Influence of the Dynamic Effects and Grasping Location on the Performance of an Adaptive Vacuum Gripper

Abstract

:1. Introduction

- The extension of the Polypus grasping model from quasi-static to dynamic behavior, i.e., by taking into account the inertial effects connected with the manipulation task of an object under grasp.

- The assessment of the minimum vacuum force (MVF) required to manipulate a given object thorough different types of grasping configurations, in terms of contact points, e.g., placing the gripper in different positions of the object even with bending fingers to enhance the potentiality of Polypus compared to a fix matrix of suction cups.

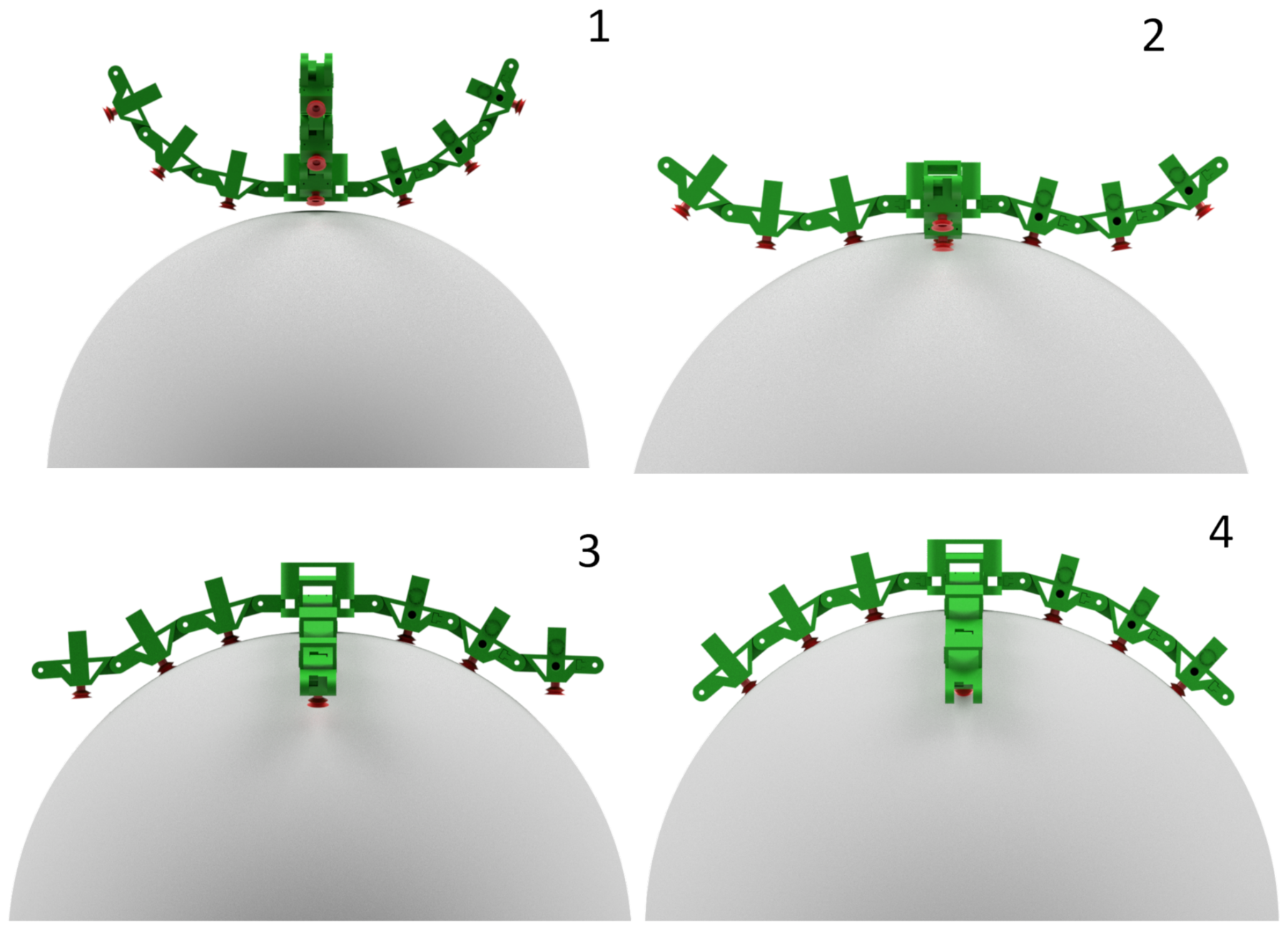

2. Polypus Design

3. Grasping Model

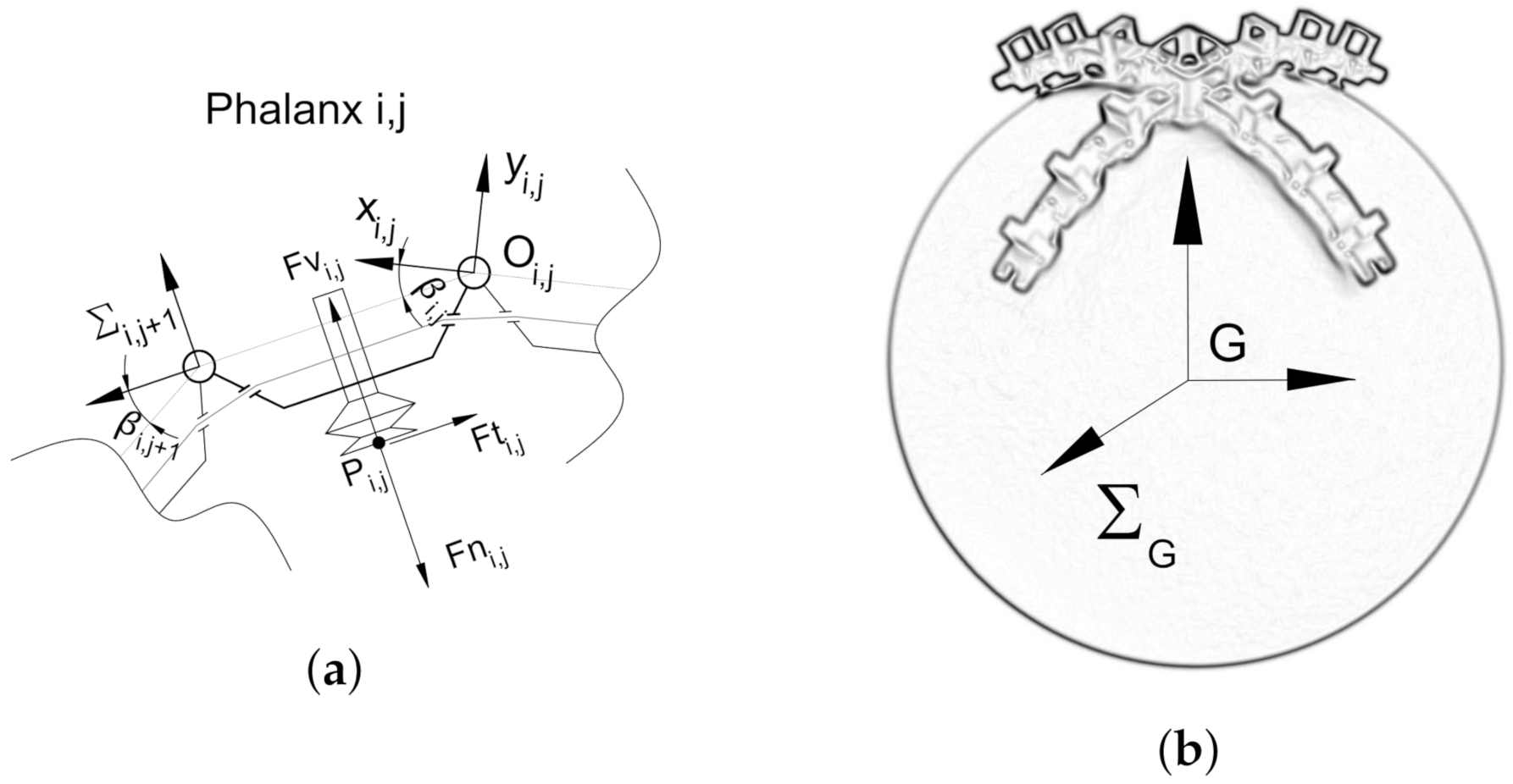

3.1. Model Description

- : The vacuum force is perpendicular to the suction cup pointing toward Polypus.

- : The normal contact force has the same direction of the vacuum force but the opposite verse.

- : The friction force has a generic direction in the contact plane with an upper limit fixed by friction constraint.

- : The contact point is in the middle of the suction cup. L is the length of the phalanx i.e., distance between two hinges, and h is the height of the phalanx i.e., distance between the line connecting two hinges and the contact point.

3.2. Trajectory Generation

3.3. Optimization

- Equilibrium of the object forces and torques expressed in the frame attached to the object (i.e., in Figure 3b).where and are, respectively, the linear and angular acceleration vector of the CoM, m is the mass of the object, is the inertia tensor relative to the CoM when expressed in , is the vector pointing in with origin in , and Q is a matrix to activate the suction cups, the element is 1 if the suction cup is in contact with the object; otherwise, it is 0.

- Positiveness of and .

- Coulomb’s law of friction.

4. Results

4.1. Case I: Flat Object—2 Fingers

4.2. Case II: Trapezoid Object—2 Fingers

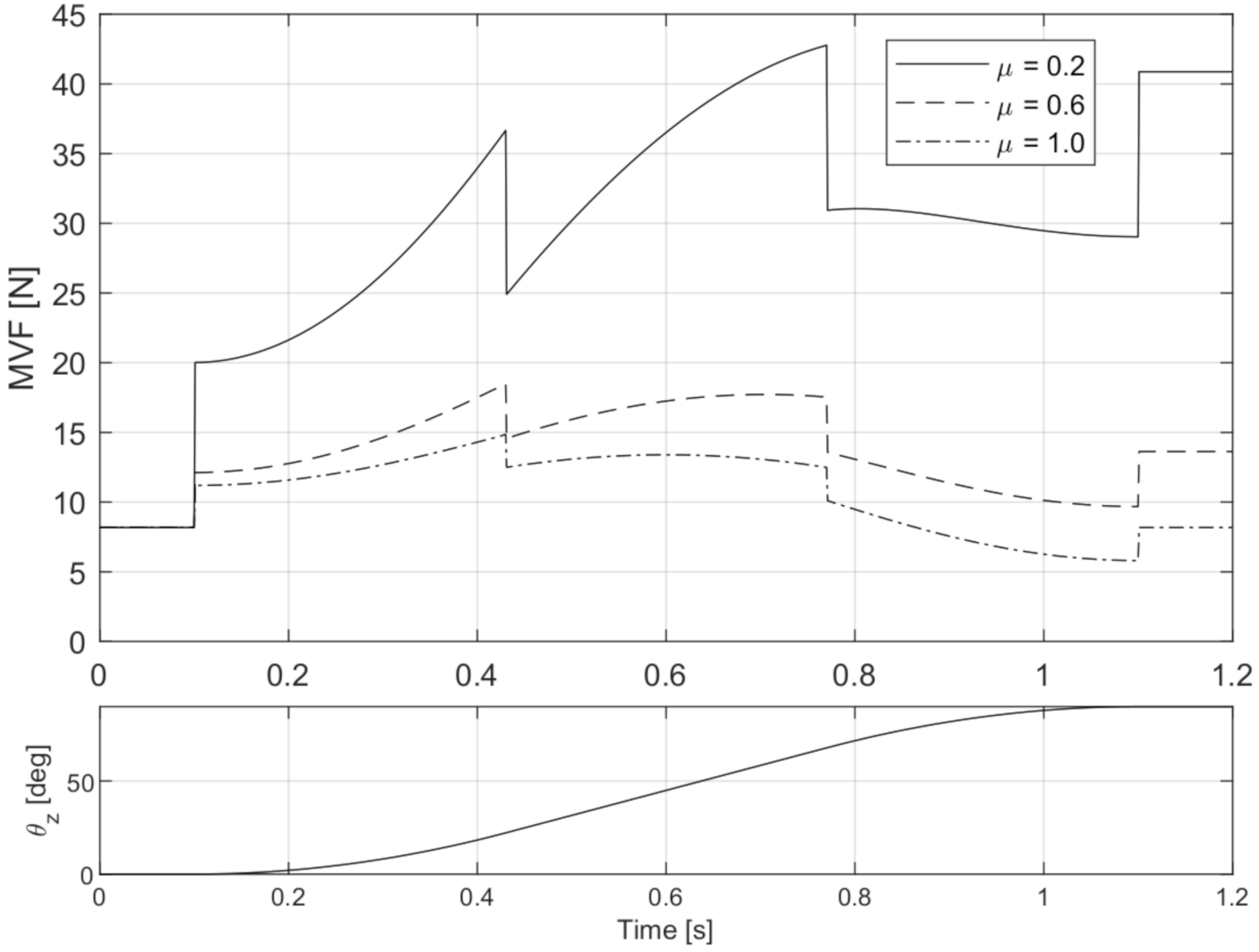

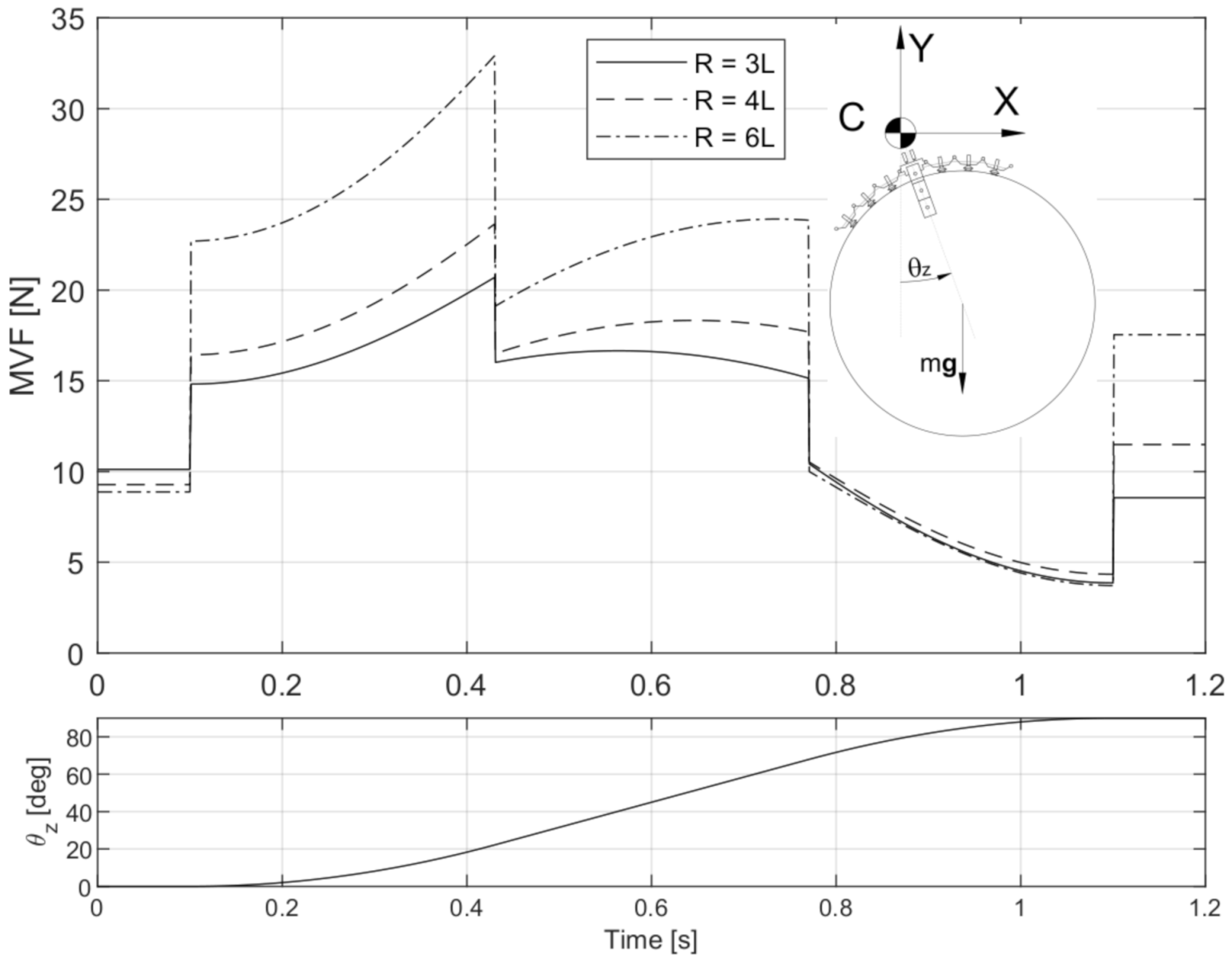

4.3. Case III: Sphere—Four Fingers

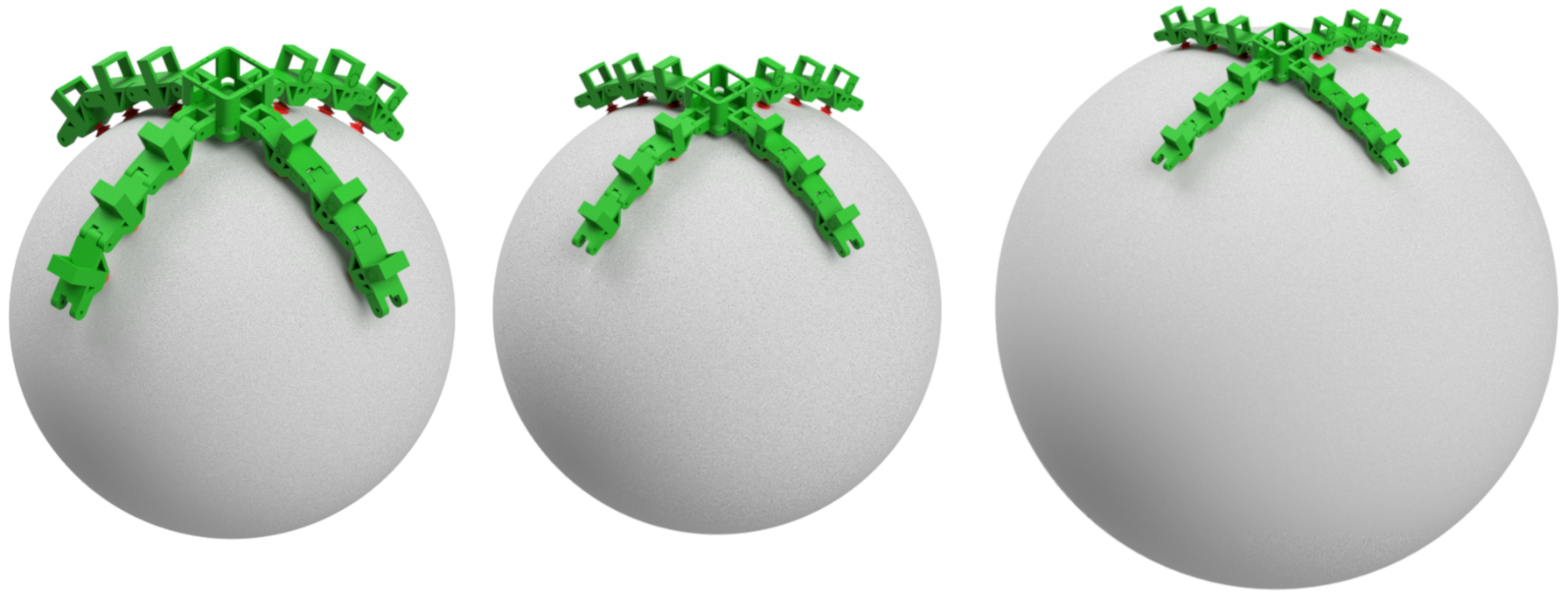

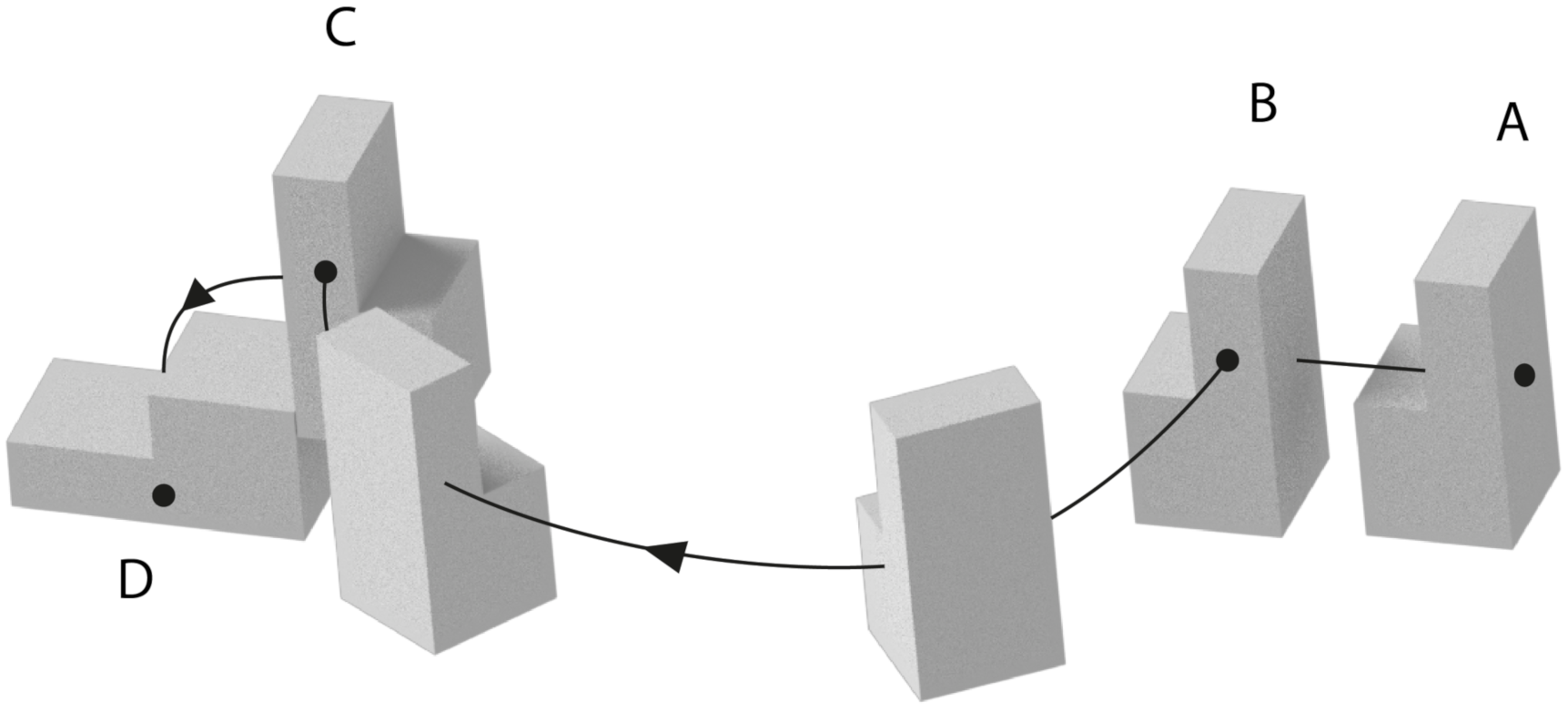

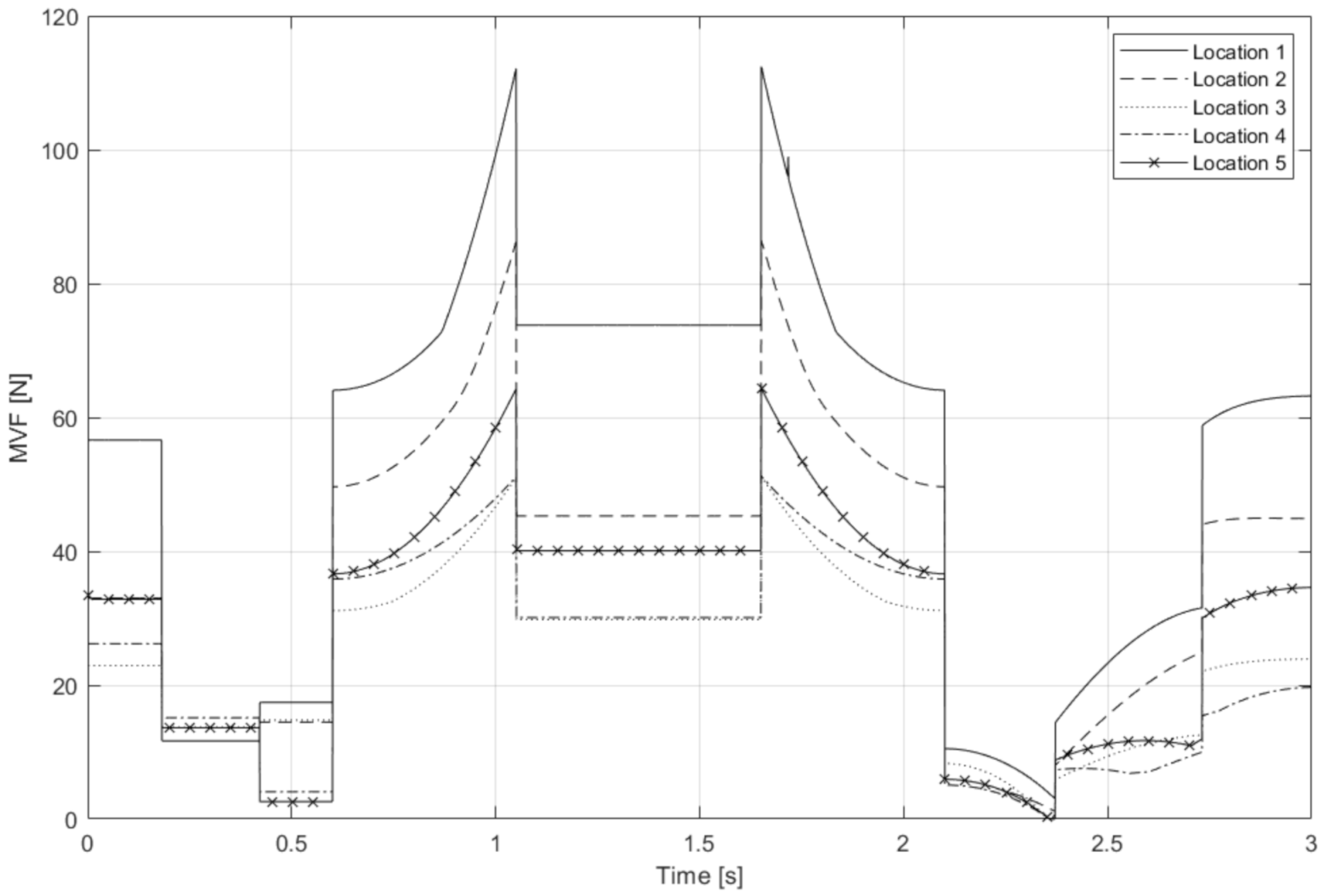

5. Optimization of the Grasping Location

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MVF | Minimum vacuum force |

| CoM | Center of mass |

| Vacuum force for the (i,j)-th phalanx | |

| Normal force for the for the (i,j)-th phalanx | |

| Tangential force for the (i,j)-th phalanx | |

| Location of contact point of the (i,j)-th phalanx | |

| Position vector from to G |

References

- Birglen, L.; Schlicht, T. A statistical review of industrial robotic grippers. Robot. Comput.-Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Piazza, C.; Grioli, G.; Catalano, M.; Bicchi, A. A century of robotic hands. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 1–32. [Google Scholar] [CrossRef]

- Watanabe, T.; Yamazaki, K.; Yokokohji, Y. Survey of robotic manipulation studies intending practical applications in real environments-object recognition, soft robot hand, and challenge program and benchmarking. Adv. Robot. 2017, 31, 1114–1132. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Zareinia, K.; Janabi-Sharifi, F. A brief review on robotic grippers classifications. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; pp. 1–4. [Google Scholar]

- Borisov, I.I.; Borisov, O.I.; Gromov, V.S.; Vlasov, S.M.; Kolyubin, S.A. Versatile gripper as key part for smart factory. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 476–481. [Google Scholar]

- Mantriota, G.; Messina, A. Theoretical and experimental study of the performance of flat suction cups in the presence of tangential loads. Mech. Mach. Theory 2011, 46, 607–617. [Google Scholar] [CrossRef]

- Mantriota, G. Theoretical model of the grasp with vacuum gripper. Mech. Mach. Theory 2007, 42, 2–17. [Google Scholar] [CrossRef]

- Guo, J.; Leng, J.; Rossiter, J. Electroadhesion technologies for robotics: A comprehensive review. IEEE Trans. Robot. 2019, 36, 313–327. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.; Tolley, M.T.; Parness, A. A soft robotic gripper with gecko-inspired adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Song, S.; Majidi, C.; Sitti, M. Geckogripper: A soft, inflatable robotic gripper using gecko-inspired elastomer micro-fiber adhesives. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 4624–4629. [Google Scholar]

- Correll, N.; Bekris, K.E.; Berenson, D.; Brock, O.; Causo, A.; Hauser, K.; Okada, K.; Rodriguez, A.; Romano, J.M.; Wurman, P.R. Analysis and observations from the first amazon picking challenge. IEEE Trans. Autom. Sci. Eng. 2016, 15, 172–188. [Google Scholar] [CrossRef]

- Eppner, C.; Höfer, S.; Jonschkowski, R.; Martín-Martín, R.; Sieverling, A.; Wall, V.; Brock, O. Lessons from the amazon picking challenge: Four aspects of building robotic systems. In Proceedings of the 2016 Robotics: Science and Systems Conference, Ann Arbor, MI, USA, 18–22 June 2016. [Google Scholar]

- Bryan, P.; Kumar, S.; Sahin, F. Design of a soft robotic gripper for improved grasping with suction cups. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; pp. 2405–2410. [Google Scholar]

- Xie, Z.; Domel, A.G.; An, N.; Green, C.; Gong, Z.; Wang, T.; Knubben, E.M.; Weaver, J.C.; Bertoldi, K.; Wen, L. Octopus arm-inspired tapered soft actuators with suckers for improved grasping. Soft Robot. 2020, 7, 639–648. [Google Scholar] [CrossRef] [PubMed]

- Mazzolai, B.; Mondini, A.; Tramacere, F.; Riccomi, G.; Sadeghi, A.; Giordano, G.; Del Dottore, E.; Scaccia, M.; Zampato, M.; Carminati, S. Octopus-Inspired Soft Arm with Suction Cups for Enhanced Grasping Tasks in Confined Environments. Adv. Intell. Syst. 2019, 1, 1900041. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, T.; Suzuki, M.; Aoyagi, S. Octopus bioinspired vacuum gripper with micro bumps. In Proceedings of the 2016 IEEE 11th Annual International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Sendai, Japan, 17–20 April 2016; pp. 508–511. [Google Scholar]

- Wei, Y.; Zhang, W. OS hand: Octopus-inspired self-adaptive underactuated hand with fluid-driven tentacles and force-changeable artificial muscles. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, Macao, 5–8 December 2017; pp. 7–12. [Google Scholar]

- Pi, J.; Liu, J.; Zhou, K.; Qian, M. An Octopus-Inspired Bionic Flexible Gripper for Apple Grasping. Agriculture 2021, 11, 1014. [Google Scholar] [CrossRef]

- Maggi, M.; Mantriota, G.; Reina, G. Introducing POLYPUS: A novel adaptive vacuum gripper. Mech. Mach. Theory 2022, 167, 104483. [Google Scholar] [CrossRef]

- Aukes, D.M.; Heyneman, B.; Ulmen, J.; Stuart, H.; Cutkosky, M.R.; Kim, S.; Garcia, P.; Edsinger, A. Design and testing of a selectively compliant underactuated hand. Int. J. Robot. Res. 2014, 33, 721–735. [Google Scholar] [CrossRef]

- Mantriota, G. Optimal grasp of vacuum grippers with multiple suction cups. Mech. Mach. Theory 2007, 42, 18–33. [Google Scholar] [CrossRef]

- Paul, R. Manipulator Cartesian path control. IEEE Trans. Syst. Man Cybern. 1979, 9, 702–711. [Google Scholar] [CrossRef]

- Farin, G. Curves and Surfaces for CAGD: A Practical Guide; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2001. [Google Scholar]

- Boston Dynamics. Available online: https://www.bostondynamics.com/products/stretch (accessed on 20 January 2022).

| Location 1 | Location 2 | Location 3 |

|  |  |

| Location 4 | Location 5 | Object Geometry |

|  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maggi, M.; Mantriota, G.; Reina, G. Influence of the Dynamic Effects and Grasping Location on the Performance of an Adaptive Vacuum Gripper. Actuators 2022, 11, 55. https://doi.org/10.3390/act11020055

Maggi M, Mantriota G, Reina G. Influence of the Dynamic Effects and Grasping Location on the Performance of an Adaptive Vacuum Gripper. Actuators. 2022; 11(2):55. https://doi.org/10.3390/act11020055

Chicago/Turabian StyleMaggi, Matteo, Giacomo Mantriota, and Giulio Reina. 2022. "Influence of the Dynamic Effects and Grasping Location on the Performance of an Adaptive Vacuum Gripper" Actuators 11, no. 2: 55. https://doi.org/10.3390/act11020055

APA StyleMaggi, M., Mantriota, G., & Reina, G. (2022). Influence of the Dynamic Effects and Grasping Location on the Performance of an Adaptive Vacuum Gripper. Actuators, 11(2), 55. https://doi.org/10.3390/act11020055