Improved Mass Flow Rate Regulation Methods Based on Variable Frequency Control: A Case Study of Oxidizer Agent Weighing for Solid Propellants

Abstract

:1. Introduction

2. Nonlinear Model

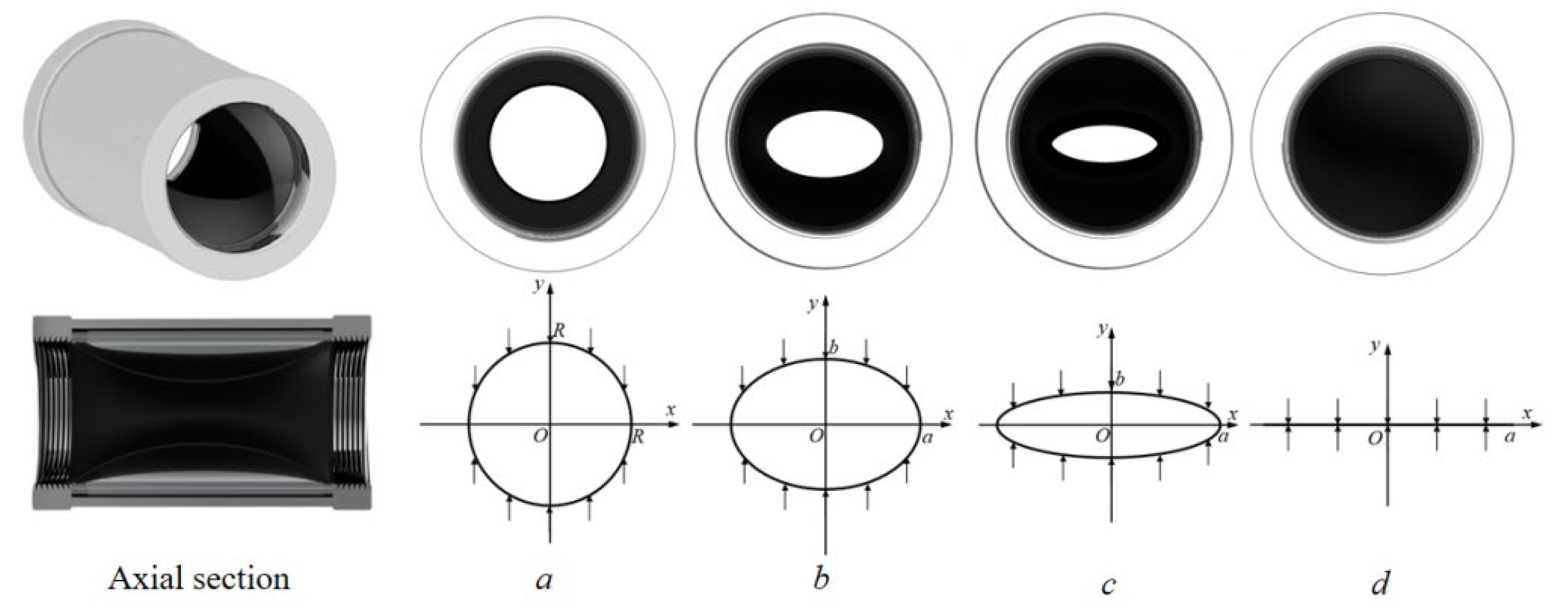

2.1. Factors Affecting the Mass Flow Rate

2.2. Nonlinear Model of the Mass Flow Rate

3. Variable Frequency Regulation Methods

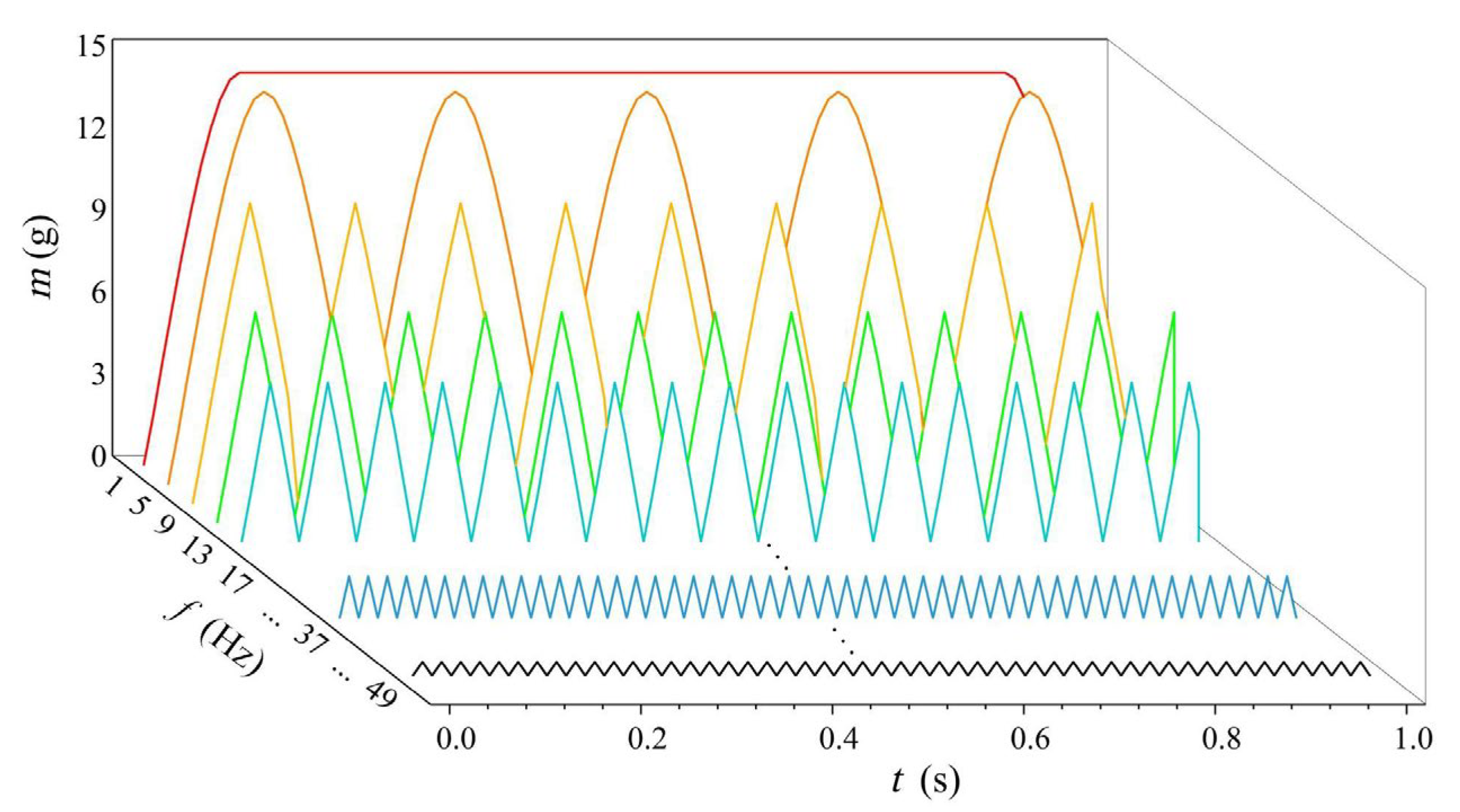

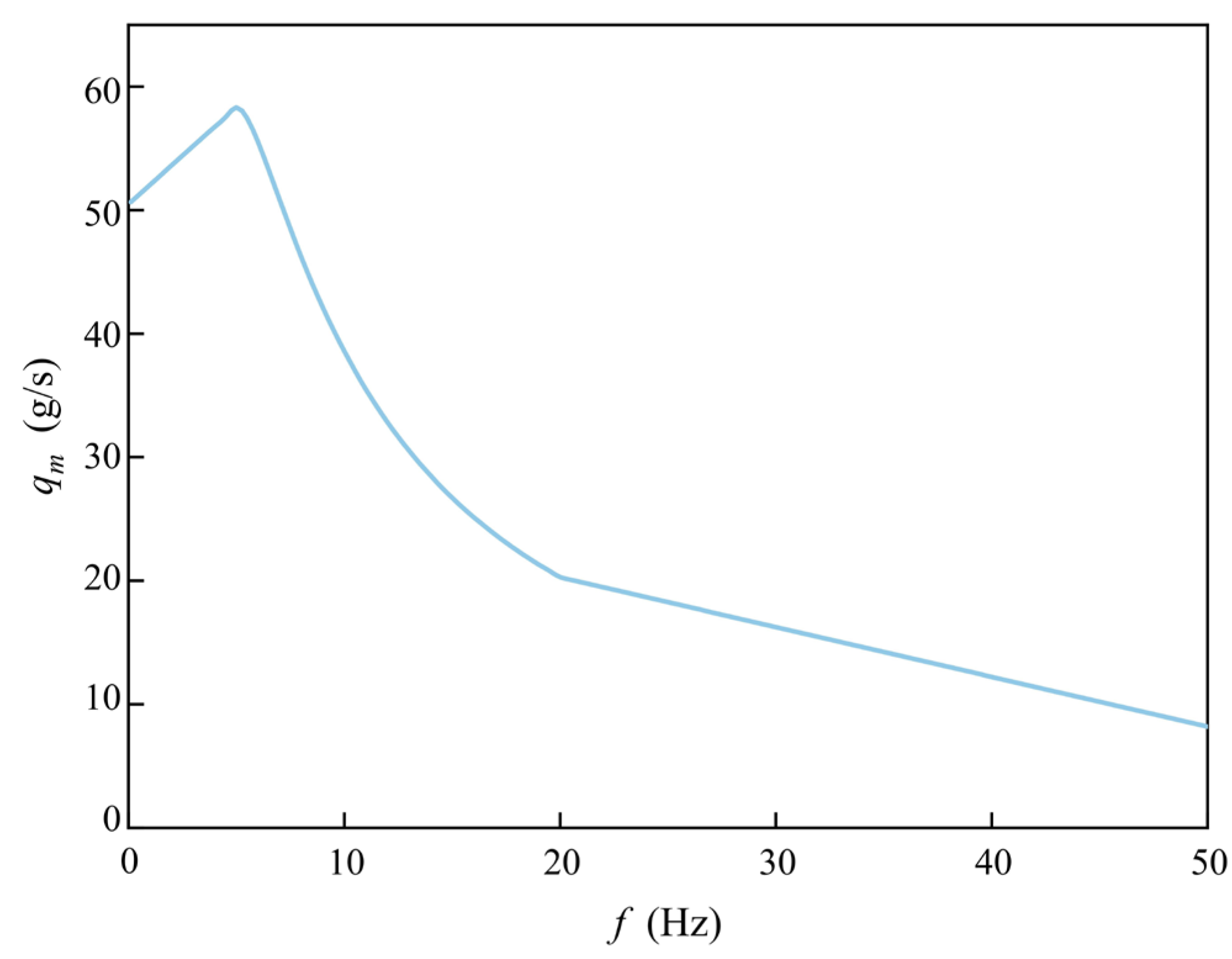

3.1. Relationship between the Mass Flow Rate and Frequency

3.2. Variable Frequency Regulation Methods

4. Simulation and Experiment

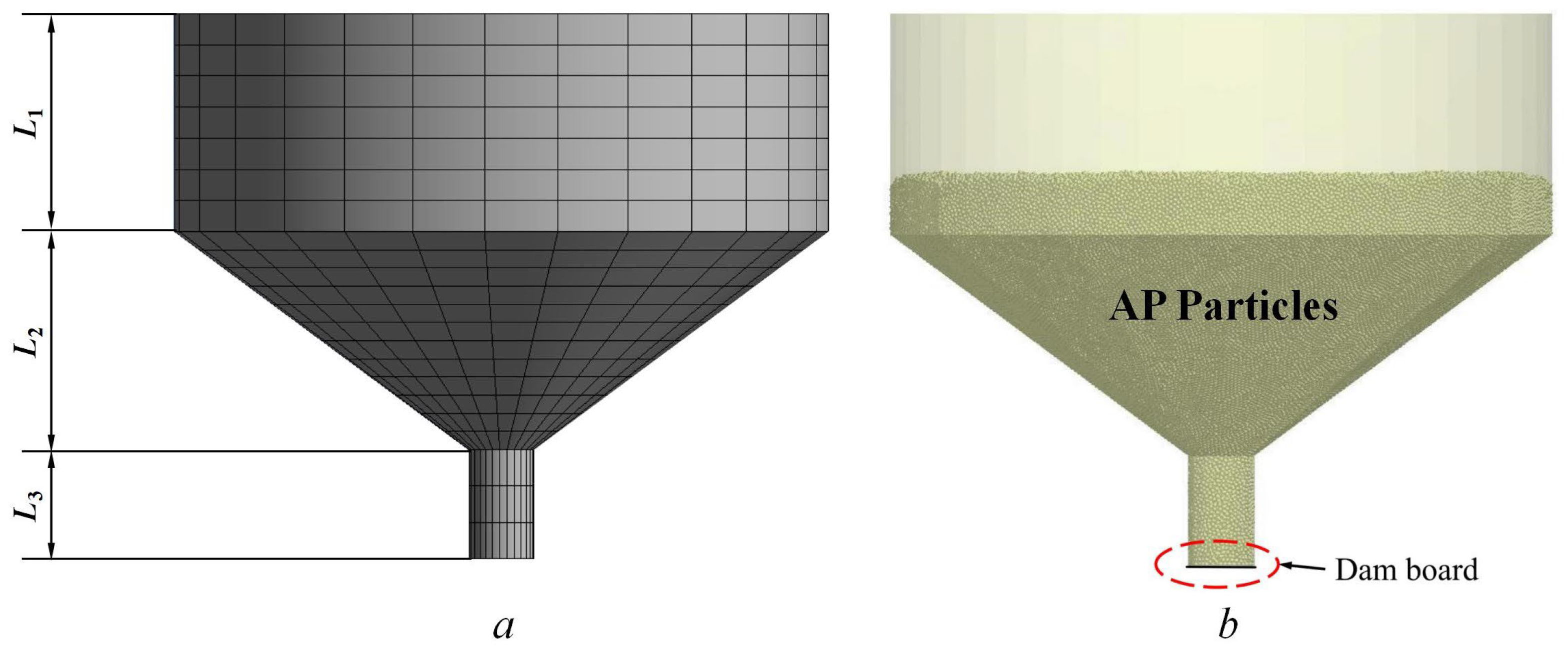

4.1. DEM Simulation

4.2. Optimize Frequency Parameters

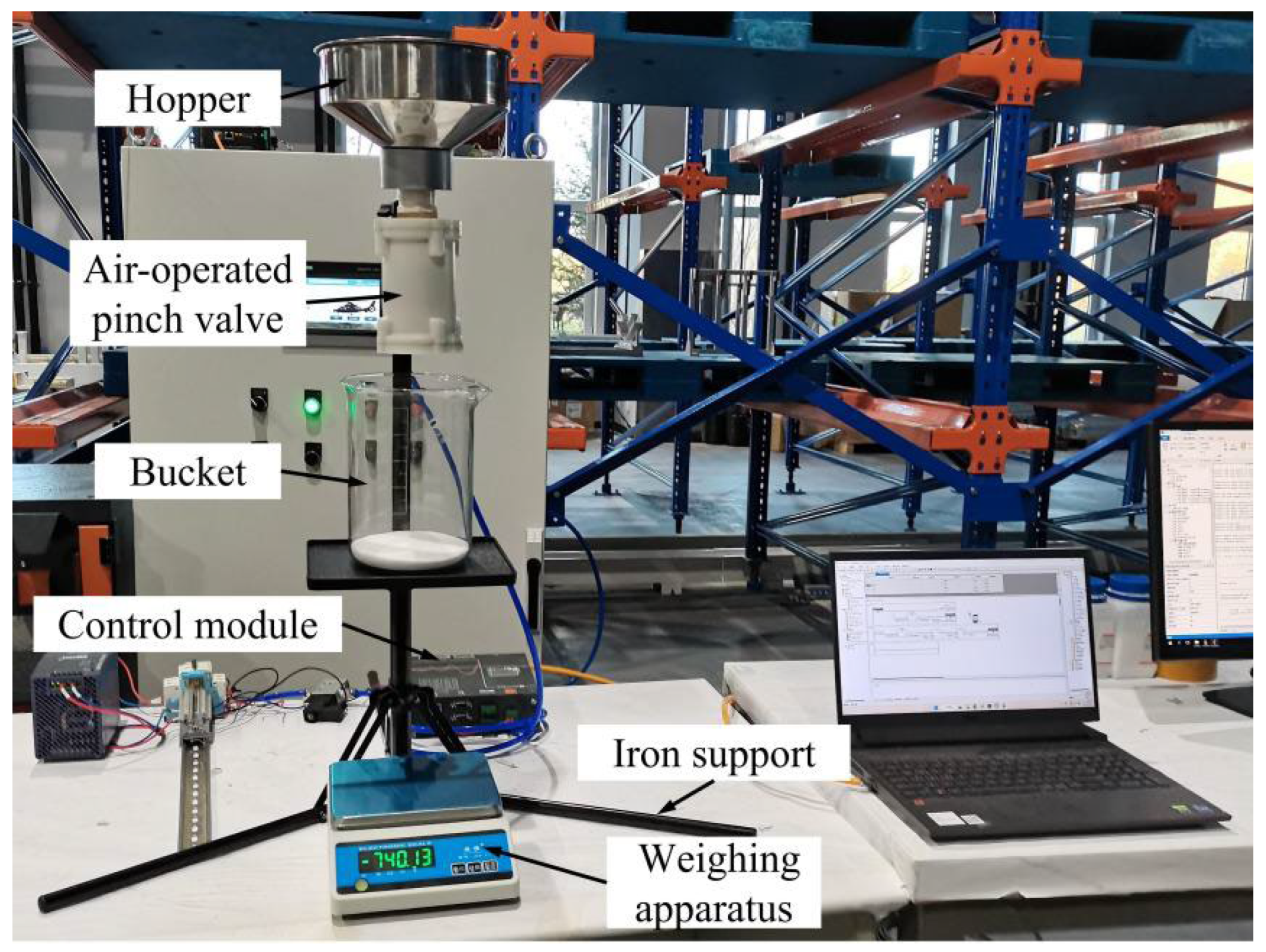

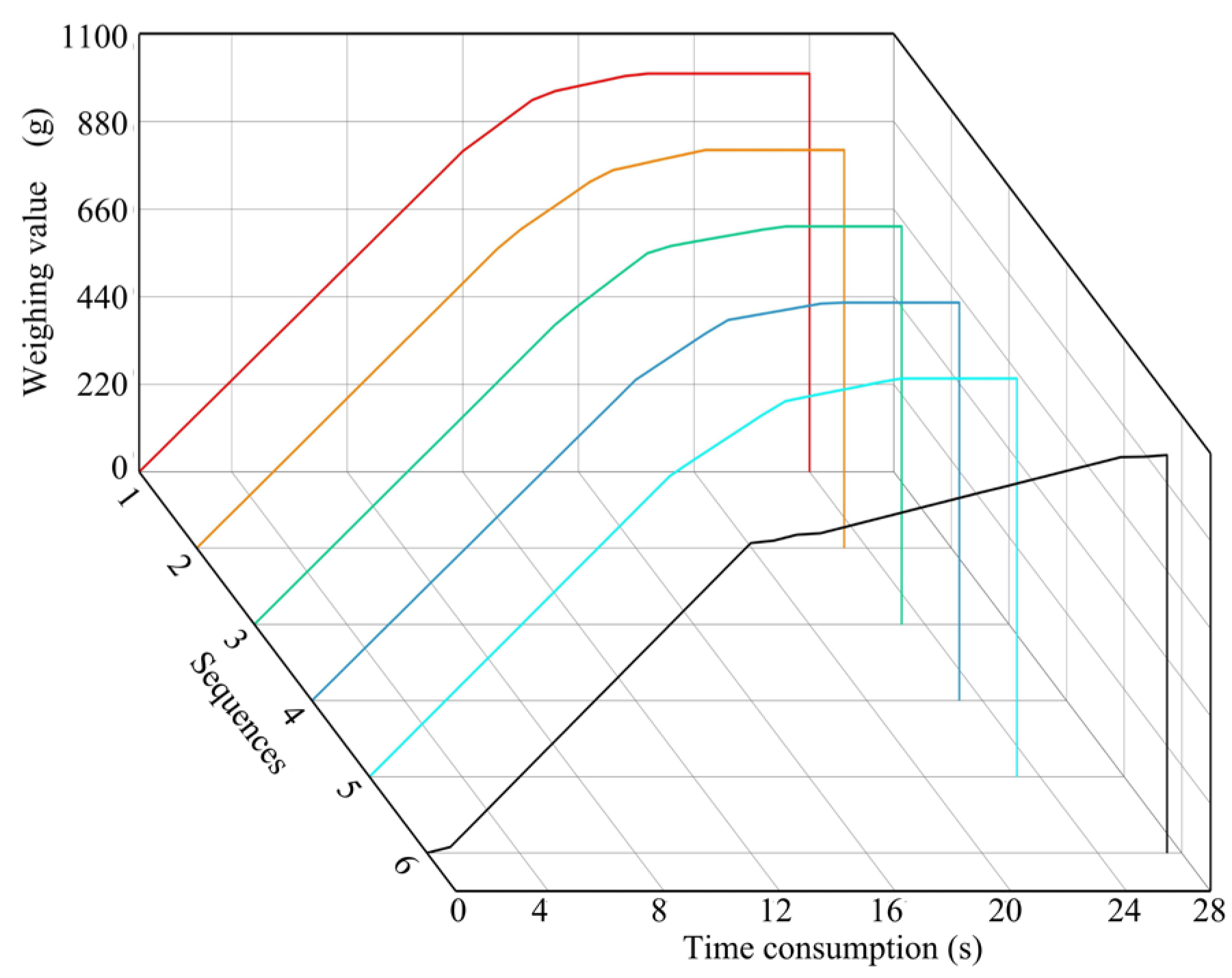

4.3. Experimental Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frederick, R.A.; Whitehead, J.J.; Knox, L.R.; Moser, M.D. Regression rates study of mixed hybrid propellants. J. Propuls. Power 2007, 23, 175–180. [Google Scholar] [CrossRef]

- Park, S.; Choi, S.; Kim, K.; Kim, W.; Park, J. Effects of Ammonium Perchlorate Particle Size, Ratio, and Total Contents on the Properties of a Composite Solid Propellant. Propellants Explos. Pyrotech. 2020, 45, 1376–1381. [Google Scholar] [CrossRef]

- Navid, H.; Taylor, R.K.; Yazgi, A.; Wang, N.; Shi, Y.; Weckler, P. Detecting grain flow rate using a laser scanner. Trans. ASABE 2015, 58, 1185–1190. [Google Scholar]

- An, J.; You, F.; Wu, M.; She, J. Iterative learning control for nonlinear weighing and feeding process. Math. Probl. Eng. 2018, 2018, 9425902. [Google Scholar] [CrossRef]

- Gopireddy, S.R.; Hildebrandt, C.; Urbanetz, N.A. Numerical simulation of powder flow in a pharmaceutical tablet press lab-scale gravity feeder. Powder Technol. 2016, 302, 309–327. [Google Scholar] [CrossRef]

- AN, J.Q.; Huang, Y.B.; Wu, M.; She, J.H. Two-Level Data-Based Adjustment of Controller Parameters for Weighing Process of Ladle Furnace. IEEE Trans. Ind. Inform. 2020, 12, 7658–7670. [Google Scholar] [CrossRef]

- Mucchi, E.; Gregorio, R.D.; Dalpiaz, G. Elastodynamic analysis of vibratory bowl feeders: Modeling and experimental validation. Mech. Mach. Theory 2013, 60, 60–72. [Google Scholar] [CrossRef]

- Yang, S.; Evans, J.R.G. Metering and dispensing of powder; the quest for new solid freeforming techniques. Powder Technol. 2007, 178, 56–72. [Google Scholar] [CrossRef]

- Despotovic, Z.V.; Urukalo, D.; Lecic, M.R.; Cosica, A. Mathematical modeling of resonant linear vibratory conveyor with electromagnetic excitation: Simulations and experimental results. Appl. Math. Model. 2017, 41, 1–24. [Google Scholar] [CrossRef]

- Sato, T. Design of a gpc-based pid controller for controlling a weigh feeder. Control Eng. Pract. 2010, 18, 105–113. [Google Scholar] [CrossRef]

- Czubak, P.; Lis, A. Analysis of a New Vibratory Conveyor Allowing for a Sudden Stopping of the Transport. Teh. Vjesn. 2020, 27, 520–526. [Google Scholar]

- Chandravanshi, M.L.; Mukhopadhyay, A.K. Dynamic analysis of vibratory feeder and their effect on feed particle speed on conveying surface. Measurement 2017, 101, 145–156. [Google Scholar] [CrossRef]

- Hua, C.; Zhang, L.; Guan, X. Distributed adaptive neural network output tracking of leader-following high-order stochastic nonlinear multiagent systems with unknown dead-zone input. IEEE Trans. Cybern. 2017, 47, 177–185. [Google Scholar] [CrossRef]

- Parameswaran, M.A.; Ganapathy, S. Vibratory conveying—Analysis and design: A review. Mech. Mach. Theory 1979, 14, 89–97. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, L.; Zhu, X. Flow pattern and normal pressure distribution in flat bottom silo discharged using wall outlet. Powder Technol. 2016, 295, 104–114. [Google Scholar] [CrossRef]

- Weinhart, T.; Labra, C.; Luding, S.; Ooi, J.Y. Influence of coarse-graining parameters on the analysis of dem simulations of silo flow. Powder Technol. 2016, 293, 138–148. [Google Scholar] [CrossRef]

- Roberts, A.W.; Wensrich, C.M. Flow dynamics or ‘quaking’ in gravity discharge from silos. Chem. Eng. Sci. 2002, 57, 295–305. [Google Scholar] [CrossRef]

- Huang, X.J.; Zheng, Q.J.; Yu, A.B.; Yan, W.Y. Optimised curved hoppers with maximum mass discharge rate—An experimental study. Powder Technol. 2021, 377, 350–360. [Google Scholar] [CrossRef]

- Huang, X.J.; Zheng, Q.J.; Yu, A.B.; Yan, W.Y. Shape optimization of conical hoppers to increase mass discharging rate. Powder Technol. 2020, 361, 179–189. [Google Scholar] [CrossRef]

- Wang, S.Q.; Yan, Y.; Ji, S.Y. Transition of granular flow patterns in a conical hopper based on superquadric DEM simulations. Granul. Matter 2020, 22, 1–16. [Google Scholar] [CrossRef]

- Gonzalez-Montellano, C.; Ayuga, F.; Ooi, J.Y. Discrete element modelling of grain flow in a planar silo: Influence of simulation parameters. Granul. Matter 2011, 13, 149–158. [Google Scholar] [CrossRef]

- Gitiaray, M.; Taghvaei, S.; Hashemnia, K. DEM Study of the design parameters of a linear vibratory feeder in packaging black pepper seeds. Granul. Matter 2023, 25, 1–13. [Google Scholar] [CrossRef]

- Hassanpour, A.; Tan, H.; Bayly, A.; Gopalkrishnan, P.; Ghadiri, M. Analysis of particle motion in a paddle mixer using discrete element method (DEM). Powder Technol. 2011, 206, 189–194. [Google Scholar] [CrossRef]

- Sarkar, A.; Wassgren, C.R. Effect of particle size on flow and mixing in a bladed granular mixer. AIChE J. 2015, 60, 46–57. [Google Scholar] [CrossRef]

- Dubey, A. Powder Flow and Blending; Woodhead Publishing: Britain, UK, 2017; pp. 36–69. [Google Scholar]

- Tanabe, S.; Gopireddy, S.R.; Minami, H.; Ando, S.; Urbanetz, N.A.; Scherließ, R. Influence of particle size and blender size on blending performance of bi-component granular mixing: A DEM and experimental study. Eur. J. Pharm. Sci. 2019, 134, 205–218. [Google Scholar] [CrossRef] [PubMed]

- Beverloo, W.A.; Leniger, H.A.; Velde, J. The flow of granular solids through orifices. Chem. Eng. Sci. 1961, 15, 260–269. [Google Scholar] [CrossRef]

- Cordero, M.J.; Pugnaloni, L.A. Dynamic transition in conveyor belt driven granular flow. Powder Technol. 2015, 272, 290–294. [Google Scholar] [CrossRef]

- Jadidi, B.; Ebrahimi, M.; Ein-Mozaffari, F.; Lohi, A. A comprehensive review of the application of DEM in the investigation of batch solid mixers. Rev. Chem. Eng. 2022, 39, 729–764. [Google Scholar] [CrossRef]

- Fransen, M.P.; Langelaar, M.L.; Schott, D.L. Application of dem-based metamodels in bulk handling equipment design: Methodology and DEM case study. Powder Technol. 2021, 393, 205–218. [Google Scholar] [CrossRef]

- Emmerink, J.; Hadi, A.; Jovanova, J.; Cleven, C.; Schott, D.L. Parametric Analysis of a Double Shaft, Batch-Type Paddle Mixer Using the Discrete Element Method (DEM). Processes 2023, 11, 738. [Google Scholar] [CrossRef]

- Mukherjee, R.; Sansare, S.; Nagarajan, V.; Chaudhuri, B. Discrete element modeling (DEM) based investigation of tribocharging in the pharmaceutical powders during hopper discharge. Int. J. Pharm. 2021, 596, 120284. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, H.; Zhao, Y.F.; Qiao, X.L.; Li, X.G.; Zhao, H. DEM-CFD Simulation of Twin Screw Extrusion Process of Composite Solid Propellant. Chin. J. Energy Mater. 2022, 30, 138–145. (In Chinese) [Google Scholar]

| Type | Parameters | Value |

|---|---|---|

| AP particle | Density, ρp (kg/m3) | 1950 |

| Poisson ratio, νp | 0.4 | |

| Shear modulus, Gp (Pa) | 1 × 108 | |

| Silo | Density, ρs (kg/m3) | 7800 |

| Poisson ratio, νs | 0.3 | |

| Shear modulus, Gs (Pa) | 7 × 1010 | |

| Particle-particle | Restitution coefficient, epp | 0.35 |

| Coefficient of static friction, μspp | 0.1 | |

| Coefficient of rolling friction, μrpp | 0.05 | |

| Particle-silo | Restitution coefficient, eps | 0.45 |

| Coefficient of static friction, μsps | 0.1 | |

| Coefficient of rolling friction, μrps | 0.01 | |

| Simulation | Time step, Δt (s) | 5 × 10−6 |

| Gravitational acceleration (m/s2) | 9.81 |

| Composition Structure | |||

|---|---|---|---|

| L1 | L2 | L3 | |

| Definition | Cylindrical Section | Conical Section | Output Section |

| Size (mm) | 200 | 200 | 100 |

| First Stage Frequency f1 (Hz) | Second Stage Frequency f2 (Hz) | Third Stage Frequency f3 (Hz) | Precision Value α (%) | Time Consumption T (s) | |

|---|---|---|---|---|---|

| 1 | 4.50 | 8.80 | 31.00 | 100.037 | 20.94 |

| 2 | 4.70 | 9.60 | 31.00 | 99.954 | 21.54 |

| 3 | 4.70 | 8.50 | 34.50 | 99.964 | 22.02 |

| 4 | 4.50 | 10.00 | 34.50 | 100.001 | 22.16 |

| 5 | 4.90 | 10.20 | 32.50 | 99.957 | 22.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Wang, H.; Chen, X.; Bai, X.; Xu, Z.; Wei, Y.; Fan, L. Improved Mass Flow Rate Regulation Methods Based on Variable Frequency Control: A Case Study of Oxidizer Agent Weighing for Solid Propellants. Actuators 2023, 12, 285. https://doi.org/10.3390/act12070285

Lu H, Wang H, Chen X, Bai X, Xu Z, Wei Y, Fan L. Improved Mass Flow Rate Regulation Methods Based on Variable Frequency Control: A Case Study of Oxidizer Agent Weighing for Solid Propellants. Actuators. 2023; 12(7):285. https://doi.org/10.3390/act12070285

Chicago/Turabian StyleLu, Han, Hongyu Wang, Xuhang Chen, Xinlin Bai, Zhigang Xu, Yaqiang Wei, and Linlin Fan. 2023. "Improved Mass Flow Rate Regulation Methods Based on Variable Frequency Control: A Case Study of Oxidizer Agent Weighing for Solid Propellants" Actuators 12, no. 7: 285. https://doi.org/10.3390/act12070285

APA StyleLu, H., Wang, H., Chen, X., Bai, X., Xu, Z., Wei, Y., & Fan, L. (2023). Improved Mass Flow Rate Regulation Methods Based on Variable Frequency Control: A Case Study of Oxidizer Agent Weighing for Solid Propellants. Actuators, 12(7), 285. https://doi.org/10.3390/act12070285