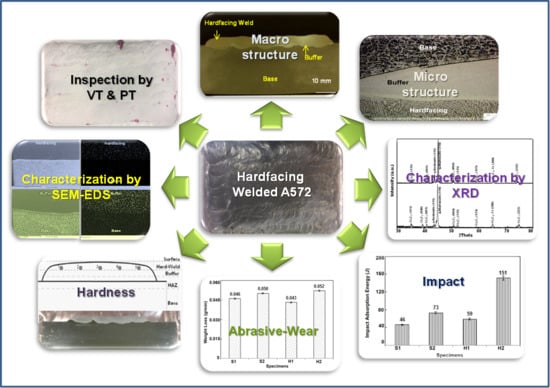

Hardfacing Welded ASTM A572-Based, High-Strength, Low-Alloy Steel: Welding, Characterization, and Surface Properties Related to the Wear Resistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments

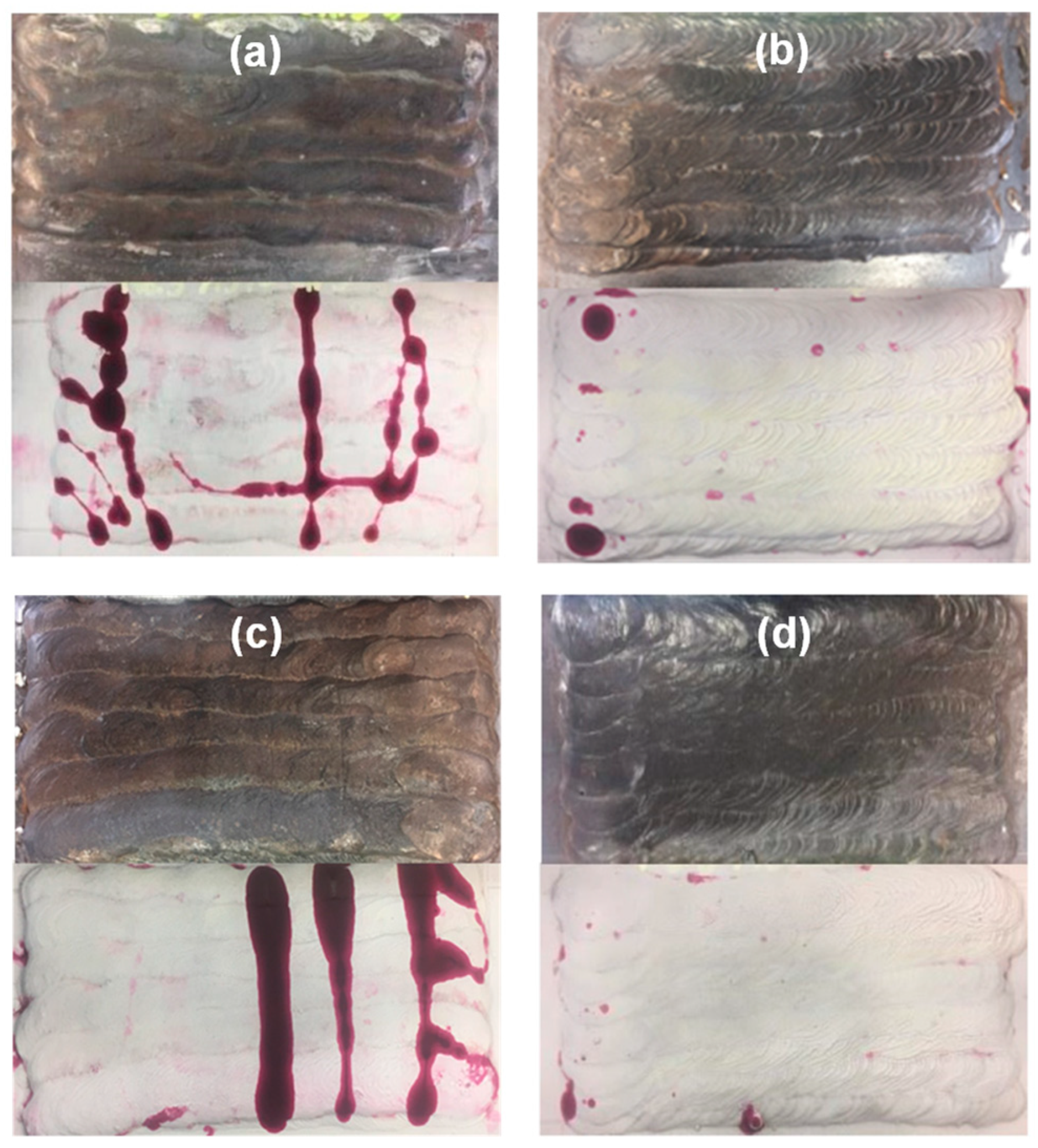

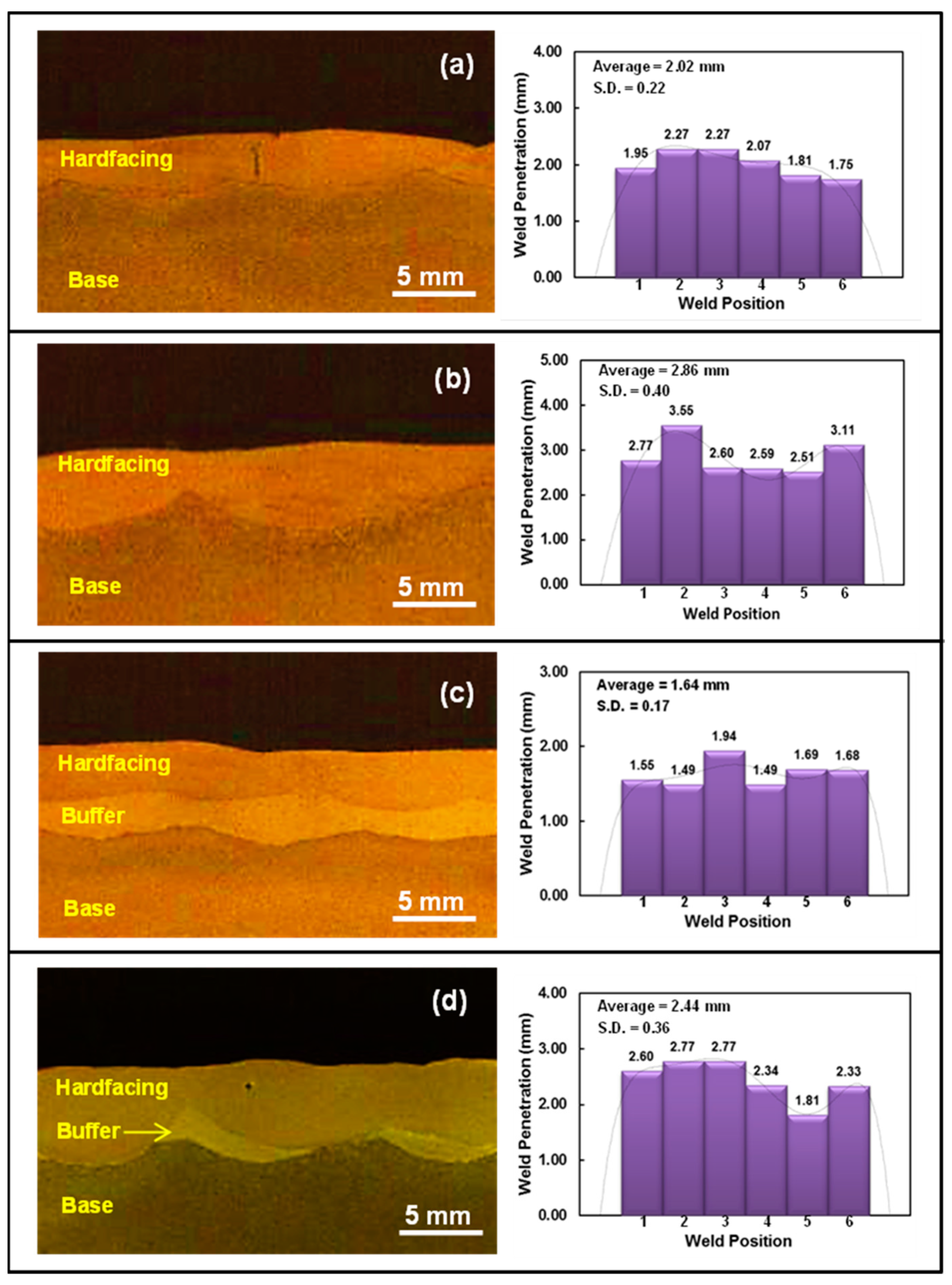

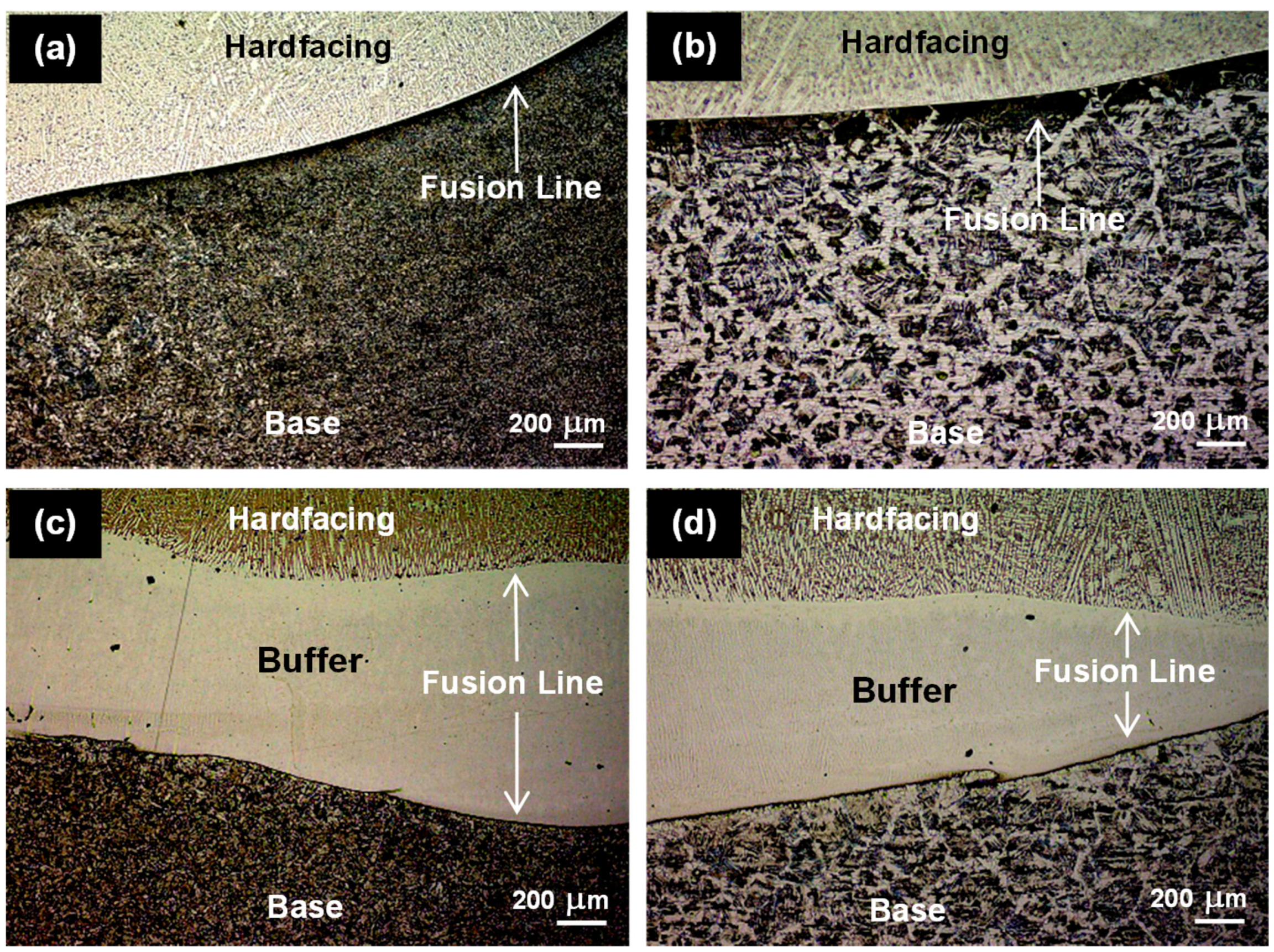

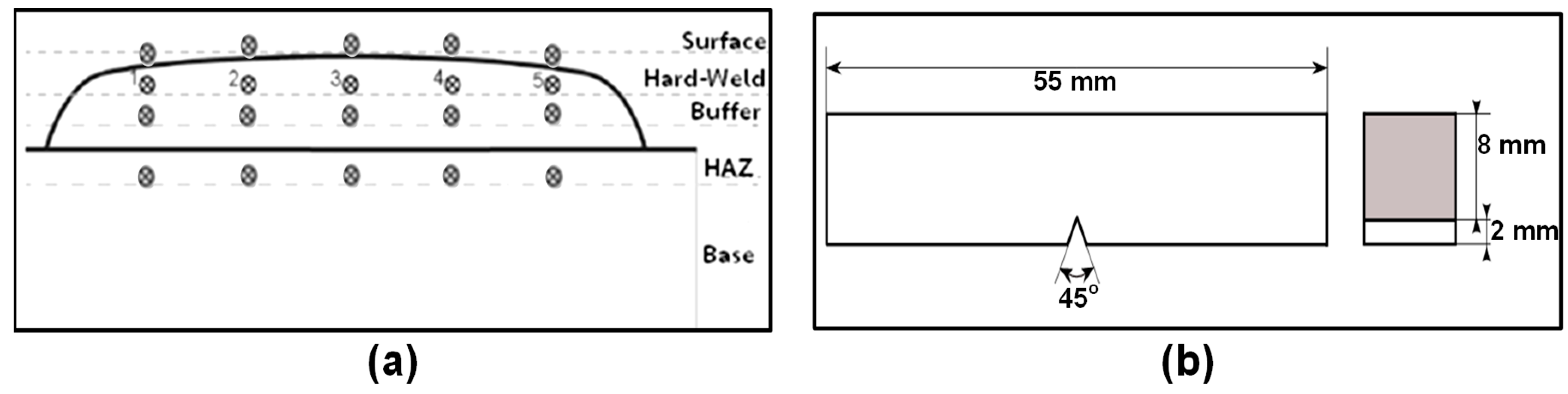

2.3. Hardfacing Welding, Inspection, and Macro–Micro Structure

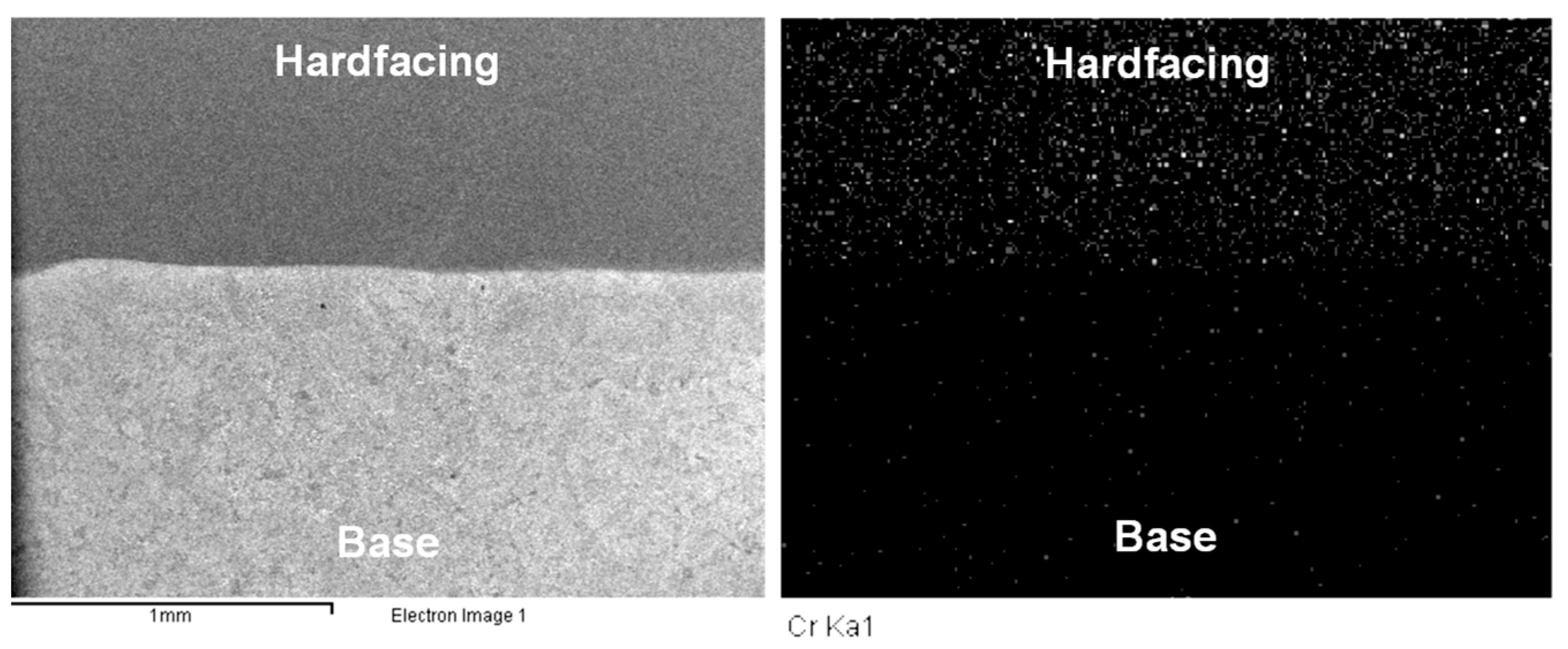

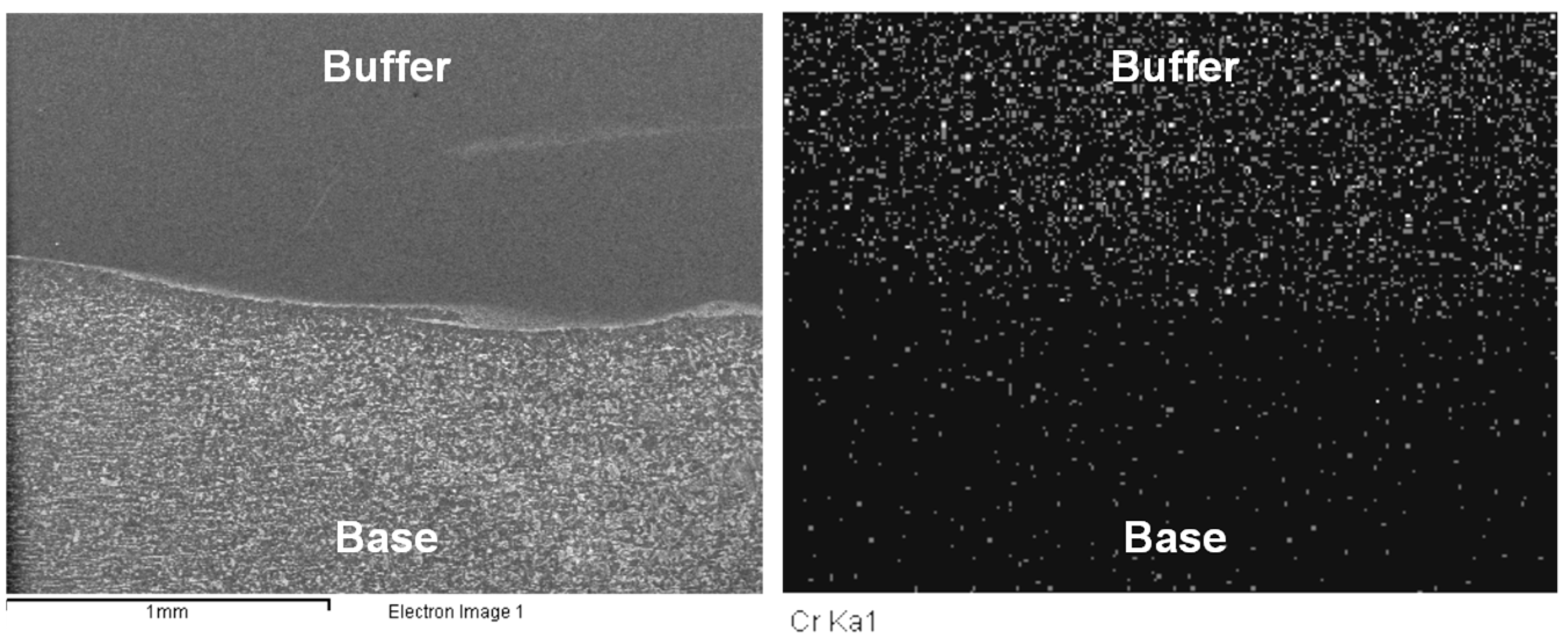

2.4. Structural Characterizations by Scanning Electron Microscope with Energy-Dispersive X-ray Spectrometer and XRD

2.5. Hardness, Impact, and Abrasive Wear Properties

3. Results and Discussion

3.1. Hardfacing Welding, Inspection, and Macro–Micro Structure

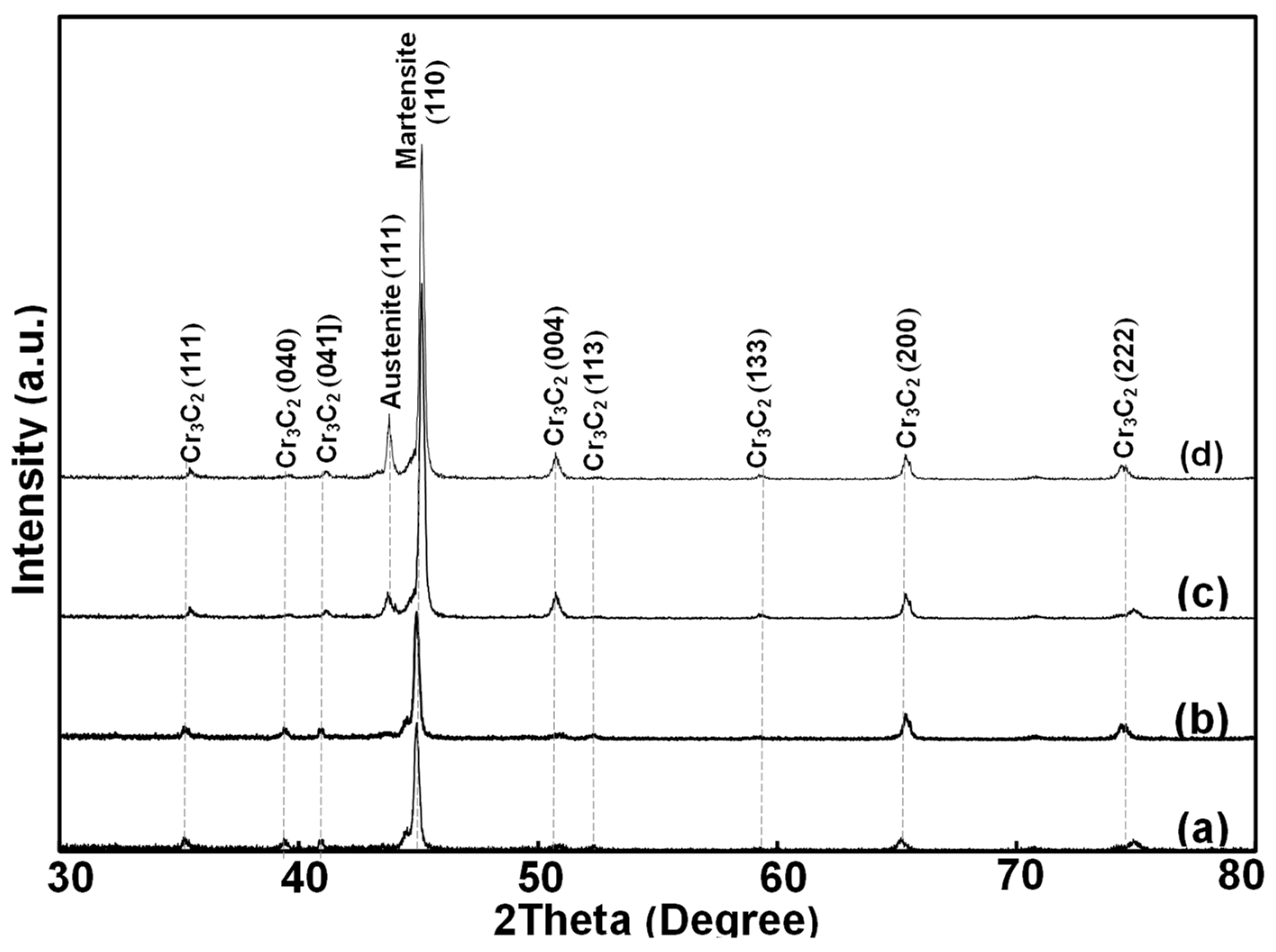

3.2. Structural Characterization by Scanning Electron Microscope with Energy-Dispersive X-ray Spectrometer and XRD

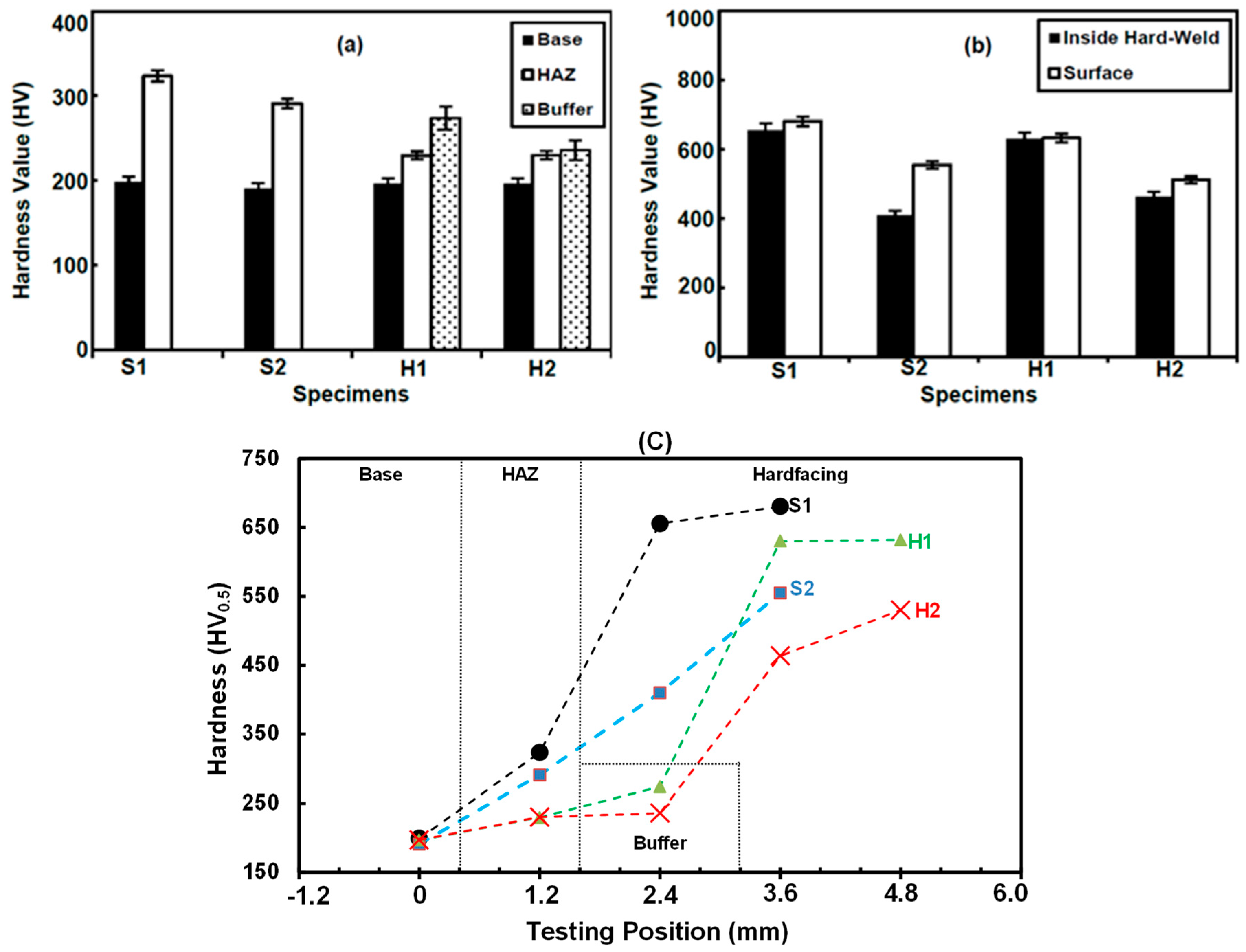

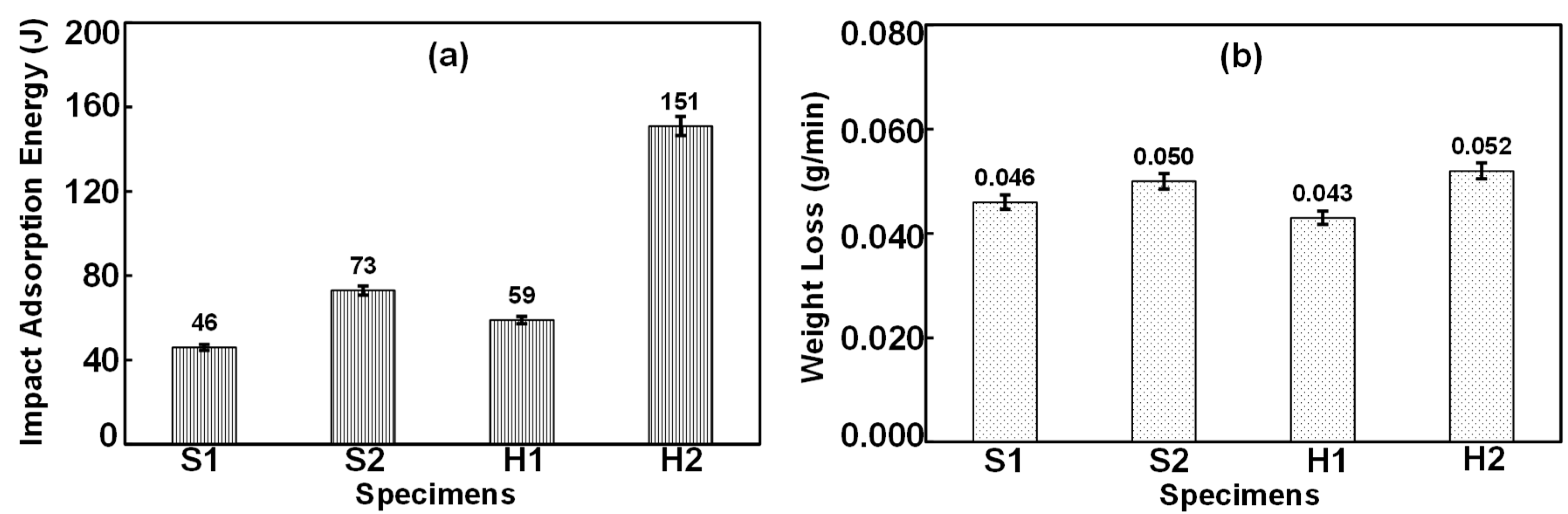

3.3. Hardness, Impact, and Abrasive Wear Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ASTM A572/A572M-15: American Society for Testing and Materials (ASTM). Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Desai, S. Plastic Design in A572 (Grade 65) Steel: Mechanical Properties of ASTM A572 Grade 65 Steel. Master’s Thesis, Lehigh University, Bethlehem, PA, USA, 1969. [Google Scholar]

- Zhou, J.; Yang, J.; Ye, Y.; Dai, G.; Peng, X. Effect of Heat Input on Microstructure and Properties in Heat Affected Zone of ASTM A572 GR.65 Steel. Adv. Mater. Res. 2011, 148, 553–557. [Google Scholar] [CrossRef]

- Doty, W.D. Weldability of constructional steels-USA Viewpoint. Suppl. Weld. J. 1971, 157, 49–57. [Google Scholar]

- Shen, Y.F.; Zuo, L. High-strength low-alloy steel strengthened by multiply nanoscale microstructure, HSLA steels 2015. In Micro Alloying 2015 & Offshore Engineering Steels 2015 Conference Proceedings; Springer: Cham, Switzerland, 2015; pp. 187–193. [Google Scholar]

- Kenchireddy, K.M.; Jayadeva, C.T.; Sreenivasan, A. Influence of material characteristics on the abrasive wear response of some hardfacing alloys. Glob. J. Eng. Sci. Res. 2014, 1, 12–21. [Google Scholar]

- Gómez, A.L.; Cañón, C.F.; Ramírez, D.E. Hard faced welded tips in shredder hammers: Technical and economical performance. Int. Sug. J. 2008, 110, 335–340. [Google Scholar]

- Kjellberg, O. Repair and Maintenance Welding Handbook, 2nd ed.; ESAB: Gothenburg, Sweden, 2006; p. 130. [Google Scholar]

- O’Brien, A. Welding Processes Part 1, Welding Handbook, 9th ed.; American Welding Society (AWS): Miami, FL, USA, 2004; Volume 2, p. 680. [Google Scholar]

- Kumsri, N.; Tippayasam, C.; Srisuwan, N.; Yingsamphancharoen, T.; Kaewvilai, A. Improvement of wear resistant properties of ASTM A572 steel by hardfacing welding process. In Proceedings of the MRS-Thailand International Conference’s E-Proceedings, Chiang Mai, Thailand, 31 October–3 November 2017; pp. 120–124. [Google Scholar]

- Lancaster, J.F. Metallurgy of Welding, 6th ed.; Elsevier: Amsterdam, The Netherlands, 1999; p. 464. [Google Scholar]

- Yurioka, N. Weldability of modern high strength steels. Adv. Weld. Metall. 1990, 1190, 79–100. [Google Scholar]

- Nasir, N.S.M.; Razab, M.K.A.A.; Mamat, S.; Iqbal, M. Review on Welding Residual Stress. ARPN J. Eng. Appl. Sci. 2016, 11, 6166–6175. [Google Scholar]

- Srivastava, B.K.; Tewari, S.P.; Prakash, J.A. Review on effect of preheating and/or post weld heat treatmemt (PWHT) on mechanical behaviour of ferrous metals. Int. J. Eng. Sci. Technol. 2010, 2, 625–631. [Google Scholar]

- Kobewelding. Available online: http://www.kobewelding.com/SelectingConsumables/hardfacing.pdf (accessed on 7 February 2019).

- Bohler-uddeholm. Available online: http://www.bohler-uddeholm.cz/media/UTP%20Maintenance_EN.pdf (accessed on 7 February 2019).

- DIN 8555-1, Filler Metals Used for Surfacing; Filler Wires, Filler Rods, Wire Electrodes, Covered Electrodes; Designation; Technical Delivery Conditions; German Institute for Standardisation: Berlin, Germany, 1983.

- Bohlerperu. Available online: http://www.bohlerperu.com/images/article/p37_UTP%20LEDURIT%2065.pdf (accessed on 7 February 2019).

- Franek, F.; Badisch, E.; Kirchgaßner, M. Advanced methods for characterization of abrasion/erosion resistance of wear protection materials. FME Trans. 2009, 37, 61–70. [Google Scholar]

- ASTM G65-16: American Society for Testing and Materials (ASTM). Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM E23-18: American Society for Testing and Materials (ASTM). Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Chakrabarty, I. Surface and Heat Treatment Processes. Compr. Mater. Finish. 2017, 2, 246–287. [Google Scholar]

- Calcagnotto, M.; Adachi, Y.; Ponge, D.; Raabe, D. Deformation and fracture mechanisms in fine-and ultrafine-grained ferrite/martensite dual-phase steels and the effect of aging. Acta Mater. 2011, 59, 658–670. [Google Scholar] [CrossRef]

- Equbal, M.I.; Alam1, P.; Ohdar, R.; Anand, K.A.; Alam, M.S. Effect of cooling rate on the microstructure and mechanical properties of medium carbon Steel. Int. J. Metall. Eng. 2016, 5, 21–24. [Google Scholar]

- Gerard, B. Fundamentals of Hardfacing by Fusion Welding, Welding Alloys Group. 2018, pp. 1–37. Available online: https://www.welding-alloys.com/uploads/pdf/brochures/en/wa-consumables/WA%20Hardfacing%20Fundamentals%20by%20arc%20welding.pdf (accessed on 7 February 2019).

| Materials | % Elemental Composition (Fe Balanced) | Hardness (HV) | ||||

|---|---|---|---|---|---|---|

| A572 grade 50 | ≤0.23 C | ≤1.35 Mn | ≤0.40 Si | ≤0.05 S | ≤0.04 P | 134–137 |

| Buffer Electrode | 0.10 C | 19.0 Cr | 8.50 Ni | 5.00 Mn | 0.80 Si | 194–258 |

| Hardfacing Electrode | 4.50 C | 23.5 Cr | 6.50 Mo | 5.50 Nb | 1.50 V | 594–834 |

| Specimen No. | Preheat Temperature (°C) | Deposited Weld Layers | Interpass Temperature (°C) | Welding Parameters | Cooling Rate (°C/min) | ||

|---|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Travel Speed (mm/min) | |||||

| S1 | - | Hardfacing | - | 168 | 26 | 20 | 20 |

| S2 | 150 | Hardfacing | 400 | 168 | 26 | 20 | 5 |

| H1 | - | Buffer | - | 106 | 24 | 30 | 20 |

| Hardfacing | - | 168 | 26 | 20 | |||

| H2 | 150 | Buffer | 150 | 106 | 24 | 30 | 5 |

| Hardfacing | 400 | 168 | 26 | 20 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srisuwan, N.; Kumsri, N.; Yingsamphancharoen, T.; Kaewvilai, A. Hardfacing Welded ASTM A572-Based, High-Strength, Low-Alloy Steel: Welding, Characterization, and Surface Properties Related to the Wear Resistance. Metals 2019, 9, 244. https://doi.org/10.3390/met9020244

Srisuwan N, Kumsri N, Yingsamphancharoen T, Kaewvilai A. Hardfacing Welded ASTM A572-Based, High-Strength, Low-Alloy Steel: Welding, Characterization, and Surface Properties Related to the Wear Resistance. Metals. 2019; 9(2):244. https://doi.org/10.3390/met9020244

Chicago/Turabian StyleSrisuwan, Nakarin, Nuengruetai Kumsri, Trinet Yingsamphancharoen, and Attaphon Kaewvilai. 2019. "Hardfacing Welded ASTM A572-Based, High-Strength, Low-Alloy Steel: Welding, Characterization, and Surface Properties Related to the Wear Resistance" Metals 9, no. 2: 244. https://doi.org/10.3390/met9020244

APA StyleSrisuwan, N., Kumsri, N., Yingsamphancharoen, T., & Kaewvilai, A. (2019). Hardfacing Welded ASTM A572-Based, High-Strength, Low-Alloy Steel: Welding, Characterization, and Surface Properties Related to the Wear Resistance. Metals, 9(2), 244. https://doi.org/10.3390/met9020244