1. Introduction

With the rapid development of modern industry, permanent magnet synchronous motors (PMSMs) are extensively utilized in various fields such as power, transportation, aerospace, etc. They are favored for their compact size, high torque output, and exceptional efficiency [

1,

2]. However, as the demand for energy efficiency, environmental sustainability, and safety continues to rise, there is an increasing need for improved performance and stability of PMSMs. Consequently, optimizing PMSMs becomes particularly crucial to meeting these evolving requirements.

The conventional design approach for PMSM typically emphasizes a single objective, focusing solely on individual motor performance aspects such as maximizing torque or minimizing losses, which leads to poor overall motor performance. Reference [

3] enhanced the electromagnetic vibration force of the stator teeth by adding the auxiliary slot structure of the motor rotor and conducted a comparative analysis of the results before and after optimization. This optimization has been proven to effectively decrease the noise and vibration of the motor while ensuring its electromagnetic performance. Reference [

4] employed the Taguchi method for structural design to mitigate the peak air gap flux density of the external rotor PMSMs resulting from slotting the stator. Reference [

5] introduced a magnetic barrier structure on the motor rotor to address the issue of uneven saturation of the rotor-side magnetic bridge. Additionally, the study utilized the Taguchi method to optimize the structural parameters of the added magnetic barrier. Subsequently, it analyzed the influence of these parameters on the electromagnetic performance of the motor. The findings suggest that maximizing the output torque is desirable without altering the no-load back electromotive force (EMF) and torque ripple. Reference [

6] introduces a new torque ripple model, which utilizes a genetic algorithm to optimize the amplitude and phase angle of stator harmonic current, effectively reducing torque ripple.

Single objective optimization is straightforward, intuitive, and easy to implement. However, in motor optimization design, multi-objective optimization is often encountered, with these objectives frequently imposing constraints on each other. Hence, in the optimization design process of PMSM, it becomes imperative to strike a balance among multiple objective functions, including motor efficiency, torque density, volume, and weight. To address the mutual constraints between these multiple objectives, researchers have increasingly turned to multi-objective optimization algorithms, enabling a more comprehensive and balanced design of PMSM.

Currently, commonly used multi-objective optimization algorithms include multi-objective particle swarm optimization (MOPSO) [

7], non-dominated sorting genetic algorithm (NSGA-II) [

8], multi-objective grey wolf algorithm (MOGWO) [

9], multi-objective evolutionary algorithm (MODA) [

10], multi-objective cuckoo algorithm (MOCS) [

11], and multi-objective artificial hummingbird algorithm (MOAHA) [

12]. The MOPSO algorithm is grounded in the concept of swarm intelligence. It offers the advantages of robust global search capability and rapid convergence speed. However, it is susceptible to getting trapped in local optima when handling high-dimensional problems. NSGA-II is rooted in the principles of natural evolution. It demonstrates strong convergence and search efficiency, but it may have limitations in handling high-dimensional problems. MOGWO draws inspiration from the predatory behavior of gray wolves. It possesses good convergence and diversity, but its capability to solve complex problems may be limited. MODA adopts the concept of evolution and is effective in exploring the solution space, but its performance may be limited in high-dimensional problems. MOCS simulates the foraging behavior of bird flocks. It exhibits strong global search ability but may encounter challenges when dealing with high-dimensional problems. MOAHA simulates the foraging behavior of hummingbirds, leveraging the benefits of diversity and efficiency. It can maintain population diversity and quickly identify the optimal solution set. However, when addressing complex problems, the algorithm’s convergence may be limited, and it may be prone to getting trapped in local optima. Reference [

12] has demonstrated, through a series of comprehensive experimental verifications, that the multi-objective artificial hummingbird algorithm exhibits superior performance in terms of convergence accuracy, diversity of solution sets, and spatial distribution when solving 28 typical benchmark problems. It surpasses several other multi-objective optimization algorithms, including multi-objective particle swarm optimization, non-dominated inheritance algorithm, decomposition evolution strategy, strength evolution algorithm, multi-objective ant optimization, multi-objective salt swarm algorithm, multi-objective wolf swarm algorithm, and multi-objective grey wolf algorithm. In essence, this study strongly validates the efficiency and leading advantages of the multi-objective artificial hummingbird algorithm in the realm of multi-objective optimization. Therefore, this paper uses a multi-objective artificial hummingbird algorithm as the optimization algorithm.

Reference [

13] proposes a multi-objective hierarchical optimization method based on parameter hierarchical design, combined with the Taguchi method and response surface method (RSM). This method is applied to optimize the rotor surface slot parameters of a V-type interior permanent magnet synchronous motor (IPMSM). By comparing the electromagnetic performance of the motor before and after optimization, it can be concluded that the optimized motor not only improves the output torque but also reduces the torque ripple. Reference [

14] proposes a multi-objective optimization method for improving the torque performance of IPMSM using a single-layer fractional slot concentrated winding. By performing parameter design on the rotor slots and employing the RSM and the seagull optimization algorithm to obtain the optimal parameter design and determine the optimal slot position. The results indicate that the optimized design leads to a reduction in torque ripple and an increase in average torque. Reference [

15] presents a multi-objective optimization design method for PMSM based on the artificial bee colony algorithm, with efficiency and the electromechanical time constant set as the optimization objectives. Through finite element analysis, the optimized motor exhibits improved efficiency and reduced mechanical time constant. Reference [

16] presents a novel comprehensive multi-objective optimization design method for a spoke-type permanent magnet motor, utilizing sensitivity analysis, RSM, and the basic multi-objective particle swarm algorithm to conduct robustness analysis of the motor. The results indicate that this optimization method not only reduces torque ripple but also enhances the reliability and robustness of the machine. Reference [

17] designed a new type of automotive permanent magnet synchronous motor (IPMSM) and conducted multi-objective optimization using the Taguchi method to reduce torque ripple and cogging torque. Reference [

18] utilized the Quantum Bat Algorithm (QBA) and Pyramid Neural Network (PNN) model to optimize the structural parameters of a High-Speed Permanent Magnet Synchronous Motor (HPMSM) and determine the optimal combination to minimize motor losses. The performance of the optimized HPMSM was validated through finite element simulation analysis and prototype experiments. Reference [

19] developed an optimal model for the PMSM prototype of an electric compressor and verified the efficiency of optimizing PMSM using the optimal Latin hypercube, Kriging model, and genetic algorithm. However, [

13,

14,

15,

16,

17,

18,

19] transforms multi-objective optimization into single-objective optimization by determining the trade-off relationship between multiple objectives, and the allocation of weights usually requires subjective judgment. Therefore, this process may not be objective enough and may lead to results biased towards a specific objective at the expense of other objectives.

Reference [

20] presents a multi-objective optimization design based on the rotor topology of a permanent magnet-assisted bearingless synchronous reluctance motor. The study combines sensitivity analysis with NSGA-II to select the optimal design variables. The research results demonstrate that the optimized motor exhibits higher average torque, average suspension force, and power factor. However, this method requires setting target function values in advance and may not effectively illustrate the relationships among multiple objectives. Reference [

21] introduces a multi-objective optimal rotor design method for an IPMSM based on finite element analysis (FEA). Sensitivity analysis is used to determine the appropriate range and initial values of each parameter, and the average torque and torque ripple of the IPMSM are optimized. Reference [

22] introduces a convolutional neural network model based on deep learning, which achieves rotor topology optimization for IPMSM. The results indicate that this method improves computational speed and average torque without compromising search capability. However, this method only considers average torque and does not take into account other performance aspects of the motor. Reference [

23] presents a multi-objective design optimization method for PMSLM based on machine learning algorithms. By optimizing the motor’s structural parameters, it achieves the optimal performance of high average thrust, low thrust ripple, and low total harmonic distortion. However, deep learning requires a large amount of data for training, as well as larger model scales and parameter quantities, which can make model deployment and maintenance more complex.

In summary, the utilization of multi-objective optimization algorithms has become a highly effective method for achieving optimal and balanced performance in the design of PMSM. These algorithms enable designers to consider multiple objectives simultaneously and find comprehensive solutions that can meet different application requirements. While multi-objective optimization algorithms have great potential in PMSM design, there is still some subjectivity and difficulties in balancing the relationships between various objectives and selecting the best solution.

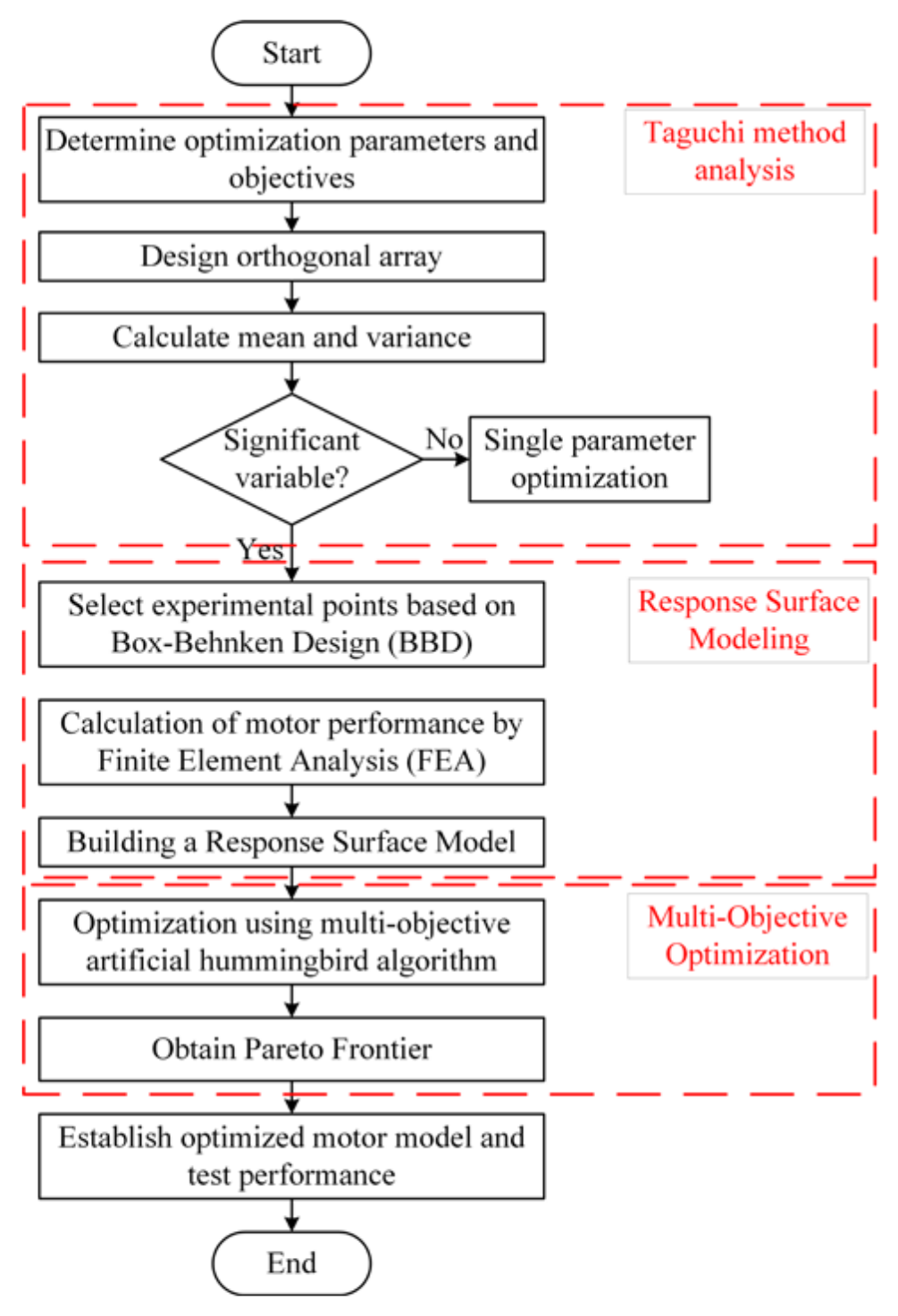

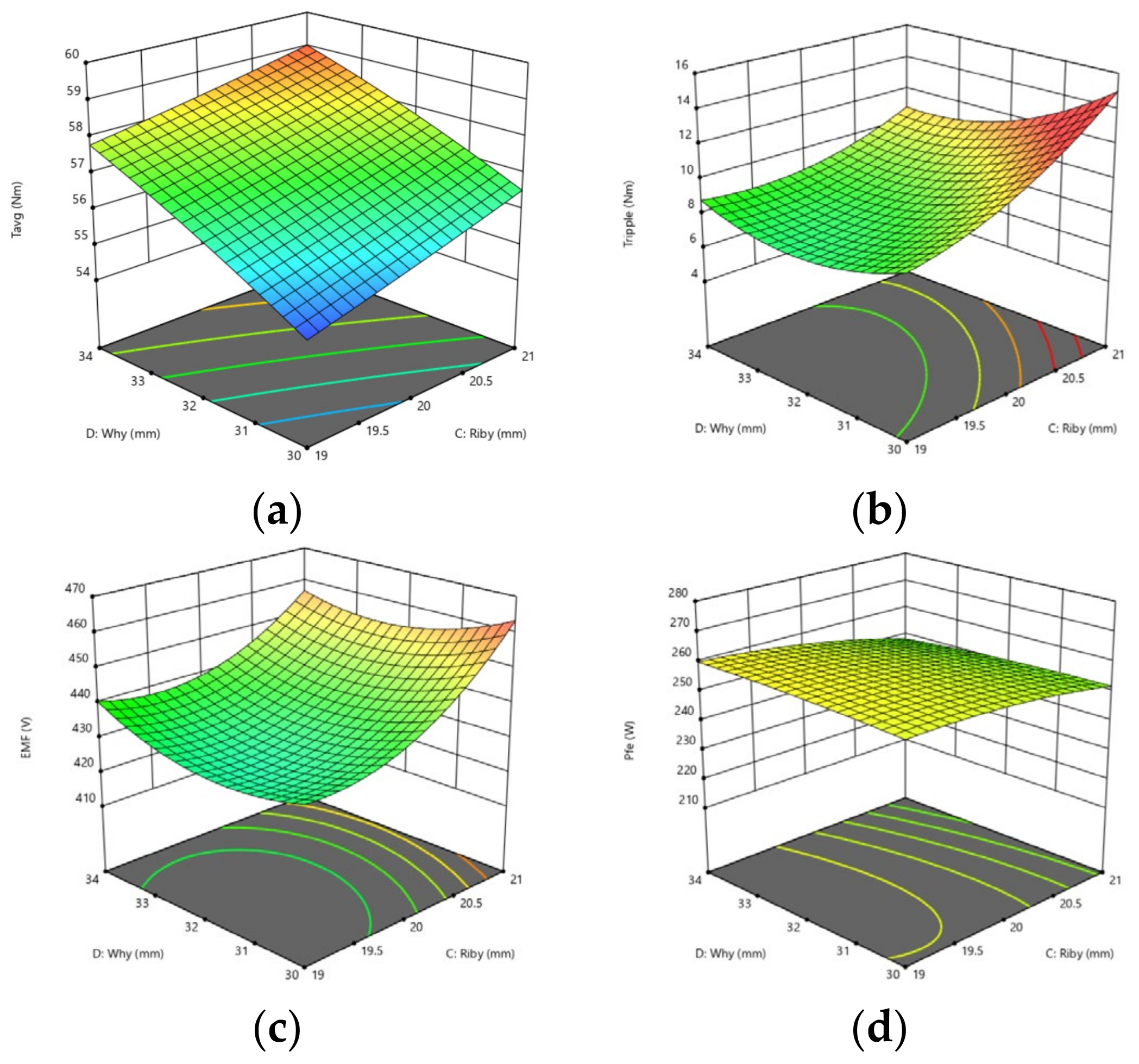

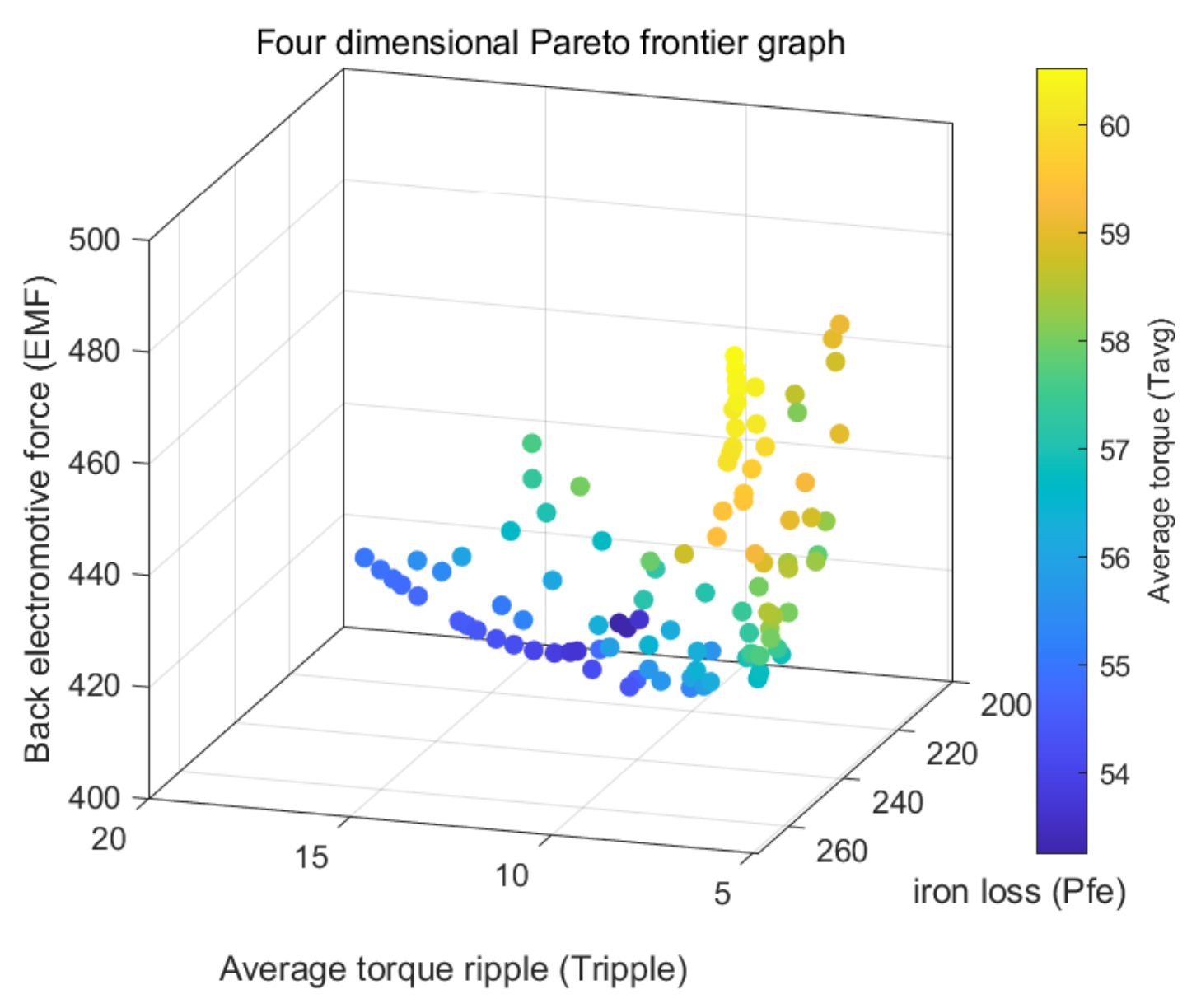

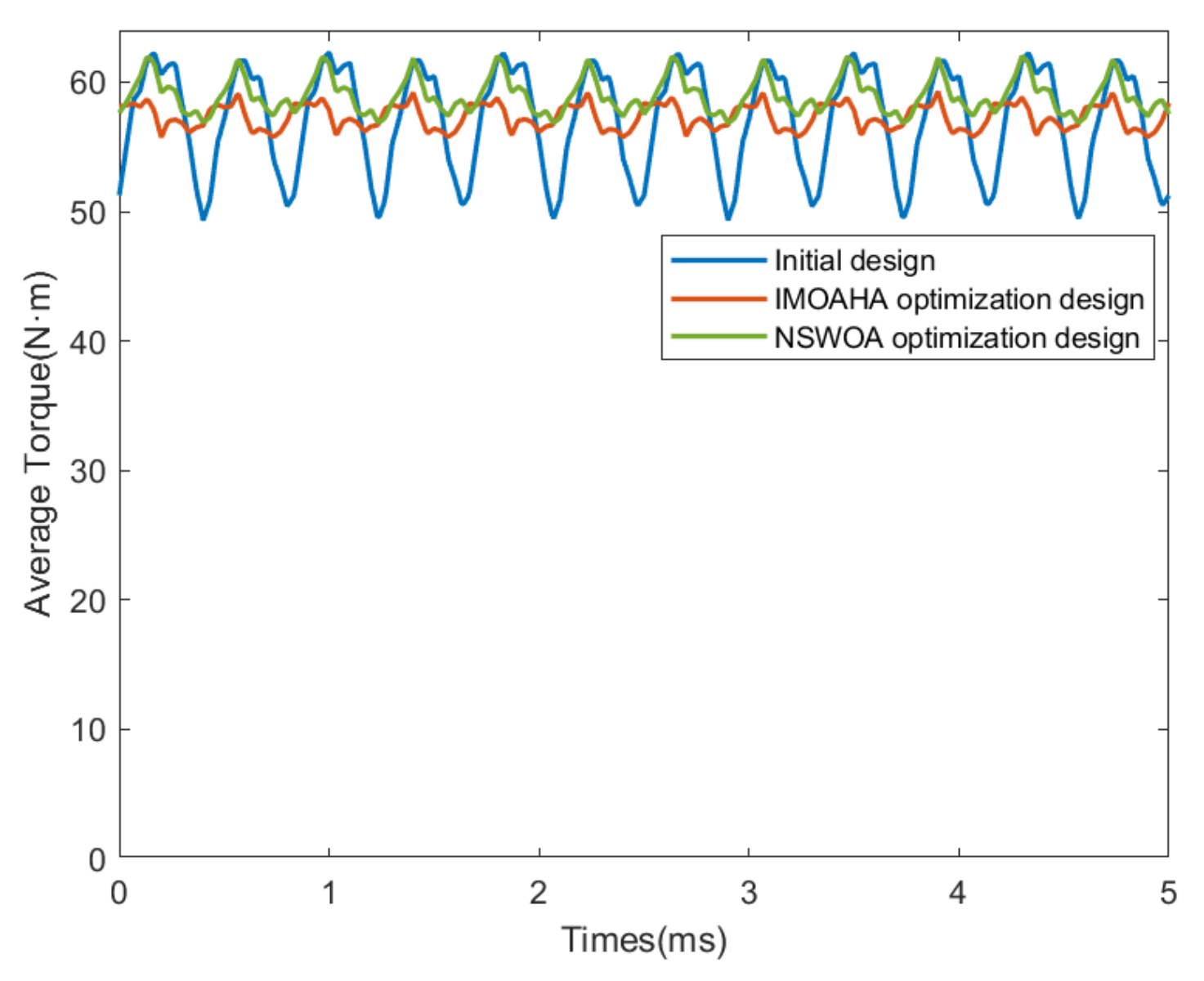

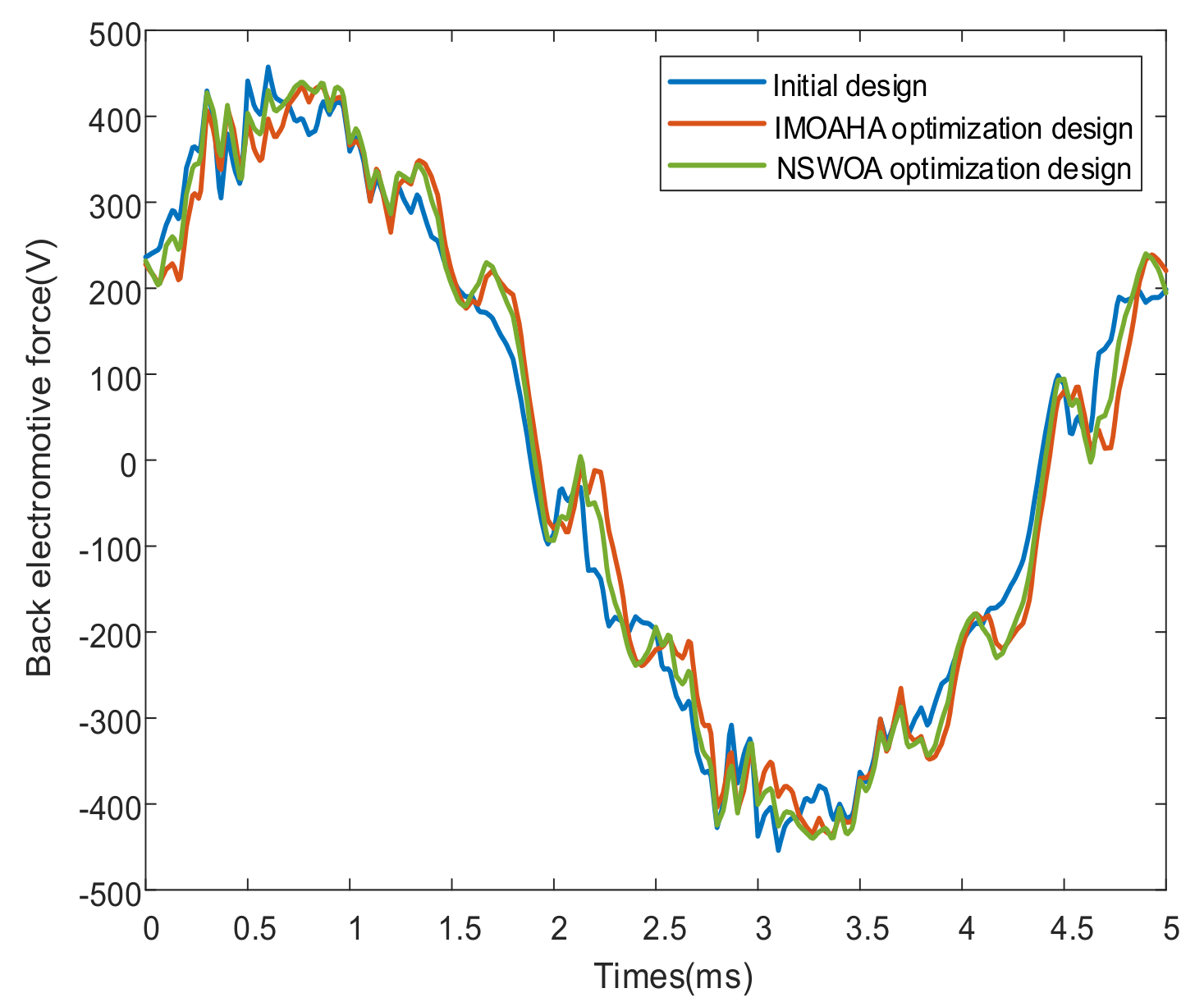

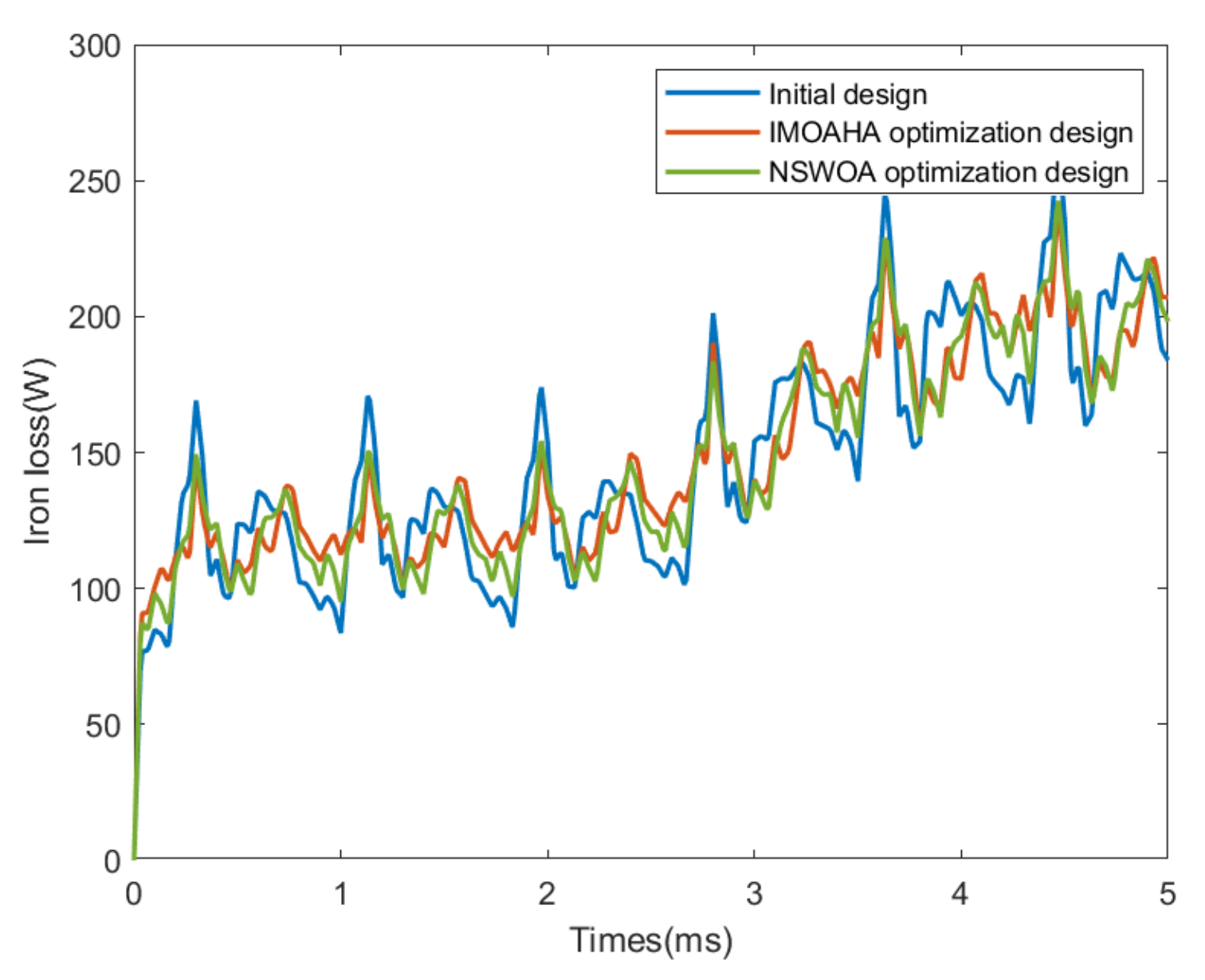

To address the issue of traditional MOAHA algorithms easily falling into local optima too early, this paper introduces chaotic mapping Bernoulli to initialize the population, nonlinear increasing adaptive weights, and an external file maintenance mechanism based on dynamic crowding entropy to improve the multi-objective artificial hummingbird optimization algorithm (IMOAHA). To effectively overcome the problem of getting stuck in local optima, this paper integrates the Taguchi method and the IMOAHA algorithm to conduct multi-objective optimization design on IPMSM, while considering average torque, torque ripple, iron loss, and EMF. The accuracy of the multi-objective optimization design is validated through finite element simulation.

The rest of this paper is structured as follows.

Section 2 provides a brief introduction and enhancement of the MOAHA. The optimization methods are presented in

Section 3.

Section 4 details the finite element simulation results. Finally, the findings of this paper are summarized in

Section 5.

2. IPMSM Basic Structure

Surface-mounted permanent magnet synchronous motors (SPMSMs) and IPMSMs are two types of PMSMs, distinguished by the placement positions of the permanent magnets. While SPMSMs exhibit low torque ripple, they have lower power density. Furthermore, at high speeds, SPMSMs are susceptible to permanent magnet detachment. The IPMSMs offer high output torque, a wide speed range, and high efficiency, making them suitable for various industrial production and other fields.

The rotor structures of the interior permanent magnet synchronous motor include “1-shaped”, “V-shaped”, and “V + 1-shaped”, each differing in structure and performance. The “1-shaped” rotor has a simple structure but low magnetic flux density, making it unsuitable for high-speed applications. The “V-shaped” rotor structure offers high magnetic flux density and is suitable for high-speed applications. However, the difference in magnetic circuit impedance between the d-axis and q-axis is small, resulting in lower reluctance torque. The “V + 1-shaped” structure is a hybrid of the “1-shaped” and “V-shaped” designs, featuring a short magnetic circuit, low magnetic resistance, higher magnetic properties, and stronger magnetic field strength [

24]. Therefore, this paper utilizes the “V + 1-shaped” IPMSM. Compared to full-pitch windings, shorted-pitch windings offer several advantages in motor design. These include reducing harmonics, enhancing the electromotive force waveform, improving efficiency and power factor, minimizing torque fluctuations, boosting dynamic response and stability, and lowering iron losses. These benefits collectively contribute to an overall enhancement of motor performance.

The electromagnetic torque formula for permanent magnet synchronous motors is [

25]:

where

p is the number of pole pairs,

ψf is the permanent magnet flux linkage,

id, and

iq are the

d-axis and

q-axis current, respectively, and

Ld and

Lq are the

d-axis and

q-axis inductance, respectively.

The average torque magnitude (

Tavg) of the interior permanent magnet synchronous motor can be defined as the peak-to-peak average of the electromagnetic torque (

Te) during steady operation of the motor as follows:

The torque ripple

Tripple used in this paper can be defined as the peak-to-peak difference of electromagnetic torque, as shown below:

where

avg means the calculated average,

Tmax is the maximum peak of the electromagnetic torque and

Tmin is the minimum peak of the electromagnetic torque.

The permanent magnet synchronous motor adopts a separate calculation model that divides iron loss into three parts [

26]:

where,

Ph,

Pc, and

Pe represent hysteresis loss, classical eddy current loss, and anomalous eddy current loss, respectively.

Bp represents magnetic flux density amplitude,

f represents frequency,

kh,

x represents hysteresis loss coefficient,

kc represents classical eddy current loss coefficient, and

ke represents anomalous loss coefficient.

This paper focuses on the finite element model of a three-phase 8-pole 48-slot IPMSM, as depicted in

Figure 1. The motor stator features a double-layer shorted pitch, while the rotor structure utilizes a “V + 1-shaped” design. The number of slots for the shorted pitch winding is five. The primary parameters of the IPMSM finite element model are presented in

Table 1.

The model of the internal permanent magnet synchronous motor was constructed according to

Table 1, and materials were assigned to each component as presented in

Table 2.

3. Improved Multi-Objective Artificial Hummingbird Algorithm

3.1. Multi-Objective Artificial Hummingbird Algorithm

The multi-objective artificial hummingbird algorithm simulates the unique flight capabilities and intelligent foraging strategies observed in hummingbirds in nature [

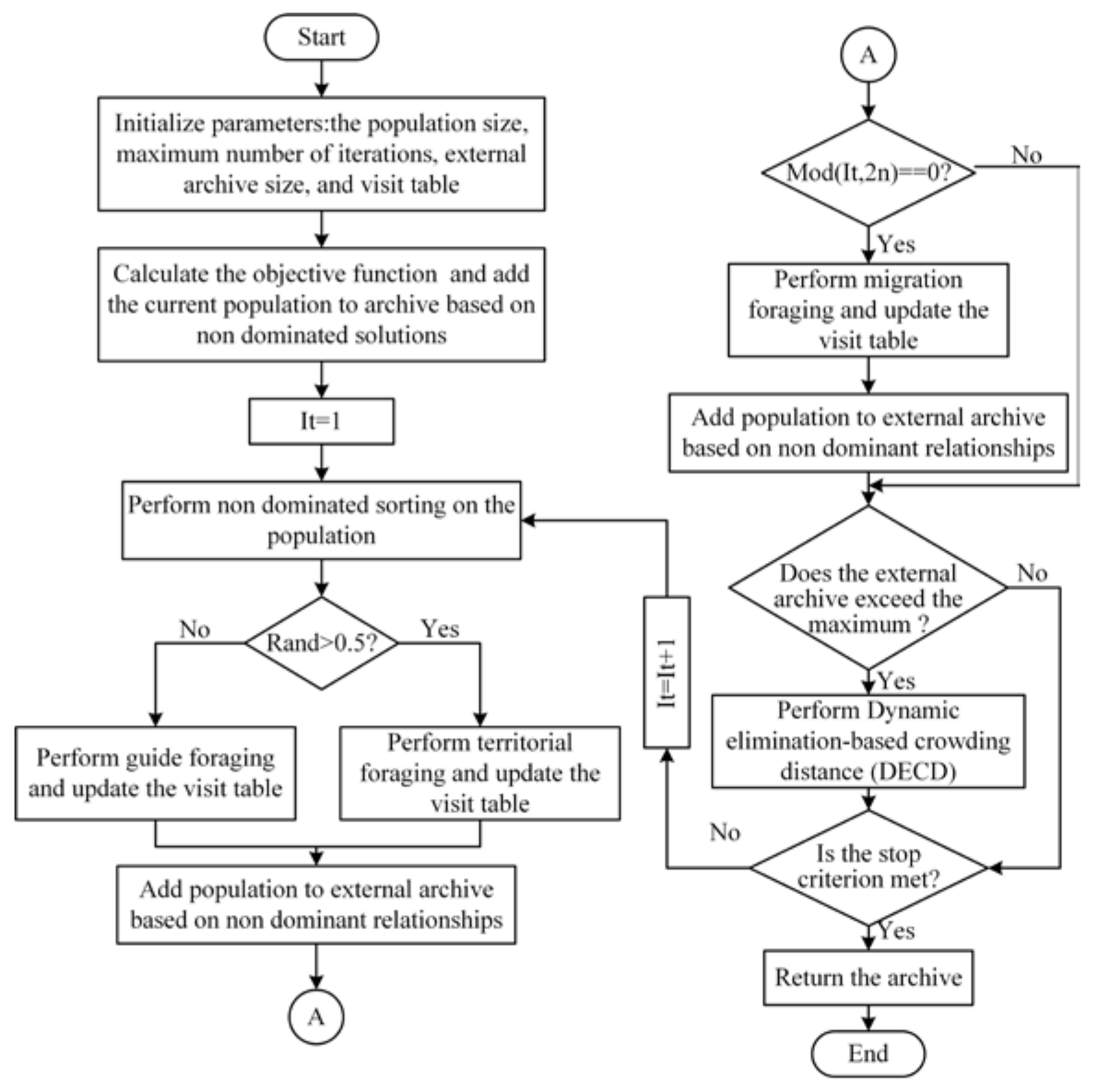

12]. It establishes three flight skill models for foraging strategies, encompassing axial flight, diagonal flight, and omnidirectional flight. Moreover, it achieves guided foraging, territorial foraging, and migratory foraging. An access table is constructed to simulate the memory function of hummingbirds regarding food sources. The MOAHA algorithm flowchart is depicted in

Figure 2.

A population of n hummingbirds is placed on n food sources randomly initialized as follows [

12]:

where

Low and

Up are the upper and lower boundaries of the d-dimensional problem,

r is a random number in the range of [0, 1], and

xi represents the position of the

i-th food source.

The initialization of the access table for food sources is as follows:

where

i =

j,

VTi,j =

null indicates that hummingbirds feed on specific food sources;

i ≠ j,

VTi,j = 0 indicates that the

j-th hummingbird has just visited the

i-th food source in the current iteration.

- 2.

Guide Foraging

During the foraging process, each hummingbird initially identifies the food source with the highest level of access and then selects the food source with the highest nectar supplementation rate from these sources as the target food source. Hummingbirds utilize directional switching vectors to control the direction of flight, assisting them in exploring the environment more effectively and finding the optimal food source.

These flight modes can be extended to d-D space, where axial flight is defined as follows:

The definition of diagonal flight is as follows:

The definition of omnidirectional flight is as follows:

where

randi([1,

d]) generates a random integer from 1 to

d,

randp(

k) creates a random permutation of integers from 1 to

k, and

r1 is a random number in the range of (0, 1].

After the hummingbird flies, it will search for the target food source and update the existing food source access table. The mathematical equation for simulating the guided foraging behavior of hummingbirds is as follows:

where

vi(

t + 1) represents the candidate food source location for the

t + 1 time,

xi(

t) represents the position of the

i-th food source at time

t,

xi,tr represents the location where the

i-th hummingbird intends to access the target food source, and

a is a guiding factor that follows the standard normal distribution

N (0,1). (6) updates the position of each current food source near the target food source and establishes a guided foraging model for hummingbirds through different flight modes. The location of the

i-th food source is updated as follows:

where

f(·) represents the fitness value of the function. (8) indicates that if the nectar supplementation rate of the candidate food source is higher than that of the current food source, the hummingbird will abandon the current food source and fly to the candidate food source to forage

- 3.

Territorial Foraging

After visiting the target food source to consume nectar, hummingbirds tend to seek new food sources rather than revisiting existing ones. Therefore, hummingbirds can easily move to nearby areas within their territory, searching for potentially better food sources as alternative solutions. To enhance the diversity of MOAHA solutions, the mathematical equation for simulating the territorial foraging strategy of hummingbirds is as follows:

where

b is a territorial foraging factor that follows a standard normal distribution and

xa (

t) is a randomly selected solution from external archives. (9) enables any hummingbird to easily discover new food sources nearby, leveraging its unique flying abilities and individual location

- 4.

Territorial Foraging

When food becomes scarce in a certain area, hummingbirds will choose to migrate to a place farther away from their current foraging site. At the same time, a migration coefficient, M, is defined to control the time of migration foraging. The determination of when hummingbirds migrate, the mathematical model of migration foraging, and the distribution of the migration coefficient are shown in Equations (10) and (11).

where

xwr is the food source with the worst nectar supplementation rate in the population, and

n represents the population size.

- 5.

Dynamic Elimination-Based Crowding Distance

The crowding distance is a widely used method in multi-objective optimization algorithms (MOAs) to maintain solution diversity. However, traditional crowding distance methods can lead to a change in the ranking of crowding distances for the remaining solutions after deleting one solution. To address this issue, MOAHA adopted an external archiving method with Dynamic Elimination-based Crowding Distance (DECD). This method only updates the crowding distance of the nearest deleted solution after deleting one solution, while keeping the crowding distances of the remaining solutions unchanged. This can ensure the diversity of solutions in external archives and enhance the algorithm’s performance.

Before removing the

i-th solution with the smallest current crowding distance, the crowding distances of the previous and next solutions adjacent to the

i-th solution are given as follows:

After removing the

i-th solution with the smallest current crowding distance, the crowding distances of the previous and next solutions adjacent to the

i-th solution are changed to:

where

dk(

xi−1) is the side length of the rectangular composed of the (

i−1)-th solution according to the crowding distance scheme and

D(

xi−1) is the crowding distance of the (

i−1)-th solution.

3.2. Chaos Mapping

The quality of the population during the initialization phase plays a crucial role in the algorithm’s overall performance. The basic multi-objective artificial hummingbird algorithm typically employs a random initialization method to generate the initial population. However, this method has drawbacks, including high randomness, poor diversity, and the population’s inability to be evenly distributed in the search space. The chaotic sequences generated by chaotic mapping can lead to a more diverse and uniform population, thereby enhancing the performance of swarm intelligence optimization algorithms.

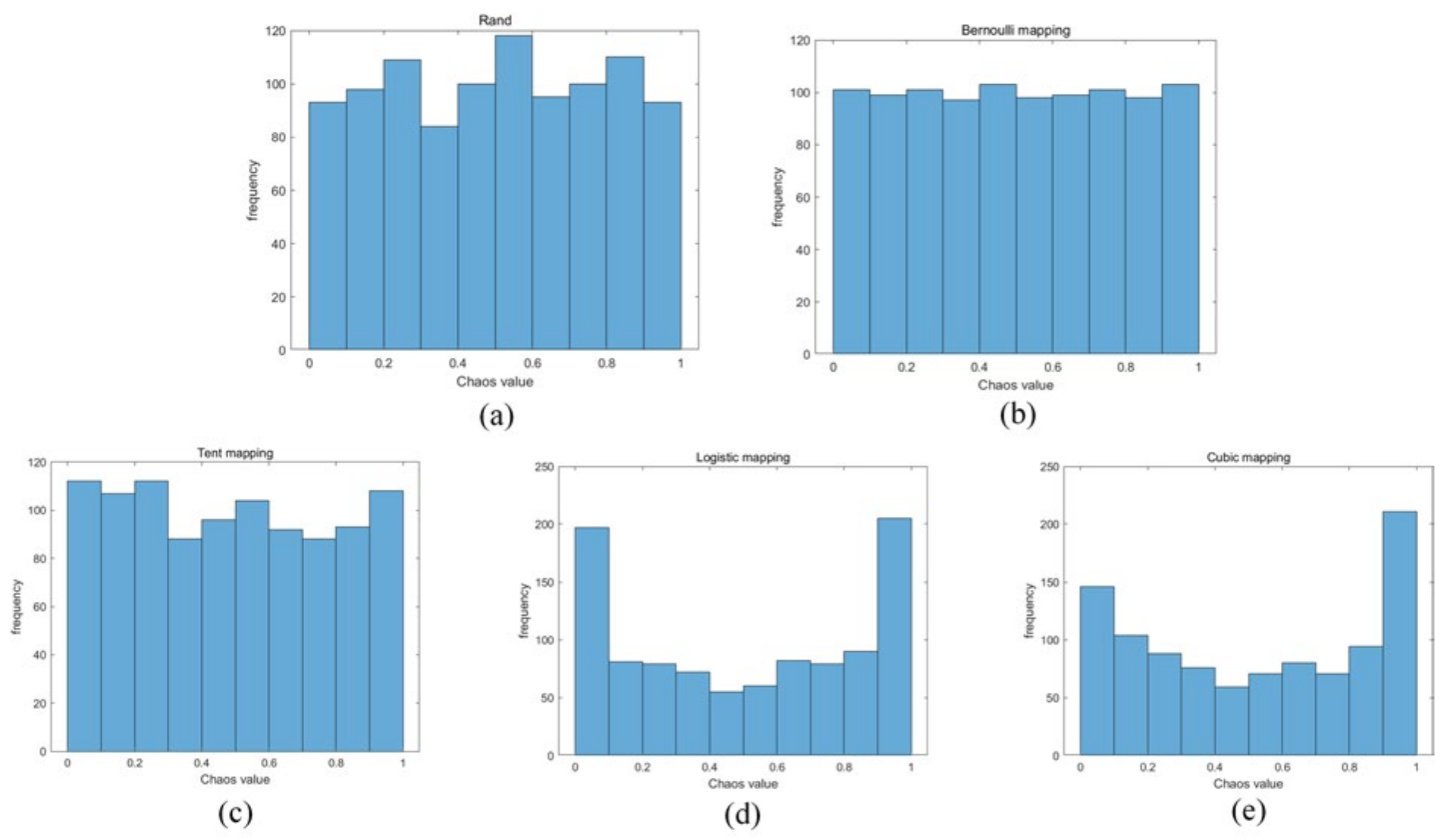

Currently, the most commonly used chaotic initialization methods include Bernoulli mapping, Logistic mapping, Tent mapping, and Cubic mapping.

Figure 3 presents the frequency distribution histograms of random initialization compared to Bernoulli mapping, Logistic mapping, Tent mapping, and Cubic mapping. It can be observed that the distribution of Bernoulli mapping between the range of [0, 1] is more uniform compared to other chaotic mappings. Therefore, this paper introduces the Bernoulli mapping in the initialization stage of the MOAHA algorithm. The Bernoulli mapping is used to initialize the population, aiming to achieve a more uniform distribution of initial solutions in the solution space, thereby enhancing the quality and performance of the population and reducing the likelihood of falling into local optimal solutions. Bernoulli mapping is defined as follows:

Assuming the population size is N, the population x = {xi, i = 1,2,..., N} is obtained. where λ(0, 1) is a chaotic parameter, and in this paper, λ = 0.4 is adopted.

Figure 3.

Histograms of random initialization and four types of chaotic mapping distributions. (a) Random Initialization. (b) Bernoulli mapping. (c) Tent mapping. (d) Logistic mapping. (e) Cubic mapping.

Figure 3.

Histograms of random initialization and four types of chaotic mapping distributions. (a) Random Initialization. (b) Bernoulli mapping. (c) Tent mapping. (d) Logistic mapping. (e) Cubic mapping.

3.3. Adaptive Weights

The inertia weight factor is a crucial parameter. When the inertia weight is relatively large, the algorithm exhibits strong global search ability, increases population diversity, and can explore larger areas [

27]. When the inertia weight is relatively small, the algorithm demonstrates strong local search ability and can finely explore the optimal solution, accelerating convergence speed. During local optimization, MOAHA utilizes territorial foraging and guided foraging for local search. When the hummingbird approaches the local optimal solution as described in (6) and (9), it can only obtain the local optimal solution and cannot achieve further local optimization. In response to this issue, this paper proposes a new adaptive weight method. When a hummingbird approaches food, a larger adaptive weight is used to adjust the optimal position of the hummingbird, thereby enhancing its local optimization ability. The adaptive weight formula is presented in Equation (17):

where

wmin = 0.3,

wmax = 0.8,

t represents the current number of iteration cycles, while

Tmax specifies the upper limit of the maximum number of iteration cycles allowed for the entire optimization process.

Utilizing the adaptive weight Formula (17), (6) and (9) are enhanced, as demonstrated in Equations (18) and (19):

By incorporating the adaptive weight factor w, each hummingbird possesses improved local optimization capabilities.

3.4. Dynamic Elimination Crowding Entropy

Unlike the single-objective artificial hummingbird optimization algorithm, MOAHA necessitates the establishment of an external archive to store non-inferior solutions. This paper utilizes entropy to depict the distribution of a solution along each objective in the objective function space. The distribution entropy of the

i-th solution along the

j-th objective function is defined as follows:

where

dlij and

duij are the distances from the

i-th solution along the

j-th objective function to its adjacent solutions below and above. However, distribution entropy alone cannot accurately reflect the degree of congestion in the solution. To estimate the density of a solution in the objective function space, it is necessary to consider both crowding distance and distribution entropy simultaneously. Drawing from the above analysis and considering both crowding distance and distribution entropy, this paper introduces a new congestion evaluation method named Dynamic Elimination Congestion Entropy (DECE) to accurately measure congestion. This method eliminates the necessity to adjust the crowding entropy ranking of the remaining solutions after deleting one solution. DECE is defined as follows:

Before removing the

i-th solution with the smallest current crowding distance, the distances between the previous and next solutions adjacent to the

i-th solution are given as follows:

After removing the

i-th solution with the smallest current crowding distance, the distances between the previous and next solutions adjacent to the

i-th solution are given as follows:

Utilizing the new dlij and duij, the formula is updated, and the crowding entropy formula is calculated (24). During the iteration process, when the external archive is full, the external archive is maintained by calculating and eliminating the non-inferior solution with the minimum DECE. This approach serves to uphold population diversity and further accelerate the iteration speed.

3.5. Performance Comparison of Algorithms before and after Improvement

To ascertain the superiority of IMOAHA, it was compared with the MOAHA, MOGWO, MOPSO, and NSGA-II algorithms. The test functions ZDT1, ZDT2, and ZDT4 were selected, with a population of 100 and 500 iterations, and each algorithm was run 30 times. The evaluation of algorithm performance was conducted using the inverse generation distance (IGD), spacing index (SP), and hypervolume index (HV).

The IGD is an indicator used to evaluate the convergence and diversity performance of an algorithm. It represents the minimum distance between the non-dominated solution set that the algorithm has searched and the actual Pareto front. A smaller IGD value indicates better convergence and diversity of the algorithm. The calculation formula is as follows [

28]:

where

PF represents a set of uniformly distributed reference points sampled from the Pareto front.

The

SP is an indicator used to evaluate algorithm diversity, representing the degree of uniformity of the distribution of non-dominated solutions obtained by the algorithm in the target space. A smaller

SP value indicates a more uniform distribution of the target in space. The calculation formula is as follows [

29]:

where

N represents the population size and

d is the average value of

di.

The HV is an indicator used to evaluate algorithm diversity and convergence, representing the volume of the region in the target space enclosed by the non-dominated solution set and reference points obtained by the algorithm. A larger HV value indicates better overall performance of the algorithm. The calculation formula is as follows [

30]:

where

S represents the non-dominated solution set calculated by the optimization algorithm and

vi represents the volume enclosed by the reference point and non-dominated solution set. The symbol

δ(∙) denotes the Lebesgue measure used for calculating volume.

The comparison results of the optimization algorithms obtained using Matlab R2021b software are shown in

Table 3, indicating that the IMOAHA algorithm outperforms in terms of IGD, SP, and HV indicators. This demonstrates that IMOAHA exhibits superior convergence and diversity.

6. Conclusions

This paper presents enhancements to the multi-objective artificial hummingbird algorithm through the incorporation of an adaptive weight method, chaotic mapping, and dynamic crowding entropy. Additionally, it proposes a novel multi-objective optimization design that combines the Taguchi method with the improved multi-objective artificial hummingbird algorithm, thereby offering a comprehensive optimization approach. Firstly, an orthogonal experimental design is conducted on the selected six parameters, utilizing the Taguchi method to identify the parameters significantly impacting the optimization objective. Secondly, a response surface model is employed to analyze the parameters and formulate the equation for the optimization objective function. Subsequently, the improved MOAHA algorithm is utilized to optimize the parameters and obtain the optimal combination. Finally, the optimization results are validated using a finite element model. The results demonstrate that the multi-objective optimization design, combining the Taguchi method and IMOAHA algorithm, effectively overcomes the limitations of single-objective algorithms, while exhibiting high optimization efficiency. The application of the optimized permanent magnet synchronous motor in this paper can serve as a driving motor for new energy vehicles, providing high power density, improving passenger comfort, and reducing vehicle noise.

The approach presented in this article is universally applicable to all configurations of permanent magnet synchronous motors. The core concept of this methodology is to provide optimization parameters and their corresponding objective functions, thereby deriving the optimized results. Consequently, by offering optimization parameters and objective functions, this method can compute the optimized results for any configuration of a permanent magnet synchronous motor.