Advanced Metal Matrix Nanocomposites

Abstract

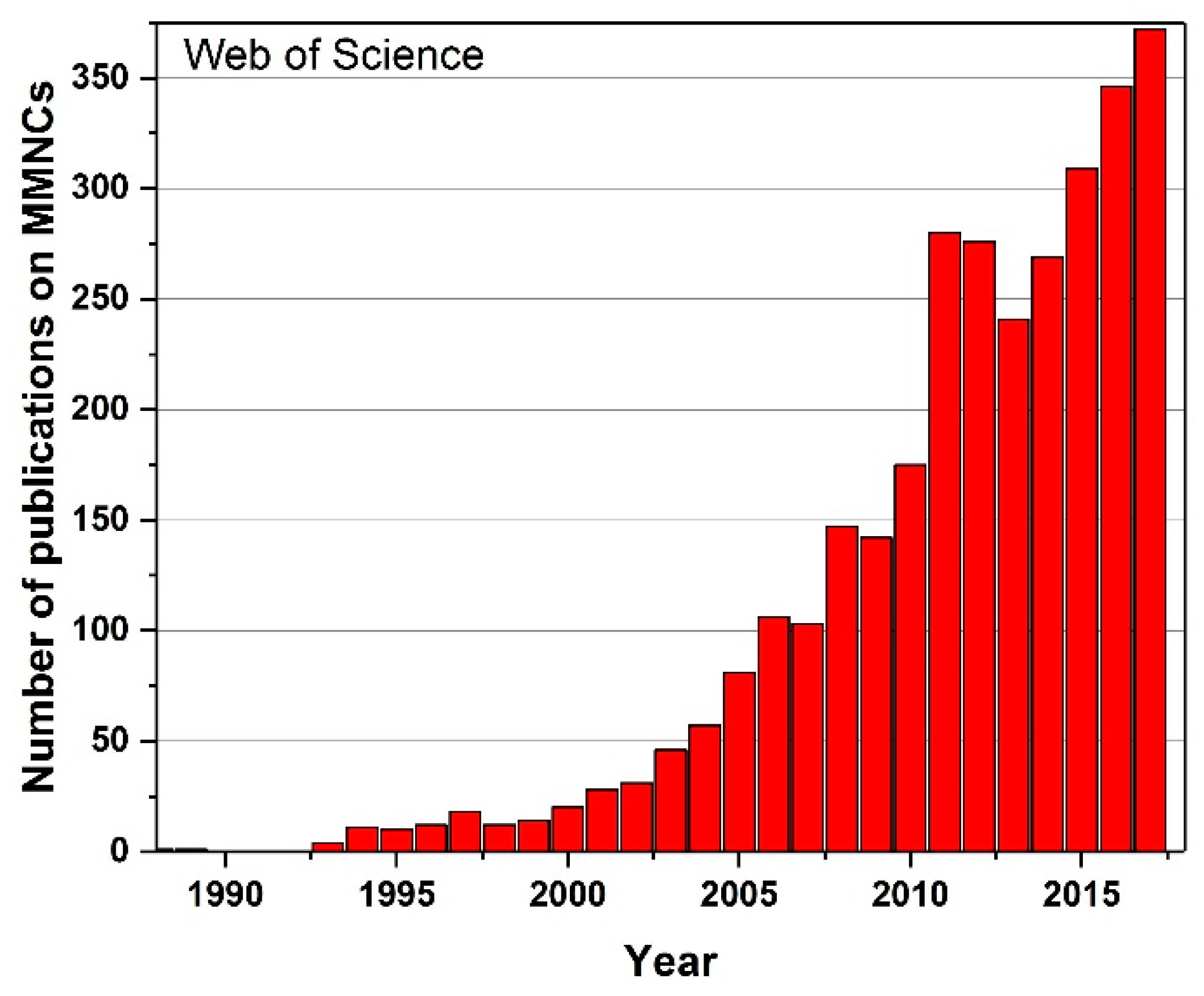

1. Introduction

- Tensile and compressive behavior.

- Ductility or elongation to failure, a must for bend than break design philosophy.

- High-temperature mechanical properties.

- Creep.

- Dynamic mechanical properties.

- Wear resistance, including scratch resistance.

- Coefficient of thermal expansion.

- Damping.

- Machining.

- Ignition resistance.

- Dry/wet corrosion resistance.

- Judicious selection of matrix and reinforcement (including its length scale).

- Careful selection of primary and secondary processing routes.

- Heat treatment.

- Particle breakage under the application of stress triggering the initiation of cracks.

- Matrix-reinforcement interfacial debonding under the application of stress.

- Current state-of-the-art in the synthesis of nanocomposites.

- An insight into microstructural characteristics of composites.

- Dispersion mechanisms of nano-particles.

- Mechanical responses, including tensile, compressive, torsion, fatigue, and damping properties.

- Particular emphasis is placed on lightweight composites, such as those based on magnesium and aluminum due to their capability to mitigate greenhouse gas emissions and global warming due to a rapid expansion in the transportation sector [3].

2. Fabrication Methods

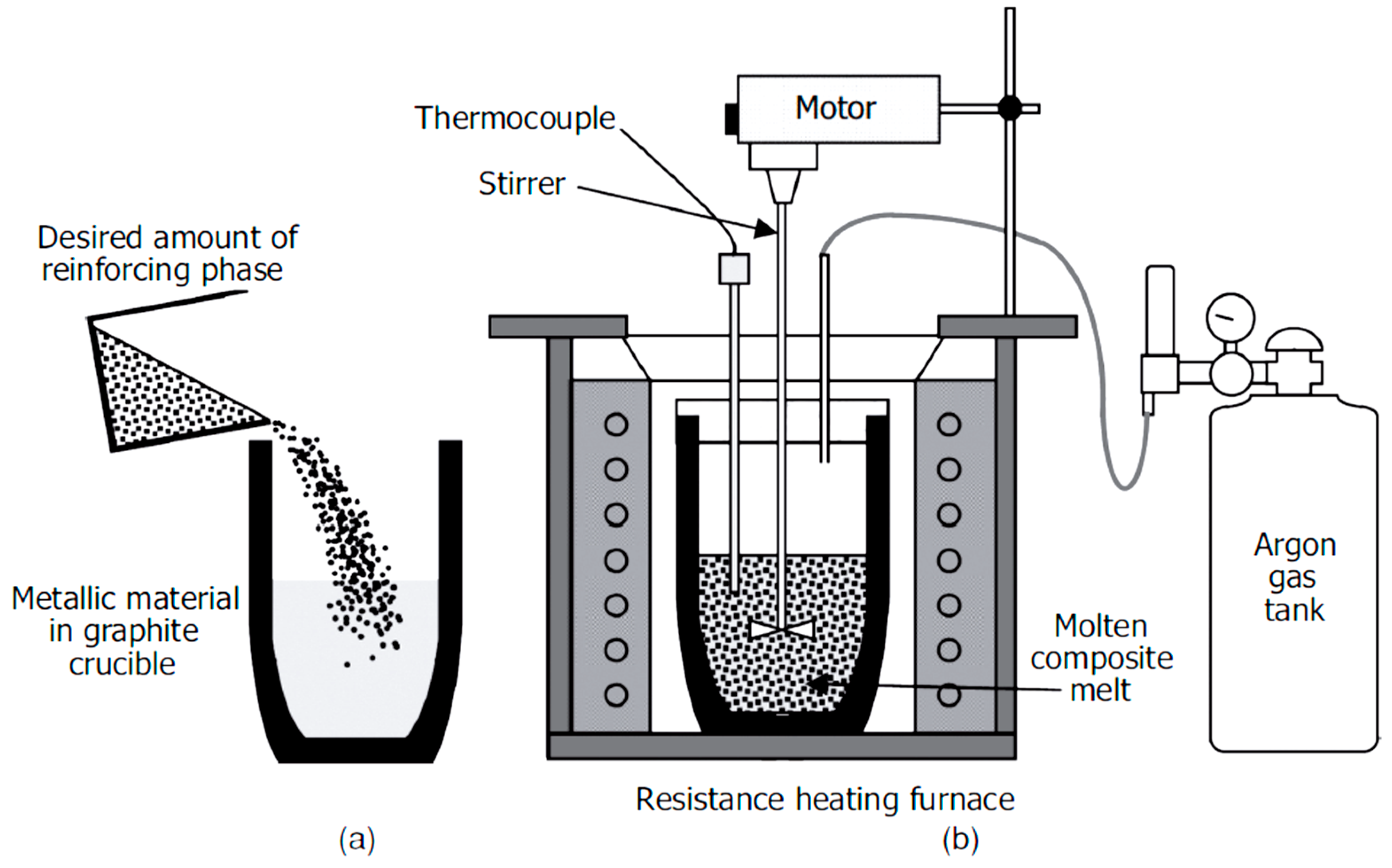

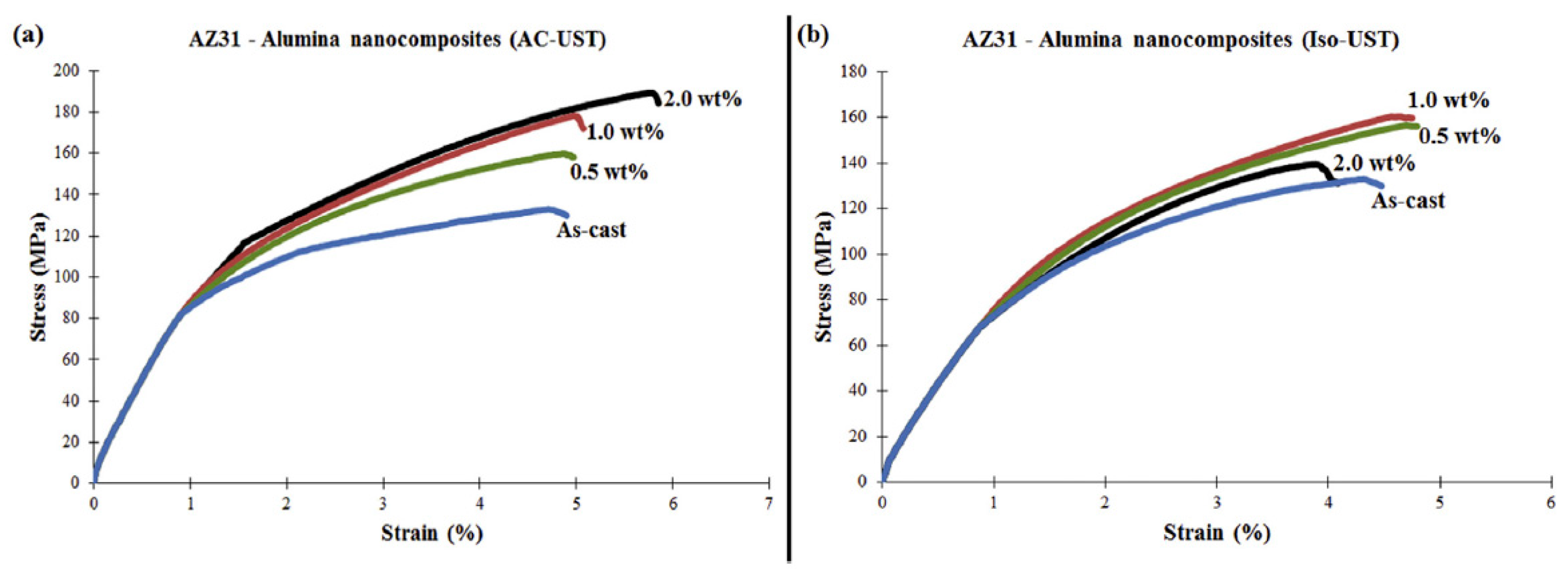

2.1. Stir-Casting

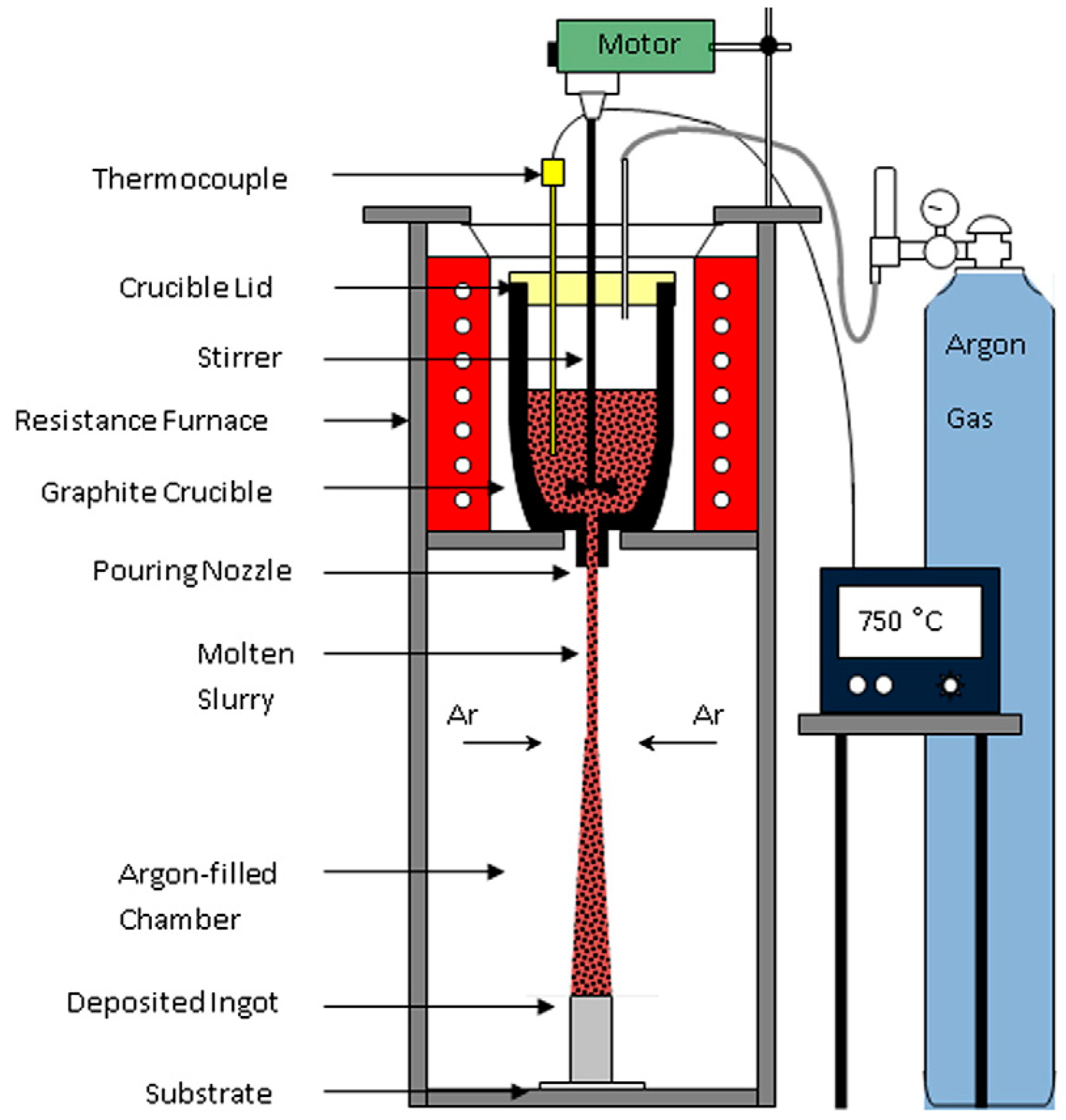

2.2. Disintegrated Melt Deposition (DMD)

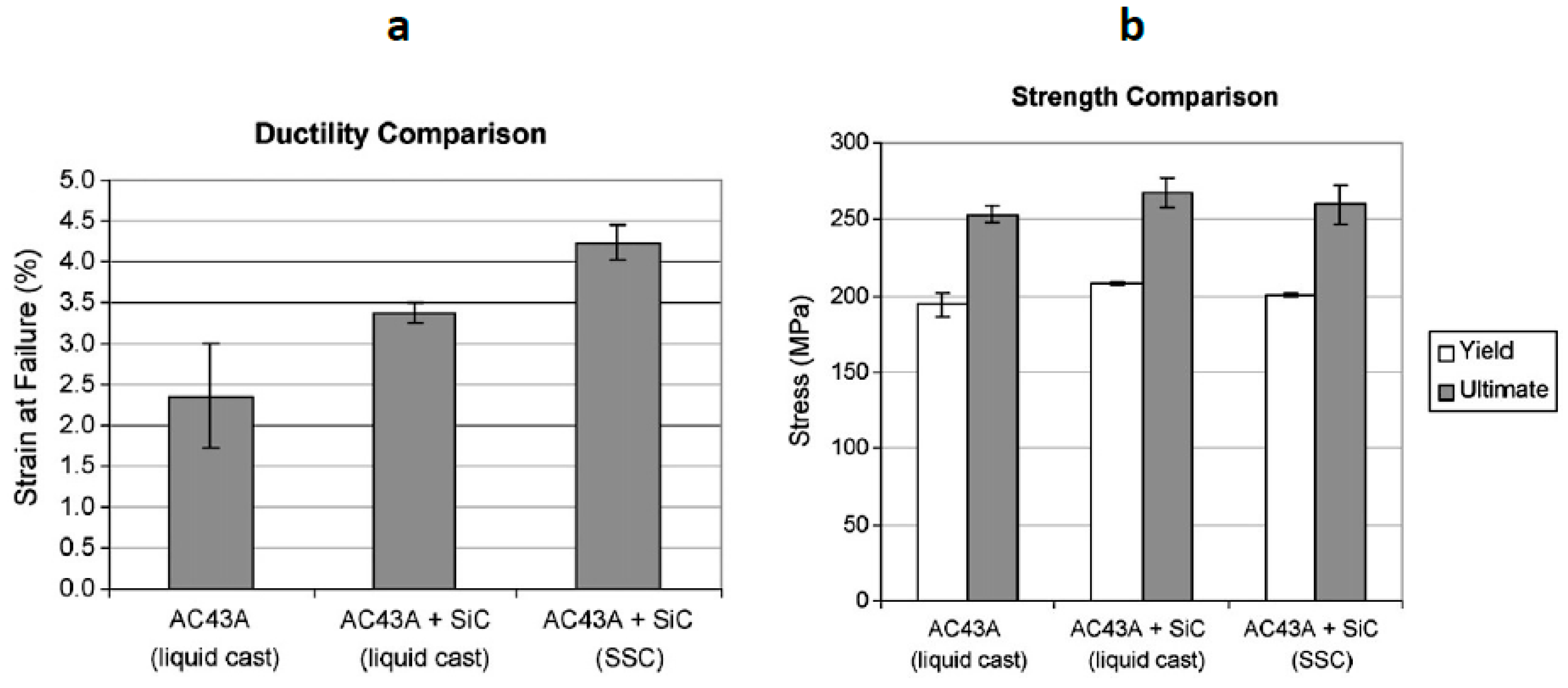

2.3. Semi-Solid Casting (SSC)

2.4. Powder Metallurgy (PM)

- Ability to produce “near-net” shape components;

- Capability to integrate higher volume fractions of the reinforcement; and

- Ability to produce large batches (i.e., for automotive applications).

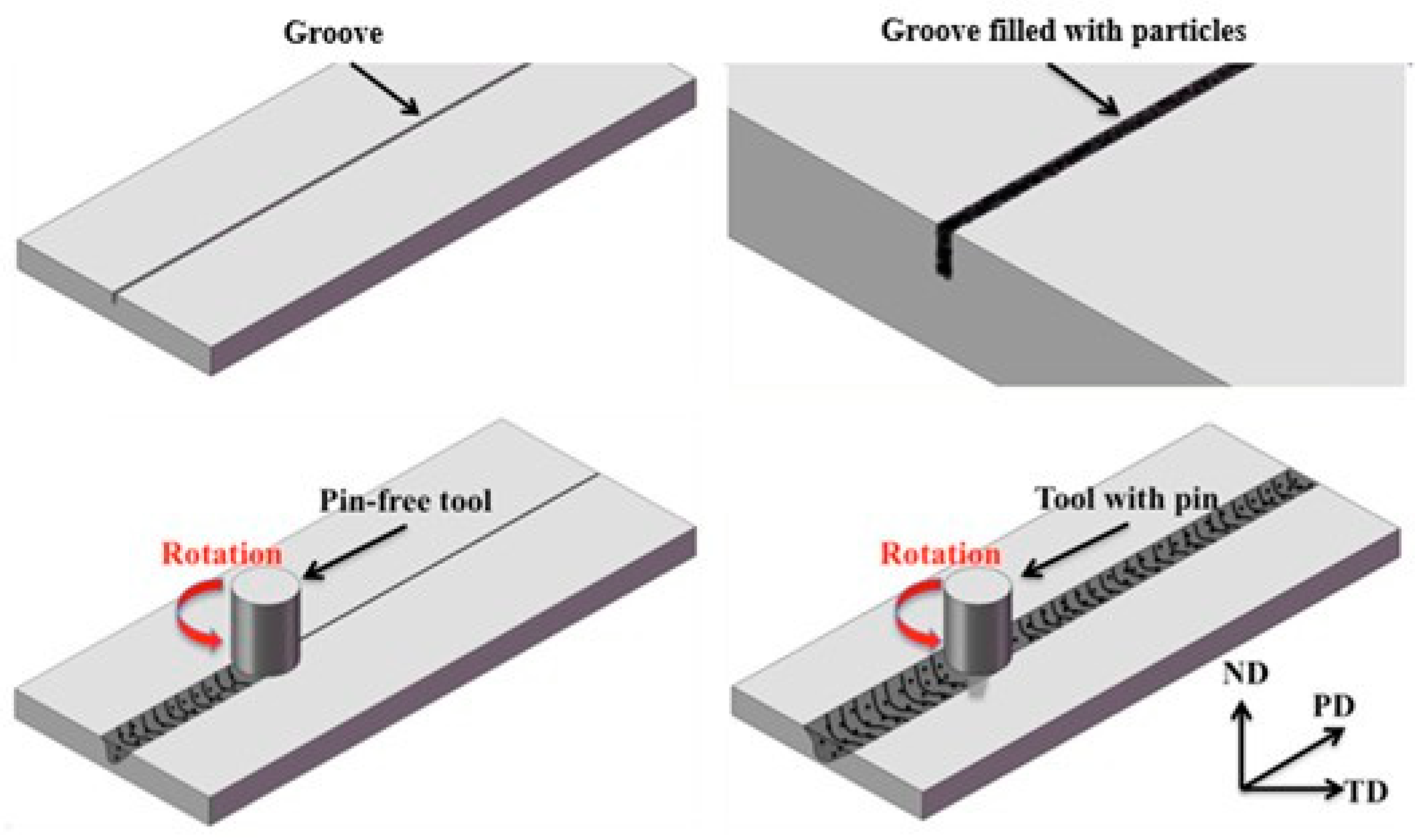

2.5. Friction Stir Processing

2.6. Accumulative Roll Bonding

- wire brushing of metal sheet surfaces to remove the oxide layer, contaminants, etc.;

- stacking of two sheets on top of each other;

- roll bonding the sheets together up to a minimum 50% thickness reduction; and

- dividing the roll-bonded sample into piece.s

3. Reinforcing Agents

- Increase in yield and tensile strength at room temperature or elevated temperature while maintaining ductility;

- Increase of creep resistance at elevated temperatures;

- Increased fatigue strength;

- Improvement of thermal shock resistance;

- Improvement of wear resistance;

- Increase of the Young’s modulus; or

- Reduction of coefficient of thermal expansion.

4. Dispersion

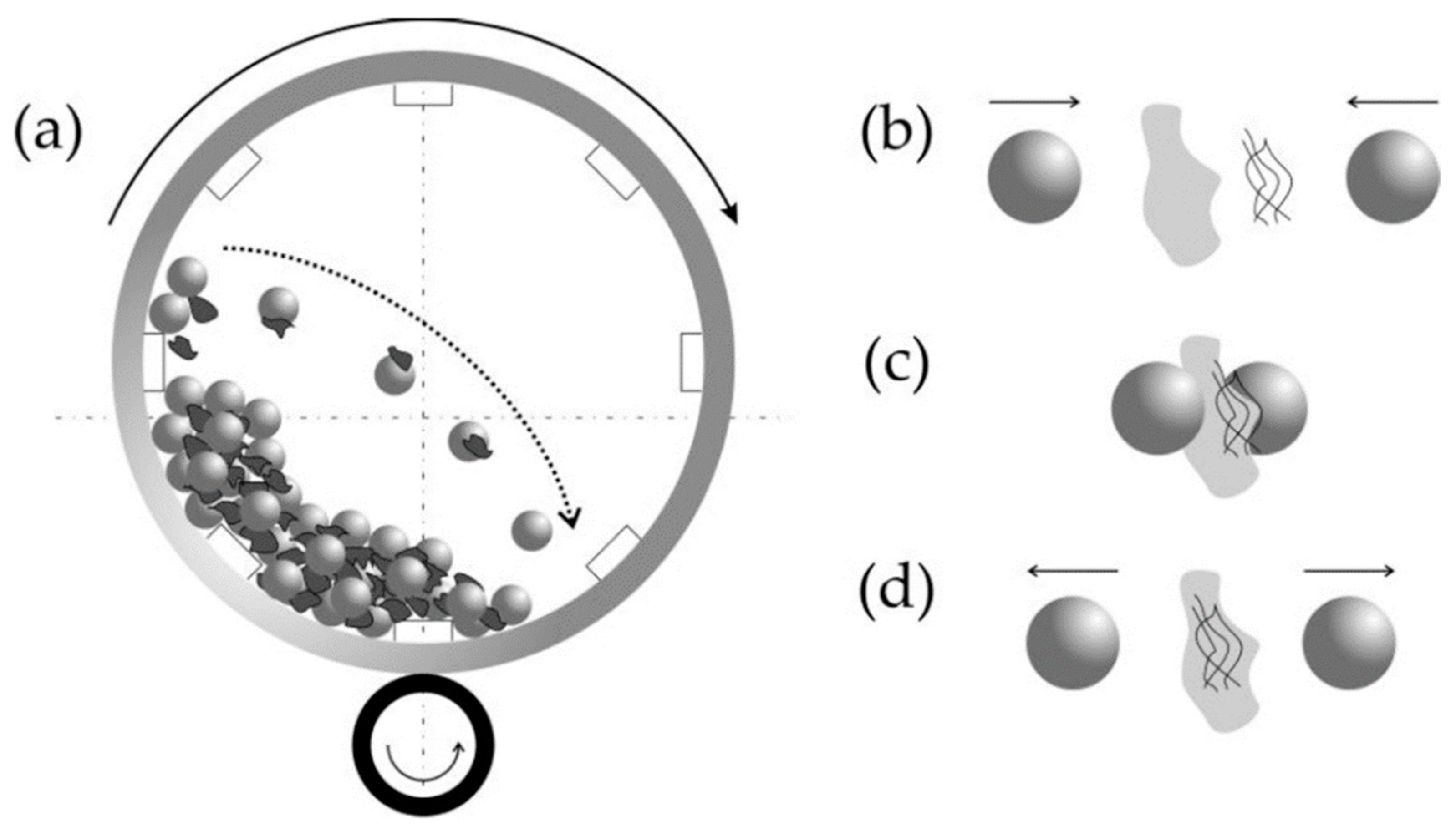

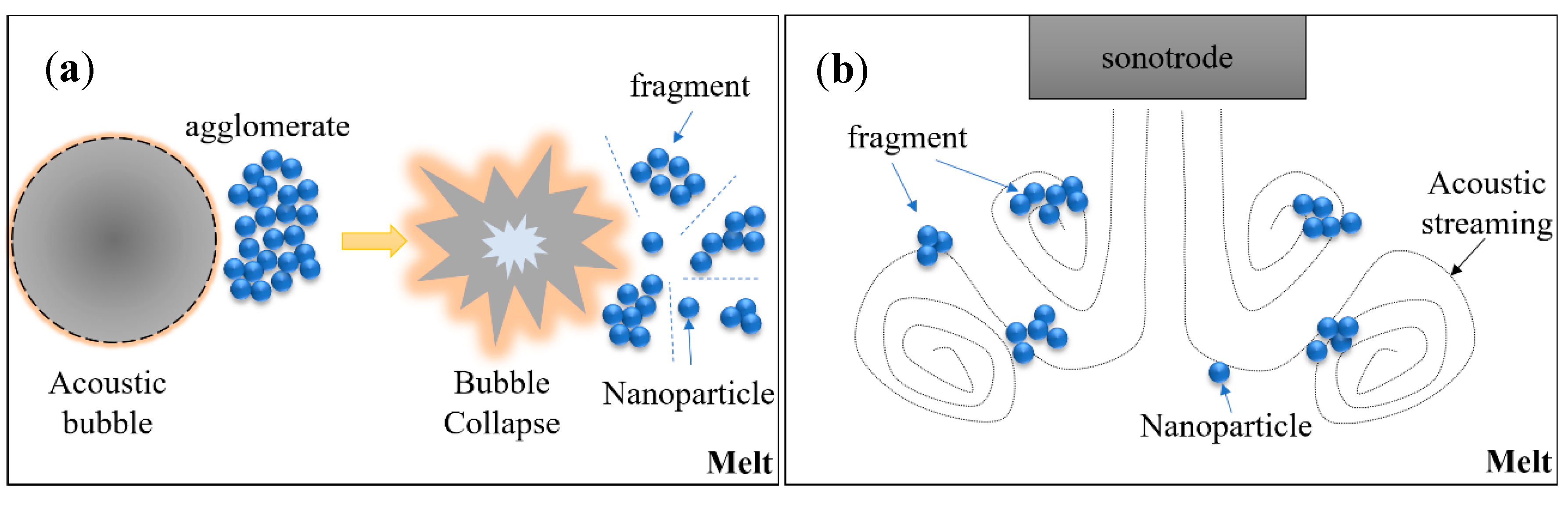

4.1. Cavitation Basics

4.2. Cavitation in Composite Systems

4.2.1. Cavitation near Solid Surfaces

4.2.2. Cavitation in Molten Metal-Nanoparticle Composite Systems

5. Strengthening Mechanisms

5.1. Orowan

5.2. Hall–Petch

5.3. Mismatch in the CTE

5.4. Mismatch in the Young’s Modulus

5.5. Load-Bearing

6. Mechanical Properties

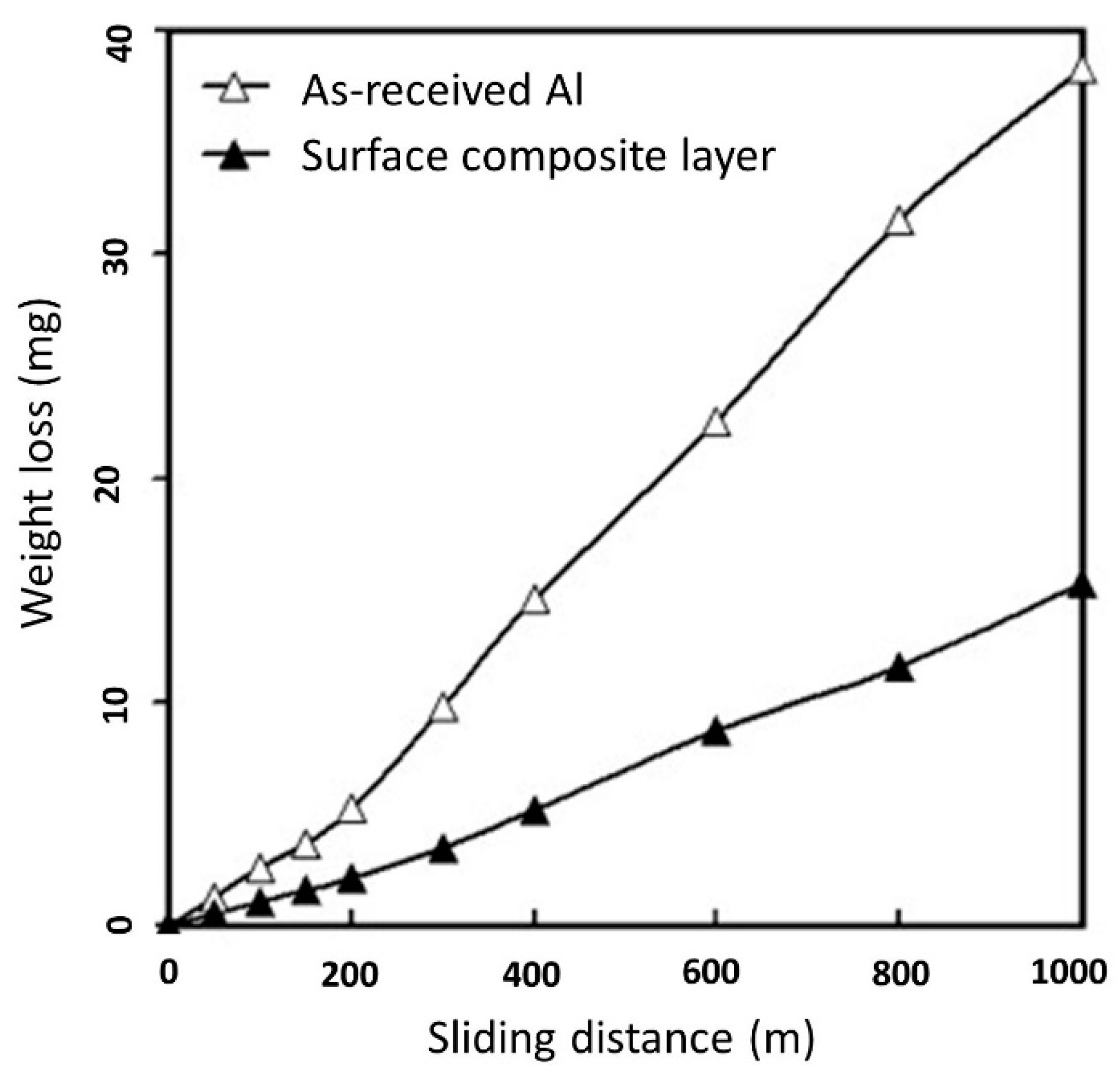

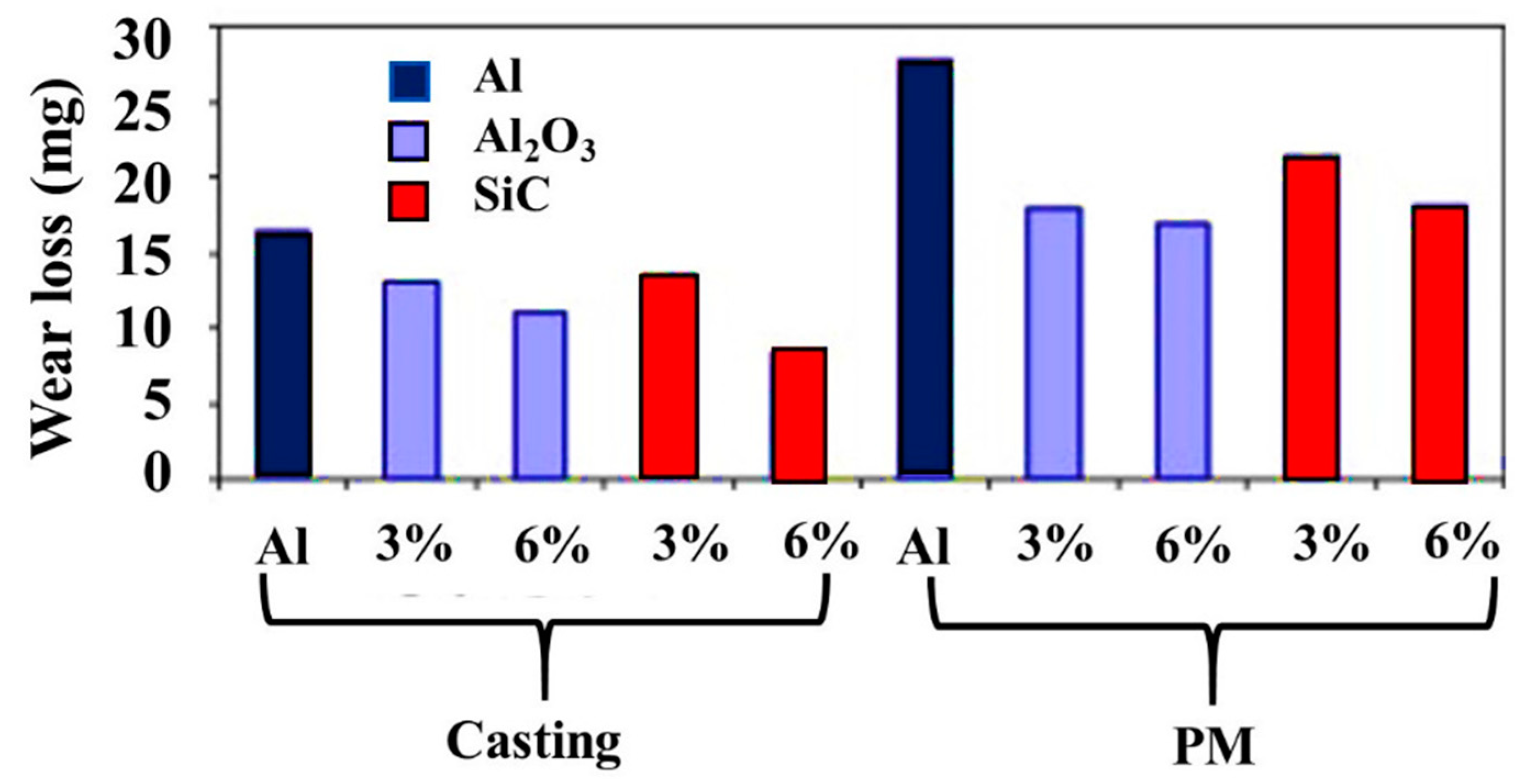

7. Tribological Properties of MMNCs

8. Conclusions, Current Challenges, and Future Remarks

Conflicts of Interest

References

- Ibrahim, I.; Mohamed, F.; Lavernia, E. Particulate reinforced metal matrix composites—A review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Yeom, M.S.; Shin, J.W.; Kim, H.; Cui, Y.; Kysar, J.W.; Hone, J.; Jung, Y.; Jeon, S. Strengthening effect of single-atomic-layer graphene in metal–graphene nanolayered composites. Nat. Commun. 2013, 4, ncomms3114. [Google Scholar] [CrossRef] [PubMed]

- Ceschini, L.; Dahle, A.; Gupta, M.; Jarfors, A.E.W.; Jayalakshmi, S.; Morri, A.; Rotundo, F.; Toschi, S.; Singh, R.A. Aluminum and Magnesium Metal Matrix Nanocomposites; Springer: New York, NY, USA, 2017. [Google Scholar]

- Lloyd, D. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Cha, S.I.; Kim, K.T.; Arshad, S.N.; Mo, C.B.; Hong, S.H. Extraordinary strengthening effect of carbon nanotubes in metal-matrix nanocomposites processed by molecular-level mixing. Adv. Mater. 2005, 17, 1377–1381. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Gupta, M.; Wong, W. Magnesium-based nanocomposites: Lightweight materials of the future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef] [PubMed]

- Riedel, R. Nanoscaled inorganic materials by molecular design. Chem. Soc. Rev. 2012, 41, 5029–5031. [Google Scholar] [CrossRef] [PubMed]

- Calvert, P. Nanotube composites: A recipe for strength. Nature 1999, 399, 210. [Google Scholar] [CrossRef]

- Flint, E.B.; Suslick, K.S. The temperature of cavitation. Science 1991, 253, 1397–1399. [Google Scholar] [CrossRef] [PubMed]

- Bang, J.H.; Suslick, K.S. Applications of ultrasound to the synthesis of nanostructured materials. Adv. Mater. 2010, 22, 1039–1059. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, A.; Pak, A.; Abdullah, M.M.; Shahidi, A.; Malaki, M. Study of the behavior of ultrasonic piezo-ceramic actuators by simulations. Electron. Mater. Lett. 2014, 10, 37–42. [Google Scholar] [CrossRef]

- Abdullah, A.; Malaki, M. On the damping of ultrasonic transducersʼ components. Aerosp. Sci. Technol. 2013, 28, 31–39. [Google Scholar] [CrossRef]

- Abdullah, A.; Malaki, M.; Baghizadeh, E. On the impact of ultrasonic cavitation bubbles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 681–694. [Google Scholar] [CrossRef]

- Gupta, M.; Seetharaman, S. Magnesium Based Nanocomposites for Cleaner Transport. Nanotechnol. Energy Sustain. 2017, 809–830. [Google Scholar] [CrossRef]

- Gupta, M.; Meenashisundaram, G.K. Insight into Designing Biocompatible Magnesium Alloys and Composites: Processing, Mechanical and Corrosion Characteristics; Springer: New York, NY, USA, 2015. [Google Scholar]

- Gong, H.; Anasori, B.; Dennison, C.R.; Wang, K.; Kumbur, E.C.; Strich, R.; Zhou, J.G. Fabrication, biodegradation behavior and cytotoxicity of Mg-nanodiamond composites for implant application. J. Mater. Sci. Mater. Med. 2015, 26, 110. [Google Scholar] [CrossRef] [PubMed]

- Paul, W.; Sharma, C.P. Nanoceramic matrices: Biomedical applications. Am. J. Biochem. Biotechnol. 2006, 2, 41–48. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Hemanth, J. Development and property evaluation of aluminum alloy reinforced with nano-ZrO2 metal matrix composites (NMMCs). Mater. Sci. Eng. A 2009, 507, 110–113. [Google Scholar] [CrossRef]

- Hamedan, A.D.; Shahmiri, M. Production of A356–1 wt% SiC nanocomposite by the modified stir casting method. Mater. Sci. Eng. A 2012, 556, 921–926. [Google Scholar] [CrossRef]

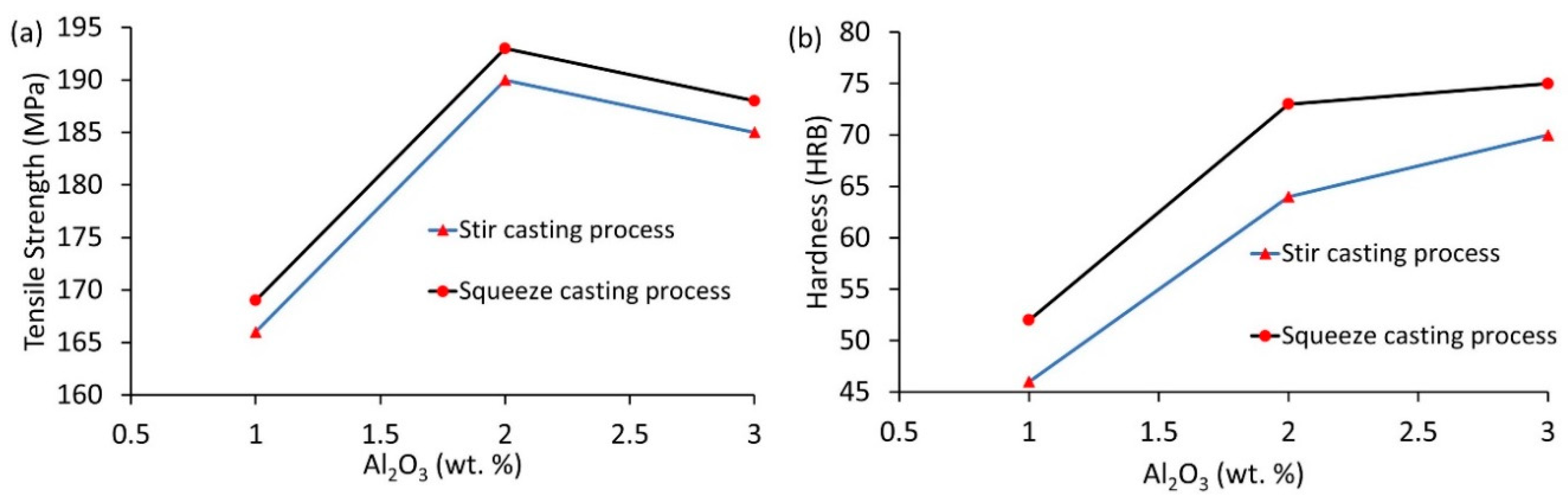

- Sajjadi, S.A.; Ezatpour, H.; Beygi, H. Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Suresh, S.; Mishra, D.; Srinivasan, A.; Arunachalam, R.; Sasikumar, R. Production and characterization of micro and nano Al2O3 particle-reinforced LM25 aluminium alloy composites. ARPN J. Eng. Appl. Sci. 2011, 6, 94–98. [Google Scholar]

- Cao, G.; Choi, H.; Oportus, J.; Konishi, H.; Li, X. Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites. Mater. Sci. Eng. A 2008, 494, 127–131. [Google Scholar] [CrossRef]

- Donthamsetty, S.; Damera, N.; Jain, P. Ultrasonic cavitation assisted fabrication and characterization of A356 metal matrix nanocomposite reiforced with Sic, B4C, CNTs. Asian Int. J. Sci. Technol. Prod. Manuf. Eng. 2009, 2, 27–34. [Google Scholar]

- Akbari, M.K.; Mirzaee, O.; Baharvandi, H. Fabrication and study on mechanical properties and fracture behavior of nanometric Al2O3 particle-reinforced A356 composites focusing on the parameters of vortex method. Mater. Des. 2013, 46, 199–205. [Google Scholar] [CrossRef]

- Gupta, M.; Ling, S.N.M. Magnesium, Magnesium Alloys, and Magnesium Composites; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ezatpour, H.R.; Sajjadi, S.A.; Sabzevar, M.H.; Huang, Y. Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater. Des. 2014, 55, 921–928. [Google Scholar] [CrossRef]

- Alam, M.T.; Arif, S.; Ansari, A.H. Mechanical Behaviour and Morphology of A356/SiC Nanocomposites Using Stir Casting. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012293. [Google Scholar]

- Khandelwal, A.; Mani, K.; Srivastava, N.; Gupta, R.; Chaudhari, G. Mechanical behavior of AZ31/Al2O3 magnesium alloy nanocomposites prepared using ultrasound assisted stir casting. Compos. Part B Eng. 2017, 123, 64–73. [Google Scholar] [CrossRef]

- Goh, C.; Wei, J.; Lee, L.; Gupta, M. Simultaneous enhancement in strength and ductility by reinforcing magnesium with carbon nanotubes. Mater. Sci. Eng. A 2006, 423, 153–156. [Google Scholar] [CrossRef]

- Srivatsan, T.; Godbole, C.; Paramsothy, M.; Gupta, M. Influence of nano-sized carbon nanotube reinforcements on tensile deformation, cyclic fatigue, and final fracture behavior of a magnesium alloy. J. Mater. Sci. 2012, 47, 3621–3638. [Google Scholar] [CrossRef]

- Ho, K.; Gupta, M.; Srivatsan, T.S. The mechanical behavior of magnesium alloy AZ91 reinforced with fine copper particulates. Mater. Sci. Eng. A 2004, 369, 302–308. [Google Scholar] [CrossRef]

- Goh, C.; Wei, J.; Lee, L.; Gupta, M. Ductility improvement and fatigue studies in Mg-CNT nanocomposites. Compos. Sci. Technol. 2008, 68, 1432–1439. [Google Scholar] [CrossRef]

- Goh, C.; Wei, J.; Lee, L.; Gupta, M. Properties and deformation behaviour of Mg–Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

- Srivatsan, T.; Godbole, C.; Quick, T.; Paramsothy, M.; Gupta, M. Mechanical behavior of a magnesium alloy nanocomposite under conditions of static tension and dynamic fatigue. J. Mater. Eng. Perform. 2013, 22, 439–453. [Google Scholar] [CrossRef]

- De Cicco, M.P.; Li, X.; Turng, L.-S. Semi-solid casting (SSC) of zinc alloy nanocomposites. J. Mater. Process. Technol. 2009, 209, 5881–5885. [Google Scholar] [CrossRef]

- Wang, Z.H.; Kang, Y.L.; Zhao, H.J.; Xu, Y. SiC nanoparticles reinforced magnesium alloys by semisolid process. In Solid State Phenomena; Trans Tech Publications: Zurich, Switzerland, 2006; pp. 163–166. [Google Scholar]

- De Cicco, M.P. Solidification Phenomena in Metal Matrix Nanocomposites; University of Wisconsin: Madison, WI, USA, 2009. [Google Scholar]

- Simões, S.; Viana, F.; Reis, M.A.; Vieira, M.F. Aluminum and nickel matrix composites reinforced by CNTs: Dispersion/mixture by ultrasonication. Metals 2017, 7, 279. [Google Scholar] [CrossRef]

- Wong, W.; Gupta, M. Development of Mg/Cu nanocomposites using microwave assisted rapid sintering. Compos. Sci. Technol. 2007, 67, 1541–1552. [Google Scholar] [CrossRef]

- Wong, W.L.E.; Gupta, M. Using microwave energy to synthesize light weight/energy saving magnesium based materials: A review. Technologies 2015, 3, 1–18. [Google Scholar] [CrossRef]

- Matli, P.R.; Shakoor, R.A.; Mohamed, A.M.A. Development of Metal Matrix Composites Using Microwave Sintering Technique. In Sintering of Functional Materials; InTech: London, UK, 2018. [Google Scholar]

- Habibi, M.K.; Joshi, S.P.; Gupta, M. Development of hierarchical magnesium composites using hybrid microwave sintering. J. Microw. Power Electromagn. Energy 2011, 45, 112–120. [Google Scholar] [CrossRef] [PubMed]

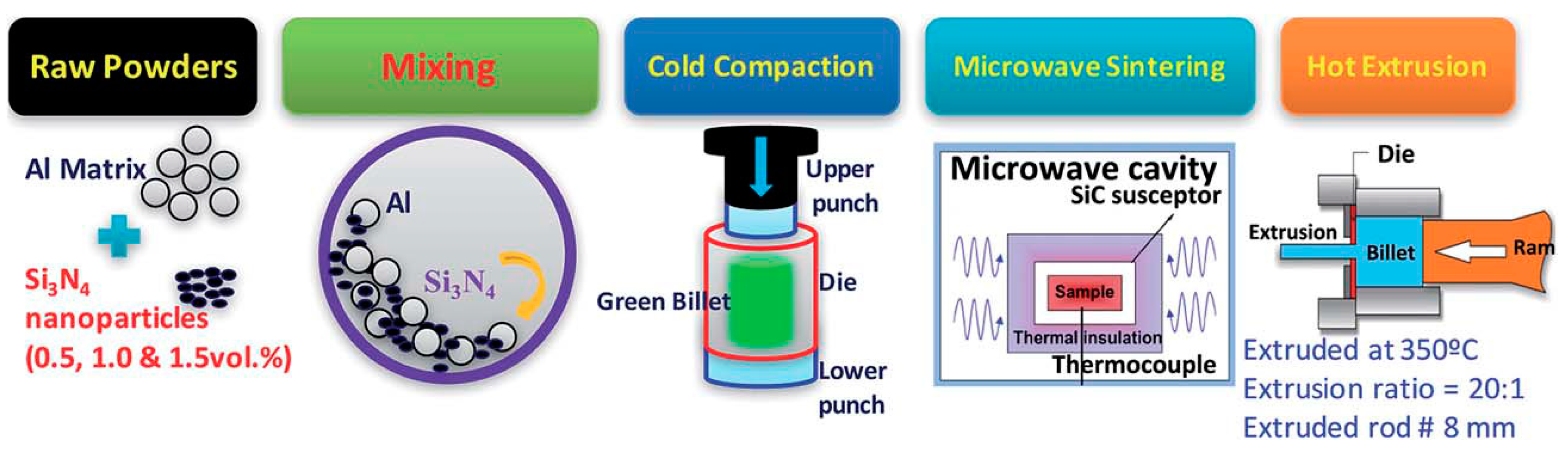

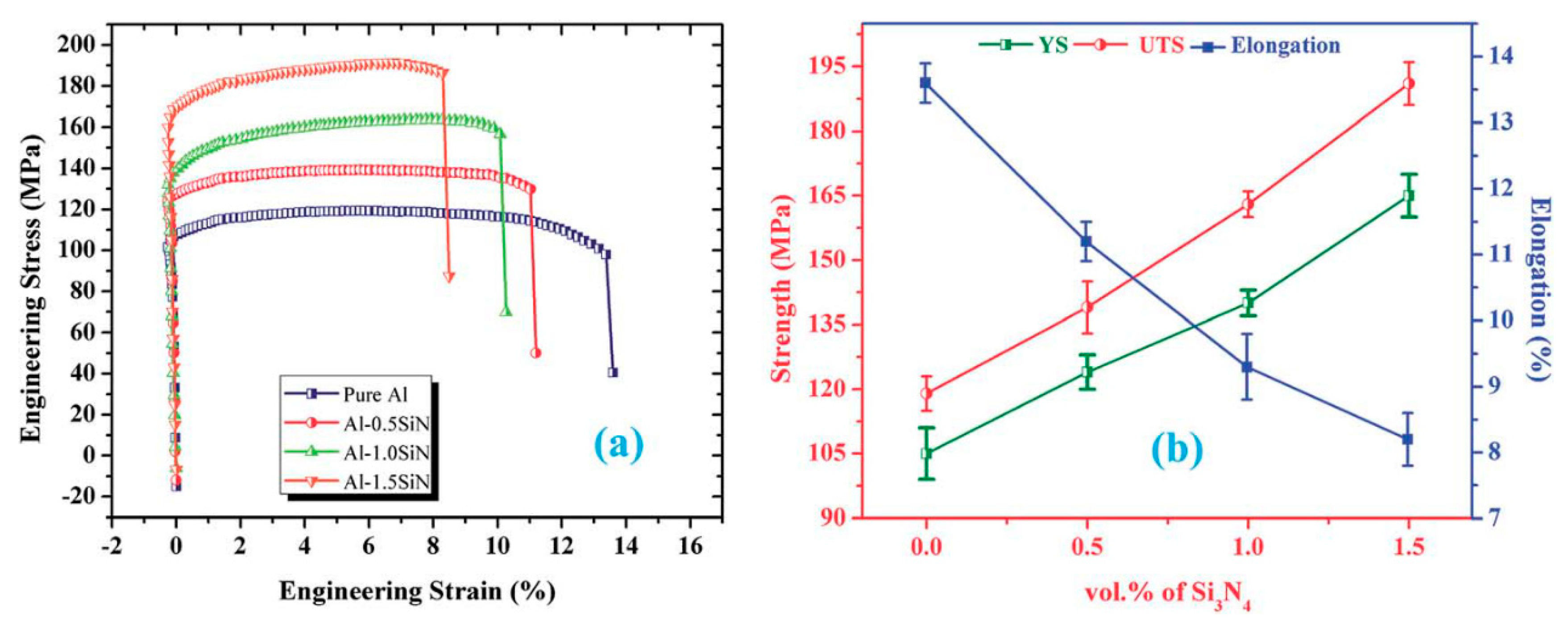

- Matli, P.R.; Ubaid, F.; Shakoor, R.A.; Parande, G.; Manakari, V.; Yusuf, M.; Mohamed, A.M.A.; Gupta, M. Improved properties of Al–Si3N4 nanocomposites fabricated through a microwave sintering and hot extrusion process. RSC Adv. 2017, 7, 34401–34410. [Google Scholar] [CrossRef]

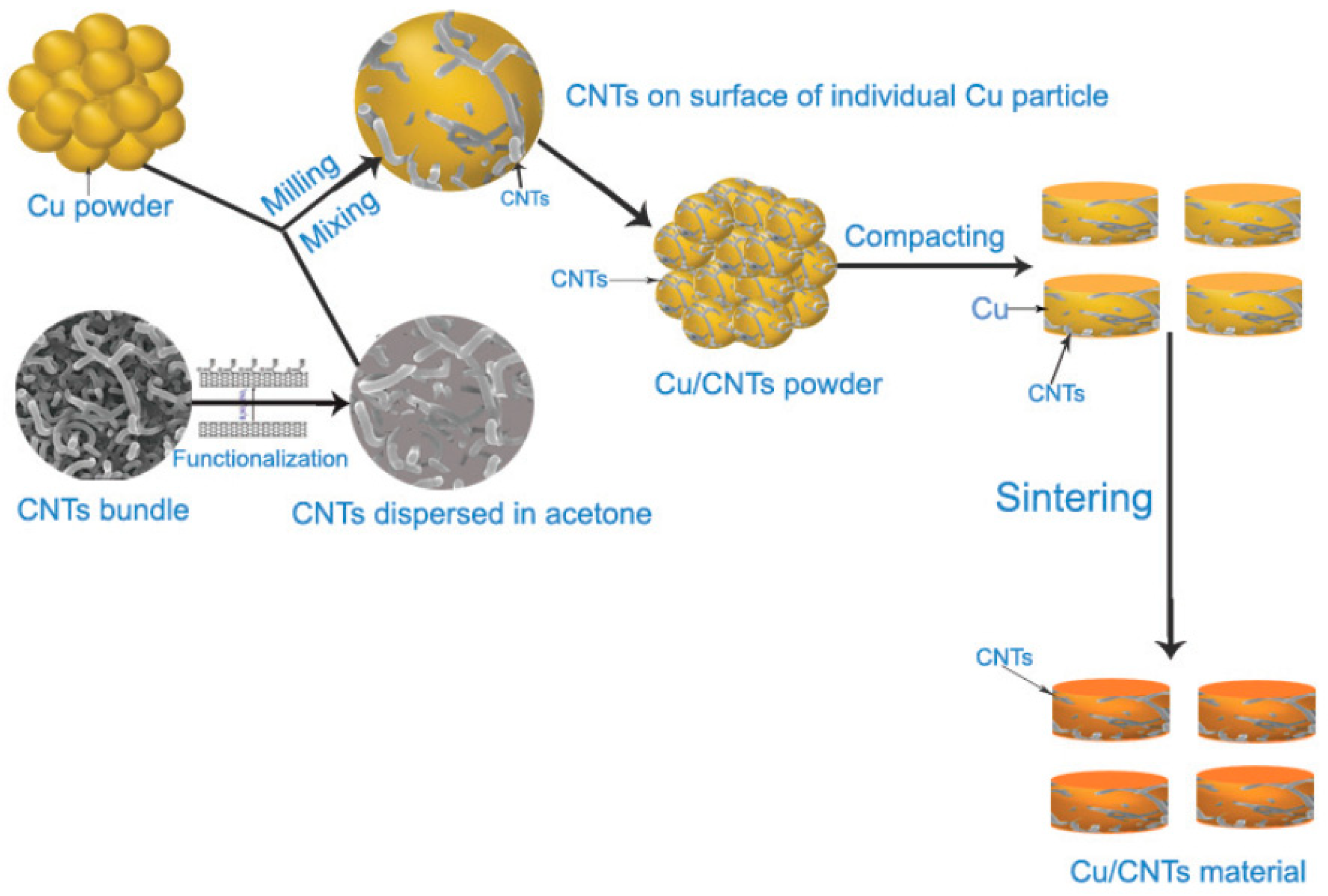

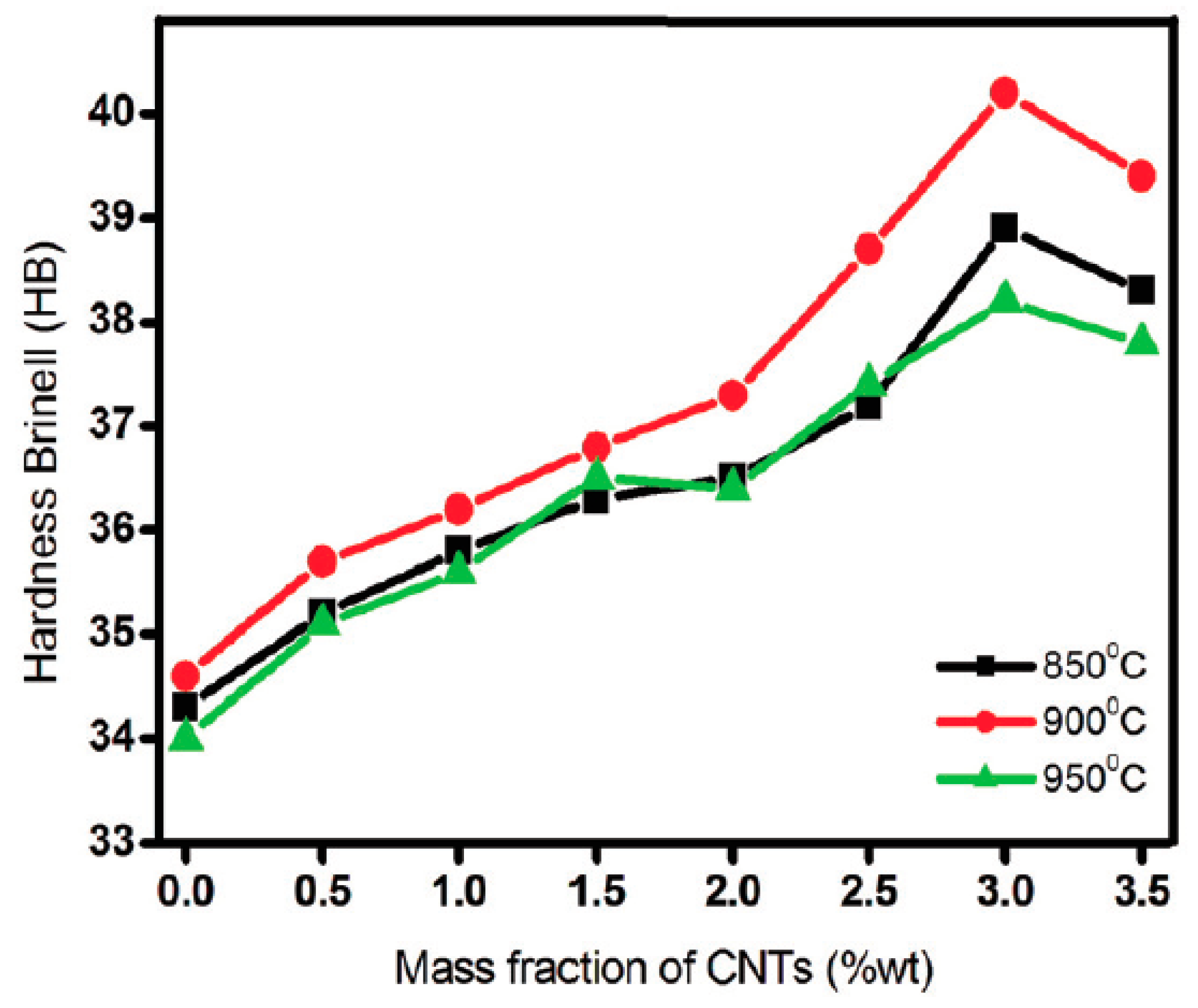

- Bui, H.T.; Tran, B.T.; Le, D.Q.; Than, X.T.; Doan, D.P.; Phan, N.M. The effect of sintering temperature on the mechanical properties of a Cu/CNT nanocomposite prepared via a powder metallurgy method. Adv. Nat. Sci. Nanosci. Nanotechnol. 2011, 2, 015006. [Google Scholar]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Suryanarayana, C. Synthesis of nanocomposites by mechanical alloying. J. Alloys Compd. 2011, 509, S229–S234. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Ye, J.; Lee, Z.; Ahn, B.; Nutt, S.R.; He, J.; Schoenung, J.M. Cryomilling for the fabrication of a particulate B4C reinforced Al nanocomposite: Part II. Mechanisms for microstructural evolution. Metall. Mater. Trans. A 2006, 37, 3111–3117. [Google Scholar] [CrossRef]

- Suárez, S.; Reinert, L.; Mücklich, F. Carbon Nanotube (CNT)-reinforced metal matrix bulk composites: Manufacturing and evaluation. In Diamond and Carbon Composites and Nanocomposites; InTech: London, UK, 2016. [Google Scholar]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. MWCNTs/AZ31 surface composites fabricated by friction stir processing. Mater. Sci. Eng. A 2006, 419, 344–348. [Google Scholar] [CrossRef]

- Lee, C.; Huang, J.; Hsieh, P. Mg based nano-composites fabricated by friction stir processing. Scr. Mater. 2006, 54, 1415–1420. [Google Scholar] [CrossRef]

- Shafiei-Zarghani, A.; Kashani-Bozorg, S.; Zarei-Hanzaki, A. Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater. Sci. Eng. A 2009, 500, 84–91. [Google Scholar] [CrossRef]

- Yang, M.; Xu, C.; Wu, C.; Lin, K.-C.; Chao, Y.J.; An, L. Fabrication of AA6061/Al2O3 nano ceramic particle reinforced composite coating by using friction stir processing. J. Mater. Sci. 2010, 45, 4431–4438. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Sarani, A.; Khorshahian, S.; Afarani, M.S. Fabrication of 5052Al/Al2O3 nanoceramic particle reinforced composite via friction stir processing route. Mater. Des. 2011, 32, 4164–4172. [Google Scholar] [CrossRef]

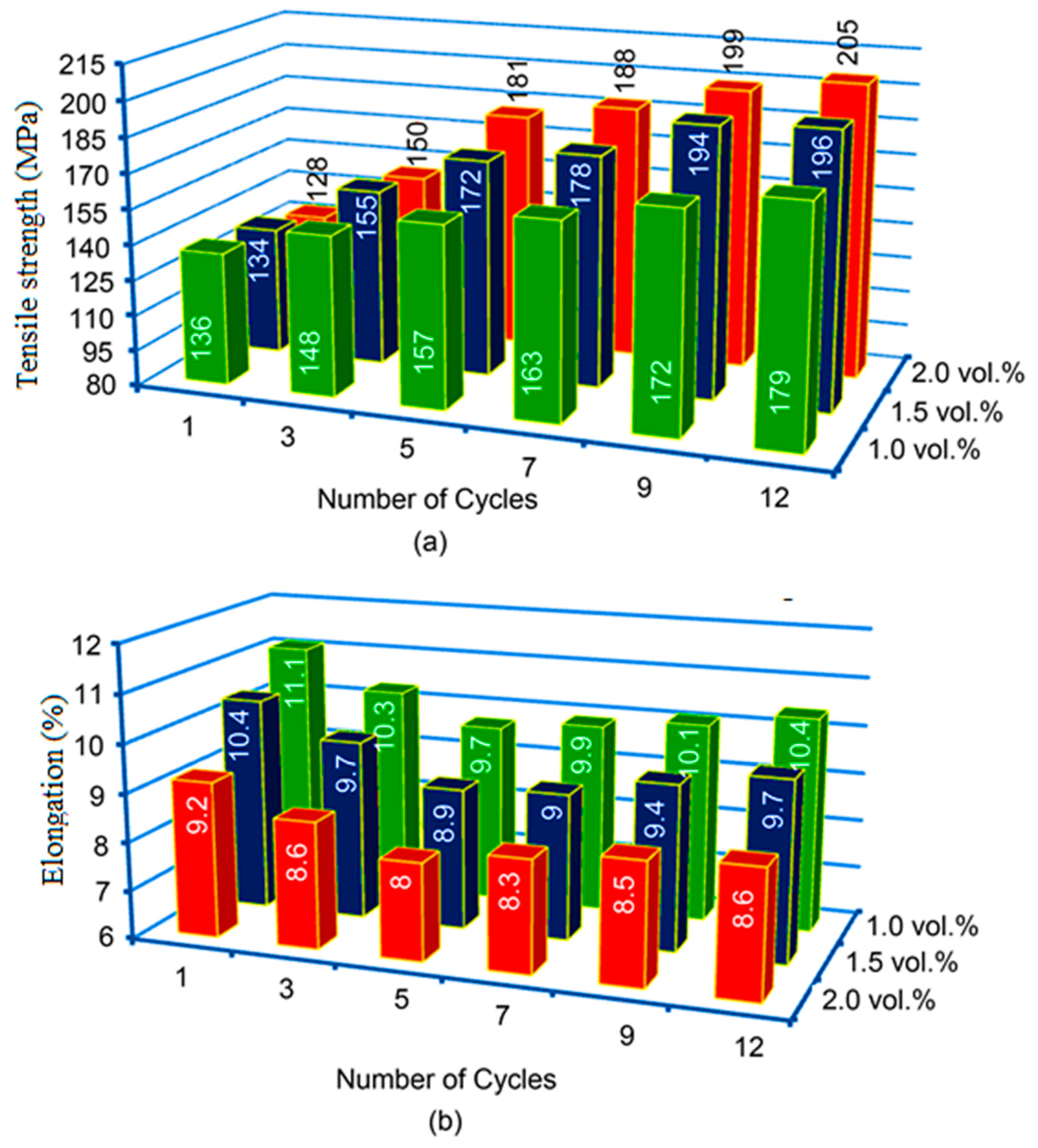

- Asadi, P.; Faraji, G.; Masoumi, A.; Givi, M.B. Experimental investigation of magnesium-base nanocomposite produced by friction stir processing: Effects of particle types and number of friction stir processing passes. Metall. Mater. Trans. A 2011, 42, 2820–2832. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Karimzadeh, F.; Enayati, M. A novel technique for development of A356/Al2O3 surface nanocomposite by friction stir processing. J. Mater. Process. Technol. 2011, 211, 1614–1619. [Google Scholar] [CrossRef]

- Hsu, C.; Chang, C.; Kao, P.; Ho, N.; Chang, C. Al–Al3Ti nanocomposites produced in situ by friction stir processing. Acta Mater. 2006, 54, 5241–5249. [Google Scholar] [CrossRef]

- Hsu, C.; Kao, P.; Ho, N. Ultrafine-grained Al–Al2Cu composite produced in situ by friction stir processing. Scr. Mater. 2005, 53, 341–345. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, B.; Wang, Q.; Ma, Z. In situ Al3Ti and Al2O3 nanoparticles reinforced Al composites produced by friction stir processing in an Al-TiO2 system. Mater. Lett. 2011, 65, 2070–2072. [Google Scholar] [CrossRef]

- Bauri, R.; Yadav, D.; Suhas, G. Effect of friction stir processing (FSP) on microstructure and properties of Al–TiC in situ composite. Mater. Sci. Eng. A 2011, 528, 4732–4739. [Google Scholar] [CrossRef]

- Arora, H.; Singh, H.; Dhindaw, B. Composite fabrication using friction stir processing—A review. Int. J. Adv. Manuf. Technol. 2012, 61, 1043–1055. [Google Scholar] [CrossRef]

- Liao, H.; Chen, J.; Peng, L.; Han, J.; Yi, H.; Zheng, F.; Wu, Y.; Ding, W. Fabrication and characterization of magnesium matrix composite processed by combination of friction stir processing and high-energy ball milling. Mater. Sci. Eng. A 2017, 683, 207–214. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Jamaati, R.; Niroumand, B.; Toroghinejad, M.R. Fabrication and characterization of Al/SiCp composites by CAR process. Mater. Sci. Eng. A 2011, 528, 4462–4467. [Google Scholar] [CrossRef]

- Jamaati, R.; Amirkhanlou, S.; Toroghinejad, M.R.; Niroumand, B. Effect of particle size on microstructure and mechanical properties of composites produced by ARB process. Mater. Sci. Eng. A 2011, 528, 2143–2148. [Google Scholar] [CrossRef]

- Alizadeh, M.; Paydar, M. Fabrication of nanostructure Al/SiCP composite by accumulative roll-bonding (ARB) process. J. Alloys Compd. 2010, 492, 231–235. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. High-strength and highly-uniform composite produced by anodizing and accumulative roll bonding processes. Mater. Des. 2010, 31, 4816–4822. [Google Scholar] [CrossRef]

- Yazdani, A.; Salahinejad, E. Evolution of reinforcement distribution in Al–B4C composites during accumulative roll bonding. Mater. Des. 2011, 32, 3137–3142. [Google Scholar] [CrossRef]

- Karimi, M.; Toroghinejad, M.R.; Dutkiewicz, J. Nanostructure formation during accumulative roll bonding of commercial purity titanium. Mater. Charact. 2016, 122, 98–103. [Google Scholar] [CrossRef]

- Soltani, M.A.; Jamaati, R.; Toroghinejad, M.R. The influence of TiO2 nano-particles on bond strength of cold roll bonded aluminum strips. Mater. Sci. Eng. A 2012, 550, 367–374. [Google Scholar] [CrossRef]

- Hashemi, M.; Jamaati, R.; Toroghinejad, M.R. Microstructure and mechanical properties of Al/SiO2 composite produced by CAR process. Mater. Sci. Eng. A 2012, 532, 275–281. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Ketabchi, M.; Parvin, N.; Khorsand, S.; Bahrami, R. Accumulative press bonding; A novel manufacturing process of nanostructured metal matrix composites. Mater. Des. 2013, 51, 367–374. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Q.; Jia, Y.; Zhang, B.; Jing, R.; Ma, M.; Jing, Q.; Liu, R. Evaluation of mechanical properties of 1060-Al reinforced with WC particles via warm accumulative roll bonding process. Mater. Des. 2013, 43, 367–372. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Q.; Jia, Y.; Zhang, B.; Jing, R.; Ma, M.; Jing, Q.; Liu, R. Effect of W particles on the properties of accumulatively roll-bonded Al/W composites. Mater. Sci. Eng. A 2012, 547, 120–124. [Google Scholar] [CrossRef]

- Abbasi, M.; Sajjadi, S. Manufacturing of Al–Al2O3–Mg multilayered nanocomposites by accumulative roll bonding process and study of its microstructure, tensile, and bending properties. J. Compos. Mater. 2018, 52, 147–157. [Google Scholar] [CrossRef]

- Lv, Z.; Ren, X.; Hou, H. Application of Accumulative Roll Bonding Process for Manufacturing Mg/2 wt.% CNTs Nanocomposite with Superior Mechanical Properties. J. Nanosci. Nanotechnol. 2017, 17, 4022–4031. [Google Scholar] [CrossRef]

- Khabushan, J.K.; Bonabi, S.B. Investigating of the Microstructure and Mechanical Properties of Al-Based Composite Reinforced with Nano-Trioxide Tungsten via Accumulative Roll Bonding Process. Open J. Met. 2017, 7, 9. [Google Scholar] [CrossRef]

- Stark, W.J.; Stoessel, P.R.; Wohlleben, W.; Hafner, A. Industrial applications of nanoparticles. Chem. Soc. Rev. 2015, 44, 5793–5805. [Google Scholar] [CrossRef] [PubMed]

- Lakhi, K.S.; Park, D.-H.; Al-Bahily, K.; Cha, W.; Viswanathan, B.; Choy, J.-H.; Vinu, A. Mesoporous carbon nitrides: Synthesis, functionalization, and applications. Chem. Soc. Rev. 2017, 46, 72–101. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Holleman, A.; Wiberg, E. Inorganic Chemistry; Academic Press: Berlin, Germany; New York, NY, USA, 2001. [Google Scholar]

- Villars, P.; Cenzual, K. Pearson’s Crystal Data®: Crystal Structure Database for Inorganic Compounds; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Mochalin, V.N.; Shenderova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotechnol. 2012, 7, 11. [Google Scholar] [CrossRef] [PubMed]

- Schrand, A.M.; Johnson, J.; Dai, L.; Hussain, S.M.; Schlager, J.J.; Zhu, L.; Hong, Y.; Ōsawa, E. Cytotoxicity and genotoxicity of carbon nanomaterials. In Safety of Nanoparticles; Springer: New York, NY, USA, 2009; pp. 159–187. [Google Scholar]

- Xing, Y.; Xiong, W.; Zhu, L.; Osawa, E.; Hussin, S.; Dai, L. DNA damage in embryonic stem cells caused by nanodiamonds. ACS Nano 2011, 5, 2376–2384. [Google Scholar] [CrossRef] [PubMed]

- Sakovich, G.; Vorozhtsov, S.; Vorozhtsov, A.; Potekaev, A.; Kulkov, S. Physical and Mechanical Properties of Composites and Light Alloys Reinforced with Detonation Nanodiamonds. Russ. Phys. J. 2016, 59. [Google Scholar] [CrossRef]

- Yu, M.-F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Goh, C.; Wei, J.; Lee, L.; Gupta, M. Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique. Nanotechnology 2005, 17, 7. [Google Scholar] [CrossRef]

- Laha, T.; Chen, Y.; Lahiri, D.; Agarwal, A. Tensile properties of carbon nanotube reinforced aluminum nanocomposite fabricated by plasma spray forming. Compos. Part A Appl. Sci. Manuf. 2009, 40, 589–594. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Cravotto, G.; Gaudino, E.C.; Cintas, P. On the mechanochemical activation by ultrasound. Chem. Soc. Rev. 2013, 42, 7521–7534. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Zeiger, B.W.; Suslick, K.S. Sonochemical synthesis of nanomaterials. Chem. Soc. Rev. 2013, 42, 2555–2567. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Chen, L.; Cao, C.; Li, X. Nanoparticle-induced unusual melting and solidification behaviours of metals. Nat. Commun. 2017, 8, 14178. [Google Scholar] [CrossRef] [PubMed]

- Brennen, C.E. Cavitation and Bubble Dynamics; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Baig, R.N.; Varma, R.S. Alternative energy input: Mechanochemical, microwave and ultrasound-assisted organic synthesis. Chem. Soc. Rev. 2012, 41, 1559–1584. [Google Scholar] [CrossRef] [PubMed]

- Lauterborn, W.; Ohl, C.-D. Cavitation bubble dynamics. Ultrason. Sonochem. 1997, 4, 65–75. [Google Scholar] [CrossRef]

- Shima, A.; Tomita, Y.; Gibson, D.; Blake, J. The growth and collapse of cavitation bubbles near composite surfaces. J. Fluid Mech. 1989, 203, 199–214. [Google Scholar] [CrossRef]

- Hasan, M.; Iyengar, K. Size and growth of cavitation bubble nuclei. Nature 1963, 199, 995. [Google Scholar] [CrossRef]

- Callenaere, M.; Franc, J.-P.; Michel, J.-M.; Riondet, M. The cavitation instability induced by the development of a re-entrant jet. J. Fluid Mech. 2001, 444, 223–256. [Google Scholar] [CrossRef]

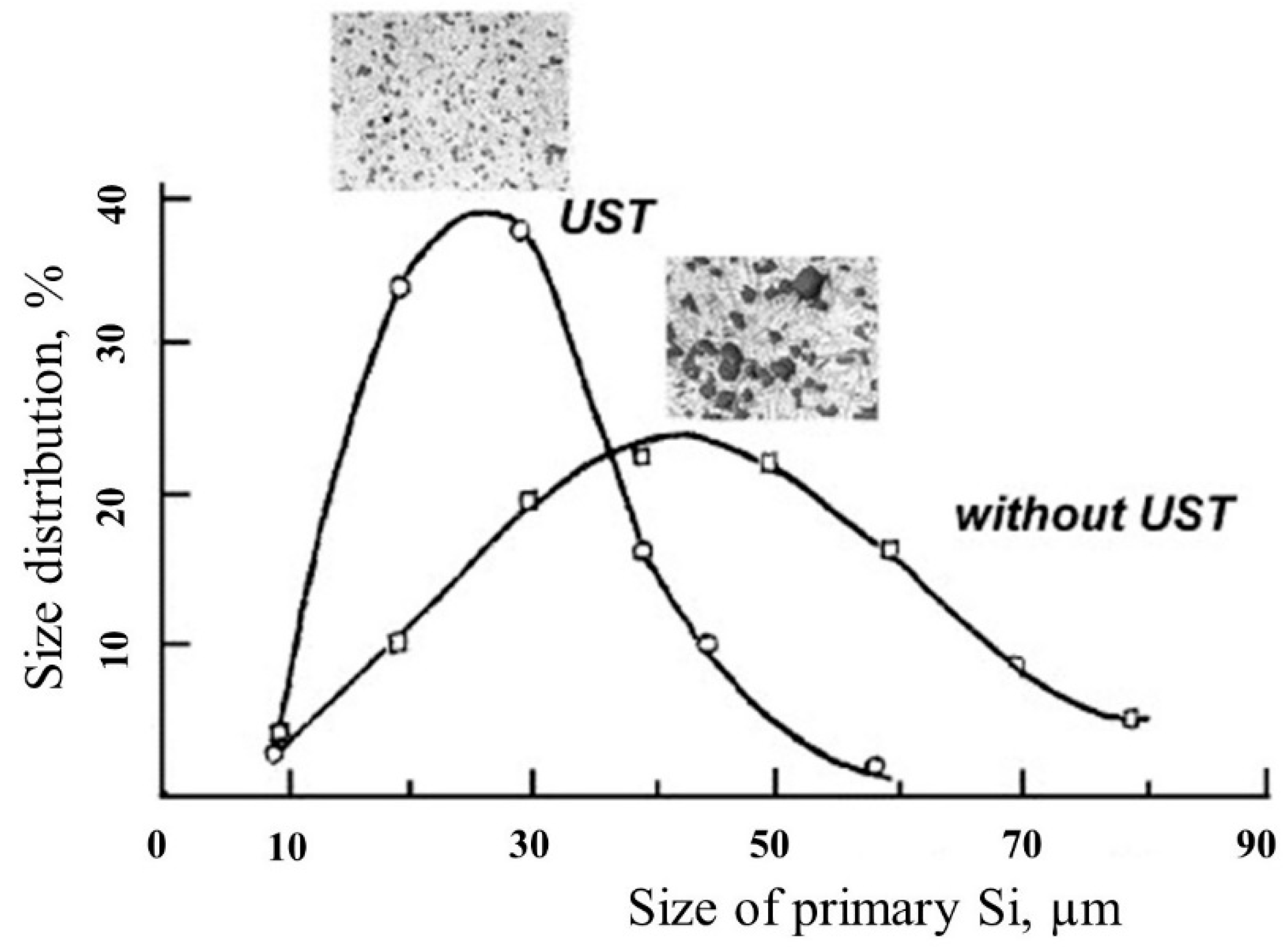

- Eskin, G.; Eskin, D. Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt. Ultrason. Sonochem. 2003, 10, 297–301. [Google Scholar] [CrossRef]

- Plesset, M.S.; Prosperetti, A. Bubble dynamics and cavitation. Annu. Rev. Fluid Mech. 1977, 9, 145–185. [Google Scholar] [CrossRef]

- Carlton, J. Marine Propellers and Propulsion; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Ensminger, D.; Stulen, D.E.-F. Ultrasonics: Data, Equations and Their Practical Uses; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Mossop, S. The freezing of supercooled water. Proc. Phys. Soc. Sect. B 1955, 68, 193. [Google Scholar] [CrossRef]

- Turnbull, D. Phase changes. In Solid State Physics; Elsevier: Amsterdam, The Netherlands, 1956; Volume 3, pp. 225–306. [Google Scholar]

- Endo, H. Thermodynamic consideration of the cavitation mechanism in homogeneous liquids. J. Acoust. Soc. Am. 1994, 95, 2409–2415. [Google Scholar] [CrossRef]

- Shchukin, D.G.; Skorb, E.; Belova, V.; Möhwald, H. Ultrasonic cavitation at solid surfaces. Adv. Mater. 2011, 23, 1922–1934. [Google Scholar] [CrossRef] [PubMed]

- Mason, T.J. Ultrasound in synthetic organic chemistry. Chem. Soc. Rev. 1997, 26, 443–451. [Google Scholar] [CrossRef]

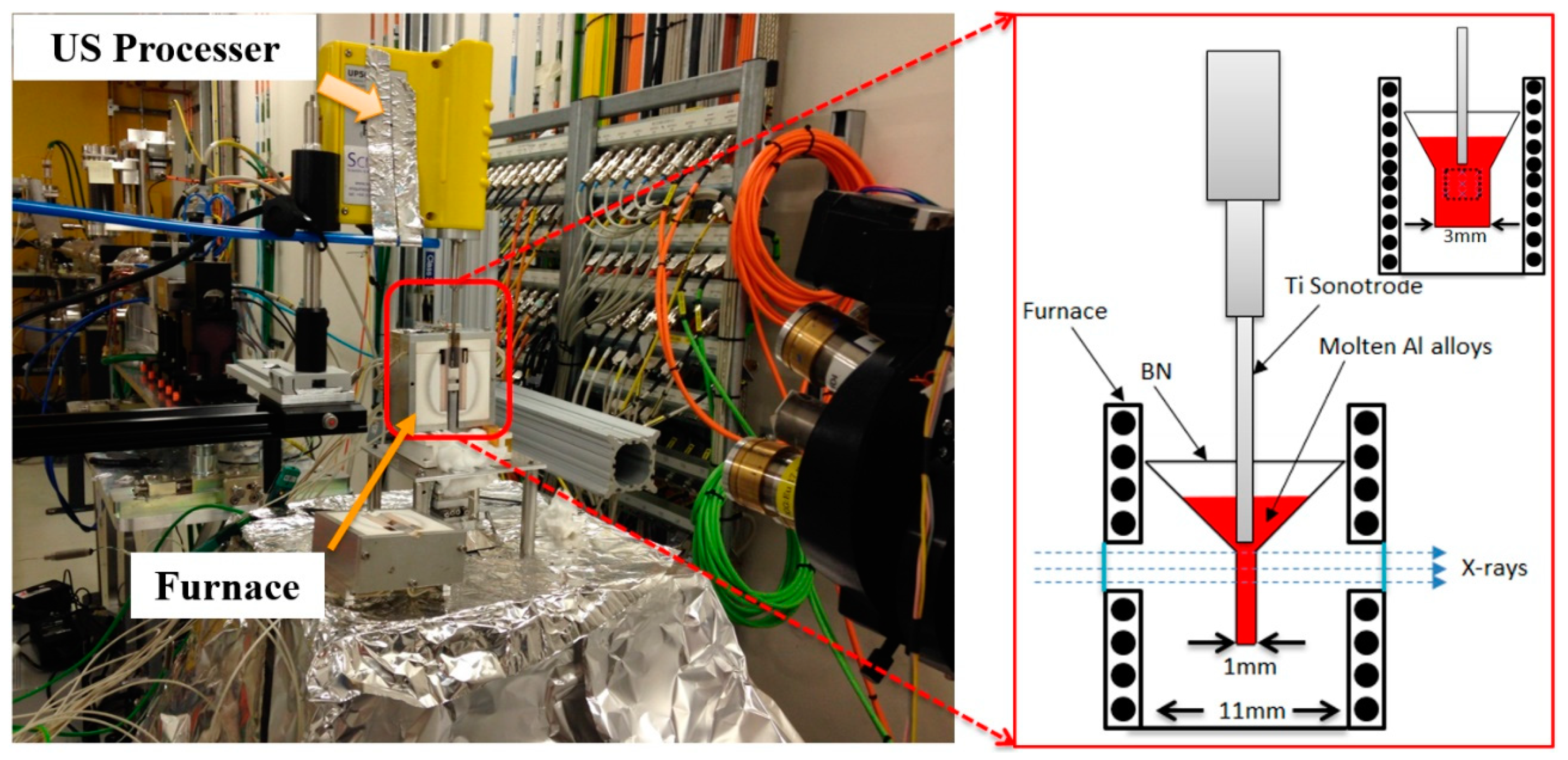

- Xu, W.; Tzanakis, I.; Srirangam, P.; Mirihanage, W.; Eskin, D.; Bodey, A.; Lee, P. Synchrotron quantification of ultrasound cavitation and bubble dynamics in Al–10Cu melts. Ultrason. Sonochem. 2016, 31, 355–361. [Google Scholar] [CrossRef] [PubMed]

- Dieringa, H. Processing of Magnesium-Based Metal Matrix Nanocomposites by Ultrasound-Assisted Particle Dispersion: A Review. Metals 2018, 8, 431. [Google Scholar] [CrossRef]

- Kudryashova, O.; Vorozhtsov, S. On the Mechanism of Ultrasound-Driven Deagglomeration of Nanoparticle Agglomerates in Aluminum Melt. JOM 2016, 68, 1307–1311. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X. Ultrasonic cavitation based nanomanufacturing of bulk aluminum matrix nanocomposites. J. Manuf. Sci. Eng. 2007, 129, 497–501. [Google Scholar] [CrossRef]

- Tzanakis, I.; Xu, W.; Eskin, D.; Lee, P.; Kotsovinos, N. In situ observation and analysis of ultrasonic capillary effect in molten aluminium. Ultrason. Sonochem. 2015, 27, 72–80. [Google Scholar] [CrossRef] [PubMed]

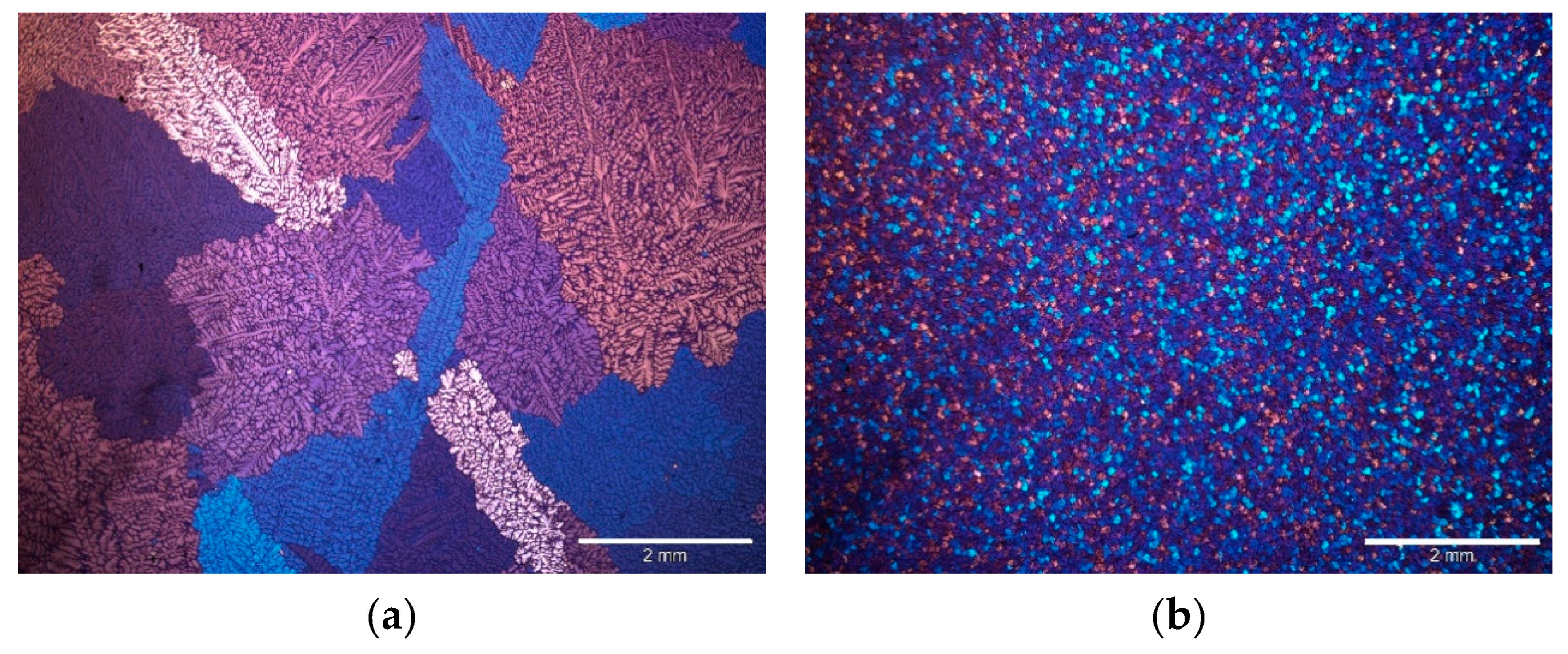

- Shu, D.; Sun, B.; Mi, J.; Grant, P.S. A high-speed imaging and modeling study of dendrite fragmentation caused by ultrasonic cavitation. Metall. Mater. Trans. A 2012, 43, 3755–3766. [Google Scholar] [CrossRef]

- Mirihanage, W.; Xu, W.; Tamayo-Ariztondo, J.; Eskin, D.; Garcia-Fernandez, M.; Srirangam, P.; Lee, P. Synchrotron radiographic studies of ultrasonic melt processing of metal matrix nano composites. Mater. Lett. 2016, 164, 484–487. [Google Scholar] [CrossRef]

- Minnaert, M. XVI. On musical air-bubbles and the sounds of running water. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1933, 16, 235–248. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Cheng, X. Ultrasonic-assisted fabrication of metal matrix nanocomposites. J. Mater. Sci. 2004, 39, 3211–3212. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, J.; Li, X. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, D.; Xuan, Y.; Nastac, L. An experimental and modeling investigation of aluminum-based alloys and nanocomposites processed by ultrasonic cavitation processing. Appl. Acoust. 2016, 103, 226–231. [Google Scholar] [CrossRef]

- Vorozhtsov, S.A.; Eskin, D.G.; Tamayo, J.; Vorozhtsov, A.B.; Promakhov, V.V.; Averin, A.A.; Khrustalyov, A.P. The application of external fields to the manufacturing of novel dense composite master alloys and aluminum-based nanocomposites. Metall. Mater. Trans. A 2015, 46, 2870–2875. [Google Scholar] [CrossRef]

- Su, H.; Gao, W.; Feng, Z.; Lu, Z. Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites. Mater. Des. 2012, 36, 590–596. [Google Scholar] [CrossRef]

- Dieringa, H.; Katsarou, L.; Buzolin, R.; Szakács, G.; Horstmann, M.; Wolff, M.; Mendis, C.; Vorozhtsov, S.; StJohn, D. Ultrasound assisted casting of an AM60 based metal matrix nanocomposite, its properties, and recyclability. Metals 2017, 7, 388. [Google Scholar] [CrossRef]

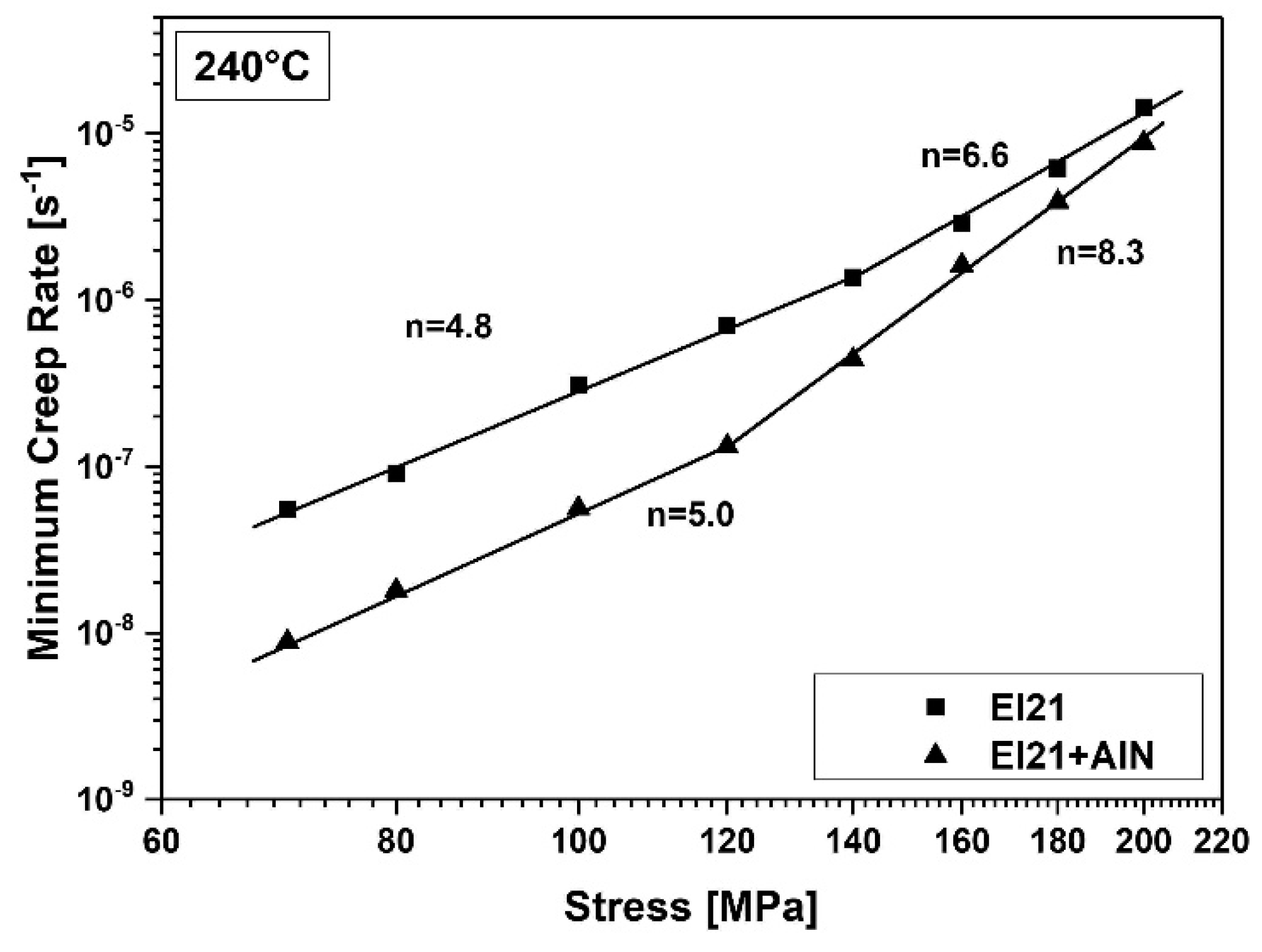

- Katsarou, L.; Mounib, M.; Lefebvre, W.; Vorozhtsov, S.; Pavese, M.; Badini, C.; Molina-Aldareguia, J.M.; Jimenez, C.C.; Prado, M.T.P.; Dieringa, H. Microstructure, mechanical properties and creep of magnesium alloy Elektron21 reinforced with AlN nanoparticles by ultrasound-assisted stirring. Mater. Sci. Eng. A 2016, 659, 84–92. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Mechanical properties and microstructure of SiC-reinforced Mg-(2,4)Al-1Si nanocomposites fabricated by ultrasonic cavitation based solidification processing. Mater. Sci. Eng. A 2008, 486, 357–362. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Lan, J.; Yang, Y.; Li, X. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method. Mater. Sci. Eng. A 2004, 386, 284–290. [Google Scholar] [CrossRef]

- Vorozhtsov, S.; Eskin, D.; Vorozhtsov, A.; Kulkov, S. Physico-mechanical and electrical properties of aluminum-based composite materials with carbon nanoparticles. In Light Metals 2014; Springer: New York, NY, USA, 2014; pp. 1373–1377. [Google Scholar]

- Chen, L.-Y.; Konishi, H.; Fehrenbacher, A.; Ma, C.; Xu, J.-Q.; Choi, H.; Xu, H.-F.; Pfefferkorn, F.E.; Li, X.-C. Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scr. Mater. 2012, 67, 29–32. [Google Scholar] [CrossRef]

- Sillekens, W.H.; Jarvis, D.J.; Vorozhtsov, A.; Bojarevics, V.; Badini, C.F.; Pavese, M.; Terzi, S.; Salvo, L.; Katsarou, L.; Dieringa, H. Physical Metallurgy and Materials Science. Metall. Mater. Trans. A 2004, 45, 3349–3361. [Google Scholar] [CrossRef]

- Gopalakannan, S.; Senthilvelan, T. EDM of cast Al/SiC metal matrix nanocomposites by applying response surface method. Int. J. Adv. Manuf. Technol. 2013, 67, 485–493. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Peng, J.-Y.; Xu, J.-Q.; Choi, H.; Li, X.-C. Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing. Scr. Mater. 2013, 69, 634–637. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, J.-Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.-M.; Mathaudhu, S.; Li, X.-C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539. [Google Scholar] [CrossRef] [PubMed]

- Min, Y.; Akbulut, M.; Kristiansen, K.; Golan, Y.; Israelachvili, J. The role of interparticle and external forces in nanoparticle assembly. Nat. Mater. 2008, 7, 527. [Google Scholar] [CrossRef] [PubMed]

- Manoylov, A.; Bojarevics, V.; Pericleous, K. Modeling the break-up of nano-particle clusters in aluminum-and magnesium-based metal matrix nano-composites. Metall. Mater. Trans. A 2015, 46, 2893–2907. [Google Scholar] [CrossRef]

- Manoylov, A.; Djambazov, G.; Pericleous, K.; Lebon, B. Modelling the deagglomeration of nanoparticle inclusions by ultrasonic melt processing. In Proceedings of the 24th International Congress on Sound and Vibration, London, UK, 23–27 July 2017; pp. 1–8. [Google Scholar]

- Syamlal, M. MFIX Documentation: Users Manual; EG and G Technical Services of West Virginia, Inc.: Morgantown, WV, USA, 1994. [Google Scholar]

- Brennen, C.E.; Brennen, C.E. Fundamentals of Multiphase Flow; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Padhi, P.; Dash, B.N.; Kar, S.K. Process modeling of deagglomeration of ceramic nanoparticles in liquid metal during synthesis of nanocomposites. J. Nanotechnol. 2011, 2011, 734013. [Google Scholar] [CrossRef]

- Zhang, D.; Nastac, L. Numerical modeling of the dispersion of ceramic nanoparticles during ultrasonic processing of aluminum-based nanocomposites. J. Mater. Res. Technol. 2014, 3, 296–302. [Google Scholar] [CrossRef]

- Miller, W.; Humphreys, F. Strengthening mechanisms in particulate metal matrix composites. Scr. Metall. Mater. 1991, 25, 33–38. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, D. A model for predicting the particle size dependence of the low cycle fatigue life in discontinuously reinforced MMCs. Scr. Mater. 2004, 51, 863–867. [Google Scholar] [CrossRef]

- Hall, E. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Kim, C.-S.; Sohn, I.; Nezafati, M.; Ferguson, J.; Schultz, B.F.; Bajestani-Gohari, Z.; Rohatgi, P.K.; Cho, K. Prediction models for the yield strength of particle-reinforced unimodal pure magnesium (Mg) metal matrix nanocomposites (MMNCs). J. Mater. Sci. 2013, 48, 4191–4204. [Google Scholar] [CrossRef]

- Dai, L.; Ling, Z.; Bai, Y. Size-dependent inelastic behavior of particle-reinforced metal–matrix composites. Compos. Sci. Technol. 2001, 61, 1057–1063. [Google Scholar] [CrossRef]

- Vogt, R.; Zhang, Z.; Li, Y.; Bonds, M.; Browning, N.; Lavernia, E.; Schoenung, J. The absence of thermal expansion mismatch strengthening in nanostructured metal–matrix composites. Scr. Mater. 2009, 61, 1052–1055. [Google Scholar] [CrossRef]

- Dunand, D.; Mortensen, A. On plastic relaxation of thermal stresses in reinforced metals. Acta Metall. Mater. 1991, 39, 127–139. [Google Scholar] [CrossRef]

- Redsten, A.; Klier, E.; Brown, A.; Dunand, D. Mechanical properties and microstructure of cast oxide-dispersion-strengthened aluminum. Mater. Sci. Eng. A 1995, 201, 88–102. [Google Scholar] [CrossRef]

- Ramakrishnan, N. An analytical study on strengthening of particulate reinforced metal matrix composites. Acta Mater. 1996, 44, 69–77. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Gao, F.-P.; Zhang, Q.-Y.; Xue, Z.; Li, W.-Z. Fabrication of carbon nanotubes reinforced AZ91D composites by ultrasonic processing. Trans. Nonferrous Met. Soc. China 2010, 20, 1222–1227. [Google Scholar] [CrossRef]

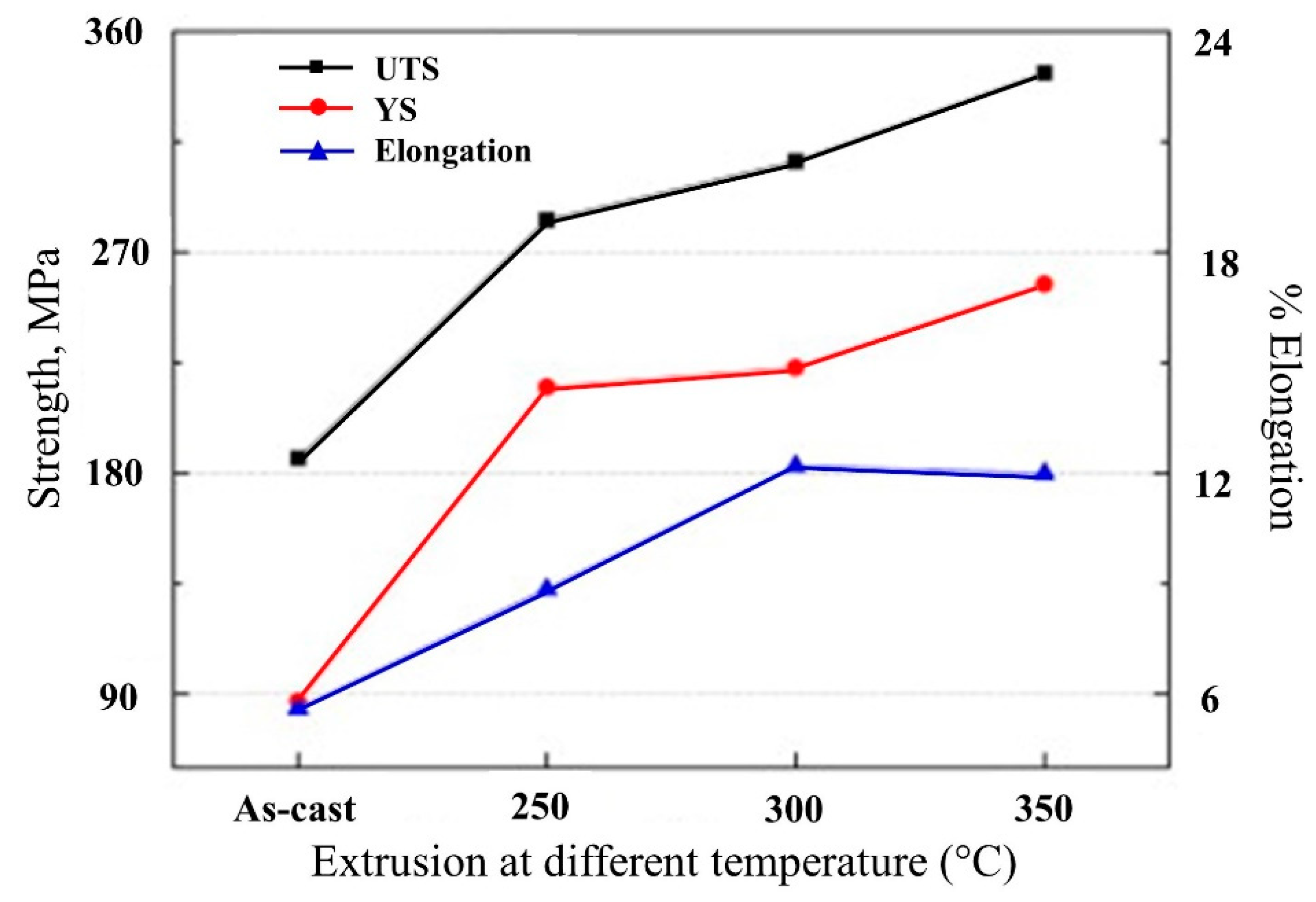

- Nie, K.B.; Wang, X.J.; Xu, L.; Wu, K.; Hu, X.S.; Zheng, M.Y. Influence of extrusion temperature and process parameter on microstructures and tensile properties of a particulate reinforced magnesium matrix nanocomposite. Mater. Des. 2012, 36, 199–205. [Google Scholar] [CrossRef]

- Xuan, Y.; Nastac, L. Microstructure Characteristics of A356 Nanocomposites Manufactured via Ultrasonic Cavitation Processing Under Controlled Solidification Conditions. In TMS 2017 146th Annual Meeting & Exhibition Supplemental Proceedings; Springer: New York, NY, USA, 2017; pp. 297–303. [Google Scholar]

- Gao, Q.; Wu, S.; Lü, S.; Xiong, X.; Du, R.; An, P. Improvement of particles distribution of in-situ 5 vol% TiB2 particulates reinforced Al-4.5 Cu alloy matrix composites with ultrasonic vibration treatment. J. Alloys Compd. 2017, 692, 1–9. [Google Scholar] [CrossRef]

- Rana, R.; Purohit, R. Development and analysis of Al-Matrix nano composites fabricated by ultrasonic assisted squeeze casting process. Mater. Today Proc. 2015, 2, 3697–3703. [Google Scholar]

- De Cicco, M.P.; Turng, L.-S.; Li, X.; Perepezko, J.H. Nucleation catalysis in aluminum alloy A356 using nanoscale inoculants. Metall. Mater. Trans. A 2011, 42, 2323–2330. [Google Scholar] [CrossRef]

- Cao, G.; Choi, H.; Konishi, H.; Kou, S.; Lakes, R.; Li, X. Mg–6Zn/1.5% SiC nanocomposites fabricated by ultrasonic cavitation-based solidification processing. J. Mater. Sci. 2008, 43, 5521. [Google Scholar] [CrossRef]

- Chen, X.-H.; Yan, H. Fabrication of nanosized Al2O3 reinforced aluminum matrix composites by subtype multifrequency ultrasonic vibration. J. Mater. Res. 2015, 30, 2197–2209. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y. Microstructure and mechanical properties of the semisolid slurries and rheoformed component of nano-sized SiC/7075 aluminum matrix composite prepared by ultrasonic-assisted semisolid stirring. Mater. Sci. Eng. A 2015, 639, 350–358. [Google Scholar] [CrossRef]

- Liu, X.; Jia, S.; Nastac, L. Ultrasonic cavitation-assisted molten metal processing of cast A356-nanocomposites. Int. J. Met. 2014, 8, 51–58. [Google Scholar] [CrossRef]

- Nampoothiri, J.; Harini, R.S.; Nayak, S.K.; Raj, B.; Ravi, K. Post in-situ reaction ultrasonic treatment for generation of Al–4.4 Cu/TiB2 nanocomposite: A route to enhance the strength of metal matrix nanocomposites. J. Alloys Compd. 2016, 683, 370–378. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, D.; Nastac, L. Experimental and numerical analysis of the 6061-based nanocomposites fabricated via ultrasonic processing. J. Mater. Eng. Perform. 2015, 24, 2225–2233. [Google Scholar] [CrossRef]

- Murthy, N.; Reddy, A.P.; Selvaraj, N.; Rao, C. Preparation of SiC based Aluminium metal matrix nano composites by high intensity ultrasonic cavitation process and evaluation of mechanical and tribological properties. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; p. 012106. [Google Scholar]

- Kasar, A.K.; Xiong, G.; Menezes, P.L. Graphene-Reinforced Metal and Polymer Matrix Composites. JOM 2018, 70, 829–836. [Google Scholar] [CrossRef]

- Lin, D.; Liu, C.R.; Cheng, G.J. Single-layer graphene oxide reinforced metal matrix composites by laser sintering: Microstructure and mechanical property enhancement. Acta Mater. 2014, 80, 183–193. [Google Scholar] [CrossRef]

- Park, J.G.; Keum, D.H.; Lee, Y.H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 2015, 95, 690–698. [Google Scholar] [CrossRef]

- Hu, Z.; Tong, G.; Nian, Q.; Xu, R.; Saei, M.; Chen, F.; Chen, C.; Zhang, M.; Guo, H.; Xu, J. Laser sintered single layer graphene oxide reinforced titanium matrix nanocomposites. Compos. Part B Eng. 2016, 93, 352–359. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Fan, G.; Pan, H.; Chen, Z.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef]

- Bastwros, M.; Kim, G.-Y.; Zhu, C.; Zhang, K.; Wang, S.; Tang, X.; Wang, X. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. Part B Eng. 2014, 60, 111–118. [Google Scholar] [CrossRef]

- Li, J.; Xiong, Y.; Wang, X.; Yan, S.; Yang, C.; He, W.; Chen, J.; Wang, S.; Zhang, X.; Dai, S. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater. Sci. Eng. A 2015, 626, 400–405. [Google Scholar] [CrossRef]

- Wozniak, J.; Kostecki, M.; Cygan, T.; Buczek, M.; Olszyna, A. Self-lubricating aluminium matrix composites reinforced with 2D crystals. Compos. Part B Eng. 2017, 111, 1–9. [Google Scholar] [CrossRef]

- Kim, W.; Lee, T.; Han, S. Multi-layer graphene/copper composites: Preparation using high-ratio differential speed rolling, microstructure and mechanical properties. Carbon 2014, 69, 55–65. [Google Scholar] [CrossRef]

- Kuzumaki, T.; Miyazawa, K.; Ichinose, H.; Ito, K. Processing of carbon nanotube reinforced aluminum composite. J. Mater. Res. 1998, 13, 2445–2449. [Google Scholar] [CrossRef]

- Kwon, H.; Park, D.H.; Silvain, J.F.; Kawasaki, A. Investigation of carbon nanotube reinforced aluminum matrix composite materials. Compos. Sci. Technol. 2010, 70, 546–550. [Google Scholar] [CrossRef]

- Bastwros, M.M.; Esawi, A.M.; Wifi, A. Friction and wear behavior of Al–CNT composites. Wear 2013, 307, 164–173. [Google Scholar] [CrossRef]

- Chen, W.; Tu, J.; Wang, L.; Gan, H.; Xu, Z.; Zhang, X. Tribological application of carbon nanotubes in a metal-based composite coating and composites. Carbon 2003, 41, 215–222. [Google Scholar] [CrossRef]

- Scharf, T.; Neira, A.; Hwang, J.; Tiley, J.; Banerjee, R. Self-lubricating carbon nanotube reinforced nickel matrix composites. J. Appl. Phys. 2009, 106, 013508. [Google Scholar] [CrossRef]

- El-Kady, O.; Fathy, A. Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater. Des. 2014, 54, 348–353. [Google Scholar] [CrossRef]

- Lim, C.; Leo, D.; Ang, J.; Gupta, M. Wear of magnesium composites reinforced with nano-sized alumina particulates. Wear 2005, 259, 620–625. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S. Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 2009, 30, 2756–2762. [Google Scholar] [CrossRef]

- Meng, J.; Zhang, P.; Wang, S. Recent progress of abrasion-resistant materials: Learning from nature. Chem. Soc. Rev. 2016, 45, 237–251. [Google Scholar] [CrossRef] [PubMed]

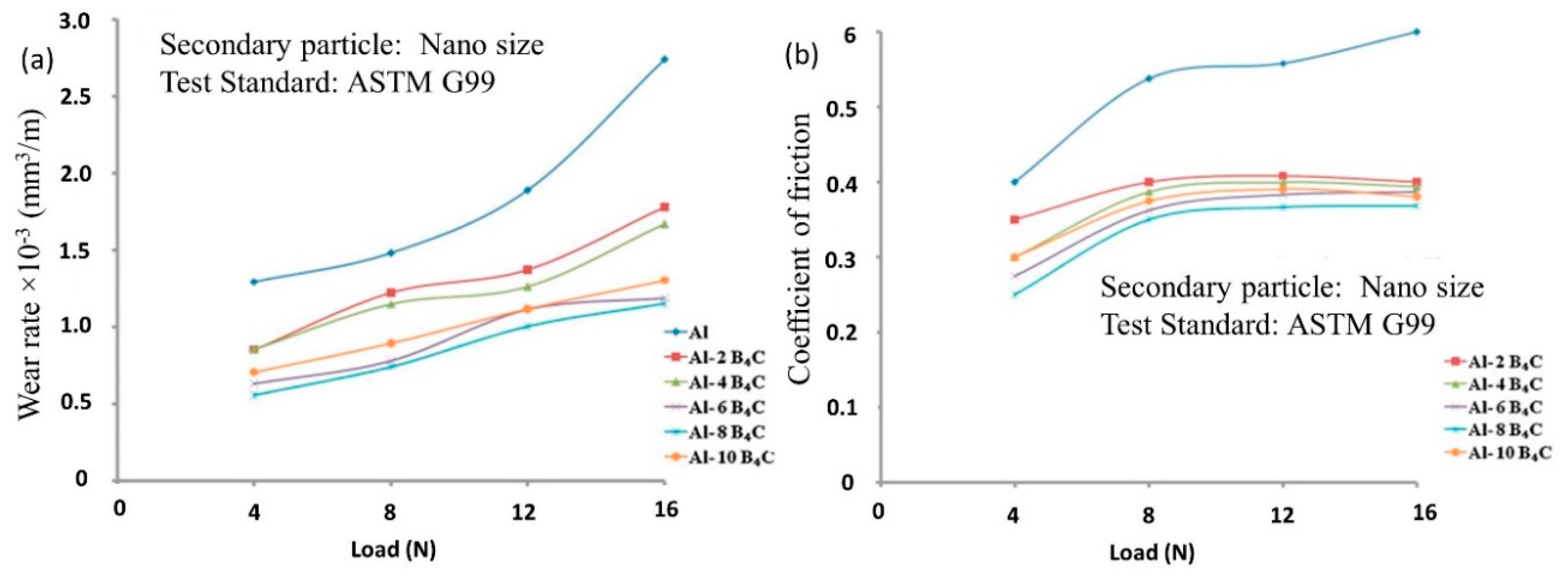

- Harichandran, R.; Selvakumar, N. Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Arch. Civ. Mech. Eng. 2016, 16, 147–158. [Google Scholar] [CrossRef]

- Poovazhagan, L.; Kalaichelvan, K.; Sornakumar, T. Processing and performance characteristics of aluminum-nano boron carbide metal matrix nanocomposites. Mater. Manuf. Process. 2016, 31, 1275–1285. [Google Scholar] [CrossRef]

- Shivakumar, N.; Vasu, V.; Narasaiah, N. Processing and dry sliding wear behavior of Al2O3 nanoparticles reinforced ZA-27 composites. Mater. Today Proc. 2017, 4, 4006–4012. [Google Scholar] [CrossRef]

- Kasar, A.K.; Menezes, P.L. Synthesis and recent advances in tribological applications of graphene. Int. J. Adv. Manuf. Technol. 2018, 97, 3999–4019. [Google Scholar] [CrossRef]

- Ünlü, B.S. Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater. Des. 2008, 29, 2002–2008. [Google Scholar] [CrossRef]

| Type | SiC | AlN | Al2O3 | B4C | TiB2 | TiC |

|---|---|---|---|---|---|---|

| Crystal structure | α: hdp | hdp | α: hdp | rhomb | hdp | cub |

| Lattice parameters [nm] | a: 0.307 c: 1.008 | a: 0.311 c: 0.498 | a: 0.476 c: 1.299 | a: 0.559 c: 1.205 | a: 0.303 c: 0.322 | a: 0.432 |

| Melting T [°C] | 2300 | 3000 | 2045 | 2450 | 2900 | 3140 |

| Young’s modulus [GPa] | 480 | 350 | 410 | 450 | 370 | 320 |

| Density [g/cm3] | 3.22 | 3.26 | 3.98 | 2.53 | 4.49 | 4.92 |

| Mohs hardness | 9.6 | - | 6.5 | 9.5 | - | - |

| CTE [10−6 K−1] | 4.9 | 6.0 | 8.3 | 5.4 | 7.4 | 7.4 |

| supplier of nanoparticles | IoLiTec Nanomaterials, Skyspring Nanomaterials, Inc., Auer-Remy GmbH, ChemPur Feinchemikalien und Forschungsbedarf GmbH, Alpha Aesar | |||||

| Base | Carbide | Nitride | Boride | Oxide |

|---|---|---|---|---|

| Aluminium | AlN | Al2O3 | ||

| Antimony | Sb2O3 | |||

| Boron | B4C | BN | B2O3 | |

| Bismuth | Bi2O3 | |||

| Cerium | CeO2 | |||

| Chromium | CrC | CrN | CrB | CrO3, Cr2O3 |

| Cobalt | CoO, Co2O3, Co3O4 | |||

| Copper | CuO | |||

| Dysprosium | Dy2O3 | |||

| Erbium | Er2O3 | |||

| Europium | Eu2O3 | |||

| Gadolinium | Gd2O3 | |||

| Hafnium | HfC | HfN | HfO2 | |

| Indium | In2O3 | |||

| Iron | Fe3O4, Fe2O3 | |||

| Lanthanum | LaB6 | La2O3 | ||

| Magnesium | MgO | |||

| Manganese | MnO2, MnO3, Mn2O3 | |||

| Molybdenum | MoC, Mo2C | MoN, Mo2N | MoB, Mo2B | MoO3 |

| Neodymium | Nd2O3 | |||

| Nickel | NiO, Ni2O3 | |||

| Niobium | Nb2O5 | |||

| Praseodymium | Pr6O11 | |||

| Samarium | Sm2O3 | |||

| Silicon | SiC | Si3N4 | SiO2 | |

| Tantalum | TaC | TaN | Ta2O5 | |

| Terbium | Tb4O7 | |||

| Tin | SnO2 | |||

| Titanium | TiC | TiN | TiB2 | TiO2 |

| Tungsten | WC, W2C | WN, W2N | WB, W2B | WO3 |

| Vanadium | VO, V2O3, V2O5 | |||

| Yttrium | Y2O3 | |||

| Ytterbium | Yb2O3 | |||

| Zinc | ZnO | |||

| Zirconium | ZrC | ZrN | ZrB2 | ZrO2 |

| Material | CTE [10−6 K−1] | 0.2 Yield Strength [MPa] | UTS [MPa] | Elongation [%] |

|---|---|---|---|---|

| Mg | 28.57 | 127 ± 5 | 205 ± 4 | 9 ± 2 |

| Mg-0.06 CNT | 27.17 | 133 ± 2 | 203 ± 1 | 12 ± 1 |

| Mg-0.18 CNT | 26.19 | 138 ± 4 | 206 ± 7 | 11 ± 1 |

| Mg-0.30 CNT | 25.90 | 146 ± 5 | 210 ± 6 | 8 ± 1 |

| Property | AM60 | AM60 + AlN |

|---|---|---|

| Grain size [µm] | 1277.0 ± 301.3 | 84.9 ± 6.2 |

| Hardness [HV5] | 48.0 ± 4.0 | 46.4 ± 6.0 |

| Density [g/cm3] | 1.7848 ± 0.0004 | 1.783 ± 0 |

| Porosity [%] | - | 0.919 |

| Yield strength [MPa] | 44.9 ± 6.9 | 91.2 ± 3.8 |

| UTS [MPa] | 109.3 ± 19.2 | 235.1 ± 6.4 |

| Elongation [%] | 6.4 ± 3.4 | 15.4 ± 4.2 |

| Matrix | wt% | % Improvement | Reference |

|---|---|---|---|

| A356 | SiC = 1.5 wt% | UTS = 100% | [117] |

| Mg-2Al-1Si | SiC = 2 wt% | UTS = 15% | [129] |

| 2024 Al alloy | Al2O3 = 1 wt% | YS = 45% | [126] |

| Mg-6Zn | SiC = 1.5 wt% | UTS = 55% | [162] |

| Al7075 | Al2O3 = 1.5 wt% | UTS = 59.6% | [163] |

| Al7075 | SiC = 1 vol% | YS = 12% | [164] |

| A356 | Al2O3 = 1 wt% | UTS = 15% | [165] |

| A356 | SiC = 1 wt% | UTS = 24% | [165] |

| Al-4.4Cu | TiB2 = 2 wt% | YS = 65% | [166] |

| AA6061 | SiC = 1 wt% | UTS = 3%, Elongation = 100% | [167] |

| AA6061 | Al2O3 = 1 wt% | UTS = 6%, Elongation = 100% | [167] |

| AA2219 | SiC = 2 wt% | UTS = 36.5% | [168] |

| Matrix | Reinforcement-Content | % Improvement in Mechanical/Tribological Properties with Respect to Matrix Material | Reference |

|---|---|---|---|

| Aluminum | Gr = 1.5 wt% | TS = 63% | [173] |

| Al6061 | Gr = 1 wt% | Flexure strength = 15% | [174] |

| Aluminum | Gr = 0.5 wt% | TS = 16% | [175] |

| AA6061 | Gr = 10 vol% | E = −35%, Hardness (H) = −13%, COF = −72%. | [176] |

| AA2124 | Gr = 3 wt% | Wear rate = −47% | [174] |

| Copper | Gr = 1 wt% | TS = 12% | [177] |

| Ti | Gr = 5 wt% | H = 200% | [172] |

| Aluminum | CNT = 5 wt% | TS = 100% | [178] |

| Aluminum | CNT~1 wt% | TS increased four times and no change in elongation | [179] |

| Aluminum | CNT = 5 wt% | Hardness = 28%, COF = −100% | [180] |

| Aluminum | CNT = 0.4 wt% | TS = 30%, Elongation reduced from 35 to 1%. | [171] |

| Copper | CNT = 16 vol% | H = 94%, COF = −100% | [181] |

| Ni | CNT = 10 vol% | COF = −100% | [182] |

| Aluminum | SiC = 10 wt% | Compressive strength = 71% | [183] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced Metal Matrix Nanocomposites. Metals 2019, 9, 330. https://doi.org/10.3390/met9030330

Malaki M, Xu W, Kasar AK, Menezes PL, Dieringa H, Varma RS, Gupta M. Advanced Metal Matrix Nanocomposites. Metals. 2019; 9(3):330. https://doi.org/10.3390/met9030330

Chicago/Turabian StyleMalaki, Massoud, Wenwu Xu, Ashish K. Kasar, Pradeep L. Menezes, Hajo Dieringa, Rajender S. Varma, and Manoj Gupta. 2019. "Advanced Metal Matrix Nanocomposites" Metals 9, no. 3: 330. https://doi.org/10.3390/met9030330

APA StyleMalaki, M., Xu, W., Kasar, A. K., Menezes, P. L., Dieringa, H., Varma, R. S., & Gupta, M. (2019). Advanced Metal Matrix Nanocomposites. Metals, 9(3), 330. https://doi.org/10.3390/met9030330