Numerical Simulation Analysis of Dual-Beam Laser Welding of Tailored Blanks with Different Thicknesses

Abstract

:1. Introduction

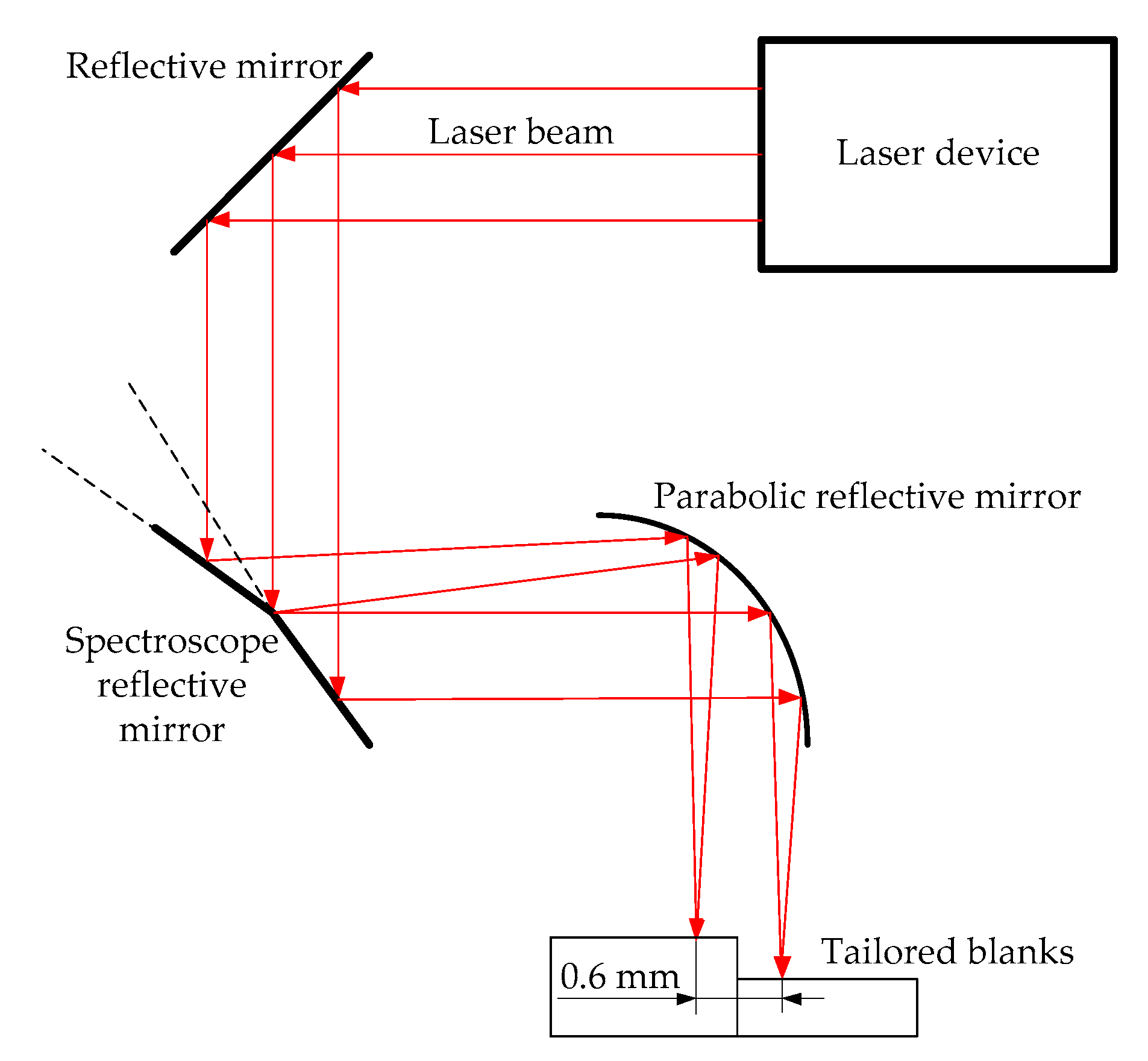

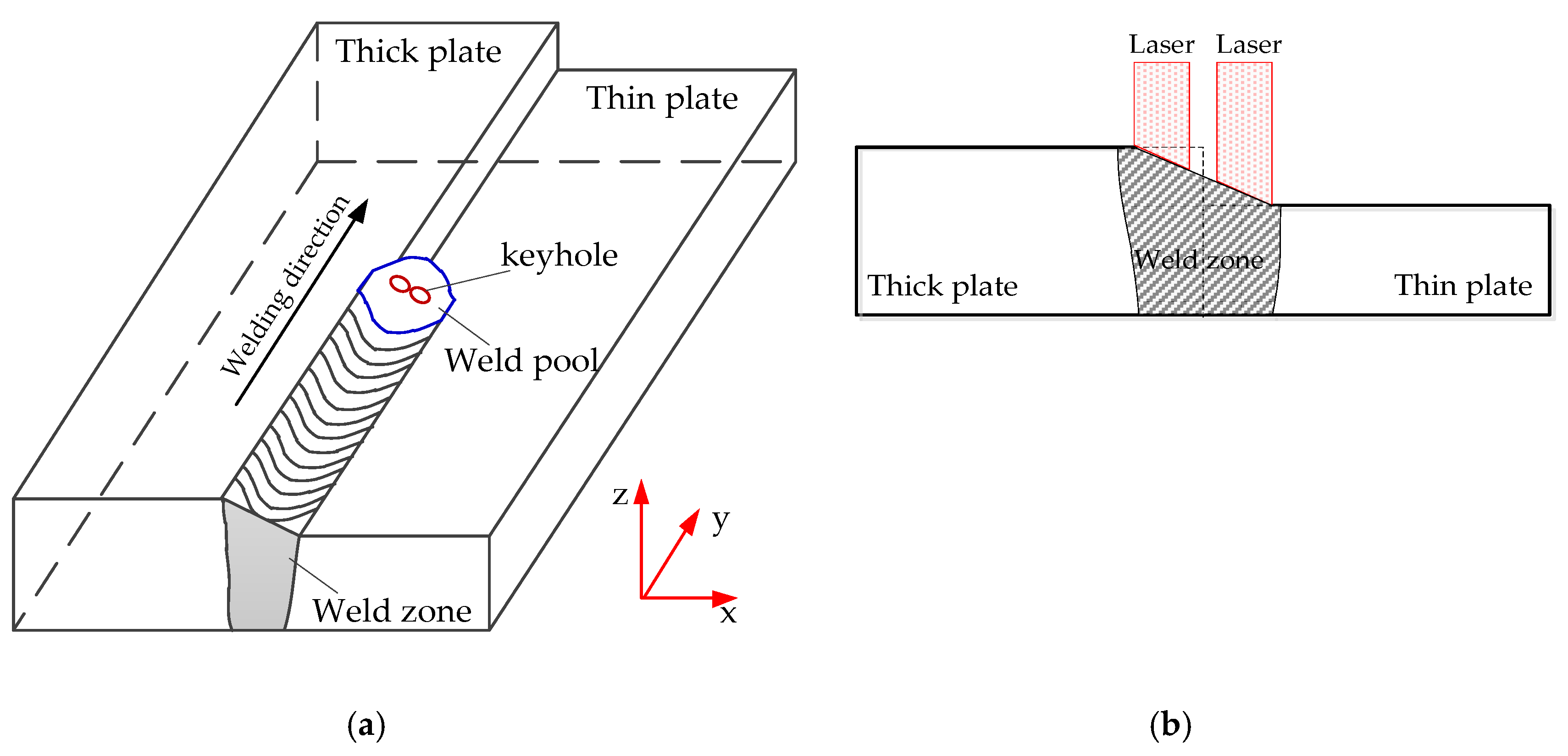

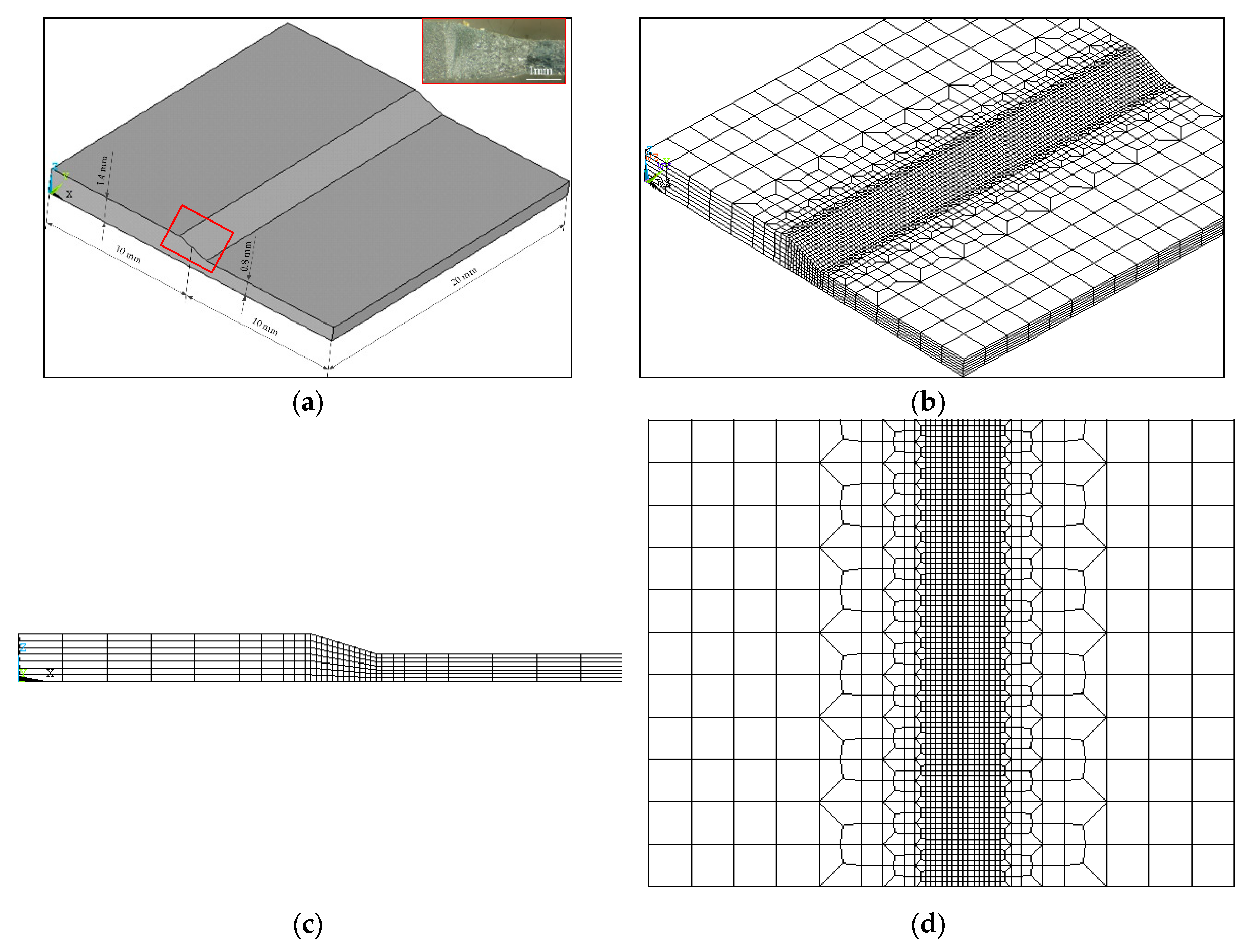

2. Experimental Procedure

3. Mathematical Modeling

3.1. Model Description

- (1)

- The welding process is quasi-steady state.

- (2)

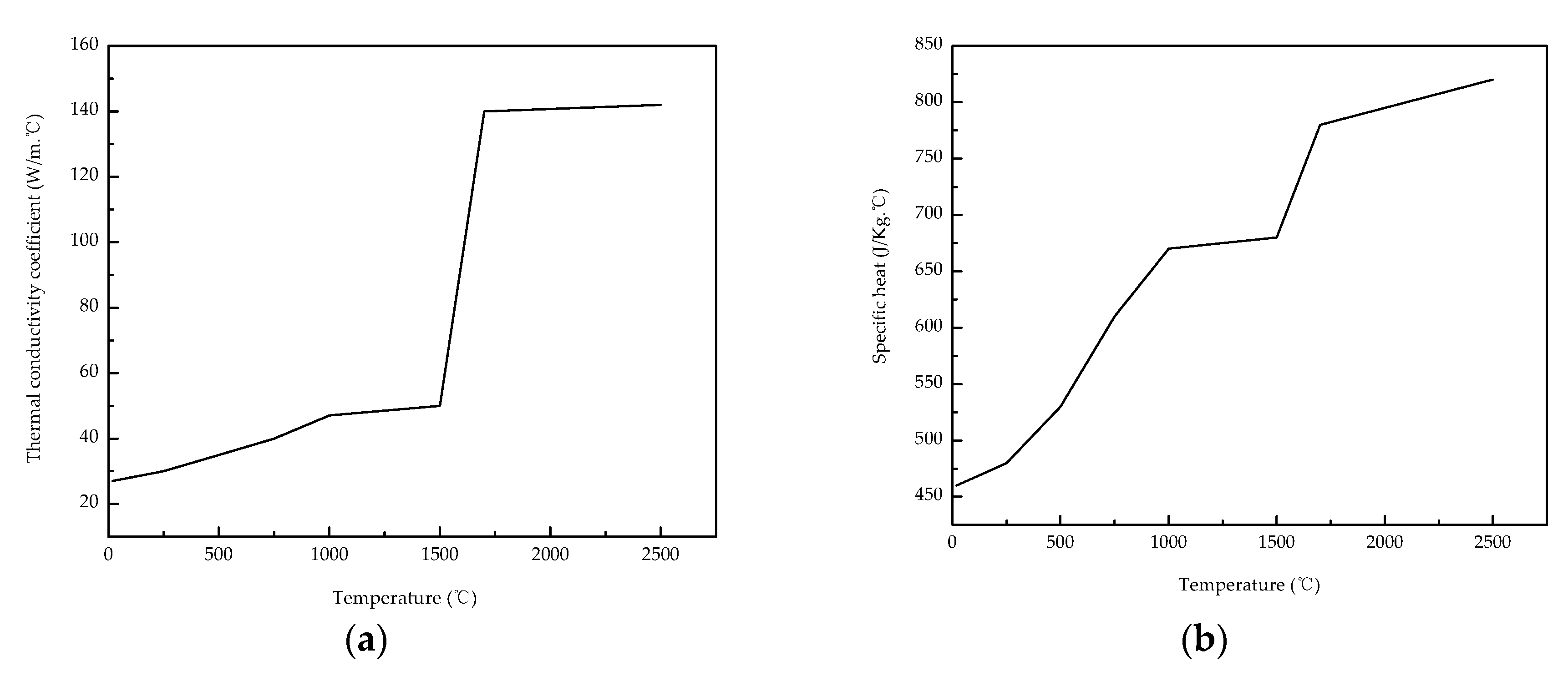

- The material is isotropic and continuous medium, and some physical properties of material (thermal conductivity and specific heat) vary with temperature. The density of material is constant.

- (3)

- The weld shape was prefabricated based on the preliminary experimental results.

- (4)

- Above melting temperature, the effect of convection on heat transfer in weld pool (caused by molten pool flow) is compensated according to the increase in thermal conductivity of the material.

- (5)

- The surface absorption of melt material is constant.

- (6)

- The heat transfer by radiation and convection between the workpiece and ambient environment are considered.

- (7)

- The latent heat of solid-liquid phase transformation is considered, but the latent heats of solid phase transformation and evaporation (much smaller than that of the solid–liquid phase transformation) are all ignored.

- (8)

- The energy density of the laser beam is Gaussian distribution.

- (9)

- The ambient temperature is 20 °C.

3.2. Heat Source Model

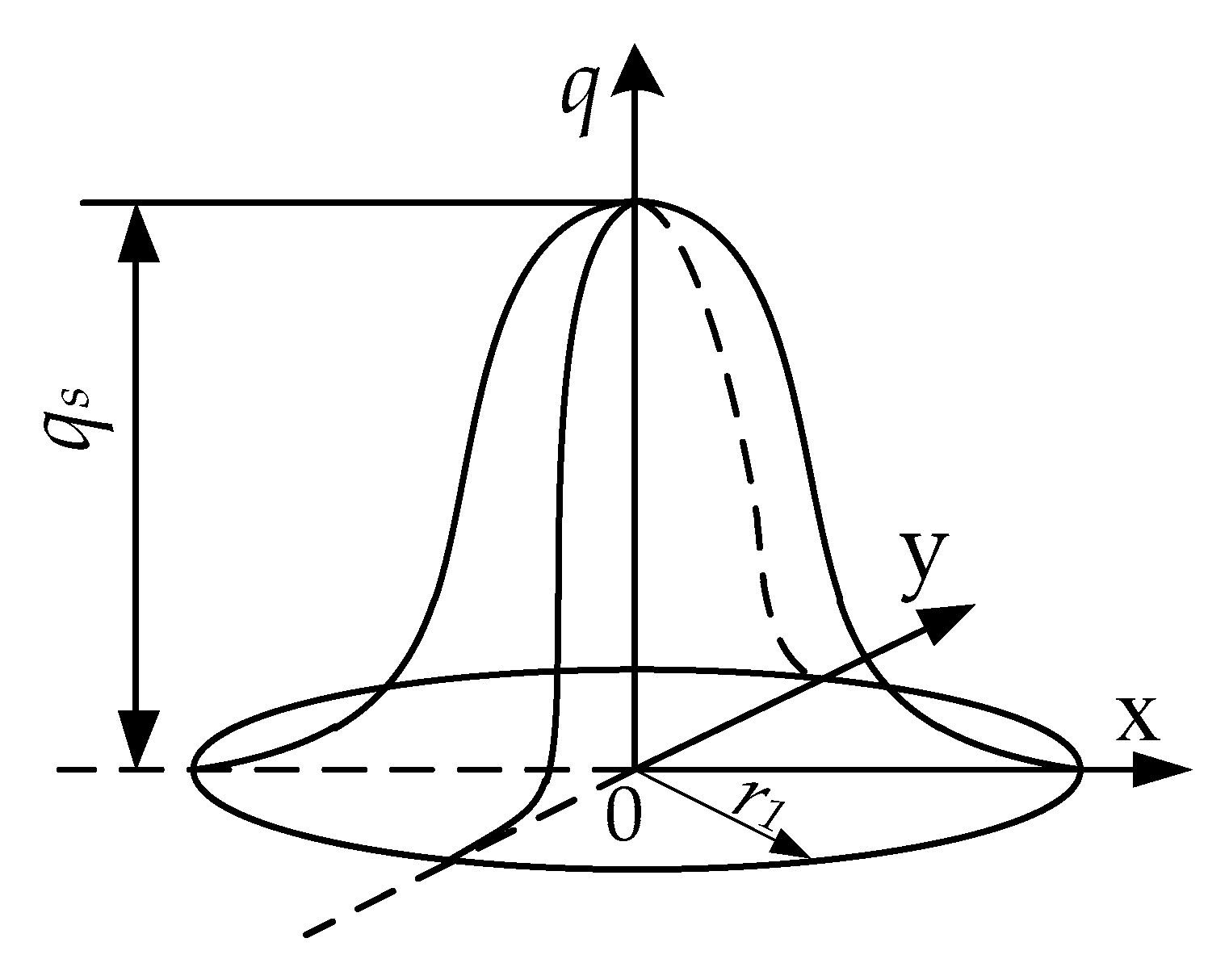

3.2.1. Surface Heat Source Model

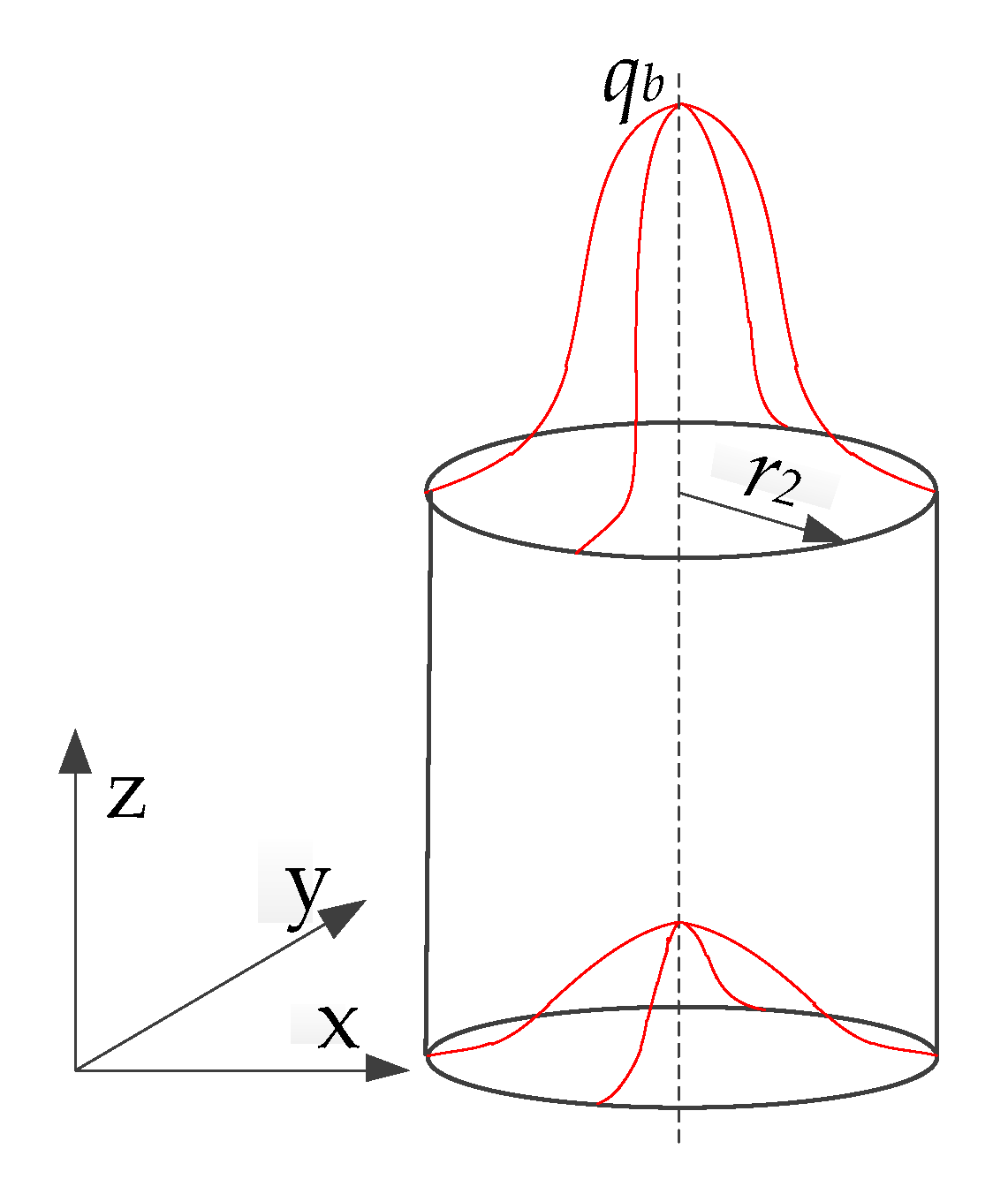

3.2.2. Body Heat Source Model

3.3. Governing Equation

3.4. Boundary Conditions

3.5. Numerical Method

3.6. Physical Properties of Material

4. Results and Discussion

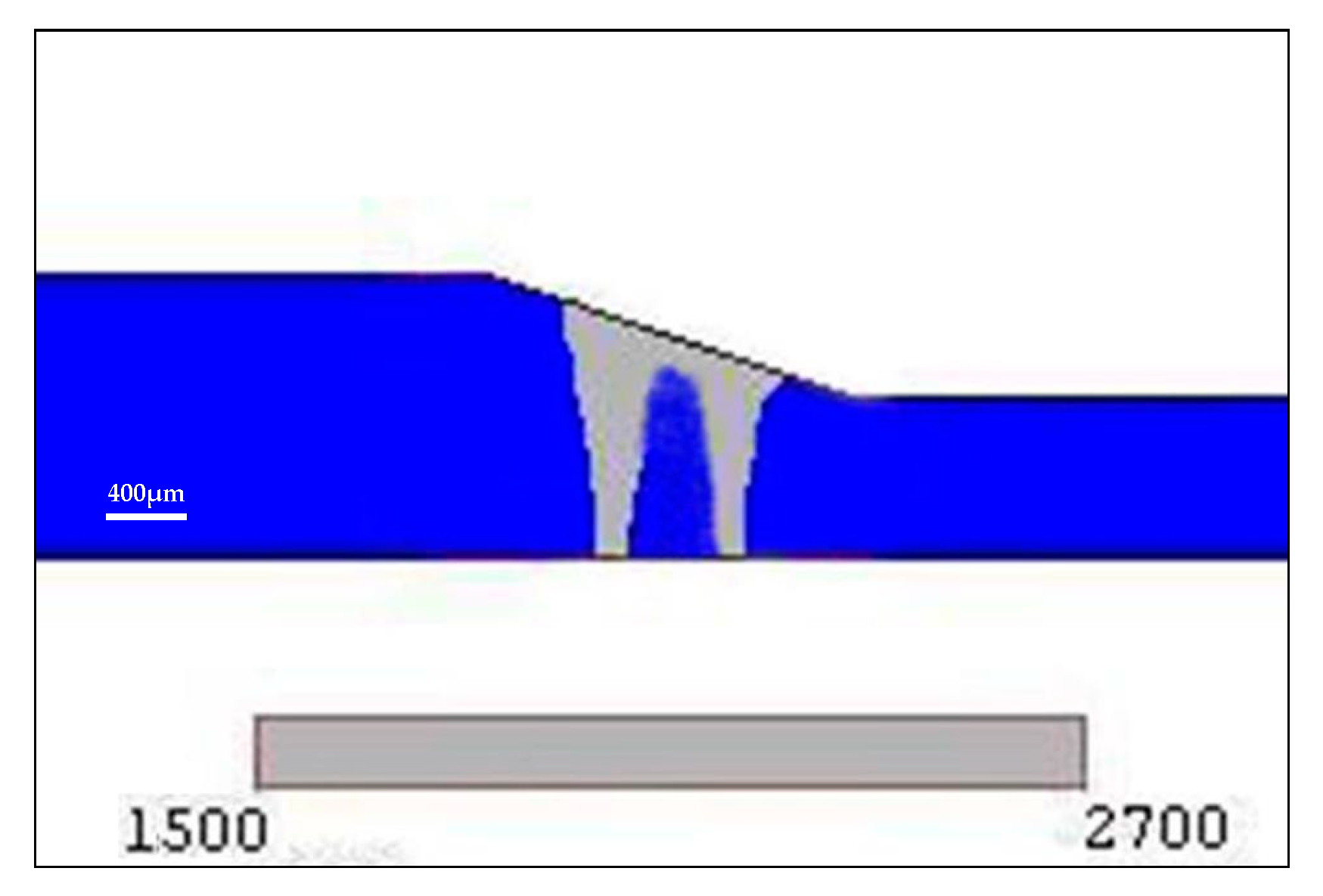

4.1. Model Validation

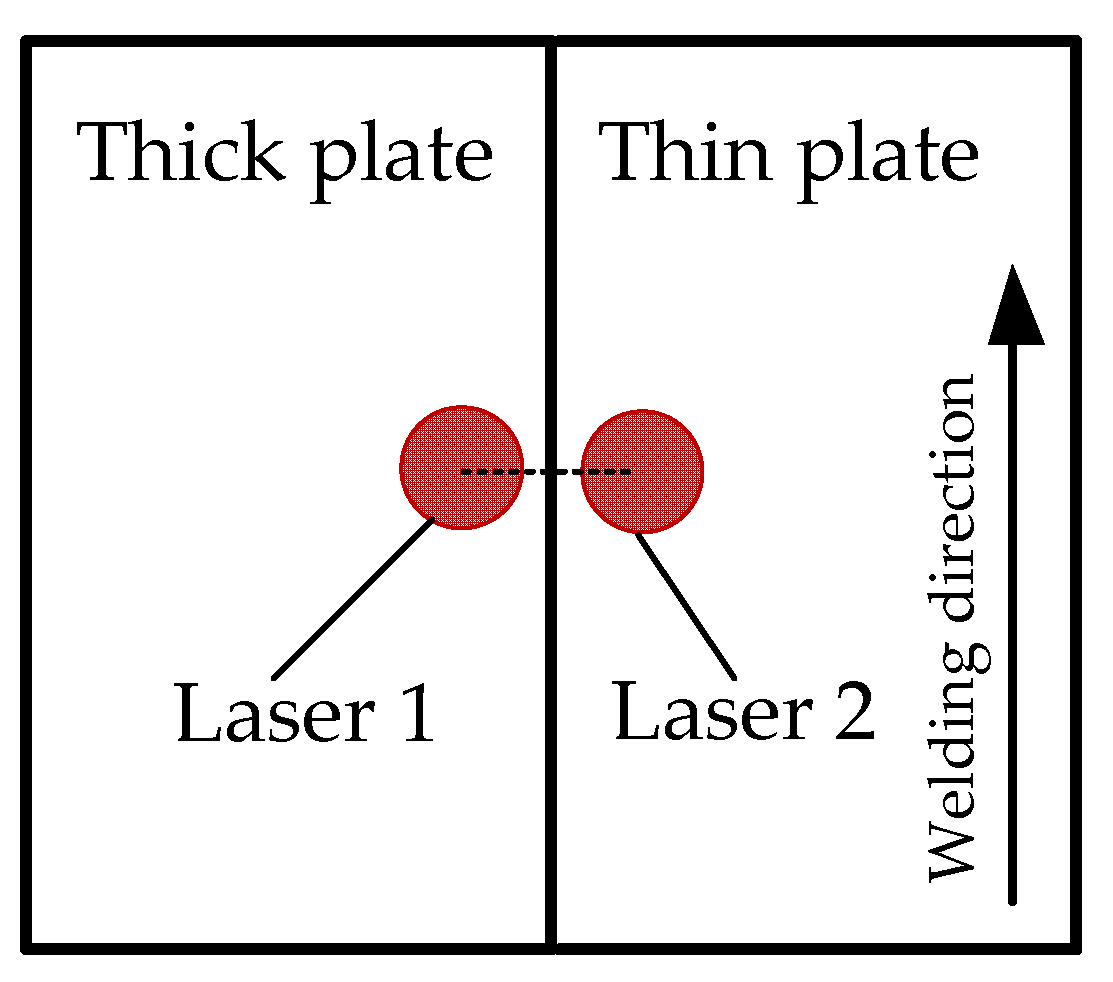

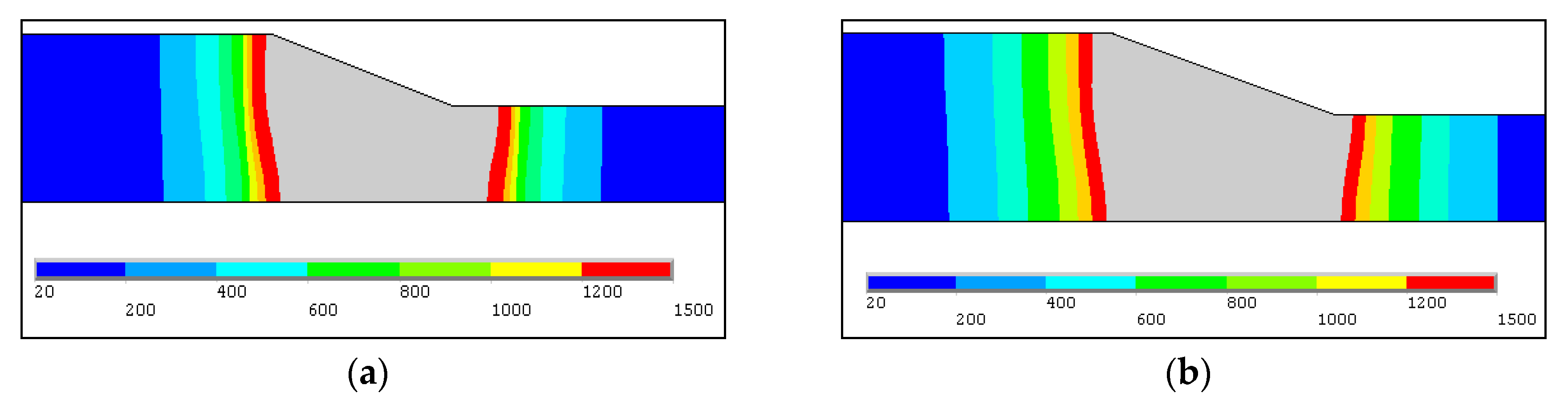

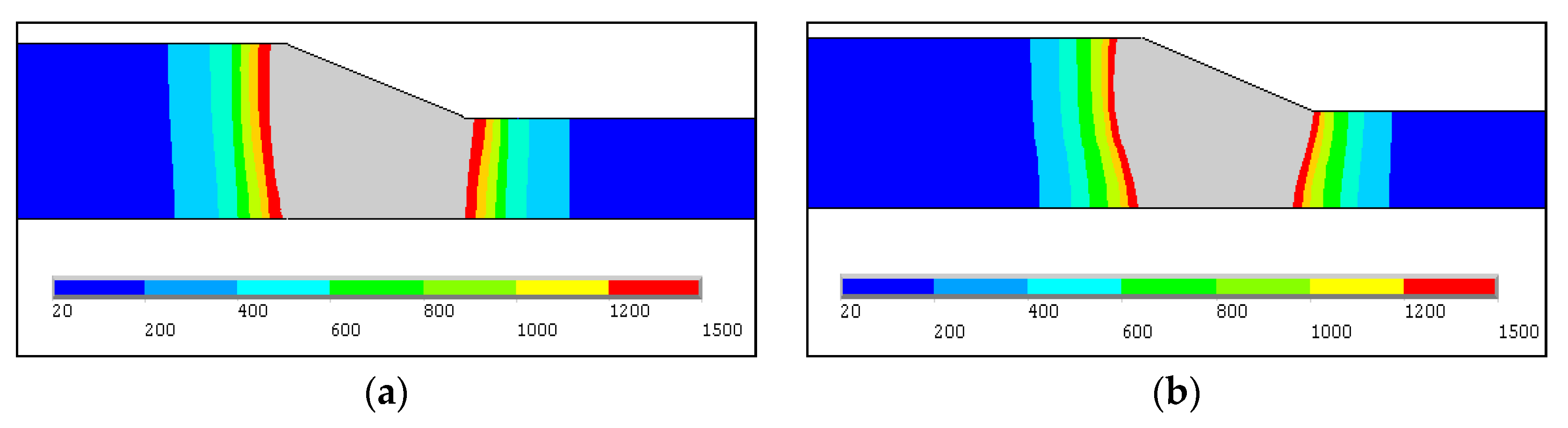

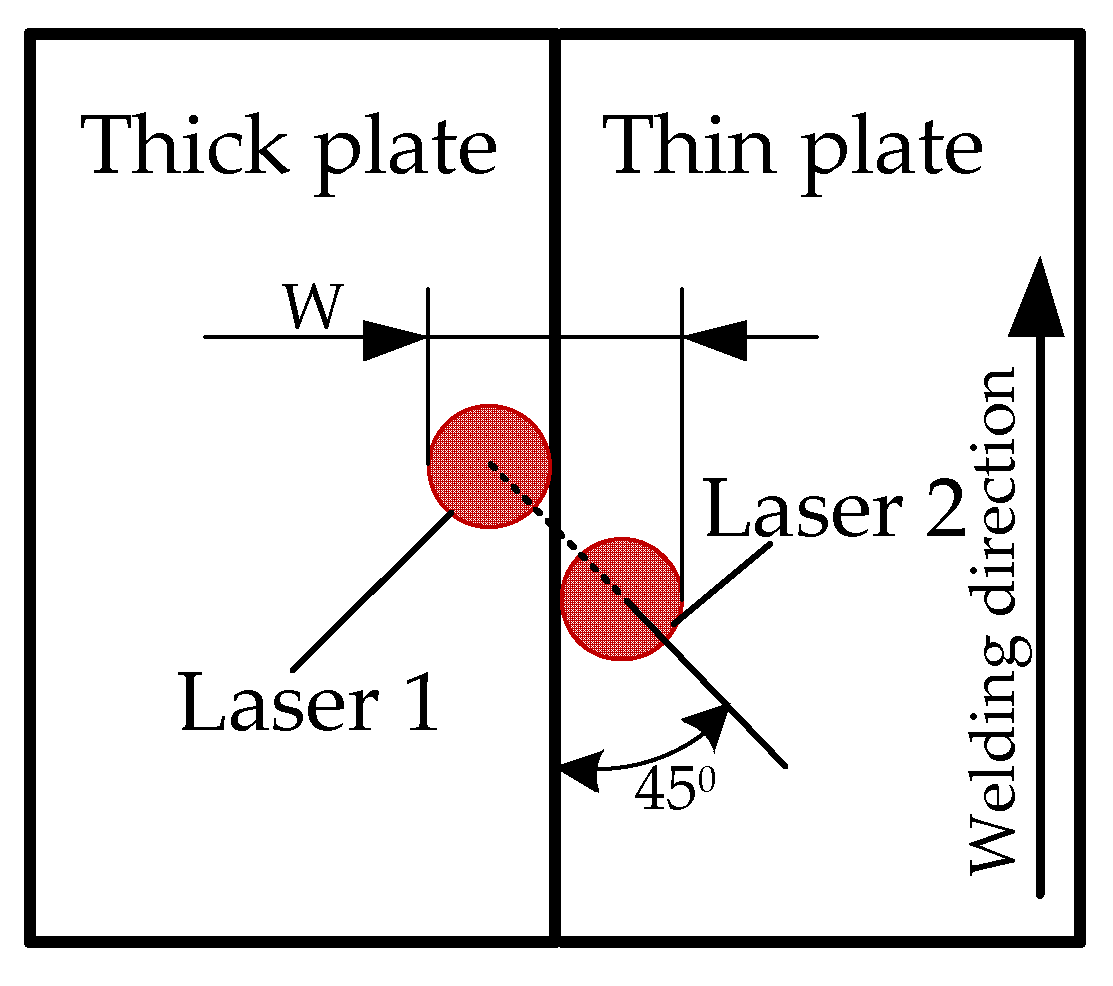

4.2. Optimization of Dual-Beam Laser Arrangement Based on Weld Profile Simulation

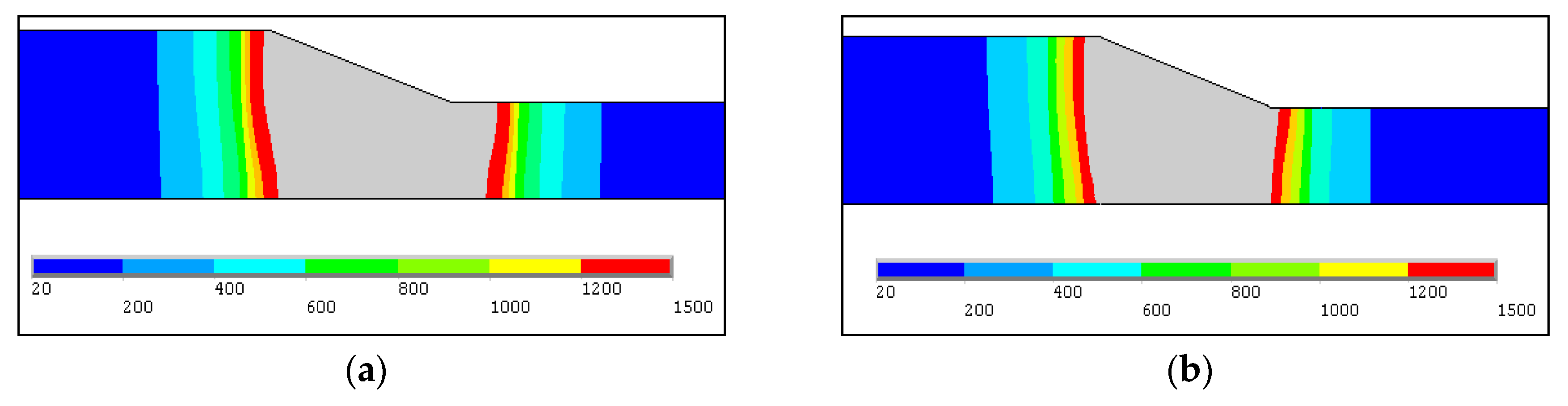

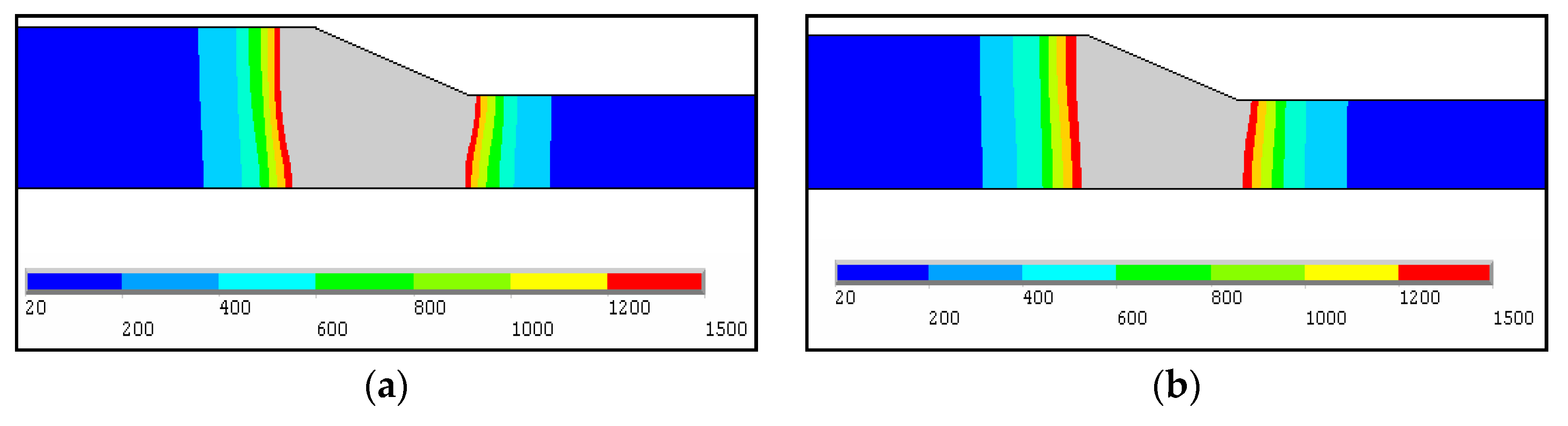

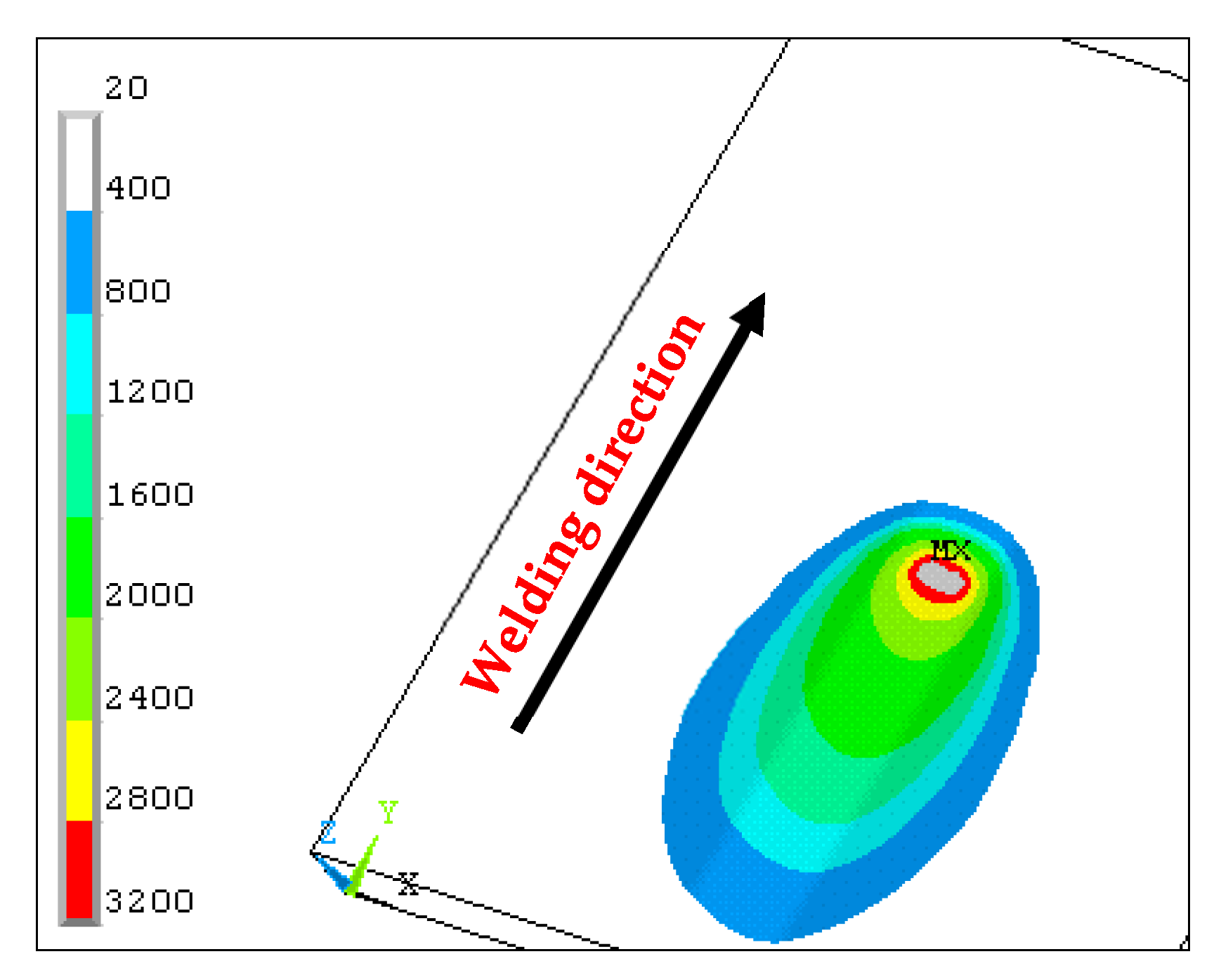

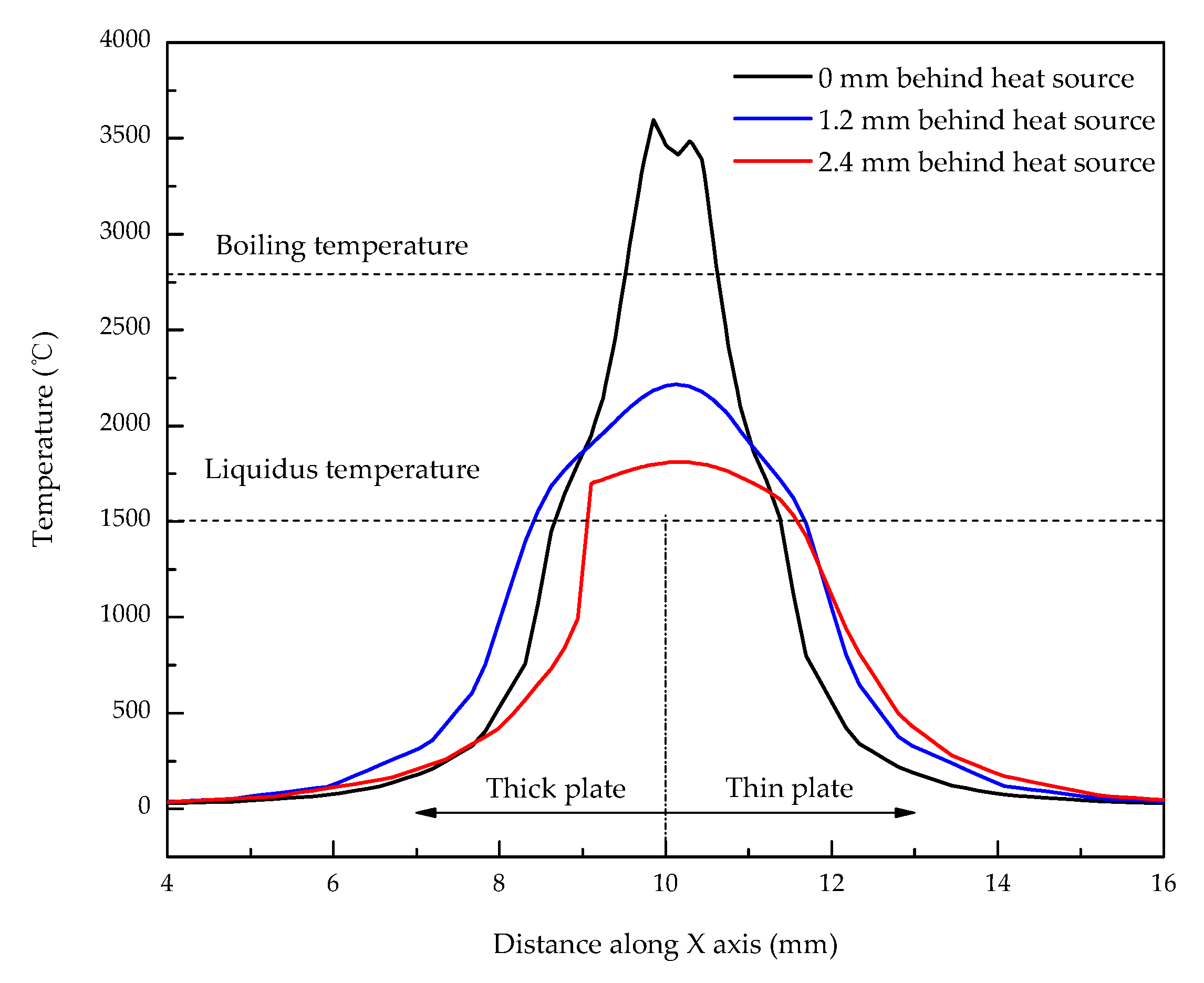

4.3. Temperature Field Characteristic

5. Conclusions

- (1)

- A hybrid heat source model consisted of one surface heat source and double body heat sources was established, namely, the plasma above the workpiece was considered by a surface heat source and heat transfer of double keyholes in the weld pool was simulated by two cylindrical heat sources. Based on the consideration of the temperature dependence of material physical properties, convection and radiation heat transfer, and latent heat of the material, the finite element model for numerical simulation of temperature field was developed by assuming and simplifying the model. When comparing the weld cross-section, the calculated result displayed a good agreement with the experimental result.

- (2)

- While the weld width on the top surface and gap tolerance were taken into account as evaluating criterion, the arrangement mode of dual-beam laser that one laser beam irradiated on the thick plate and the other laser beam on the thin plate, and the line connecting the dual-beam laser focused spot centers inclines to the welding direction at an angle of 45°, with 2:1 power ratio was the preferable process for dual-beam laser welding of tailored blanks with different thicknesses.

- (3)

- The opening of keyhole was expanded, which helps the plasma ejection from the keyhole, and although the cooling rate was very fast, it was obviously lower than that of single beam laser welding, which was favorable to reduce welding defects and improve weld quality. The peak temperature points were not located on the center of the weld pool, but on dual-beam laser irradiated positions. The weld width can be mainly controlled by the laser acting on the thin plate based on the temperature field distribution during dual-beam laser welding of tailored blanks.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Song, Y.; Yu, C.; Yu, H.; Zhao, C. Mechanical properties improvement of laser tailor welded blanks of DP600 steel by magnetic treatment. Metals 2017, 7, 85. [Google Scholar] [CrossRef]

- Yun, J.-G.; Lee, J.-H.; Kwak, S.-Y.; Kang, C.-Y. Study on the formation of reaction phase to Si addition in boron steel Hot-Dipped in Al–7Ni Alloy. Coatings 2017, 7, 186. [Google Scholar] [CrossRef]

- Chan, S.M.; Chan, L.C.; Lee, T.C. Tailor-welded blanks of different thickness ratios effects on forming limit diagrams. J. Mater. Process. Technol. 2003, 132, 95–101. [Google Scholar] [CrossRef]

- Min, K.B.; Kim, K.S.; Kang, S.S. A study on resistance welding in steel sheets using a tailor-welded blank (1st report) evaluation of upset weldability and formability. J. Mater. Process. Technol. 2000, 101, 186–192. [Google Scholar] [CrossRef]

- Davies, R.W.; Grant, G.J.; Eddie Oliver, H.; Khaleel, M.A.; Smith, M.T. Forming-limit diagrams of aluminum tailor-welded blank weld material. Metall. Mater. Trans. A 2001, 32, 275–283. [Google Scholar] [CrossRef]

- Shakeri, H.R.; Buste, A.; Worswick, M.J.; Clarke, J.A.; Feng, F.; Jain, M.; Finn, M. Study of damage initiation and fracture in aluminum tailor welded blanks made via different welding techniques. J. Light Met. 2002, 2, 95–110. [Google Scholar] [CrossRef]

- Zadpoor, A.A.; Sinke, J.; Benedictus, R. Mechanics of tailor welded blanks: an overview. Key Eng. Mater. 2007, 344, 373–382. [Google Scholar] [CrossRef]

- Staud, D.; Merklein, M.; Fratini, L.; Buffa, G. Investigations on the mechanical properties and formability of friction stir welded and laser welded aluminum tailored blanks. Key Eng. Mater. 2007, 344, 143–150. [Google Scholar]

- Anand, D.; Chen, D.L.; Bhole, S.D.; Andreychuck, P.; Boudreau, G. Fatigue behavior of tailor (laser)-welded blanks for automotive applications. Mater. Sci. Eng. A 2006, 420, 199–207. [Google Scholar] [CrossRef]

- Farabi, N.; Chen, D.L.; Li, J.; Zhou, Y.; Dong, S.J. Microstructure and mechanical properties of laser welded DP600 steel joints. Mater. Sci. Eng. A 2010, 527, 1215–1222. [Google Scholar] [CrossRef]

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A review on tailored blanks—production, applications and evaluation. J. Mater. Process. Technol. 2014, 214, 151–164. [Google Scholar] [CrossRef]

- Hsu, R.; Engler, A.; Heinemann, S. The gap bridging capability in laser tailored blank welding. In Proceedings of the 17th International Congress on Application of Lasers and Electro-Optics (ICALEO’98), Orlando, FL, USA, 16–19 November 1998; pp. 224–231. [Google Scholar]

- Swif-Hook, D.T.; Gick, A.E.F. Penetration welding with lasers—Analytical study indicates that present laser beam welding capabilities may be extended tenfold. Weld. J. 1973, 52, 492–499. [Google Scholar]

- Steen, W.M.; Dowden, J.; Davis, M.; Kapadia, P. A point and line source model of laser keyhole welding. J. Phys. D Appl. Phys. 1998, 21, 1255–1260. [Google Scholar] [CrossRef]

- Kazemi, K.; Goldak, J.A. Numerical simulation of laser penetration welding. Comp. Mater. Sci. 2009, 44, 841–849. [Google Scholar] [CrossRef]

- Shanmugam, N.S.; Buvanashekaran, G.; Sankaranarayanasamy, K.; Kumarc, S.R. A transient finite element simulation of the temperature and bead profiles of T-joint laser welds. Mater. Des. 2010, 31, 4528–4542. [Google Scholar] [CrossRef]

- Yu, S.R.; Xiong, J.H.; Fan, D.; Chen, J.H. Numerical simulation on temperature field in laser welding of thin aluminum alloy plate with different thickness. Trans. China Weld. Inst. 2007, 28, 17–20. [Google Scholar]

- Yu, S.R.; Fan, D.; Xiong, J.H. Numerical simulation on stress-strain field of laser welding aluminum alloy joints with different thickness. Trans. China Weld. Inst. 2008, 29, 25–28. [Google Scholar]

- Hu, J.; Tsai, H.L. Fluid flow and weld pool dynamics in dual-beam laser keyhole welding. In Proceedings of the 2003 ASME International Mechanical Engineering Congress & Exposition (IMECE’03), Washington, DC, USA, 16–21 November 2003. IMECE2003-41711. [Google Scholar]

- Hu, J.; Tsai, H.L.; Lee, Y.K. Modeling of weld pool dynamics during dual-beam laser welding process. In Proceedings of the 22th International Congress on Application of Lasers and Electro-Optics (ICALEO’03), Jacksonville, FL, USA, 13–16 October 2003; p. 1009. [Google Scholar]

- Zhou, J.; Tsai, H.L. Investigation of fluid flow and heat transfer in 3-D dual-beam laser keyhole welding. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2010; pp. 247–254. [Google Scholar]

- Hou, C.A. Finite element simulation of dual-beam laser welding using ANSYS. In Proceedings of the Conference of the International Association for the Study of Traditional Environments, Pittsburgh, PA, USA, 15–18 May 1994; pp. 430–433. [Google Scholar]

- Liu, Y.N.; Kannatey-Asibu, E. Finite Element Analysis of heat flow in dual-beam laser welded tailored blanks. J. Manuf. Sci. Eng. 1998, 120, 272–278. [Google Scholar] [CrossRef]

- Solana, P.; Ocaña, J.L. A mathematical model for penetration laser welding as a free-boundary problem. J. Phys. D Appl. Phys. 1997, 30, 1300–1313. [Google Scholar] [CrossRef]

- Feng, X.S. The Analysis of Temperature Field and Stress-Strain Field in Laser Welding of Titanium Alloy T-Joint. Master’s Thesis, Harbin Institute of Technology, Harbin, China, July 2003. [Google Scholar]

- Deng, D.; Murakawa, H. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comp. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

- Zain-ul-abdein, M.; Nélias, D.; Jullien, J.F.; Boitout, F.; Dischert, L.; Noe, X. Finite element analysis of metallurgical phase transformations in AA 6056-t4 and their effects upon the residual stress and distortion states of a laser welded t-joint. Int. J. Pres. Ves. Pip. 2011, 88, 45–56. [Google Scholar] [CrossRef]

- Lamprecht, K.; Geiger, M. Experimental and numerical investigation of the formability of laser welded patchwork blanks. Adv. Mater. Res. 2005, 6, 689–696. [Google Scholar] [CrossRef]

- Qiu, X.G.; Chen, W.L. The study of numerical simulation on the laser tailor welded blanks stamping. J. Mater. Process. Technol. 2007, 187, 128–131. [Google Scholar] [CrossRef]

- Forsman, T.; Sweden, S. Laser welding of tailored blanks. In Proceedings of the 21th International Congress on Application of Lasers and Electro-Optics (ICALEO’02), Scottsdale, AZ, USA, 14–17 October 2002; pp. 956–960. [Google Scholar]

- Cho, W.I.; Na, S.J.; Thomy, C.; Vollertsen, F. Numerical simulation of molten pool dynamics in high power disk laser welding. J. Mater. Process. Technol. 2012, 212, 262–275. [Google Scholar] [CrossRef]

- Deutsh, M.G.; Punkari, A.; Weckman, D.C.; Kerr, H.W. Weldability of 1.6 mm thick aluminium alloy 5182 sheet by single and dual beam Nd:YAG laser welding. Sci. Technol. Weld. Joi. 2003, 8, 246–256. [Google Scholar] [CrossRef]

| Component | C | Mn | Si | S | P | Fe |

|---|---|---|---|---|---|---|

| wt.% | 0.09 | 0.30 | 0.25 | 0.03 | 0.02 | Balance |

| Density kg/m3 | Solidus Temperature °C | Liquidus Temperature °C | Boiling Temperature °C | Melting Latent Heat J/kg |

|---|---|---|---|---|

| 7778 | 1460 | 1500 | 2700 | 2.5 × 105 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, L.; Chen, Y.; Zhu, X.; Ji, S. Numerical Simulation Analysis of Dual-Beam Laser Welding of Tailored Blanks with Different Thicknesses. Metals 2019, 9, 135. https://doi.org/10.3390/met9020135

Zhang X, Li L, Chen Y, Zhu X, Ji S. Numerical Simulation Analysis of Dual-Beam Laser Welding of Tailored Blanks with Different Thicknesses. Metals. 2019; 9(2):135. https://doi.org/10.3390/met9020135

Chicago/Turabian StyleZhang, Xinge, Liqun Li, Yanbin Chen, Xiaocui Zhu, and Shijun Ji. 2019. "Numerical Simulation Analysis of Dual-Beam Laser Welding of Tailored Blanks with Different Thicknesses" Metals 9, no. 2: 135. https://doi.org/10.3390/met9020135

APA StyleZhang, X., Li, L., Chen, Y., Zhu, X., & Ji, S. (2019). Numerical Simulation Analysis of Dual-Beam Laser Welding of Tailored Blanks with Different Thicknesses. Metals, 9(2), 135. https://doi.org/10.3390/met9020135