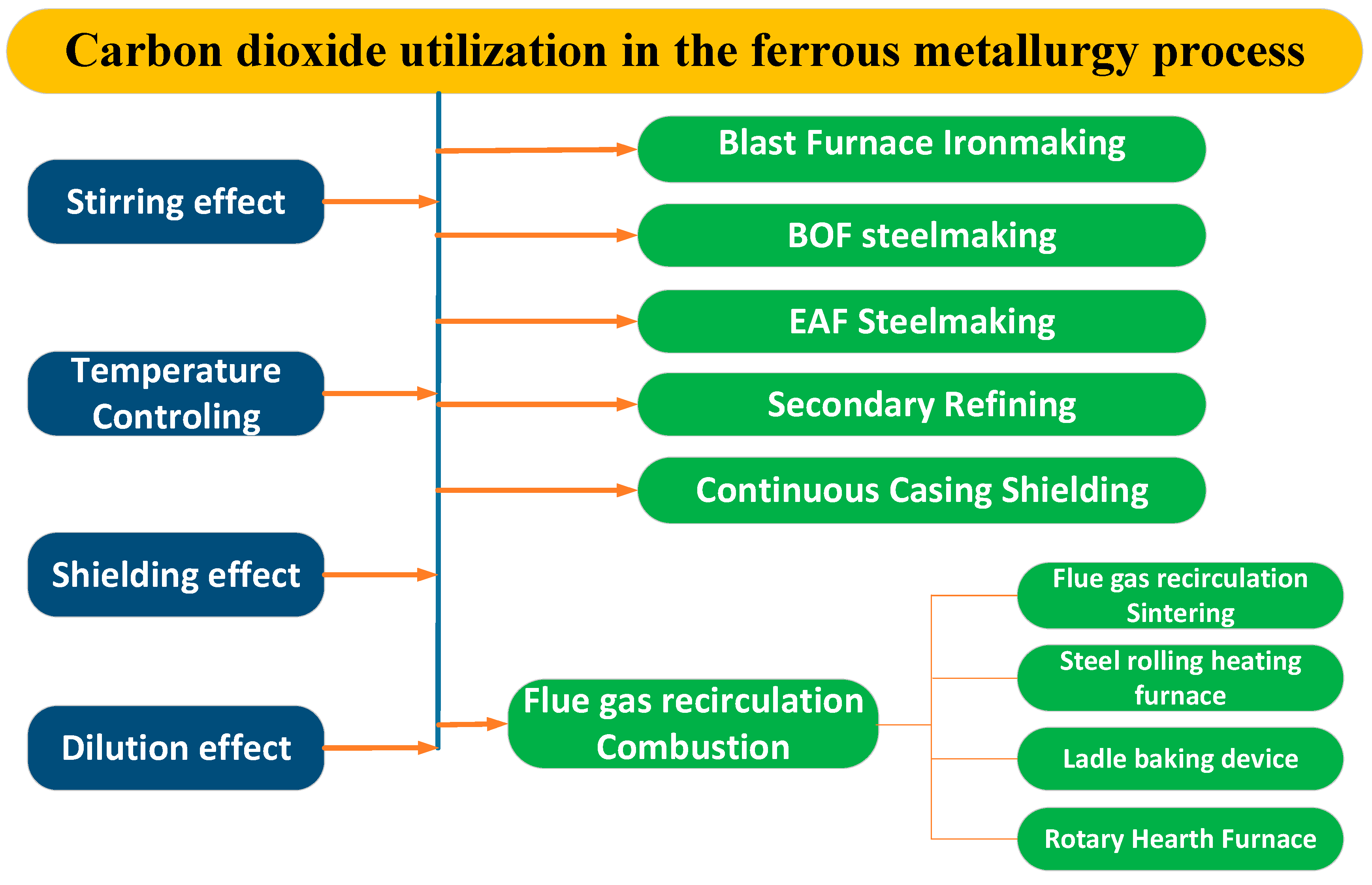

CO2 Utilization in the Ironmaking and Steelmaking Process

Abstract

:1. Introduction

2. Application in the Steelmaking Process.

2.1. Top-Blowing Carbon Dioxide in Converter

2.2. Bottom-Blowing Carbon Dioxide in the BOF

2.3. Bottom-Blowing Stirring in the Ladle Furnace

2.4. Bottom-Blowing Stirring in the Electric Arc Furnace

2.5. Shielding Gas in Continuous Casting Process

3. Application in Sintering and Blast Furnace

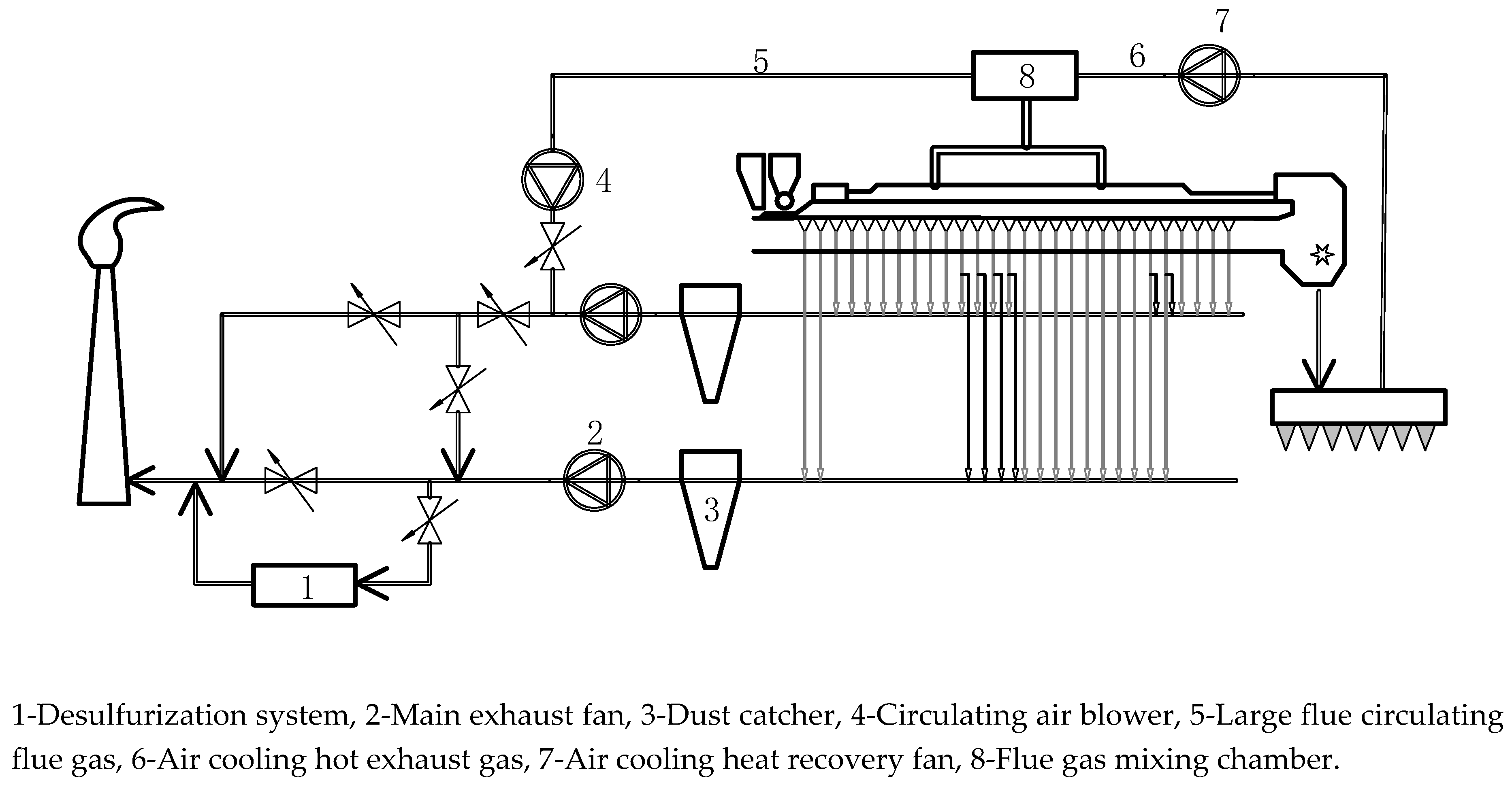

3.1. Flue Gas Recirculation (FGR) Sintering

3.2. CO2 Injection Through the Blast Furnace Tuyere

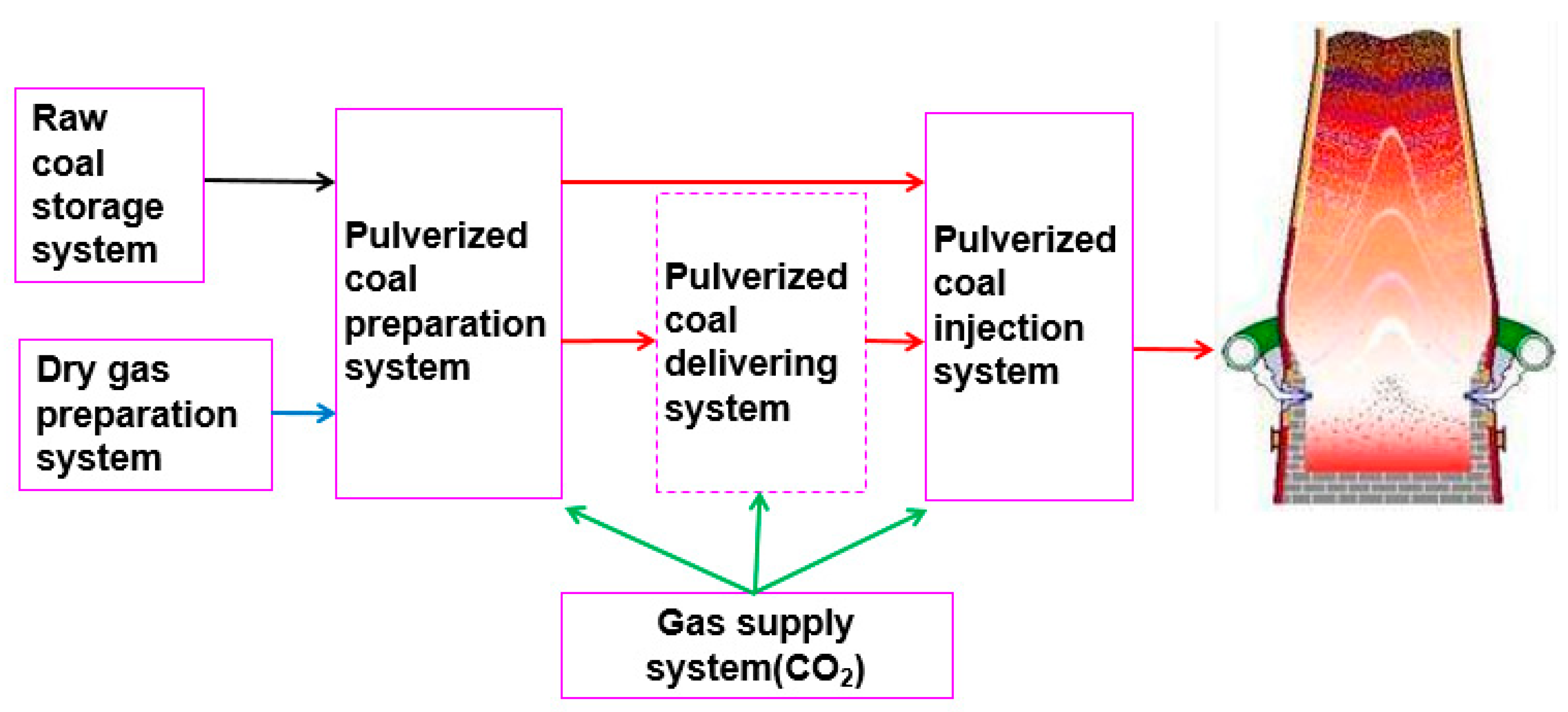

3.3. Carrier Gas of Pulverized Coal Injection

4. Applications in Other Ferrous Metallurgy Processes

4.1. Application in Smelting Stainless Steel

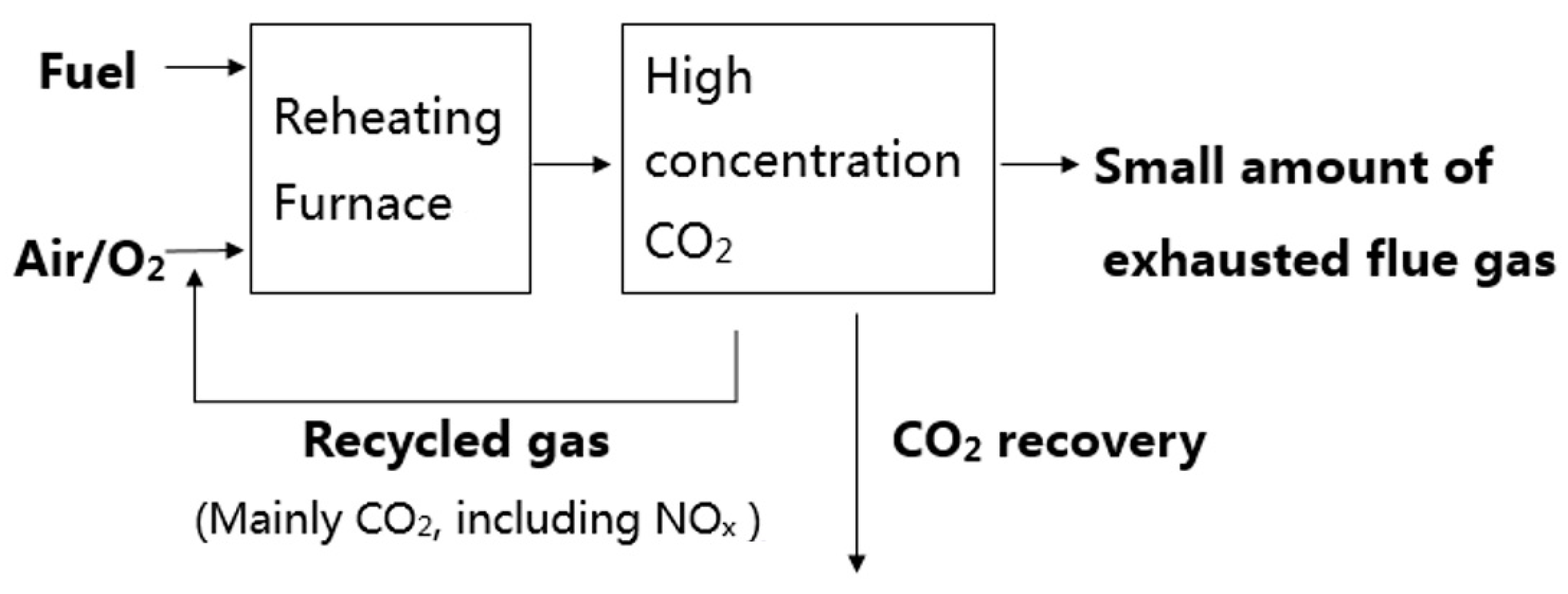

4.2. CO2 Circulation Combustion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Shangguan, F.Q.; Zhang, C.X.; Hu, C.Q.; Li, X.P.; Zhou, J.C. Estimation of CO2 Emission in Chinese Steel Industry. China Metall. 2010, 19, 37–42. [Google Scholar]

- Aresta, M.; Dibenedetto, A.; Angelini, A. The changing paradigm in CO2 utilization. J. CO2 Util. 2013, 1, 65–73. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Carbon capture, storage and utilisation technologies: A critical analysis and comparison of their life cycle environmental impacts. J. CO2 Util. 2015, 3, 82–102. [Google Scholar] [CrossRef]

- Olajire, A.A. Valorization of greenhouse carbon dioxide emissions into value-added products by catalytic processes. J. CO2 Util. 2013, 1, 74–92. [Google Scholar] [CrossRef]

- Hu, B.; Guild, C.; Suib, S.L. Thermal, electrochemical, and photochemical conversion of CO2 to fuels and value-added products. J. CO2 Util. 2013, 1, 18–27. [Google Scholar] [CrossRef]

- Saeidi, S.; Amin, N.A.S.; Rahimpour, M.R. Hydrogenation of CO2 to value-added products—A review and potential future developments. J. CO2 Util. 2014, 2, 66–81. [Google Scholar] [CrossRef]

- Yin, Z.J.; Zhu, R.; Yi, C.; Chen, B.Y.; Wang, C.R. Fundamental Research on Controlling BOF Dust by COMI Steel Making Process. Iron Steel 2009, 53, 92–94. [Google Scholar]

- Jin, R.J.; Zhu, R.; Feng, L.X.; Yin, Z.J. Experimental study of steelmaking with CO2 and O2 mixed blowing. J. Univ. Sci. Technol. Beijing 2007, 29, 77–80. [Google Scholar]

- Lv, M.; Zhu, R.; Bi, X.R.; Lin, T.C. Application research of carbon dioxide in BOF steelmaking process. J. Univ. Sci. Technol. Beijing 2011, 33, 126–130. [Google Scholar]

- Yi, C.; Zhu, R.; Yin, Z.J.; Hou, N.N.; Chen, B.Y. Experimental Research of COMI Steelmaking Process Based on 30t Converter. Chin. J. Process Eng. 2009, 9, 222–225. [Google Scholar]

- Ning, X.J.; Yin, Z.J.; Yi, C.; Zhu, R.; Dong, K. Experimental research on dust reduction in steelmaking by CO2. Steelmaking 2009, 35, 32–34. [Google Scholar]

- Zhu, R.; Yi, C.; Chen, B.Y.; Wang, C.R.; Ke, J.X. Inner circulation research of steelmaking dust by COMI steelmaking process. Energy Metall. Ind. 2010, 29, 48–51. [Google Scholar]

- Lv, M.; Zhu, R.; Bi, X.R.; Wei, N.; Wang, C.R. Fundamental research on dephosphorization of BOF by COMI steelmaking process. Iron Steel 2011, 55, 31–35. [Google Scholar]

- Bi, X.R.; Liu, R.Z.; Zhu, R.; Lv, M. Research on Mechanism of Dust Generation in Converter. Ind. Heat. 2010, 39, 13–16. [Google Scholar]

- Li, Z.Z. Investigations on Fundamental Theory of CO2 Applied in Steelmaking Processes. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2017. [Google Scholar]

- O’Hara, R.D.; Spence, A.G.R.; Eisenwasser, J.D. Carbon Dioxide Shrouding and Purging at Ipsco’s Melt Shop. Iron Steelmak. 1986, 13, 24–27. [Google Scholar]

- Guo, X.; Chen, W. Action mechanism of bottom-blown CO2 in the bath of combined-blown converter. J. Iron Steel Res. 1993, 5, 9–14. [Google Scholar]

- Gu, Y.L.; Zhu, R.; Lv, M.; Chen, L.; Liu, R.Z. Exploratory research on bottom blowing CO2 during the LF process. Iron Steel 2013, 57, 34–39. [Google Scholar]

- Li, C.B.; Han, Y. The application of the combined blowing technique with CO2 bottom blowing to the converters of Anshan Iron and Steel Company. Steelmaking 1996, 12, 19–25. [Google Scholar]

- Zhu, R.; Bi, X.R.; Lv, M. Application and development of CO2 in the steelmaking process. Iron Steel 2012, 56, 1–5. [Google Scholar]

- Wang, H.; Zhu, R.; Liu, R.Z. Application Research of Carbon Dioxide in EAF Bottom Blowing. Ind. Heat. 2014, 43, 12–14. [Google Scholar]

- Anderson, S.A.H.; Foulard, J.; Lutgen, V. Inert Gas Technology for the Production of Low Nitrogen Steels. In Proceedings of the 47th Electric Furnace Conference, Orlando, FL, USA, 29 October–1 November 1989; pp. 365–375. [Google Scholar]

- Yu, H.; Wang, H.; Zhang, C. Analysis on advantages and disadvantages of sintering waste gas recirculation process. Sinter. Pelletizing 2014, 6, 51–55. [Google Scholar]

- Eisen, H.P.; Hüsig, K.R.; Köfler, A. Construction of the exhaust recycling facilities at a sintering plant. Stahl Eisen 2004, 124, 37–40. [Google Scholar]

- Hu, B.; He, X.H.; Wang, Z.C.; Ye, H.D.; Chen, Y.Y. Wind and Oxygen Balance based on Flue Gas Circulation Sintering Process. Iron Steel 2014, 58, 15–20. [Google Scholar]

- Menad, N.; Tayibi, H.; Carcedo, F.G.; Hernández, A. Minimization methods for emissions generated from sinter strands. J. Clean. Prod. 2006, 14, 740–747. [Google Scholar] [CrossRef]

- Fleischanderl, A. MEROS-Improved dry sintering waste gas treatment process. Rev. Métall. 2006, 29, 481–484. [Google Scholar] [CrossRef]

- Brunnbauer, G.; Ehler, W.; Zwittag, E.; Schmid, H.; Reidetschlaeger, J.; Kainz, K. New waste-gas recycling system for the sinter plant at Voestalpine Stah. MPT Metall. Plant Technol. Int. 2006, 29, 38–42. [Google Scholar]

- Alexander, F.; Christoph, A.; Erwin, Z. New Developments for Achieving Environmentally Friendly Sinter Production—Eposint and MEROS. China Metall. 2008, 17, 41–46. [Google Scholar]

- Fu, Z.X.; Liu, S.J.; Fu, X.; Liu, L.M.; Liu, D.P.; Cui, F.H. A Method of Injecting Carbon Dioxide into Blast Furnace. CN Patent No. 201010199232.6, 12 June 2010. [Google Scholar]

- Guo, X.Q.; Yuan, L.; Zhang, J.; Wu, S.Q.; Ma, X.Y. The Method of Using Carbon Dioxide as Transport Medium for Pulverized Coal Injection in Blast Furnace. CN Patent No. 201010268748.1, 30 August 2010. [Google Scholar]

- Tang, F.P.; Zhao, G.; Li, D.G.; Cao, D.; Zhao, C.L.; Xue, J. A Method of AOD Injecting CO2 for Producing Stainless Steel. CN Patent No. 201010108211.9, 5 February 2010. [Google Scholar]

- Bi, X.R.; Zhu, R.; Liu, R.Z.; Lv, M.; Yi, C. Fundamental research on CO2 and O2 mixed injection stainless steelmaking process. Steelmaking 2012, 28, 67–70. [Google Scholar]

- Okazaki, K.; Anda, T. NOx reduction mechanism in coal combustion with recycled CO2. Energy 1997, 22, 207–215. [Google Scholar] [CrossRef]

- Scheele, J.V.; Gartz, M.; Paul, R.; Lantz, M.T.; Riegert, J.P.; Söderlund, S. Flamless oxyfuel combustion for increased production and reduced CO2 and NOx emissions. Stahl Eisen 2008, 128, 35–41. [Google Scholar]

| Elements | Chemical Reactions | ΔGθ (J/mol) | ΔGθ (kJ/mol) 1773 K | ΔH (kJ/mol) 298 K |

|---|---|---|---|---|

| C | 1/2O2 + [C] = CO(g) | −140,580 − 42.09 T | −215.21 | −139.70 |

| O2 + [C] = CO2(g) | −419,050 + 42.34 T | −343.98 | −393.52 | |

| CO2(g) + [C] = 2CO(g) | 137,890 − 126.52 T | −86.43 | 172.52 | |

| Fe | 1/2O2(g) + Fe(l) = (FeO) | −229,490 + 43.81 T | −151.81 | −272.04 |

| CO2(g) + Fe(l) = (FeO) + CO(g) | 48,980 − 40.62 T | −23.04 | 40.37 | |

| Si | O2 + [Si] = (SiO2) | −804,880 + 210.04 T | −432.48 | −910.36 |

| 2CO2(g) + [Si] = (SiO2) + 2CO(g) | −247,940 + 41.18 T | −174.93 | −344.36 | |

| Mn | 1/2O2 + [Mn] = (MnO) | −412,230 + 126.94 T | −187.17 | −384.93 |

| CO2(g) + [Mn] = (MnO) + CO(g) | −133,760 + 42.51 T | −58.39 | −101.91 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, K.; Wang, X. CO2 Utilization in the Ironmaking and Steelmaking Process. Metals 2019, 9, 273. https://doi.org/10.3390/met9030273

Dong K, Wang X. CO2 Utilization in the Ironmaking and Steelmaking Process. Metals. 2019; 9(3):273. https://doi.org/10.3390/met9030273

Chicago/Turabian StyleDong, Kai, and Xueliang Wang. 2019. "CO2 Utilization in the Ironmaking and Steelmaking Process" Metals 9, no. 3: 273. https://doi.org/10.3390/met9030273

APA StyleDong, K., & Wang, X. (2019). CO2 Utilization in the Ironmaking and Steelmaking Process. Metals, 9(3), 273. https://doi.org/10.3390/met9030273