PSO-Based Variable Parameter Linear Quadratic Regulator for Articulated Vehicles Snaking Oscillation Yaw Motion Control

Abstract

:1. Introduction

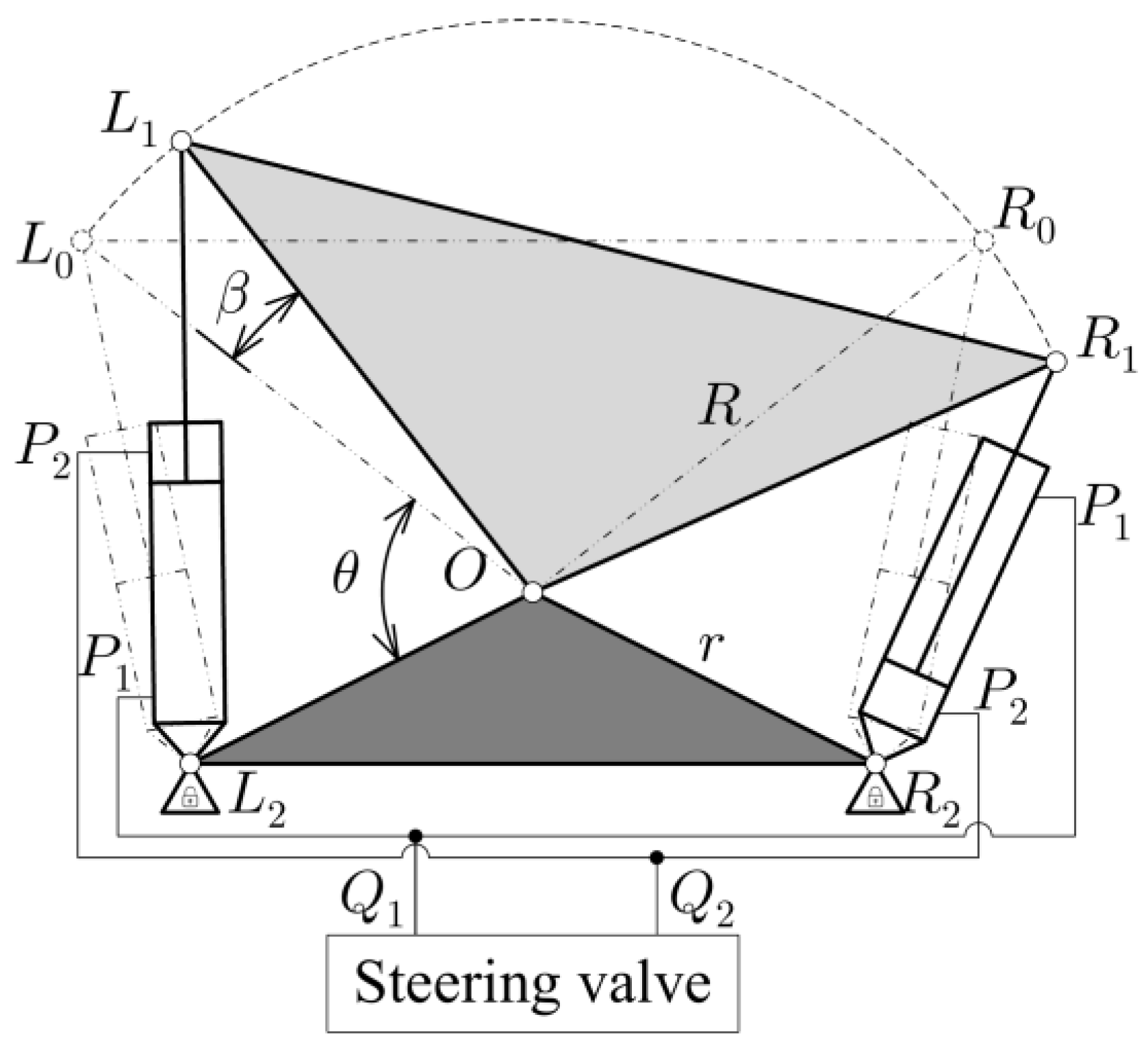

2. Modeling of Nonlinear Systems for Articulated Vehicles

2.1. Vehicle Dynamics Analysis and Modeling

- (1)

- The front and rear body centers are located on the longitudinal central axis, and the vehicle is symmetrical with respect to the longitudinal central axis;

- (2)

- The influence of the tire camber angle and return torque are disregarded;

- (3)

- Air resistance is disregarded, and the road surface is flat and two-dimensional.

2.2. Tire Models

2.3. Hydraulic Steering System Model

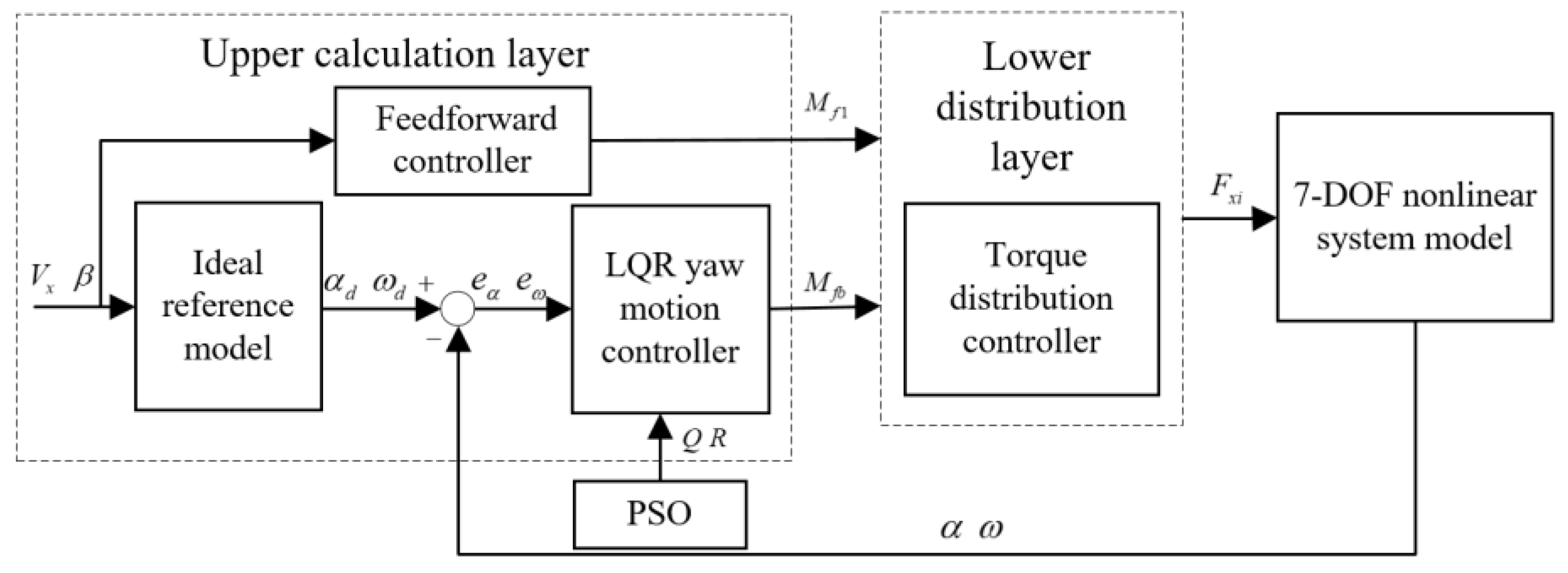

3. Snaking Oscillation Suppression Control of the Articulated Vehicle

3.1. Articulated Vehicle Three DOF Reference Model

3.2. Variable Parameter LQR(VLQR) Yaw Motion Controller

3.3. Optimization of VLQR Controller Based on PSO

3.4. The Lower Torque Distribution Layer

4. Simulation Analysis

4.1. Comparative Analysis of Uncontrolled Conditions and LQR Control

4.2. Comparative Analysis of LQR and PSO-LQR

4.2.1. Comparative Analysis of Front-Based Control

4.2.2. Comparative Analysis of Rear-Based Control

4.2.3. Comparative Analysis of Front and Rear Integrated Control

5. Conclusions

6. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Front vehicle coordinate system | |

| Rear vehicle coordinate system | |

| Longitudinal velocity of the front vehicle | |

| Longitudinal velocity of the rear vehicle | |

| Lateral velocity of the front vehicle | |

| Lateral velocity of the front vehicle | |

| Angular velocity about the z-axis of the front vehicle | |

| Angular velocity about the z-axis of the rear vehicle | |

| Distance from the center of the front vehicle gravity to the front axles | |

| Distance from the articulated point to the center of the front vehicle gravity | |

| Distance from the center of the rear vehicle gravity to the front axles | |

| Distance from the articulated point to the center of the rear vehicle gravity | |

| Vertical tire force | |

| Longitudinal tire stiffness | |

| Lateral tire stiffness | |

| Swing angle | |

| Vehicle rotational inertia about the -axis of the front vehicle | |

| Vehicle rotational inertia about the -axis of the rear vehicle | |

| Longitudinal tire force | |

| Lateral tire force | |

| Torque of the steering mechanism on the front vehicle | |

| Torque of the steering mechanism on the rear vehicle | |

| Mass of the front vehicle | |

| Mass of the rear vehicle | |

| Longitudinal force of the steering mechanism on the front vehicle | |

| Longitudinal force of the steering mechanism on the rear vehicle | |

| Lateral force of the steering mechanism on the front vehicle | |

| Lateral force of the steering mechanism on the rear vehicle | |

| Friction coefficient | |

| Distance between the hinge points of the hydraulic cylinder rod and articulated point | |

| Distance between the hinge points of the hydraulic cylinder seat and articulated point | |

| Initial angle of the hydraulic cylinder |

Abbreviations

| DOF | Degree of freedom |

| MPC | Model predictive control |

| PSO | Particle swarm optimization |

| LQR | Linear quadratic regulator |

| VLQR | Variable parameter LQR |

| PSO-LQR | The LQR controller with the optimized parameters of PSO |

| ITAE | The sum of integrated time and absolute error |

Appendix A

Appendix B

References

- Lashgarian Azad, N.; Khajepour, A.; Mcphee, J. Robust state feedback stabilization of articulated steer vehicles. Veh. Syst. Dyn. 2007, 45, 249–275. [Google Scholar] [CrossRef]

- Dudziński, P.; Skurjat, A. Directional dynamics problems of an articulated frame steer wheeled vehicles. J. KONES 2012, 19, 89–98. [Google Scholar] [CrossRef]

- Crolla, D. The steering behaviour of articulated body steer vehicles. In Proceedings of the Road Vehicle Handling, I Mech E Conference Publications 1983-5. Sponsored by Automobile Division of the Institution of Mechanical Engineers under patronage of Federation Internationale des Societies d’Ingenieurs des Techniques de l’Automobile (FISITA), Motor Industry Research Association, Nuneaton, UK, 24–26 May 1983. [Google Scholar]

- Azad, N.L.; Khajepour, A.; McPhee, J. Effects of locking differentials on the snaking behaviour of articulated steer vehicles. Int. J. Veh. Syst. Model. Test. 2007, 2, 101. [Google Scholar] [CrossRef]

- Horton, D.N.L.; Crolla, D.A. Theoretical Analysis of the Steering Behaviour of Articulated Frame Steer Vehicles. Veh. Syst. Dyn. 1986, 15, 211–234. [Google Scholar] [CrossRef]

- He, Y.; Khajepour, A.; McPhee, J.; Wang, X. Dynamic modelling and stability analysis of articulated frame steer vehicles. Int. J. Heavy Veh. Syst. 2005, 12, 28. [Google Scholar] [CrossRef]

- Gao, Y.; Shen, Y.; Yang, Y.; Zhang, W.; Güvenç, L. Modelling, verification and analysis of articulated steer vehicles and a new way to eliminate jack-knife and snaking behaviour. Int. J. Heavy Veh. Syst. 2019, 26, 375. [Google Scholar] [CrossRef]

- Azad, N.L.; Khajepour, A.; McPhee, J. A survey of stability enhancement strategies for articulated steer vehicles. Int. J. Heavy Veh. Syst. 2009, 16, 26. [Google Scholar] [CrossRef]

- Azad, N.L.; Khajepour, A.; Mcphee, J. Stability Control of Articulated Steer Vehicles by Passive and Active Steering Systems. In Proceedings of the 2005 SAE Commercial Vehicle Engineering Conference, Rosemont, IL, USA, 1–3 November 2005. [Google Scholar] [CrossRef]

- Xu, T.; Ji, X.; Shen, Y. A novel assist-steering method with direct yaw moment for distributed-drive articulated heavy vehicle. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2020, 234, 214–224. [Google Scholar] [CrossRef]

- Ono, E.; Hattori, Y.; Muragishi, Y.; Koibuchi, K. Vehicle dynamics integrated control for four-wheel-distributed steering and four-wheel-distributed traction/braking systems. Veh. Syst. Dyn. 2006, 44, 139–151. [Google Scholar] [CrossRef]

- He, P.; Hori, Y. Optimum traction force distribution for stability improvement of 4WD EV in critical driving condition. In Proceedings of the 9th IEEE International Workshop on Advanced Motion Control, Istanbul, Turkey, 27–29 March 2006. [Google Scholar]

- Bharali, J.; Buragohain, M. Design and performance analysis of Fuzzy LQR; Fuzzy PID and LQR controller for active suspension system using 3 Degree of Freedom quarter car model. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; pp. 1–6. [Google Scholar]

- Gao, L.; Jin, L.; Wang, F.; Zheng, Y.; Li, K. Genetic algorithm–based varying parameter linear quadratic regulator control for four-wheel independent steering vehicle. Adv. Mech. Eng. 2015, 7, 168781401561863. [Google Scholar] [CrossRef] [Green Version]

- Nie, Z.; Gao, J.; Zhang, K. Integrated control strategy for articulated heavy vehicles based on a linear model with real-time parameters. Int. J. Heavy Veh. Syst. 2019, 26, 432. [Google Scholar] [CrossRef]

- Esmaeili, N.; Kazemi, R.; Tabatabaei Oreh, S.H. An adaptive sliding mode controller for the lateral control of articulated long vehicles. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2019, 233, 487–515. [Google Scholar] [CrossRef]

- Jiang, Z.; Xiao, B. LQR optimal control research for four-wheel steering forklift based-on state feedback. J. Mech. Sci. Technol. 2018, 32, 2789–2801. [Google Scholar] [CrossRef]

- Azad, N.L. Dynamic Modelling and Stability Controller Development for Articulated Steer Vehicles. Ph.D. Thesis., University of Waterloo, Waterloo, ON, Canada, 2006; p. 196. Available online: http://hdl.handle.net/10012/2633 (accessed on 26 October 2022).

- Wang, W.; Fan, J.; Xiong, R.; Sun, F. Lateral stability control of four wheels independently drive articulated electric vehicle. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 27–29 June 2016; pp. 1–5. [Google Scholar]

- Abroshan, M.; Hajiloo, R.; Hashemi, E.; Khajepour, A. Model predictive-based tractor-trailer stabilisation using differential braking with experimental verification. Veh. Syst. Dyn. 2021, 59, 1190–1213. [Google Scholar] [CrossRef]

- Dudziński, P.; Skurjat, A. System for Improving Directional Stability for Articulated Vehicles. In Proceedings of the Computational Technologies in Engineering (TKI’2018): Proceedings of the 15th Conference on Computational Technologies in Engineering, Jora Wielka, Poland, 16–19 December 2018; p. 020084. [Google Scholar] [CrossRef]

- Lin, C.; Cheng, X. A Traction Control Strategy with an Efficiency Model in a Distributed Driving Electric Vehicle. Sci. World J. 2014, 2014, 261085. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, Y.; Shen, Y.; Xu, T.; Zhang, W.; Guvenc, L. Oscillatory Yaw Motion Control for Hydraulic Power Steering Articulated Vehicles Considering the Influence of Varying Bulk Modulus. IEEE Trans. Control Syst. Technol. 2019, 27, 1284–1292. [Google Scholar] [CrossRef]

- Xu, T.; Ji, X.; Liu, Y.; Liu, Y. Differential Drive Based Yaw Stabilization Using MPC for Distributed-Drive Articulated Heavy Vehicle. IEEE Access 2020, 8, 104052–104062. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| m2 | |||

| 1.35 m | |||

| 32,977 | |||

| I2 | 13,228 |

| Name | |||

|---|---|---|---|

| Range | |||

| Optimal result |

| Name | |||

|---|---|---|---|

| Range | |||

| Optimal result |

| Name | ||||||

|---|---|---|---|---|---|---|

| Range | ||||||

| Optimal result |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, T.; Gu, X.; Zhang, K.; Li, X.; Wang, J. PSO-Based Variable Parameter Linear Quadratic Regulator for Articulated Vehicles Snaking Oscillation Yaw Motion Control. Actuators 2022, 11, 337. https://doi.org/10.3390/act11110337

Lei T, Gu X, Zhang K, Li X, Wang J. PSO-Based Variable Parameter Linear Quadratic Regulator for Articulated Vehicles Snaking Oscillation Yaw Motion Control. Actuators. 2022; 11(11):337. https://doi.org/10.3390/act11110337

Chicago/Turabian StyleLei, Tianlong, Xiaochao Gu, Kanghua Zhang, Xiang Li, and Jixin Wang. 2022. "PSO-Based Variable Parameter Linear Quadratic Regulator for Articulated Vehicles Snaking Oscillation Yaw Motion Control" Actuators 11, no. 11: 337. https://doi.org/10.3390/act11110337

APA StyleLei, T., Gu, X., Zhang, K., Li, X., & Wang, J. (2022). PSO-Based Variable Parameter Linear Quadratic Regulator for Articulated Vehicles Snaking Oscillation Yaw Motion Control. Actuators, 11(11), 337. https://doi.org/10.3390/act11110337