Switching Model Predictive Control for Thin McKibben Muscle Servo Actuator

Abstract

:1. Introduction

2. Materials and Methods

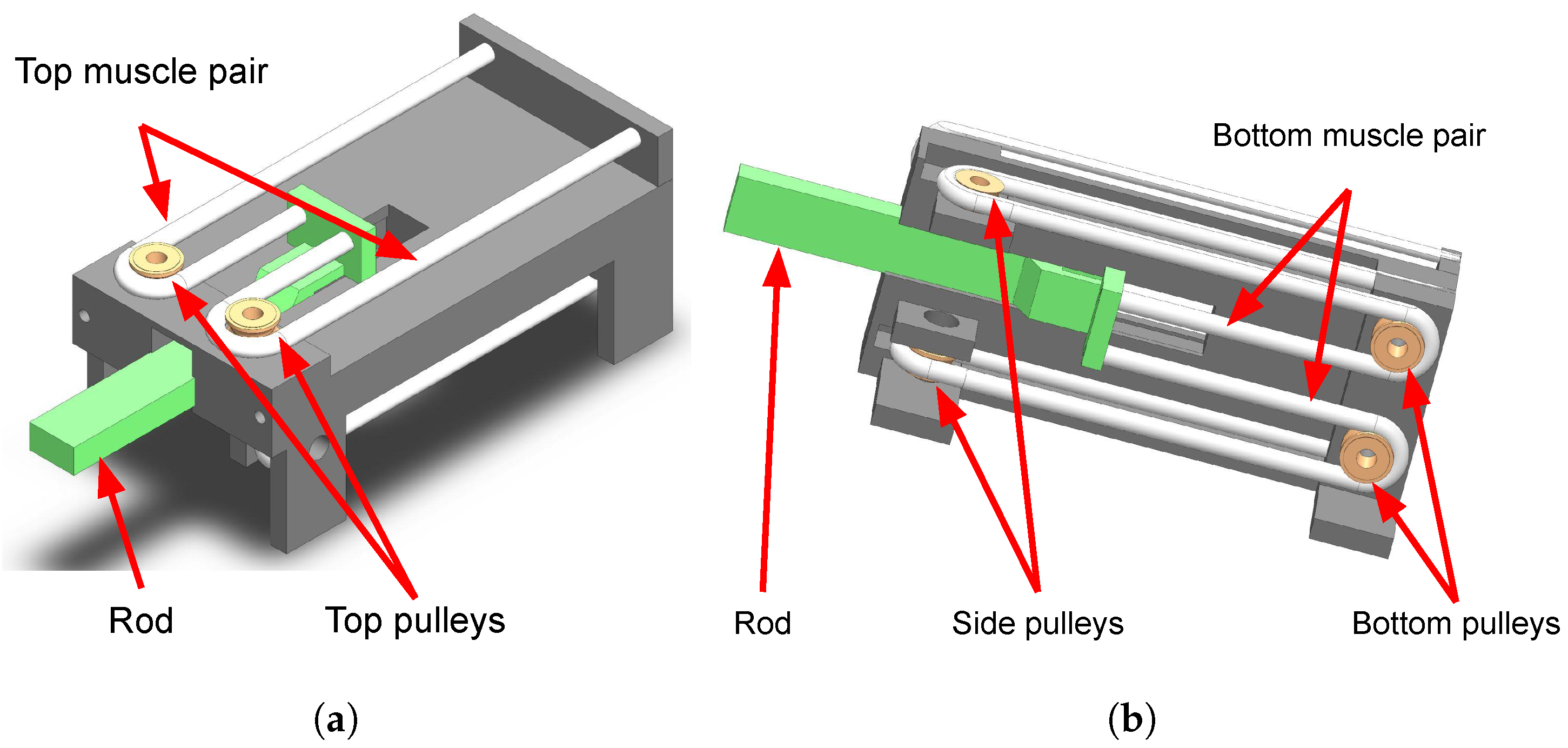

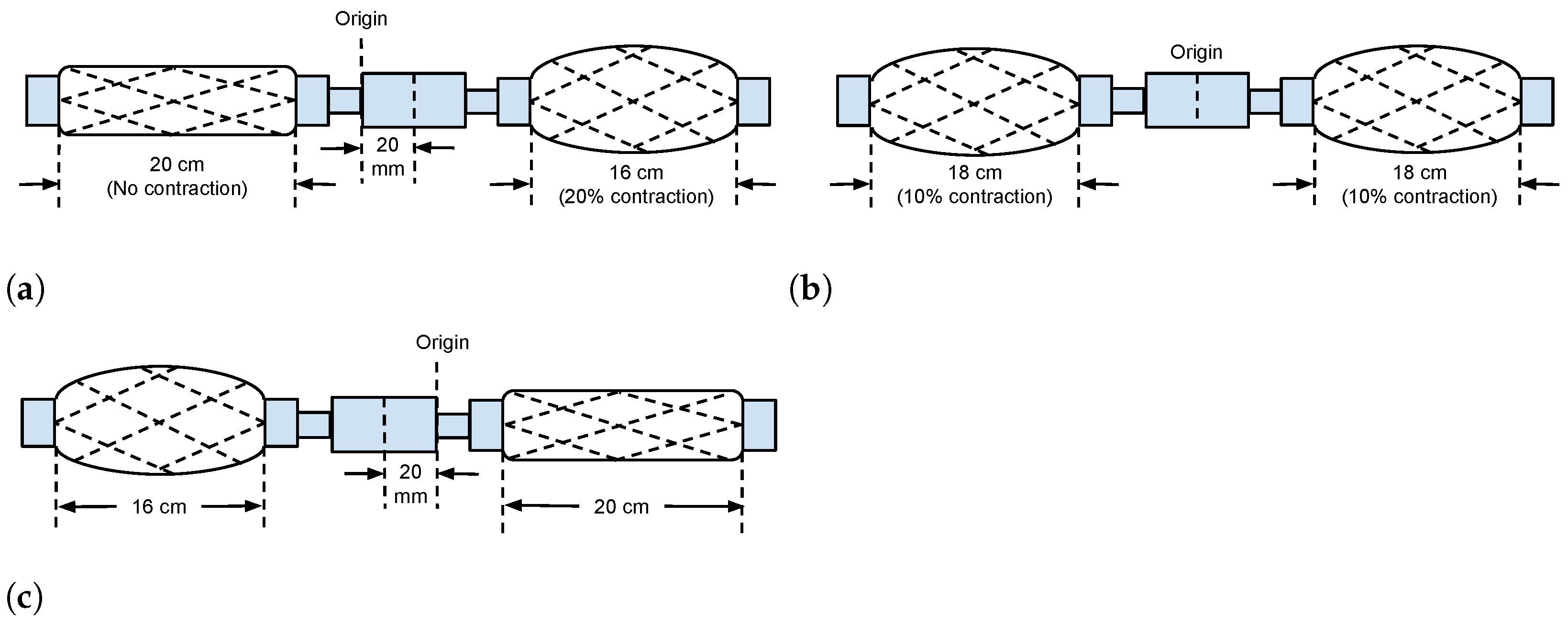

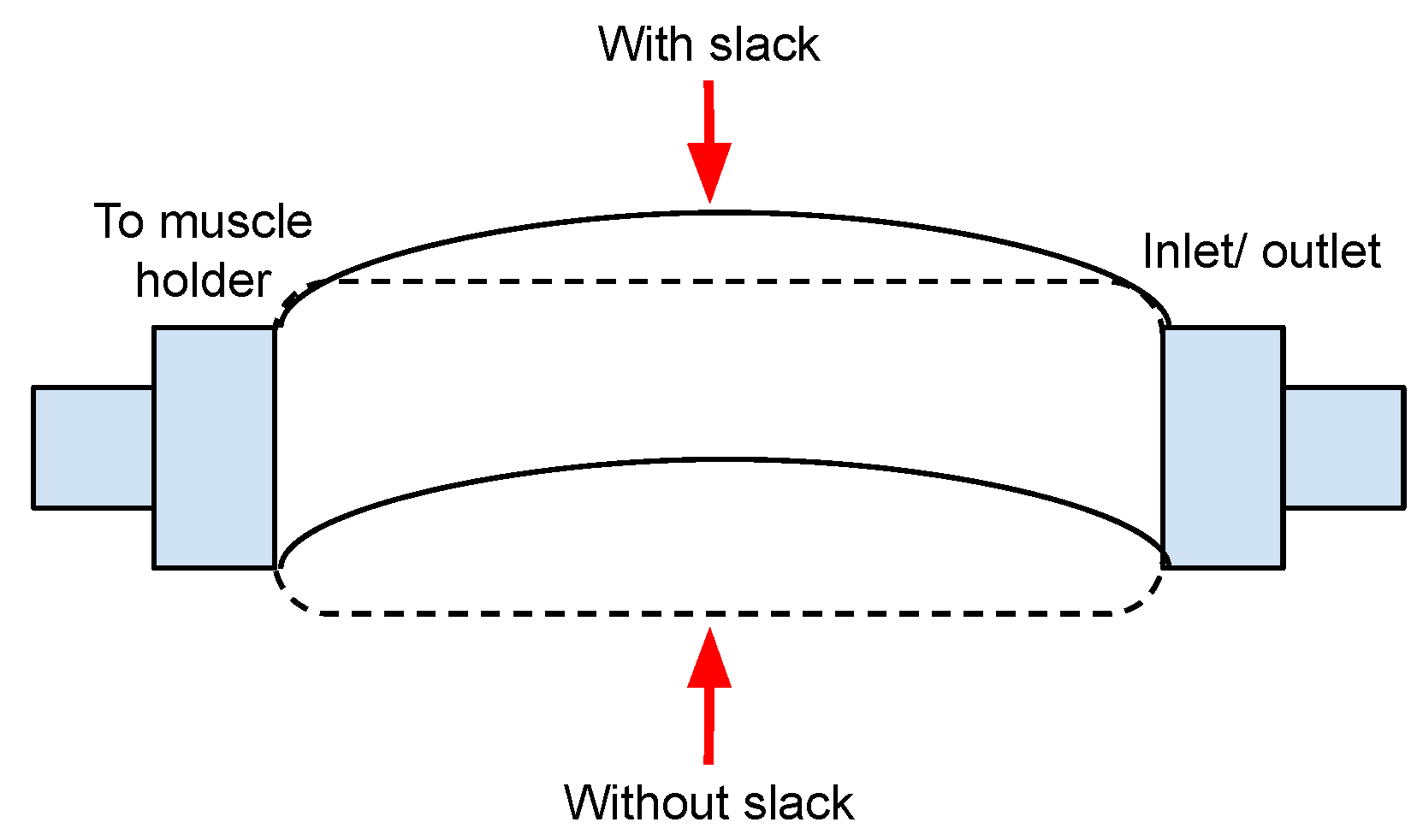

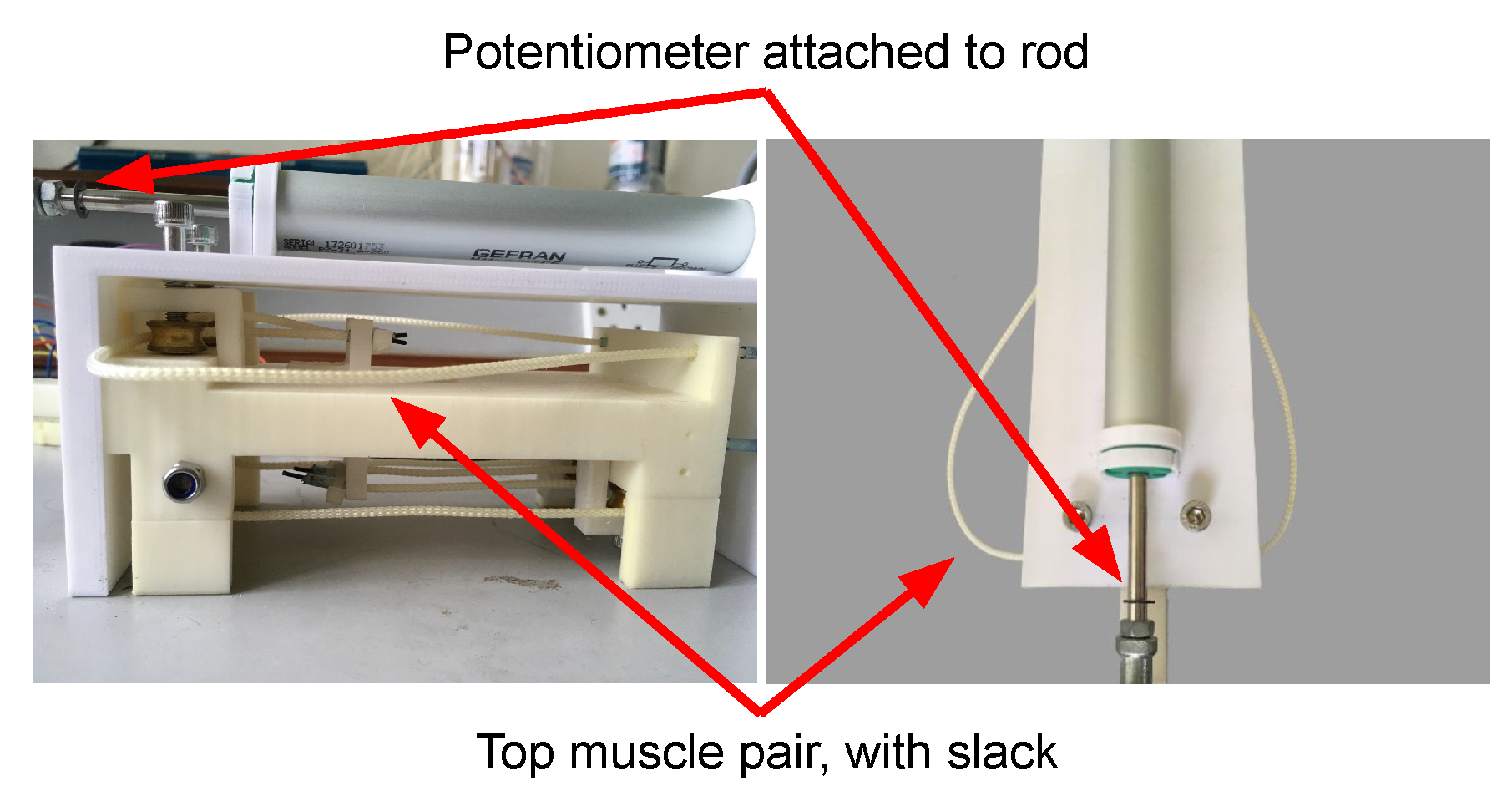

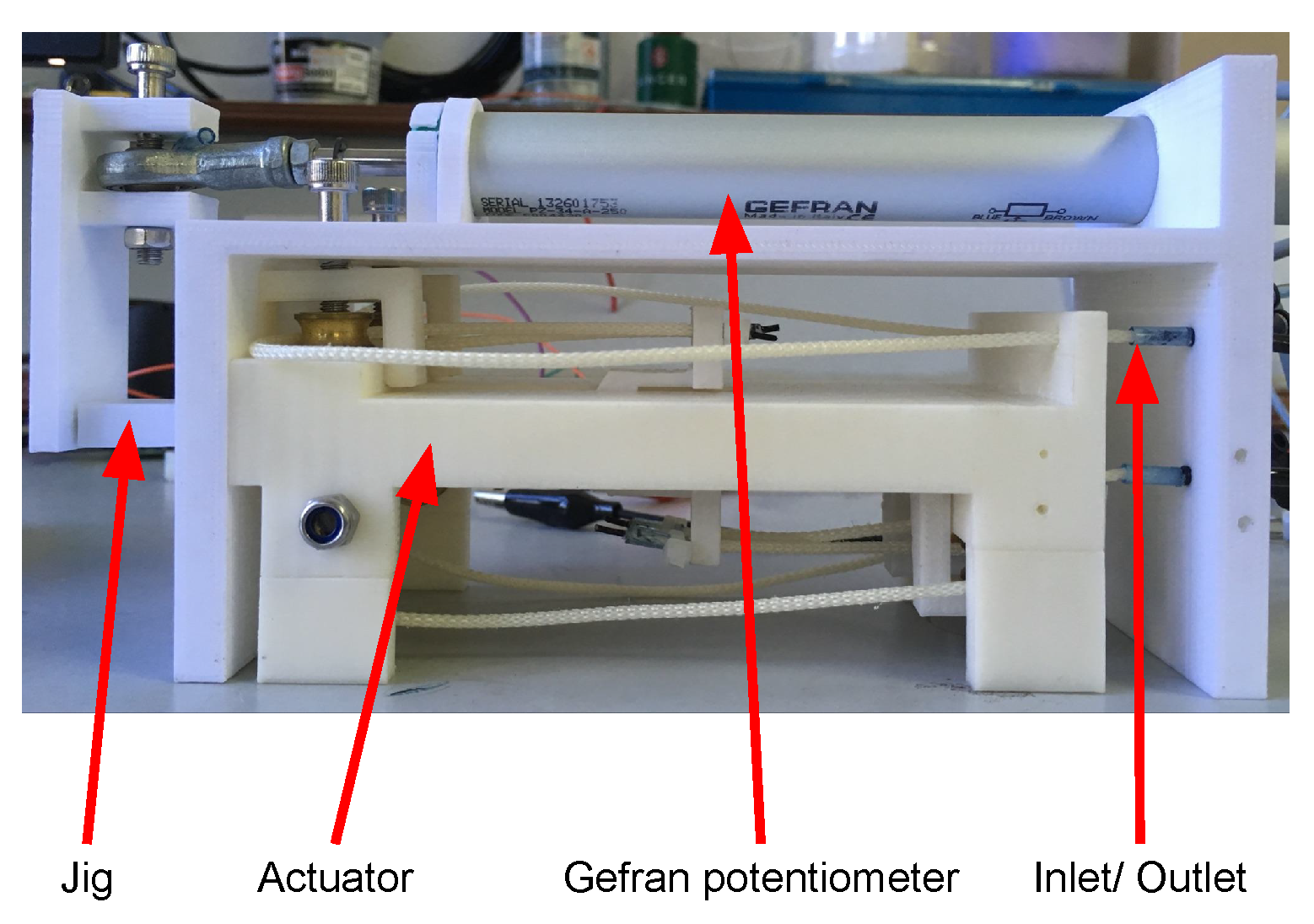

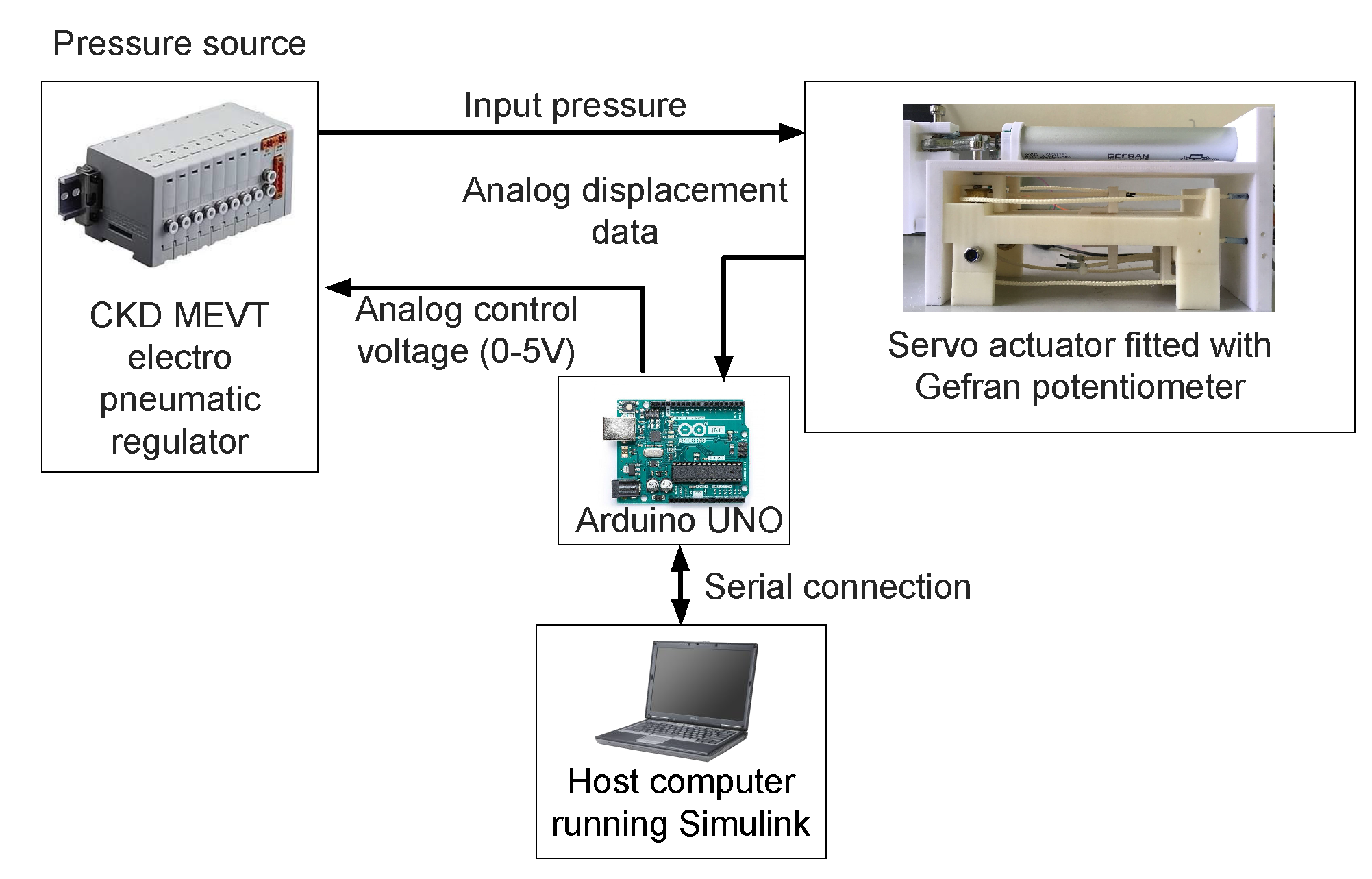

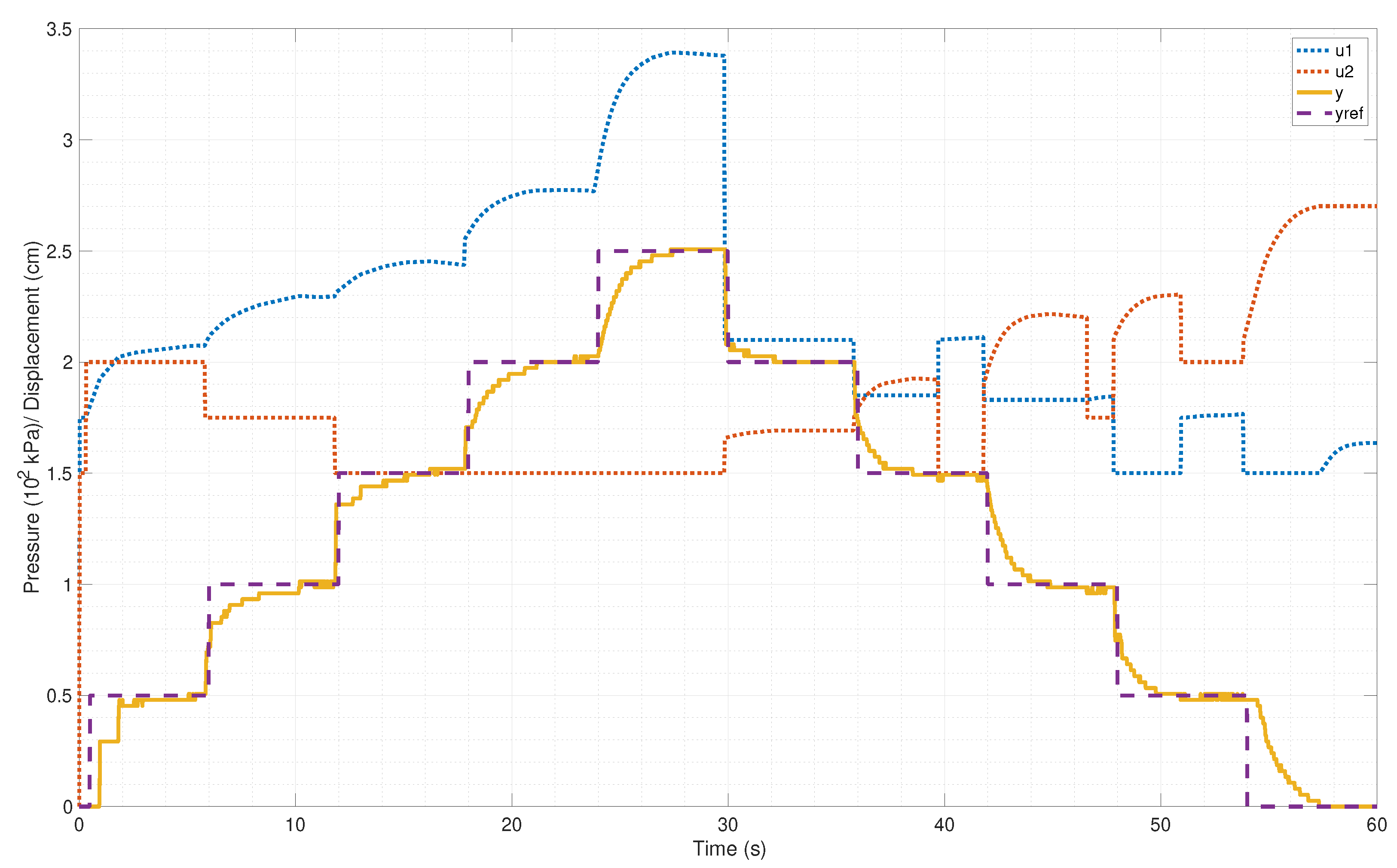

2.1. TMM Servo Actuator and Its PWA Model

2.2. Tracking MPC

2.3. Experiment Setup

2.4. Stability of Finite Horizon Optimal Controller

2.5. Stability of SMPC

2.6. Gain-Scheduled Proportional-Integral-Derivative

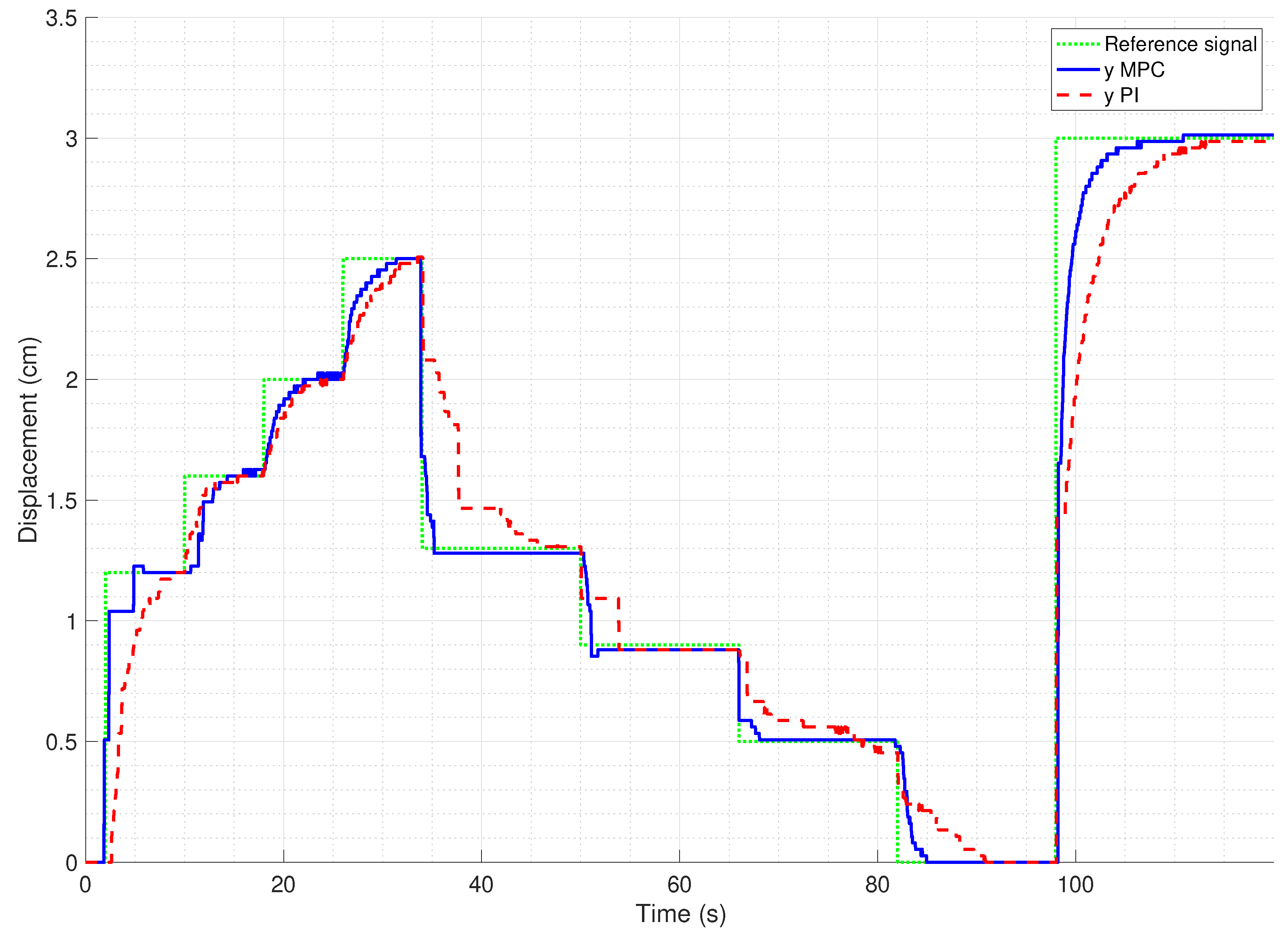

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| GSPID | Gain-scheduled Proportional–Integral–Derivative |

| MM | McKibben muscle |

| MPC | Model Predictive Control |

| NN | Neural network |

| PAM | Pneumatic artificial muscle |

| PID | Proportional–Integral–Derivative |

| PMA | Pneumatic muscle actuator |

| PWA | Piecewise Affine |

| SMPC | Switching Model Predictive Control |

| TMM | Thin McKibben muscle |

References

- Mao, Z.; Iizuka, T.; Maeda, S. Bidirectional Electrohydrodynamic Pump with High Symmetrical Performance and Its Application to a Tube Actuator. Sens. Actuat. A Phys. 2021, 332, 113168. [Google Scholar] [CrossRef]

- Faudzi, A.A.; Azmi, N.I.; Sayahkarajy, M.; Xuan, W.L.; Suzumori, K. Soft Manipulator Using Thin McKibben Actuator. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; pp. 334–339. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, Y.; Yang, Y.; Liu, N.; Sun, Y.; Liu, Y.; Pu, H.; Xie, S.; Luo, J. Development of Continuum Manipulator Actuated by Thin McKibben Pneumatic Artificial Muscle. Mechatronics 2019, 60, 56–65. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Peng, Y.; Zhong, S.; Liu, N.; Pu, H. A Light Soft Manipulator With Continuously Controllable Stiffness Actuated by a Thin McKibben Pneumatic Artificial Muscle. IEEE Asme Trans. Mechatronics 2020, 25, 1944–1952. [Google Scholar] [CrossRef]

- Mohamed, M.F.; Hanif, A.S.M.; Faudzi, A.A. Segmentation of a Soft Body and Its Bending Performance Using Thin McKibben Muscle. Int. J. Automot. Mech. Eng. 2020, 17, 7533–7541. [Google Scholar] [CrossRef]

- Wang, S.; Sato, K. High-Precision Motion Control of a Stage with Pneumatic Artificial Muscles. Precis. Eng. 2016, 43, 448–461. [Google Scholar] [CrossRef]

- Shen, X. Nonlinear Model-Based Control of Pneumatic Artificial Muscle Servo Systems. Control Eng. Pract. 2010, 18, 311–317. [Google Scholar] [CrossRef]

- Abd. Rahman, R.; Sepehri, N. Design and Experimental Evaluation of a Dynamical Adaptive Backstepping-Sliding Mode Control Scheme for Positioning of an Antagonistically Paired Pneumatic Artificial Muscles Driven Actuating System. Int. J. Control 2017, 90, 265–290. [Google Scholar] [CrossRef]

- Dao, Q.T.; Nguyen, M.L.; Yamamoto, S.i. Discrete-Time Fractional Order Integral Sliding Mode Control of an Antagonistic Actuator Driven by Pneumatic Artificial Muscles. Appl. Sci. 2019, 9, 2503. [Google Scholar] [CrossRef]

- Ohta, P.; Valle, L.; King, J.; Low, K.; Yi, J.; Atkeson, C.G.; Park, Y.L. Design of a Lightweight Soft Robotic Arm Using Pneumatic Artificial Muscles and Inflatable Sleeves. Soft Robot. 2018, 5, 204–215. [Google Scholar] [CrossRef] [PubMed]

- Jiang, F.; Tao, G.; Li, Q. Analysis and Control of a Parallel Lower Limb Based on Pneumatic Artificial Muscles. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Son, N.N.; Kien, C.V.; Anh, H.P.H. A Novel Adaptive Feed-Forward-PID Controller of a SCARA Parallel Robot Using Pneumatic Artificial Muscle Actuator Based on Neural Network and Modified Differential Evolution Algorithm. Robot. Auton. Syst. 2017, 96, 65–80. [Google Scholar] [CrossRef]

- Ugurlu, B.; Forni, P.; Doppmann, C.; Sariyildiz, E.; Morimoto, J. Stable Control of Force, Position, and Stiffness for Robot Joints Powered via Pneumatic Muscles. IEEE Trans. Ind. Inform. 2019, 15, 6270–6279. [Google Scholar] [CrossRef]

- Anh, H.P.H. Online Tuning Gain Scheduling MIMO Neural PID Control of the 2-Axes Pneumatic Artificial Muscle (PAM) Robot Arm. Exp. Syst. Appl. 2010, 37, 6547–6560. [Google Scholar] [CrossRef]

- Zhong, J.; Zhou, X.; Luo, M. A New Approach to Modeling and Controlling a Pneumatic Muscle Actuator-Driven Setup Using Back Propagation Neural Networks. Complexity 2018, 2018, 4160504. [Google Scholar] [CrossRef]

- Anh, H.P.H.; Son, N.N.; Nam, N.T. Adaptive Evolutionary Neural Control of Perturbed Nonlinear Serial PAM Robot. Neurocomputing 2017, 267, 525–544. [Google Scholar] [CrossRef]

- Al-Ibadi, A.; Nefti-Meziani, S.; Davis, S.; Theodoridis, T. Novel Design and Position Control Strategy of a Soft Robot Arm. Robotics 2018, 7, 72. [Google Scholar] [CrossRef]

- Yager, R.R.; Zadeh, L.A. An Introduction to Fuzzy Logic Applications in Intelligent Systems; Springer: New York, USA, 2012; Volume 165. [Google Scholar]

- Leephakpreeda, T. Fuzzy Logic Based PWM Control and Neural Controlled-Variable Estimation of Pneumatic Artificial Muscle Actuators. Exp. Syst. Appl. 2011, 38, 7837–7850. [Google Scholar] [CrossRef]

- Anh, H.P.H.; Ahn, K.K. Hybrid Control of a Pneumatic Artificial Muscle (PAM) Robot Arm Using an Inverse NARX Fuzzy Model. Eng. Appl. Artif. Intell. 2011, 24, 697–716. [Google Scholar] [CrossRef]

- Chandrapal, M.; Chen, X.; Wang, W.; Hann, C. Nonparametric Control Algorithms for a Pneumatic Artificial Muscle. Exp. Syst. Appl. 2012, 39, 8636–8644. [Google Scholar] [CrossRef]

- Feng, Y.; Ide, T.; Nabae, H.; Endo, G.; Sakurai, R.; Ohno, S.; Suzumori, K. Experimental Comparison of Antagonistic Hydraulic Muscle Actuation under Single/Dual and Zero/Overlapped Servovalve Configurations. Mechatronics 2022, 83, 102737. [Google Scholar] [CrossRef]

- Mohd Faudzi, A.A.; Ooga, J.; Goto, T.; Takeichi, M.; Suzumori, K. Index Finger of a Human-Like Robotic Hand Using Thin Soft Muscles. IEEE Robot. Autom. Lett. 2018, 3, 92–99. [Google Scholar] [CrossRef]

- Mohd Faudzi, A.A.; Endo, G.; Kurumaya, S.; Suzumori, K. Long-Legged Hexapod Giacometti Robot Using Thin Soft McKibben Actuator. IEEE Robot. Autom. Lett. 2018, 3, 100–107. [Google Scholar] [CrossRef]

- Woods, B.K.S.; Choi, Y.T.; Kothera, C.S.; Wereley, N.M. Control System Development for Pneumatic Artificial Muscle-Driven Active Rotor Systems. J. Guid. Control Dyn. 2013, 36, 1177–1185. [Google Scholar] [CrossRef]

- Al-Fahaam, H.; Nefti-Meziani, S.; Theodoridis, T.; Davis, S. The Design and Mathematical Model of a Novel Variable Stiffness Extensor-Contractor Pneumatic Artificial Muscle. Soft Robot. 2018, 5, 576–591. [Google Scholar] [CrossRef] [PubMed]

- Andrikopoulos, G.; Nikolakopoulos, G.; Manesis, S. Pneumatic Artificial Muscles: A Switching Model Predictive Control Approach. Control Eng. Pract. 2013, 21, 1653–1664. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Nikolakopoulos, G.; Manesis, S. Advanced Nonlinear PID-based Antagonistic Control for Pneumatic Muscle Actuators. IEEE Trans. Ind. Electron. 2014, 61, 6926–6937. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, X.; Wang, T. Observer-Based Nonlinear Decoupling Control for Two-Joint Manipulator Systems Driven by Pneumatic Artificial Muscles. J. Dyn. Syst. Meas. Control Trans. ASME 2020, 142, 041001. [Google Scholar] [CrossRef]

- Schindele, D.; Aschemann, H. Nonlinear Model Predictive Control of a High-Speed Linear Axis Driven by Pneumatic Muscles. In Proceedings of the 2008 American Control Conference, Seattle, WA, USA, 11–13 June 2008; pp. 3017–3022. [Google Scholar]

- Andrikopoulos, G.; Nikolakopoulos, G.; Arvanitakis, I.; Manesis, S. Switching Model Predictive Control of a Pneumatic Artificial Muscle. Int. J. Control Autom. Syst. 2013, 11, 1223–1231. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Nikolakopoulos, G.; Arvanitakis, I.; Manesis, S. Piecewise Affine Modeling and Constrained Optimal Control for a Pneumatic Artificial Muscle. IEEE Trans. Ind. Electron. 2014, 61, 904–916. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Nikolakopoulos, G.; Manesis, S. Adaptive Internal Model Control Scheme for a Pneumatic Artificial Muscle. In Proceedings of the 2013 European Control Conference, Zurich, Switzerland, 17–19 July 2013; pp. 772–777. [Google Scholar]

- Andrikopoulos, G.; Nikolakopoulos, G.; Manesis, S. Non-Linear Control of Pneumatic Artificial Muscles. In Proceedings of the 2013 21st Mediterranean Conference on Control and Automation, Crete, Greece, 25–28 June 2013; Antsaklis, P., Valavanis, K., Tsourveloudis, N., Zingaretti, P., Moreno, L., Eds.; pp. 729–734. [Google Scholar]

- Anh, H.P.H.; Son, N.N.; Kien, C.V. Adaptive Neural Compliant Force-Position Control of Serial PAM Robot. J. Intell. Robot. Syst. 2018, 89, 351–369. [Google Scholar] [CrossRef]

- Chan, C.Y.; Chong, S.H.; Loh, S.L.; Alias, A.; Kasdirin, H.A. Positioning Control of an Antagonistic Pneumatic Muscle Actuated System Using Feedforward Compensation with Cascaded Control Scheme. Int. J. Integr. Eng. 2020, 12, 70–74. [Google Scholar] [CrossRef]

- Martens, M.; Zawatzki, J.; Seel, T.; Boblan, I. A Pneumatic-Muscle-Actuator-Driven Knee Rehabilitation Device for CAM Therapy. In Proceedings of the 2019 41st Annual International Conference of the Ieee Engineering in Medicine and Biology Society (Embc), Berlin, Germany, 23–27 July 2019; pp. 6237–6242. [Google Scholar]

- Tang, T.F.; Chong, S.H. Practical Controller Design for Ultra-Precision Positioning of Stages with a Pneumatic Artificial Muscle Actuator. In Proceedings of the International Technical Postgraduate Conference, Johor, Malaysia, 7 December 2017; IOP Conference Series-Materials Science and Engineering. Harun, S.W., Latiff, A.A., Eds.; Volume 210. [Google Scholar]

- Tang, T.F.; Chong, S.H.; Noto, R.M.; Sato, K. Practical Control Strategy for Positioning Control of Pneumatic Artificial Muscles Driven Stage: Improved NCTF Control. IEEE Access 2019, 7, 85513–85524. [Google Scholar] [CrossRef]

- Jouppila, V.; Gadsden, S.A.; Ellman, A. Experimental Comparisons of Sliding Mode Controlled Pneumatic Muscle and Cylinder Actuators. J. Dyn. Syst. Meas. Control Trans. ASME 2014, 136, 044503. [Google Scholar] [CrossRef]

- Kurumaya, S.; Nabae, H.; Endo, G.; Suzumori, K. Design of Thin McKibben Muscle and Multifilament Structure. Sens. Actuat. A Phys. 2017, 261, 66–74. [Google Scholar] [CrossRef]

- Mhd Yusoff, M.; Mohd Faudzi, A.; Hassan Basri, M.; Rahmat, M.F. A Piecewise Affine System Modeling Approach of Thin McKibben Muscle Servo Actuator. In Proceedings of the Enabling Industry 4.0 through Advances in Mechatronics, Pekan, Malaysia, 20 September 2021; Springer Nature Singapore: Pekan, Malaysia, 2021. [Google Scholar] [CrossRef]

- Schulte, H.F., Jr. The Characteristics of the McKibben Artificial Muscle (1961) The Application of External Power in Prosthetics and Orthotics; National Academy of Sciences-National Research Council: Washington, DC, USA, 1961; pp. 94–115. [Google Scholar]

- Bemporad, A. Hybrid Toolbox—User’s Guide; IMT School for Advanced Studies Lucca: Lucca, Italy, 2004. [Google Scholar]

- Mhd Yusoff, M.A.; Mohd Faudzi, A.A.; Hassan Basri, M.S. Feasibility of Pi Control for a Double-Acting Cylinder Actuated by Mckibben Muscles. In Proceedings of the RiTA 2020, Cardiff, UK, 30 October–1 November 2020; Lecture Notes in Mechanical Engineering. Chew, E., Abdul Majeed, P.P., Liu, A., Platts, P., Myung, J., Kim, H., Kim, J.H., Eds.; Springer: Singapore, 2021; pp. 327–339. [Google Scholar] [CrossRef]

- Herceg, M.; Kvasnica, M.; Jones, C.N.; Morari, M. Multi-Parametric Toolbox 3.0. In Proceedings of the 2013 European Control Conference (ECC), Zurich, Switzerland, 17–19 July 2013; pp. 502–510. [Google Scholar] [CrossRef]

- Lofberg, J. YALMIP: A Toolbox for Modeling and Optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 1 May 2004; (IEEE Cat. No.04CH37508). pp. 284–289. [Google Scholar] [CrossRef]

- Torrisi, F.; Bemporad, A. HYSDEL—A Tool for Generating Computational Hybrid Models for Analysis and Synthesis Problems. IEEE Trans. Control Syst. Technol. 2004, 12, 235–249. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Mayne, D.Q.; Diehl, M.M. Model Predictive Control: Theory, Computation and Design, 2nd ed.; Nob Hill Publishing: Santa Barbara, CA, USA, 2020. [Google Scholar]

- Borrelli, F.; Bemporad, A.; Morari, M. Predictive Control for Linear and Hybrid Systems; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Mayne, D.Q.; Rawlings, J.B.; Rao, C.V.; Scokaert, P.O.M. Constrained Model Predictive Control: Stability and Optimality. Automatica 2000, 36, 789–814. [Google Scholar] [CrossRef]

- Liberzon, D. Switching in Systems and Control; Birkhauser: Boston, MA, USA, 2003. [Google Scholar]

- Özkan, L.; Kothare, M.V. Stability Analysis of a Multi-Model Predictive Control Algorithm with Application to Control of Chemical Reactors. J. Process Control 2006, 16, 81–90. [Google Scholar] [CrossRef]

| Contribution | Details | Main References |

|---|---|---|

| Configuration | Translational antagonistic-pair thin McKibben muscle (TMM) servo actuator with maximum control of 40 mm | Shen et al. [7] (conventional McKibben muscle (MM), max. control 15 mm), Tang et al. [39] (conventional MM, max. control 6.5 mm) |

| Control | Switching Model Predictive Control (SMPC) | Shen et al. [7] (sliding mode control, conventional MM), Andrikopoulos et al. [31,32] (single-acting, conventional MM) |

| Pressure (MPa) | Maximum Force a (N) | Maximum Contraction Ratio a (%) |

|---|---|---|

| 0.1 | 1 | 2.5 |

| 0.2 | 5 | 15 |

| 0.3 | 10 | 21 |

| 0.4 | 15 | 25 |

| 0.5 | 20 | 28 |

| Reference Displacement (cm) | Forward-Reverse Switch | Feedforward Control (MPa) |

|---|---|---|

| 1 | 0.175 | |

| 1 | 0.18 | |

| 1 | 0.21 | |

| 1 | 0.218 | |

| 1 | 0.225 | |

| 0 | 0.21 | |

| 0 | 0.19 | |

| 0 | 0.175 | |

| 0 | 0.165 |

| (s) | (s) | (%) | (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Step (cm) | MPC | PID | MPC | PID | MPC | PID | MPC | PID |

| 0.5 | 2.25 | 3.10 | 4.53 | 9.60 | 2.00 | 1.40 | 2.00 | 1.40 |

| 1.0 | 1.51 | 3.80 | 3.68 | 6.40 | 1.00 | 1.00 | 1.00 | 1.00 |

| 1.5 | 0.03 | 4.40 | 5.45 | 8.20 | 0.00 | 1.33 | −0.67 | 1.33 |

| 2.0 | 1.71 | 4.60 | 2.58 | 11.30 | 0.00 | 1.50 | 0.00 | 1.50 |

| 2.5 | 1.10 | 5.40 | 3.15 | 10.80 | 0.40 | 0.40 | 0.40 | 0.40 |

| 3.0 | 2.32 | 6.40 | 2.72 | 12.60 | 0.33 | 0.33 | 0.33 | 0.33 |

| Average | 1.49 | 4.62 | 3.69 | 9.82 | 0.62 | 0.99 | 0.51 | 0.99 |

| Actuation | (cm) | (cm) | (s) | (s) | (%) | (%) |

|---|---|---|---|---|---|---|

| Forward | 0.0 | 0.5 | 0.90 | 4.55 | 2.00 | 2.00 |

| 0.5 | 1.0 | 2.31 | 4.16 | 1.00 | 1.00 | |

| 1.0 | 1.5 | 2.06 | 3.04 | 1.33 | 1.33 | |

| 1.5 | 2.0 | 3.14 | 3.15 | 1.50 | 1.50 | |

| 2.0 | 2.5 | 2.39 | 2.47 | 0.40 | 0.40 | |

| Average | 2.16 | 3.47 | 1.25 | 1.25 | ||

| Reverse | 2.5 | 2.0 | 0.72 | 0.95 | 0.00 | 0.00 |

| 2.0 | 1.5 | 1.16 | 1.30 | 0.67 | 0.67 | |

| 1.5 | 1.0 | 1.28 | 1.98 | 1.00 | 1.00 | |

| 1.0 | 0.5 | 1.29 | 3.83 | 4.00 | −2.00 | |

| 0.5 | 0.0 | 1.86 | 3.31 | 0.00 | 0.00 | |

| Average | 1.26 | 2.27 | 1.13 | −0.07 |

| Actuation | (s) | (s) | (%) | (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (cm) | (cm) | MPC | PID | MPC | PID | MPC | PID | MPC | PID | |

| Forward | 0.0 | 1.2 | 2.85 | 3.70 | 3.82 | 5.60 | 2.50 | 0.00 | 0.00 | 0.00 |

| 0.0 | 3.0 | 2.32 | 5.90 | 2.72 | 12.38 | 0.33 | −0.33 | 0.33 | −0.33 | |

| 1.2 | 1.6 | 2.91 | 3.10 | 4.30 | 3.20 | 1.88 | 0.00 | 1.88 | 0.00 | |

| 1.6 | 2.0 | 3.86 | 3.80 | 3.99 | 3.90 | 1.50 | 0.00 | 1.50 | 0.00 | |

| 2.0 | 2.5 | 2.86 | 4.90 | 3.50 | 5.20 | 0.00 | 0.40 | 0.00 | 0.40 | |

| Average | 2.96 | 4.28 | 3.67 | 6.06 | 1.24 | 0.01 | 0.74 | 0.01 | ||

| Reverse | 2.5 | 1.3 | 1.01 | 8.60 | 1.19 | 10.10 | 1.54 | 0.77 | −1.54 | 0.77 |

| 1.3 | 0.9 | 0.75 | 3.80 | 1.73 | 3.90 | 5.56 | −2.22 | −2.22 | −2.22 | |

| 0.9 | 0.5 | 1.64 | 11.80 | 2.05 | 14.30 | −2.00 | −10.00 | 2.00 | −10.00 | |

| 0.5 | 0.0 | 1.30 | 8.80 | 2.93 | 8.80 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Average | 1.53 | 7.46 | 2.31 | 8.63 | 1.27 | −2.29 | −0.20 | −2.29 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mhd Yusoff, M.A.; Mohd Faudzi, A.A.; Hassan Basri, M.S.; Rahmat, M.F.; Shapiai, M.I.; Mohamaddan, S. Switching Model Predictive Control for Thin McKibben Muscle Servo Actuator. Actuators 2022, 11, 233. https://doi.org/10.3390/act11080233

Mhd Yusoff MA, Mohd Faudzi AA, Hassan Basri MS, Rahmat MF, Shapiai MI, Mohamaddan S. Switching Model Predictive Control for Thin McKibben Muscle Servo Actuator. Actuators. 2022; 11(8):233. https://doi.org/10.3390/act11080233

Chicago/Turabian StyleMhd Yusoff, Mohd Akmal, Ahmad Athif Mohd Faudzi, Mohd Shukry Hassan Basri, Mohd Fuaad Rahmat, Mohd Ibrahim Shapiai, and Shahrol Mohamaddan. 2022. "Switching Model Predictive Control for Thin McKibben Muscle Servo Actuator" Actuators 11, no. 8: 233. https://doi.org/10.3390/act11080233

APA StyleMhd Yusoff, M. A., Mohd Faudzi, A. A., Hassan Basri, M. S., Rahmat, M. F., Shapiai, M. I., & Mohamaddan, S. (2022). Switching Model Predictive Control for Thin McKibben Muscle Servo Actuator. Actuators, 11(8), 233. https://doi.org/10.3390/act11080233