Prescribed Performance Control with Sliding-Mode Dynamic Surface for a Glue Pump Motor Based on Extended State Observers

Abstract

:1. Introduction

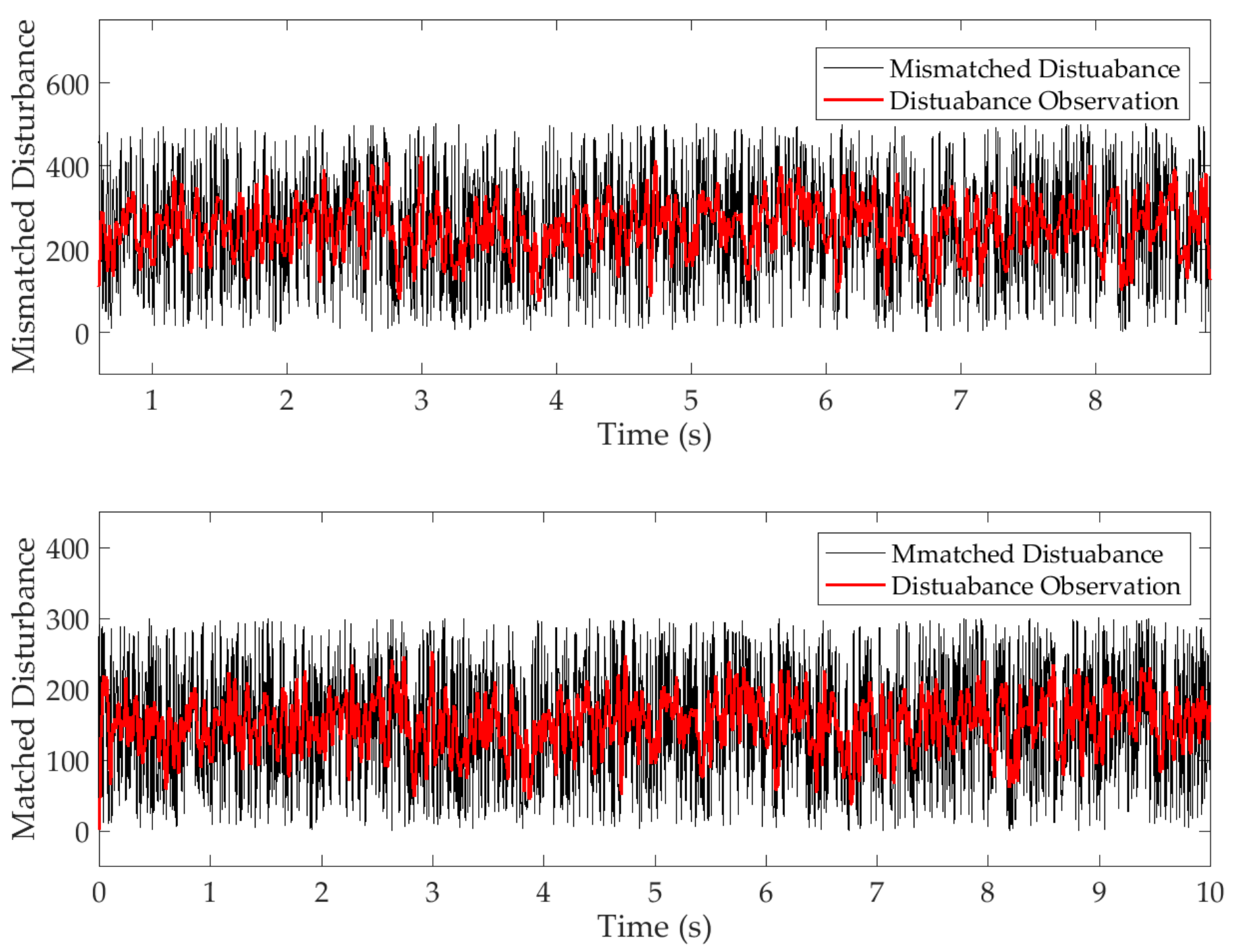

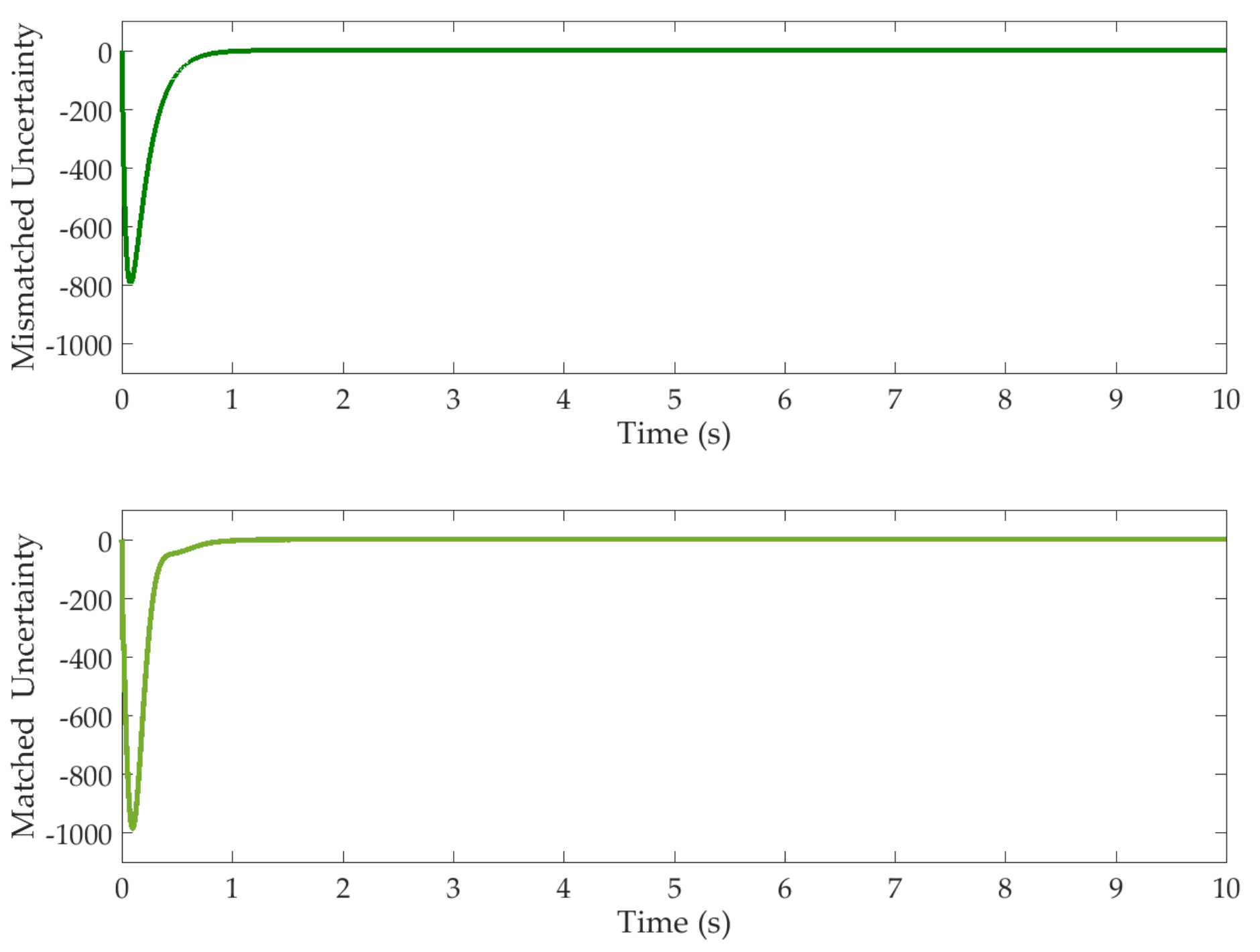

- Two extended state observers are constructed for each channel in a glue-dosing system that contains uncertainties. The matched and unmatched uncertainties are estimated, such that the compound controller can compensate for them in a feed-forward manner;

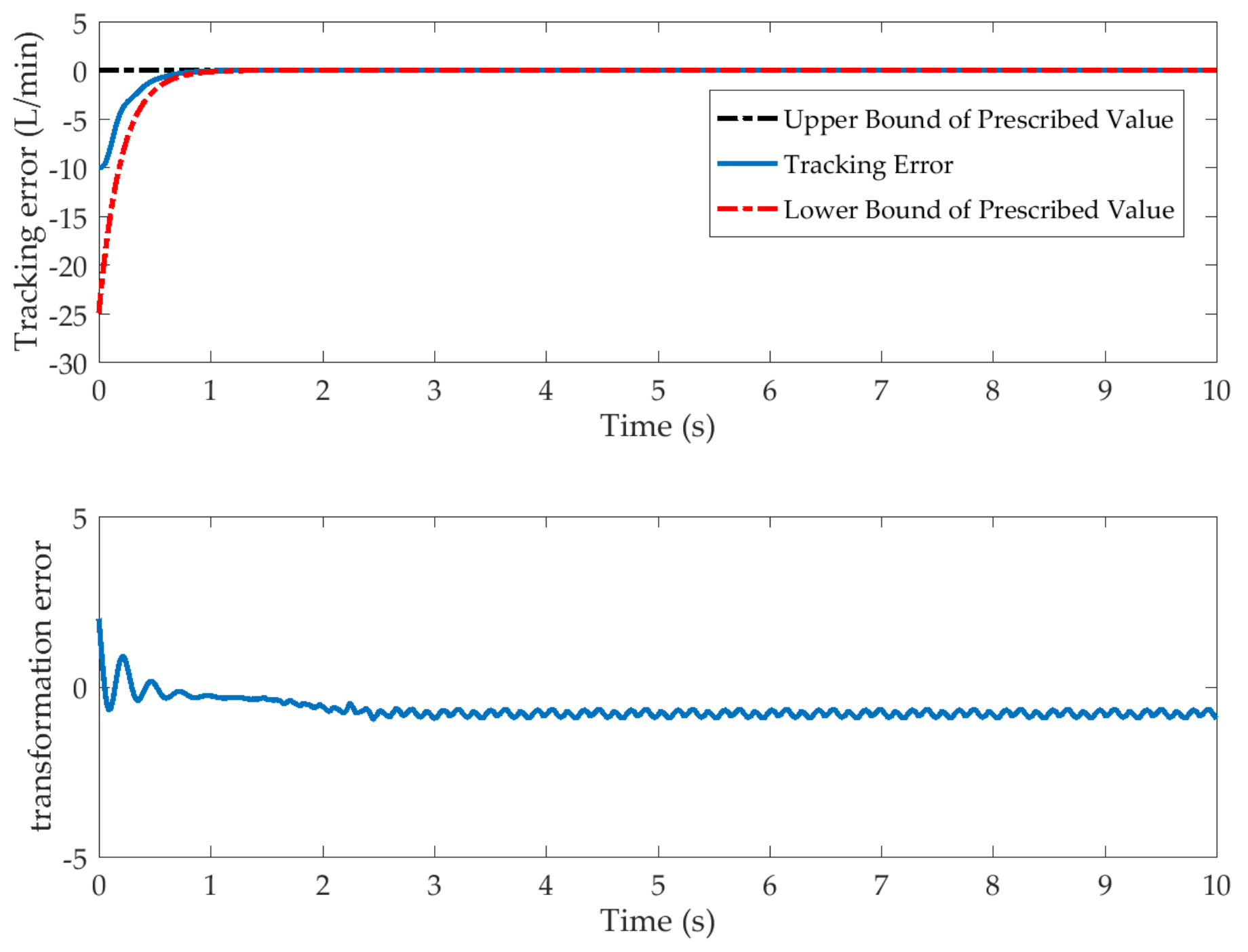

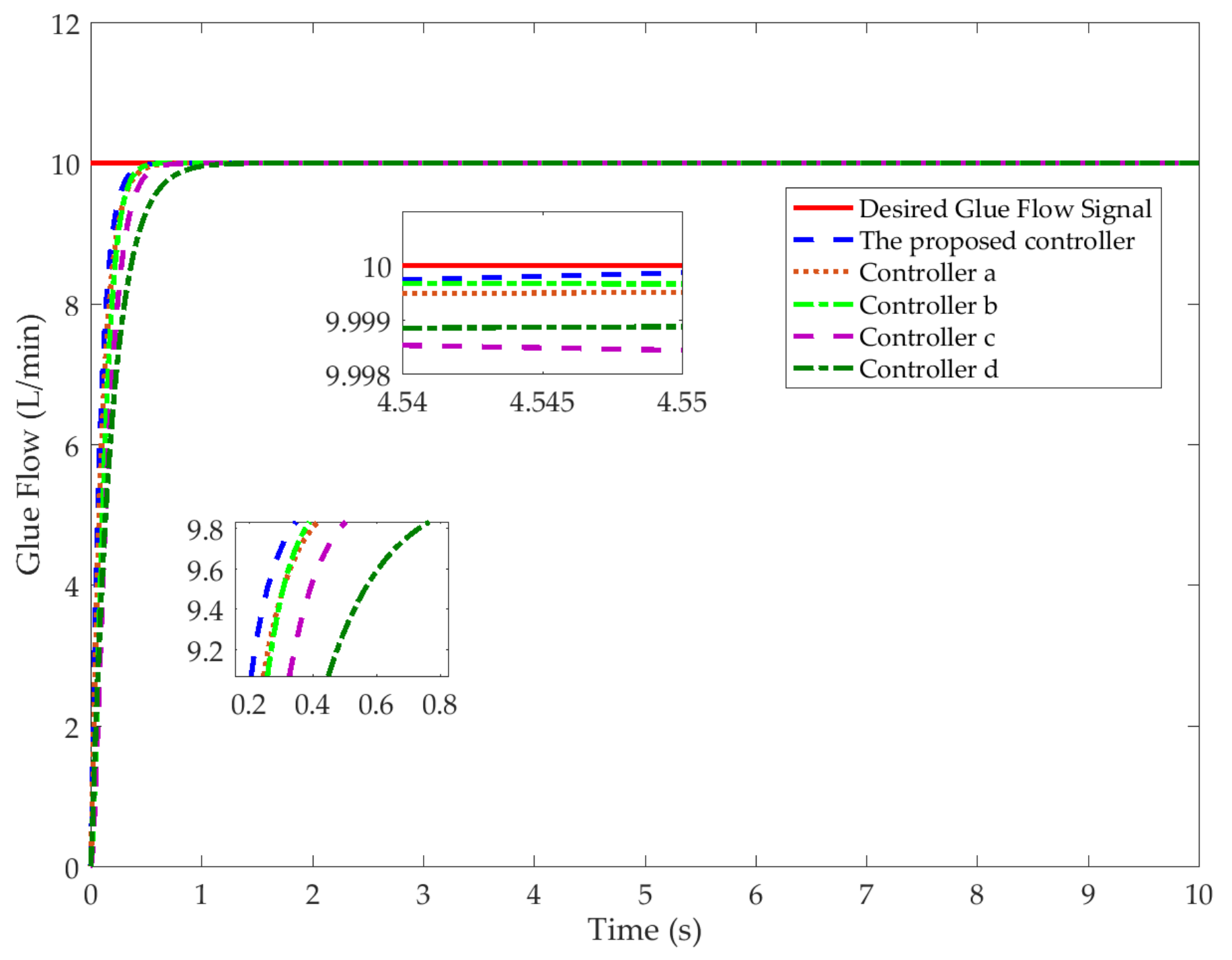

- A compound controller is proposed, in combination with the prescribed performance method and the sliding-mode dynamic surface control method. With this control scheme, the transient and steady-state performance of the system are guaranteed, by limiting the output error to a specified range. By introducing a specific error conversion function, the prescribed performance specifications are incorporated into a closed-loop design with the controller, which effectively promotes the derivation of the design process;

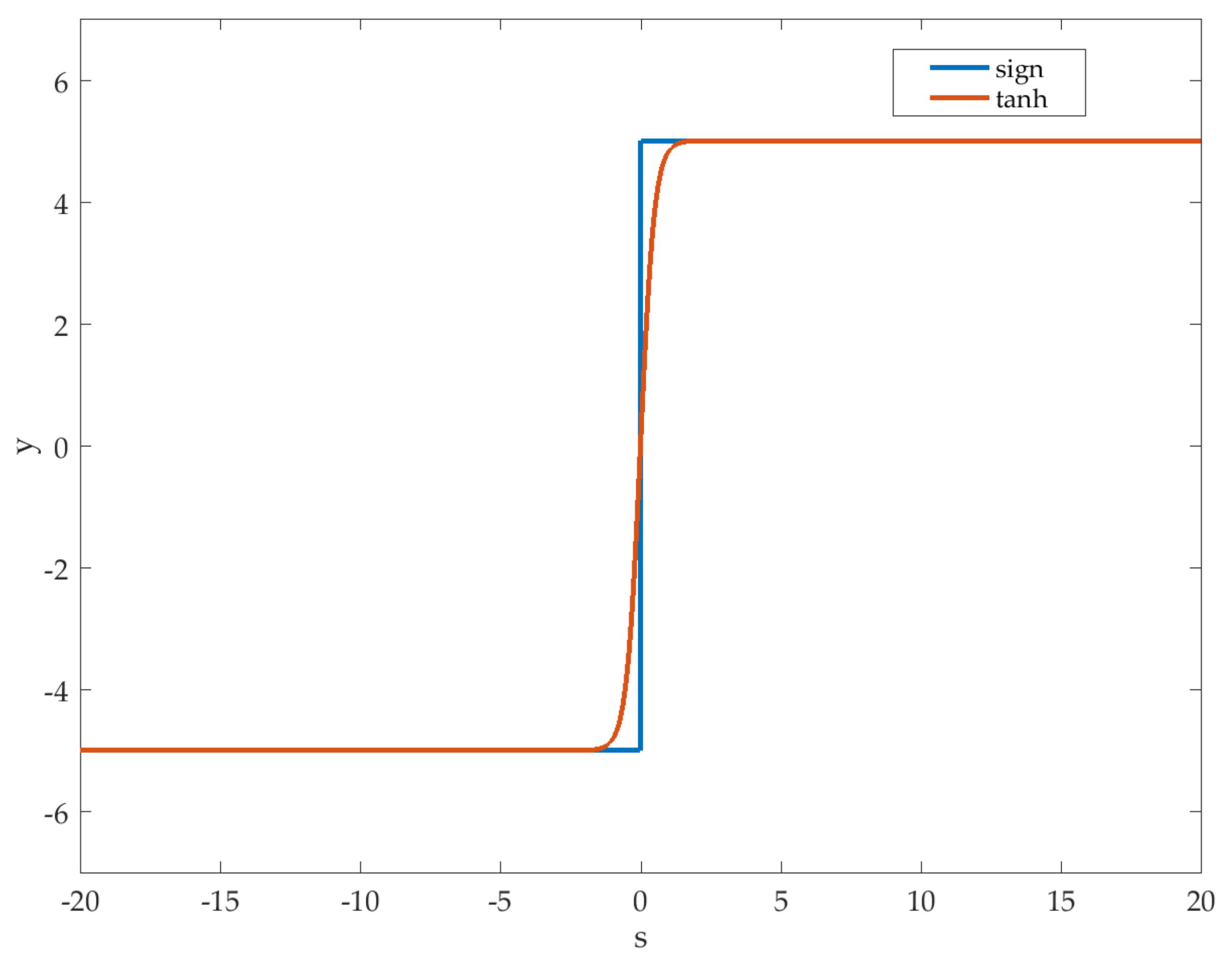

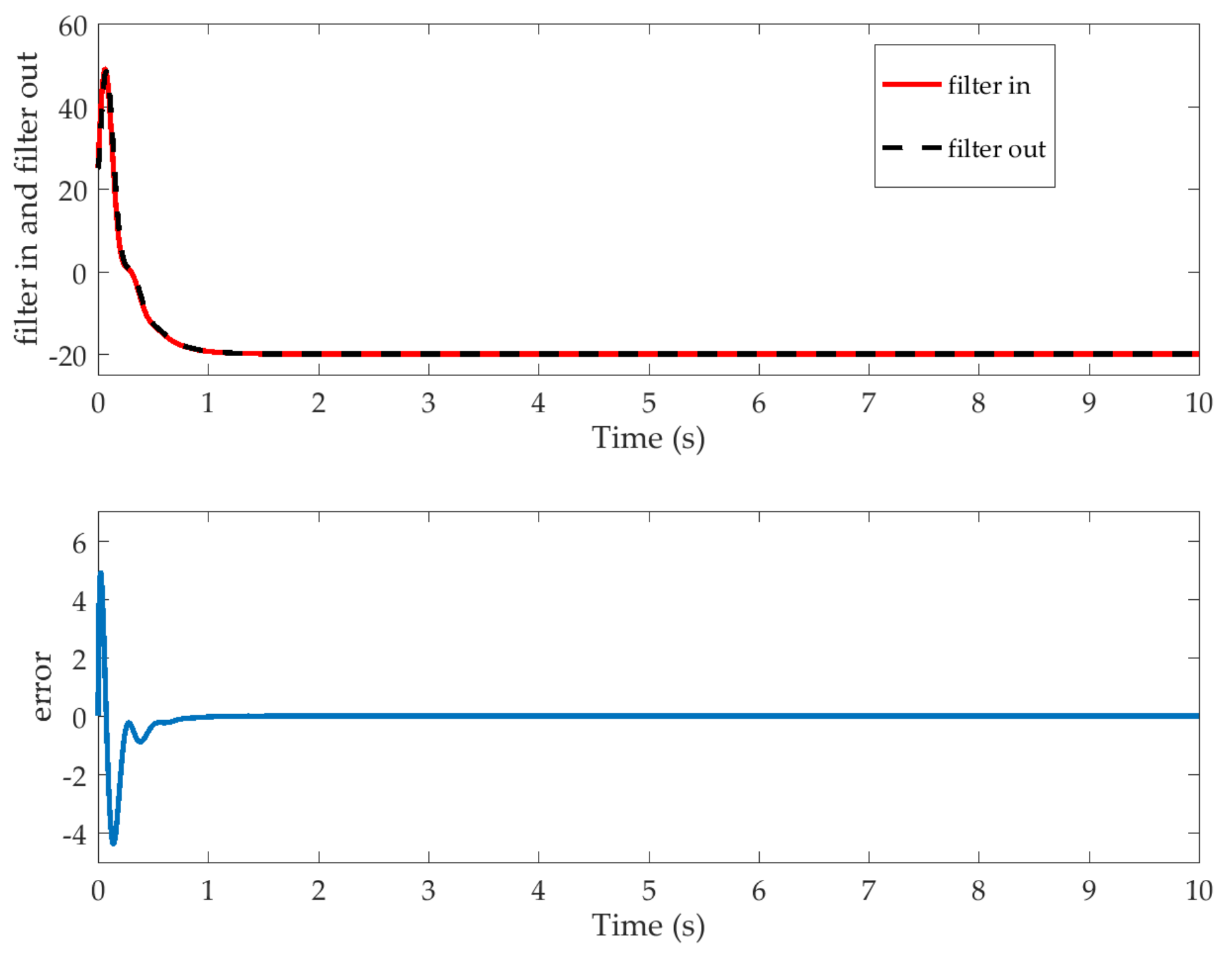

- Considering that the observers cannot completely estimate and compensate for the uncertainty in each channel, the sliding-mode surface with the hyperbolic tangent function is introduced into the dynamic surface, in which the complexity explosion problem is addressed by introducing a first-order filter into the control steps, and the learning burden of the ESOs is reduced without chattering to the actuator, in order to avoid high-gain or high-frequency feedback.

2. Process and Plant Description

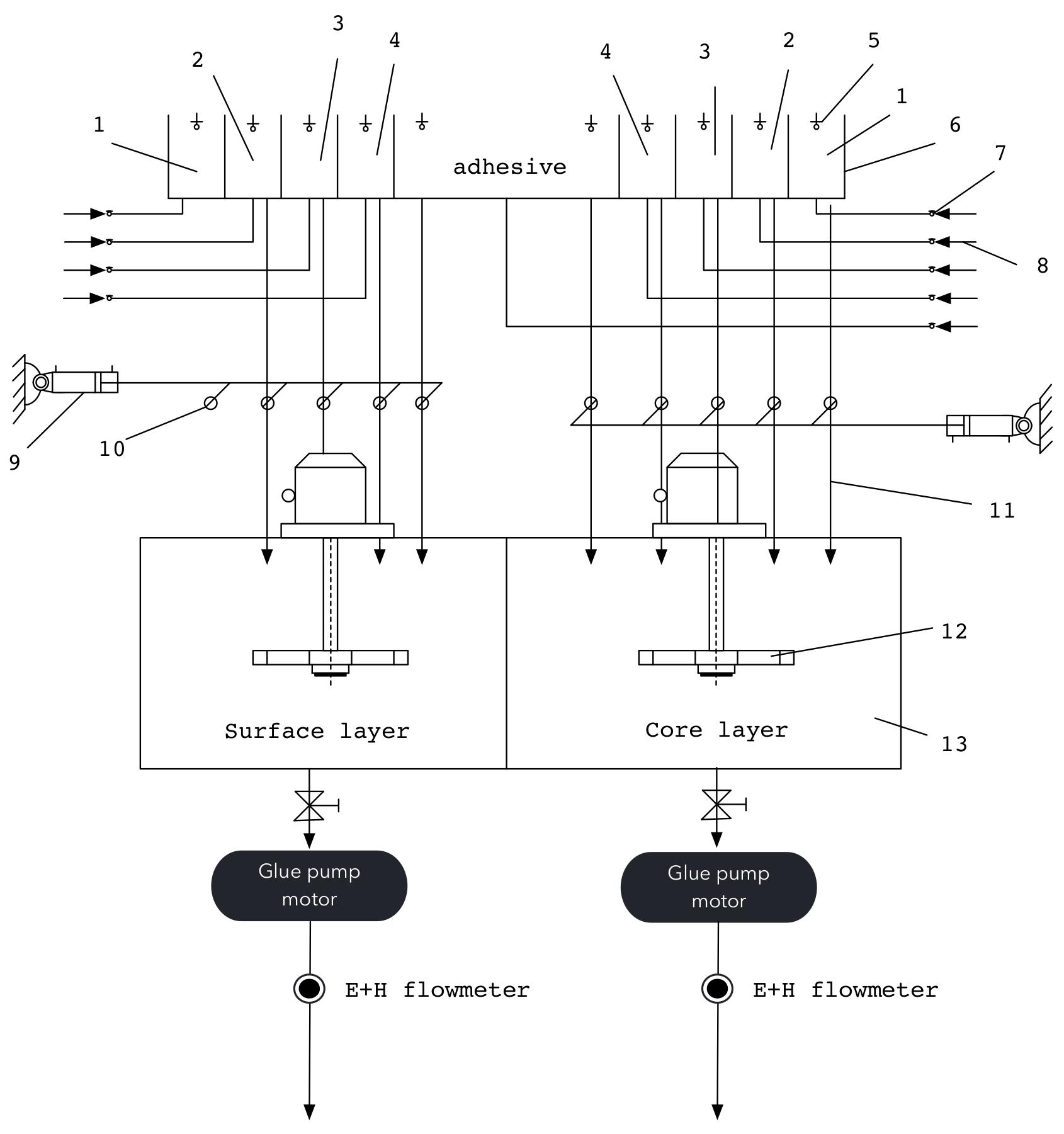

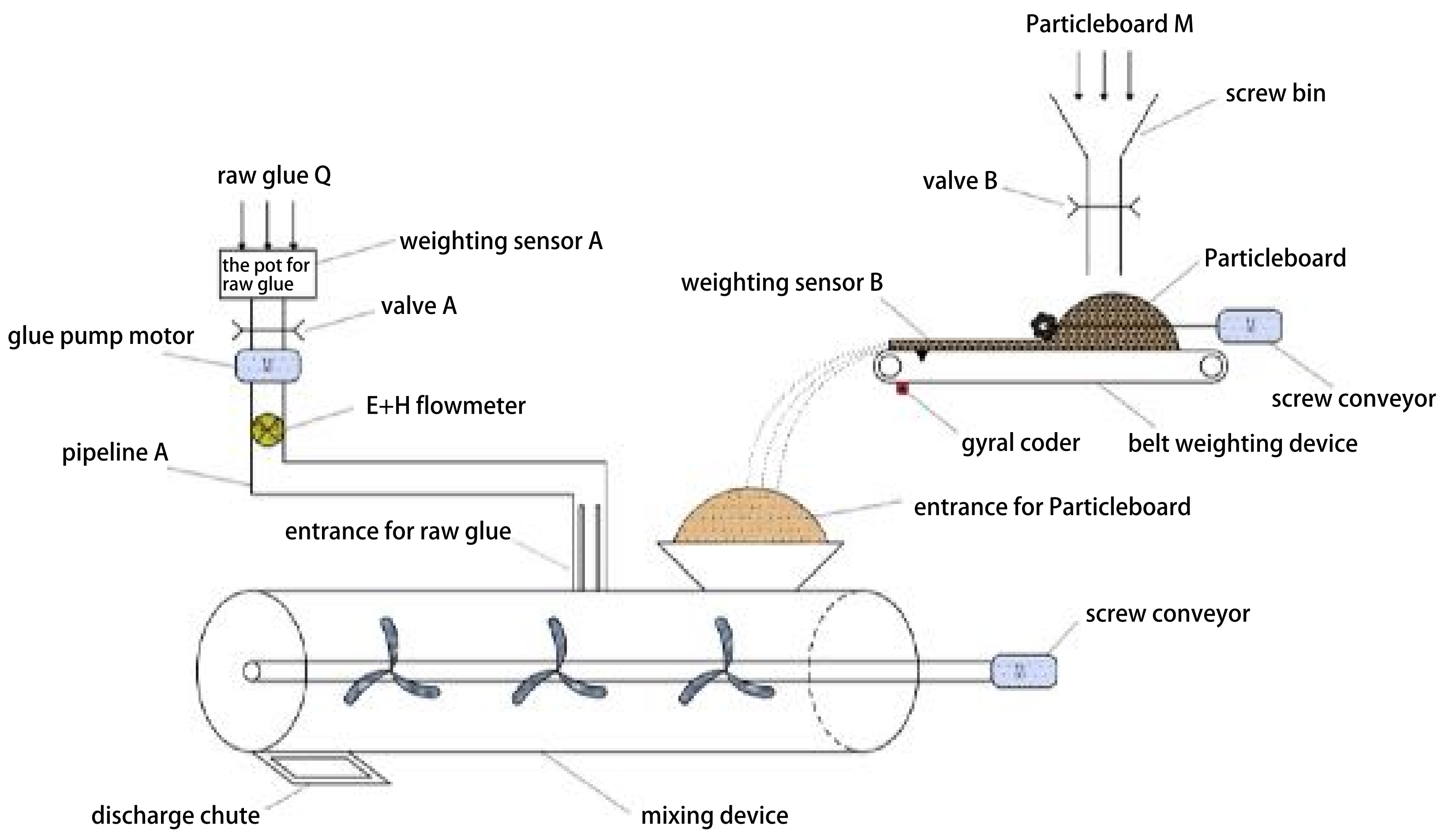

2.1. Particleboard Glue-Dosing Process

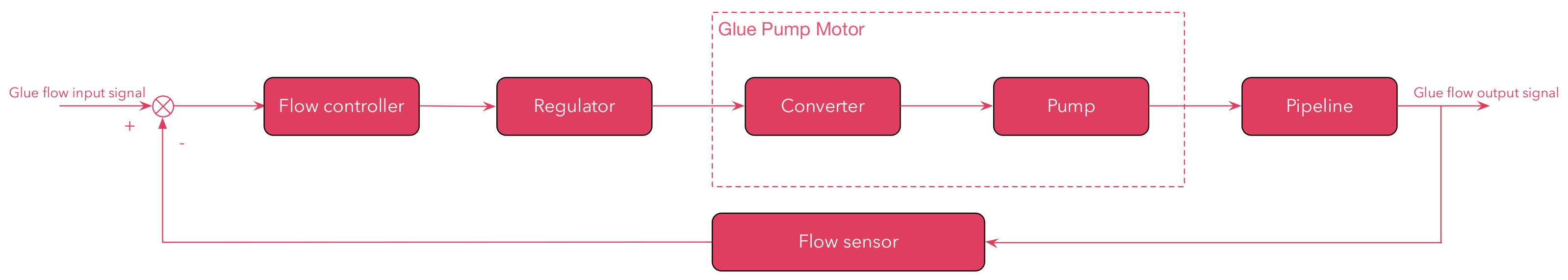

2.2. Plant Description

3. Controller Design

3.1. Prescribed Performance Control

- ρ is positive and decreasing;

- .

3.2. Extend State Observer Design

3.3. Design Steps for a Compound Controller

3.4. Stability Analyses

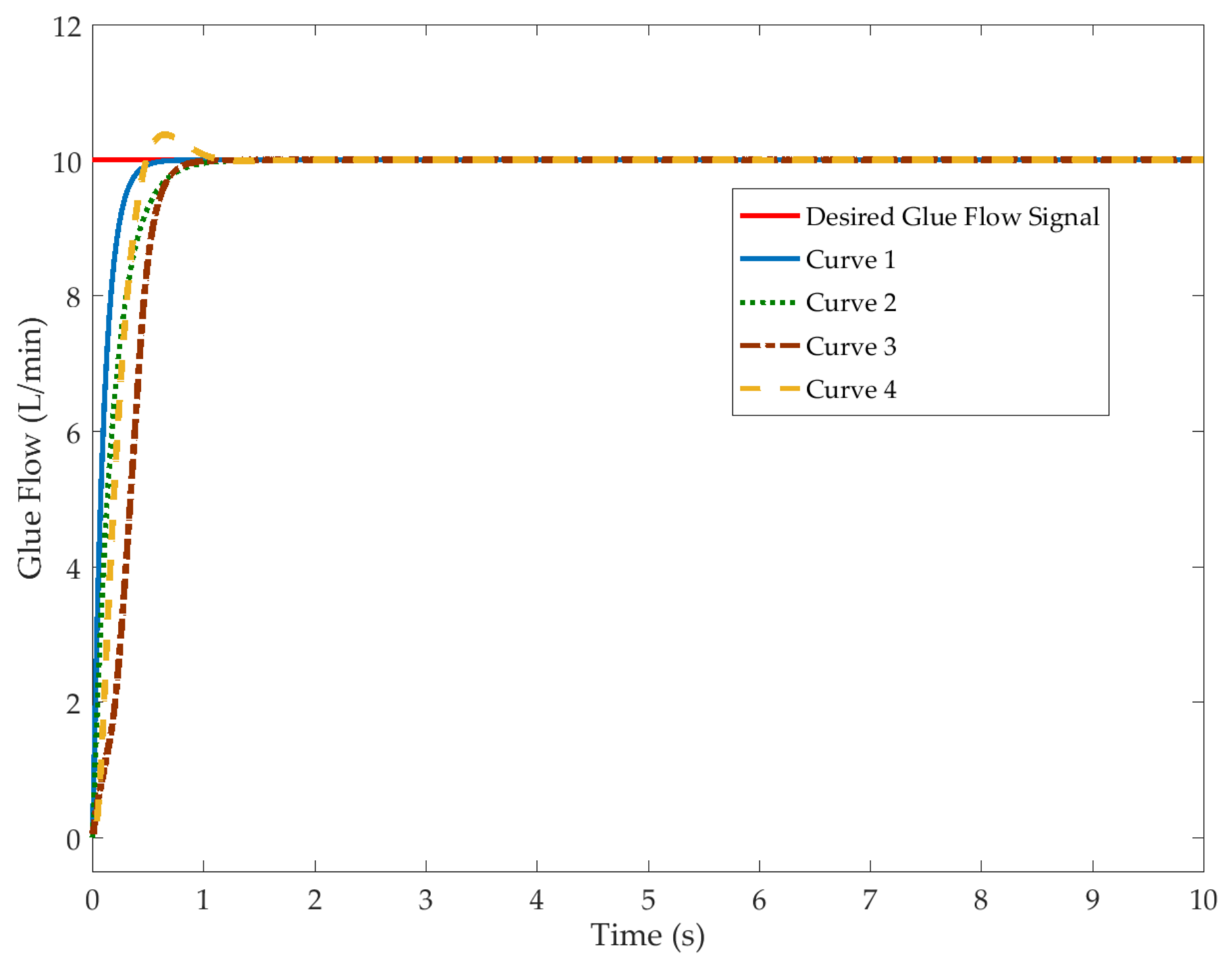

4. Analysis of the Simulation Results

4.1. Simulation Preparation

4.2. Simulation Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Oshaba, A.S.; Ali, E.S.; Abd Elazim, S.M. PI controller design via ABC algorithm for MPPT of PV system supplying DC motor-pump load. Electr. Eng. 2017, 99, 505–518. [Google Scholar] [CrossRef]

- Helian, B.; Chen, Z.; Yao, B. Precision Motion Control of a Servomotor-Pump Direct-Drive Electrohydraulic System with a Nonlinear Pump Flow Mapping. IEEE Trans. Ind. Electron. 2020, 67, 8638–8648. [Google Scholar] [CrossRef]

- Gherbi, A.D.; Arab, A.H.; Salhi, H. Improvement and validation of PV motor-pump model for PV pumping system performance analysis. Sol. Energy 2017, 144, 310–320. [Google Scholar] [CrossRef]

- Wang, S.; Tao, L.; Chen, Q.; Na, J.; Ren, X. USDE-Based Sliding Mode Control for Servo Mechanisms With Unknown System Dynamics. IEEE/Asme Trans. Mechatron. 2020, 25, 1056–1066. [Google Scholar] [CrossRef]

- Chalanga, A.; Kamal, S.; Fridman, L.; Bandyopadhyay, B.; Moreno, J. How to Implement Super-Twisting Controller based on Sliding Mode Observer? In Proceedings of the 13th International Work- shop on Variable Structure Systems, Nantes, France, 29 June–2 July 2014. [Google Scholar] [CrossRef]

- Chalanga, A.; Kamal, S.; Fridman, L.; Bandyopadhyay, B.; Moreno, J. Implementation of Super-Twisting Control: Super-Twisting and Higher Order Sliding Mode Observer Based Approaches. IEEE Trans. Ind. Electron. 2015, 63, 3677–3685. [Google Scholar] [CrossRef]

- Meguenni, K.Z.; Tahar, M.; Benhadria, M.R.; Bestaoui, Y. Fuzzy integral sliding-mode based on backstepping control synthesis for an autonomous helicopter. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2013, 227, 751–765. [Google Scholar] [CrossRef]

- Wu, M.; Zhu, H. Backstepping control of three-pole radial hybrid magnetic bearing. IET Electr. Power Appl. 2020, 14, 1405–1411. [Google Scholar] [CrossRef]

- Sun, K.; Mou, S.; Qiu, J.; Wang, T.; Gao, H. Adaptive Fuzzy Control for Nontriangular Structural Stochastic Switched Nonlinear Systems With Full State Constraints. IEEE Trans. Fuzzy Syst. 2019, 27, 1587–1601. [Google Scholar] [CrossRef]

- Shao, X.; Hu, Q.; Shi, Y. Adaptive Pose Control for Spacecraft Proximity Operations with Prescribed Performance Under Spatial Motion Constraints. IEEE Trans. Control. Syst. Technol. 2020, 29, 1405–1419. [Google Scholar] [CrossRef]

- Liu, Y.J.; Tong, S. Barrier Lyapunov functions for Nussbaum gain adaptive control of full state constrained nonlinear systems. Automatica 2017, 76, 143–152. [Google Scholar] [CrossRef]

- Preitl, S.; Precup, R.E.; János, F.; Bede, B. Iterative Feedback Tuning in Fuzzy Control Systems. Theory and Applications. Acta Polytech. Hung. 2006, 3, 81–96. [Google Scholar]

- Turnip, A.; Panggabean, J.H. Hybrid controller design based magneto-rheological damper lookup table for quarter car suspension. Int. J. Artif. Intell. 2020, 18, 193–206. [Google Scholar]

- Roman, R.C.; Precup, R.E.; Petriu, E.M. Hybrid data-driven fuzzy active disturbance rejection control for tower crane systems. Eur. J. Control 2021, 58, 373–387. [Google Scholar] [CrossRef]

- Bechlioulis, C.P.; Rovithakis, G.A. Robust Adaptive Control of Feedback Linearizable MIMO Nonlinear Systems with Prescribed Performance. IEEE Trans. Autom. Control 2008, 53, 2090–2099. [Google Scholar] [CrossRef]

- Dai, S.L.; He, S.; Lin, H.; Wang, C. Platoon Formation Control With Prescribed Performance Guarantees for USVs. IEEE Trans. Ind. Electron. 2018, 65, 4237–4246. [Google Scholar] [CrossRef]

- Zhu, Y.; Qiao, J.; Guo, L. Adaptive Sliding Mode Disturbance Observer-Based Composite Control with Prescribed Performance of Space Manipulators for Target Capturing. IEEE Trans. Ind. Electron. 2019, 66, 1973–1983. [Google Scholar] [CrossRef]

- Shao, X.; Hu, Q.; Shi, Y.; Jiang, B. Fault-Tolerant Prescribed Performance Attitude Tracking Control for Spacecraft Under Input Saturation. IEEE Trans. Control. Syst. Technol. 2020, 28, 574–582. [Google Scholar] [CrossRef]

- Zheng, Z.; Feroskhan, M. Path Following of a Surface Vessel With Prescribed Performance in the Presence of Input Saturation and External Disturbances. IEEE/Asme Trans. Mechatron. 2017, 22, 2564–2575. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, J.; Zheng, Y. Improved decentralized prescribed performance control for non-affine large-scale systems with uncertain actuator nonlinearity. J. Frankl. Inst. 2019, 356, 7091–7111. [Google Scholar] [CrossRef]

- Tooranjipour, P.; Vatankhah, R.; Arefi, M. Prescribed performance adaptive fuzzy dynamic surface control of non-affine time-varying delayed systems with unknown control directions and dead-zone input. Int. J. Adapt. Control Signal Process. 2019, 33, 1134–1156. [Google Scholar] [CrossRef]

- Zhang, J.J.; Sun, Q.M. Prescribed performance adaptive neural output feedback dynamic surface control for a class of strict-feedback uncertain nonlinear systems with full state constraints and unmodeled dynamics. Int. J. Robust Nonlinear Control 2020, 30, 459–483. [Google Scholar] [CrossRef]

- Tee, K.P.; Ge, S.S.; Tay, E.H. Barrier Lyapunov Functions for the control of output-constrained nonlinear systems. Automatica 2009, 45, 918–927. [Google Scholar] [CrossRef]

- Hu, Y.A.; Li, H.Y.; Huang, H. Prescribed performance-based backstepping design for synchronization of cross-strict feedback hyperchaotic systems with uncertainties. Nonlinear Dyn. 2014, 76, 103–113. [Google Scholar] [CrossRef]

- Jin, Z.; Zhang, W.; Liu, S.; Gu, M. Command-Filtered Backstepping Integral Sliding Mode Control with Prescribed Performance for Ship Roll Stabilization. Appl. Sci. 2019, 9, 4288. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Zhang, Y.; Celler, B.G.; Su, S.W. Neural Adaptive Backstepping Control of a Robotic Manipulator With Prescribed Performance Constraint. IEEE Trans. Neural Networks Learn. Syst. 2019, 30, 3572–3583. [Google Scholar] [CrossRef]

- Song, M.; Lin, Y. Modified adaptive backstepping design method for linear systems. IET Control Theory Appl. 2012, 6, 1137–1144. [Google Scholar] [CrossRef]

- Dai, J.; Ren, B.; Zhong, Q.C. Uncertainty and Disturbance Estimator-Based Backstepping Control for Nonlinear Systems With Mismatched Uncertainties and Disturbances. J. Dyn. Syst. Meas. Control 2018, 140, 121005. [Google Scholar] [CrossRef] [Green Version]

- Swaroop, D.; Hedrick, J.K.; Yip, P.P.; Gerdes, J.C. Dynamic surface control for a class of nonlinear systems. IEEE Trans. Autom. Control 2000, 45, 1893–1899. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Du, J.; Hu, X. Robust adaptive prescribed performance control for dynamic positioning of ships under unknown disturbances and input constraints. Ocean Eng. 2020, 206, 107254. [Google Scholar] [CrossRef]

- Guo, Q.; Liu, Y.; Jiang, D.; Wang, Q.; Xiong, W.; Liu, J.; Li, X. Prescribed Performance Constraint Regulation of Electrohydraulic Control Based on Backstepping with Dynamic Surface. Appl. Sci. 2018, 8, 776. [Google Scholar] [CrossRef] [Green Version]

- Chen, L. Asymmetric prescribed performance-barrier Lyapunov function for the adaptive dynamic surface control of unknown pure-feedback nonlinear switched systems with output constraints. Int. J. Adapt. Control Signal Process. 2018, 32, 1417–1439. [Google Scholar] [CrossRef]

- Jia, F.; Wang, X.; Zhou, X. Robust adaptive prescribed performance control for a class of nonlinear pure-feedback systems. Int. J. Robust Nonlinear Control 2019, 29, 3971–3987. [Google Scholar] [CrossRef]

- Lei, D.; Wang, T.; Cao, D.; Fei, J. Adaptive Dynamic Surface Control of MEMS Gyroscope Sensor Using Fuzzy Compensator. IEEE Access 2016, 4, 4148–4154. [Google Scholar] [CrossRef]

- Han, S.I.; Lee, J.M. Adaptive dynamic surface control with sliding-mode control and RWNN for robust positioning of a linear motion stage. Mechatronics 2012, 22, 222–238. [Google Scholar] [CrossRef]

- Keighobadi, J.; Hosseini-Pishrobat, M.; Faraji, J. Adaptive neural dynamic surface control of mechanical systems using integral terminal sliding-mode. Neurocomputing 2020, 379, 141–151. [Google Scholar] [CrossRef]

- Jing, C.; Xu, H.; Niu, X. Adaptive sliding-mode disturbance rejection control with prescribed performance for robotic manipulators. ISA Trans. 2019, 91, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xu, D.; Jiang, B.; Pan, T. Prescribed performance based model-free adaptive sliding-mode constrained control for a class of nonlinear systems. Inf. Sci. 2021, 544, 97–116. [Google Scholar] [CrossRef]

- Luenberger, D.G. Observing the State of a Linear System. IEEE Trans. Mil. Electron. 1964, 8, 74–80. [Google Scholar] [CrossRef]

- Ma, H.; Li, H.; Liang, H.; Dong, G. Adaptive Fuzzy Event-Triggered Control for Stochastic Nonlinear Systems With Full State Constraints and Actuator Faults. IEEE Trans. Fuzzy Syst. 2019, 27, 2242–2254. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, F.; Xu, L.; Yang, E. State filtering-based least squares parameter estimation for bilinear systems using the hierarchical identification principle. IET Control Theory Appl. 2018, 12, 1704–1713. [Google Scholar] [CrossRef] [Green Version]

- Cui, R.; Chen, L.; Yang, C.; Chen, M. Extended State Observer-Based Integral Sliding Mode Control for an Underwater Robot With Unknown Disturbances and Uncertain Nonlinearities. IEEE Trans. Ind. Electron. 2017, 64, 6785–6795. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Xi, J.; He, M.; Liu, G. Robust time-varying formation design for multiagent systems with disturbances: Extended-state-observer method. Int. J. Robust Nonlinear Control 2020, 30, 2796–2808. [Google Scholar] [CrossRef] [Green Version]

- Yao, J.; Deng, W. Active Disturbance Rejection Adaptive Control of Hydraulic Servo Systems. IEEE Trans. Ind. Electron. 2017, 64, 8023–8032. [Google Scholar] [CrossRef]

- Hamidat, A.; Benyoucef, B. Mathematic models of photovoltaic motor-pump systems. Renew. Energy 2008, 33, 933–942. [Google Scholar] [CrossRef]

- Singh, B.; Putta Swamy, C.L.; Singh, B.P. Analysis and development of a low-cost permanent magnet brushless DC motor drive for PV-array fed water pumping system. Sol. Energy Mater. Sol. Cells 1998, 51, 55–67. [Google Scholar] [CrossRef]

- Tee, K.P.; Ren, B.; Ge, S.S. Control of nonlinear systems with time-varying output constraints. Automatica 2011, 47, 2511–2516. [Google Scholar] [CrossRef]

- Ren, B.B.; Ge, S.S.; Tee, K.P.; Lee, T.H. Adaptive Neural Control for Output Feedback Nonlinear Systems Using a Barrier Lyapunov Function. IEEE Trans. Neural Netw. 2010, 21, 1339–1345. [Google Scholar] [CrossRef]

- Mien, V.; Mavrovouniotis, M.; Ge, S.S. An Adaptive Backstepping Nonsingular Fast Terminal Sliding Mode Control for Robust Fault Tolerant Control of Robot Manipulators. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 1448–1458. [Google Scholar] [CrossRef] [Green Version]

- Chang, Y.H.; Chan, W.S. Adaptive Dynamic Surface Control for Uncertain Nonlinear Systems With Interval Type-2 Fuzzy Neural Networks. IEEE Trans. Cybern. 2014, 44, 293–304. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, C.; Zhu, L.; Wang, C. The Research of Improved Active Disturbance Rejection Control Algorithm for Particleboard Glue System Based on Neural Network State Observer. Algorithms 2019, 12, 259. [Google Scholar] [CrossRef] [Green Version]

| Time (s) | Glue Flow (L/min) | Time (s) | Glue Flow (L/min) |

|---|---|---|---|

| 10 | 0.0438 | 90 | 8.4125 |

| 20 | 0.1375 | 100 | 9.0313 |

| 30 | 0.8938 | 110 | 9.4375 |

| 40 | 1.8625 | 120 | 9.7437 |

| 50 | 3.1813 | 130 | 10.1187 |

| 60 | 4.9625 | 140 | 10.2188 |

| 70 | 6.4812 | 150 | 10.3000 |

| 80 | 7.5813 | 160 | 10.3500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zhu, L.; Zhang, C.; Wang, C.; Xiao, K. Prescribed Performance Control with Sliding-Mode Dynamic Surface for a Glue Pump Motor Based on Extended State Observers. Actuators 2021, 10, 282. https://doi.org/10.3390/act10110282

Wang P, Zhu L, Zhang C, Wang C, Xiao K. Prescribed Performance Control with Sliding-Mode Dynamic Surface for a Glue Pump Motor Based on Extended State Observers. Actuators. 2021; 10(11):282. https://doi.org/10.3390/act10110282

Chicago/Turabian StyleWang, Peiyu, Liangkuan Zhu, Chunrui Zhang, Chengcheng Wang, and Kangming Xiao. 2021. "Prescribed Performance Control with Sliding-Mode Dynamic Surface for a Glue Pump Motor Based on Extended State Observers" Actuators 10, no. 11: 282. https://doi.org/10.3390/act10110282

APA StyleWang, P., Zhu, L., Zhang, C., Wang, C., & Xiao, K. (2021). Prescribed Performance Control with Sliding-Mode Dynamic Surface for a Glue Pump Motor Based on Extended State Observers. Actuators, 10(11), 282. https://doi.org/10.3390/act10110282