Microstructure Characterization and Mechanical Property of Mg/Al Laminated Composite Prepared by the Novel Approach: Corrugated + Flat Rolling (CFR)

Abstract

:1. Introduction

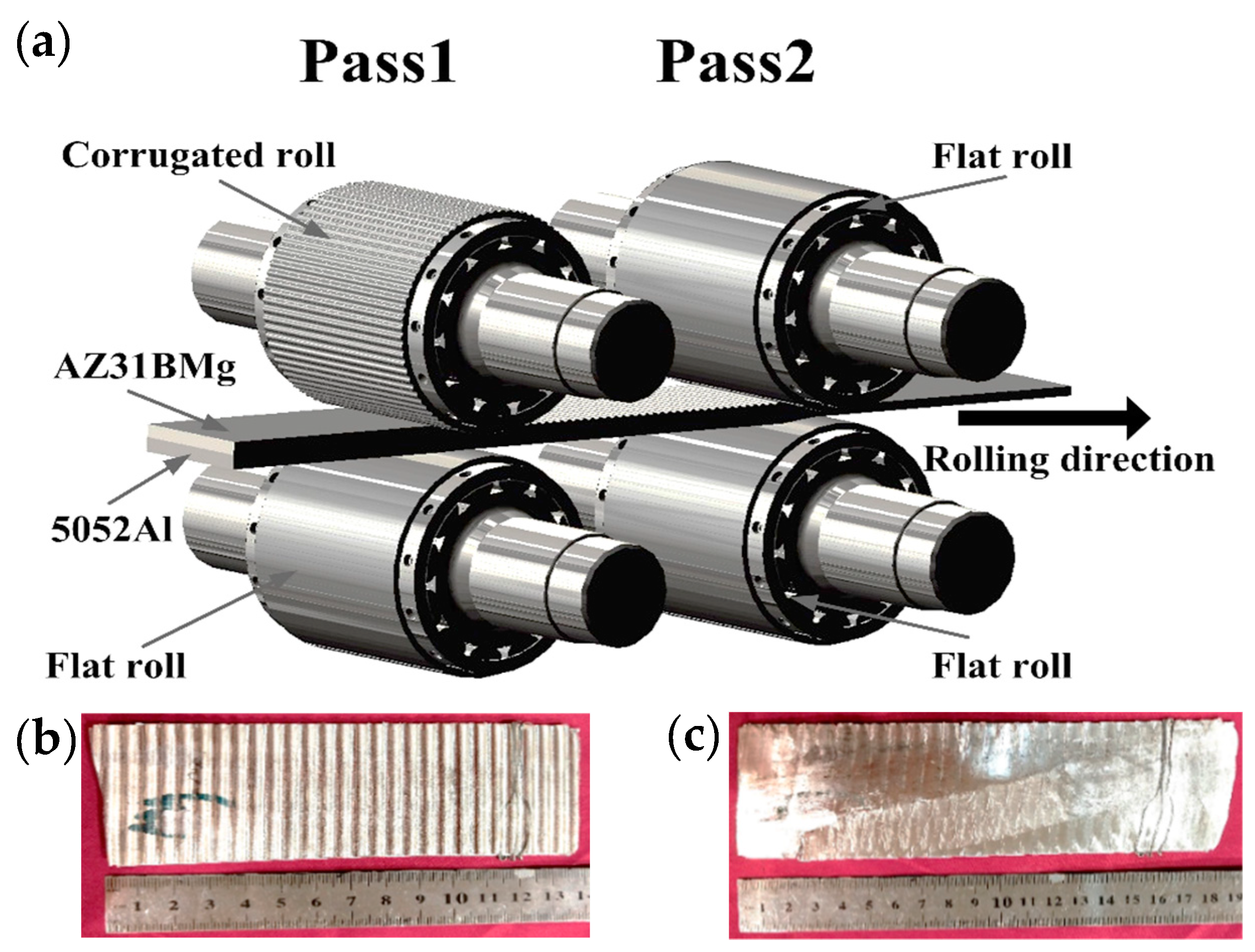

2. Experimental Research and Numerical Simulation Analysis

2.1. Experimental Research

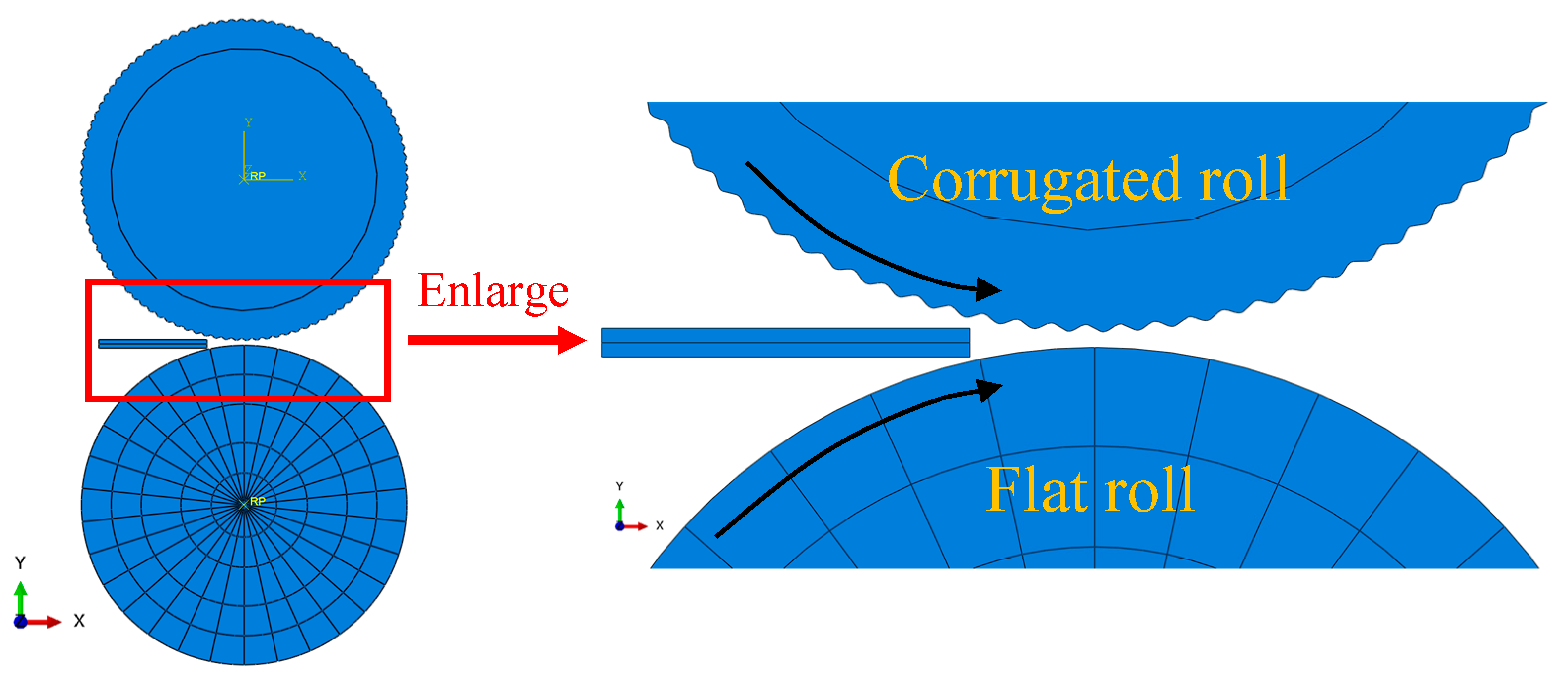

2.2. Numerical Simulation Analysis

3. Results and Discussion

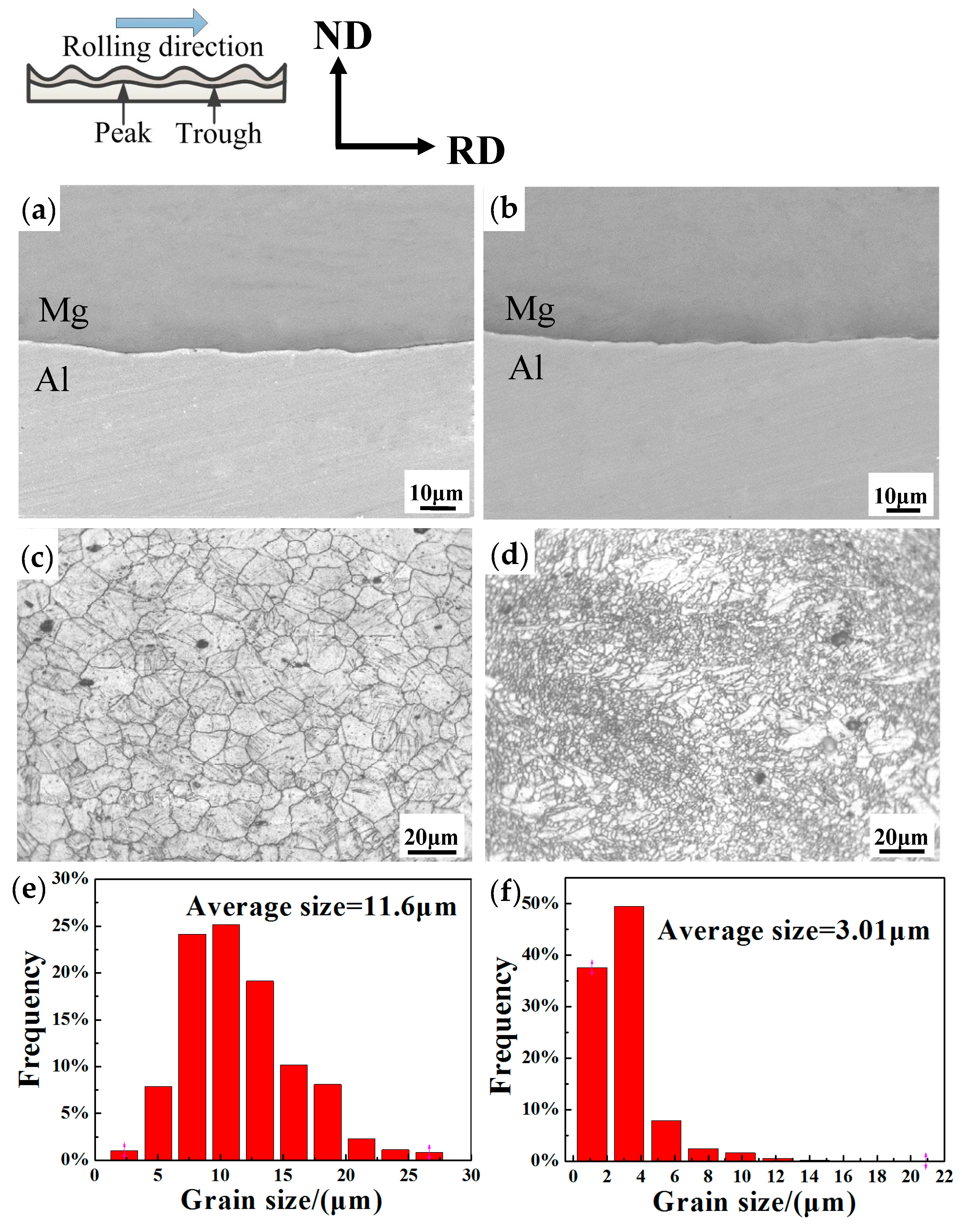

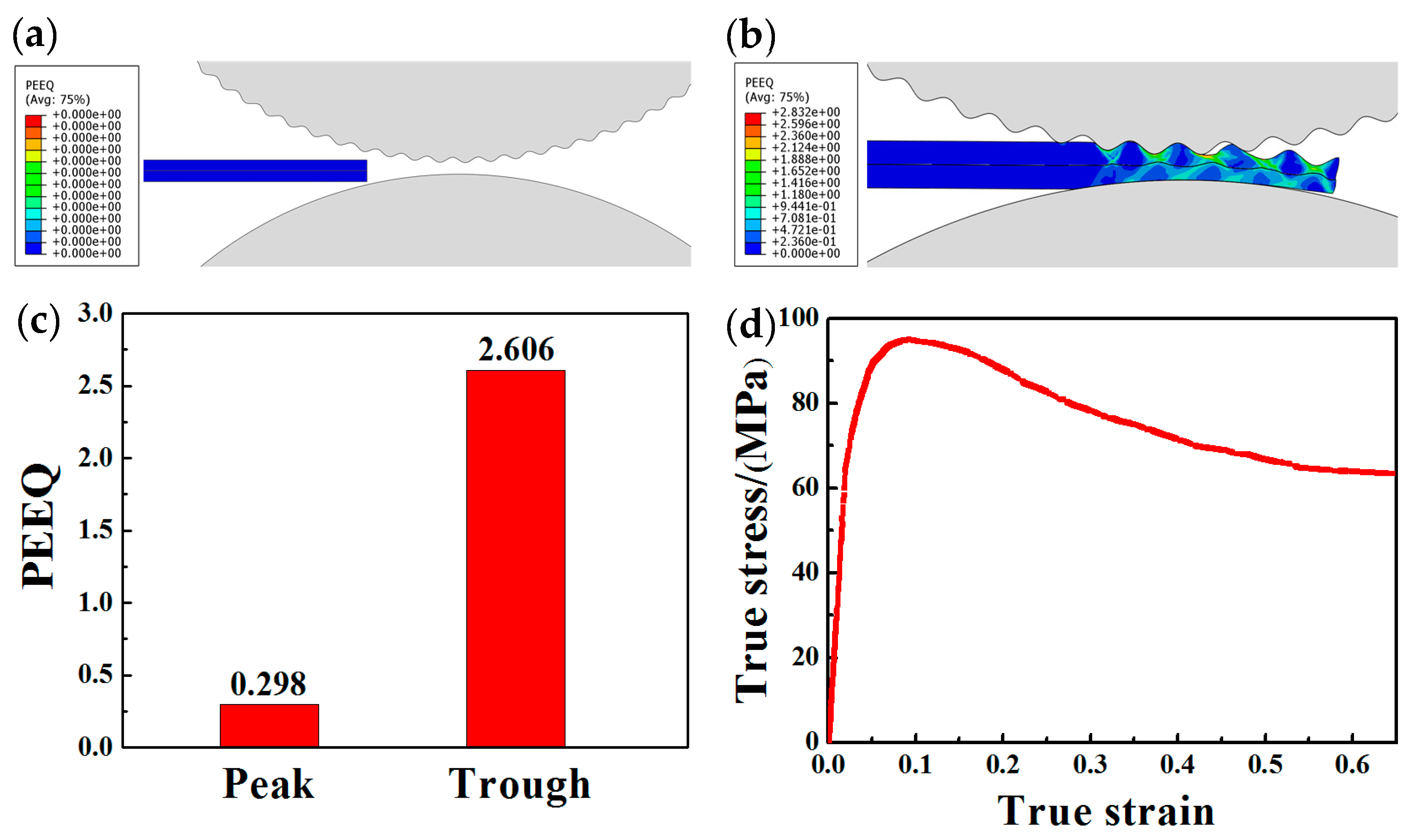

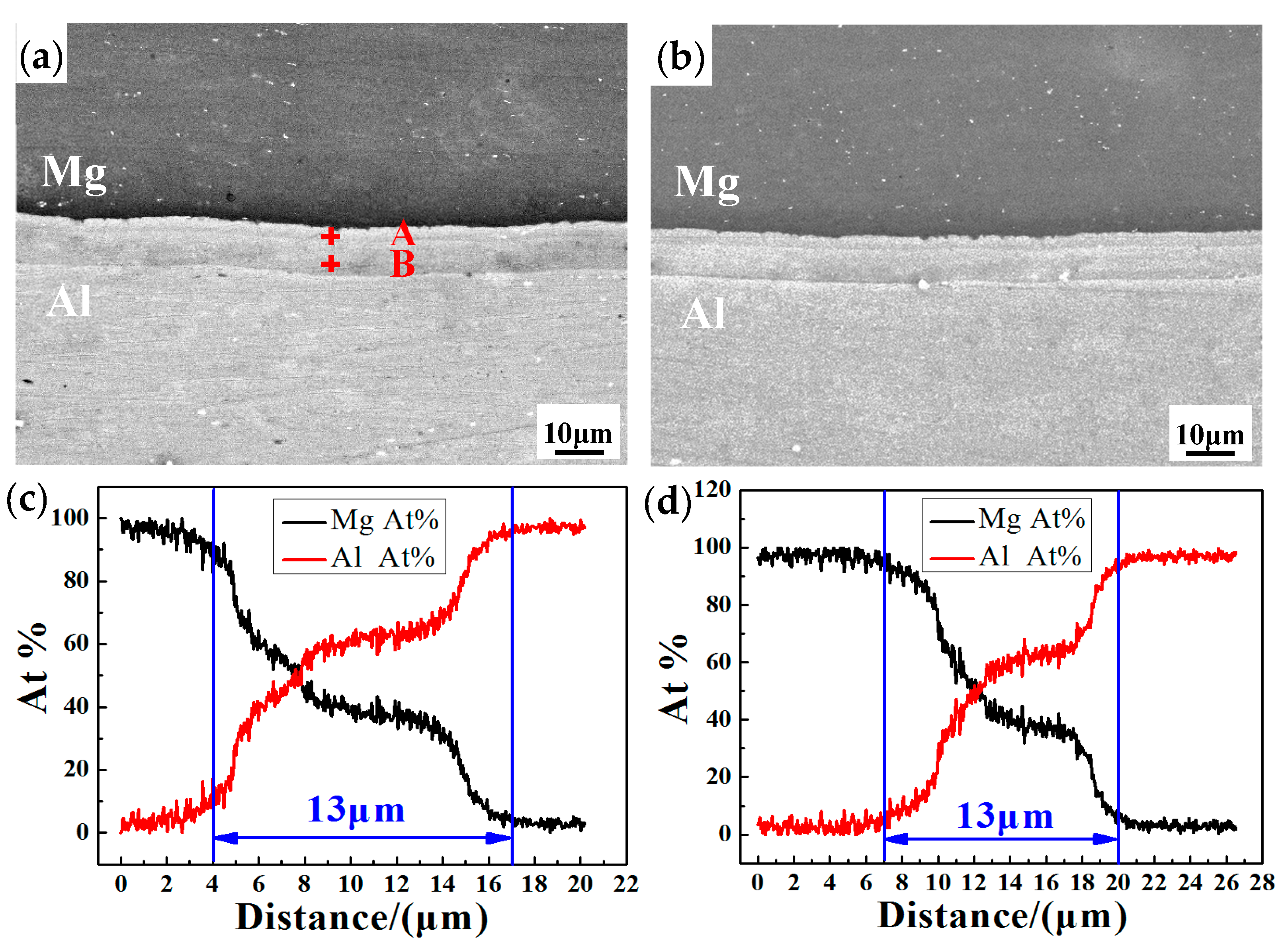

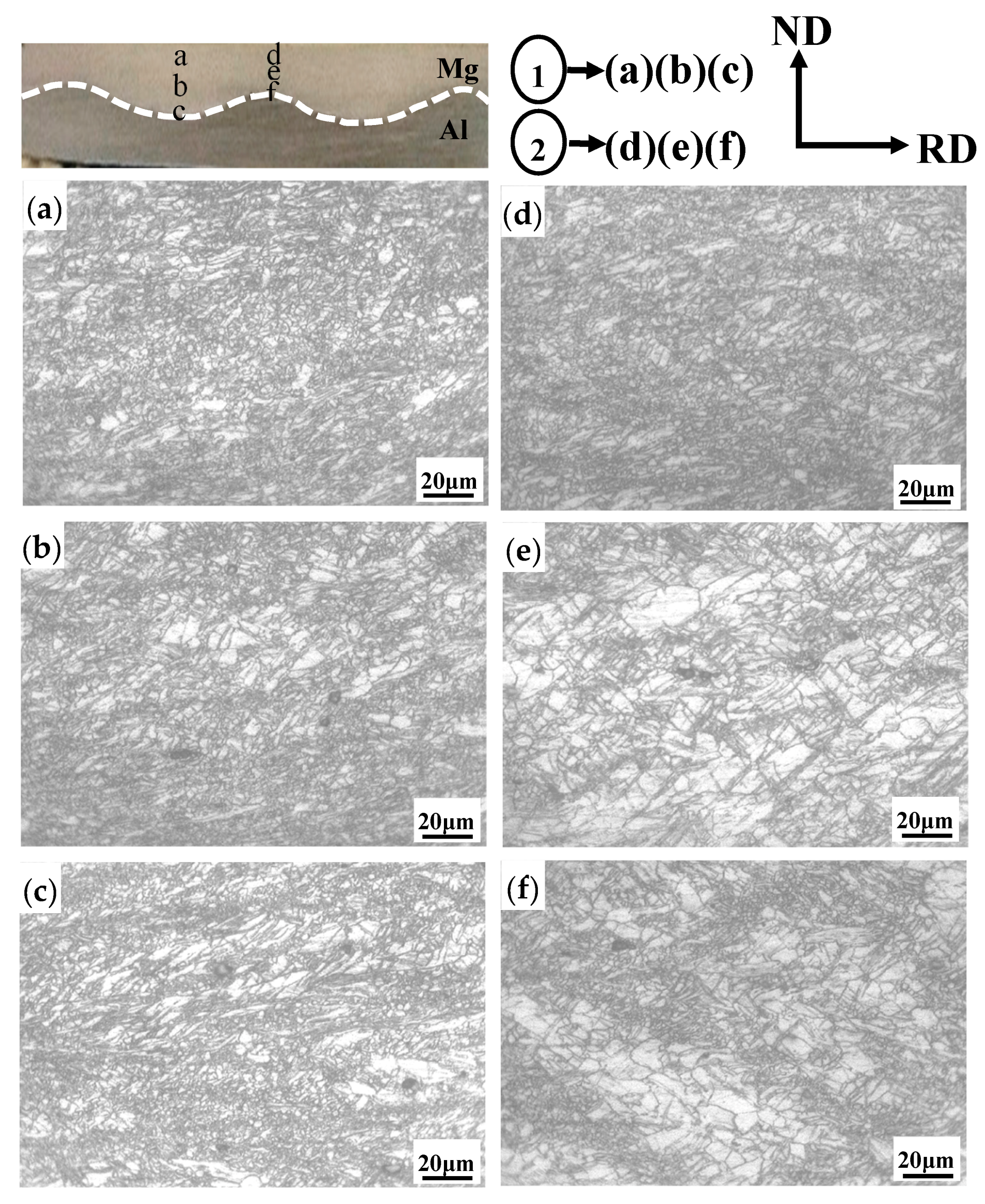

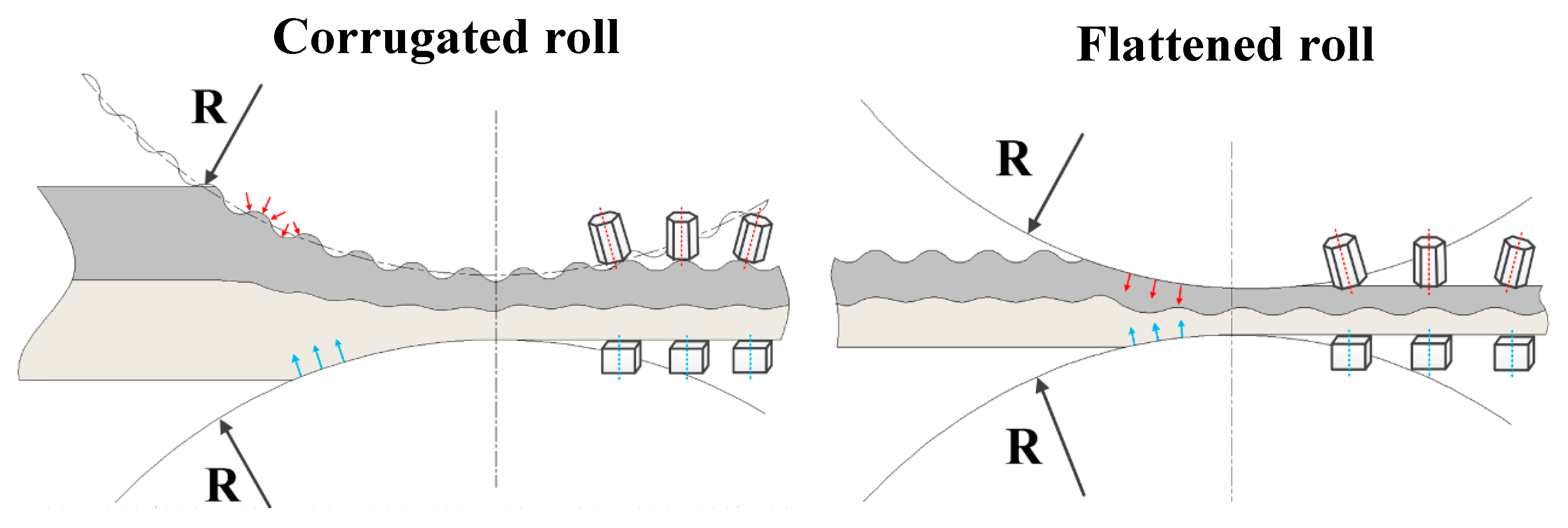

3.1. Interfacial Microstructure and Rolling Simulation of the Corrugated Mg/Al Laminated Composite

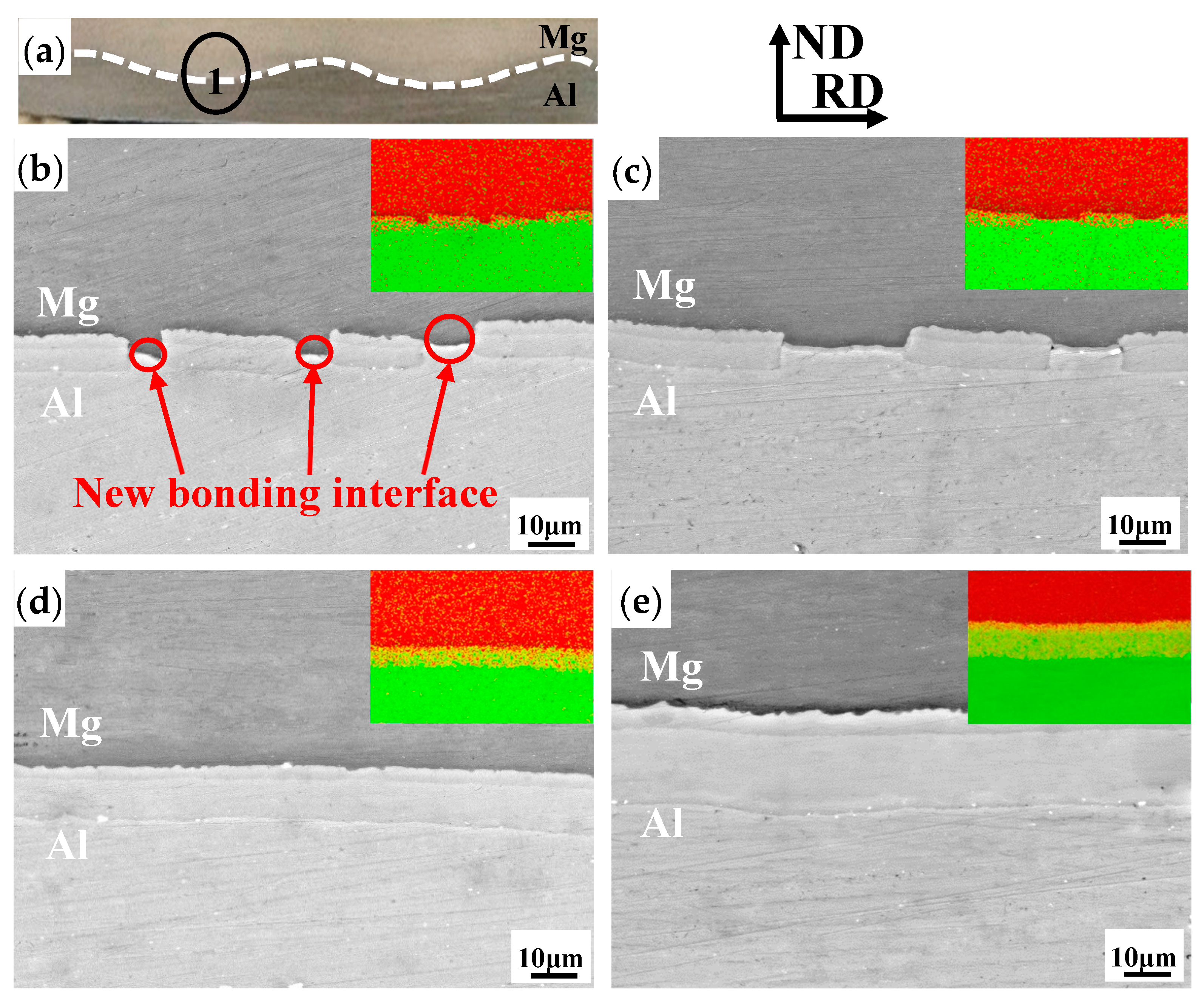

3.2. Interfacial Microstructure after Intermediate Annealing

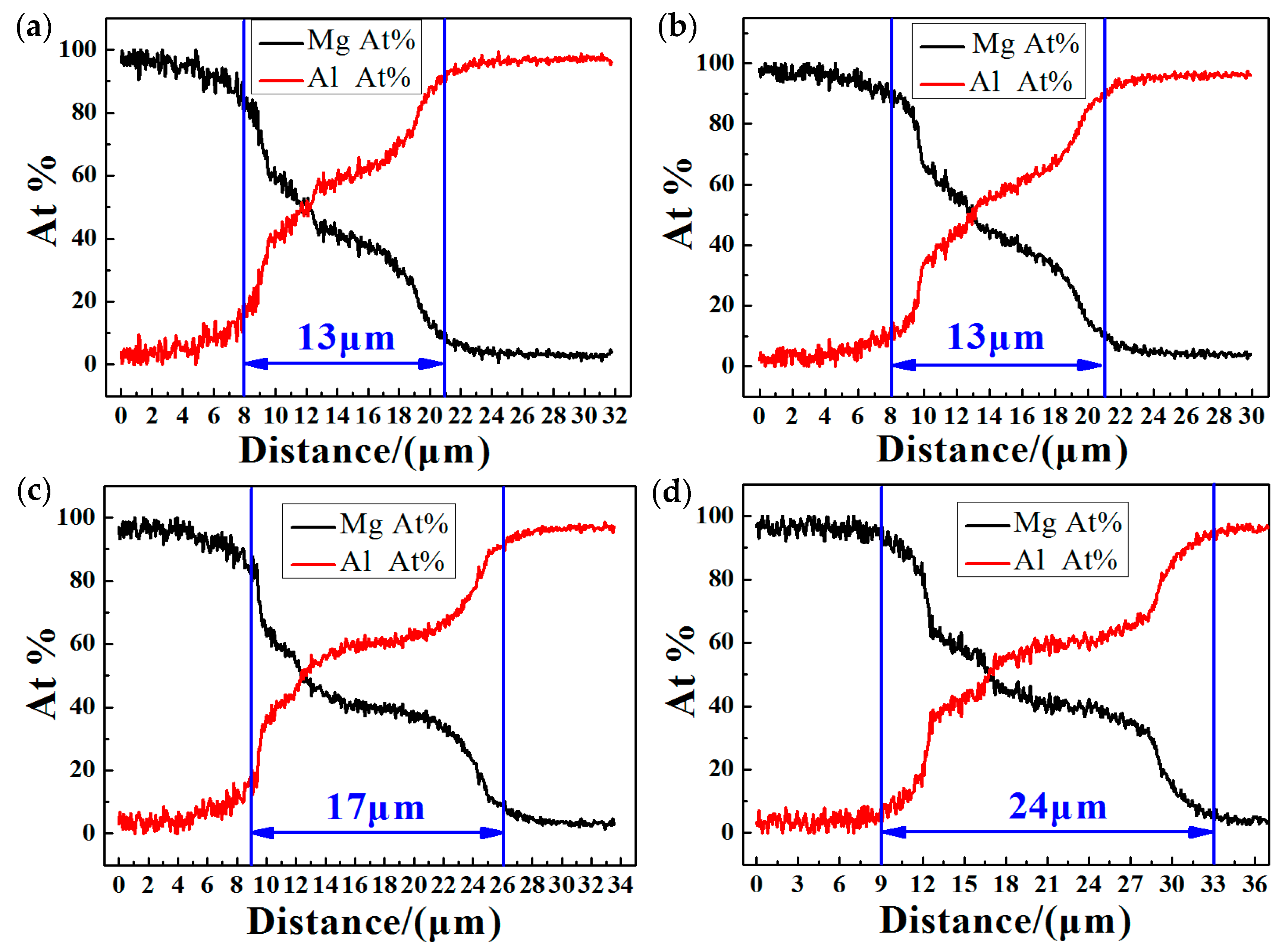

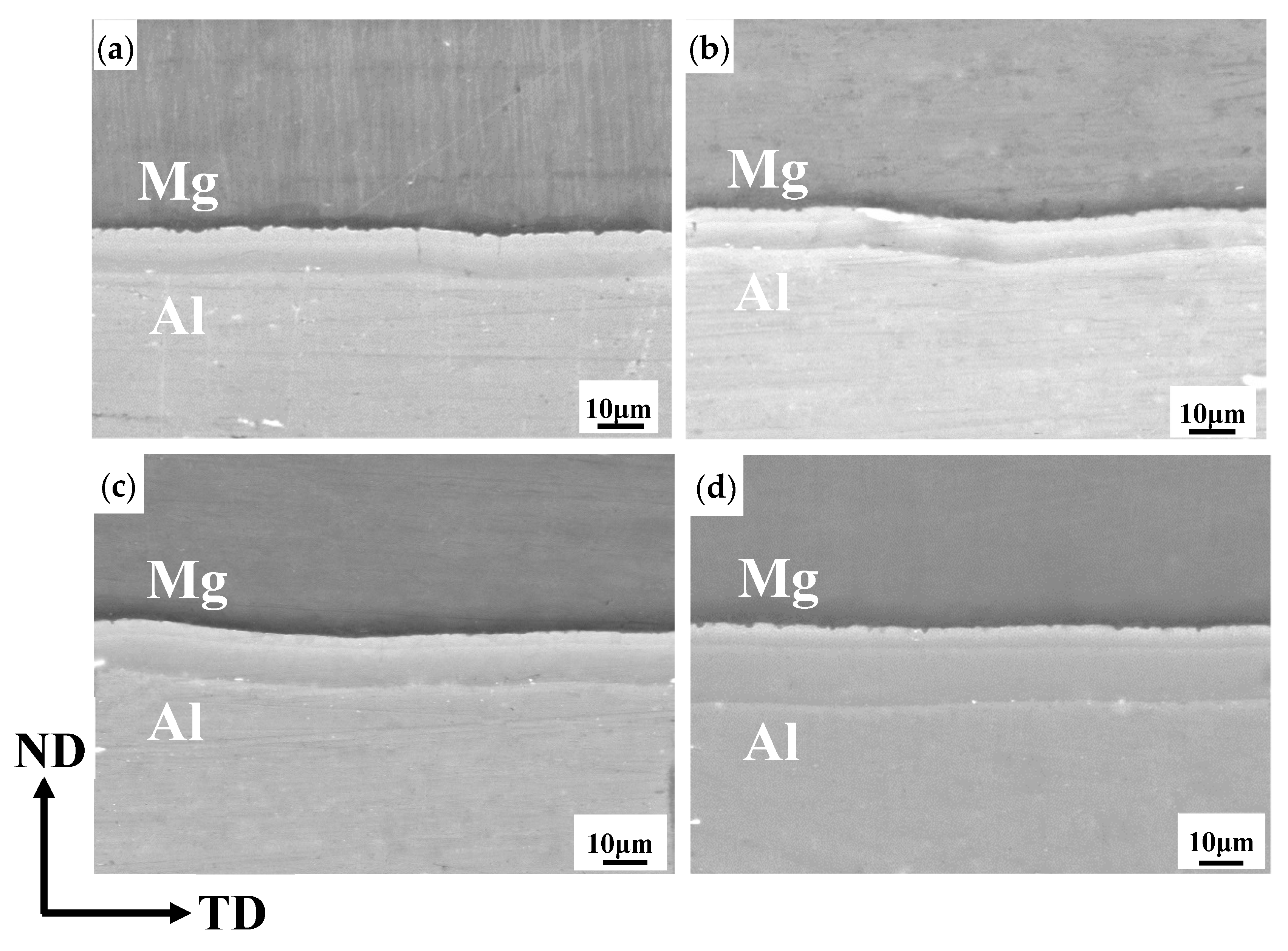

3.3. Interfacial Microstructure of the Flattened Mg/Al Laminated Composite

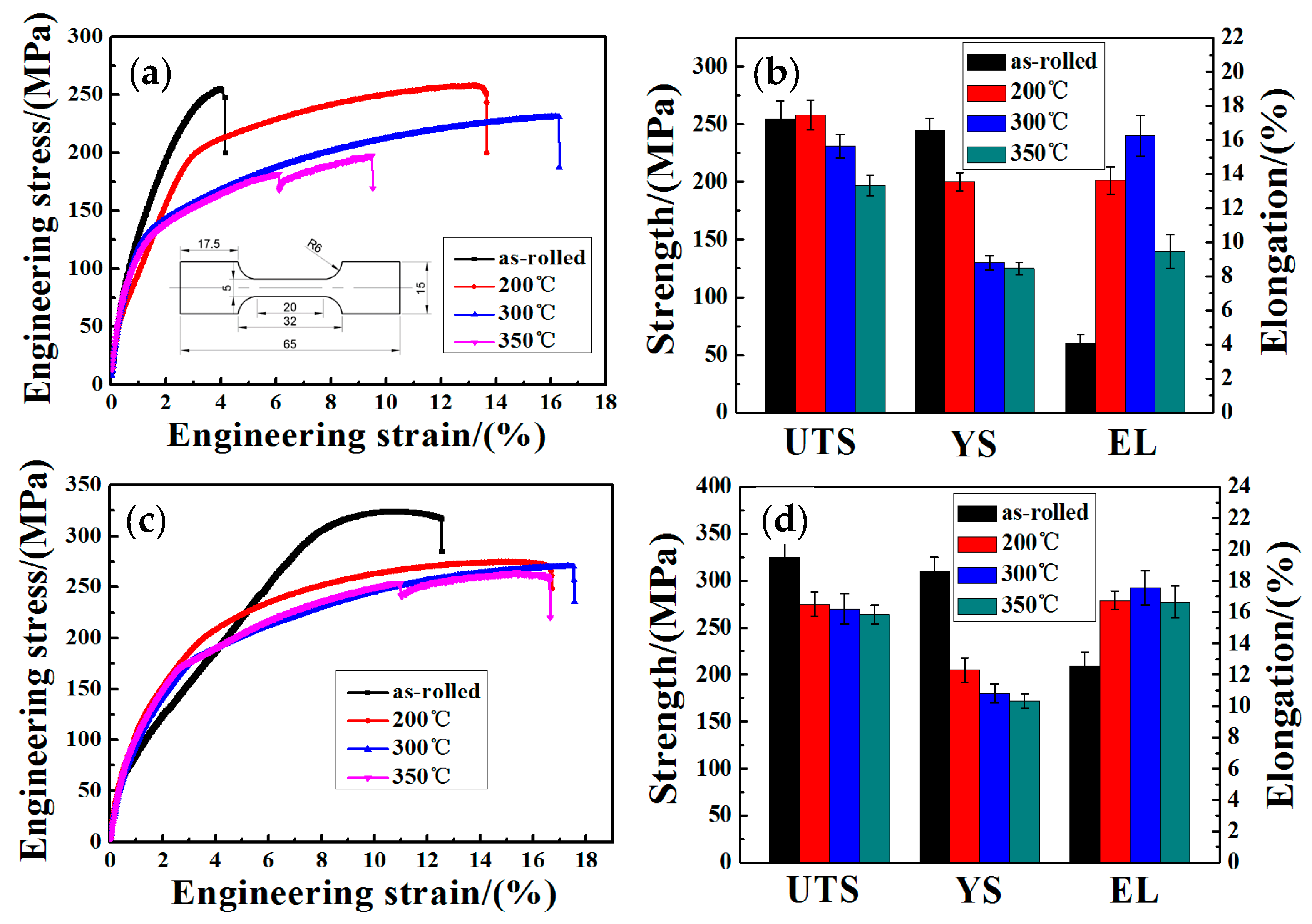

3.4. Mechanical Properties of the Flattened Mg/Al Laminated Composite

4. Conclusions

- (1)

- During the first corrugated rolling process, severe plastic deformation occurs at the trough position. This periodic larger strain at the trough position contributes to the tight bonding and grain refinement than that of the peak position.

- (2)

- The IMC layer is discontinuous along the longitudinal direction while being continuous along the transverse direction for the flattened as-rolled sample. The spatial distribution of the microstructure can be observed along the thickness and rolling direction for magnesium alloy and aluminum alloy after the CFR process.

- (3)

- The Mg/Al laminated composites prepared by CFR exhibit outstanding tensile properties along both RD and TD, which can be attributed to the microstructure refinement induced by the severe shear strain. Mg/Al composites produced by CFR not only result in a reduction in the longitudinal tensile properties, but also greatly improves the transverse tensile properties.

- (4)

- The tensile properties along TD are higher than that along RD in both the as-rolled and heat-treated state, and this significant anisotropy of the tensile property is mainly owed to the microstructure spatial distribution and the IMC’s layer along the different directions.

Author Contributions

Funding

Conflicts of Interest

References

- Wasekar, N.P.; Latha, S.M.; Ramakrishna, M.; Rao, D.S.; Sundararajan, G. Pulsed electrodeposition and mechanical properties of Ni-W/SiC nano-composite coatings. Mater. Des. 2016, 112, 140–150. [Google Scholar] [CrossRef]

- Li, X.B.; Zu, G.Y.; Wang, P. High strain rate tensile performance and microstructural evolution of Al/Cu laminated composite under dynamic loading. Mater. Sci. Eng. A 2014, 612, 89–95. [Google Scholar] [CrossRef]

- Kim, I.K.; Hong, S.I. Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates. Mater. Des. 2013, 47, 590–598. [Google Scholar] [CrossRef]

- Ahledel, N.; Schulz, R.; Gariepy, M.; Hermawan, H.; Alamdari, H. Electrochemical corrosion behavior of Fe3Al/TiC and Fe3Al-Cr/TiC coatings prepared by HVOF in NaCl solution. Metals 2019, 9, 437. [Google Scholar] [CrossRef]

- Chen, L.; Fu, Y.; Yin, F.; Liu, N.; Liang, C. Microstructure and mechanical properties of Mg/Al clad bars with Ni interlayer processed by compound castings and multi-pass caliber rolling. Metals 2018, 8, 704. [Google Scholar] [CrossRef]

- Romberg, J.; Freudenberger, J.; Watanabe, H.; Scharnweber, J.; Eschke, A.; Kühn, U.; Klauß, H.; Oertel, C.-G.; Skrotzki, W.; Eckert, J.; et al. Ti/Al multi-layered sheets: Differential speed rolling (part b). Metals 2016, 6, 31. [Google Scholar] [CrossRef]

- Priel, E.; Ungarish, Z.; Navi, N.U. Co-extrusion of a Mg/Al composite billet: A computational study validated by experiments. J. Mater. Process. Technol. 2016, 236, 103–113. [Google Scholar] [CrossRef]

- Tabei, A.; Li, D.S.; Lavender, C.A.; Garmestani, H. Investigation of precipitate refinement in Mg alloys by an analytical composite failure model. Mech. Mater. 2015, 89, 59–71. [Google Scholar] [CrossRef] [Green Version]

- Qi, Z.C.; Yu, C.; Xiao, H. Microstructure and bonding properties of magnesium alloy AZ31/CP-Ti clad plates fabricated by rolling bonding. J. Manuf. Process. 2018, 32, 175–186. [Google Scholar] [CrossRef]

- Nemcko, M.J.; Qiao, H.; Wu, P.D.; Wilkinson, D.S. Effects of void fraction on void growth and linkage in commercially pure magnesium. Acta Mater. 2016, 113, 68–80. [Google Scholar] [CrossRef]

- Yang, M.; Liu, X.B.; Zhang, Z.Y.; Song, Y.L. Stress corrosion behavior of AM50Gd magnesium alloy in different environments. Metals 2019, 9, 616. [Google Scholar] [CrossRef]

- Liu, X.W.; Sun, J.K.; Zhou, F.Y.; Yang, Y.H.; Chang, R.C.; Qiu, K.J.; Pu, Z.J.; Li, L.; Zheng, Y.F. Micro-alloying with Mn in Zn–Mg alloy for future biodegradable metals application. Mater. Des. 2016, 94, 95–104. [Google Scholar] [CrossRef]

- Jiang, M.G.; Yan, H.; Chen, R.S. Microstructure, texture and mechanical properties in an as-cast AZ61 Mg alloy during multi-directional impact forging and subsequent heat treatment. Mater. Des. 2015, 87, 891–900. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. On mechanism of in-situ microwave casting of aluminium alloy 7039 and cast microstructure. Mater. Des. 2016, 112, 97–106. [Google Scholar] [CrossRef]

- Simar, A.; Bréchet, Y.; de Meester, B.; Denquin, A.; Gallais, C.; Pardoen, T. Integrated modeling of friction stir welding of 6xxx series Al alloys: Process, microstructure and properties. Prog. Mater. Sci. 2012, 57, 95–183. [Google Scholar] [CrossRef] [Green Version]

- Cui, H.; Tao, K.; Zhou, X.; Zhang, J. Thermal stability of nanostructured NiCrC coating prepared by HVAF spraying of cryomilled powders. Rare Met. 2008, 27, 418–424. [Google Scholar] [CrossRef]

- Nie, H.H.; Liang, W.; Chen, H.S.; Zheng, L.W.; Chi, C.Z.; Li, X.R. Effect of annealing on the microstructures and mechanical properties of Al/Mg/Al laminates. Mater. Sci. Eng. A 2018, 732, 6–13. [Google Scholar] [CrossRef]

- Nie, H.H.; Liang, W.; Zheng, L.W.; Ren, X.X.; Chi, C.Z. The microstructure, texture and mechanical properties of the rolled Al/Mg/Al clad sheets. J. Mater. Eng. Perform. 2016, 25, 4695–4705. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, W.X.; Cao, X.Q.; Wu, J.Q. The effect of annealing on the interface microstructure and mechanical characteristics of AZ31B/AA6061 composite plates fabricated by explosive welding. Mater. Des. 2015, 65, 1100–1109. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Wang, D.Y.; Cao, X.Q.; Yang, W.W.; Wang, W.X. Influence of multi-pass rolling and subsequent annealing on the interface microstructure and mechanical properties of the explosive welding Mg/Al composite plates. Mater. Sci. Eng. A 2018, 723, 97–108. [Google Scholar] [CrossRef]

- Liu, W.S.; Long, L.P.; Ma, Y.Z.; Wu, L. Microstructure evolution and mechanical properties of Mg/Al diffusion bonded joints. J. Alloy. Compd. 2015, 643, 34–39. [Google Scholar] [CrossRef]

- Tang, J.W.; Chen, L.; Zhao, G.Q.; Zhang, C.S.; Yu, J.Q. Study on Al/Mg/Al sheet fabricated by combination of porthole die co-extrusion and subsequent hot rolling. J. Alloy. Compd. 2019, 784, 727–738. [Google Scholar] [CrossRef]

- Abbasi, M.; Sajjadi, S.A. Mechanical properties and interface evaluation of Al/AZ31 multilayer composites produced by ARB at different rolling temperatures. J. Mater. Eng. Perform. 2018, 27, 3508–3520. [Google Scholar] [CrossRef]

- Ebrahimi, S.H.S.; Dehghani, K.; Aghazadeh, J.; Ghasemian, M.B.; Zangeneh, S. Investigation on microstructure and mechanical properties of Al/Al-Zn-Mg–Cu laminated composite fabricated by accumulative roll bonding (ARB) process. Mater. Sci. Eng. A 2018, 718, 311–320. [Google Scholar] [CrossRef]

- Shimoyama, K.; Yokoyama, S.; Kaneko, S.; Fujita, F. Effect of grooved roll profiles on microstructure evolutions of AZ31 sheets in Periodical Straining Rolling process. Mater. Sci. Eng. A 2014, 611, 58–68. [Google Scholar] [CrossRef]

- Luo, C.Z.; Liang, W.; Chen, Z.Q.; Zhang, J.J.; Chi, C.Z.; Yang, F.Q. Effect of high temperature annealing and subsequent hot rolling on microstructural evolution at the bond-interface of Al/Mg/Al alloy laminated composites. Mater. Charact. 2013, 84, 34–40. [Google Scholar] [CrossRef]

- Wang, T.; Li, S.; Ren, Z.; Han, J.; Huang, Q. A novel approach for preparing Cu/Al laminated composite based on corrugated roll. Mater. Lett. 2019, 234, 79–82. [Google Scholar] [CrossRef]

- Wang, H.; Su, L.H.; Yu, H.L.; Lu, C.; Tieu, A.K.; Liu, Y.; Zhang, J. A new finite element model for multi-cycle accumulative roll-bonding process and experiment verification. Mater. Sci. Eng. A 2018, 726, 93–101. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.; Chen, L.; Fu, Y.; Zhang, Y.; Tan, T.; Yin, F.; Liang, C. Interfacial characteristic of multi-pass caliber-rolled Mg/Al compound castings. J. Mater. Process. Technol. 2019, 267, 196–204. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Roostaei, M.; Parsa, M.H.; Mahmudi, R. Rate controlling mechanisms during hot deformation of Mg–3Gd–1Zn magnesium alloy: Dislocation glide and climb, dynamic recrystallization, and mechanical twinning. Mater. Des. 2015, 68, 228–231. [Google Scholar] [CrossRef]

- Eizadjou, M.; Danesh Manesh, H.; Janghorban, K. Mechanism of warm and cold roll bonding of aluminum alloy strips. Mater. Des. 2009, 30, 4156–4161. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Hosseini, M.; Danesh Manesh, H. Bond strength evaluation of roll bonded bi-layer copper alloy strips in different rolling conditions. Mater. Des. 2011, 32, 76–81. [Google Scholar] [CrossRef]

- Yousefi Mehr, V.; Toroghinejad, M.R.; Rezaeian, A. The effects of oxide film and annealing treatment on the bond strength of Al–Cu strips in cold roll bonding process. Mater. Des. 2014, 53, 174–181. [Google Scholar] [CrossRef]

- Jia, W.; Ma, L.; Le, Q.; Zhi, C.; Liu, P. Deformation and fracture behaviors of AZ31B Mg alloy at elevated temperature under uniaxial compression. J. Alloy. Compd. 2019, 783, 863–876. [Google Scholar] [CrossRef]

- Wang, H.Y.; Feng, T.T.; Zhang, L.; Liu, C.G.; Pan, Y.; Zha, M.; Nan, X.L.; Wang, C.; Jiang, Q.C. Achieving a weak basal texture in a Mg–6Al–3Sn alloy by wave-shaped die rolling. Mater. Des. 2015, 88, 157–161. [Google Scholar] [CrossRef]

- Timmermans, G.; Froyen, L. Tribological performance of hypereutectic P/M Al–Si during sliding in oil. Wear 1999, 231, 77–88. [Google Scholar] [CrossRef]

- Lee, K.S.; Yoon, D.H.; Kim, H.K.; Kwon, Y.-N.; Lee, Y.-S. Effect of annealing on the interface microstructure and mechanical properties of a STS–Al–Mg 3-ply clad sheet. Mater. Sci. Eng. A 2012, 556, 319–330. [Google Scholar] [CrossRef]

- Straumal, B.B.; Dobatkin, S.V.; Rodin, A.O.; Protasova, S.G.; Mazilkin, A.A.; Goll, D.; Baretzky, B. Structure and properties of nanograined Fe-C alloys after severe plastic deformation. Adv. Eng. Mater. 2011, 13, 463–469. [Google Scholar] [CrossRef]

- Brennan, S.; Bermudez, K.; Kulkarni, N.S.; Sohn, Y. Interdiffusion in the Mg-Al system and intrinsic diffusion in β-Mg2Al3. Metall. Mater. Trans. A 2012, 43, 4043–4052. [Google Scholar] [CrossRef]

- Negendank, M.; Mueller, S.; Reimers, W. Coextrusion of Mg–Al macro composites. J. Mater. Process. Technol. 2012, 212, 1954–1962. [Google Scholar] [CrossRef]

- Macwan, A.; Jiang, X.Q.; Li, C.; Chen, D.L. Effect of annealing on interface microstructures and tensile properties of rolled Al/Mg/Al tri-layer clad sheets. Mater. Sci. Eng. A 2013, 587, 344–351. [Google Scholar] [CrossRef]

- Chen, L.; Tang, J.; Zhao, G.; Zhang, C.; Chu, X. Fabrication of Al/Mg/Al laminate by a porthole die co-extrusion process. J. Mater. Process. Technol. 2018, 258, 165–173. [Google Scholar] [CrossRef]

- Mazilkin, A.A.; Straumal, B.B.; Borodachenkova, M.V.; Valiev, R.Z.; Kogtenkova, O.A.; Baretzky, B. Gradual softening of Al–Zn alloys during high-pressure torsion. Mater. Lett. 2012, 84, 63–65. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Ivanisenko, Y.; Mazilkina, A.A.; Kogtenkova, O.A.; Kurmanaeva, L.; Korneva, A.; Zieba, P.; Baretzky, B. Phase transitions induced by severe plastic deformation: Steady-state and equifinality. Int. J. Mater. Res 2015, 106, 657–664. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abou-Ras, D. Microstructure and mechanical properties of commercially pure aluminum processed by accumulative back extrusion. Mater. Sci. Eng. A 2013, 584, 73–81. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.; Wang, J.; Lv, B.; Kong, F. The directional solidification, microstructural characterization and deformation behavior of beta-solidifying TiAl alloy. Materials 2019, 12, 1203. [Google Scholar] [CrossRef]

- Kudo, S.; Yokoyama, S.; Shimoyama, K.; Kaneko, S.; Fujita, F. Effect of dimple patterning conditions of Periodical Straining Rolling on microstructures and mechanical properties of AZ31 sheets. Mater. Sci. Eng. A 2017, 680, 75–84. [Google Scholar] [CrossRef]

- Chen, S.X.; Li, W.G.; Liu, X.H. Calculation of rolling pressure distribution and force based on improved Karman equation for hot strip mill. Int. J. Mech. Sci. 2014, 89, 256–263. [Google Scholar] [CrossRef]

- Nie, H.; Liang, W.; Yang, F.; Zheng, L.; Li, X.; Fan, H. Texture Evolution of Single-Pass Hot-Rolled 5052/AZ31/5052 Clad Sheets. JOM 2016, 68, 2274–2287. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, J.S.; Jo, Y.M.; Lee, S.E.; Heo, J.; Chang, Y.W.; Lee, Y.S. Interface-correlated deformation behavior of a stainless steel-Al–Mg 3-ply composite. Mater. Charact. 2013, 75, 138–149. [Google Scholar] [CrossRef]

| Materials | Mg | Cu | Ca | Mn | Si | Al | Zn | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| AZ31B | Rest | 0.01 | 0.04 | 0.8 | 0.07 | 3.2 | 1.2 | - | - |

| 5052 | 2.2–2.8 | 0.10 | - | 0.10 | 0.25 | Rest | 0.10 | 0.15–0.35 | 0.4 |

| Materials | Mg (at%) | Al (at%) | IMCs |

|---|---|---|---|

| A | 59.9 ± 4 | 40.1 ± 4 | Mg17Al12 |

| B | 38.2 ± 3 | 61.8 ± 3 | Mg2Al3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Li, S.; Ren, Z.; Jia, Y.; Fu, W.; Guo, M.; Ma, X.; Han, J. Microstructure Characterization and Mechanical Property of Mg/Al Laminated Composite Prepared by the Novel Approach: Corrugated + Flat Rolling (CFR). Metals 2019, 9, 690. https://doi.org/10.3390/met9060690

Wang T, Li S, Ren Z, Jia Y, Fu W, Guo M, Ma X, Han J. Microstructure Characterization and Mechanical Property of Mg/Al Laminated Composite Prepared by the Novel Approach: Corrugated + Flat Rolling (CFR). Metals. 2019; 9(6):690. https://doi.org/10.3390/met9060690

Chicago/Turabian StyleWang, Tao, Sha Li, Zhongkai Ren, Yi Jia, Wenshi Fu, Miao Guo, Xiaochang Ma, and Jianchao Han. 2019. "Microstructure Characterization and Mechanical Property of Mg/Al Laminated Composite Prepared by the Novel Approach: Corrugated + Flat Rolling (CFR)" Metals 9, no. 6: 690. https://doi.org/10.3390/met9060690

APA StyleWang, T., Li, S., Ren, Z., Jia, Y., Fu, W., Guo, M., Ma, X., & Han, J. (2019). Microstructure Characterization and Mechanical Property of Mg/Al Laminated Composite Prepared by the Novel Approach: Corrugated + Flat Rolling (CFR). Metals, 9(6), 690. https://doi.org/10.3390/met9060690