A Modeling and Control Algorithm for a Commercial Vehicle Electronic Brake System Based on Vertical Load Estimation

Abstract

:1. Introduction

- (1)

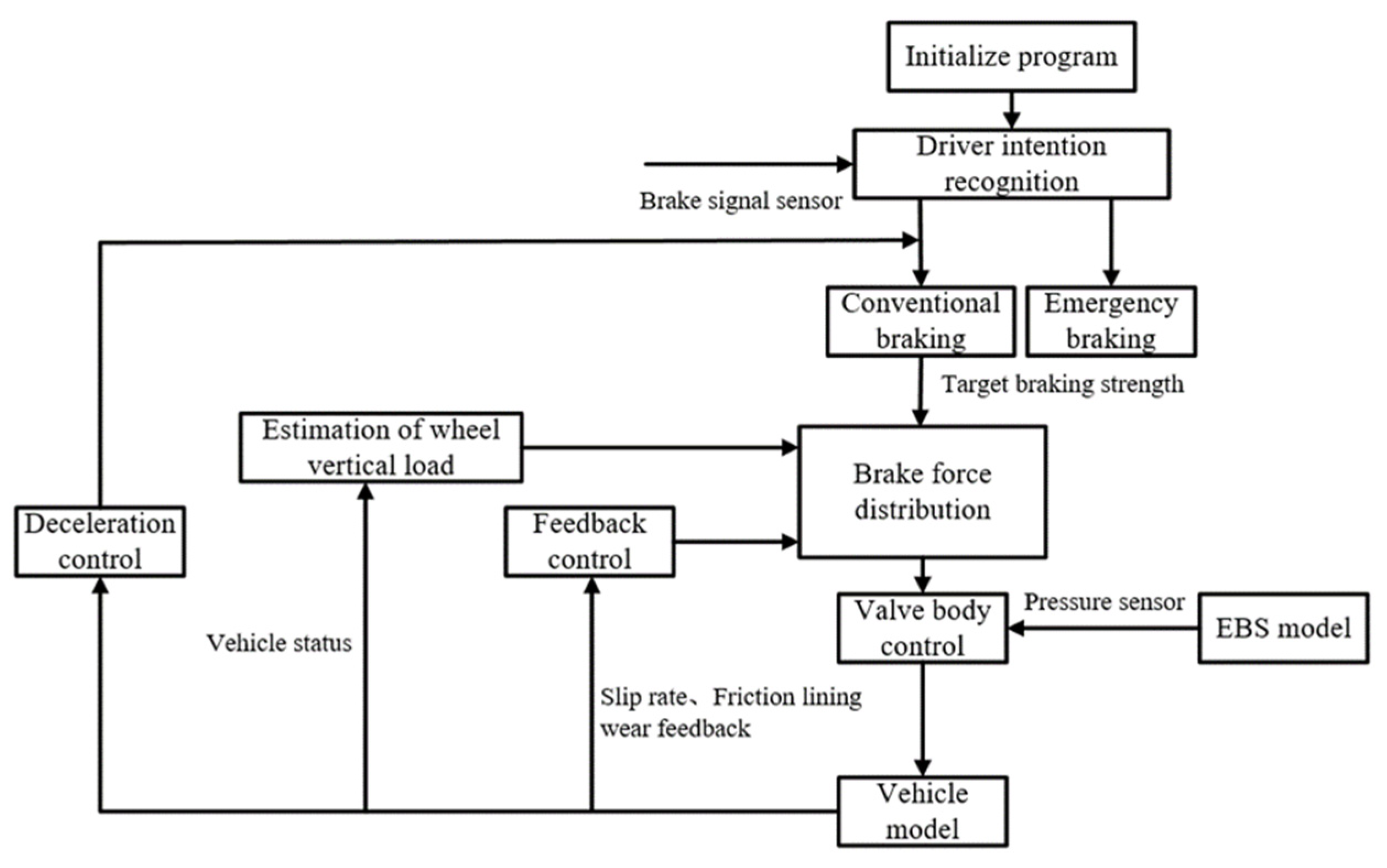

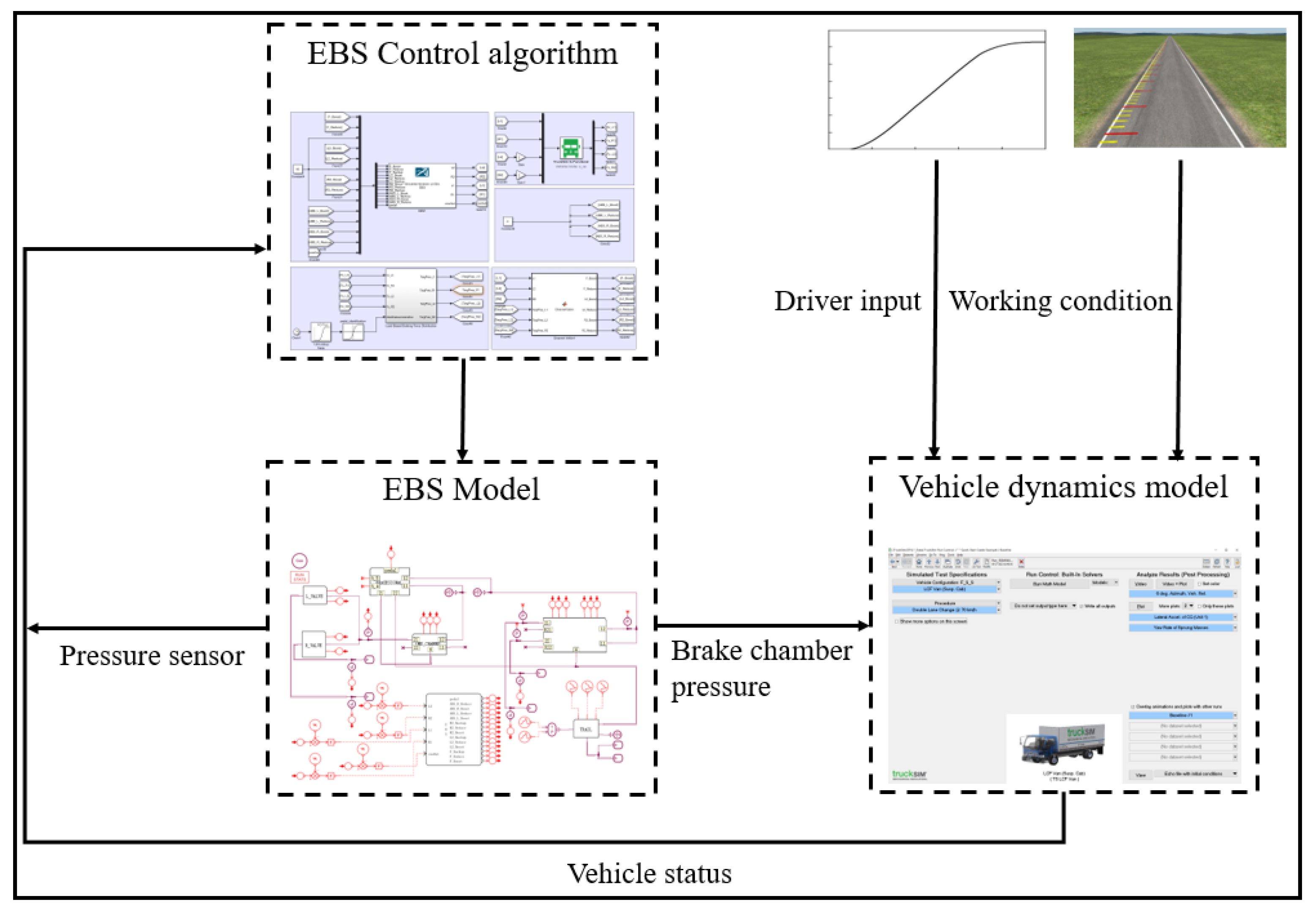

- The designed vertical load estimation algorithm based on unscented particle filtering (UPF) is validated through simulation and can accurately estimate the vertical load of wheels. In order to study the gas transmission of an EBS more accurately, an EBS valve model is established.

- (2)

- A commercial vehicle EBS control algorithm is proposed to achieve better braking performance, which includes a vertical load estimation and a valve control algorithm.

2. Vertical Load Estimation

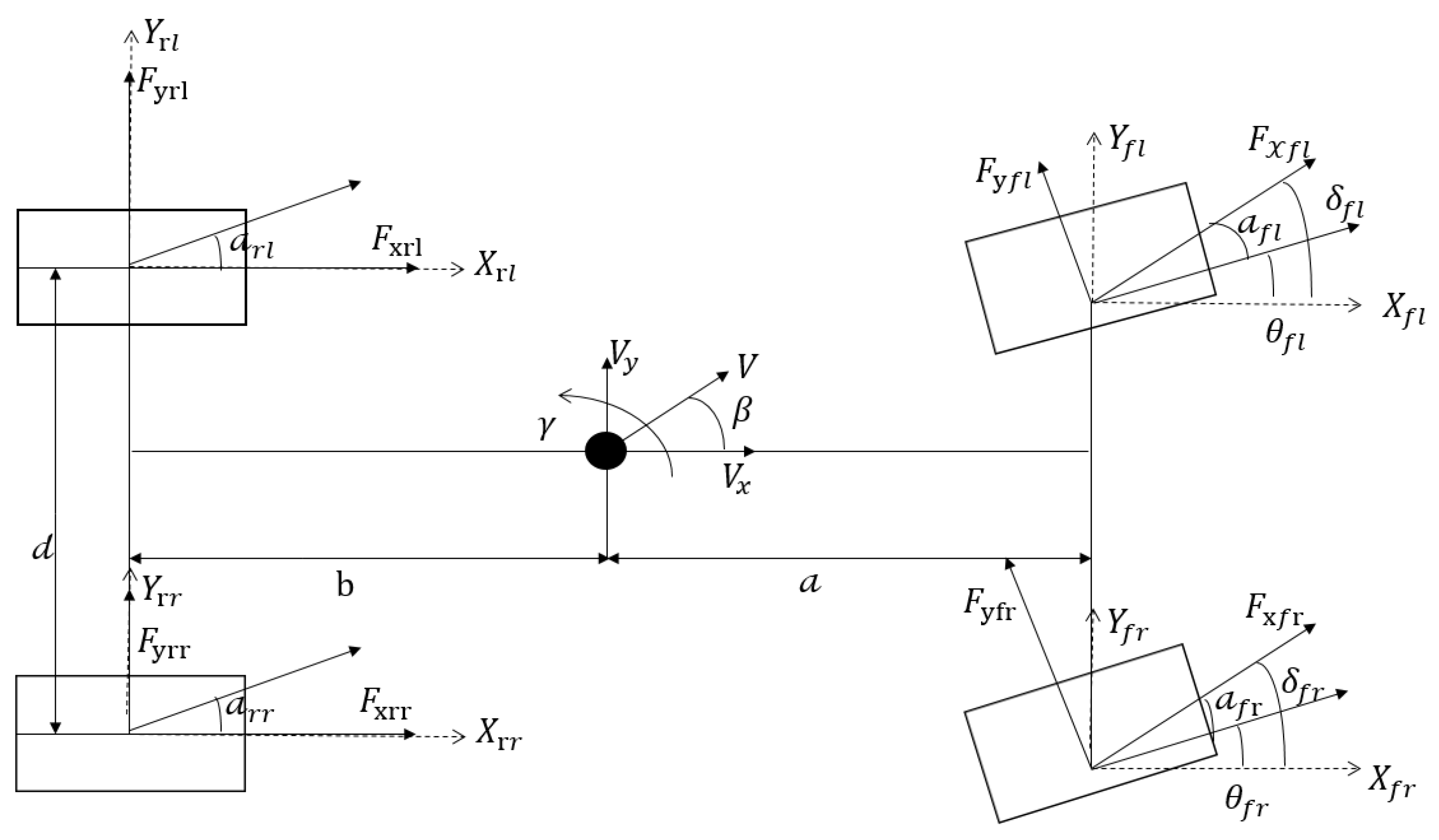

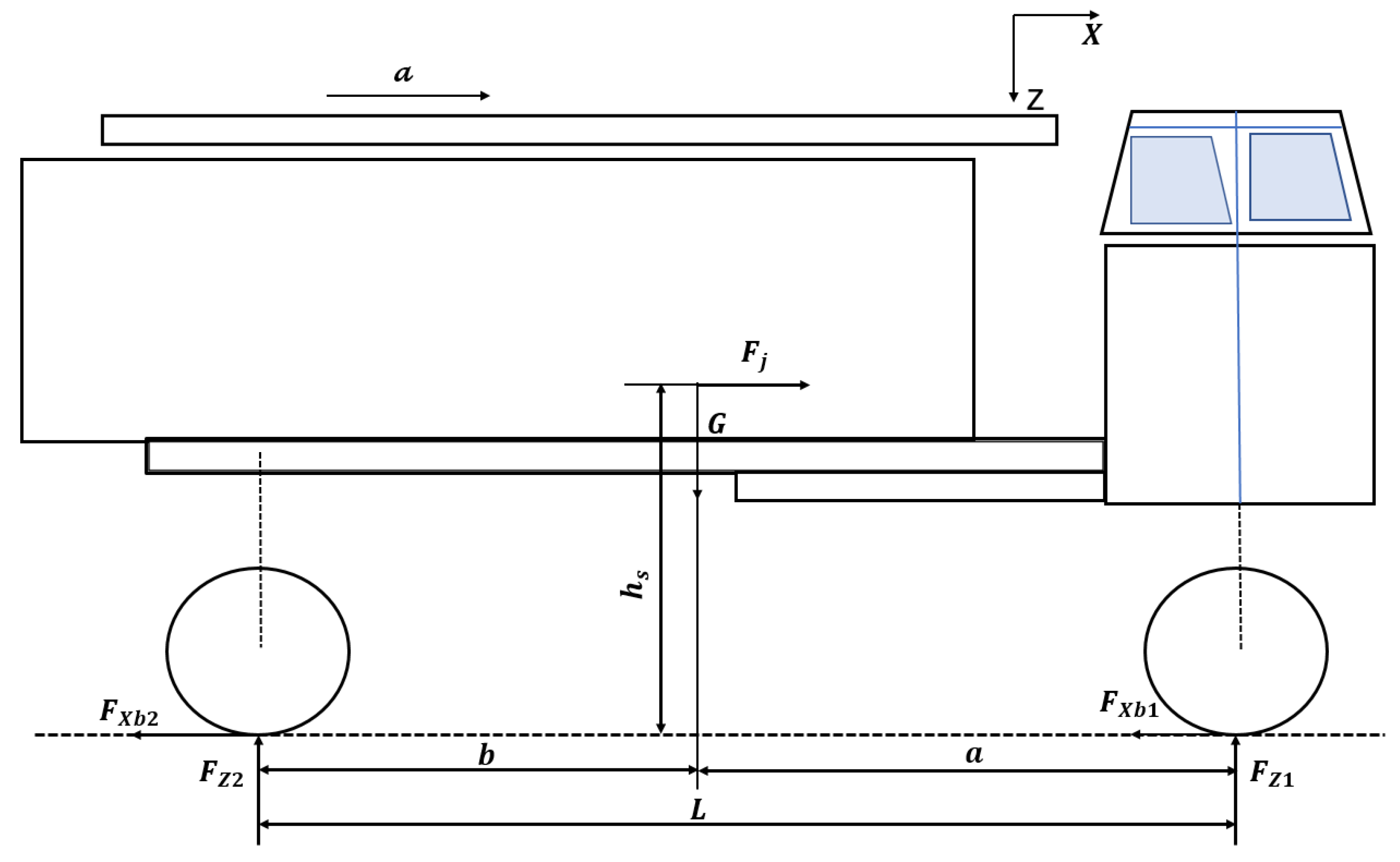

2.1. Commercial Vehicle Dynamics Model

2.2. Vertical Load Estimation Based on Unscented Particle Filter

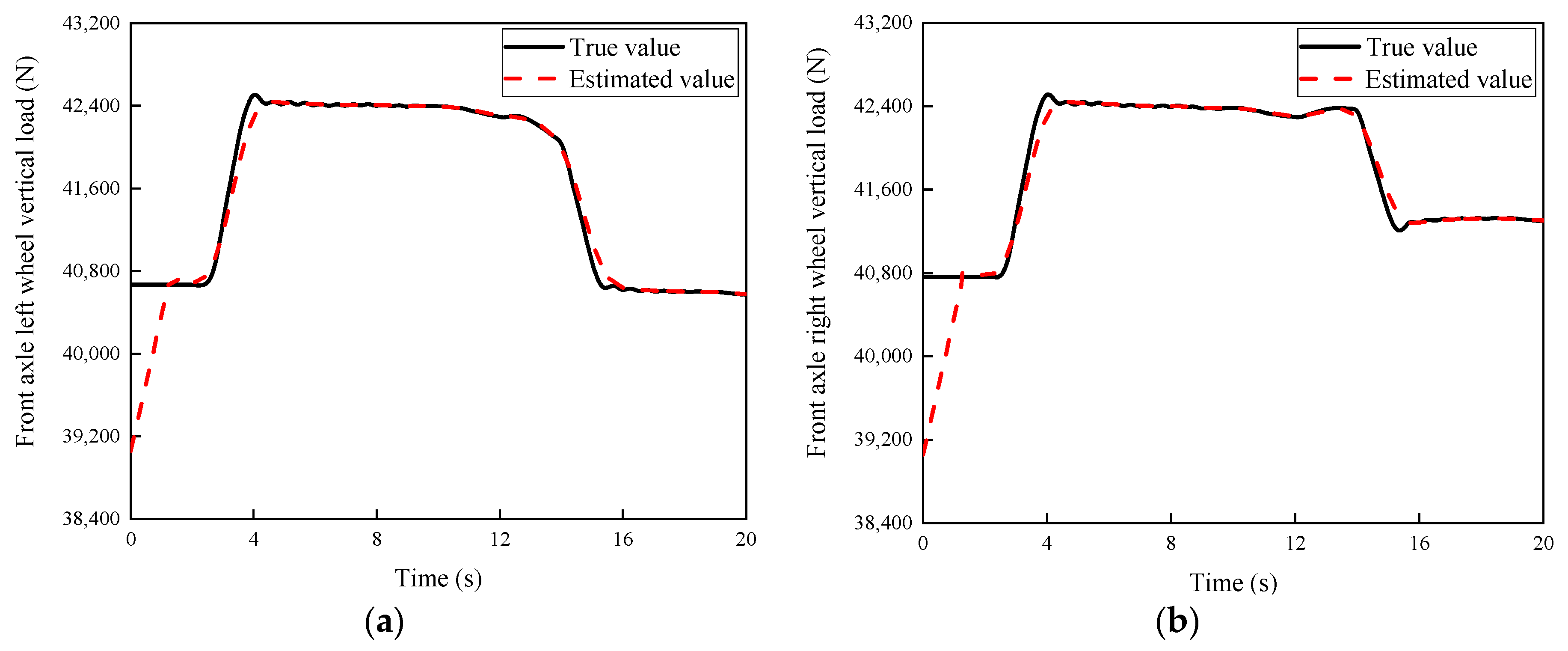

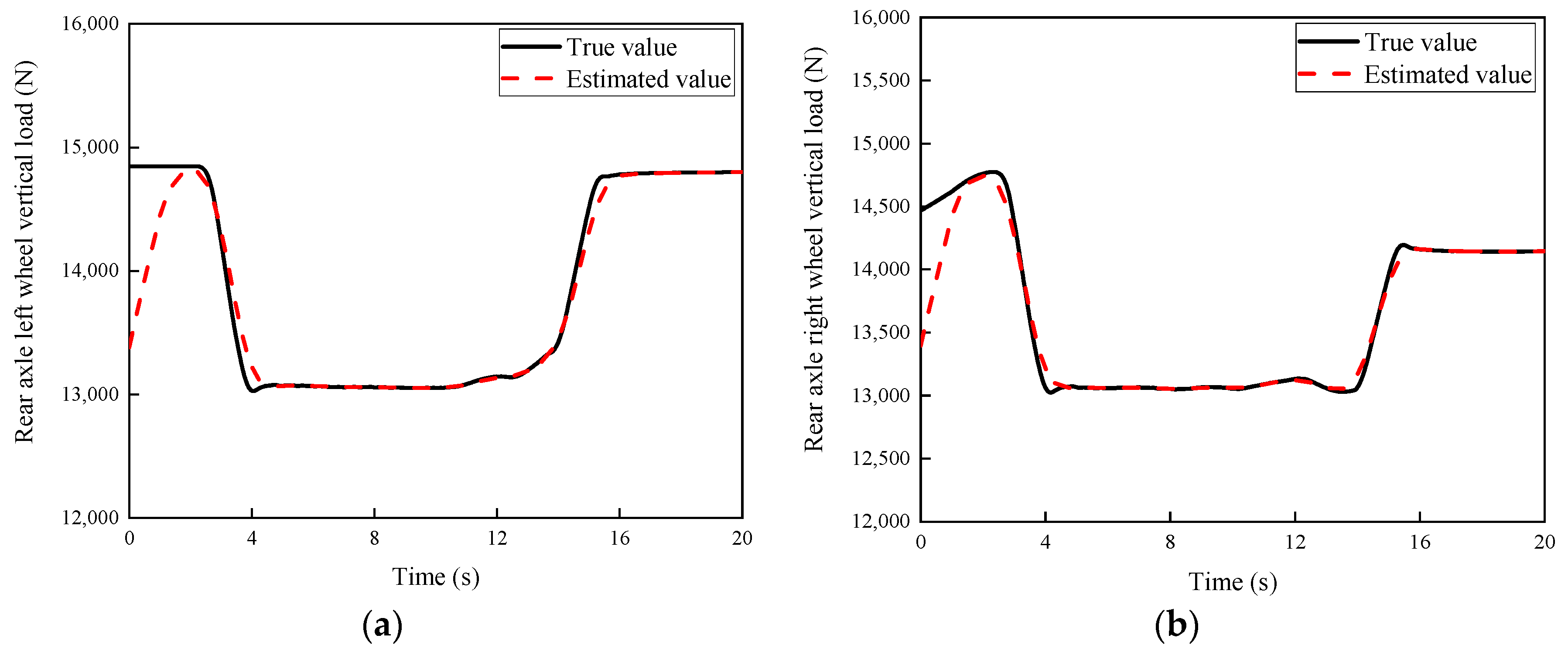

2.3. Simulation Verification

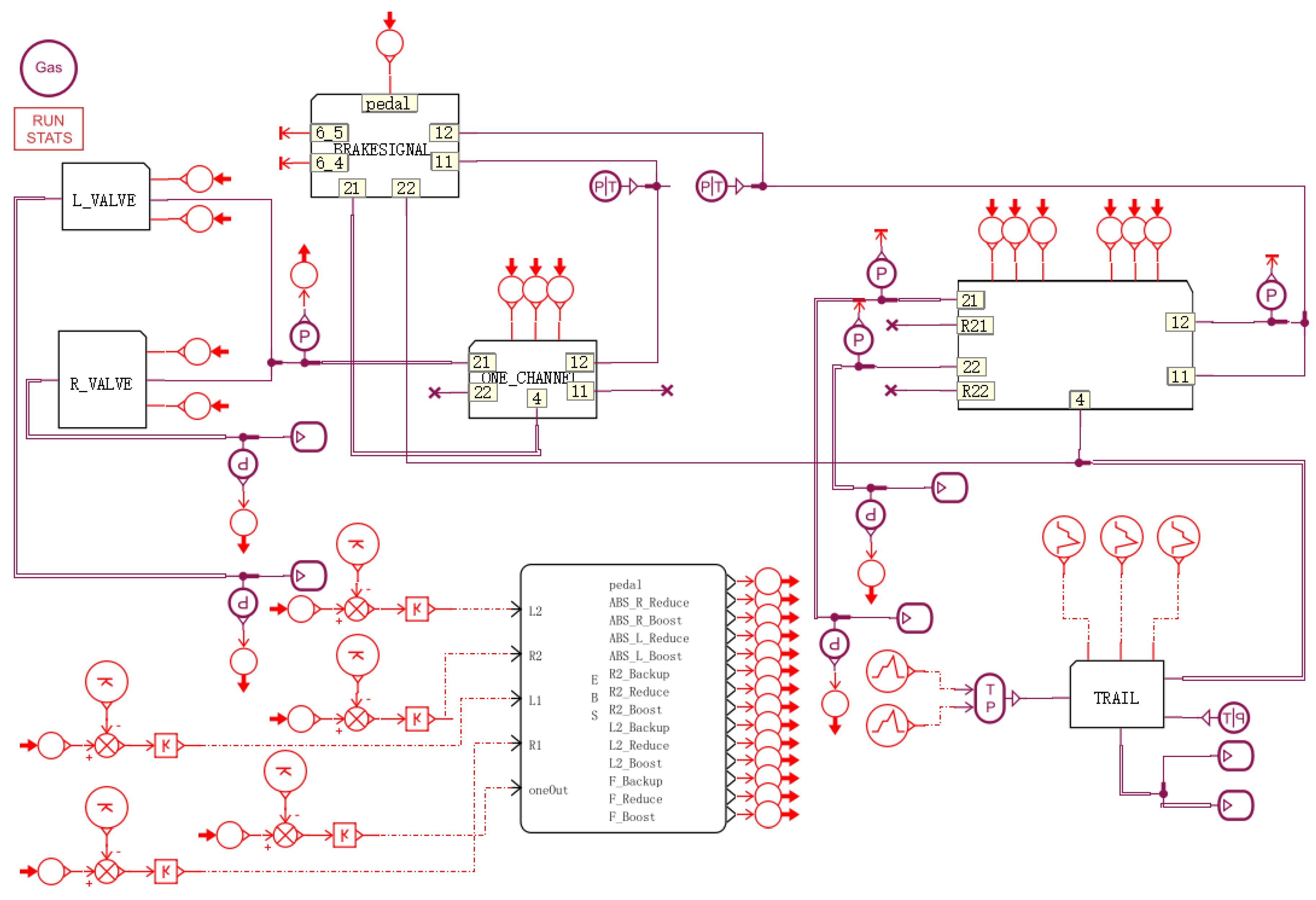

3. Commercial Vehicle EBS Modeling

3.1. Working Principle and Modeling of Brake Signal Sensors

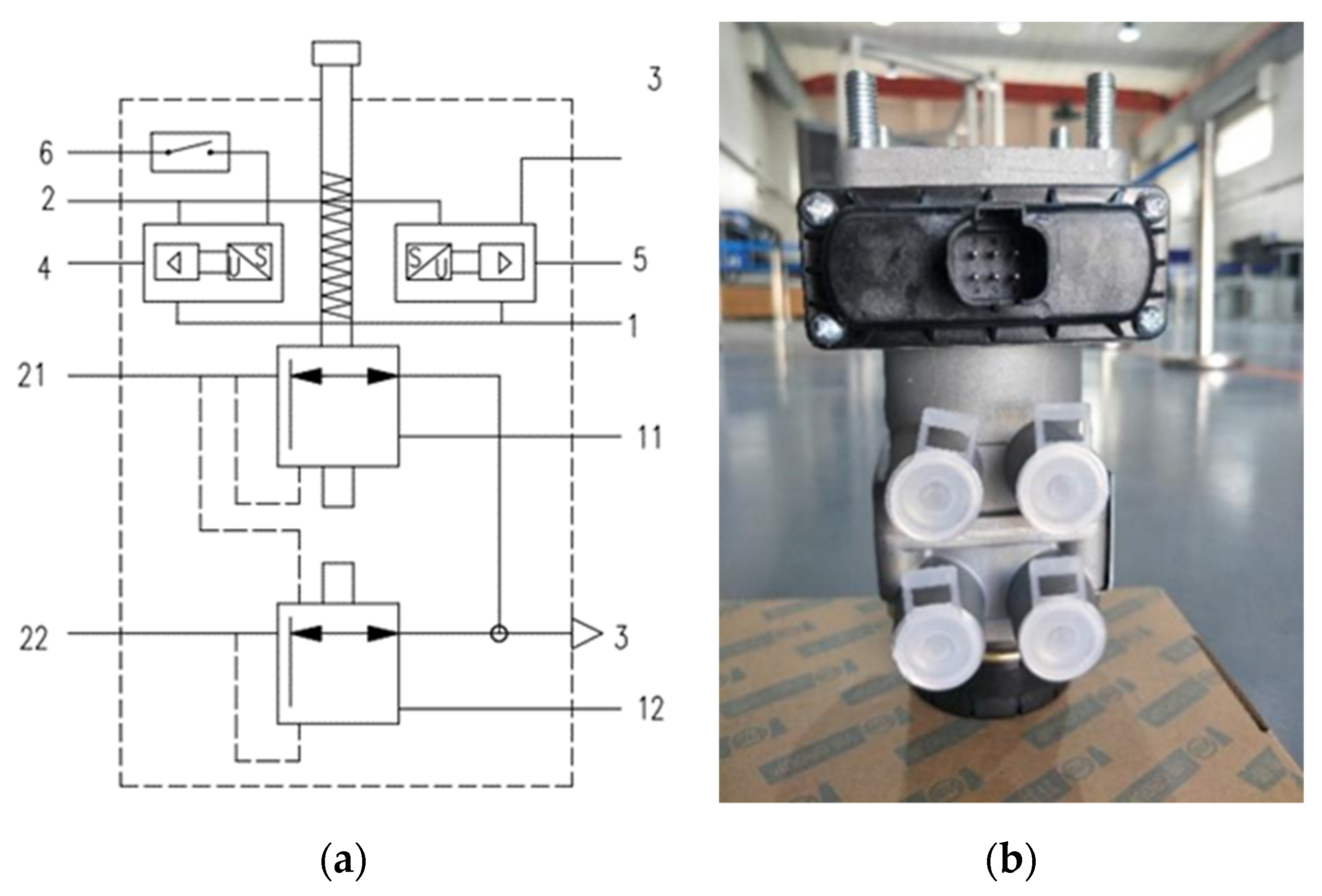

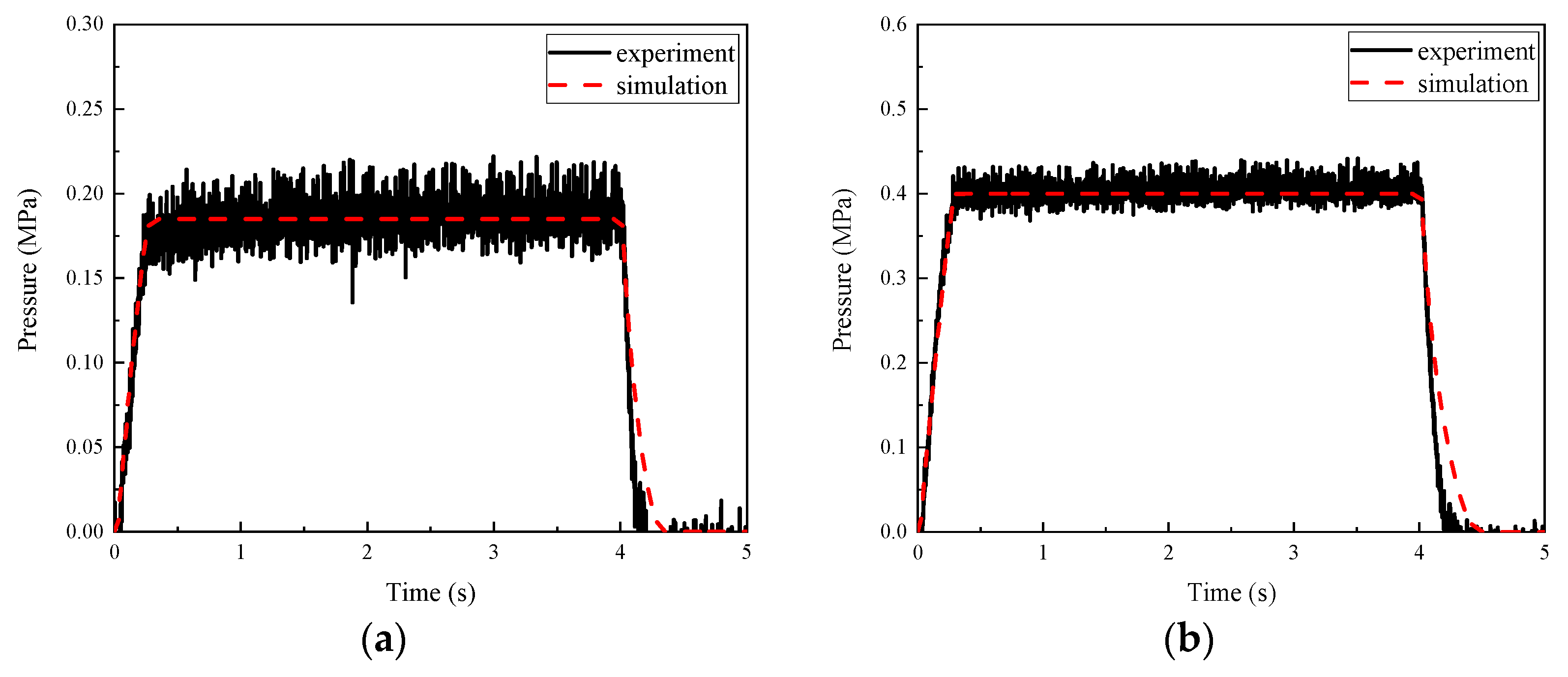

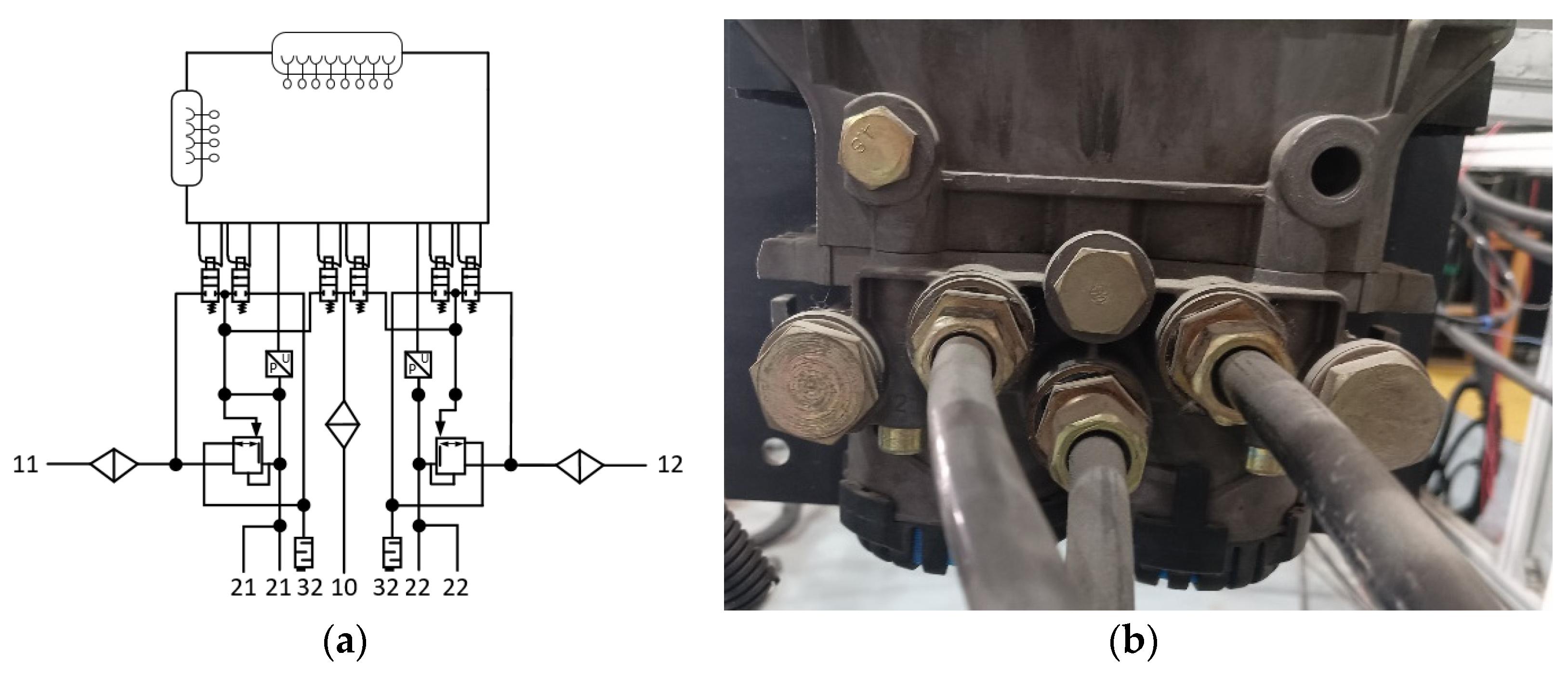

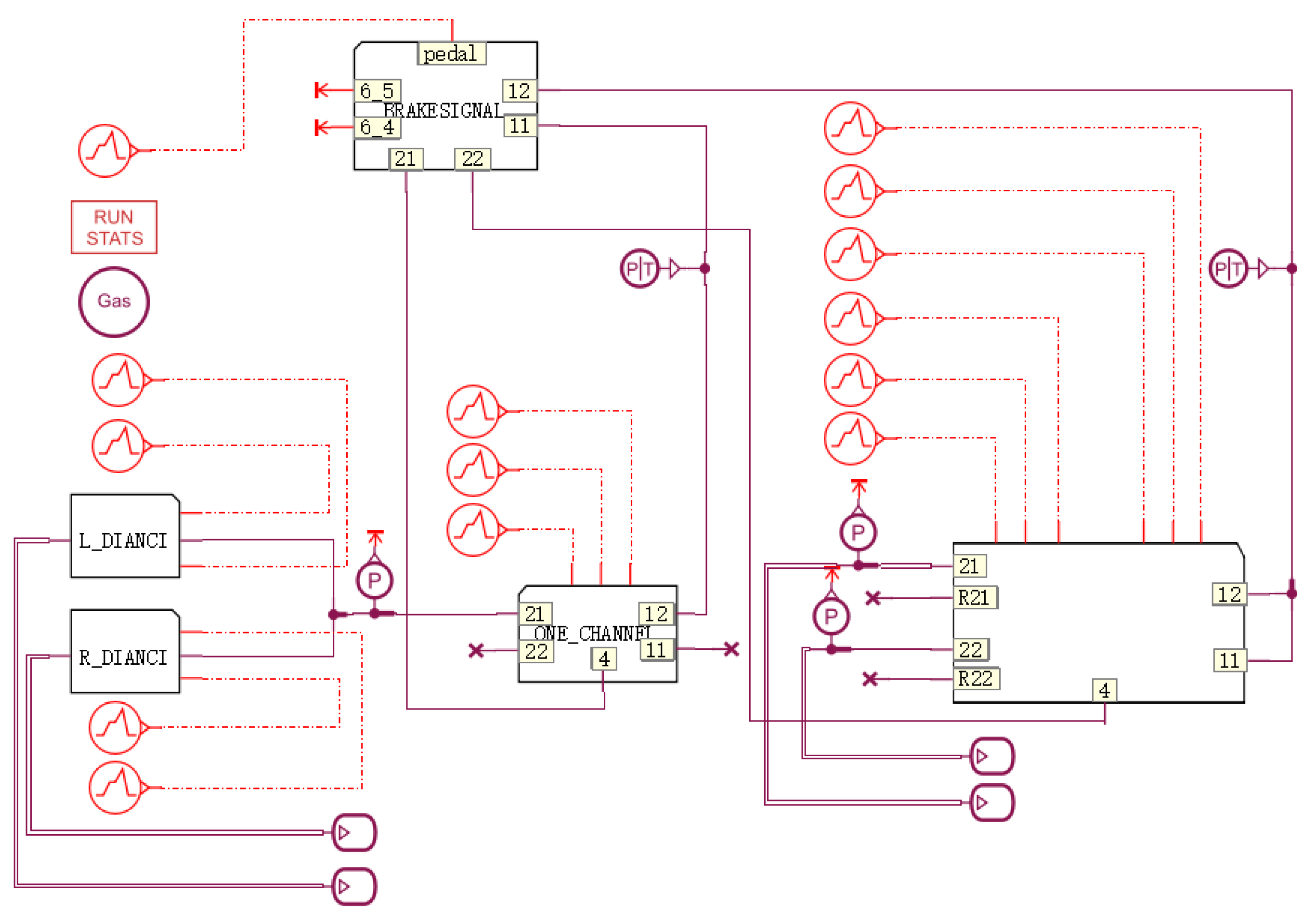

3.2. Working Principle and Modeling of Single-Channel Bridge Control Module

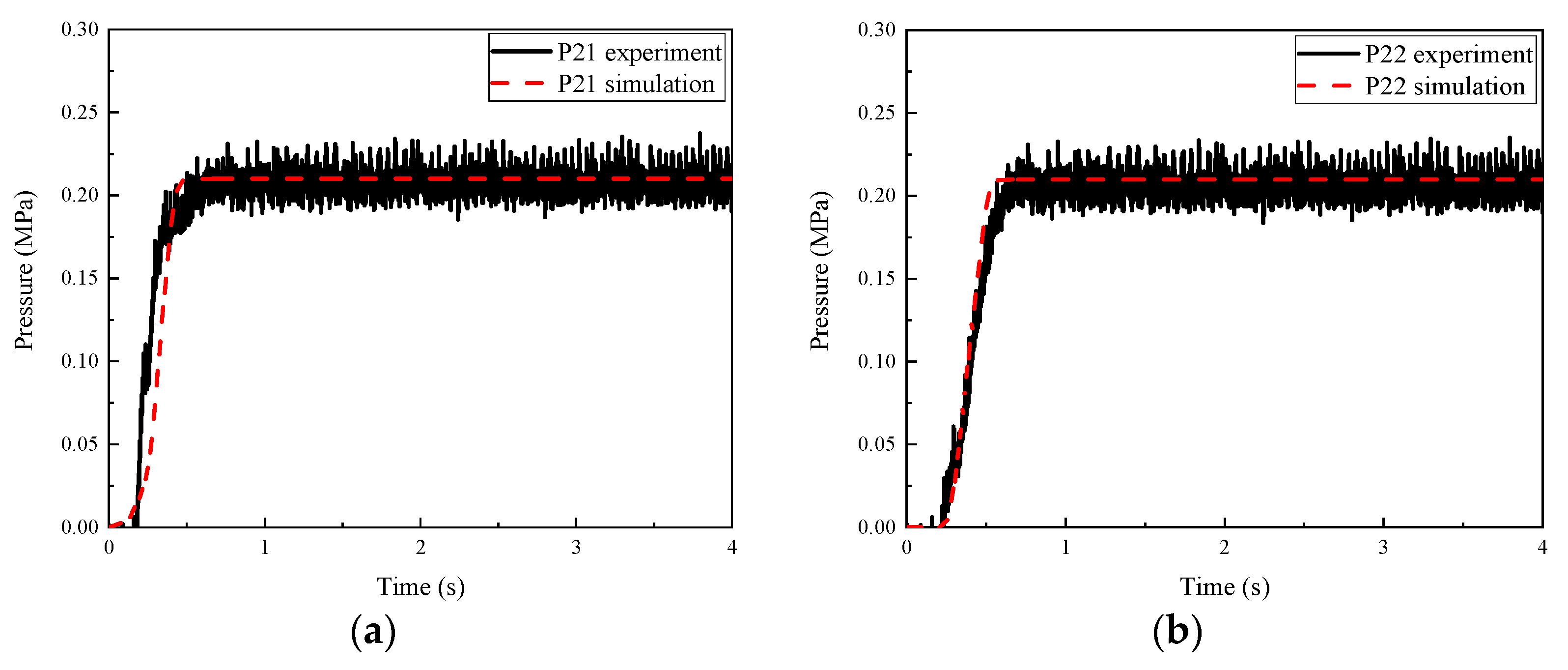

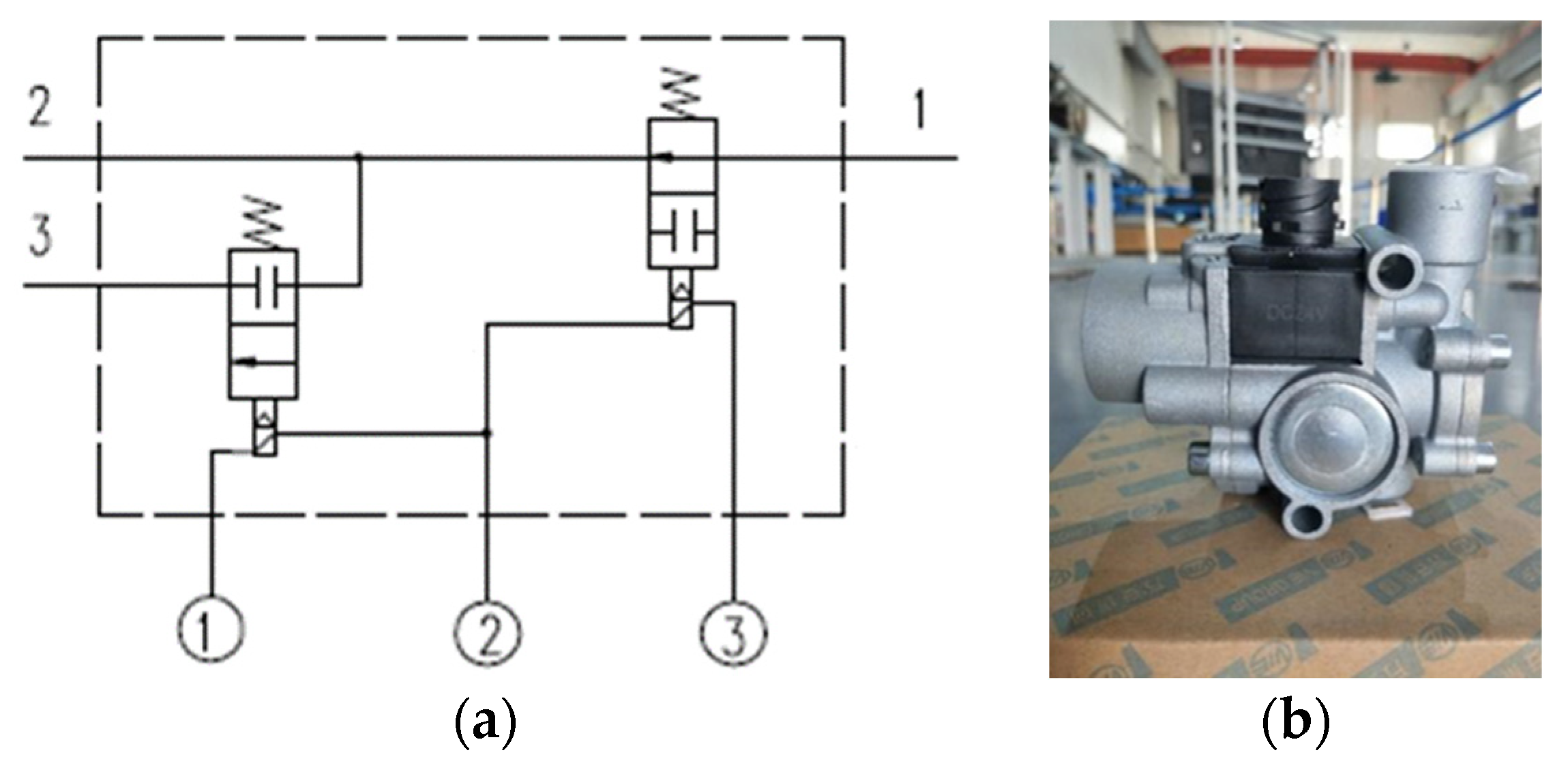

3.3. Working Principle and Modeling of ABS Electromagnetic Valve

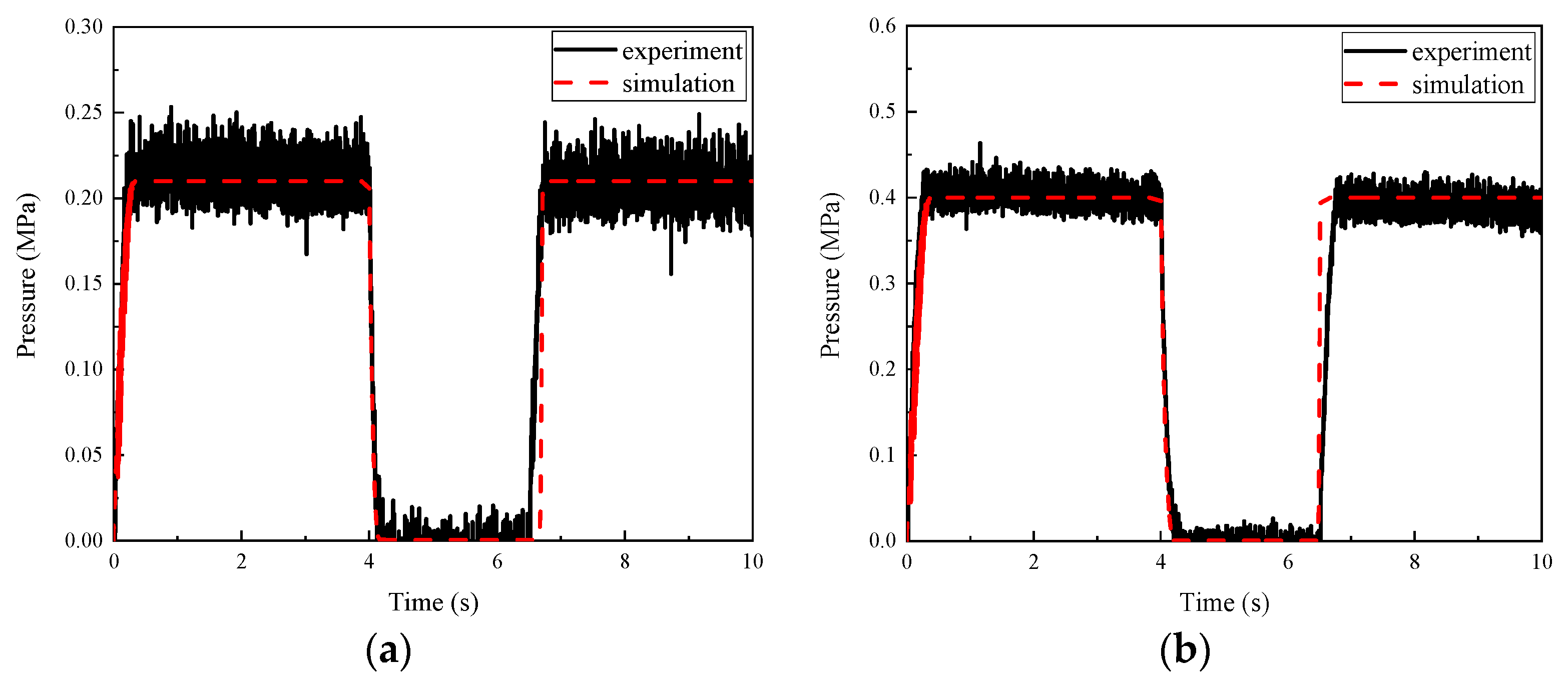

3.4. Working Principle and Modeling of Dual-Channel Bridge Control Module

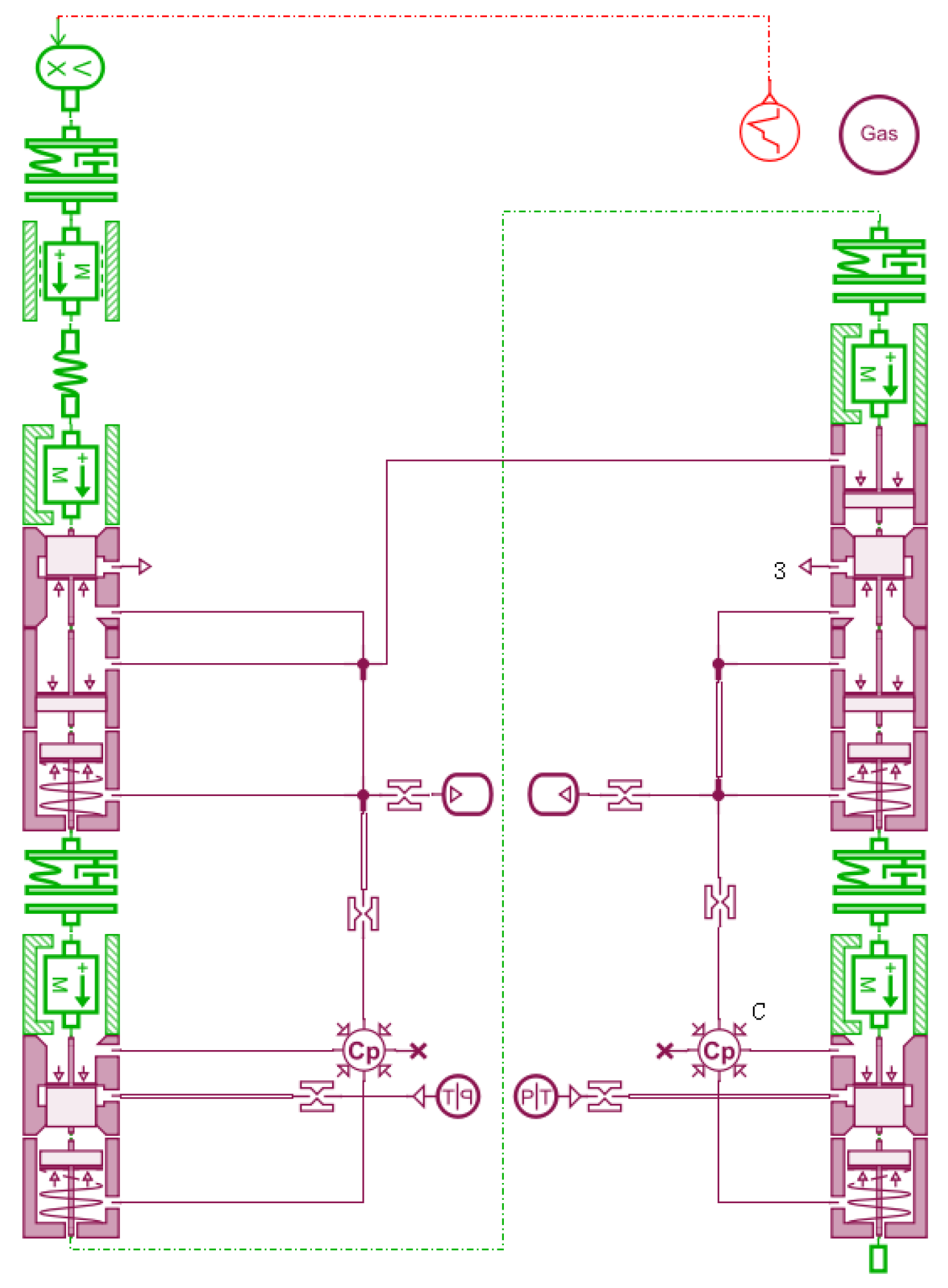

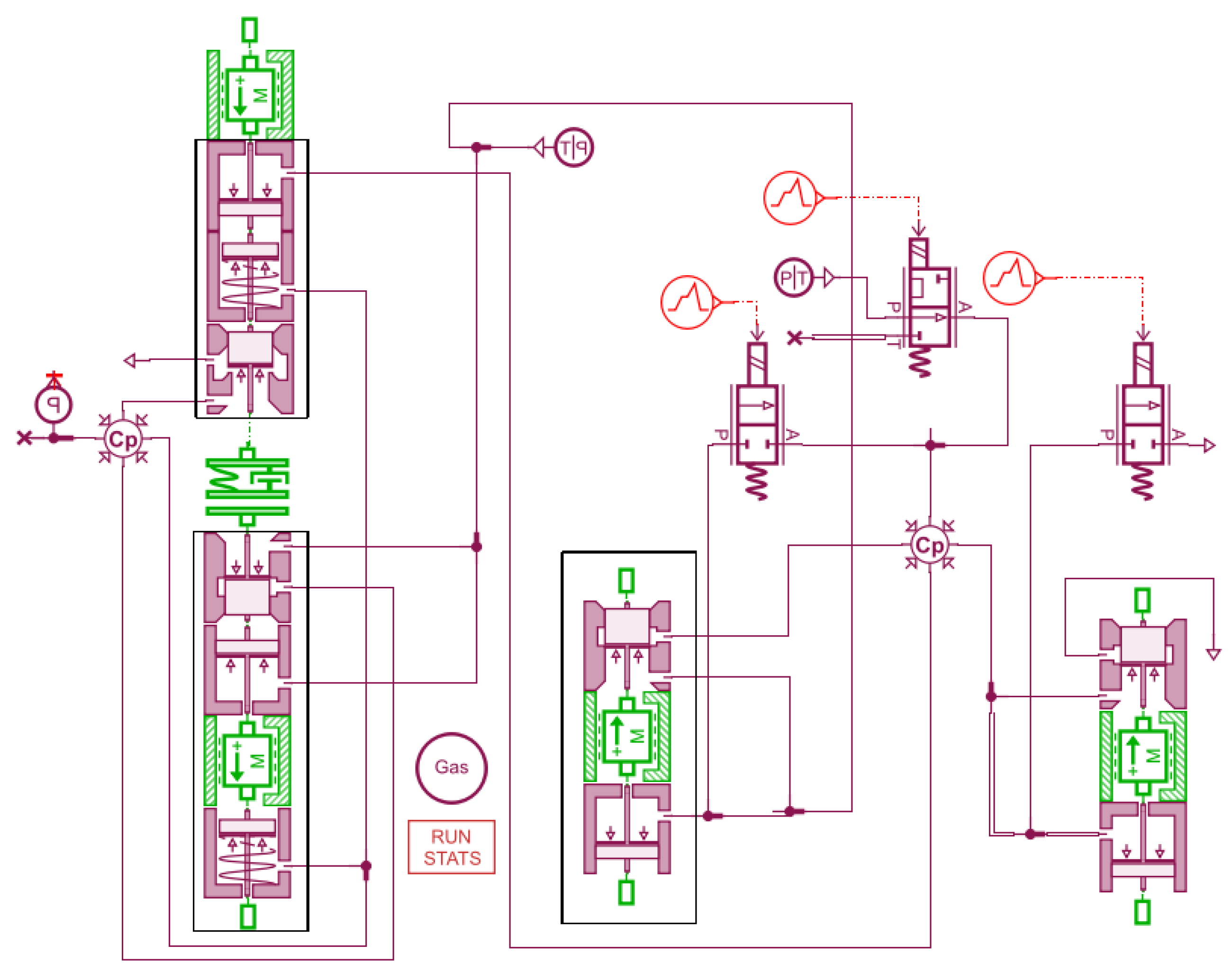

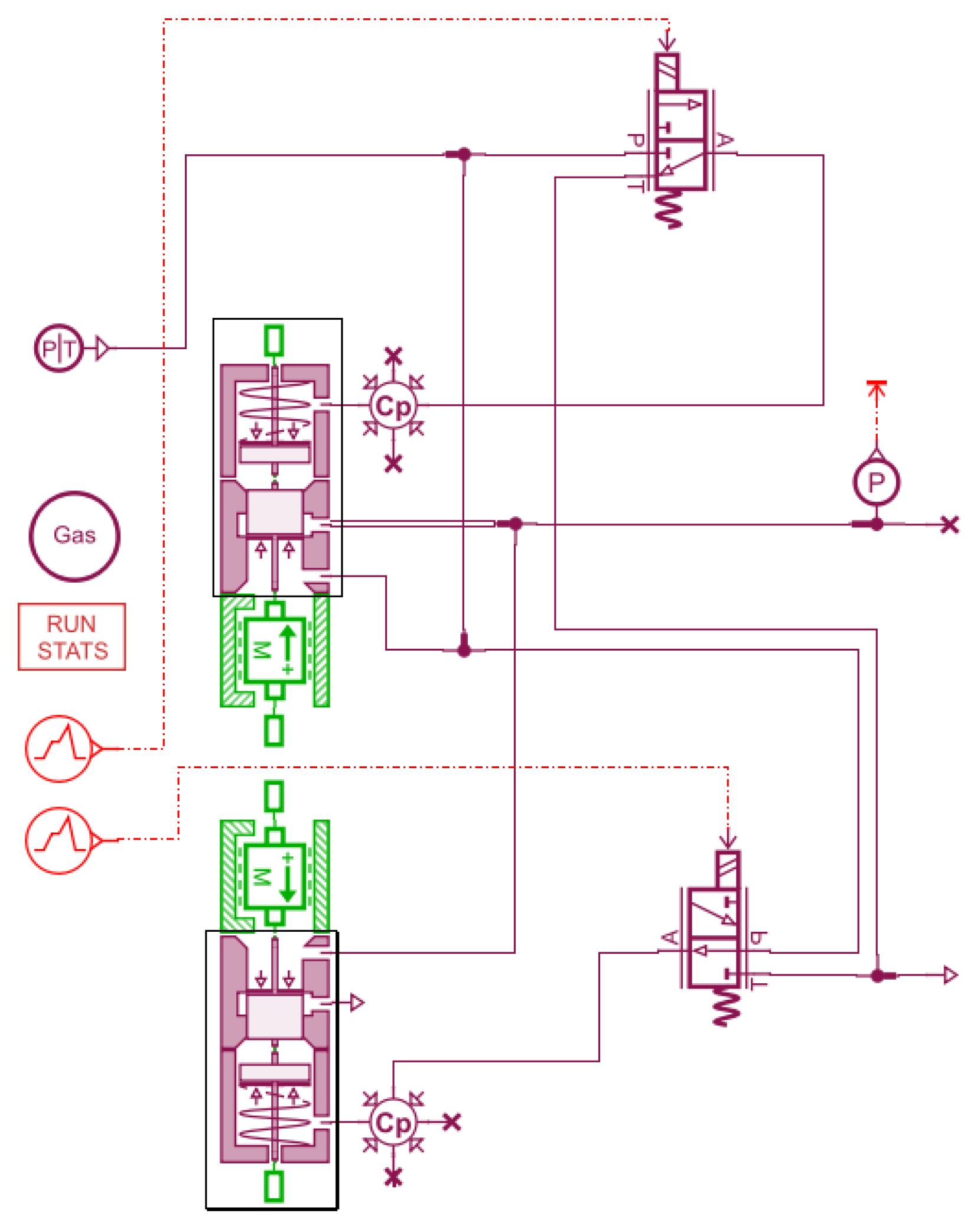

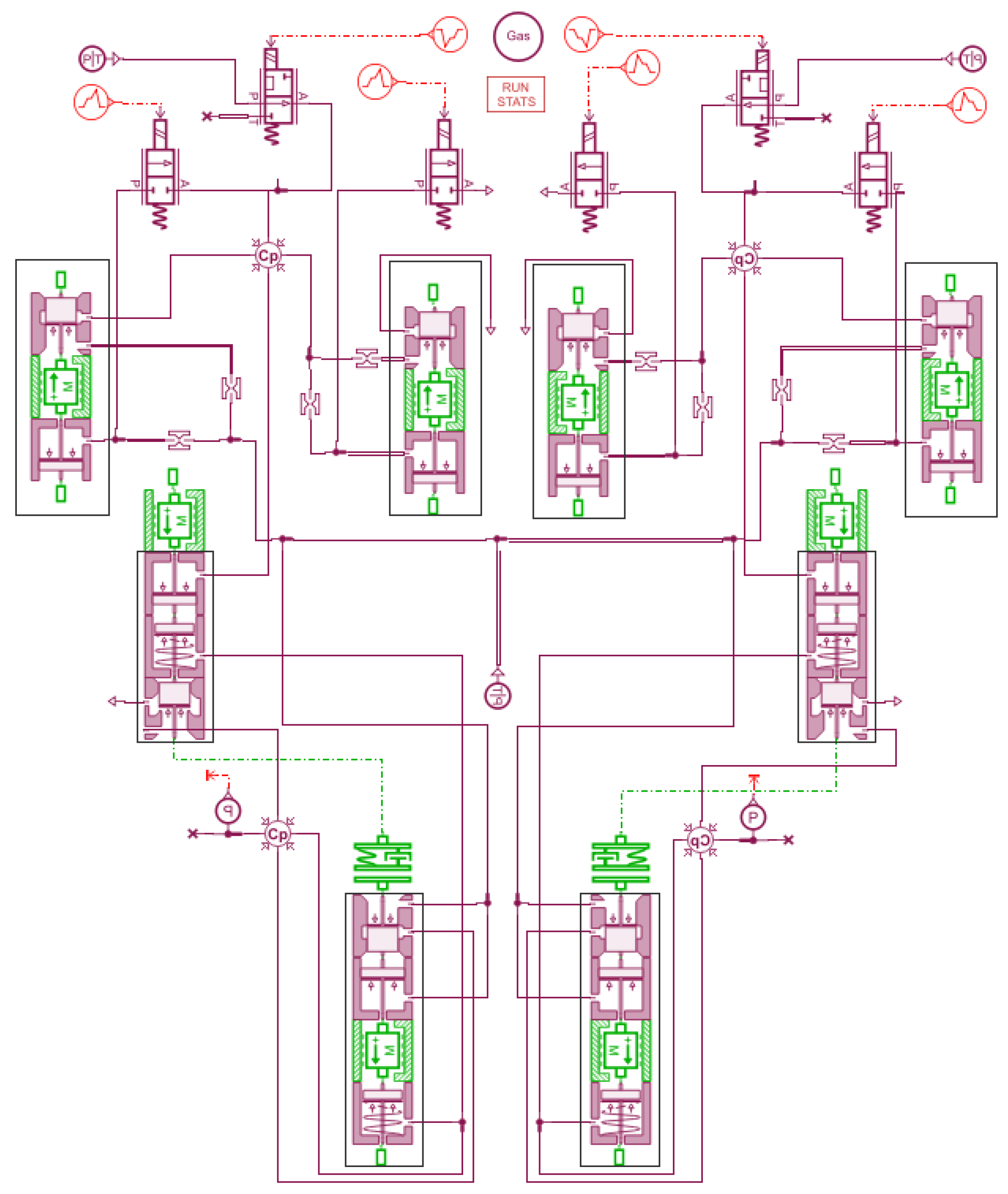

3.5. Dynamic Model of a Commercial Vehicle EBS

4. Design of a Commercial Vehicle EBS Control Algorithm

4.1. EBS Valve Control Algorithm

- (1)

- When the actual pressure at the output port of the valve , the valve needs to be rapidly pressurized.is the lower limit of the threshold value, and is the proportional parameter obtained through empirical debugging.

- (2)

- When the actual pressure at the output port of the valve , the valve needs to be slowly pressurized.is the lower limit of the threshold value, and is the proportional parameter obtained through empirical debugging.

- (3)

- When the actual pressure at the output port of the valve , the valve needs to be slowly depressurized.is the lower limit of the threshold value, and is the proportional parameter obtained through empirical debugging.

- (4)

- When the actual pressure at the output port of the valve , the valve needs to be quickly depressurized.is the lower limit of the threshold value, and is the proportional parameter obtained through empirical debugging.

- (5)

- When the actual pressure at the output port of the valve is , the valve needs to maintain pressure.

4.2. EBS Control Algorithm Process

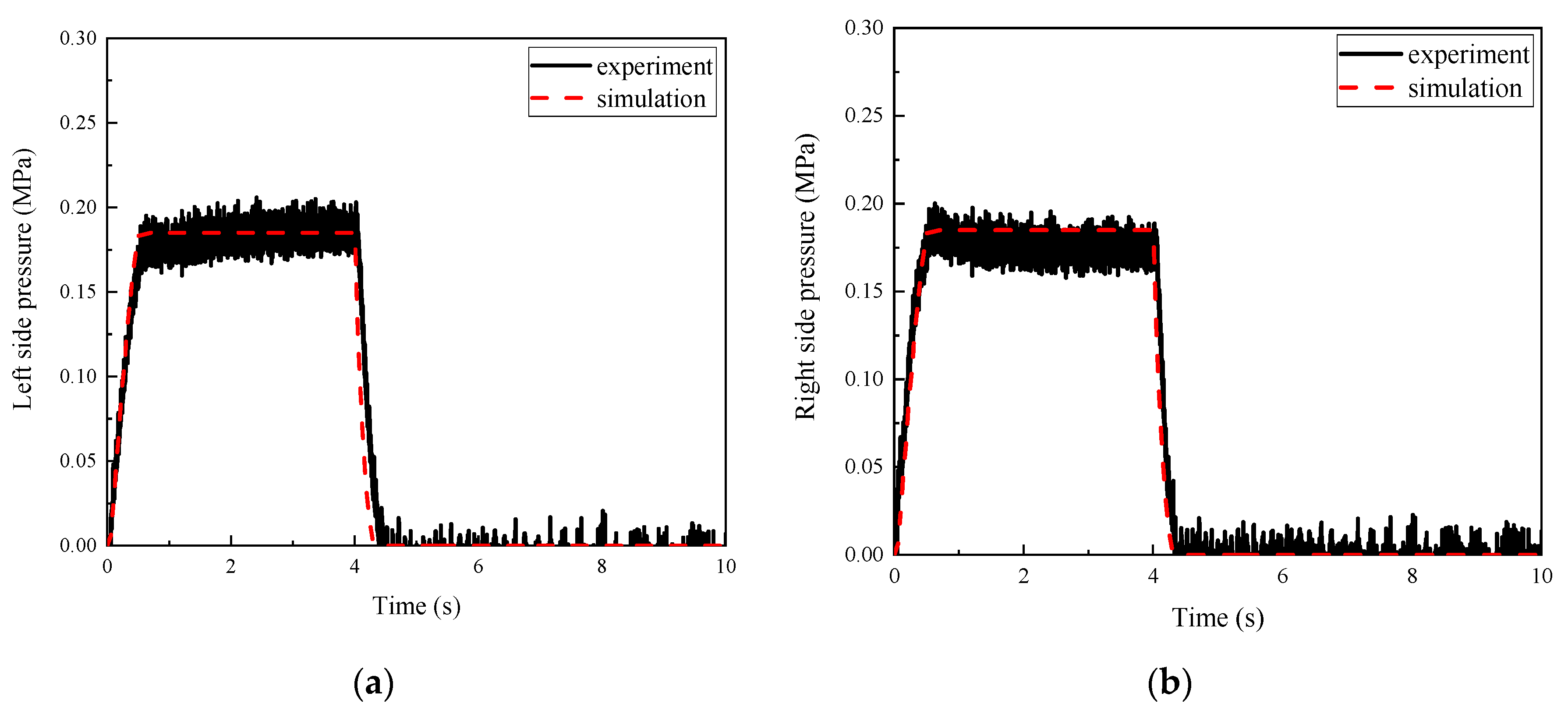

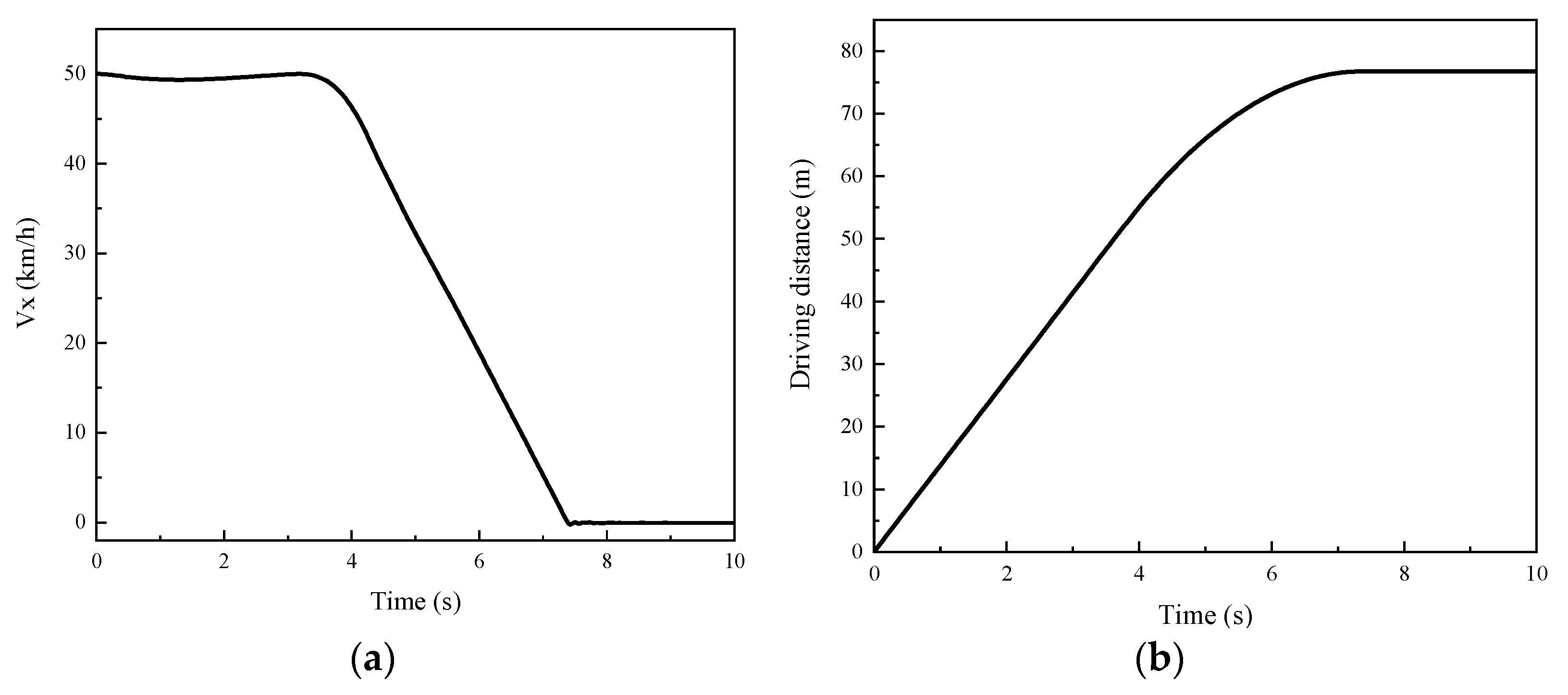

5. Hardware-in-the-Loop Experimental Verification of the Commercial Vehicle EBS Control Algorithm

5.1. Experimental Verification of Brake Force Distribution Control

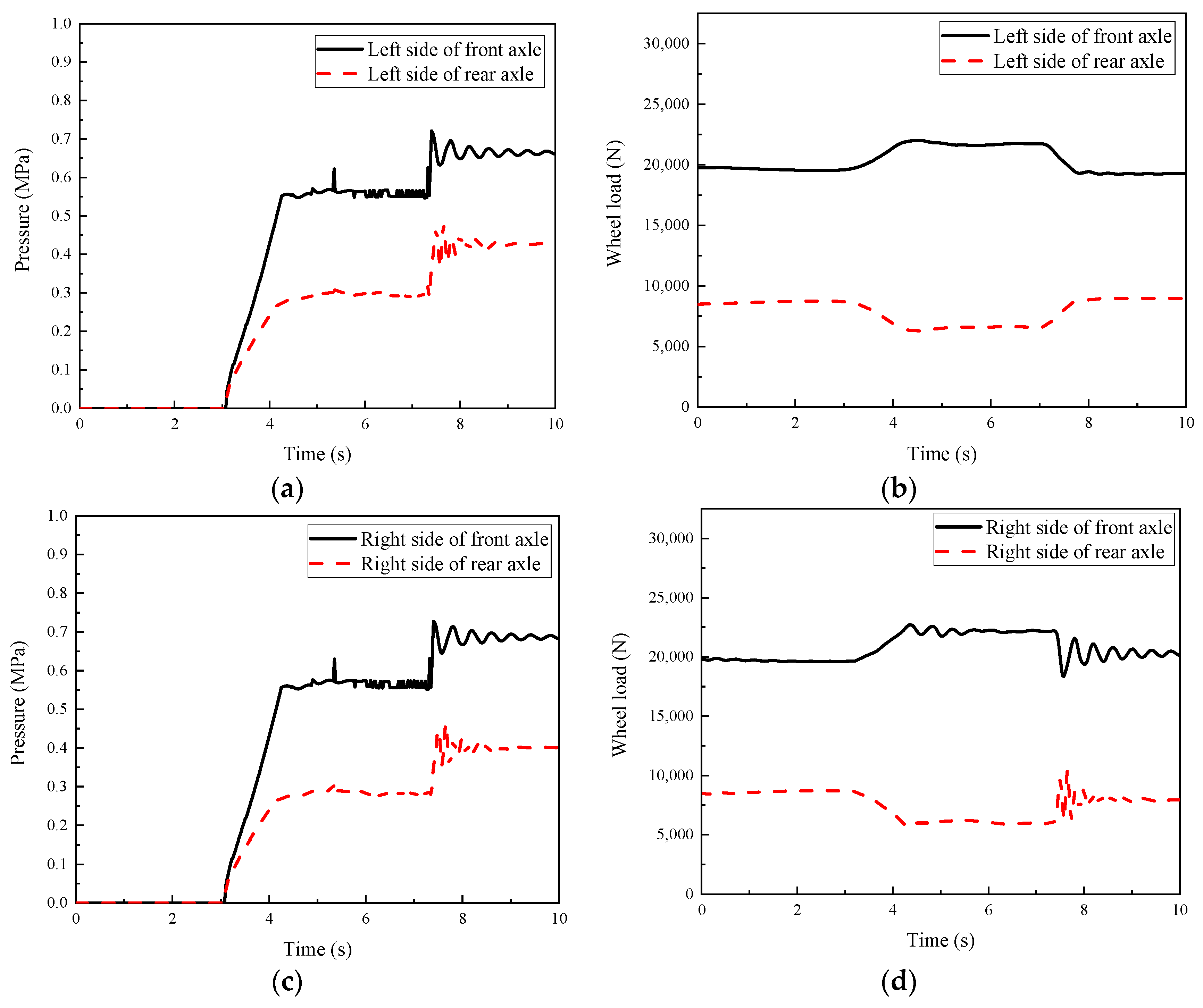

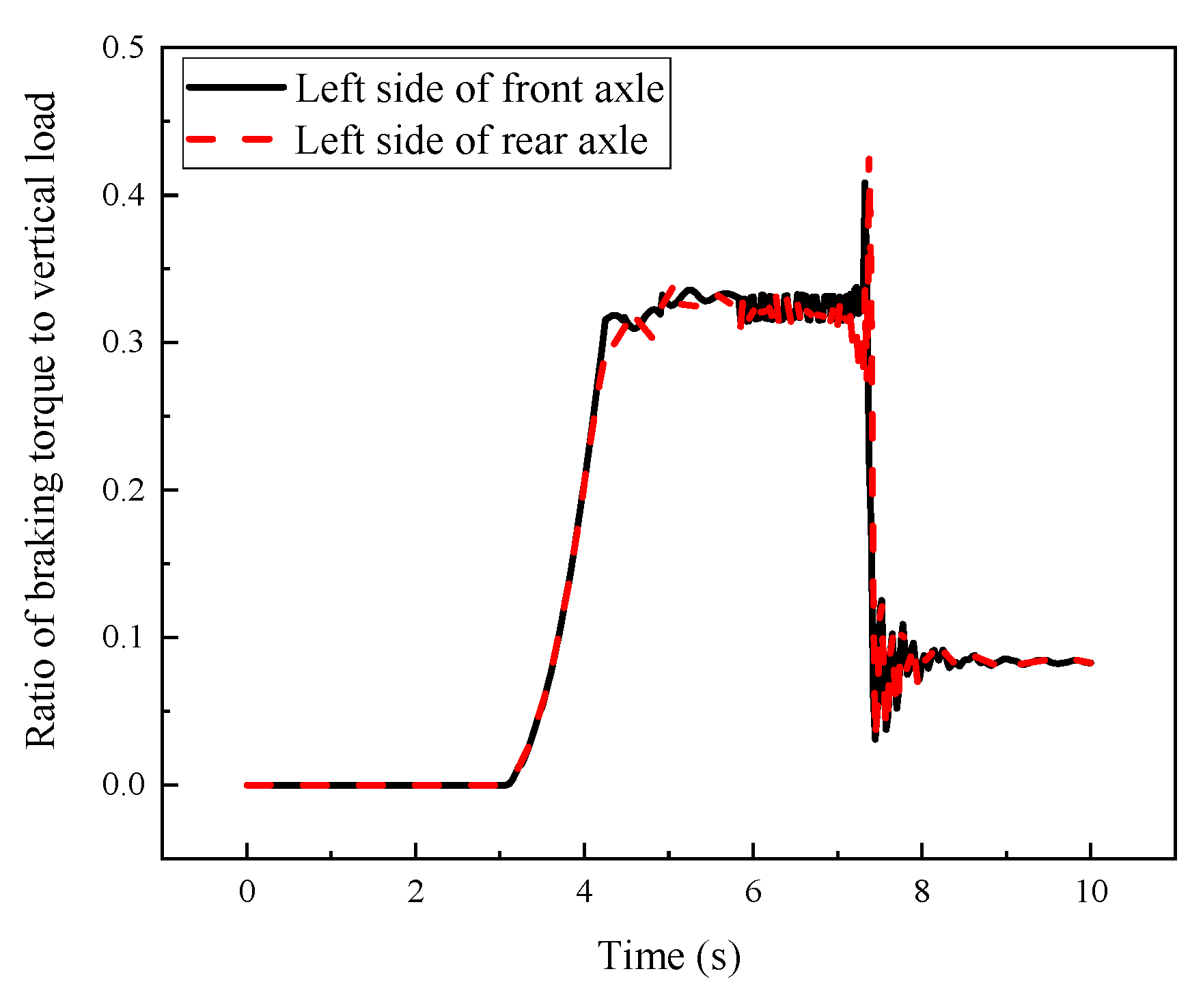

5.1.1. Unloaded Condition

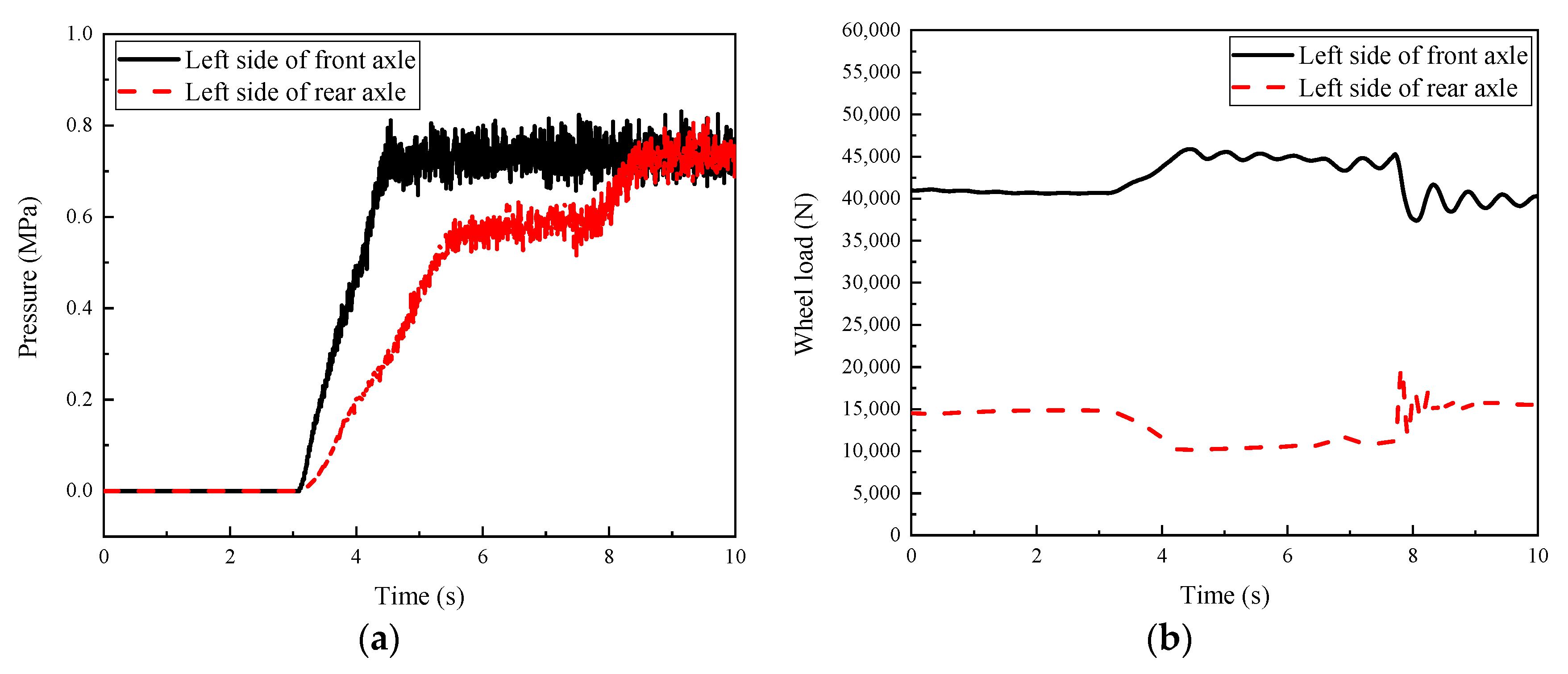

5.1.2. Full-Load Condition

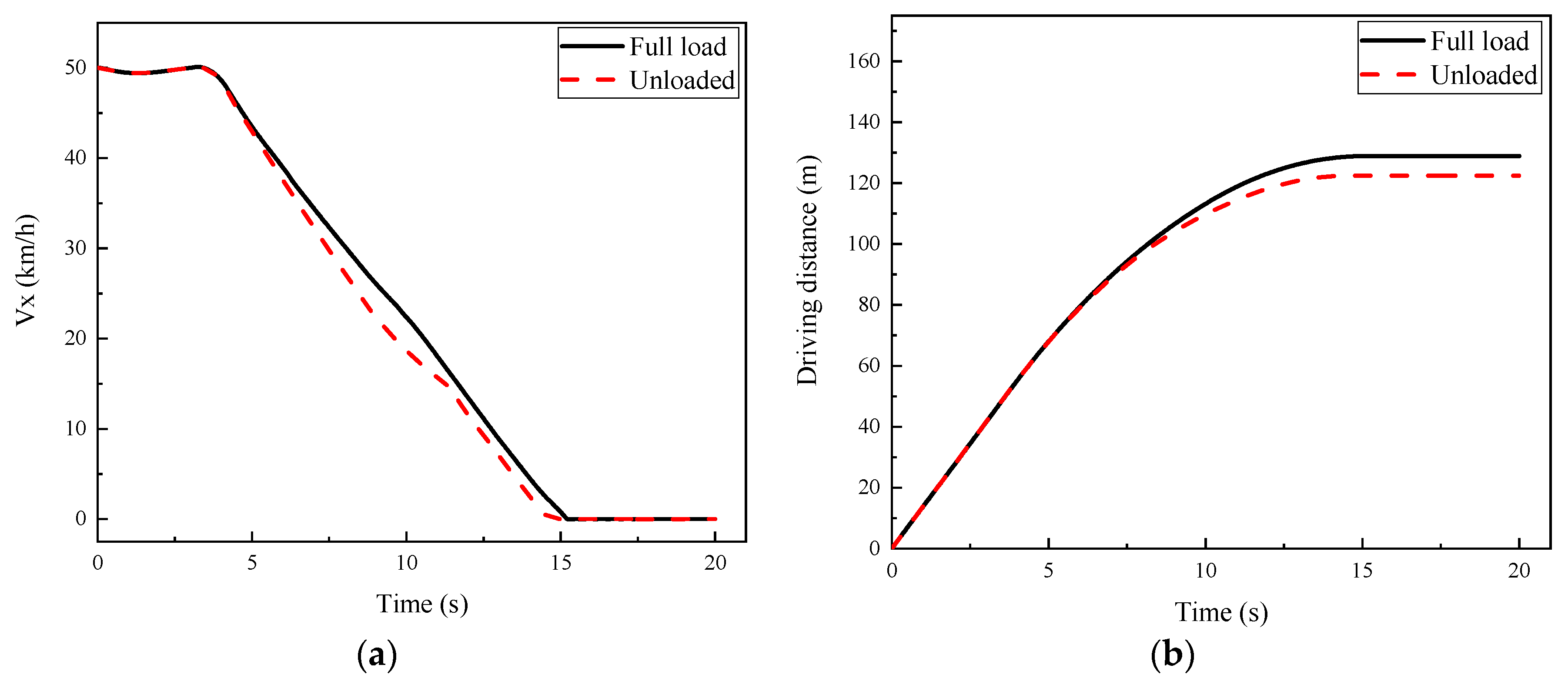

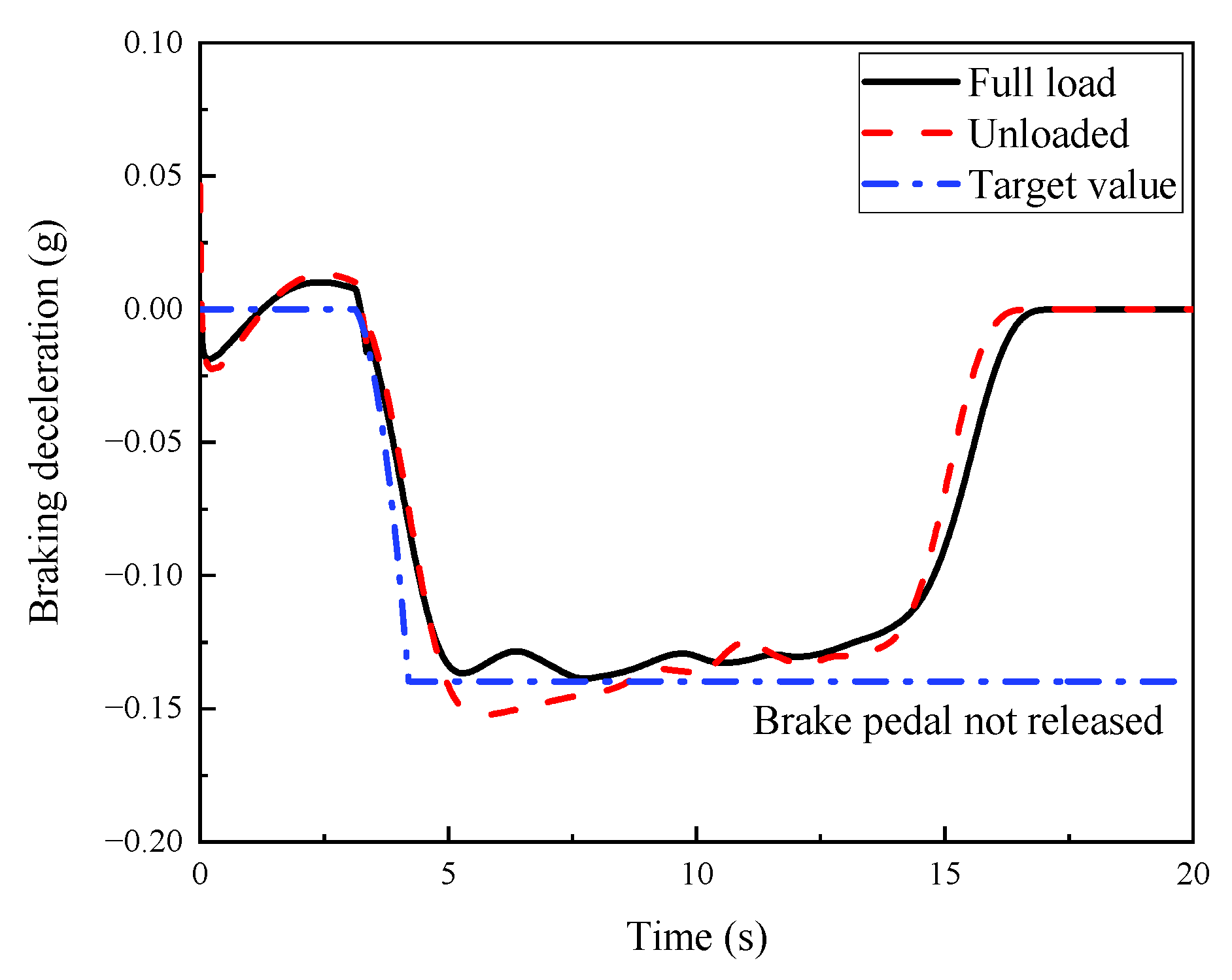

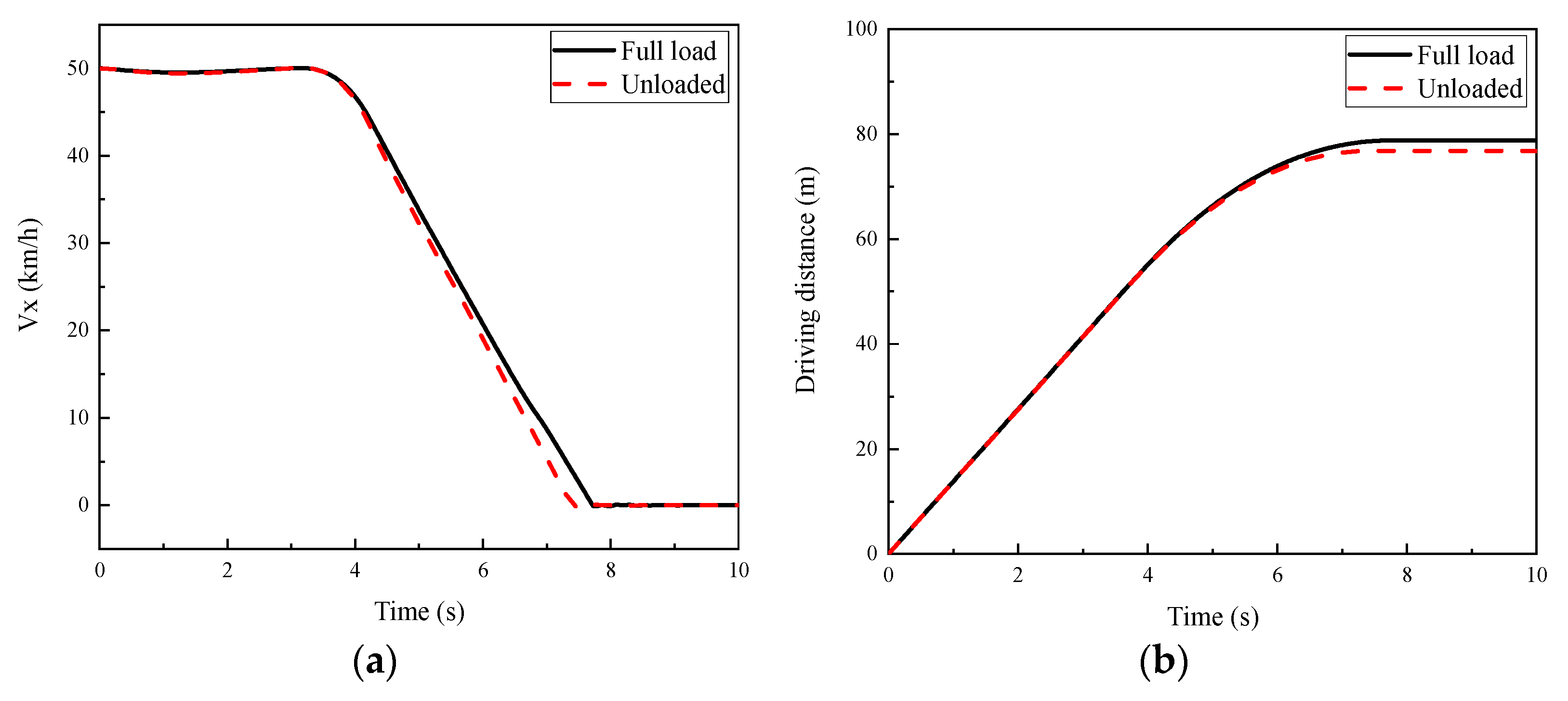

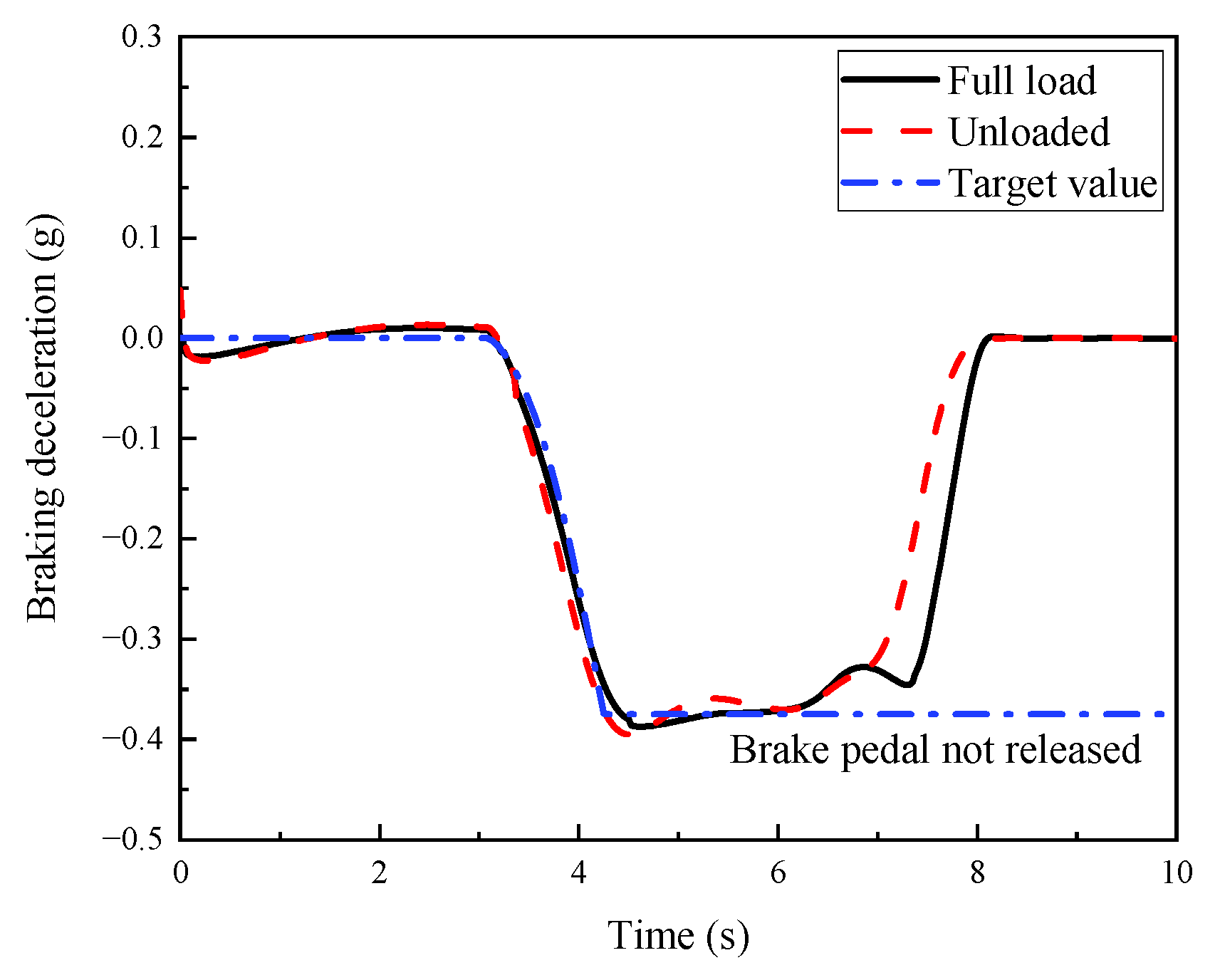

5.2. Experimental Verification of Deceleration Control

5.2.1. Pedal Stroke 30%

5.2.2. Pedal Stroke 50%

6. Conclusions

- (1)

- A commercial vehicle EBS dynamic model was established, including a brake signal sensor, a single-channel bridge control module, an ABS solenoid valve, and a dual-channel bridge control module.

- (2)

- A vertical load estimation algorithm based on UPF was designed, enabling the real-time estimation of wheel vertical load during vehicle operation.

- (3)

- This study developed an algorithm based on the characteristics of the EBS valve in order to quickly and accurately control the valve. And based on a hardware-in-the-loop experimental platform, the above algorithm was analyzed to verify the effectiveness of the control algorithm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.; Wu, X.; Song, Z.; Sun, L.; Wang, X. Practical hybrid model predictive control for electric pneumatic braking system with on-off solenoid valves. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Y.; Wu, X.; Tao, X. Research on accurate modeling and control for pneumatic electric braking system of commercial vehicle based on multi-dynamic parameters measurement. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 803–815. [Google Scholar] [CrossRef]

- Hamada, A.T.; Orhan, M.F. An overview of regenerative braking systems. J. Energy Storage 2022, 52, 105033. [Google Scholar] [CrossRef]

- Shan, T.; Li, L.; Wu, X.; Cheng, S. Pressure control based on reinforcement learning strategy of the pneumatic relays for an elec-tric-pneumatic braking system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 237, 09544070221108855. [Google Scholar]

- Zhang, L.; Yan, Y.; Zhu, Q.; Zhao, G.; Feng, D.; Wu, J. A Pneumatic Control Method for Commercial Vehicle Electronic Brake System Based on EPV Module. Actuators 2022, 11, 316. [Google Scholar] [CrossRef]

- Wu, J.; Kong, Q.; Yang, K.; Liu, Y.; Cao, D.; Li, Z. Research on the steering torque control for intelligent vehicles co-driving with the penalty factor of human–machine intervention. IEEE Trans. Syst. Man Cybern. Syst. 2022, 53, 59–70. [Google Scholar] [CrossRef]

- Yan, Y.; Wu, J.; Liu, X.; Zhao, Y.; Wang, S. A lateral trajectory tracking control method for intelligent commercial vehicles considering active anti-roll decision based on Stackelberg equilibrium. IET Intell. Transp. Syst. 2022, 16, 1193–1208. [Google Scholar] [CrossRef]

- Li, G.; Wei, X.; Wang, Z.; Bao, H. Study on the Pressure Regulation Method of New Automatic Pressure Regulating Valve in the Electronically Controlled Pneumatic Brake Systems in Commercial Vehicles. Sensors 2022, 22, 4599. [Google Scholar] [CrossRef]

- Zhang, R.; Peng, J.; Li, H.; Chen, B.; Liu, W.; Huang, Z.; Wang, J. A predictive control method to improve pressure tracking precision and reduce valve switching for pneumatic brake systems. IET Control. Theory Appl. 2021, 15, 1389–1403. [Google Scholar] [CrossRef]

- Zhao, Q.; Zheng, H.; Kaku, C.; Cheng, F.; Zong, C. Safety spacing control of truck platoon based on emergency braking under different road conditions. SAE Int. J. Veh. Dyn. Stab. NVH 2022, 7, 69–81. [Google Scholar] [CrossRef]

- Bao, H.; Wang, Z.; Liu, Z.; Li, G. Study on Pressure Change Rate of the Automatic Pressure Regulating Valve in the Electronic-Controlled Pneumatic Braking System of Commercial Vehicle. Processes 2021, 9, 938. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Y. Pressure control for pneumatic electric braking system of commercial vehicle based on model predictive control. IET Intell. Transp. Syst. 2021, 15, 1522–1532. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; Wang, X.; Chen, X.; Cheng, S. Nonlinear controller design and testing for chatter suppression in an electric-pneumatic braking system with parametric variation. Mech. Syst. Signal Process. 2020, 135, 106401. [Google Scholar] [CrossRef]

- Yang, Y.; Tang, Q.; Bolin, L.; Fu, C. Dynamic coordinated control for regenerative braking system and anti-lock braking system for electrified vehicles under emergency braking conditions. IEEE Access 2020, 8, 172664–172677. [Google Scholar] [CrossRef]

- Leng, B.; Xiong, L.; Yu, Z.; Sun, K.; Liu, M. Robust variable structure anti-slip control method of a distributed drive electric vehicle. IEEE Access 2020, 8, 162196–162208. [Google Scholar] [CrossRef]

- Han, W.; Xiong, L.; Yu, Z. Interconnected pressure estimation and double closed-loop cascade control for an integrated electro-hydraulic brake system. IEEE/ASME Trans. Mechatron. 2020, 25, 2460–2471. [Google Scholar] [CrossRef]

- Xu, C.; Zhao, W.; Li, L.; Chen, Q.; Kuang, D.; Zhou, J. A nash Q-learning based motion decision algorithm with considering interaction to traffic partici-pants. IEEE Trans. Veh. Technol. 2020, 69, 12621–12634. [Google Scholar] [CrossRef]

- Zheng, H.; Ma, S.; Fang, L.; Zhao, W.; Zhu, T. Braking intention recognition algorithm based on electronic braking system in commercial ve-hicles. Int. J. Heavy Veh. Syst. 2019, 26, 268–290. [Google Scholar] [CrossRef]

- Mishra, P.; Kumar, V.; Rana, K. An online tuned novel nonlinear PI controller for stiction compensation in pneumatic control valves. ISA Trans. 2015, 58, 434–445. [Google Scholar] [CrossRef]

- Meng, F.; Zhang, H.; Cao, D.; Chen, H. System modeling, coupling analysis, and experimental validation of a proportional pressure valve with pulsewidth modulation control. IEEE/ASME Trans. Mechatron. 2015, 21, 1742–1753. [Google Scholar] [CrossRef]

- Guo, J.; Li, W.; Wang, J.; Luo, Y.; Li, K. Safe and energy-efficient car-following control strategy for intelligent electric vehicles considering regenerative braking. IEEE Trans. Intell. Transp. Syst. 2021, 23, 7070–7081. [Google Scholar] [CrossRef]

- Santini, S.; Albarella, N.; Arricale, V.M.; Brancati, R.; Sakhnevych, A. On-board road friction estimation technique for autonomous driving vehi-cle-following maneuvers. Appl. Sci. 2021, 11, 2197. [Google Scholar] [CrossRef]

- Hellgren, J.; Jonasson, E. Maximisation of brake energy regeneration in a hybrid electric parallel car. Int. J. Electr. Hybrid Veh. 2007, 1, 95. [Google Scholar] [CrossRef]

- Mosconi, L.; Farroni, F.; Sakhnevych, A.; Timpone, F.; Gerbino, F.S. Adaptive vehicle dynamics state estimator for onboard automotive applications and performance analysis. Veh. Syst. Dyn. 2022, 1–25. [Google Scholar] [CrossRef]

- Chu, W.; Luo, Y.; Dai, Y.; Li, K. In–wheel motor electric vehicle state estimation by using unscented particle filter. Int. J. Veh. Des. 2015, 67, 115–136. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, Y.; Xie, W.; Zhao, Q.; Lin, F. Hierarchical estimation of vehicle state and tire forces for distributed in-wheel motor drive electric vehicle without previously established tire model. J. Frankl. Inst. 2022, 359, 7051–7068. [Google Scholar] [CrossRef]

- Lui, D.G.; Tartaglione, G.; Conti, F.; De Tommasi, G.; Santini, S. Long Short-Term Memory-Based Neural Networks for Missile Maneuvers Trajectories Prediction⋆. IEEE Access 2023, 11, 30819–30831. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Zhang, Y.; Hu, Z.; Sun, Q.; Lu, B. An enhanced adaptive unscented kalman filter for vehicle state estimation. IEEE Trans. Instrum. Meas. 2022, 71, 6502412. [Google Scholar] [CrossRef]

- Liu, H.; Wang, P.; Lin, J.; Ding, H.; Chen, H.; Xu, F. Real-time longitudinal and lateral state estimation of preceding vehicle based on moving horizon estimation. IEEE Trans. Veh. Technol. 2021, 70, 8755–8768. [Google Scholar] [CrossRef]

| (a) | |||

| Symbol | Meaning | ||

| the left wheel angle of the front axle | |||

| the right wheel angle of the front axle | |||

| the left wheel angle of the rear axle | |||

| the right wheel angle of the rear axle | |||

| the longitudinal forces on the left wheel of the front axle | |||

| the longitudinal forces on the right wheel of the front axle | |||

| the longitudinal forces on the right wheel of the rear axle | |||

| the longitudinal forces on the right wheel of the rear axle | |||

| the lateral forces on the left wheel of the front axle | |||

| the lateral forces on the right wheel of the front axle | |||

| the lateral forces on the left wheel of the rear axle | |||

| the lateral forces on the right wheel of the rear axle | |||

| the longitudinal component forces on the left wheel of the front axle | |||

| the longitudinal component forces on the right wheel of the front axle | |||

| the longitudinal component forces on the left wheel of the rear axle | |||

| the longitudinal component forces on the right wheel of the rear axle | |||

| the lateral component forces on the left wheel of the front axle | |||

| the lateral component forces on the right wheel of the front axle | |||

| the lateral component forces on the left wheel of the rear axle | |||

| the lateral component forces on the right wheel of the rear axle | |||

| the air density | |||

| the wind resistance coefficient | |||

| the contact area | |||

| the longitudinal speed of the vehicle | |||

| the vertical load of the left wheels on the front axle | |||

| the vertical load of the right wheels on the front axle | |||

| the vertical load of the left wheels on the rear axle | |||

| the vertical load of the right wheels on the rear axle | |||

| the front wheelbase of the vehicle | |||

| the rear wheelbase of the vehicle | |||

| the spring-loaded mass | |||

| the height from the center of the sprung mass to the ground | |||

| (b) | |||

| Parameter | Value | Unit | |

| Unloaded sprung mass | 4450 | kg | |

| Fully loaded sprung mass | 10,000 | kg | |

| Centroid height | 1.175 | m | |

| Tread | 2.03 | m | |

| Wheel radius | 510 | mm | |

| 1.2258 | N × s2 × m−4 | ||

| 0.3 | / | ||

| 7.125 | m2 | ||

| Boost Valve | Pressure-Reducing Valve | Backup Valve | |

|---|---|---|---|

| Boosting | power on | power outage | power on |

| Reduce pressure | power outage | power on | power on |

| Maintaining pressure | power outage | power outage | power on |

| Intake Valve | Exhaust Valve | |

|---|---|---|

| Boosting | power outage | power outage |

| Reduce pressure | power on | power on |

| Maintaining pressure | power on | power outage |

| Boost Valve | Pressure-Reducing Valve | Backup Valve | |

|---|---|---|---|

| Boosting | power on | power outage | power on |

| Reduce pressure | power outage | power on | power on |

| Maintaining pressure | power outage | power outage | power on |

| Boost Valve | Pressure-Reducing Valve | Backup Valve | |

|---|---|---|---|

| Boosting | power on | power outage | power on |

| Reduce pressure | power outage | power on | power on |

| Maintaining pressure | power outage | power outage | power on |

| Boost Valve | Pressure-Reducing Valve | Backup Valve | |

|---|---|---|---|

| Quick boost | 100% | 0% | 100% |

| Slow boost | 50% | 0% | 100% |

| Maintain pressure | 0% | 0% | 100% |

| Slowly reduce pressure | 0% | 50% | 100% |

| Quickly reduce pressure | 0% | 100% | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.; Xin, Y.; He, Y.; Jiang, T.; Liu, X.; Jin, L. A Modeling and Control Algorithm for a Commercial Vehicle Electronic Brake System Based on Vertical Load Estimation. Actuators 2023, 12, 376. https://doi.org/10.3390/act12100376

Zheng H, Xin Y, He Y, Jiang T, Liu X, Jin L. A Modeling and Control Algorithm for a Commercial Vehicle Electronic Brake System Based on Vertical Load Estimation. Actuators. 2023; 12(10):376. https://doi.org/10.3390/act12100376

Chicago/Turabian StyleZheng, Hongyu, Yafei Xin, Yutai He, Tong Jiang, Xiangzheng Liu, and Liqiang Jin. 2023. "A Modeling and Control Algorithm for a Commercial Vehicle Electronic Brake System Based on Vertical Load Estimation" Actuators 12, no. 10: 376. https://doi.org/10.3390/act12100376

APA StyleZheng, H., Xin, Y., He, Y., Jiang, T., Liu, X., & Jin, L. (2023). A Modeling and Control Algorithm for a Commercial Vehicle Electronic Brake System Based on Vertical Load Estimation. Actuators, 12(10), 376. https://doi.org/10.3390/act12100376