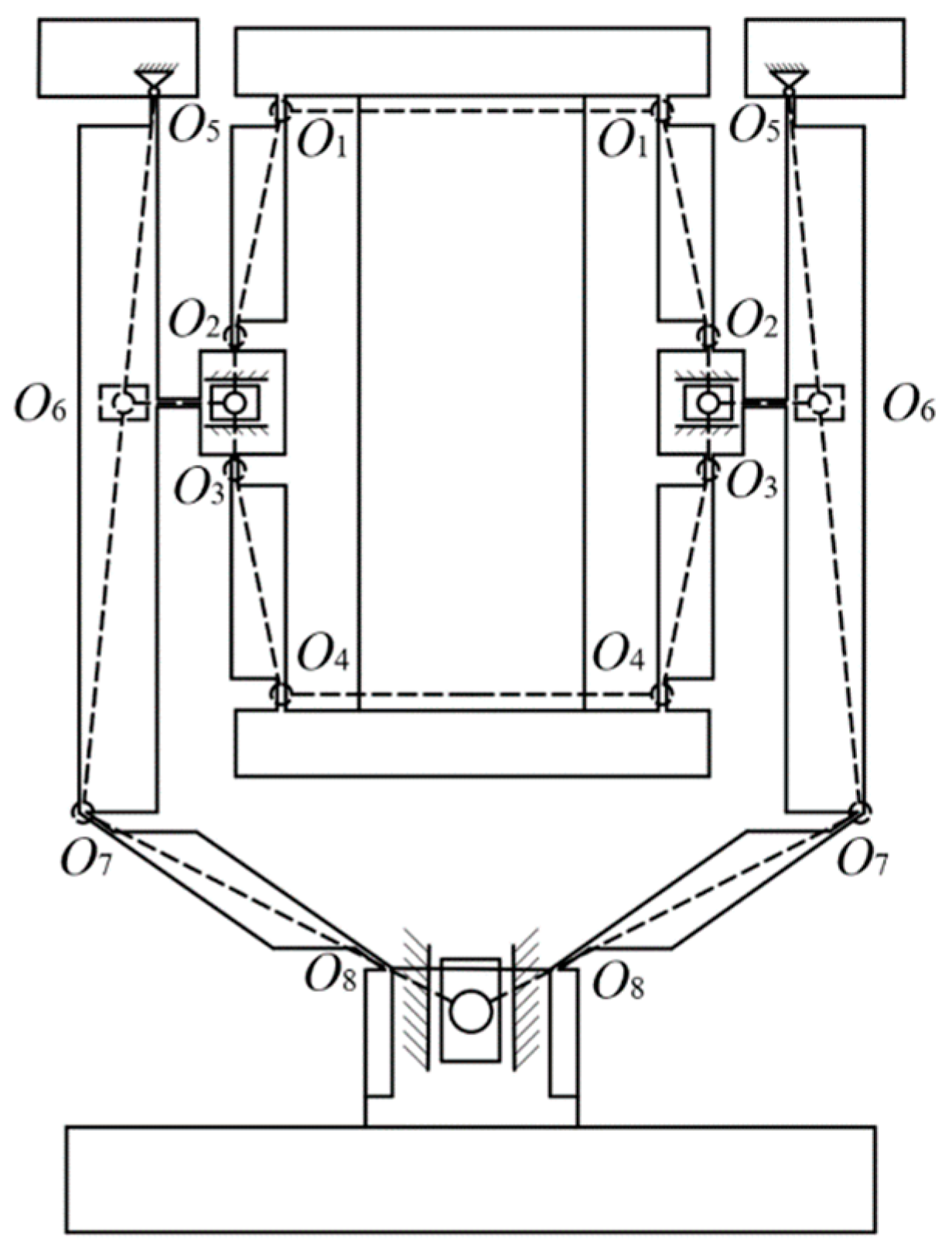

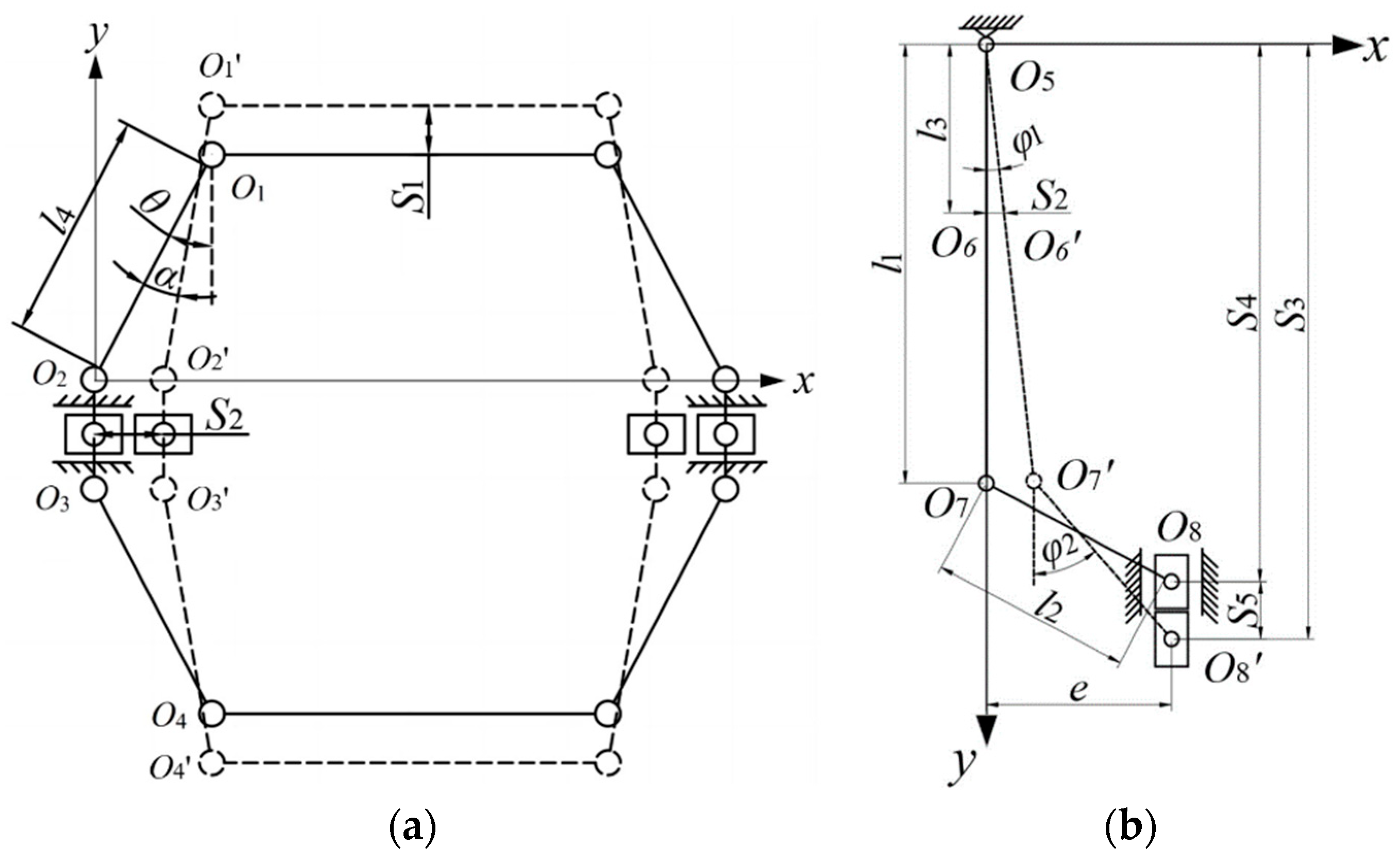

2. Structure and Operating Principle

3. Output Displacement Equation of Micro-Displacement Amplifying Mechanism

4. Result Analysis

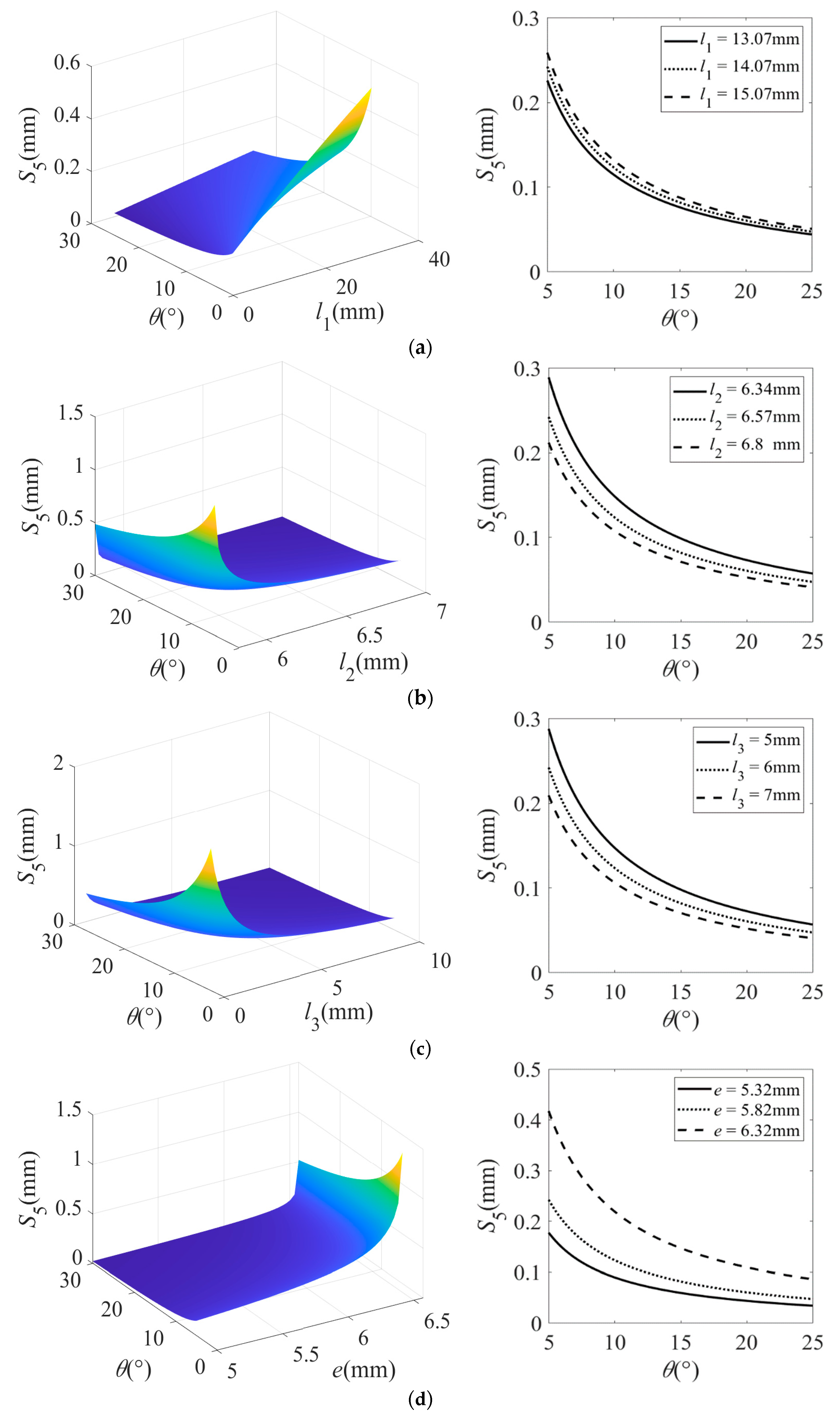

4.1. Variation in Output Characteristics of Micro-Displacement Amplifying Mechanism with Parameters

- (1)

- Under the same lever rod length , bridge structure II rod length , power arm length of bridge structure I driving the lever motion, and bridge structure II’s rod horizontal projection length , the output displacement of the micro-displacement amplifying mechanism decreases nonlinearly with the increase in the bridge structure I’s initial angle , while the decrease rate gradually slows down.

- (2)

- Under the same bridge structure I’s initial angle , the output displacement of the micro-displacement amplifying mechanism increases significantly with the increase in the lever’s rod length and bridge structure II’s rod horizontal projection length . Moreover, the output displacement increases greatly with the increase in horizontal projection length .

- (3)

- Under the same bridge structure I’s initial angle , the output displacement of the micro-displacement amplifying mechanism decreases with the increase in the bridge structure II’s rod length and the power arm length of the bridge structure I driving the lever motion. Furthermore, with the increase in the two parameters, the reduction in the output displacement becomes smaller.

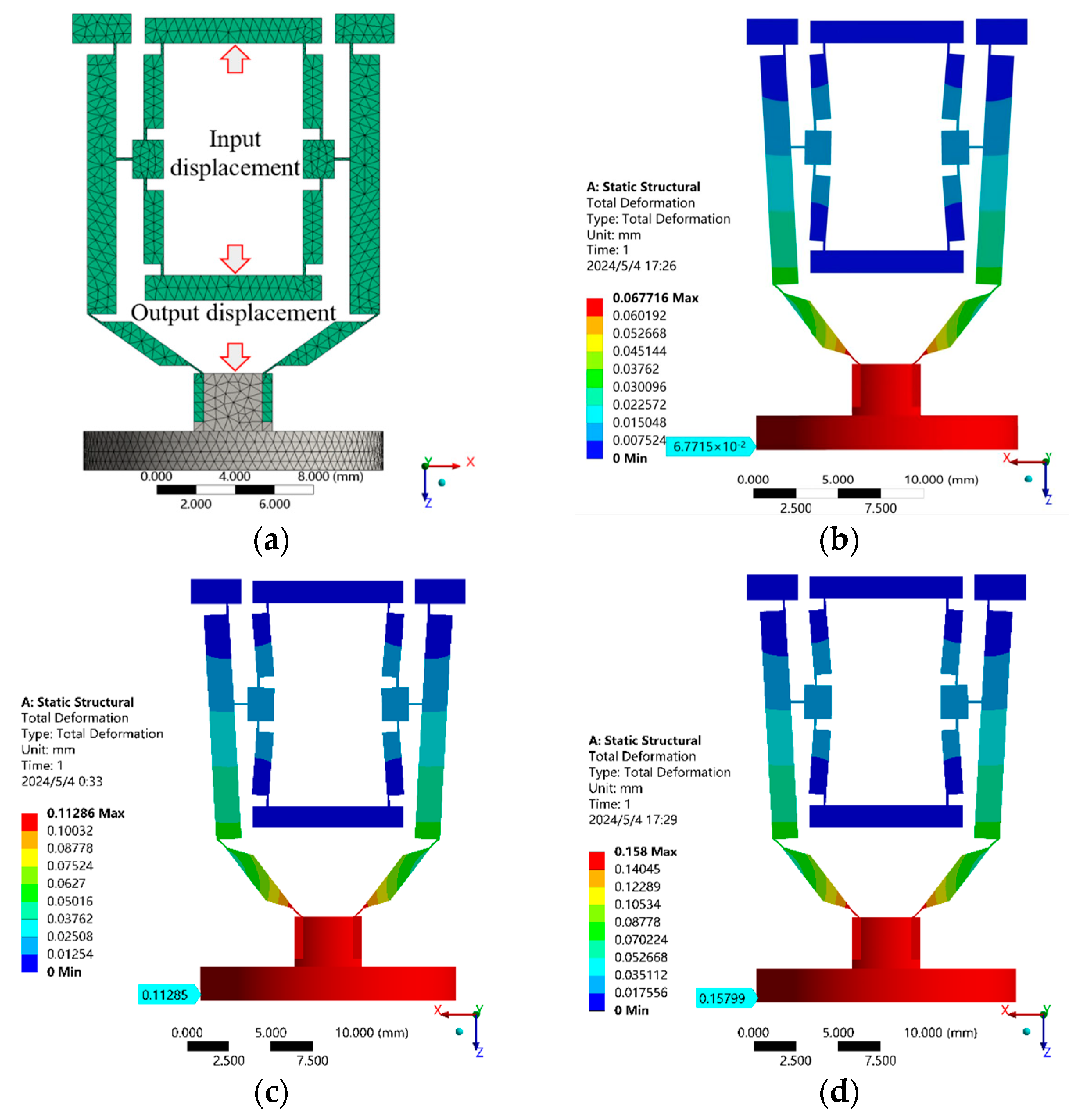

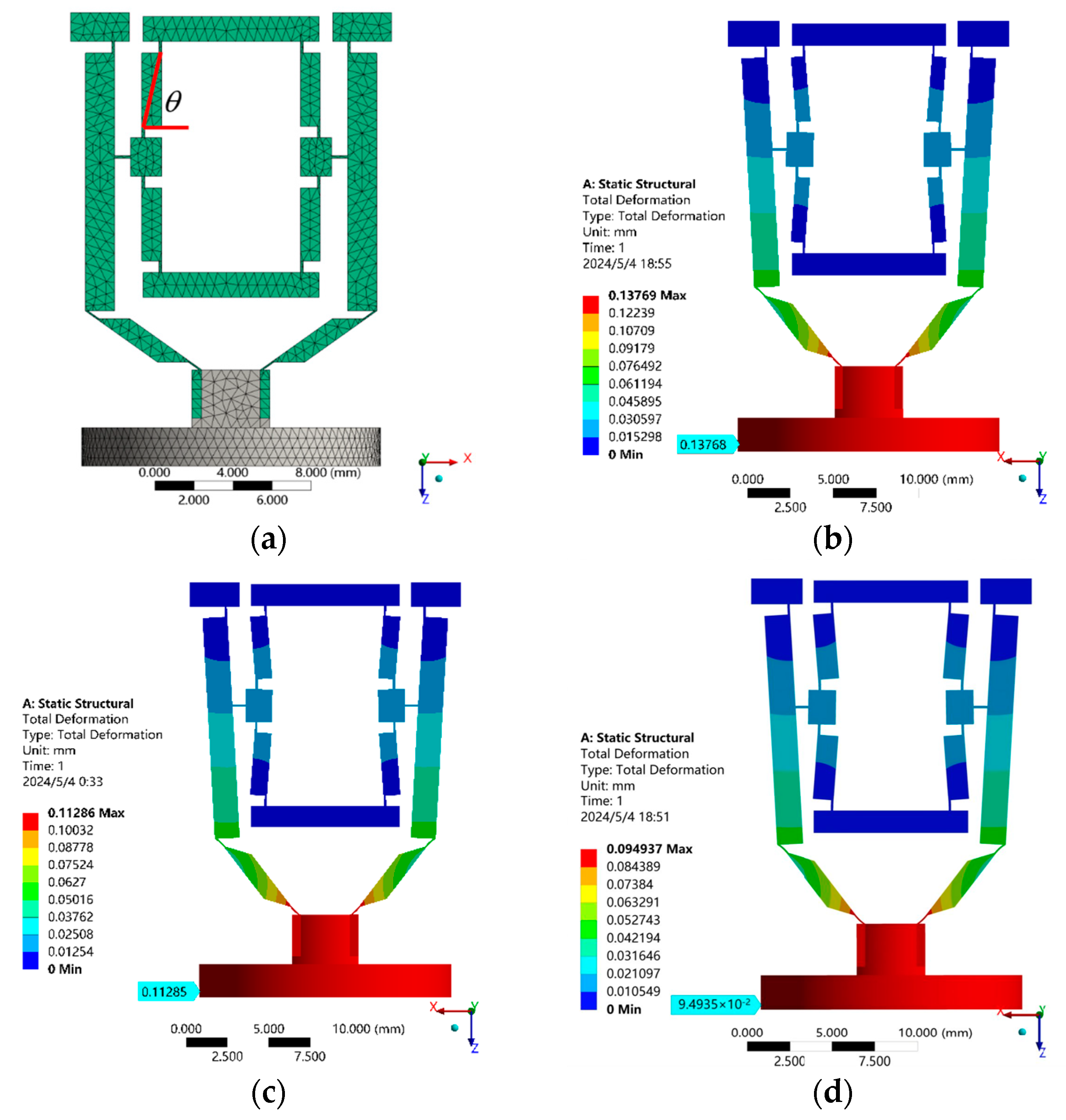

4.2. Simulation Analysis for Output Characteristics of Micro-Displacement Amplifying Mechanism

- (1)

- As the piezoelectric stack’s input displacement increases, the theoretical and simulated output displacements amplified by the micro-displacement amplifying mechanism increase. The theoretical displacement magnification decreases, whereas the simulated displacement magnification remains constant.

- (2)

- Compared with the simulated output displacement, the theoretical output displacement of the micro-displacement amplifying mechanism is slightly larger than the simulated displacement, and there are some errors between them. However, as the input displacement increases, the error gradually decreases. This is because each rod is assumed to be rigid in the theoretical calculation, and the deformation only occurs at the flexible hinge. However, the simulation cloud diagrams show that when each rod’s size is small, there is a slight deformation in each rod in addition to at the flexible hinge. This results in a discrepancy between the theoretical and simulation values, although the error is less than 10%, which still meets the practical requirements. As the input displacement of the micro-displacement amplifying mechanism continues to increase, the simulated value and the theoretical value will tend to be consistent.

- (1)

- As bridge structure I’s initial angle increases, the theoretical and simulated output displacements amplified by the micro-displacement amplifying mechanism are reduced. Moreover, the displacement magnification of both of them also decreased.

- (2)

- Compared with the simulated output displacement, the theoretical output displacement of the micro-displacement amplifying mechanism is slightly larger than the simulated displacement, and there are some errors between them. Furthermore, as bridge structure I’s initial angle increases, the error gradually decreases.

- (3)

- When bridge structure I’s initial angle is small (less than 10°), although the theoretical and simulated output displacements are large, and the displacement magnification is also large, it can be seen from the analysis of cloud images that each rod’s deformation is large, resulting in more invalid energy consumption, leading to a large error between the two.

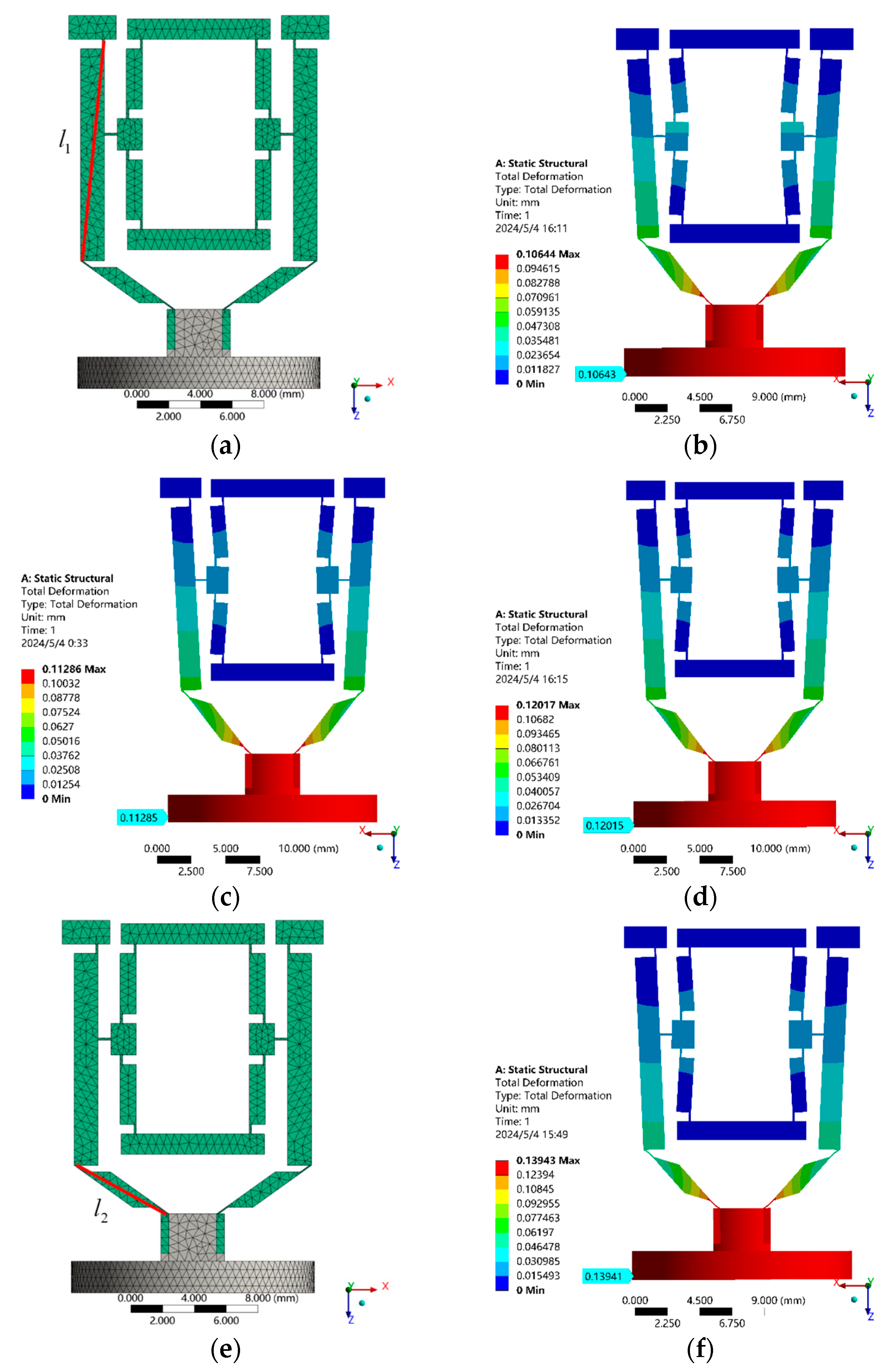

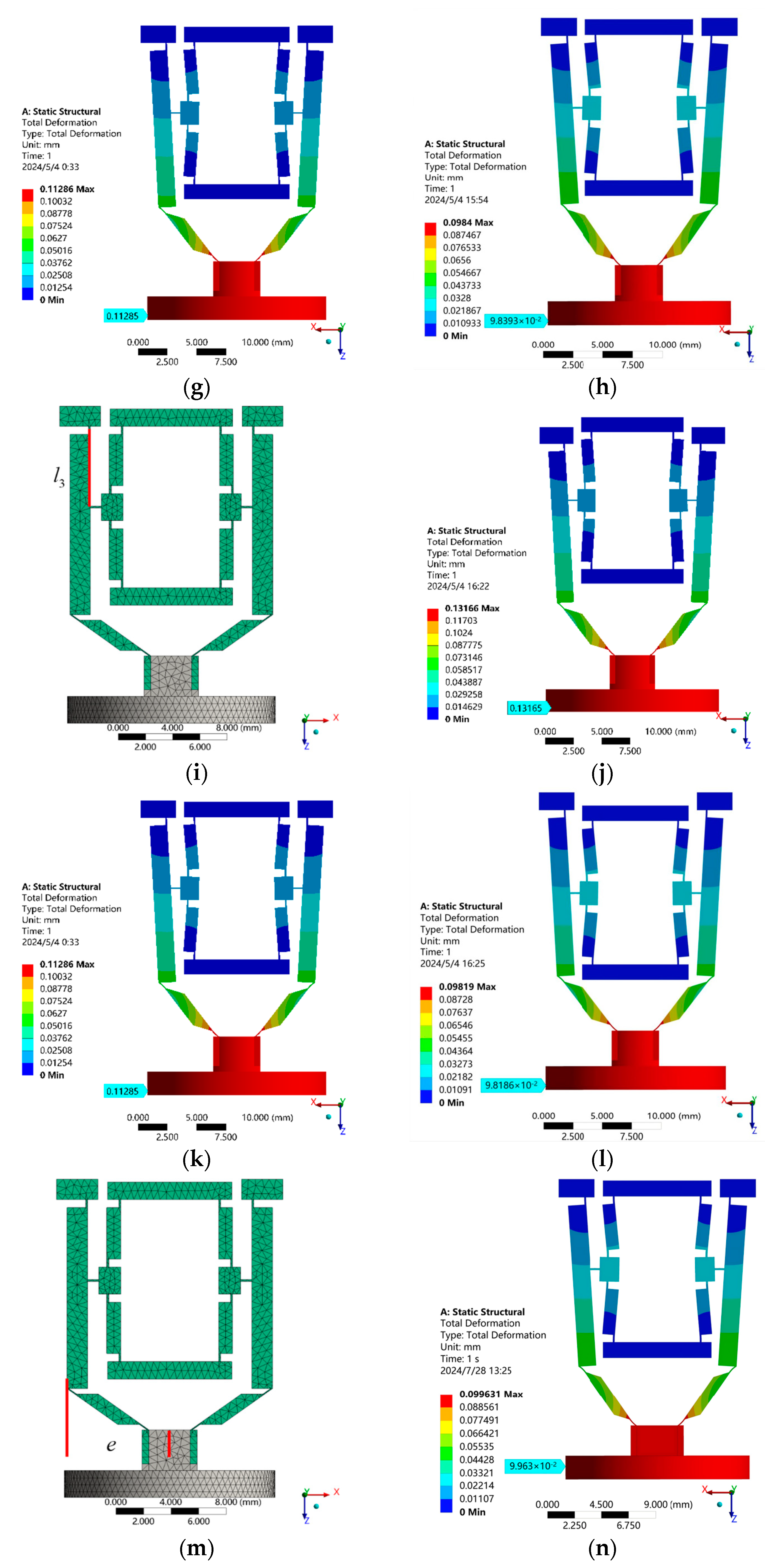

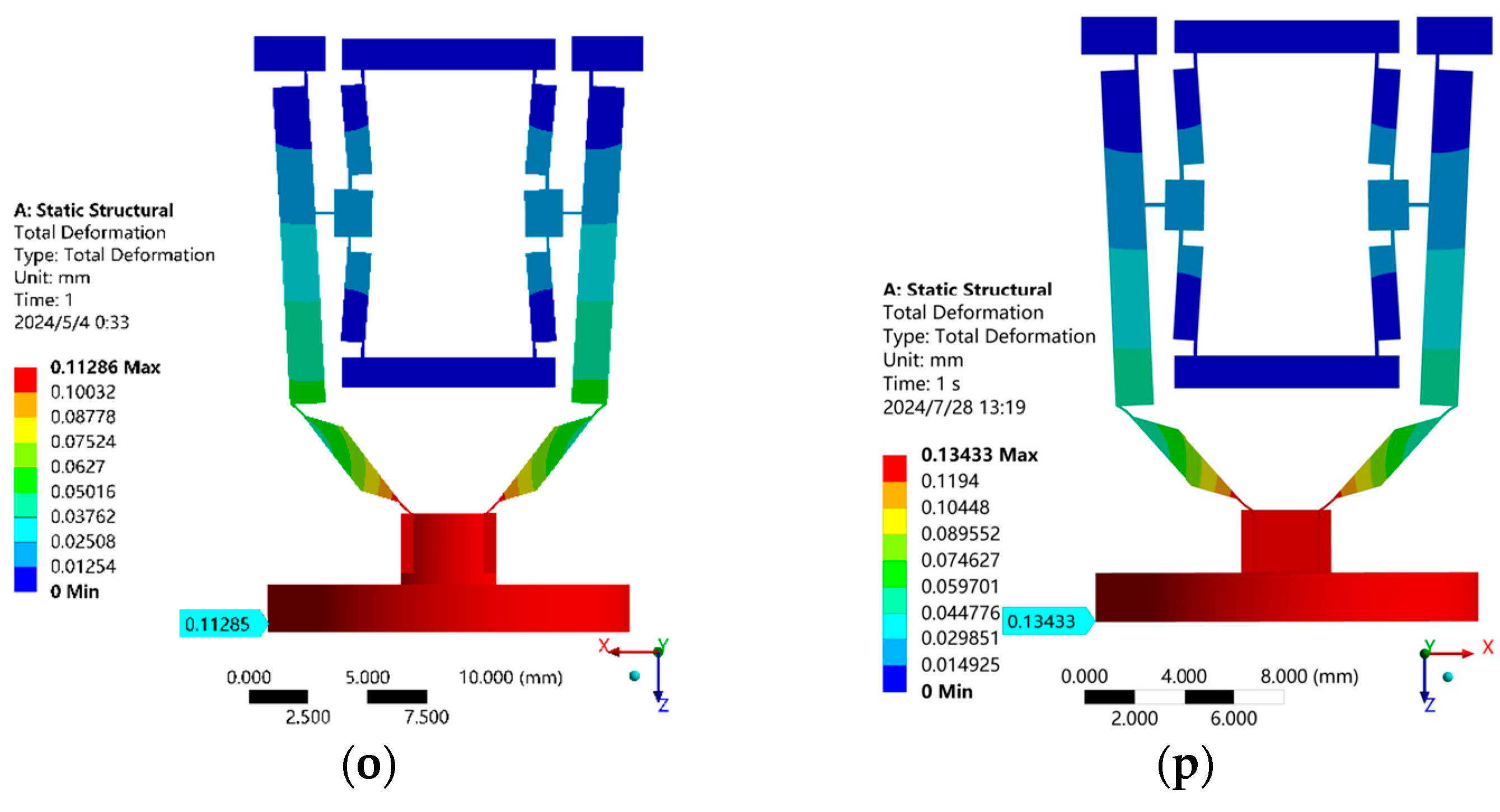

- (1)

- As the lever’s rod length and the bridge structure II’s rod horizontal projection length increase, both the theoretical and simulated displacements amplified by the micro-displacement amplifying mechanism increase, and the displacement magnifications also increase.

- (2)

- As the bridge structure II’s rod length and the power arm length of bridge structure I drive lever motion, the theoretical and simulated displacements amplified by the micro-displacement amplifying mechanism decrease, and the displacement magnifications also decrease.

- (3)

- Compared with the simulated displacement, the theoretical displacement amplified by the micro-displacement amplifying mechanism is slightly larger than the simulated displacement. There is a certain error between the two, and the error is about 10%, which meets the design requirements. The validity of the theoretical analysis method is verified.

5. Optimal Design

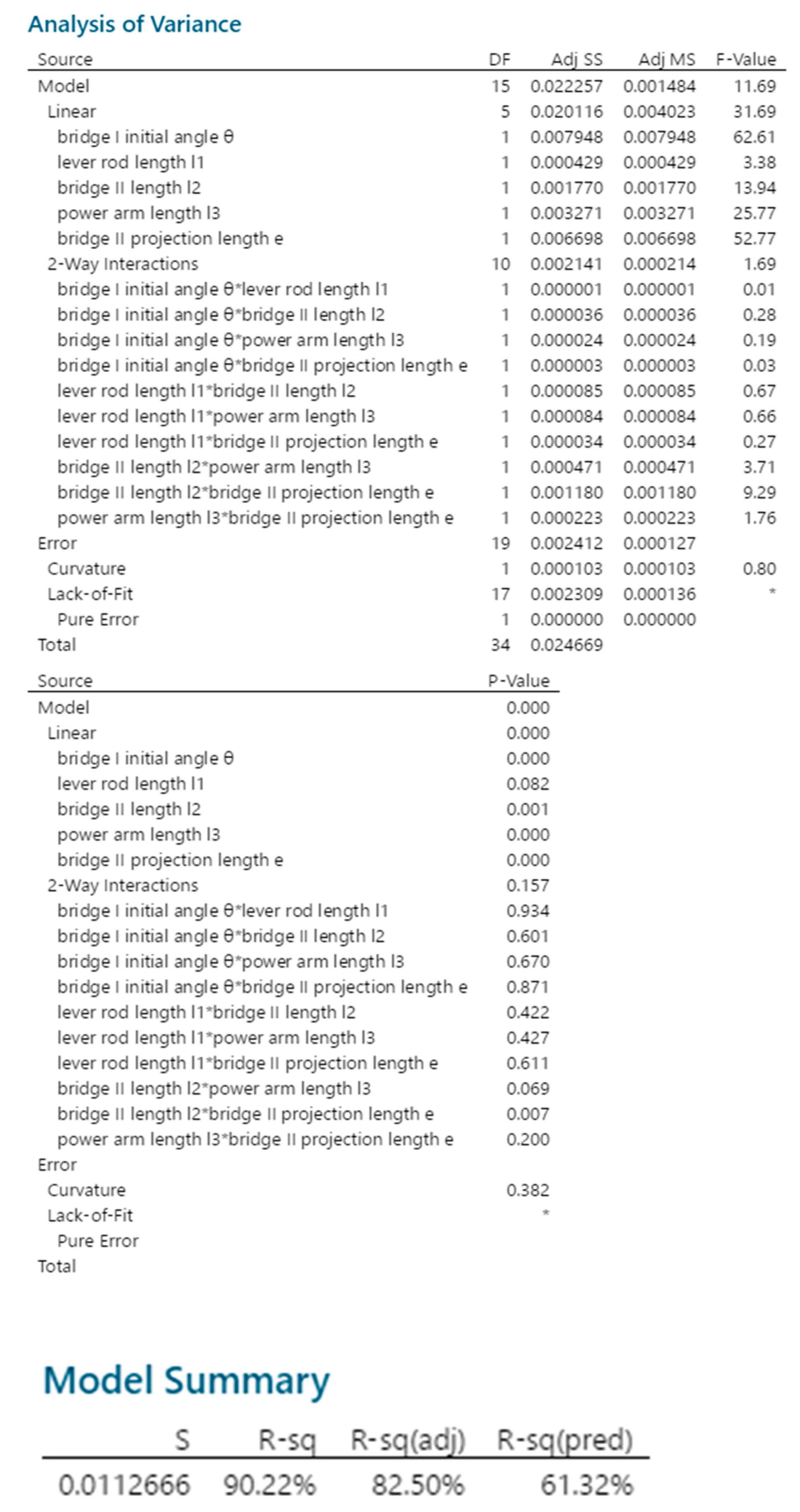

5.1. Fitting Mathematical Model

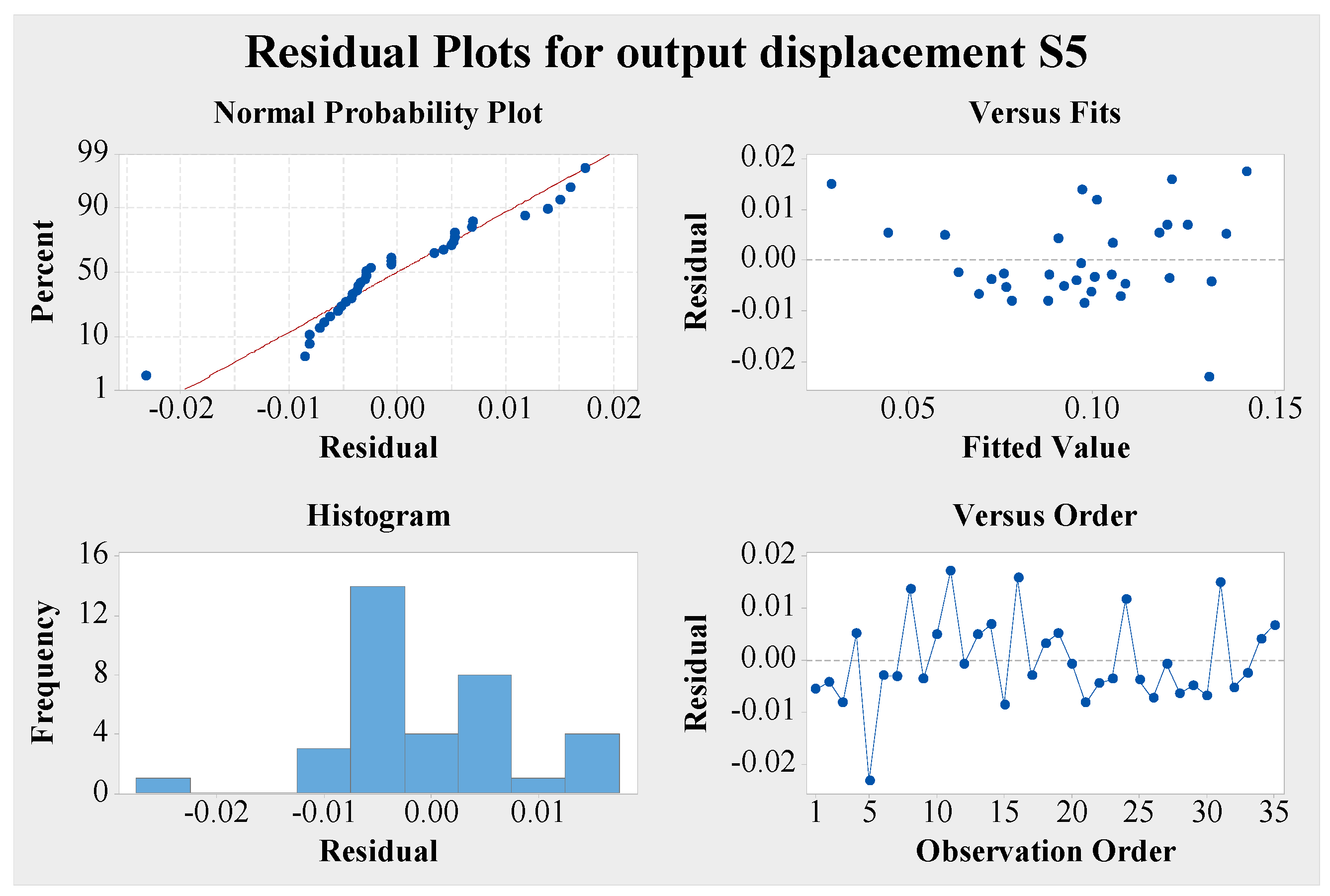

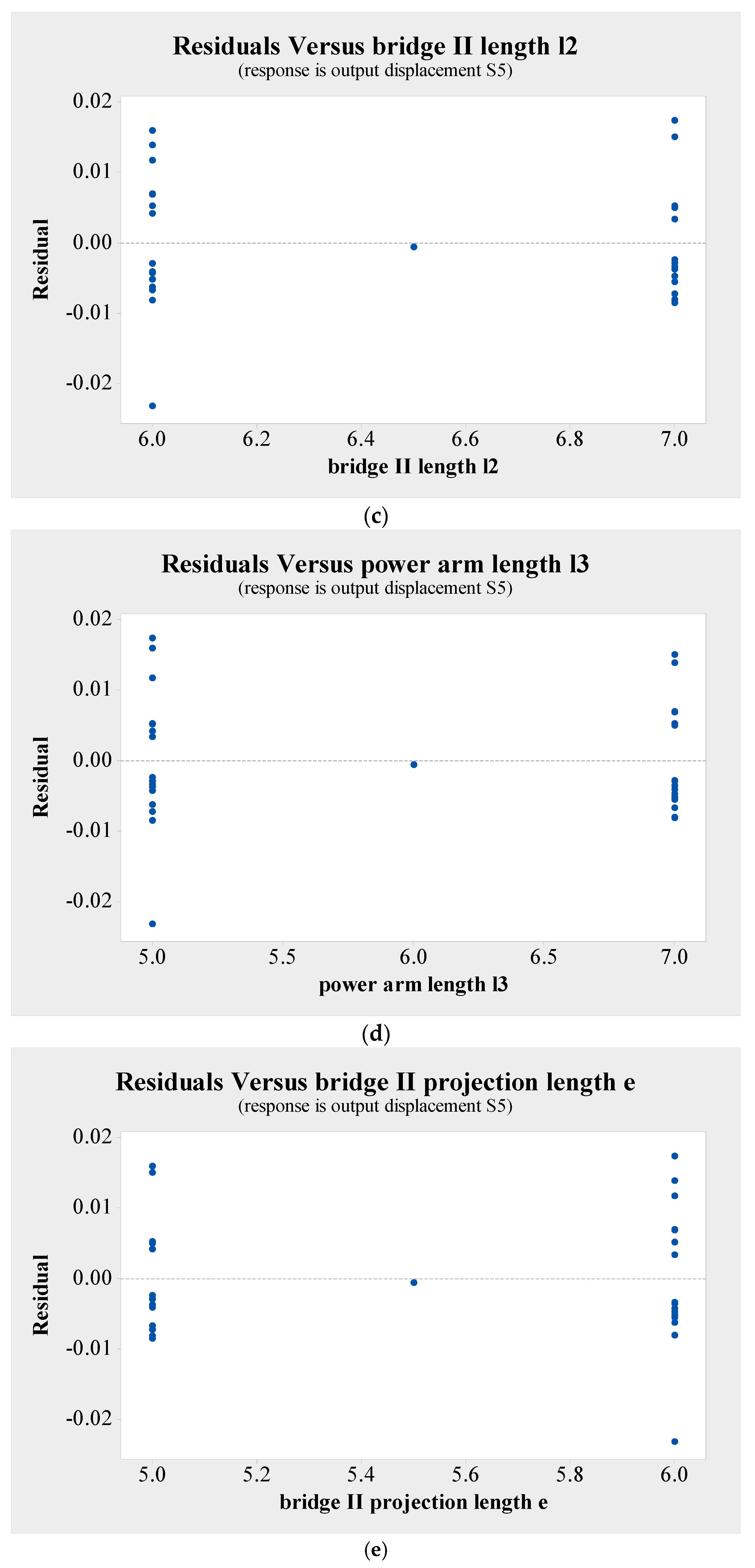

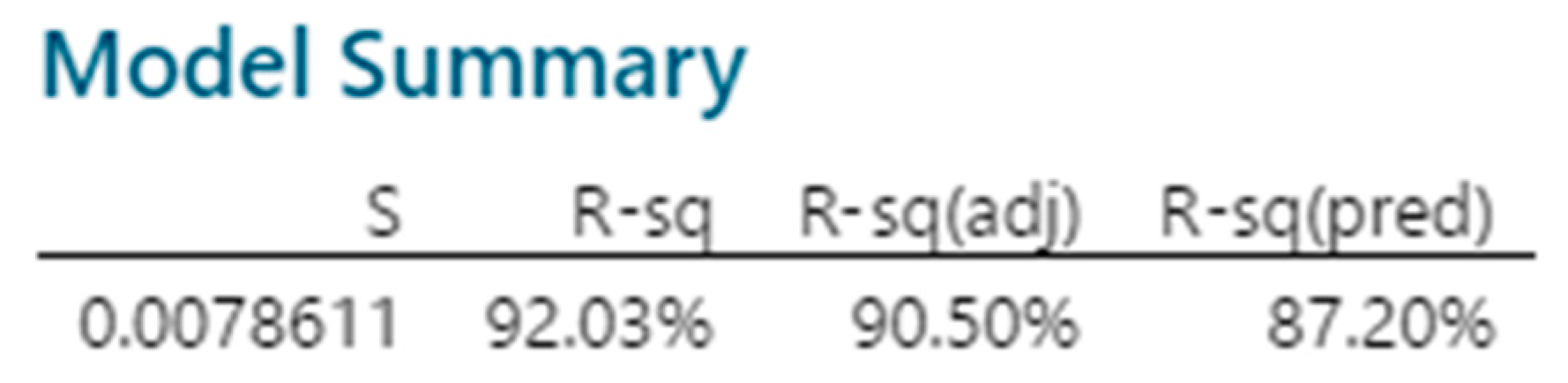

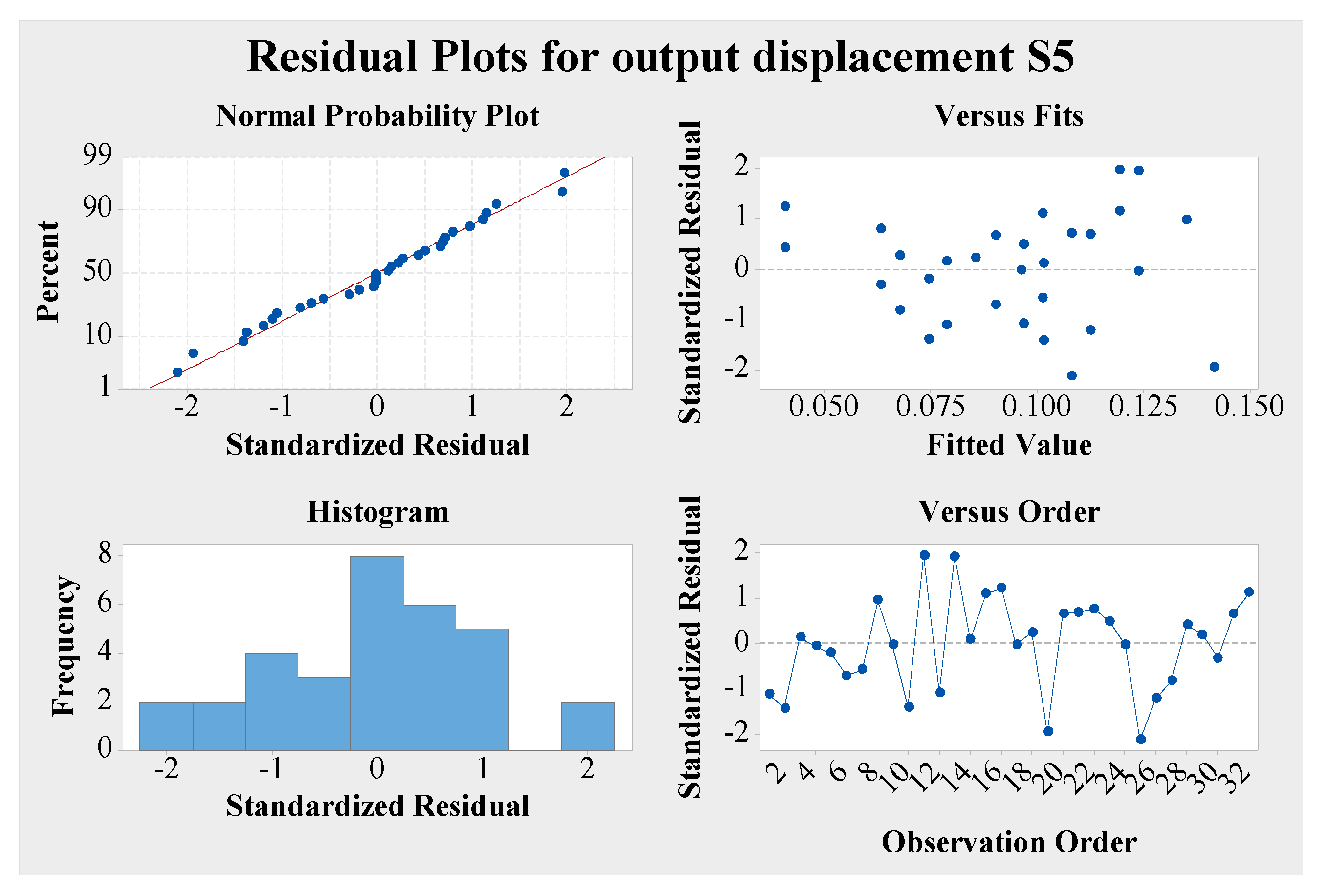

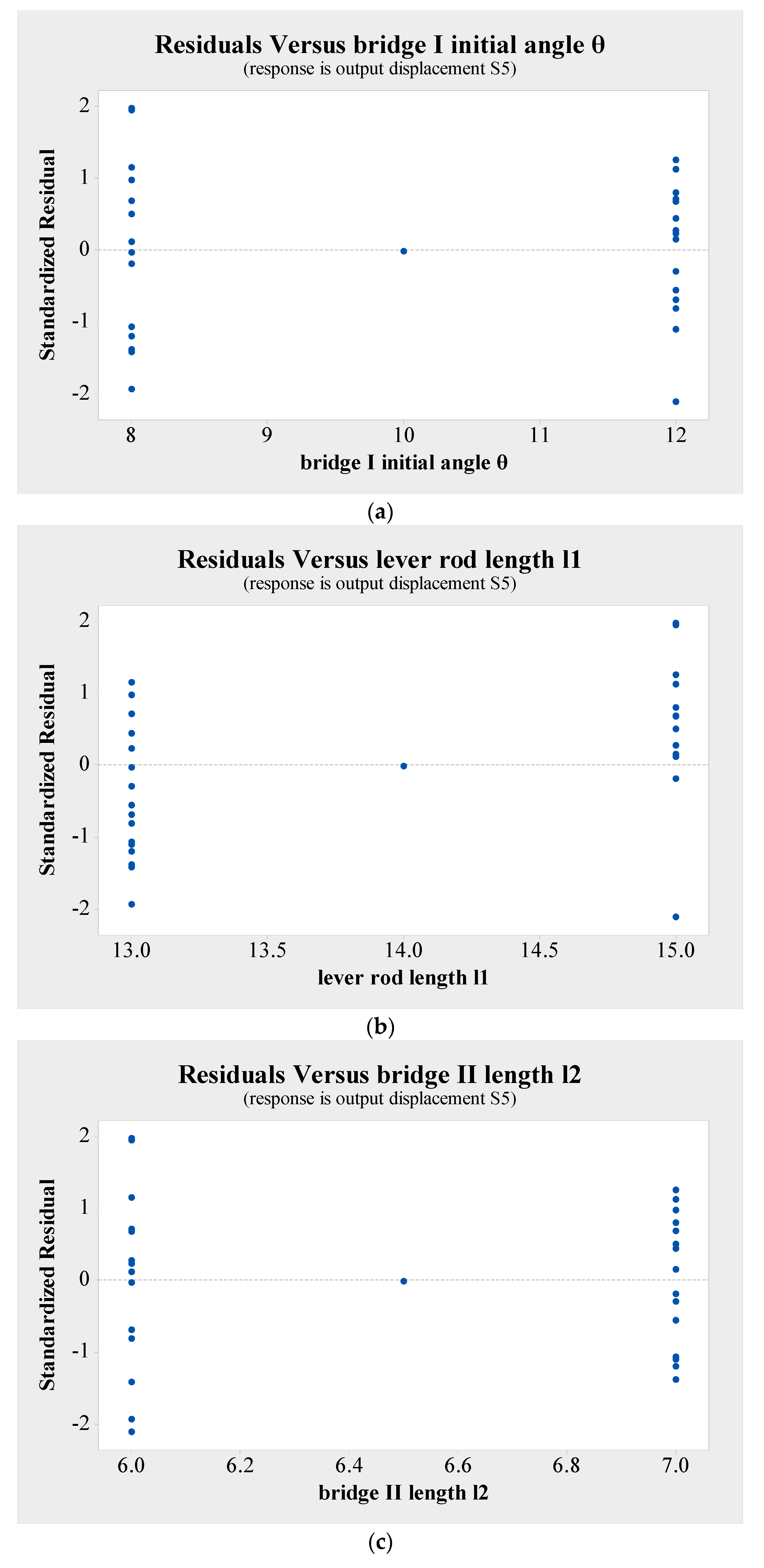

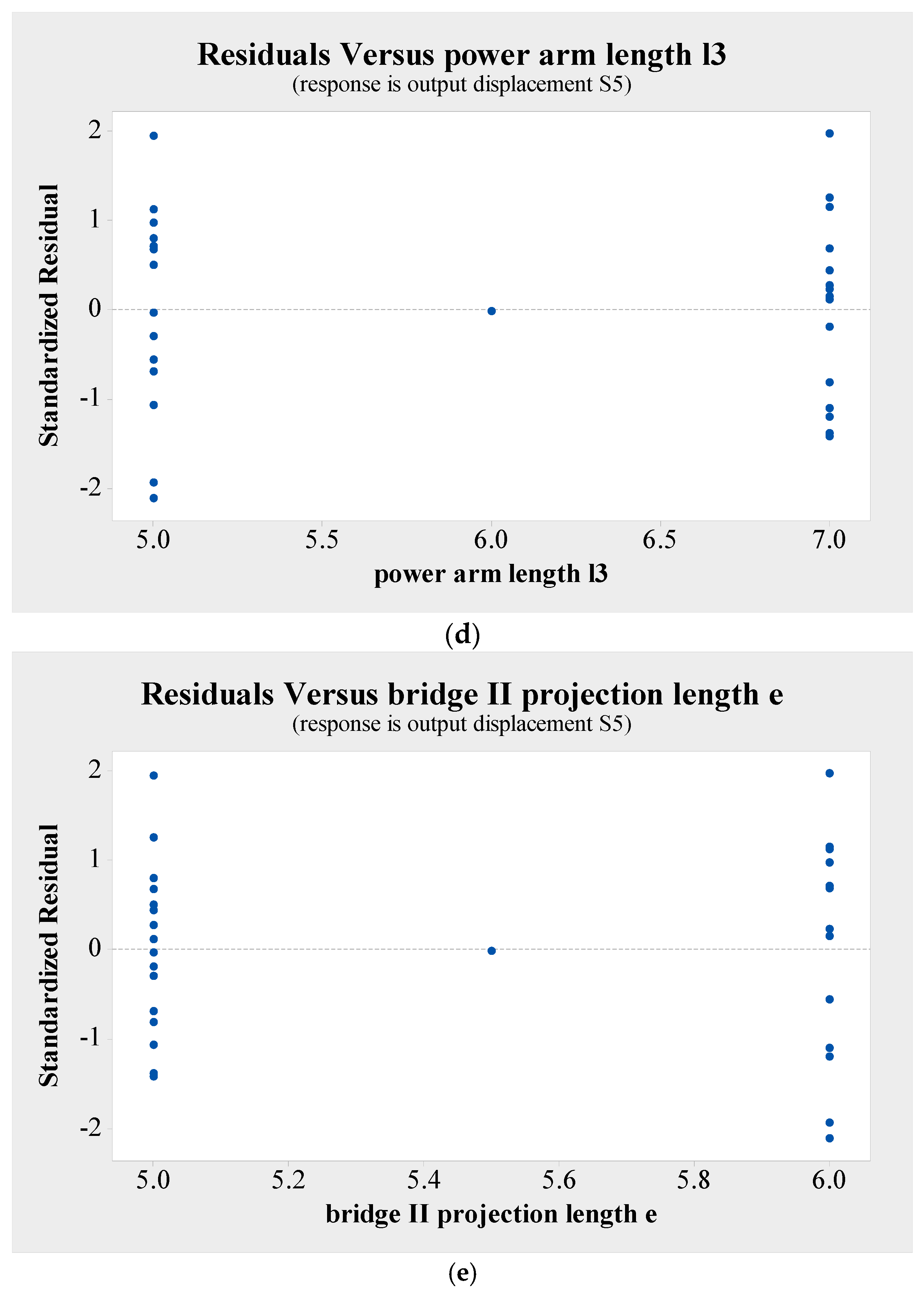

5.2. Residual Diagnosis

- (1)

- In the scatter plot (bottom right) with the observation order as the horizontal axis, each point fluctuates randomly up and down the horizontal axis.

- (2)

- In the scatter plot (top right) with the predicted output displacement as the horizontal axis, there is no funnel type, and the residuals maintain equal variance.

- (3)

- In the normal probability graph on the upper left (or the histogram on the lower left), the residuals basically follow a normal distribution.

- (4)

- There is no bending tendency in the scatter plots with each influence factor as the horizontal axis.

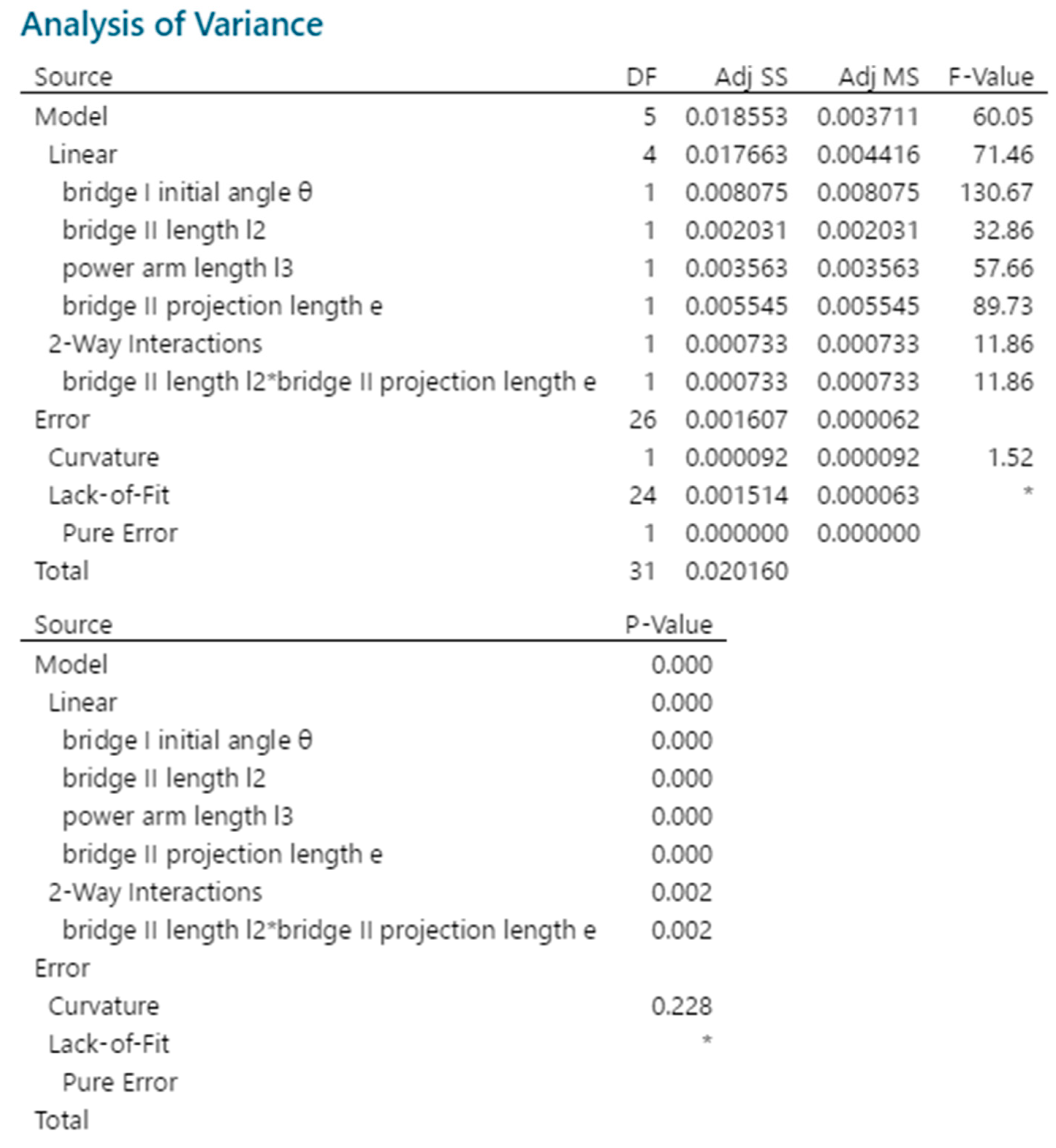

5.3. Mathematical Model Improvement

- (1)

- The p-values of the main effects and the second-order interaction are 0.000 and 0.002, respectively, and both are less than 0.05, indicating that the deleted model is valid.

- (2)

- R-sq(pred) after deletion = 87.20% > R-sq(pred) before deletion = 61.32%, standard deviation S = 0.0078611 after deletion < S = 0.0112666 before deletion, so the regression effect of the model is better after the deletion of insignificant main factors and interaction terms.

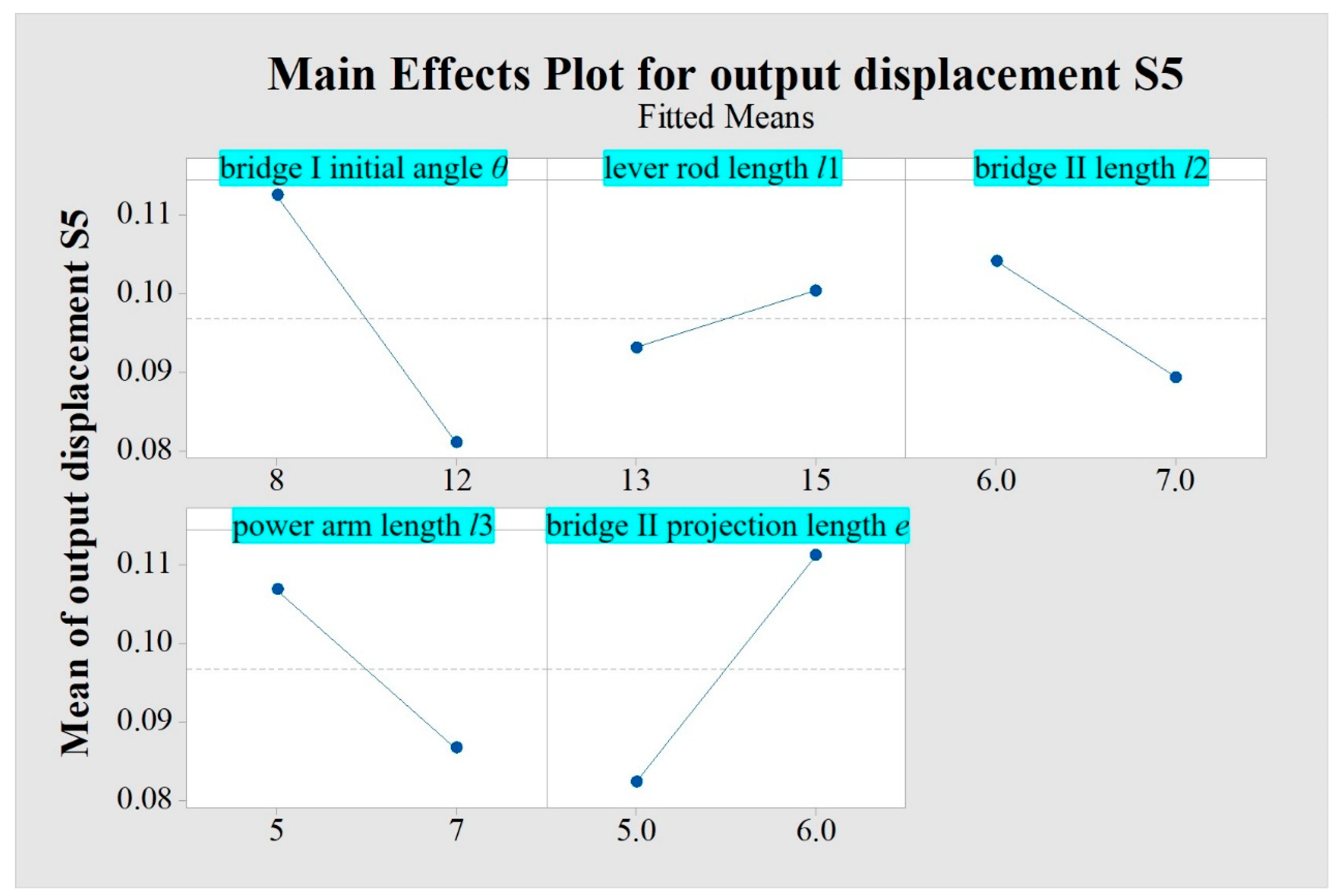

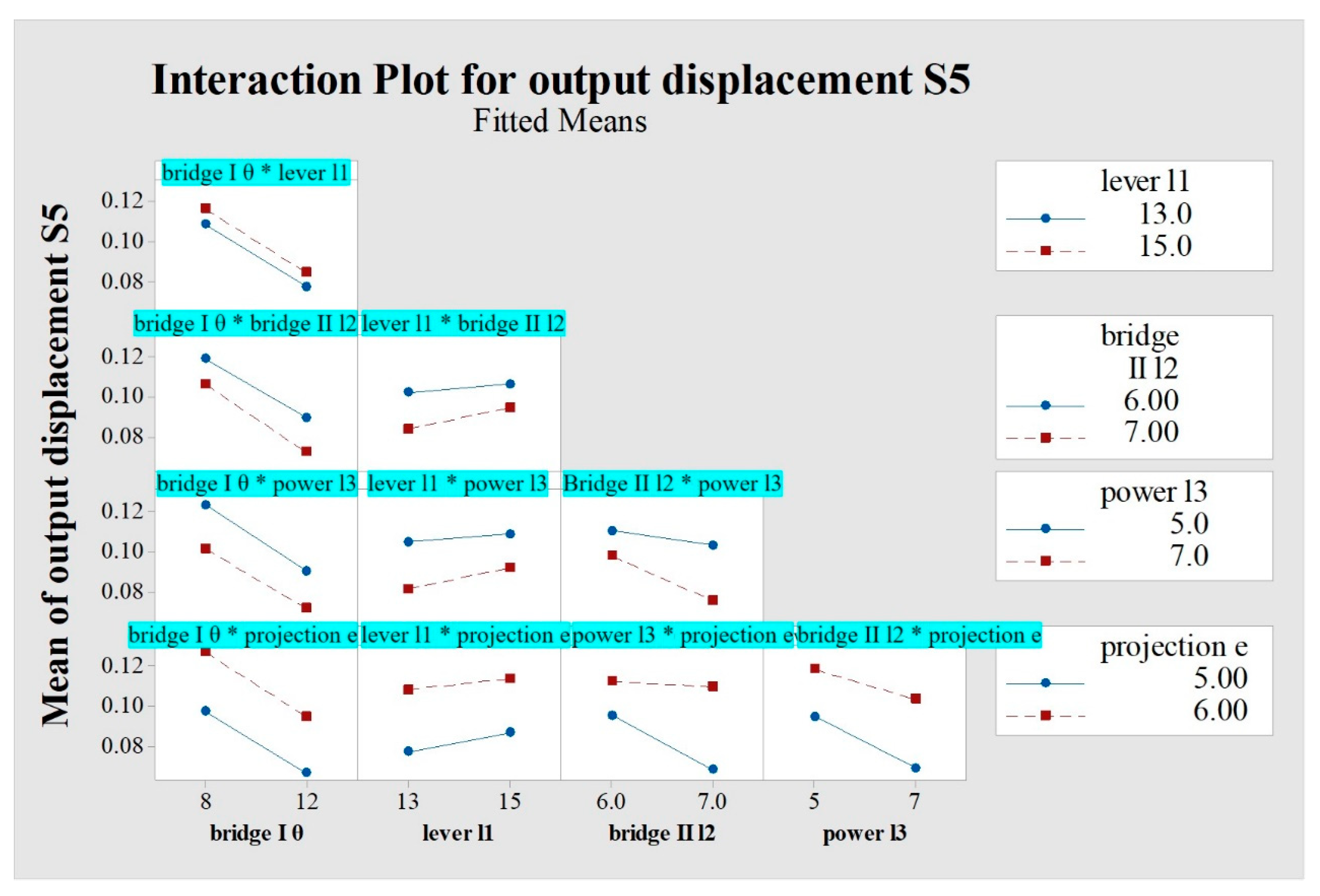

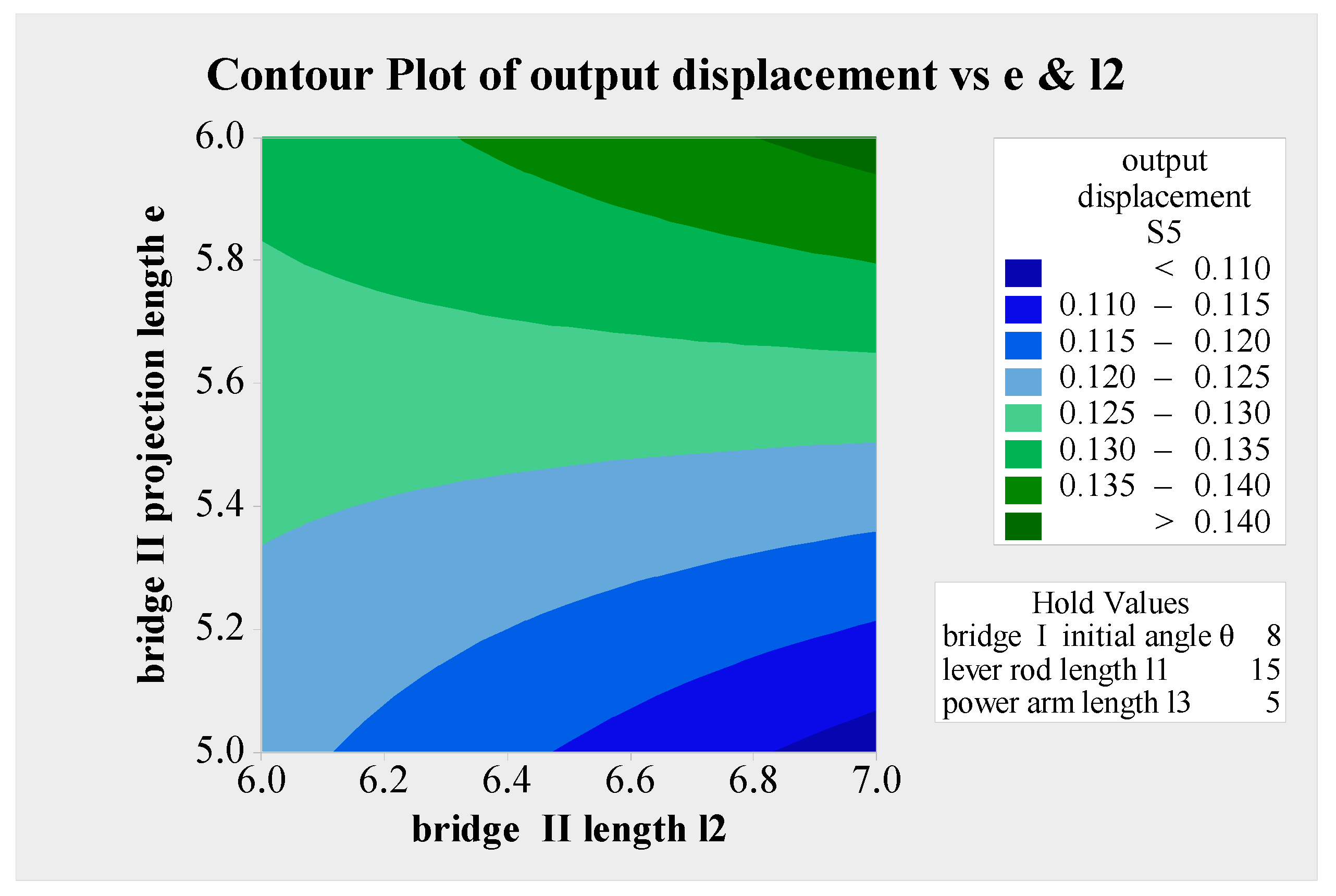

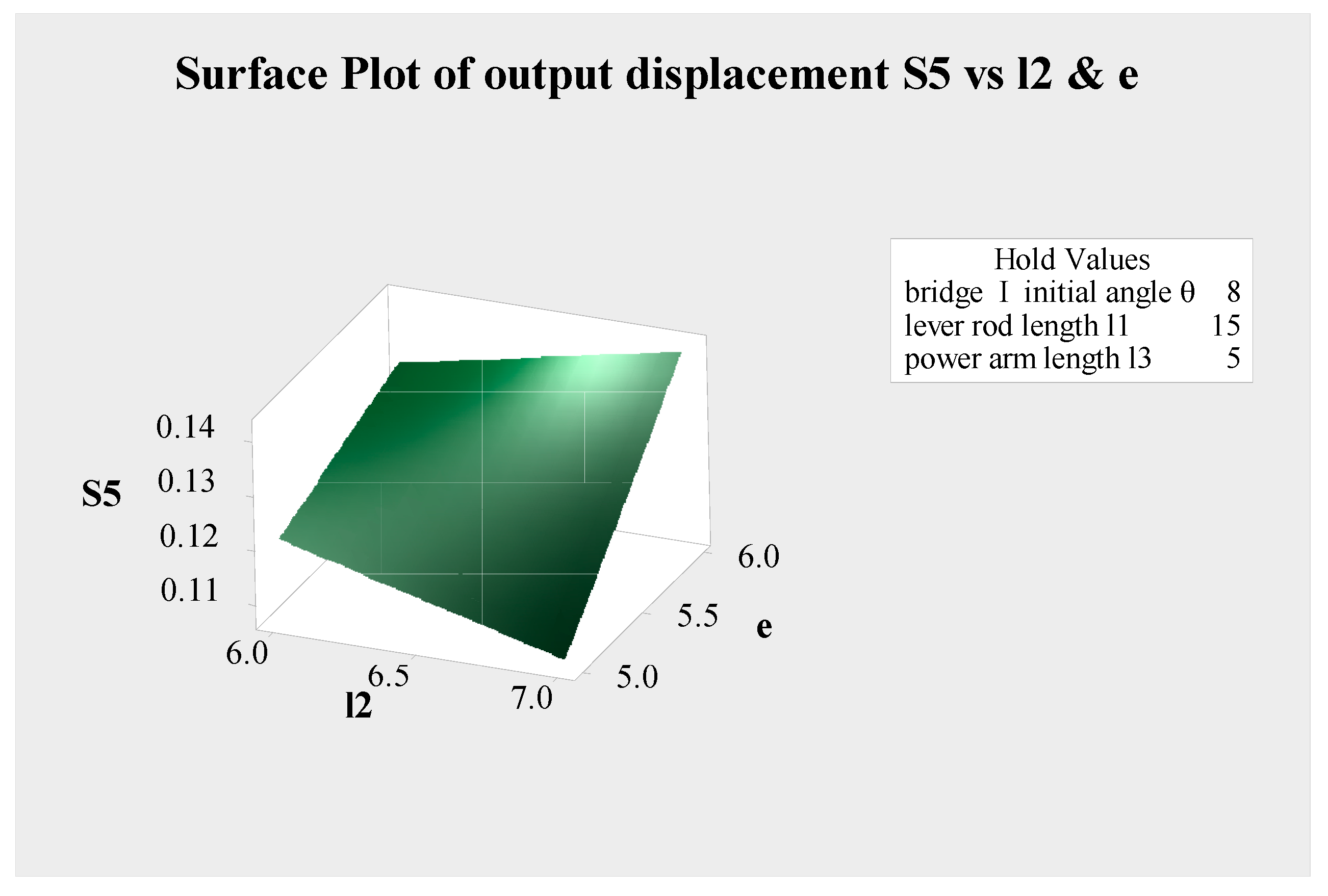

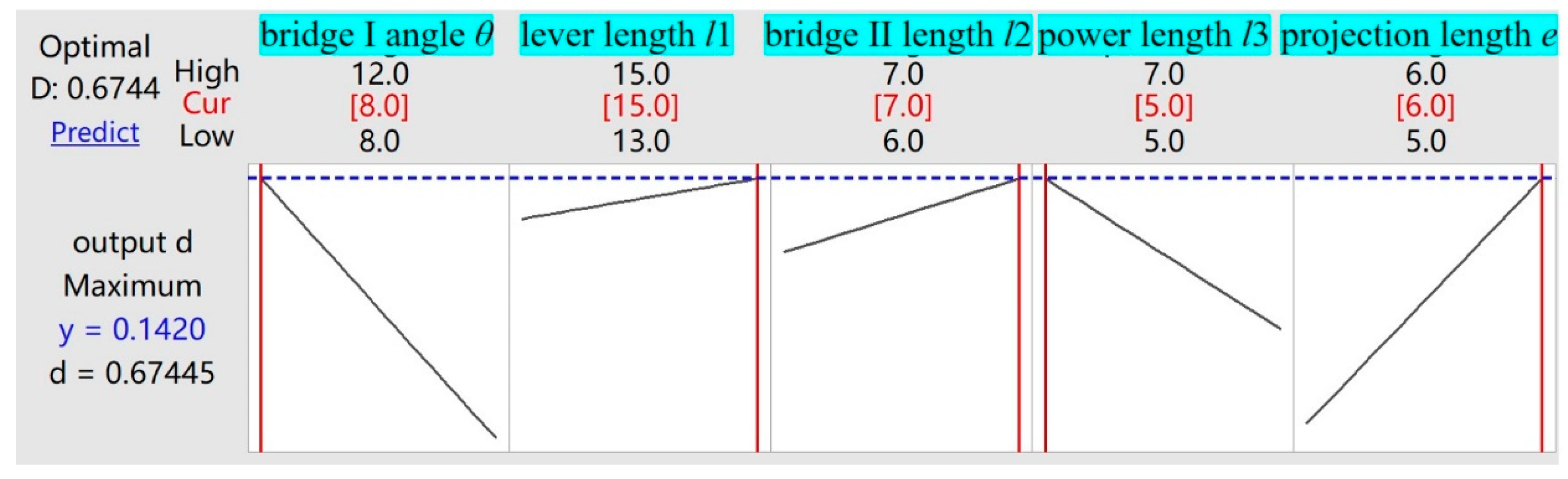

5.4. Optimization Analysis

- (1)

- The regression lines of factors such as bridge structure I’s initial angle, bridge structure II’s rod length, the power arm length of bridge structure I driving lever motion, and bridge structure II’s rod horizontal projection length are steep, so the influences of these main effects are indeed significant, while the regression line of a factor such as lever’s rod length is relatively flat, so the influence of that main effect is not significant.

- (2)

- In order to obtain the maximum output displacement of the micro-displacement amplifying mechanism, the smaller the bridge structure II’s rod length, the power arm length of the bridge structure I driving the lever motion, and the bridge structure I’s initial angle, and the larger the lever’s rod length and bridge structure II’s rod horizontal projection length, the better. The correctness of the above theoretical analysis is verified again.

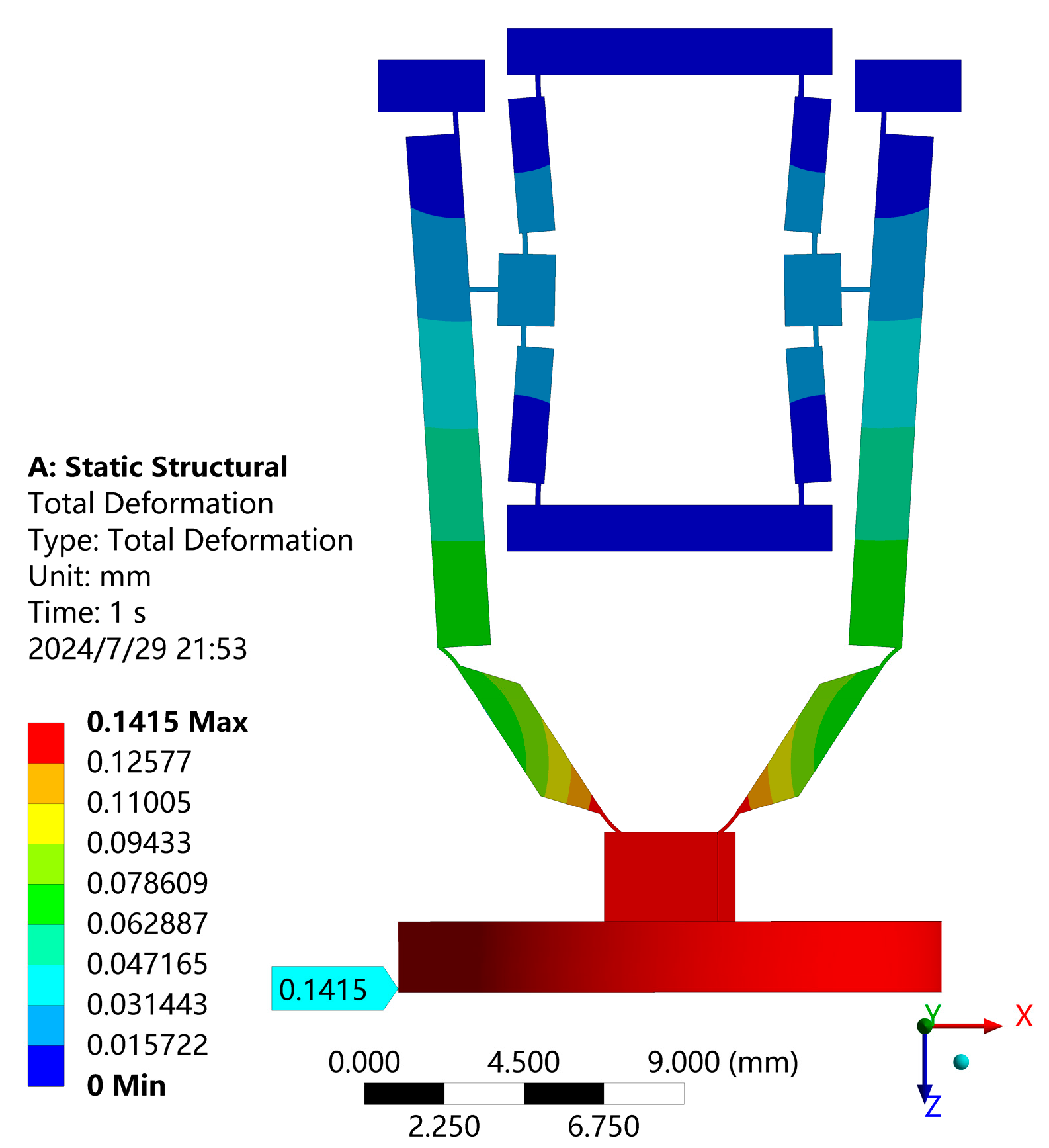

5.5. Optimization Result Verification

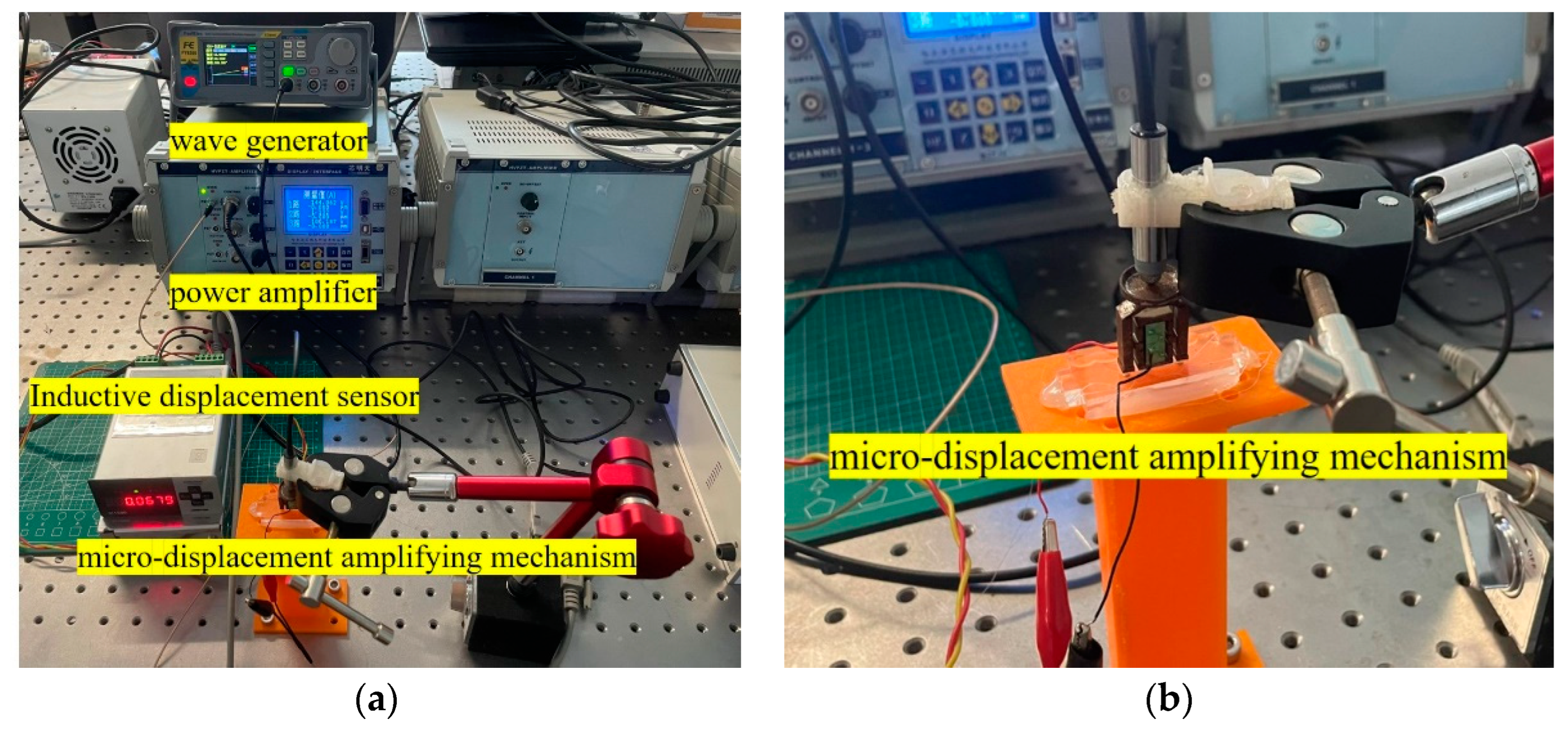

6. Experimental Test

- (1)

- Under the same input displacement excitation, the test values of the output displacement of the micro-displacement amplifying mechanism are smaller than the theoretical and simulated values. There are errors, and the error compared with the theoretical values is larger than that with the simulated values.

- (2)

- The smaller the input excitation displacement, the greater the error, and the larger the input excitation displacement, the smaller the error. Compared with the theoretical values, the maximum error is 29.43% and the minimum error is 19.8%, and compared with the simulated values, the maximum error is 21.45% and the minimum error is 12.44%.

- (1)

- Processing factors. Due to the machining accuracy errors of the contact surface matching the piezoelectric stack, flexure hinges, and symmetrical parts in the micro-displacement amplifying mechanism, the partial deformation of the piezoelectric stack is canceled, and the remaining deformation amplified by the micro-displacement amplifying mechanism is small.

- (2)

- Experimental factors. The installation method of the fixed micro-displacement amplifying mechanism and the displacement sensor, the displacement sensor’s accuracy, and the vibration generated by the test instrument on the workbench will all have a certain impact on the test results of the micro-displacement amplifying mechanism, producing small displacements.

7. Conclusions

- (1)

- A non-contact piezoelectric actuator is proposed. The non-contact power transmission between the stator and rotor is realized by pneumatic conveying, which has the characteristics of fast response, low heat, long service life, compact structure, and easy miniaturization and control, especially suitable for the field of high-speed and small-load micro-drive. The structure of the non-contact piezoelectric actuator is designed and its operation principle is expounded.

- (2)

- The parametric model of the non-contact piezoelectric actuator is established. The equation of the relationship between the output displacements of the micro-displacement amplifying mechanism for non-contact piezoelectric actuators and the input displacements of the piezoelectric stack is deduced, and the simulation analysis method of output displacements of the micro-displacement amplifying mechanism is established. The output characteristics of the micro-displacement amplifying mechanism for the non-contact piezoelectric actuator and their changes along with the input displacement and size parameters are studied from both theoretical and simulation aspects.

- (3)

- Compared with the parameter changes of bridge structure I, and the composite structure composed of lever and bridge II, the bridge structure I’s initial angle has an obvious effect on the output characteristics of the micro-displacement amplifying mechanism in the range of 5°–15°. Under the condition that the composite structure consisting of the lever and bridge II meets the design requirements, the lever’s rod length is 13 mm–15 mm, the bridge structure II’s rod length is 6 mm–7 mm, the power arm length of the bridge structure I driving lever is 5 mm–7 mm, the bridge structure II’ s rod horizontal projection length is 5 mm–6 mm and the output displacement of the micro-displacement amplifying mechanism is larger. According to the optimal design results, the bridge structure I’s initial angle is 8°, the lever’s rod length is 15 mm, the bridge structure II’s rod length is 7 mm, the power arm length of bridge structure I driving lever is 5 mm, and the bridge structure II’s rod horizontal projection length is 6 mm, the simulated output displacement of the micro-displacement amplifying mechanism is the maximum, which is 0.1415 mm.

- (4)

- When the relevant parameters change, the theoretical output displacement of the micro-displacement amplifying mechanism is slightly larger than the simulated displacement, and the error is about 10%. It can be seen from the prototype test that the smaller the input excitation displacement of the micro-displacement amplifying mechanism, the larger the error, whereas the larger the input excitation displacement, the smaller the error. When the input excitation displacement is 0.005 mm, the test value of the output displacement of the micro-displacement amplifying mechanism is 0.1239 mm, and the error compared with the theoretical value is 19.8% and the error compared with the simulated value is 12.44%. The error causes are analyzed and the improvement measures are put forward. The validity of the micro-displacement amplifying mechanism design, the accuracy of the theoretical calculation method, and the simulation analysis approach for output characteristics have been confirmed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aoyagi, M.; Beeby, S.; White, N. A novel multi-degree-of-freedom thick-film ultrasonic motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yan, P. A novel bidirectional complementary-type inchworm actuator with parasitic motion based clamping. Mech. Syst. Signal Process. 2019, 134, 106360. [Google Scholar] [CrossRef]

- Li, H.; Tong, Y.; Li, C. Modeling and Control of a Linear Piezoelectric Actuator. Actuators 2024, 13, 55. [Google Scholar] [CrossRef]

- Wang, T.; Xu, L. Chaotic vibrations by a novel non-contact piezoelectric actuator. Appl. Math. Model. 2022, 106, 199–224. [Google Scholar] [CrossRef]

- Li, H.; Gao, S.; Chen, Z.; Yin, Y. Structural design and dynamic characteristic analysis of short-column micro piezoelectric power actuator. Recent Pat. Mech. Eng. 2024, 17, 143–156. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Y.; Shen, D.; Ma, J.; Li, J.; Wen, J. A novel piezoelectric inchworm actuator driven by one channel direct current signal. IEEE Trans. Ind. Electron. 2021, 68, 2015–2023. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.; Ci, P.; Liu, G.; Dong, S. A standing wave linear ultrasonic motor operating in in-plane expanding and bending modes. Rev. Sci. Instrum. 2015, 86, 035002. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Xu, L. A Hybrid Dynamic Model for a Rotary Piezoelectric Motor Without Sliding Friction. J. Vib. Eng. Technol. 2023, 11, 3549–3564. [Google Scholar] [CrossRef]

- Jeong, S.; Park, C.; Park, T. Optimal design of V-type ultrasonic motor. J. Cent. South Univ. Technol. 2010, 17, 1247–1250. [Google Scholar] [CrossRef]

- Ghosh, B.; Jain, R.; Majumder, S.; Roy, S.; Mukhopadhyay, S. Experimental characterizations of bimorph piezoelectric actuator for robotic assembly. J. Intell. Mater. Syst. Struct. 2017, 28, 2095–2109. [Google Scholar] [CrossRef]

- Mohd, R.; Wan, Y.; Mat, P. Increasing the efficiency of traveling wave ultrasonic motor by modifying the stator geometry. Ultrasonics 2016, 64, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Lim, B.; Jang, N.; Hwang, D. Compact stick–slip piezoelectric rotary motor with reduced undesired backward motion. Microsyst. Technol. 2024, 30, 1049–1061. [Google Scholar] [CrossRef]

- Timmermann, E.; Bansemer, R.; Gerling, T.; Hahn, V.; Weltmann, K.; Nettesheim, S.; Puff, M. Piezoelectric-driven plasma pen with multiple nozzles used as a medical device: Risk estimation and antimicrobial efficacy. J. Phys. D Appl. Phys. 2021, 54, 107231. [Google Scholar] [CrossRef]

- Moallemi, A.; Fan, R.; Zhang, Y.; Forughi, A.; Chen, L.; Zhao, Y.; Wu, Z.; Nagamune, R.; Chou, K.; Zeng, H.; et al. Development of a hybrid piezoelectric and pneumatic miniature optical scanner for endoscopic applications. Sens. Actuators A Phys. 2020, 315, 112311. [Google Scholar] [CrossRef]

- Ho, S.; Jan, S. A piezoelectric motor for precision positioning applications. Precis. Eng. 2016, 43, 285–293. [Google Scholar] [CrossRef]

- Saikumar, J.; Kim, J.; Byrns, C.; Hemphill, M.; Meaney, D.; Bonini, N. Inducing different severities of traumatic brain injury in Drosophila using a piezoelectric actuator. Nat. Protoc. 2021, 16, 263–282. [Google Scholar] [CrossRef] [PubMed]

- Lau, J.; Liang, W.; Liaw, H.; Tan, K. Sliding mode disturbance observer-based motion control for a piezoelectric actuator-based surgical device. Asian J. Control 2018, 20, 1194–1203. [Google Scholar] [CrossRef]

- Mashimo, T.; Izuhara, S.; Arai, S.; Zhang, Z.; Oku, H. High-speed visual feedback control of miniature rotating mirror system using a micro ultrasonic motor. IEEE Access 2019, 8, 38546–38553. [Google Scholar] [CrossRef]

- Hunstig, M. Piezoelectric inertia motors—A critical review of history, concepts, design, applications, and perspectives. Actuators 2017, 6, 7. [Google Scholar] [CrossRef]

- Sashida, T. Trial construction and operation of an ultrasonic vibration driven motor. Oyo Butsiuri 1982, 6, 713–718. [Google Scholar]

- Sashida, T. Motor Device Utilizing Ultrasonic Oscillation. U.S. Patent US4562374, 31 December 1985. [Google Scholar]

- Yukihiro, I. Ultrasonic motor. J. Acoust. Soc. Jpn. 1987, 43, 184–188. [Google Scholar]

- Xu, L.; Li, H.; Li, C. Displacements of the flexible ring for an electromechanical integrated harmonic piezodrive system. Struct. Eng. Mech. Int. J. 2016, 60, 1079–1092. [Google Scholar] [CrossRef]

- Delibas, B.; Koc, B. L1B2 Piezo Motor Using D33 Effect. In ACTUATOR 2018, Proceedings of the 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Xing, J.; Ren, W.; Qin, Y. Electromagnetic torque analysis for a non-contact piezoelectric motor modulated by an electromagnetic field. Int. J. Appl. Electromagn. Mech. 2020, 62, 383–401. [Google Scholar] [CrossRef]

- Hirose, S.; Yamayoshi, Y.; Ono, H. A small noncontact ultrasonic motor. In Proceedings of the 1993 Proceedings IEEE Ultrasonics Symposium, Baltimore, MD, USA, 31 October–3 November 1993; IEEE: Piscataway, NJ, USA, 1993; Volume 1, pp. 453–456. [Google Scholar]

- Nakamura, K.; Maruyama, M.; Ueha, S. A new ultrasonic motor using electro-rheological fluid and torsional vibration. Ultrasonics 1996, 34, 261–264. [Google Scholar] [CrossRef]

- Ueha, S.; Hashimoto, Y.; Koike, Y. Non-contact transportation using near-field acoustic levitation. Ultrasonics 2000, 38, 26–32. [Google Scholar] [CrossRef]

- Wang, T.; Xu, L.; Xing, J. Torque for non-contact piezoelectric motor modulated by electromagnetic force. Int. J. Appl. Electromagn. Mech. 2021, 67, 409–429. [Google Scholar] [CrossRef]

- Nakamura, K.; Ito, T.; Kurosawa, M.; Ueha, S. A trial construction of an ultrasonic motor with fluid coupling. Jpn. J. Appl. Phys. 1990, 29, 160–161. [Google Scholar] [CrossRef]

- Hu, J.; Yamazaki, T.; Nakamura, K.; Ueha, S. Analyses of an ultrasonic motor driving fluid directly. Jpn. J. Appl. Phys. 1995, 34, 2702–2706. [Google Scholar] [CrossRef]

- Yamayoshi, Y.; Hirose, S. Ultrasonic motor not using mechanical friction force. Int. J. Appl. Electromagn. Mater. 1992, 3, 179–182. [Google Scholar]

- Stepanenko, D.; Minchenya, V. Development and study of novel non-contact ultrasonic motor based on principle of structural asymmetry. Ultrasonics 2012, 52, 866–872. [Google Scholar] [CrossRef]

- Qiu, W.; Hong, Y.; Mizuno, Y.; Wen, W.; Nakamura, K. Non-contact piezoelectric rotary motor modulated by giant electrorheological fluid. Sens. Actuators A Phys. 2014, 217, 124–128. [Google Scholar] [CrossRef]

- Nandi, A.; Neogy, S.; Bhaduri, S. Performance analysis of a non-contact vibration damper made up of a piezoelectric stack and an electromagnet. J. Vib. Eng. Technol. 2015, 3, 401–418. [Google Scholar]

- Xing, J.; Zhao, L. Free vibration analysis for a non-contact piezoelectric motor modulated by electromagnetic field. Int. J. Appl. Electromagn. Mech. 2017, 55, 435–451. [Google Scholar] [CrossRef]

- Xing, J.; Zhao, L.; Li, C. Analysis for forced response of a non-contact piezoelectric driving system modulated by electromagnetic field under coupling excitation. J. Mech. Sci. Technol. 2018, 32, 1529–1537. [Google Scholar] [CrossRef]

- Shi, M.; Liu, X.; Feng, K.; Zhang, K. Experimental and numerical investigation of a self-adapting non-contact ultrasonic motor. Tribol. Int. 2021, 153, 106624. [Google Scholar] [CrossRef]

- Wang, T.; Xing, J.; Xu, L. Coupled Dynamics for Noncontact Piezoelectric Motor Modulated by Electromagnetic Force. J. Comput. Nonlinear Dyn. 2020, 15, 051007. [Google Scholar] [CrossRef]

- Chen, S.; Shi, M.; Zhang, S.; Song, D. Simulation Analysis and Experimental Research of Non-Contact Ultrasonic Motor Based on Acoustic Streaming. Tribology 2024, 44, 10–17. [Google Scholar]

| (mm) | (mm) | (mm) | (mm) | (°) |

|---|---|---|---|---|

| 14.07 | 6.57 | 6 | 5.82 | 10 |

| Density (kg/m3) | Modulus of Elasticity (Pa) | Bending Modulus (Pa) | Tensile Strength (Pa) | Poisson’s Ratio |

|---|---|---|---|---|

| 7.85 × 103 | 2 × 1011 | 7.69 × 1010 | 4.6 × 108 | 0.3 |

| Input Value (mm) | Theoretical Displacement (mm) | Theoretical Magnification | Simulated Displacement (mm) | Simulation Magnification | Error (%) |

|---|---|---|---|---|---|

| 0.003 | 0.07493 | 24.98 | 0.06772 | 22.57 | 9.62 |

| 0.005 | 0.12356 | 24.71 | 0.11285 | 22.57 | 8.67 |

| 0.007 | 0.17118 | 24.45 | 0.15799 | 22.57 | 7.71 |

| Initial Angle (°) | Theoretical Displacement (mm) | Theoretical Magnification | Simulated Displacement (mm) | Simulation Magnification | Error (%) |

|---|---|---|---|---|---|

| 8 | 0.15399 | 30.8 | 0.13768 | 27.54 | 10.6 |

| 10 | 0.12356 | 24.71 | 0.11285 | 22.57 | 8.67 |

| 12 | 0.10297 | 20.59 | 0.09494 | 18.99 | 7.8 |

| Parameter | Input Value (mm) | Theoretical Displacement(mm) | Theoretical Magnification | Simulated Displacement (mm) | Simulation Magnification | Error (%) |

|---|---|---|---|---|---|---|

| l1 | 13.07 | 0.11499 | 23 | 0.10643 | 21.29 | 7.44 |

| 14.07 | 0.12356 | 24.71 | 0.11285 | 22.57 | 8.67 | |

| 15.07 | 0.13211 | 26.42 | 0.12015 | 24.03 | 9.05 | |

| l2 | 6.34 | 0.14847 | 29.69 | 0.13941 | 27.88 | 6.1 |

| 6.57 | 0.12356 | 24.71 | 0.11285 | 22.57 | 8.67 | |

| 6.8 | 0.10761 | 21.52 | 0.09839 | 19.68 | 8.57 | |

| l3 | 5 | 0.14750 | 29.5 | 0.13165 | 26.33 | 10.7 |

| 6 | 0.12356 | 24.71 | 0.11285 | 22.57 | 8.67 | |

| 7 | 0.10631 | 21.26 | 0.09819 | 19.64 | 7.64 | |

| e | 5.62 | 0.10731 | 21.46 | 0.09963 | 19.93 | 7.16 |

| 5.82 | 0.12356 | 24.71 | 0.11285 | 22.57 | 8.67 | |

| 6.02 | 0.14701 | 29.40 | 0.13433 | 26.87 | 8.63 |

| Serial Number | Bridge I Initial Angle θ | Lever Length l1 | Bridge II Length l2 | Power Arm Length l3 | Bridge II Horizontal Projection Length e | Output Displacement S5 |

|---|---|---|---|---|---|---|

| 1 | 12 | 13 | 7 | 7 | 6 | 0.07106 |

| 2 | 8 | 13 | 6 | 7 | 5 | 0.09147 |

| 3 | 12 | 15 | 7 | 7 | 6 | 0.07994 |

| 4 | 8 | 13 | 6 | 5 | 5 | 0.12362 |

| 5 | 8 | 15 | 6 | 5 | 6 | 0.10852 |

| 6 | 8 | 15 | 7 | 7 | 5 | 0.07314 |

| 7 | 12 | 13 | 6 | 5 | 5 | 0.08530 |

| 8 | 12 | 15 | 6 | 7 | 6 | 0.11118 |

| 9 | 12 | 13 | 7 | 5 | 6 | 0.09728 |

| 10 | 8 | 13 | 7 | 5 | 6 | 0.14153 |

| 11 | 8 | 15 | 7 | 5 | 6 | 0.15940 |

| 12 | 10 | 14 | 6.5 | 6 | 5.5 | 0.09616 |

| 13 | 8 | 13 | 7 | 7 | 5 | 0.06471 |

| 14 | 8 | 15 | 6 | 7 | 6 | 0.13291 |

| 15 | 8 | 13 | 7 | 5 | 5 | 0.08936 |

| 16 | 8 | 15 | 6 | 5 | 5 | 0.13757 |

| 17 | 8 | 15 | 6 | 7 | 5 | 0.10234 |

| 18 | 12 | 15 | 7 | 5 | 6 | 0.10907 |

| 19 | 12 | 15 | 7 | 7 | 5 | 0.04964 |

| 20 | 10 | 14 | 6.5 | 6 | 5.5 | 0.09616 |

| 21 | 12 | 15 | 6 | 7 | 5 | 0.06976 |

| 22 | 8 | 13 | 6 | 5 | 6 | 0.12833 |

| 23 | 8 | 15 | 7 | 7 | 6 | 0.11734 |

| 24 | 12 | 13 | 6 | 5 | 6 | 0.1129 |

| 25 | 12 | 15 | 7 | 5 | 5 | 0.06884 |

| 26 | 8 | 15 | 7 | 5 | 5 | 0.10040 |

| 27 | 10 | 14 | 6.5 | 6 | 5.5 | 0.09616 |

| 28 | 12 | 15 | 6 | 5 | 6 | 0.09334 |

| 29 | 8 | 13 | 7 | 7 | 6 | 0.10408 |

| 30 | 12 | 13 | 6 | 7 | 5 | 0.06217 |

| 31 | 12 | 13 | 7 | 7 | 5 | 0.04391 |

| 32 | 12 | 13 | 6 | 7 | 6 | 0.08715 |

| 33 | 12 | 13 | 7 | 5 | 5 | 0.06108 |

| 34 | 12 | 15 | 6 | 5 | 5 | 0.09500 |

| 35 | 8 | 13 | 6 | 7 | 6 | 0.12722 |

| (mm) | (mm) | (mm) | (mm) | |

|---|---|---|---|---|

| 15 | 7 | 5 | 6 | 8 |

| Input Value (mm) | Theoretical Value (mm) | Simulated Value (mm) | Test Value (mm) | Error (%) (Test and Theory) | Error(%) (Test and Simulation) |

|---|---|---|---|---|---|

| 0.003 | 0.09452 | 0.08491 | 0.0667 | 29.43 | 21.45 |

| 0.004 | 0.12533 | 0.11321 | 0.0942 | 24.84 | 16.79 |

| 0.005 | 0.15449 | 0.14150 | 0.1239 | 19.8 | 12.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhang, D.; Lin, Y.; Chen, Z.; Shi, Z.; Li, C.; Zhao, L. Research on Output Characteristics of a Non-Contact Piezoelectric Actuator’s Micro-Displacement Amplifying Mechanism. Actuators 2024, 13, 309. https://doi.org/10.3390/act13080309

Li H, Zhang D, Lin Y, Chen Z, Shi Z, Li C, Zhao L. Research on Output Characteristics of a Non-Contact Piezoelectric Actuator’s Micro-Displacement Amplifying Mechanism. Actuators. 2024; 13(8):309. https://doi.org/10.3390/act13080309

Chicago/Turabian StyleLi, Huaiyong, Dongya Zhang, Yusheng Lin, Zhong Chen, Zhiwei Shi, Chong Li, and Liang Zhao. 2024. "Research on Output Characteristics of a Non-Contact Piezoelectric Actuator’s Micro-Displacement Amplifying Mechanism" Actuators 13, no. 8: 309. https://doi.org/10.3390/act13080309

APA StyleLi, H., Zhang, D., Lin, Y., Chen, Z., Shi, Z., Li, C., & Zhao, L. (2024). Research on Output Characteristics of a Non-Contact Piezoelectric Actuator’s Micro-Displacement Amplifying Mechanism. Actuators, 13(8), 309. https://doi.org/10.3390/act13080309