Effects of Macro-Pitting Fault on Dynamic Characteristics of Planetary Gear Train Considering Surface Roughness

Abstract

:1. Introduction

2. Calculation Model of TVMS Based on Fractal Theory

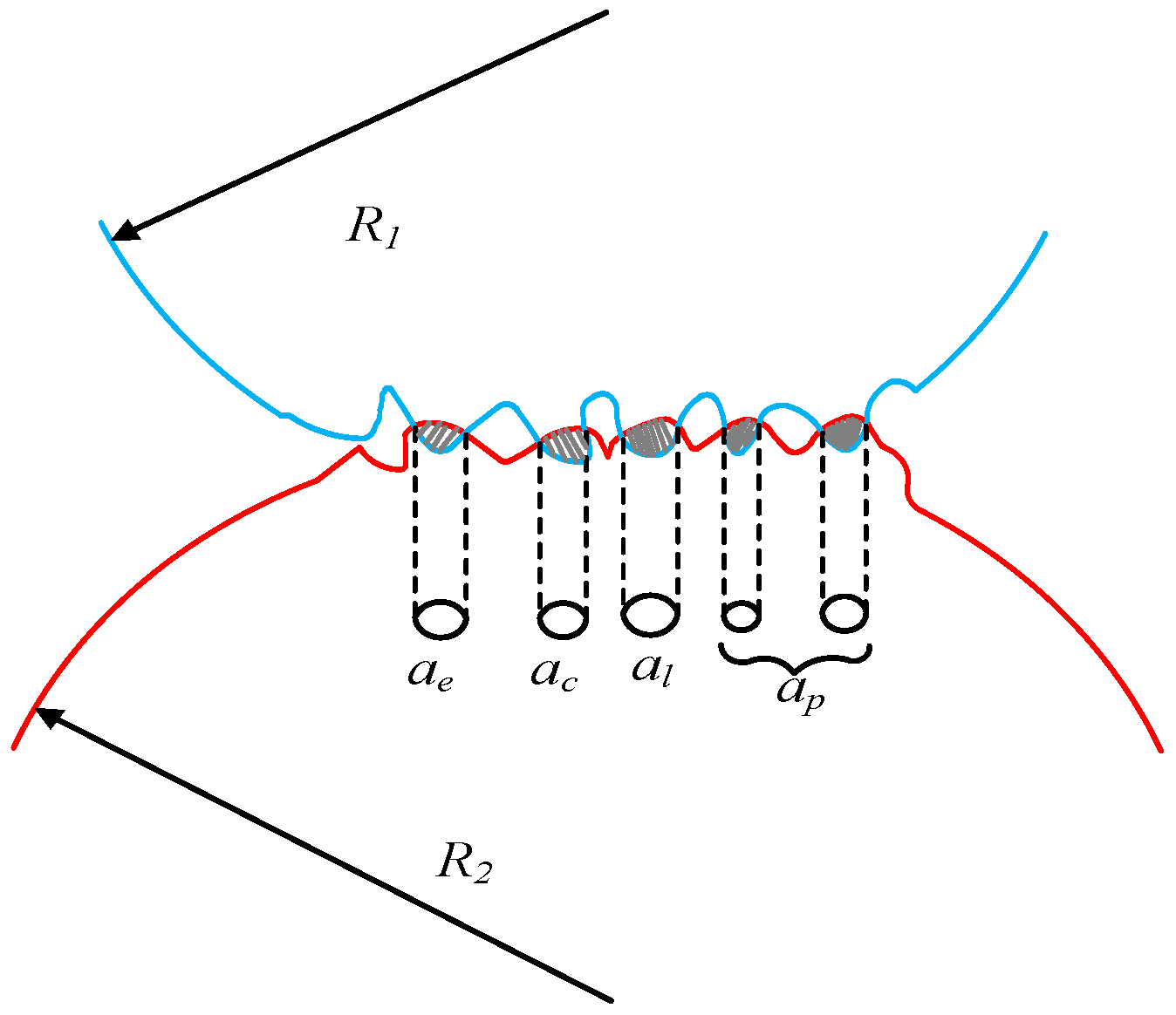

2.1. Fractal Tooth Surface Contact Model

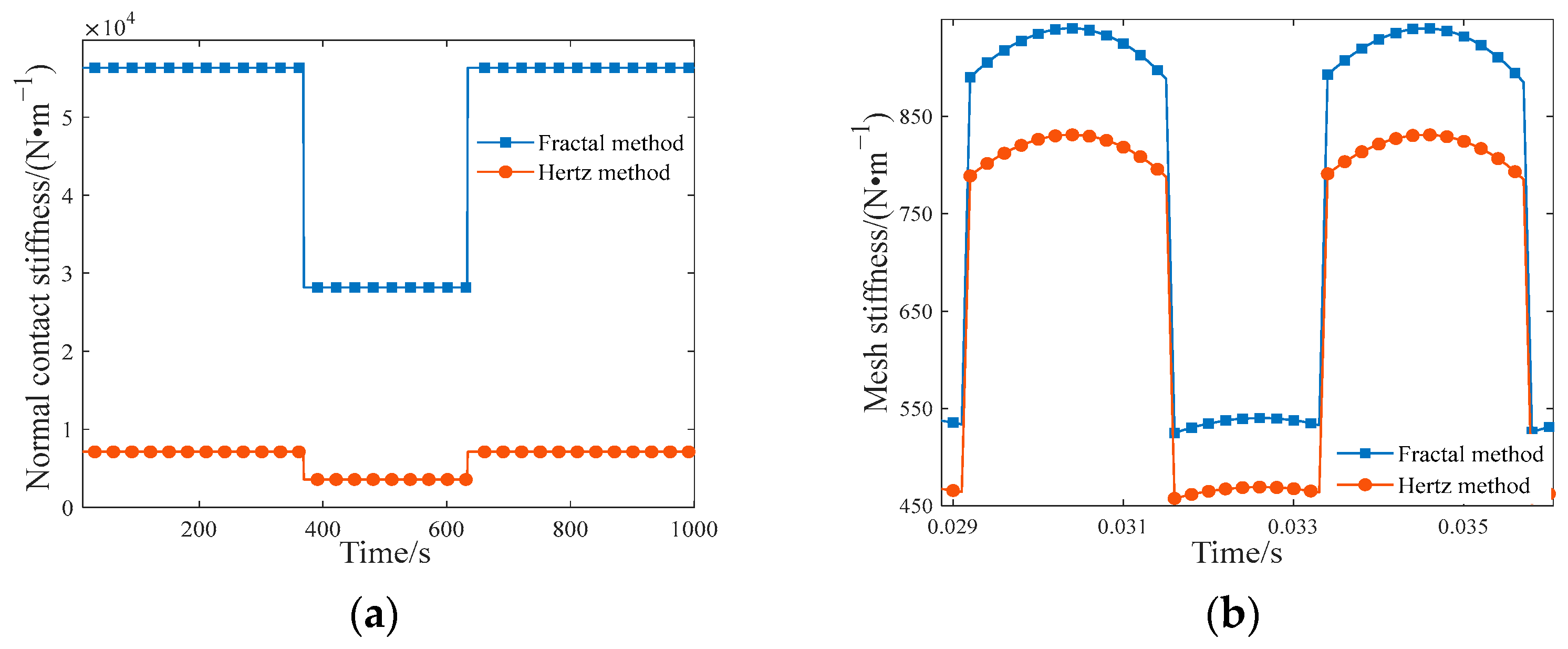

2.2. Meshing Characteristics of Fractal Rough Tooth Surface

3. TVMS Calculation Model Considering Fractal Surface Contact and Gear Macro-Pitting

3.1. TVMS Calculation of Gears with Macro-Pitting Fault

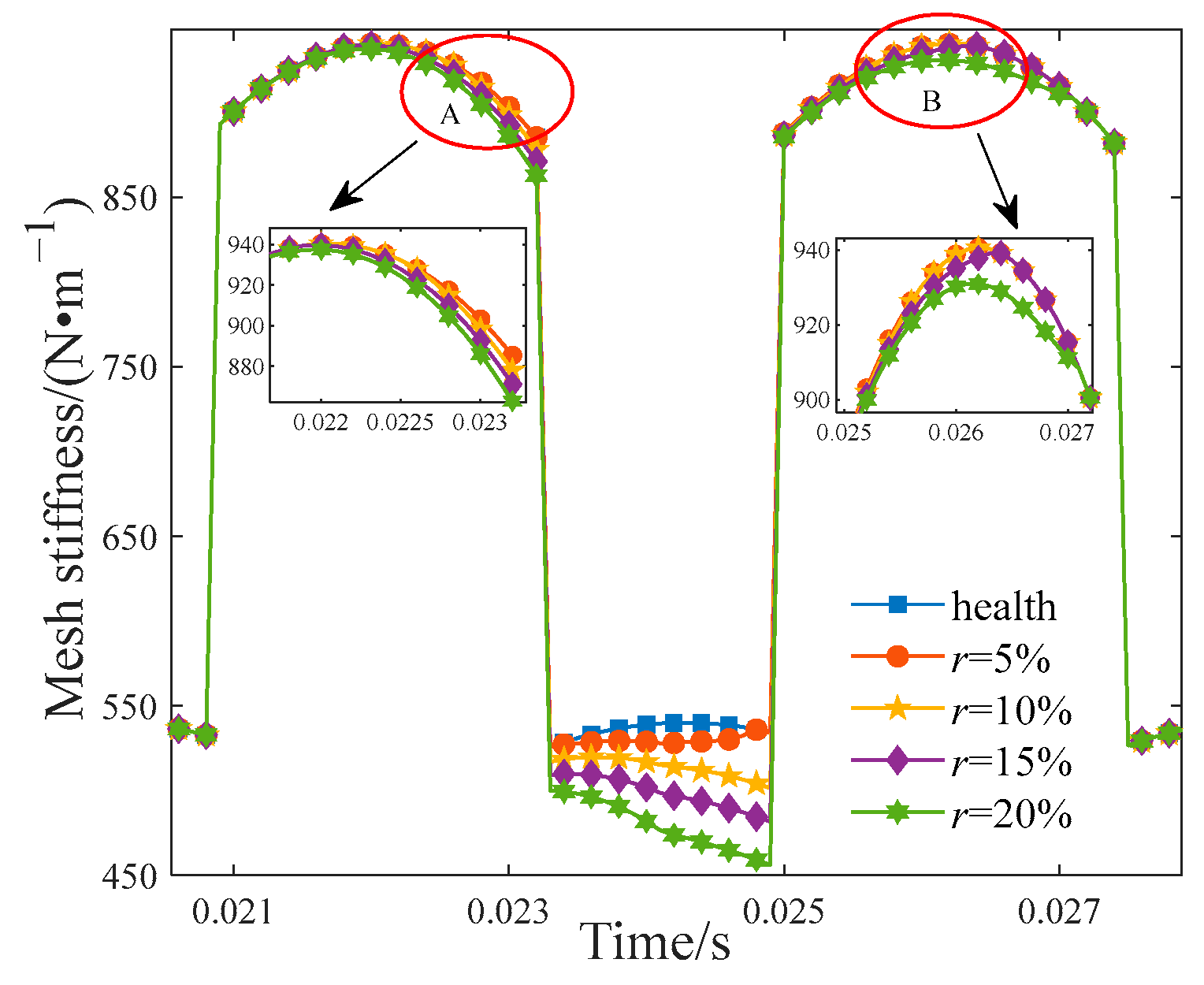

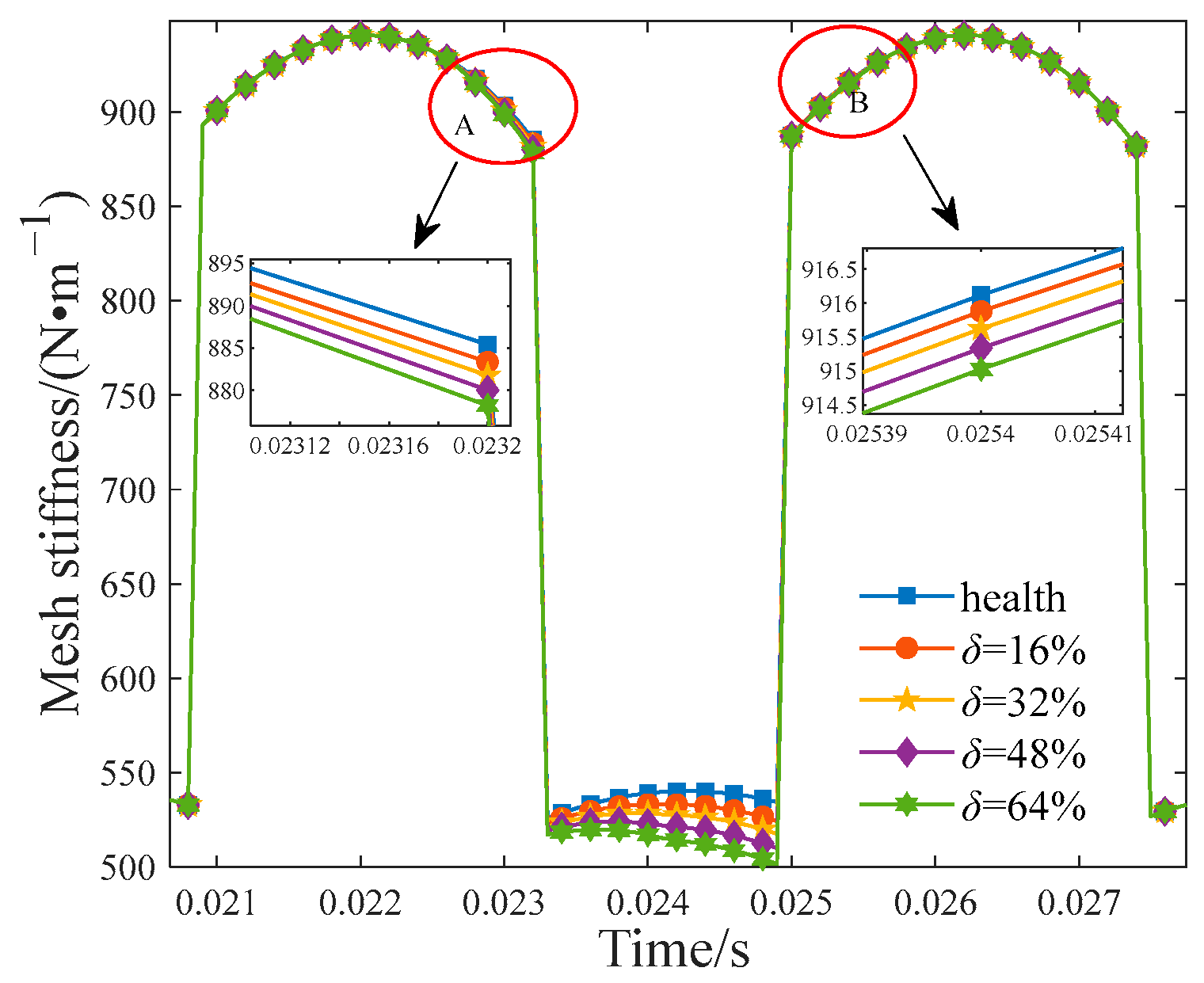

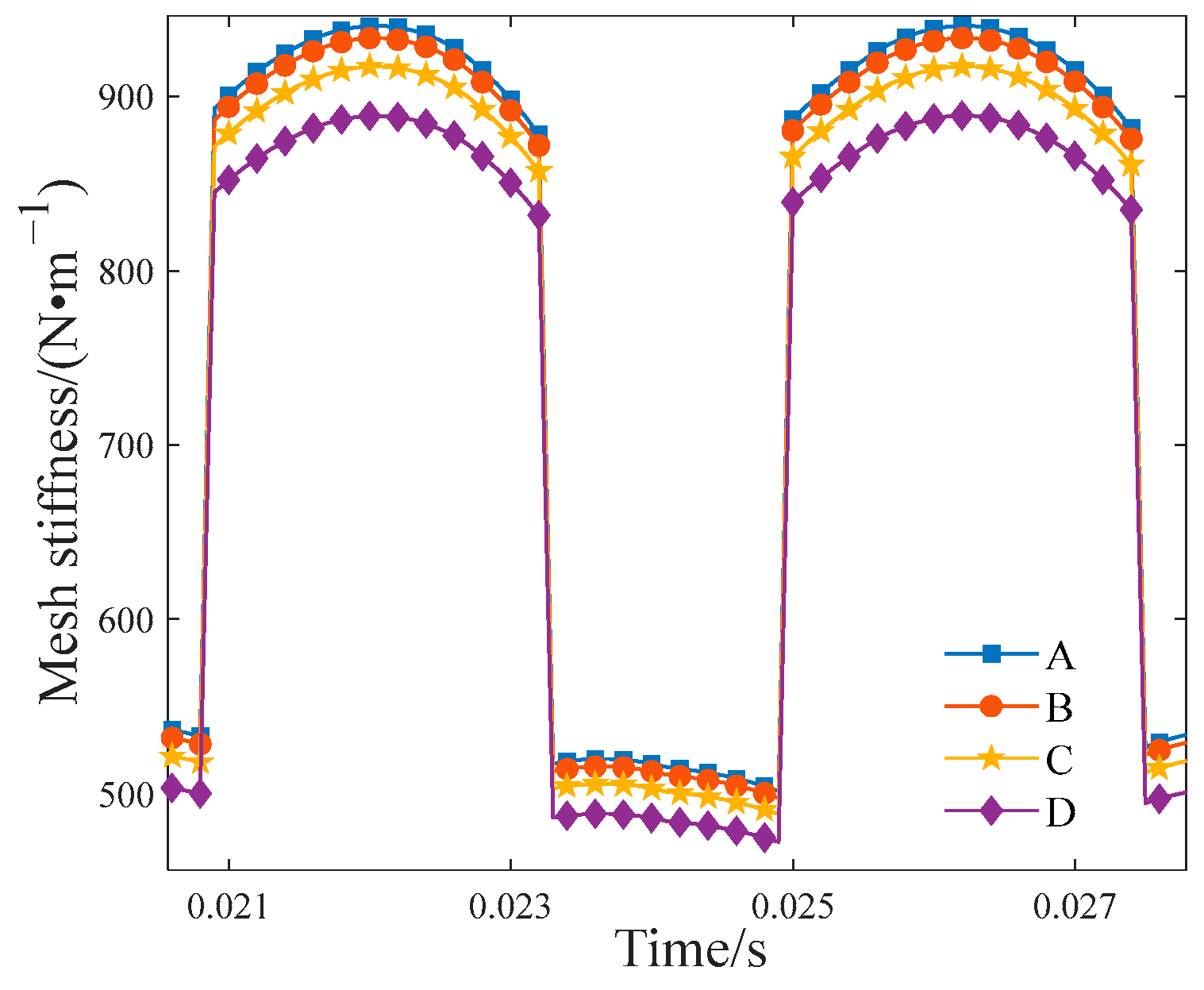

3.2. Gear Meshing Characteristics with Macro-Pitting Fault

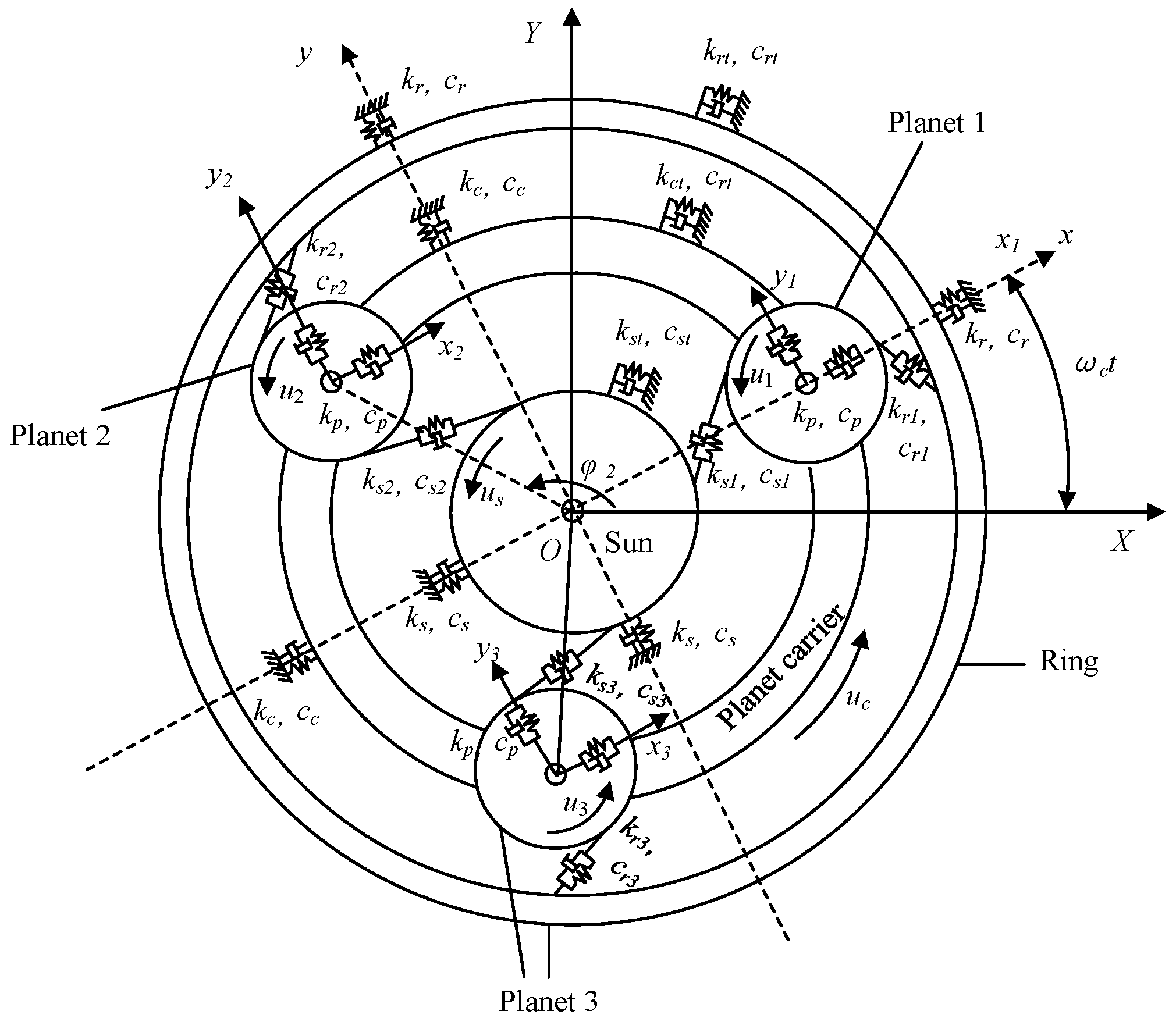

4. Planetary Gear Train Dynamics Model Considering Fractal Surface Contact

5. Model Simulation and Analysis

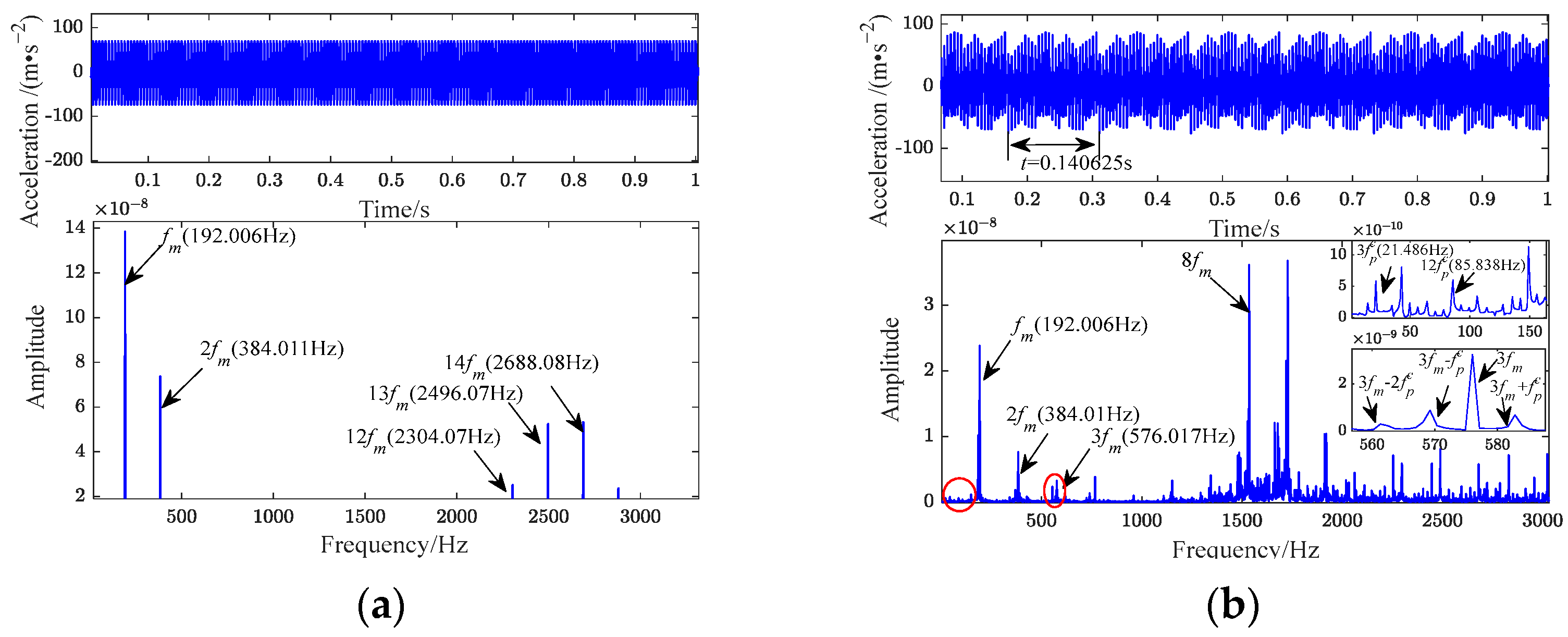

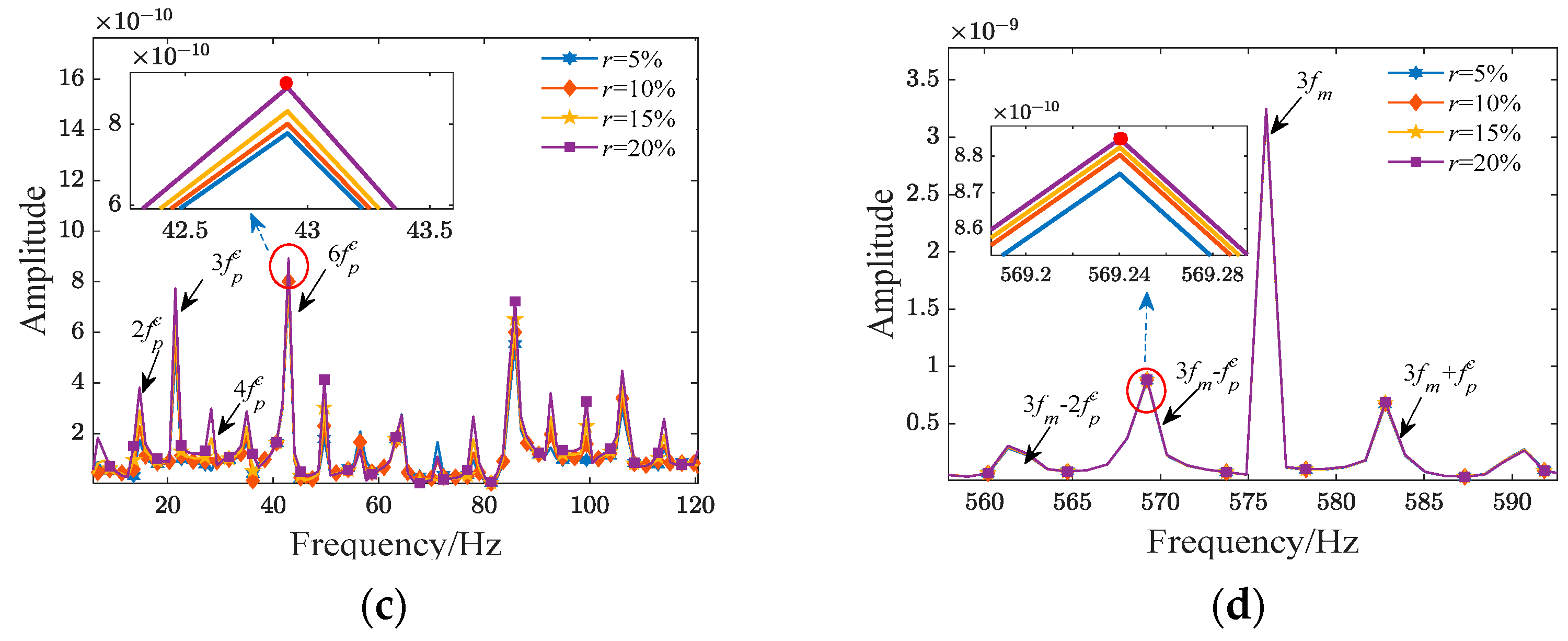

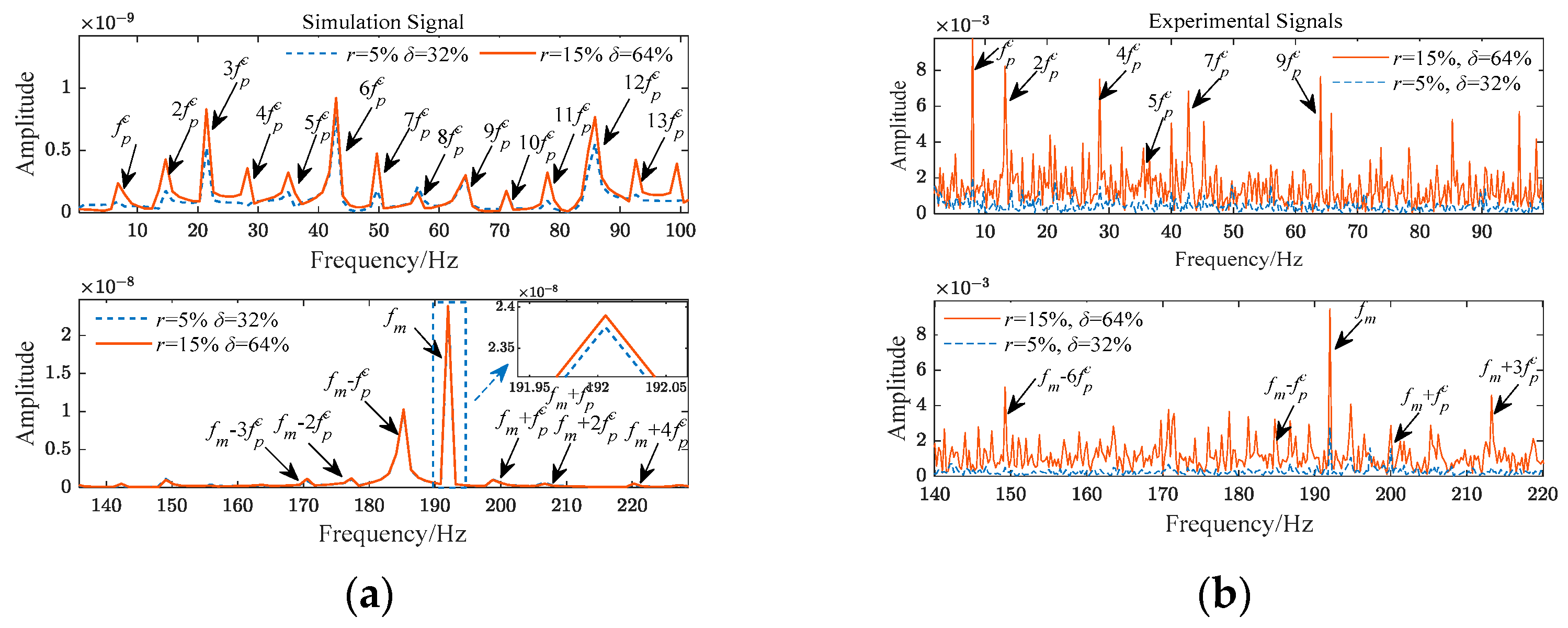

5.1. Dynamic Effects of Macro-Pitting Fault on the Planetary Gear Train with Surface Roughness

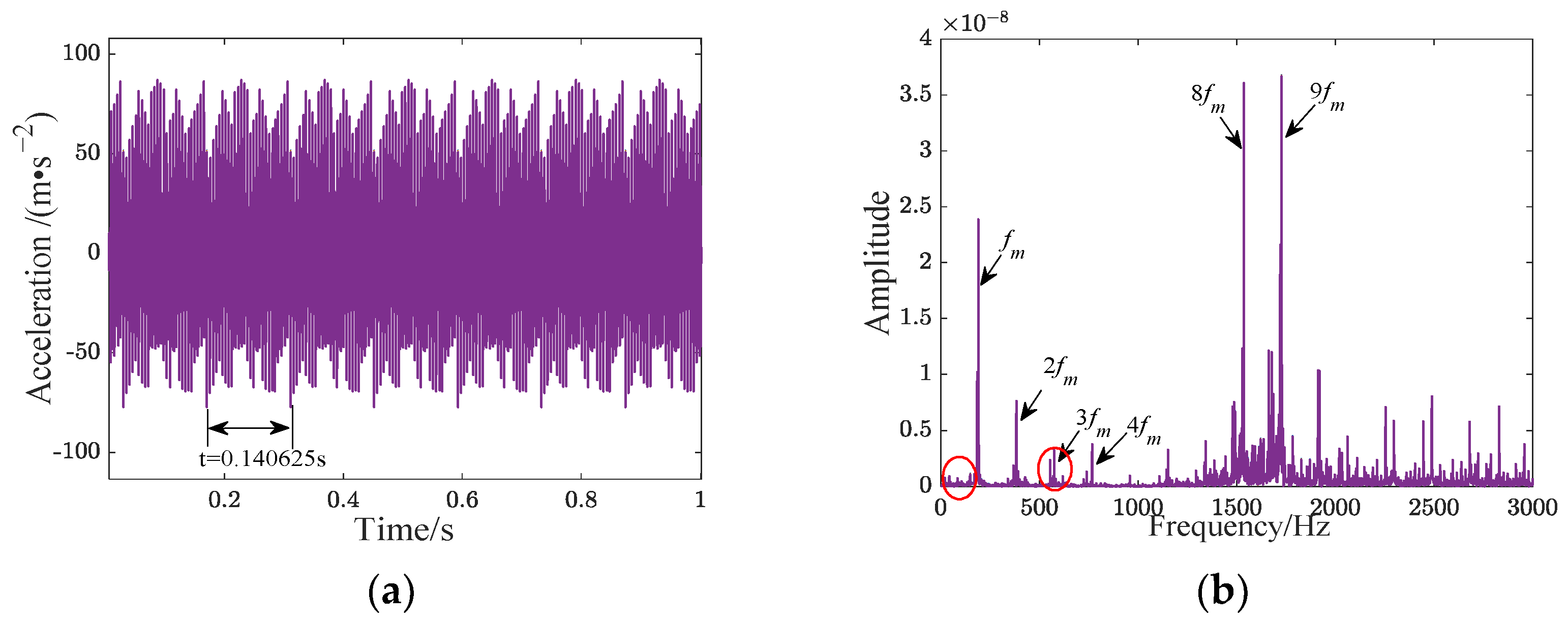

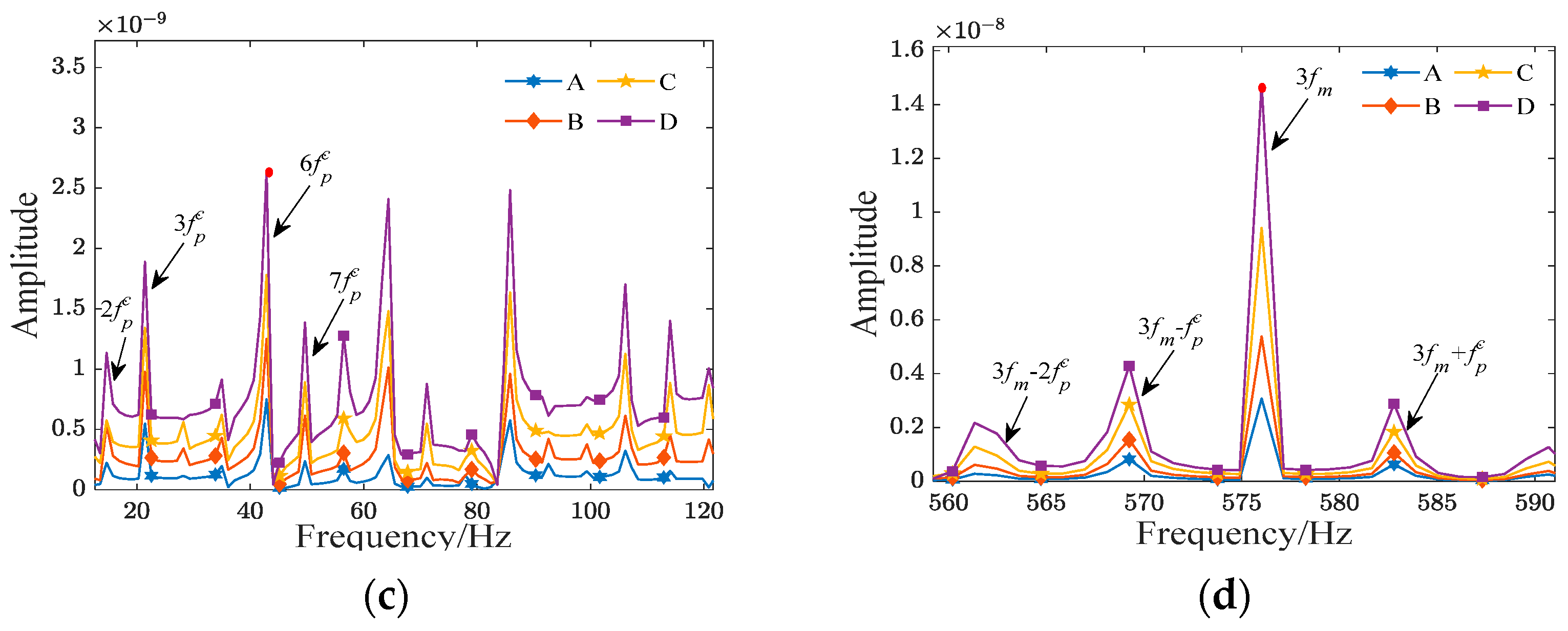

5.2. Dynamic Effects of Surface Roughness on the Planetary Gear Train with Macro-Pitting Fault

6. Experimental Verifications

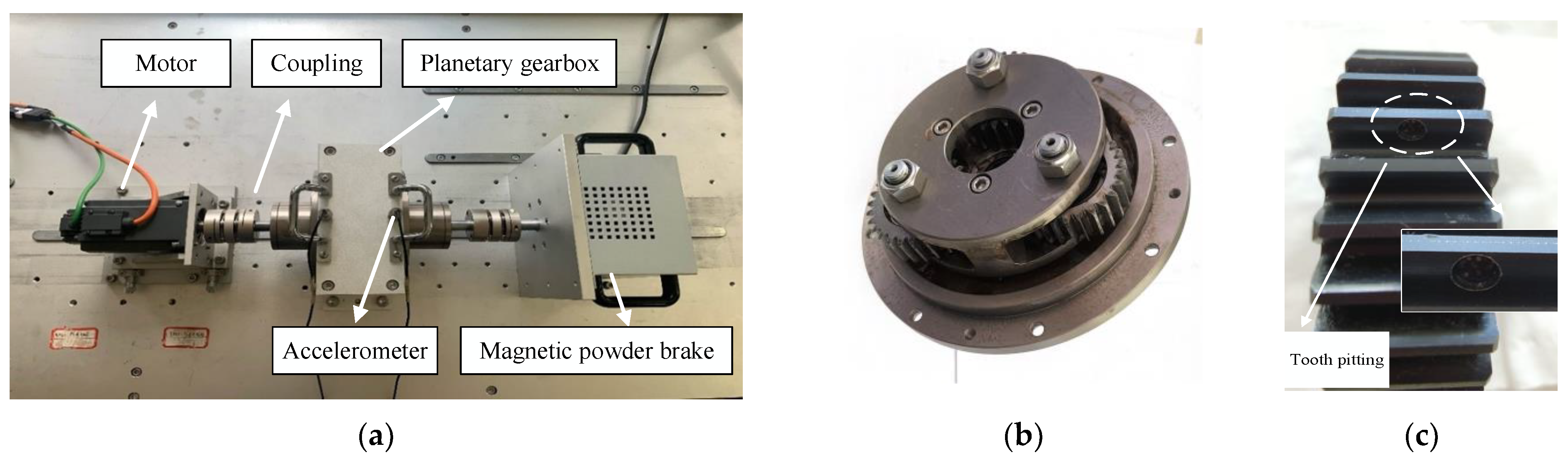

6.1. Experimental Platforms

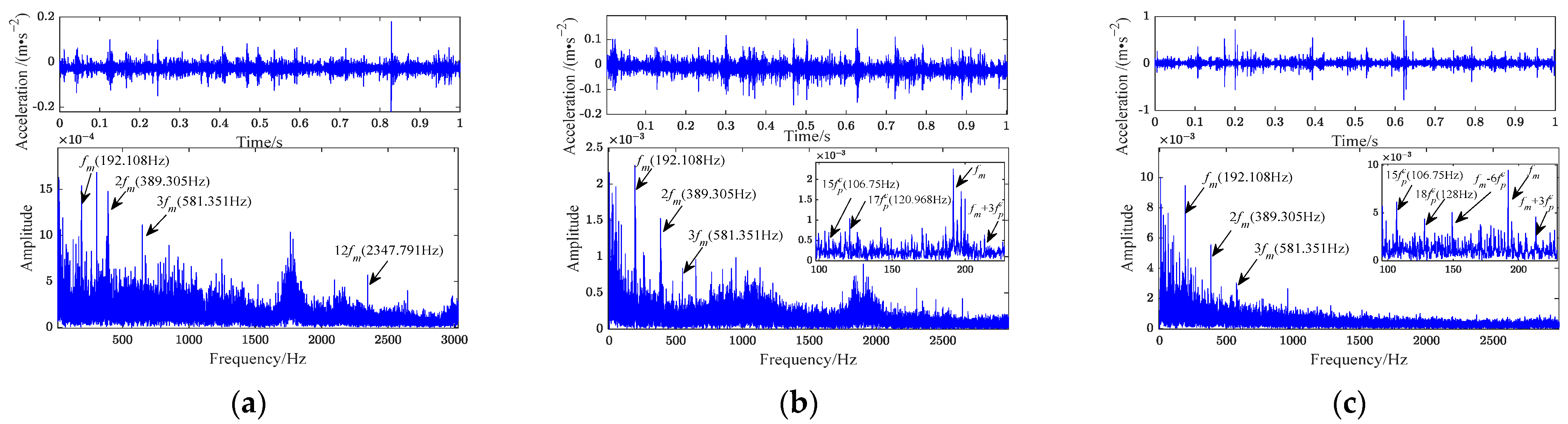

6.2. Experimental Signal Verification under Healthy and Fault Conditions

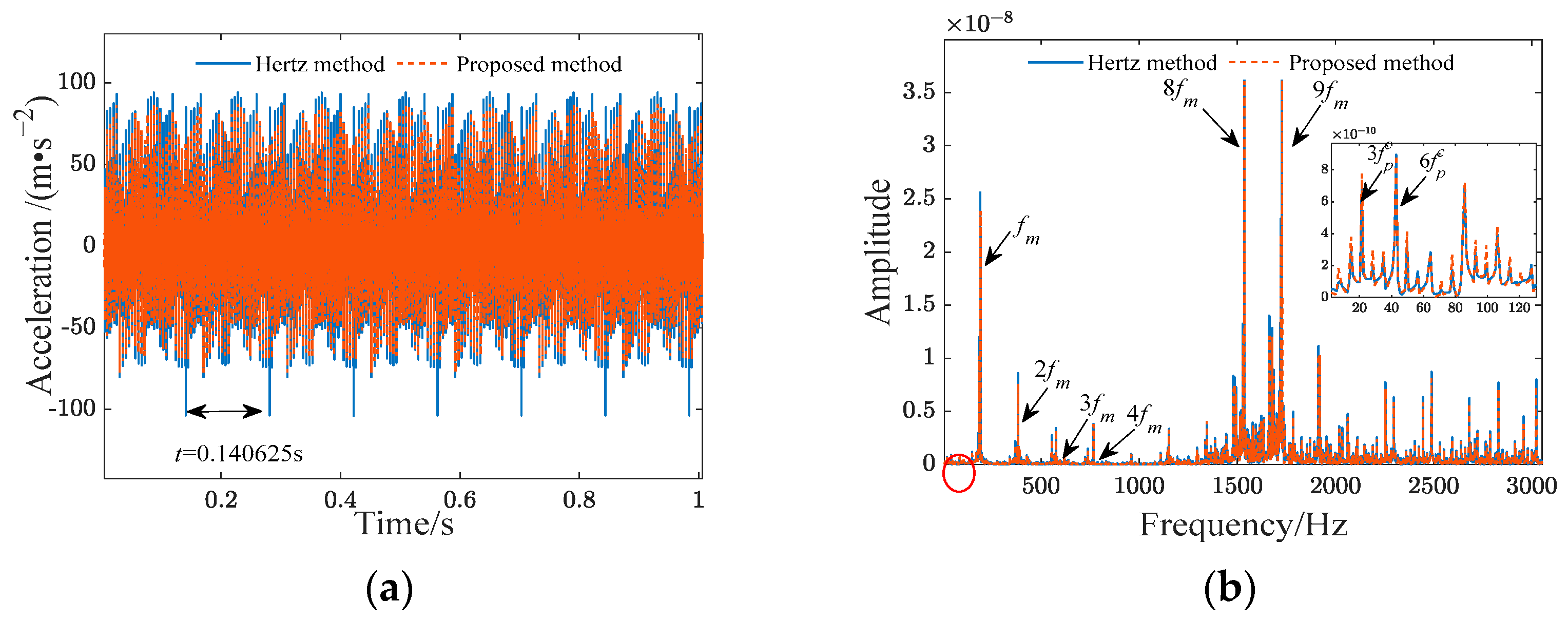

6.3. Comparative of the Model Descriptive Capability

7. Conclusions

- (1)

- When macro-pitting occurs in the planet gear, the TVMS amplitude of the gear pair in the fault area begins to decrease. With larger fault sizes, the change in TVMS becomes more pronounced. Simultaneously, as the fractal dimension D decreases, which means the tooth surface is rougher, the decrease in TVMS becomes greater. Additionally, in the time domain, the vibration signals of the planet gear have exhibited periodic impact signals, and in the frequency domain, modulation sidebands spaced by the faulty gear rotation frequency have appeared.

- (2)

- With the increasing severity of gear macro-pitting faults and the worsening of tooth surface roughness, the fault characteristic amplitude is increased. When the surface is relatively rough, there is a phenomenon in the spectrum where some meshing frequency modulation sidebands, spaced at intervals corresponding to the gear’s rotation frequency , appear to be higher than the meshing frequency. Therefore, when analyzing the fault dynamic characteristics of the planetary gear train, consideration of surface roughness is indispensable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| G | The rough surface height parameter | The reduction in the area when the distance between gear tooth contact points is x | |

| D | Fractal dimension | m | Mass |

| l | The length of a single asperity | I | Moment of inertia |

| Critical contact area of asperity | r | Base circle radius | |

| R | The radius of curvature of the tip | T | External torque |

| K | The correlation coefficient between the surface hardness and the yield strength of the material | c, s, r, p | Planet carrier, sun gear, ring, and planet gear |

| The material property parameter | , , | Relative displacements of the plane carrier with respect to the planet gears in the x, y, and u directions | |

| The gear surface contact coefficient | , | Meshing forces between the sun gear-planet gear pair and ring-planet gear pair | |

| The maximum contact area | , | The TVMS corresponding to the external meshing of the sun gear-planet gear pair and the internal meshing of the planet gear-ring gear pair | |

| L | Tooth width | Damping coefficient corresponding to meshing pair | |

| R1, R2 | The radius of curvature of the gears | Stiffness of the bearings supporting the respective components | |

| The integrated modulus of elasticity | Torsional stiffness of the components | ||

| The area distribution function of asperity | , | Rotational frequencies of the planet carrier and sun gear | |

| Dimensional true contact area | , | The relative displacement of the sun gear-planet gear meshing pair and planet gear-ring gear pair | |

| Dimensional critical contact area | , | Static transmission errors of the sun gear-planet gear meshing pair and planet gear-ring gear pair | |

| Dimensional-normal contact stiffness | b | Backlash constant | |

| Kb | Bending stiffness | zs, zp, zr | The number of teeth of the sun gear, planet gear, and ring gear |

| Ks | Shear stiffness | Meshing frequency | |

| Ka | Axial compression stiffness | Fault frequency of the planet gear | |

| Kf | Flexible deformation stiffness | r | The ratio of macro-pitting length to tooth width |

| The gear rotation angle | δ | The ratio of macro-pitting depth to tooth thickness | |

| The half-tooth angle on the base circle | TVMS | Time-varying meshing stiffness | |

| The contact angle corresponding to the gear meshing point | |||

| E | The elastic modulus of the gear | ||

| v | Poisson’s ratio | ||

| Rb | Base circle radius | ||

| The reduction in area moment of inertia when the distance between gear tooth contact points is x |

References

- Liang, X.; Zuo, M.J.; Feng, Z. Dynamic modeling of gearbox faults: A review. Mech. Syst. Signal Process. 2018, 98, 852–876. [Google Scholar] [CrossRef]

- Meng, Z.; Shi, G.; Wang, F. Vibration response and fault characteristics analysis of gear based on time-varying mesh stiffness. Mech. Mach. Theory 2020, 148, 103786. [Google Scholar] [CrossRef]

- Wang, Z.G.; He, W.P.; Liao, N.N.; Dou, Y.H.; Guo, B.L. Study on vibration response mechanism of tooth root crack and tooth surface spalling fault. J. Xidian Univ. 2021, 48, 131–137. [Google Scholar]

- Liang, X.H.; Zhang, H.S.; Liu, L.B.; Zuo, M.J. The influence of tooth pitting on the mesh stiffness of a pair of external spur gears. Mech. Mach. Theory 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Concli, F.; Kolios, A. Preliminary evaluation of the influence of surface and tooth root damage on the stress and strain state of a planetary gearbox: An innovative hybrid numerical-analytical approach for further development of structural health monitoring models. Computation 2021, 9, 38. [Google Scholar] [CrossRef]

- Sheng, L.; Ahmet, K. Scuffing model for spur gear contacts. Mech. Mach. Theory 2021, 156, 104161. [Google Scholar]

- Brumercik, F.; Lukac, M.; Caban, J.; Krzysiak, Z.; Glowacz, A. Comparison of selected parameters of a planetary gearbox with involute and convex–concave teeth flank profiles. Appl. Sci. 2020, 10, 1417. [Google Scholar] [CrossRef]

- Drechsel, A.; Constien, L.; Pellkofer, J.; Boiadjiev, I.; Karsten, S. Extended calculation method for determining the pitting load carrying capacity of bevel and hypoid gears. Forsch. Im Ingenieurwesen 2022, 86, 829–844. [Google Scholar] [CrossRef]

- Constien, L.; Drechsel, A.; Pellkofer, J.; Reimann, T.; Karsten, S. Consideration of the influences of the driving direction within the calculation of the pitting load-carrying capacity of bevel and hypoid gears. J. Braz. Soc. Mech. Sci. 2023, 45, 523–538. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.K.; Zang, L.B.; Liu, Y.Q.; Bi, W.Y.; Yang, X.P. Experimental study on dynamic simulation pre-diction and fault identification of fatigue pitting helical gear. J. Mech. Eng. Chin. Ed. 2021, 57, 61–70. [Google Scholar]

- Wang, S.Y.; Zhu, R.P. Research on dynamics and failure mechanism of herringbone planetary gearbox in wind turbine under gear surface pitting. Eng. Fail. Anal. 2023, 146, 107130. [Google Scholar] [CrossRef]

- Gao, C.W.; Liu, W.Z.; Zhu, R.P.; Wang, H.Y. Dynamic Characteristics and experimental study of gears based on evolution of tooth pitting. J. Eng. Therm. Energy Power 2023, 38, 125–130. [Google Scholar]

- Han, H.Z.; Zhao, Z.F.; Tian, H.X.; Ma, H.; Yang, Y.; Li, X. Fault feature analysis of planetary gear set influenced by cracked gear tooth and pass effect of the planet gears. Eng. Fail. Anal. 2021, 121, 105162. [Google Scholar] [CrossRef]

- Shen, Z.X.; Qiao, B.J.; Yang, L.H.; Luo, W.; Yang, Z.B.; Chen, X.F. Fault mechanism and dynamic modeling of planetary gear with gear wear. Mech. Mach. Theory 2021, 155, 104098. [Google Scholar] [CrossRef]

- Sheng, Z.Y.; Zhang, Z.; WANG, Y.R.; Li, H.K. Analysis of transmission characteristics of sun wheel root cracks in planetary wheel gearboxes. China Mech. Eng. 2023, 34, 2177–2185. [Google Scholar]

- Majumdar, A.A.; Bhushan, B. Role of fractal geometry in roughness characterization and contact mechanics of surfaces. Trans. ASME J. Tribol. 1990, 112, 205–216. [Google Scholar] [CrossRef]

- Wang, X.P.; Liu, S.J. Fractal prediction model of normal contact stiffness of micro-pitting gear. J. Mech. Eng. Chin. Ed. 2021, 57, 68–76. [Google Scholar] [CrossRef]

- Zhao, Z.F.; Han, H.Z.; Wang, P.F.; Ma, H.; Yang, Y. An improved model for meshing characteristics analysis of spur gears considering fractal surface contact and friction. Mech. Mach. Theory 2021, 158, 104219. [Google Scholar] [CrossRef]

- Wu, J.Z.; Xiao, H.F.; Yang, D.B. Time-varying meshing stiffness algorithm and characteristic analysis of gear rough interface. J. Vib. Meas. Diagn. 2022, 42, 56–61+194. [Google Scholar]

- Chen, L.; Fan, Z.M.; Yin, Z.M. Fractal model of double involute gears time-varying meshing stiffness considering friction factors. Tribology 2023, 43, 358–367. [Google Scholar]

- Lan, G.S.; Ji, C.L.; Li, X.; Li, S.Q.; Li, Y.; Yang, Q. Normal contact stiffness model of mixed lubrication joint surface. J. Vib. Shock 2023, 42, 220–227. [Google Scholar]

- Du, X.; Chen, B.K.; Liu, R.R.; Li, C.Y. Research on fractal model of load distribution and axial Stiffness of planetary roller screw mechanism considering surface roughness and friction factor. Adv. Theory Simul. 2022, 5, 2100399. [Google Scholar] [CrossRef]

- Li, X.P.; Mou, J.X.; Pan, W.J.; Wen, B.C. Influence of fractal backlash on dynamic behavior of gear-bearing system. J. Mech. Eng. Chin. Ed. 2018, 54, 153–160. [Google Scholar] [CrossRef]

- Li, X.P.; Xv, J.C.; Pan, W.J.; Mou, J.X.; Wang, L.L.; Yang, Z.M.; Wen, B.C. Dynamics of gear transmission system with fractal meshing stiffness on tooth surface. J. Harbin Inst. Technol. 2019, 51, 56–62. [Google Scholar]

- Meng, F.S.; Xia, H.; Zhang, X.; Wang, J.X.; Jin, Y.L. Study on nonlinear dynamic characteristics of gear system with 3D anisotropic rough tooth surface based on fractal theory. Int. J. Non Linear Mech. 2023, 150, 104366. [Google Scholar] [CrossRef]

- Stanojević, M.; Tomović, R.; Ivanović, L.; Stojanović, B. Critical analysis of design of ravigneaux planetary gear Trains. Appl. Phys. Lett. 2022, 7, 32–44. [Google Scholar] [CrossRef]

- Miladinović, S.; Veličković, S.; Novaković, M. Application of taguchi method for the selection of optimal parameters of planetary driving gear. Appl. Phys. Lett. 2016, 1, 98–104. [Google Scholar]

- Blagojevic, M.; Marjanovic, N.; Djordjevic, Z.; Stojanovic, B.; Marjanovic, V.; Vujanac, R.; Disic, A. Numerical and experimental analysis of the cycloid disc stress state. Teh. Vjesn. 2014, 21, 377–382. [Google Scholar]

- Yu, X.; Sun, Y.Y.; Li, H.G.; Wu, S.J. An improved meshing stiffness calculation algorithm for gear pair involving fractal contact stiffness based on dynamic contact force. Eur. J. Mech. A Solids 2022, 94, 104595. [Google Scholar] [CrossRef]

- Luo, W.; Qiao, B.; Shen, Z.X.; Yang, Z.B.; Cao, H.R.; Chen, X.F. Investigation on the influence of spalling defects on the dynamic performance of planetary gear sets with sliding friction. Tribol. Int. 2021, 154, 106639. [Google Scholar] [CrossRef]

- Blau, P.J. Friction, Lubrication, and Wear Technology; ASM International: Materials Park, OH, USA, 1992. [Google Scholar] [CrossRef]

- Feng, K.; Smith, W.A.; Borghesani, P.; Randall, R.B.; Peng, Z. Use of cyclostationary properties of vibration signals to identify gear wear mechanisms and track wear evolution. Mech. Syst. Signal Process. 2020, 150, 107258. [Google Scholar] [CrossRef]

- Dai, H.; Long, X.H.; Chen, F.; Xun, C. An improved analytical model for gear mesh stiffness calculation. Mech. Mach. Theory 2021, 159, 104262. [Google Scholar] [CrossRef]

- Shen, Z.X.; Qiao, B.J.; Yang, L.H.; Luo, W.; Chen, X.F. Evaluating the influence of tooth surface wear on TVMS of planetary gear set. Mech. Mach. Theory 2019, 136, 206–223. [Google Scholar] [CrossRef]

- Hu, J.; Hu, N.; Yang, Y.; Zhang, L.; Shen, G. Nonlinear dynamic modeling and analysis of a helicopter planetary gear set for tooth crack diagnosis. Measurement 2022, 198, 111347. [Google Scholar] [CrossRef]

- Xiang, L.; Gao, N.; Hu, A.J. Dynamic analysis of a planetary gear system with multiple nonlinear parameters. J. Comput. Appl. Math. 2017, 327, 325–340. [Google Scholar] [CrossRef]

| Parameters | Planet | Sun | Ring |

|---|---|---|---|

| Teeth Numbers | 18 | 27 | 72 |

| Modulus | 2 mm | ||

| Pressure angle | 20° | ||

| Tooth width | 20 mm | ||

| Young’s modulus | 2.06 × 105 MPa | ||

| Poisson’s ratio | 0.3 | ||

| Material yield strength | 835 MPa | ||

| Surface Roughness | D | G |

|---|---|---|

| A | 1.56 | 10−11 |

| B | 1.5195 | 2.0014 × 10−9 |

| C | 1.4407 | 7.8357 × 10−10 |

| D | 1.3797 | 2.5723 × 10−10 |

| Parameters | Value |

|---|---|

| Sun gear speed (r/min) | = 800 |

| Bearing support stiffness (N/m) | = = = = 1.0 × 108 |

| Torsional stiffness (N/m) | = 1.0 × 108; = = 0 |

| Meshing frequency (Hz) | = 192 |

| Planet gear fault frequency (Hz) | = 7 |

| 1st Harmonic | 2nd Harmonic | 3rd Harmonic | 4th Harmonic | 5th Harmonic | |

|---|---|---|---|---|---|

| Simulation value | 7.111 Hz | 14.682 Hz | 21.486 Hz | 28.236 Hz | 35.013 Hz |

| Experimental value | 7.162 Hz | 14.25 Hz | 21.25 Hz | 28.5 Hz | 35.5 Hz |

| Error | 0.712% | 3.031% | 1.111% | 0.926% | 1.372% |

| Modeling Method | Proposed Method | Hertz Method [36] |

|---|---|---|

| RMSE | 16.7 | 18.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Xiong, X.; Ma, J.; Zou, M. Effects of Macro-Pitting Fault on Dynamic Characteristics of Planetary Gear Train Considering Surface Roughness. Actuators 2024, 13, 1. https://doi.org/10.3390/act13010001

Li R, Xiong X, Ma J, Zou M. Effects of Macro-Pitting Fault on Dynamic Characteristics of Planetary Gear Train Considering Surface Roughness. Actuators. 2024; 13(1):1. https://doi.org/10.3390/act13010001

Chicago/Turabian StyleLi, Rong, Xin Xiong, Jun Ma, and Mengting Zou. 2024. "Effects of Macro-Pitting Fault on Dynamic Characteristics of Planetary Gear Train Considering Surface Roughness" Actuators 13, no. 1: 1. https://doi.org/10.3390/act13010001

APA StyleLi, R., Xiong, X., Ma, J., & Zou, M. (2024). Effects of Macro-Pitting Fault on Dynamic Characteristics of Planetary Gear Train Considering Surface Roughness. Actuators, 13(1), 1. https://doi.org/10.3390/act13010001