Control Design and Testing for a Finger Exoskeleton Mechanism

Abstract

:1. Introduction

- Degrees of Freedom: Most finger exoskeletons have one, two, or three DoFs. Exoskeletons with three DoFs are characterised by a fully guided motion capability and active control of the position of each phalanx of a finger. Exoskeletons with one DoF maintain active control of the first phalanx (the phalanx with the wider motion range) or the fingertip (passively forcing motion in all three phalanxes). Exoskeletons usually possess active control on the third phalanx with two DoFs. However, as restoring motion in the first and second phalanxes of the finger is usually deemed more critical, some exoskeletons with two DoFs actively control the fingertip and either the first or second phalanx with convenient design or control architecture.

- Actuation: Most finger exoskeletons favor electric motors (DC, stepper, servo). These motors can be embedded in the finger or remotely placed on the wrist or in a dedicated static actuation unit. The embedded solution would be ideal, but the weight and bulk of most actuation force units use static or uncomfortable wrist-worn actuators. This situation limits the usage of these exoskeletons to static exercising, potentially discouraging continuous or semi-continuous use that would benefit the patient in a diary usage.

- Transmission: since the motors cannot act directly on the finger joints, a mechanical transmission is required to achieve the desired motion. This transmission is commonly based on linkages and gears; cable-driven mechanisms enable remote actuation (cables).

- Feedback: There is no consensus on the best closed-loop control method for finger exoskeletons since different designs and sensing solutions achieve similar performance. Some solutions prefer a more straightforward design with force/torque control at the motor level, closing the loop on actuation variables and using feed-forward models to consider the transmission. Other designs place force sensors (e.g., force-sensing resistors, strain gauges, or pressure sensors) at the interface between the mechanism and the patient to measure the actual force exerted on the finger. A third solution is represented by muscle electrical signal sensors (i.e., EMG sensors) that aim to close the loop through the patients’ reactions.

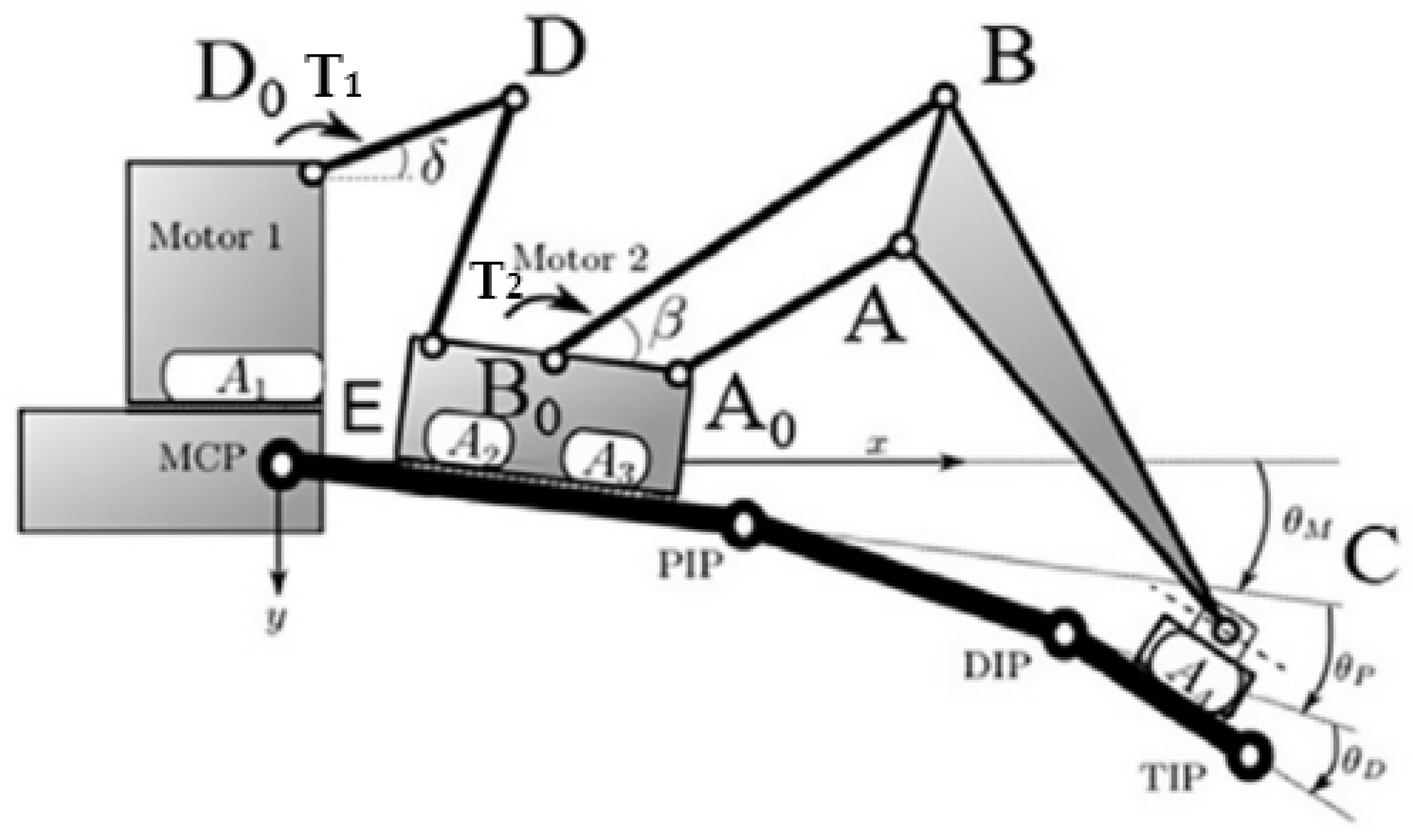

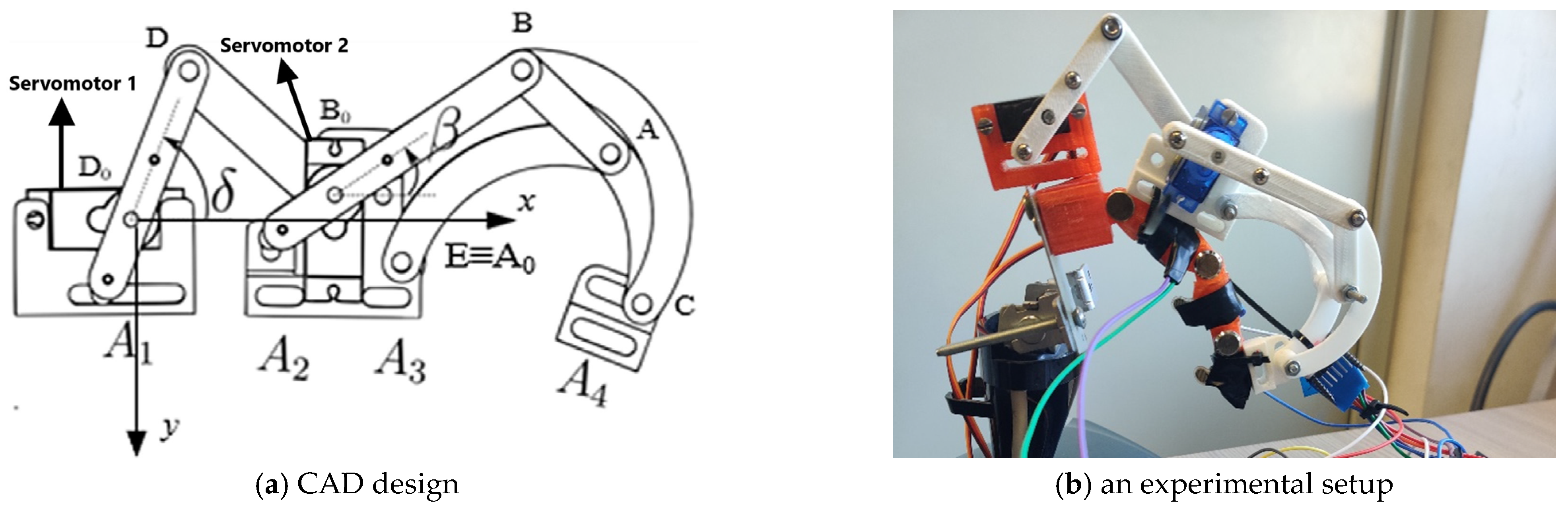

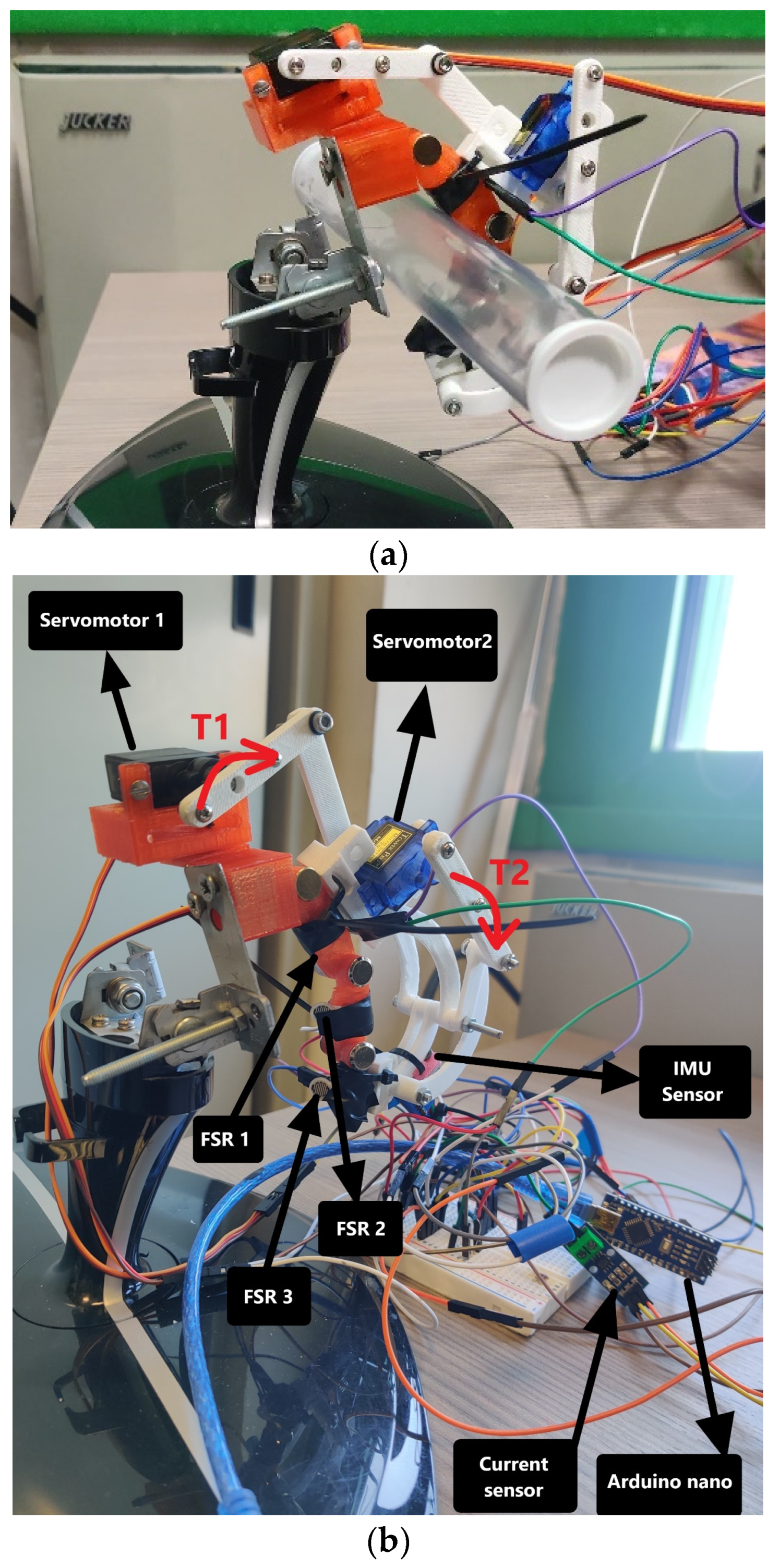

2. ExoFinger

3. Conceptual Design

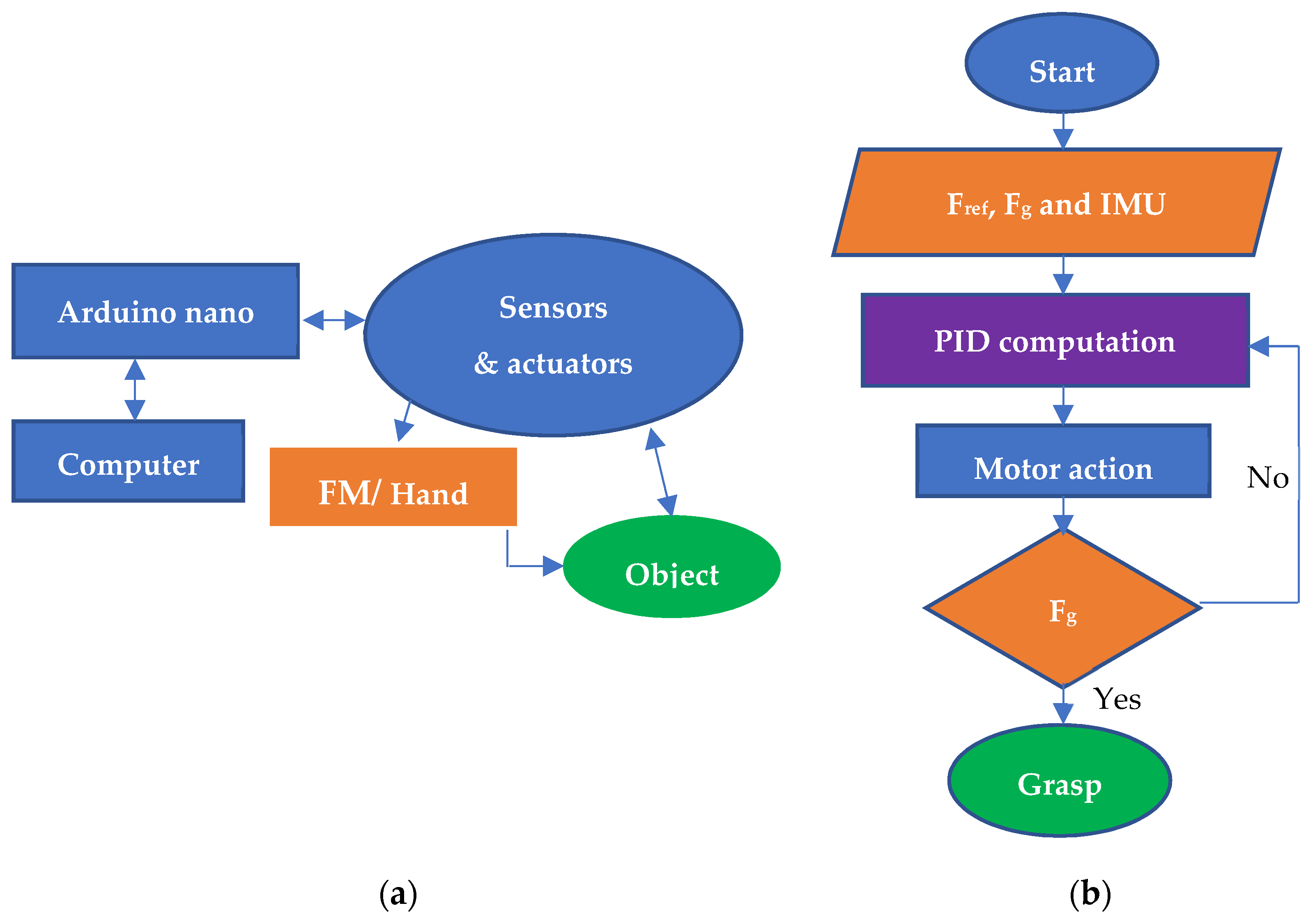

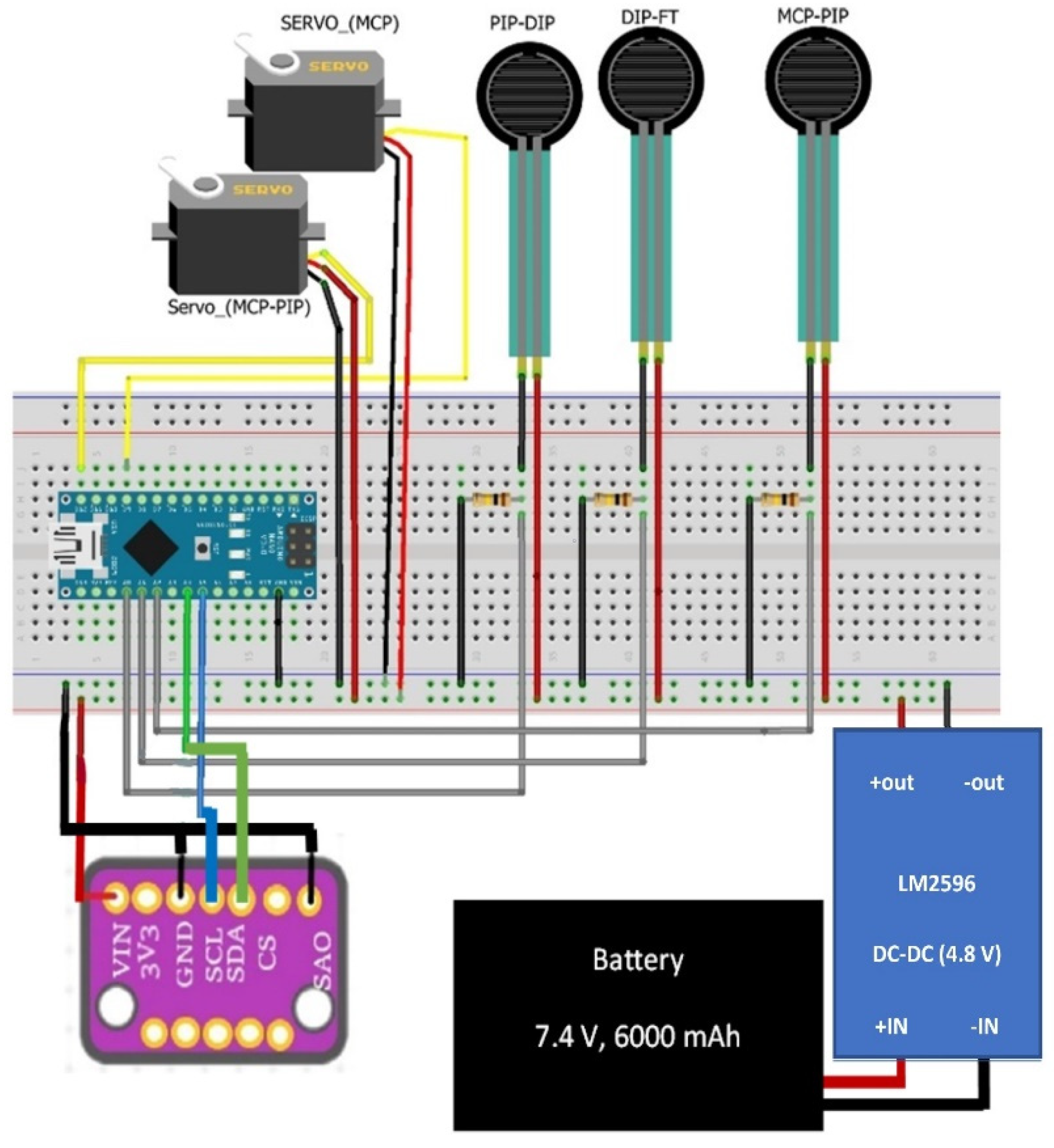

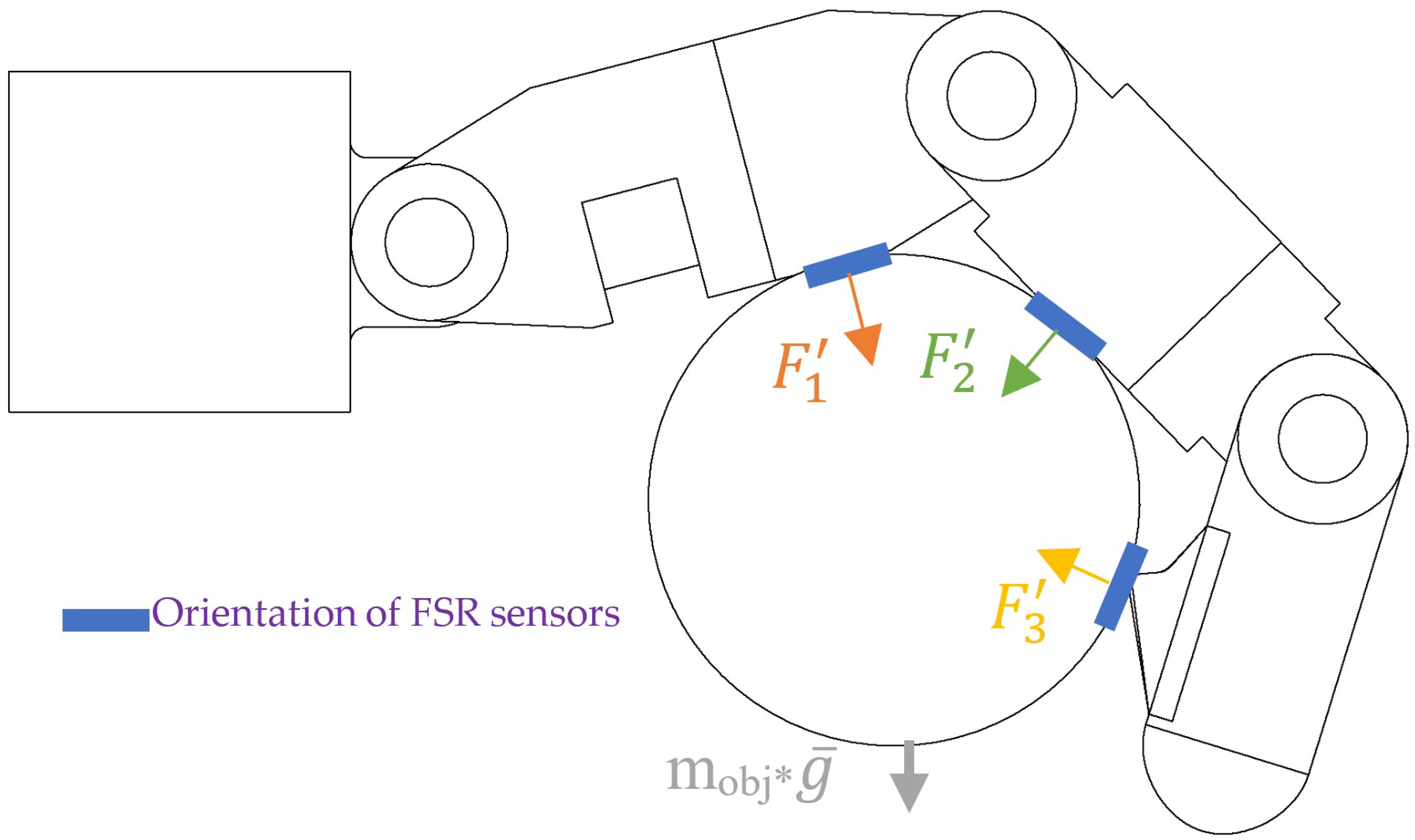

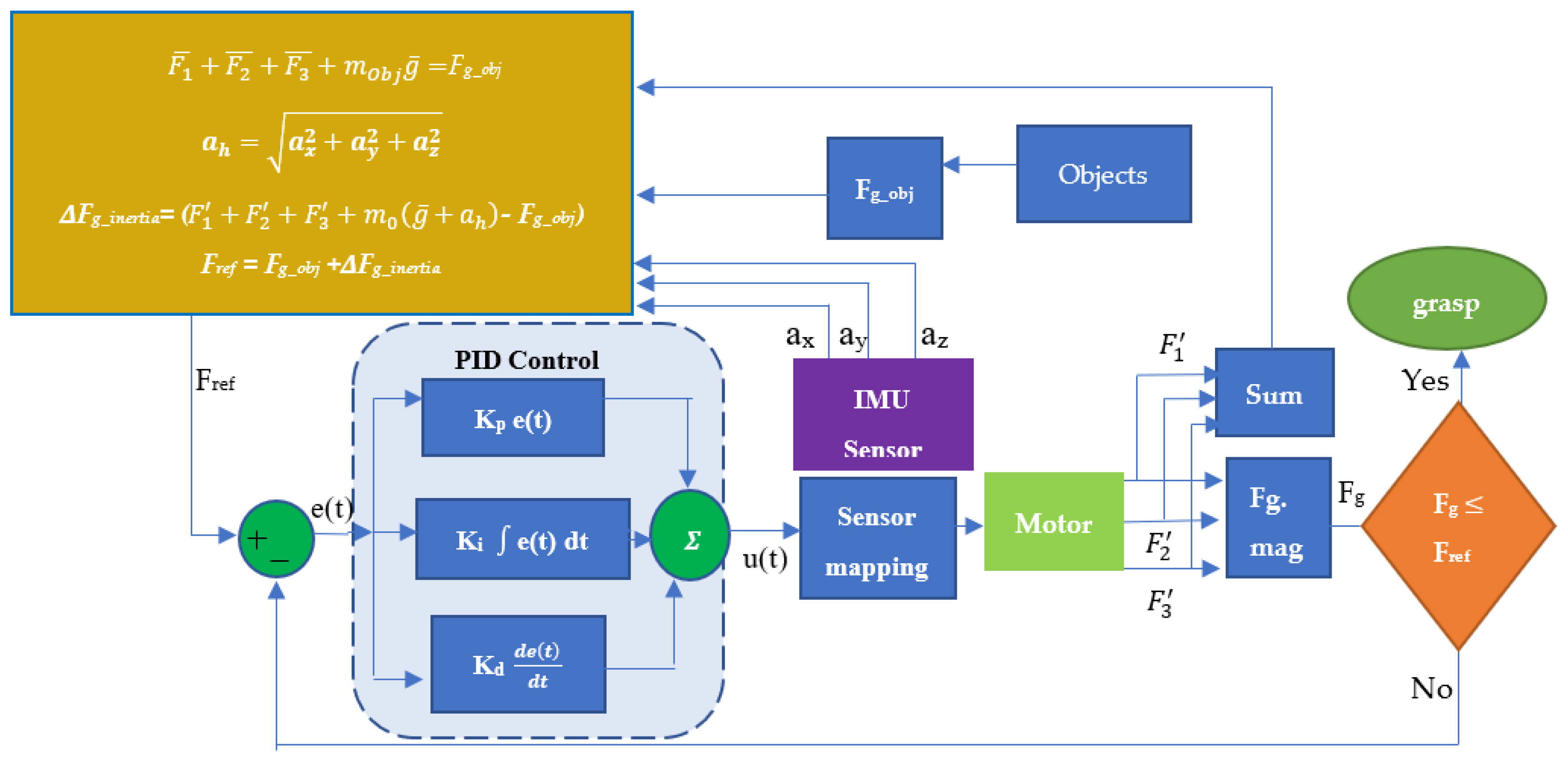

4. Control Design

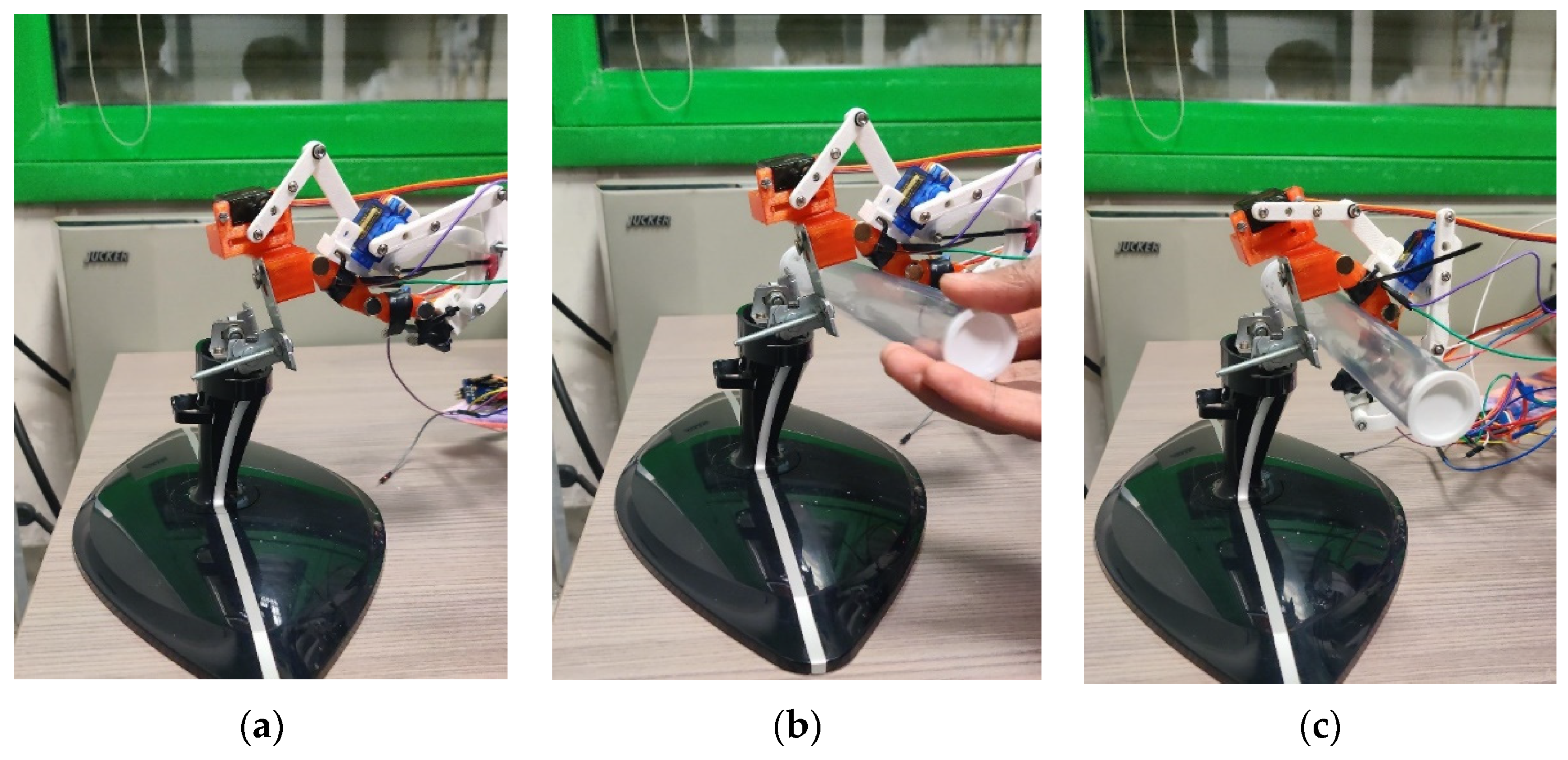

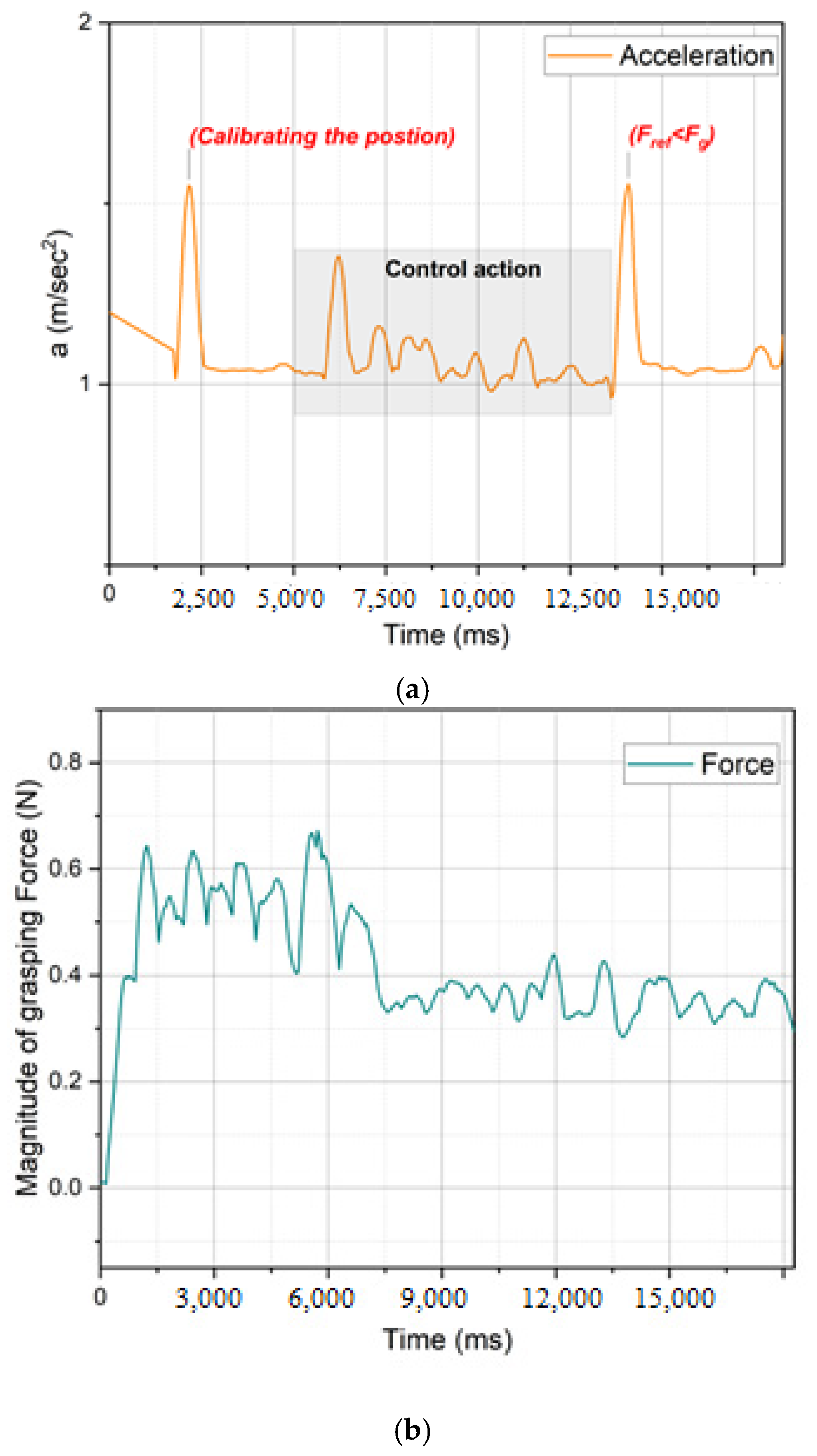

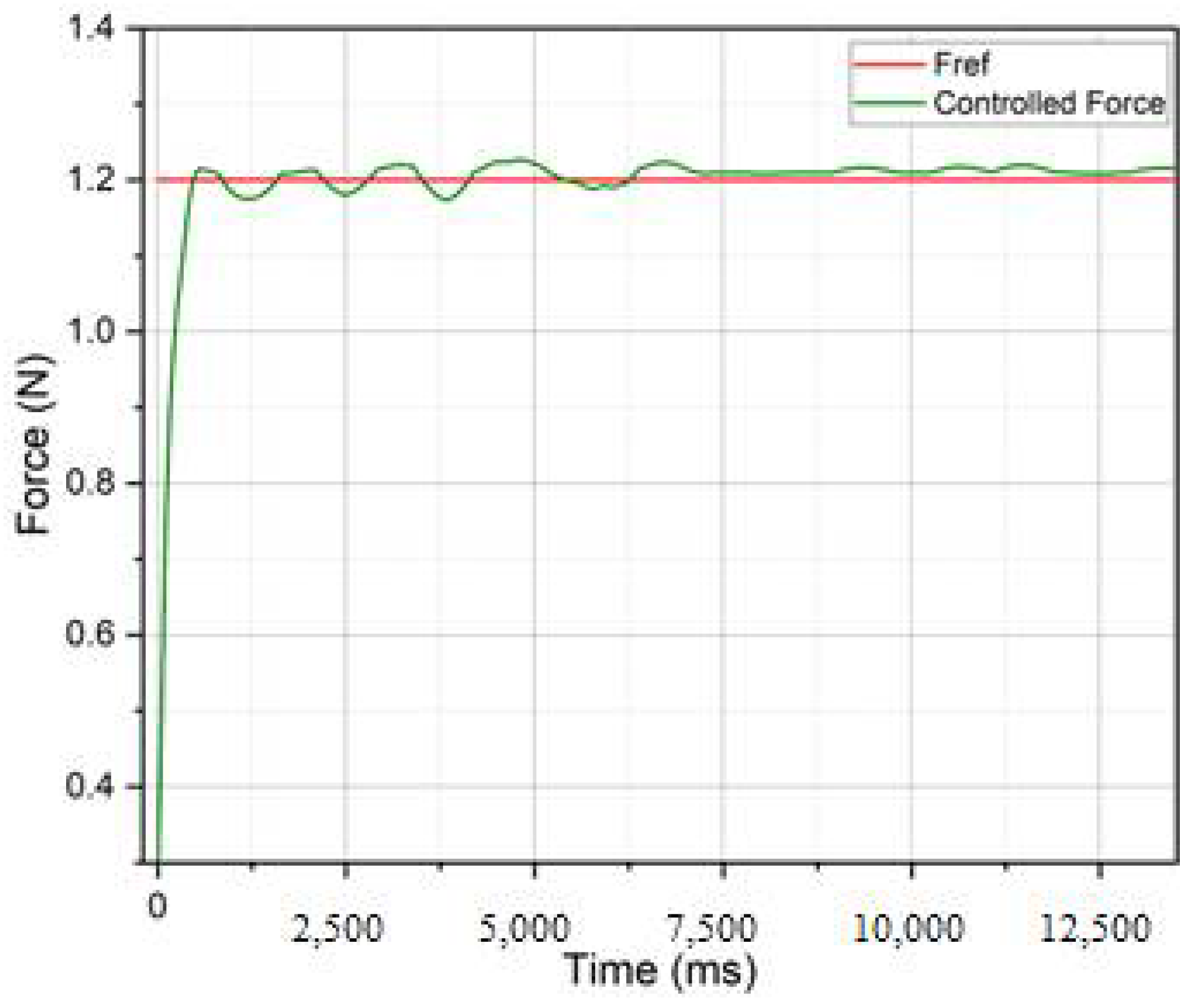

5. Experimental Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yue, Z.; Zhang, X.; Wang, J. Hand rehabilitation robotics on poststroke motor recovery. Behav. Neurol. 2017, 2017, 3908135. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, S.; Klein, J.; Burdet, E. Robot-assisted rehabilitation of hand function. Curr. Opin. Neurol. 2010, 23, 661–670. [Google Scholar] [CrossRef] [PubMed]

- Moggio, L.; de Sire, A.; Marotta, N.; Demeco, A.; Ammendolia, A. Exoskeleton versus end-effector robot-assisted therapy for finger-hand motor recovery in stroke survivors: Systematic review and meta-analysis. Top. Stroke Rehabil. 2021, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Worsnopp, T.T.; Peshkin, M.A.; Colgate, J.E.; Kamper, D.G. An actuated finger exoskeleton for hand rehabilitation following stroke. In Proceedings of the 2007 IEEE 10th International Conference on Rehabilitation Robotics, Noordwijk, The Netherlands, 13–15 June 2007; pp. 896–901. [Google Scholar] [CrossRef] [Green Version]

- Jones, C.L.; Wang, F.; Morrison, R.; Sarkar, N.; Kamper, D.G. Design and development of the cable actuated finger exoskeleton for hand rehabilitation following stroke. IEEE/Asme Trans. Mechatron. 2012, 19, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Ngeo, J.; Tamei, T.; Shibata, T.; Orlando, M.F.; Behera, L.; Saxena, A.; Dutta, A. Control of an optimal finger exoskeleton based on continuous joint angle estimation from EMG signals. In Proceedings of the 2013 35th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Osaka, Japan, 3–7 July 2013; pp. 338–341. [Google Scholar]

- Yang, J.; Xie, H.; Shi, J. A novel motion-coupling design for a jointless tendon-driven finger exoskeleton for rehabilitation. Mech. Mach. Theory 2016, 99, 83–102. [Google Scholar] [CrossRef]

- Li, C.; Yan, Y.; Ren, H. Compliant finger exoskeleton with telescoping super-elastic transmissions. J. Intell. Robot. Syst. 2020, 100, 435–444. [Google Scholar] [CrossRef]

- Agarwal, P.; Fox, J.; Yun, Y.; O’Malley, M.K.; Deshpande, A.D. An index finger exoskeleton with series elastic actuation for rehabilitation: Design, control and performance characterisation. Int. J. Robot. Res. 2015, 34, 1747–1772. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Zhang, Y.; Wang, S. Design of an exoskeleton for index finger rehabilitation. In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneaplolis, MN, USA, 3–6 September 2009; pp. 5957–5960. [Google Scholar]

- Sun, N.; Li, G.; Cheng, L. Design and validation of a self-aligning index finger exoskeleton for post-stroke rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2021, 29, 1513–1523. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Cheng, L.; Sun, N. Design, manipulability analysis and optimisation of an index finger exoskeleton for stroke rehabilitation. Mech. Mach. Theory 2022, 167, 104526. [Google Scholar] [CrossRef]

- Hernández-Santos, C.; Davizón, Y.A.; Said, A.R.; Soto, R.; Felix-Herrán, L.C.; Vargas-Martínez, A. Development of a Wearable Finger Exoskeleton for Rehabilitation. Appl. Sci. 2021, 11, 4145. [Google Scholar] [CrossRef]

- Hsu, T.H.; Chiang, Y.C.; Chan, W.T.; Chen, S.J. A finger exoskeleton robot for finger movement rehabilitation. Inventions 2017, 2, 12. [Google Scholar] [CrossRef] [Green Version]

- Ertas, I.H.; Hocaoglu, E.; Barkana, D.E.; Patoglu, V. Finger exoskeleton for treatment of tendon injuries. In Proceedings of the 2009 IEEE International Conference on Rehabilitation Robotics, Kyoto, Japan, 23–26 June 2009; pp. 194–201. [Google Scholar]

- Ertas, I.H.; Hocaoglu, E.; Patoglu, V. AssistOn-Finger: An under-actuated finger exoskeleton for robot-assisted tendon therapy. Robotica 2014, 32, 1363–1382. [Google Scholar] [CrossRef]

- Heo, P.; Kim, J. Power-assistive finger exoskeleton with a palmar opening at the fingerpad. IEEE Trans. Biomed. Eng. 2014, 61, 2688–2697. [Google Scholar] [CrossRef] [PubMed]

- Battezzato, A. Towards an underactuated finger exoskeleton: An optimisation process of a two-phalange device based on kinetostatic analysis. Mech. Mach. Theory 2014, 78, 116–130. [Google Scholar] [CrossRef]

- Lemerle, S.; Nozaki, T.; Ohnishi, K. Design and evaluation of a remote actuated finger exoskeleton using motion-copying system for tendon rehabilitation. IEEE Trans. Ind. Inform. 2018, 14, 5167–5177. [Google Scholar] [CrossRef]

- Xiong, X.; Manoonpong, P. A Variable Soft Finger Exoskeleton for Quantifying Fatigue-induced Mechanical Impedance. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 10347–10352. [Google Scholar]

- Attal, A.; Dutta, A. Design of a variable stiffness index finger exoskeleton. Robotica 2022, 40, 1151–1167. [Google Scholar] [CrossRef]

- Li, H.; Cheng, L.; Sun, N.; Cao, R. Design and Control of an Underactuated Finger Exoskeleton for Assisting Activities of Daily Living. IEEE/ASME Trans. Mechatron. 2021, 1–11. [Google Scholar] [CrossRef]

- Sarac, M.; Solazzi, M.; Frisoli, A. Design requirements of generic hand exoskeletons and survey of hand exoskeletons for rehabilitation, assistive, or haptic use. IEEE Trans. Haptics 2019, 12, 400–413. [Google Scholar] [CrossRef] [Green Version]

- Reyes-Perez, G.A.; Garcia-Hernandez, N.; Parra-Vega, V. Development of a Wearable Underactuated Finger Exoskeleton for Haptics: Preliminary Formal Results. In Proceedings of the 2021 Latin American Robotics Symposium (LARS), 2021 Brazilian Symposium on Robotics (SBR), and 2021 Workshop on Robotics in Education (WRE), Natal, Brazil, 11–15 October 2021; pp. 150–155. [Google Scholar]

- Gerding, E.C.; Carbone, G.; Cafolla, D.; Russo, M.; Ceccarelli, M.; Rink, S.; Corves, B. Design and testing of a finger exoskeleton prototype. In Proceedings of the International Conference of IFToMM ITALY, Cassino, Italy, 29–30 November 2018; Springer: Cham, Switzerland; pp. 342–349. [Google Scholar]

- Carbone, G.; Gerding, E.C.; Corves, B.; Cafolla, D.; Russo, M.; Ceccarelli, M. Design of a Two-DOFs driving mechanism for a motion-assisted finger exoskeleton. Appl. Sci. 2020, 10, 2619. [Google Scholar] [CrossRef] [Green Version]

- Ceccarelli, M.; Morales-Cruz, C. A prototype characterisation of ExoFinger, a finger exoskeleton. Int. J. Adv. Robot. Syst. 2021, 18, 17298814211024880. [Google Scholar] [CrossRef]

- Carbone, G.; Ceccarelli, M.; Capalbo, C.E.; Caroleo, G.; Morales-Cruz, C. Numerical and experimental performance estimation for a ExoFing—2 DOFs finger exoskeleton. Robotica 2021, 40, 1820–1832. [Google Scholar] [CrossRef]

- Talat, H.; Munawar, H.; Hussain, H.; Azam, U. Design, modeling and control of an index finger exoskeleton for rehabilitation. Robotica 2022, 1–25. [Google Scholar] [CrossRef]

- Shojaei Barjuei, E.; Caldwell, D.G.; Ortiz, J. Bond graph modeling and kalman filter observer design for an industrial back-support exoskeleton. Designs 2020, 4, 53. [Google Scholar] [CrossRef]

- Toxiri, S.; Calanca, A.; Ortiz, J.; Fiorini, P.; Caldwell, D.G. A parallel-elastic actuator for a torque-controlled back-support exoskeleton. IEEE Robot. Autom. Lett. 2017, 3, 492–499. [Google Scholar] [CrossRef]

- Dragusanu, M.; Iqbal, M.Z.; Baldi, T.L.; Prattichizzo, D.; Malvezzi, M. Design, Development, and Control of a Hand/Wrist Exoskeleton for Rehabilitation and Training. IEEE Trans. Robot. 2022, 38, 3. [Google Scholar] [CrossRef]

- Aliexpress Webpage 2022. Datasheet of MR.RC, Standard Servo Motor. Available online: https://it.aliexpress.com/item/32911665593.html?gatewayAdapt=glo2ita (accessed on 6 July 2022).

- Electronicoscaldas Webpage. Datasheet of Tower Pro (MG90S), Micro Servo Motor. Available online: https://www.electronicoscaldas.com/datasheet/MG90S_Tower-Pro.pdf (accessed on 6 July 2022).

- Bosch Webpage. BMI 160 IMU Combining Accelerometer and Gyroscope Its Datasheet. Available online: https://www.bosch-sensortec.com/products/motion-sensors/imus/bmi160/ (accessed on 6 July 2022).

- Falco, J.; Hemphill, D.; Kimble, K.; Messina, E.; Norton, A.; Ropelato, R.; Yanco, H. Benchmarking protocols for evaluating grasp strength, grasp cycle time, finger strength, and finger repeatability of robot end-effectors. IEEE Robot. Autom. Lett. 2020, 5, 644–651. [Google Scholar] [CrossRef]

| Parameter | Length (mm) | Parameter | Length (mm) | Parameter | Length (mm) |

|---|---|---|---|---|---|

| MCP–PIP | 43.0 | A0–B0 | 19.5 | B–C | 53.0 |

| PIP–DIP | 42.8 | B0–B | 46.0 | D0–D | 32.0 |

| DIP–FT | 25.0 | A–B | 24.9 | D–E | 58.1 |

| A1–D0 | 27.8 | A–C | 30.7 | A0–A | 48.2 |

| Components | Specifications |

|---|---|

| MR.RC (Servomotor 1) [33] & SG90 (Servomotor 2) [34] | 0.28 N-m (4.8 V) & 0.18 N-m (4.8 V) |

| Three FSR sensors | 10 MΩ Activation time: <10 ms (0 N–14.7 N) |

| Three resistors | |

| BMI 160 IMU Sensor [35] | (3.3 V) |

| LM2596 DC-DC | Tunned to 4.8 V |

| Arduino Nano | Atmega328 |

| Gains | Values |

|---|---|

| Kp [mm/N] | 0.01 |

| Ki [mm/Ns] | 0.2 |

| Kd [mms/N] | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damarla, A.P.; Russo, M.; Ceccarelli, M. Control Design and Testing for a Finger Exoskeleton Mechanism. Actuators 2022, 11, 230. https://doi.org/10.3390/act11080230

Damarla AP, Russo M, Ceccarelli M. Control Design and Testing for a Finger Exoskeleton Mechanism. Actuators. 2022; 11(8):230. https://doi.org/10.3390/act11080230

Chicago/Turabian StyleDamarla, Adithya Prakash, Matteo Russo, and Marco Ceccarelli. 2022. "Control Design and Testing for a Finger Exoskeleton Mechanism" Actuators 11, no. 8: 230. https://doi.org/10.3390/act11080230

APA StyleDamarla, A. P., Russo, M., & Ceccarelli, M. (2022). Control Design and Testing for a Finger Exoskeleton Mechanism. Actuators, 11(8), 230. https://doi.org/10.3390/act11080230