VHCF Response of Two AISI H13 Steels: Effect of Manufacturing Process and Size-Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and ESR Process

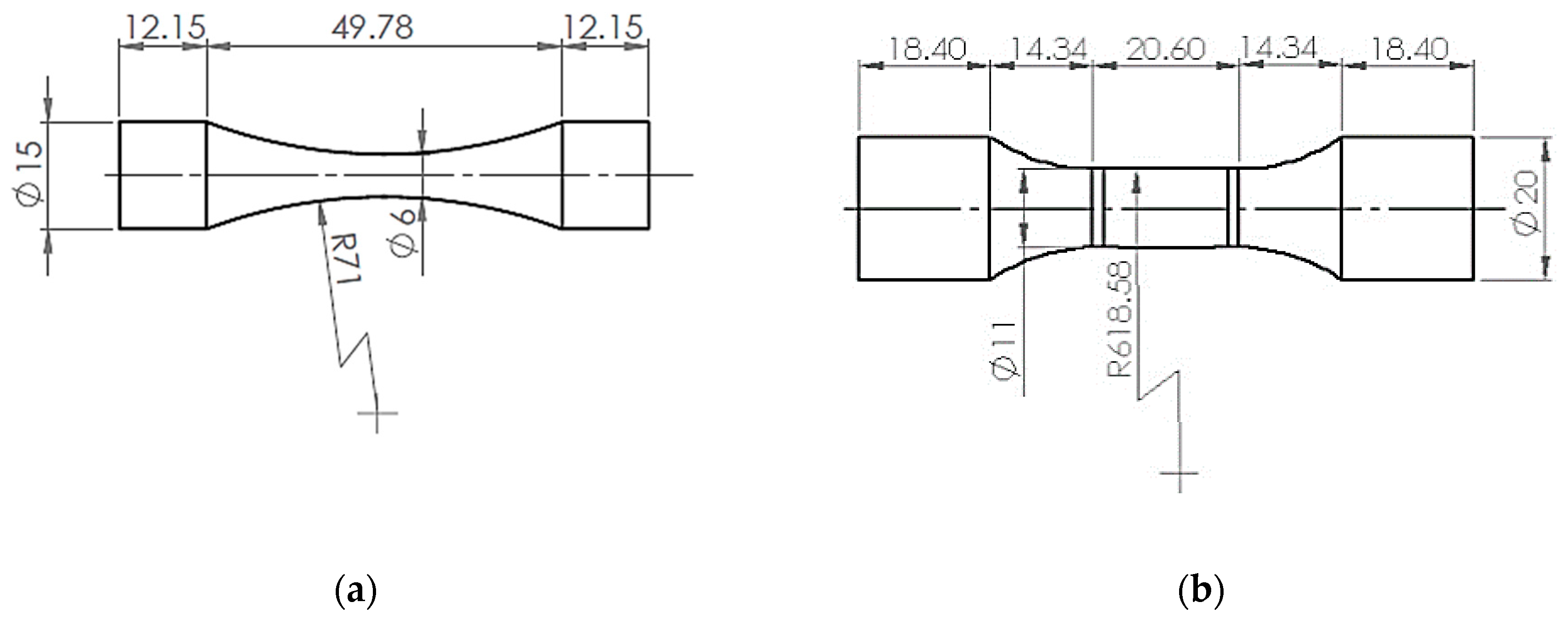

2.2. Specimen Design

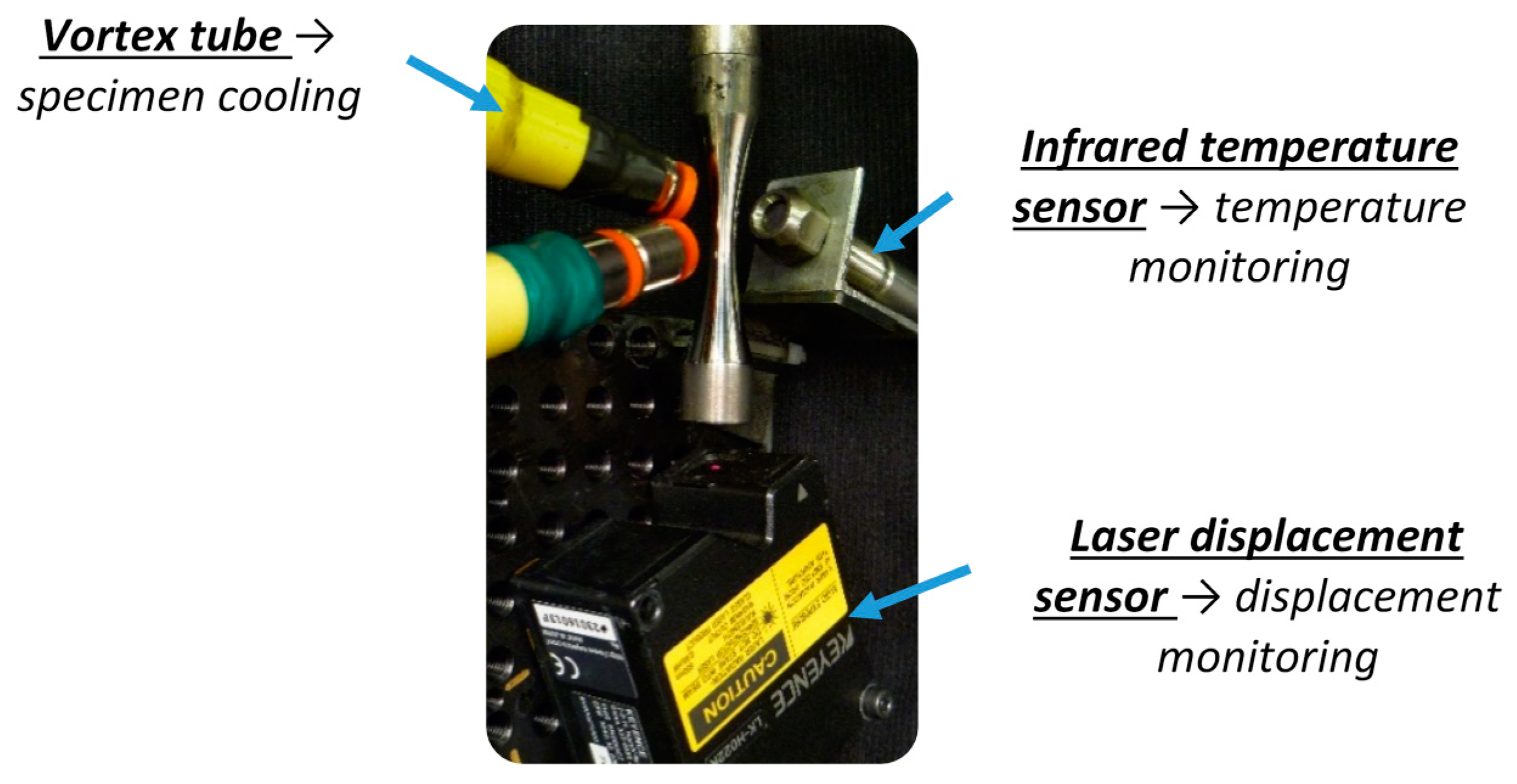

2.3. Ultrasonic Testing Configuration

3. Experimental Results

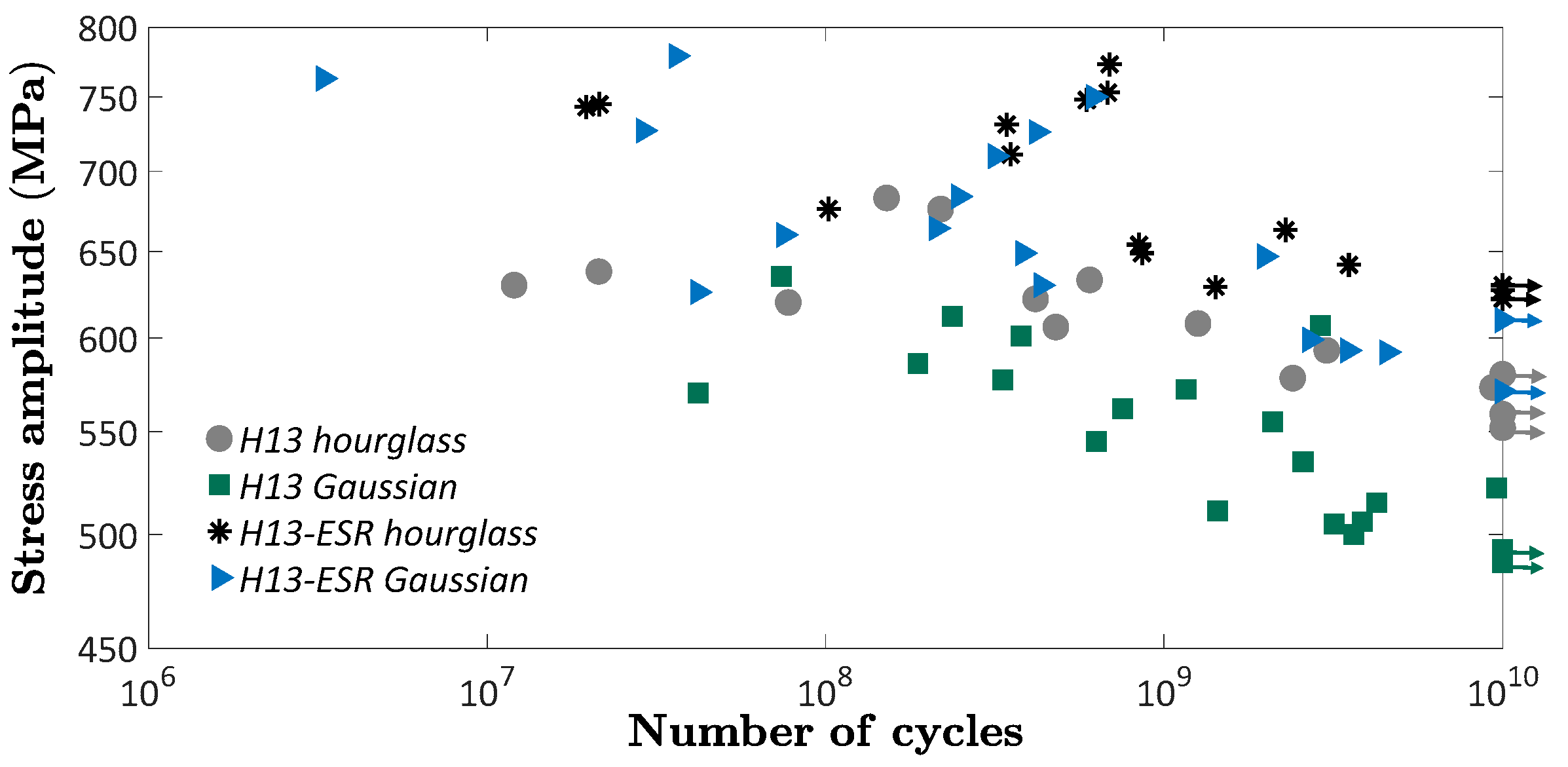

3.1. Experimental Dataset

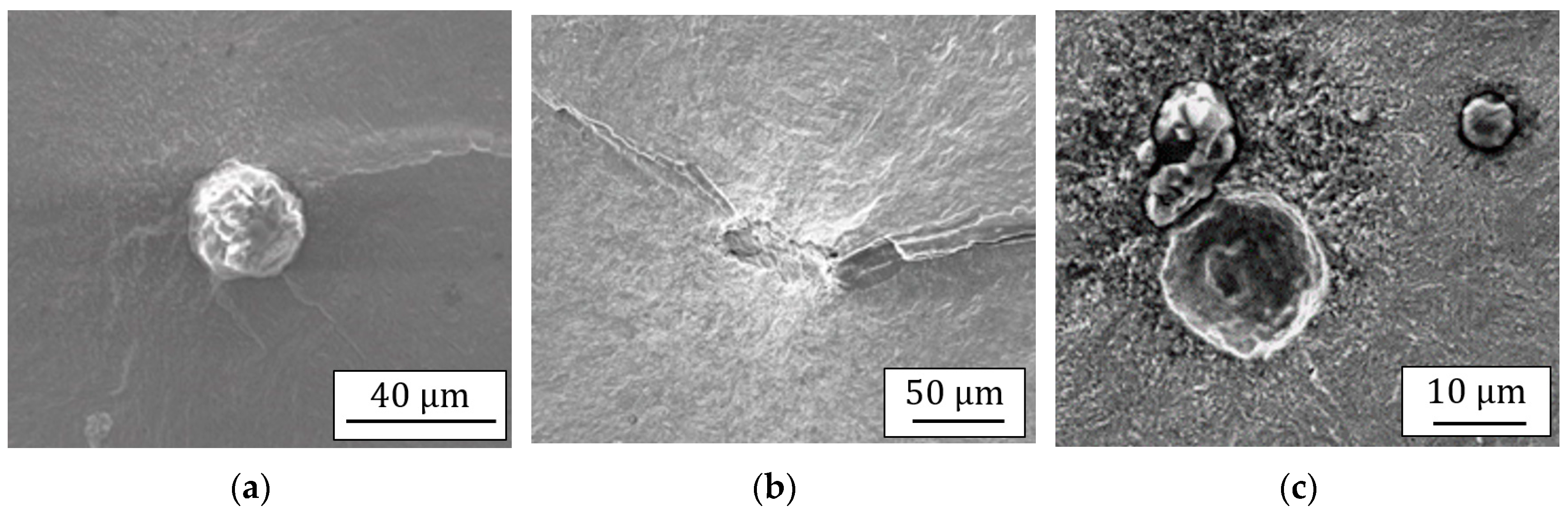

3.2. Defect Analysis

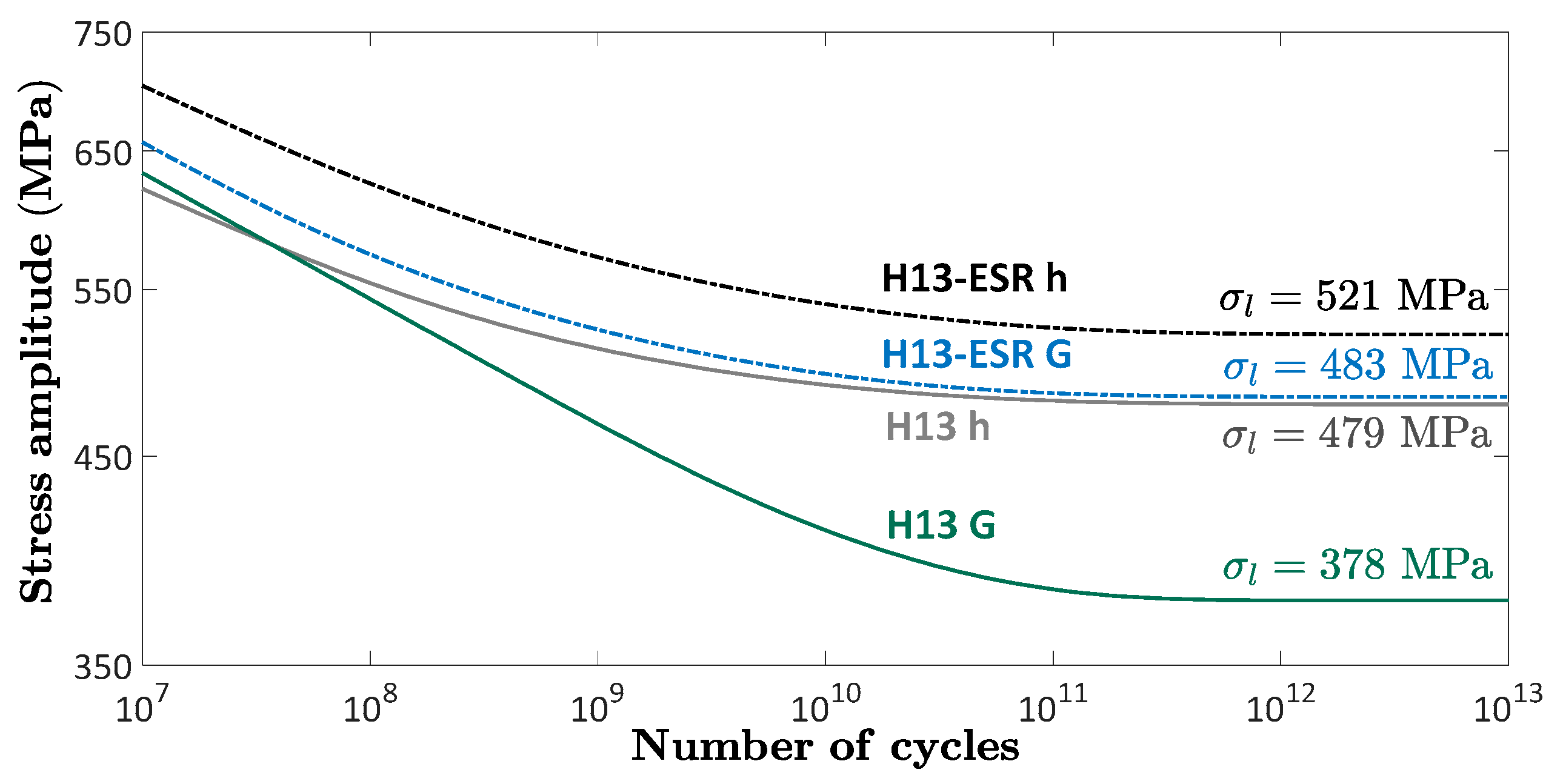

3.3. Size-Effect and ESR Process: Influence on the VHCF Strength

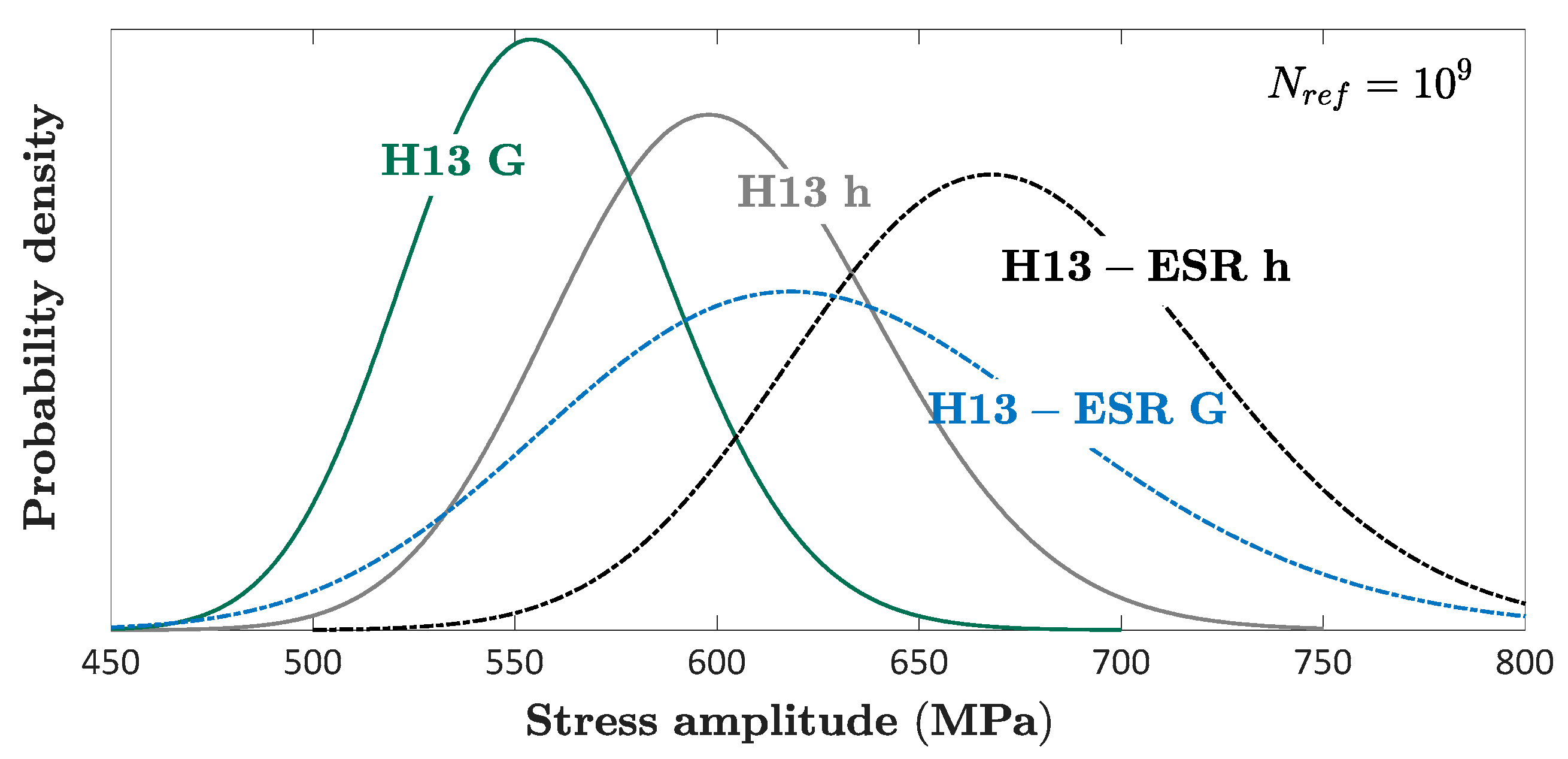

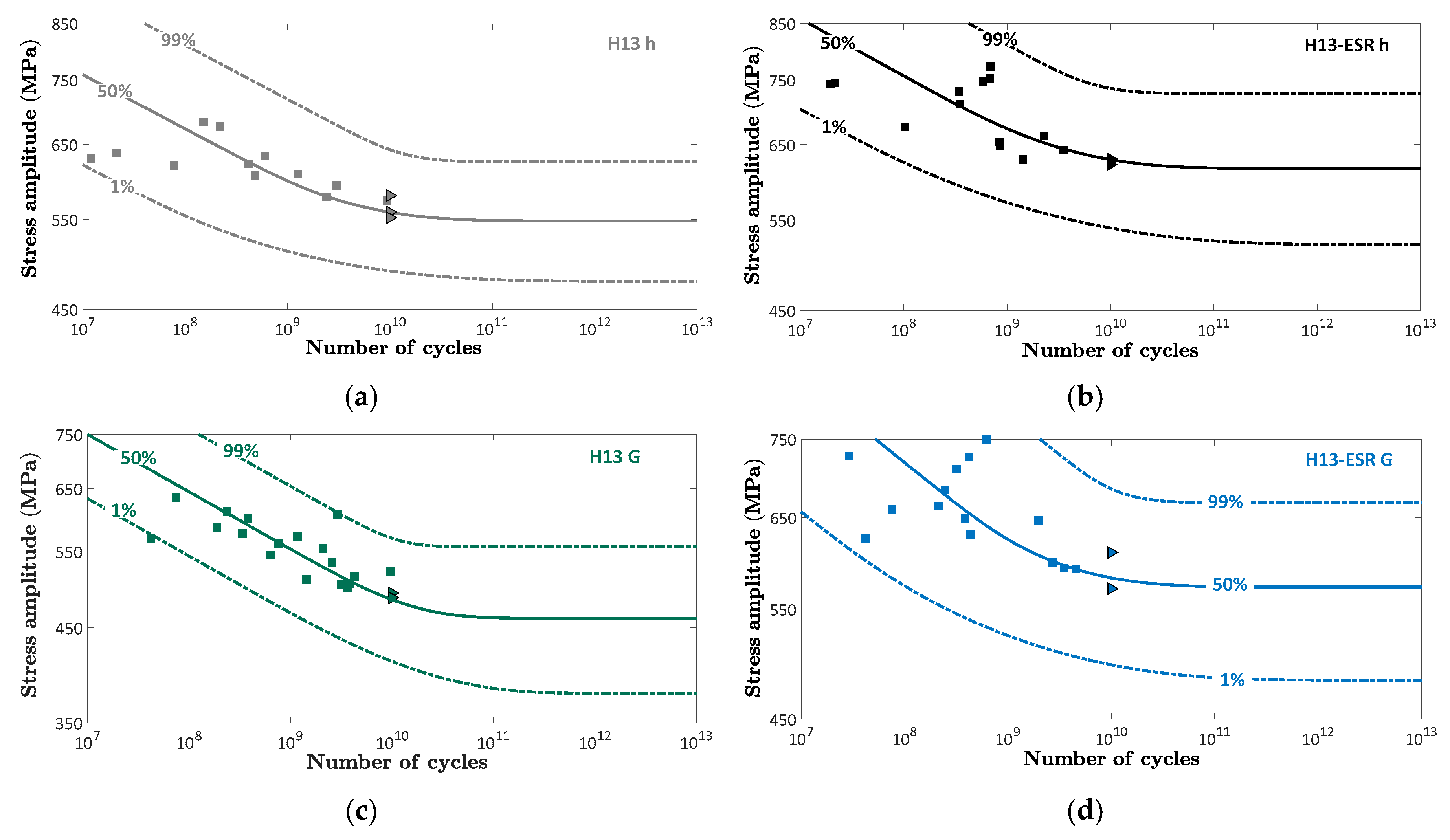

3.4. P–S–N Curves

4. Conclusions

Funding

Conflicts of Interest

References

- Bathias, C.; Paris, P.C. Gigacycle Fatigue in Mechanical Practice, 1st ed.; CRC Dekker: New York, NY, USA, 2004. [Google Scholar]

- Shanyavskiy, A.A. Very-high-cycle-fatigue of in-service air-engine blades, compressor and turbine. Sci. China Phys. Mech. Astron. 2014, 57, 19–29. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, 1st ed.; Elsevier Ltd: Oxford, UK, 2002. [Google Scholar]

- Akiniwa, Y.; Stanzl-Tschegg, S.; Mayer, H.; Wakita, M.; Tanaka, K. Fatigue strength of spring steel under axial and torsional loading in the very high cycle regime. Int. J. Fatigue 2008, 94, 178–191. [Google Scholar] [CrossRef]

- Furuya, Y. Notable size effects on very high cycle fatigue properties of high strength steel. Mater. Sci. Eng. A 2011, 528, 5234–5240. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. Crack growth from internal defects and related size-effect in VHCF. Proced. Struct. Integr. 2017, 5, 247–254. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. Effect of defect size on P-S-N curves in very-high-cycle fatigue. Proced. Struct. Integr. 2017, 7, 335–342. [Google Scholar] [CrossRef]

- Totten, G.E.; Xie, L.; Funatani, K. Handbook of Mechanical Alloy Design, 1st ed.; CRC Press: New York, NY, USA, 2003. [Google Scholar]

- Sawahata, A.; Tanigawa, H.; Enomoto, M. Effects of ElectroSlag Remelting on inclusion formation and impact property of reduced activation ferritic/martensitic steels. J. Jpn. Inst. Met. 2008, 72, 176–180. [Google Scholar] [CrossRef]

- Zhang, L.; Allanore, A.; Wang, C.; Yurko, J.A.; Crapps, J. Materials Processing Fundamentals, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. Analytical design of gigacycle fatigue specimens for size effect evaluation. Key Eng. Mater. 2014, 577–558, 369–372. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. On specimen design for size effect evaluation in ultrasonic gigacycle fatigue testing. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 570–579. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. VHCF response of AISI H13 steel: Assessment of size effects through Gaussian specimens. Proced. Eng. 2015, 109, 121–127. [Google Scholar] [CrossRef]

- Tridello, A. VHCF response of Gaussian specimens made of high-strength steels: Comparison between unrefined and refined AISI H13. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1676–1689. [Google Scholar] [CrossRef]

- Paolino, D.S.; Rossetto, M.; Chiandussi, G.; Tridello, A. Sviluppo di una Macchina a Ultrasuoni per Prove di Fatica Gigaciclica. In Proceedings of the 41th AIAS Conference, Vicenza, Italy, 5–8 September 2012. (In Italian). [Google Scholar]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. VHCF strength decrement in large H13 steel specimens subjected to ESR process. Proced. Struct. Integr. 2016, 2, 1117–1124. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. S-N curves in the very-high-cycle fatigue regime: Statistical modeling based on the hydrogen embrittlement consideration. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1319–1336. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration; ASTM Standard E1876-09; ASTM Standard: West Conshohocken, PA, USA, 2009. [Google Scholar]

- EN ISO 6507-1 Metallic Materials—Vickers Hardness Test—Part 1: Test Method; International Standard Organization (ISO): Genève, Switzerland, 2005.

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. Comparison between dog-bone and Gaussian specimens for size effect evaluation in gigacycle fatigue. Frattura e Integrità Strutturale 2013, 26, 49–56. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. VHCF response of H13 steels produced with different manufacturing processes. Proced. Eng. 2016, 160, 93–100. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. Effect of electroslag remelting on the VHCF response of an AISI H13 steel. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1783–1794. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S. Very high cycle fatigue measuring techniques. Int. J. Fatigue 2014, 60, 2–17. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. Gaussian specimens for gigacycle fatigue tests: Evaluation of temperature increment. Key Eng. Mater. 2015, 625, 85–88. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. Gaussian specimens for VHCF tests: Analytical prediction of damping effects. Int. J. Fatigue 2016, 83, 36–41. [Google Scholar] [CrossRef]

- Bathias, C. There is no infinite fatigue life in metallic materials. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 559–565. [Google Scholar] [CrossRef]

- Sakai, T.; Lian, B.; Takeda, M.; Shiozawa, K.; Oguma, N.; Ochi, Y.; Nakajima, M.; Nakamura, T. Statistical duplex S-N characteristics of high carbon chromium bearing steel in rotating bending in very high cycle regime. Int. J. Fatigue 2010, 32, 497–504. [Google Scholar] [CrossRef]

- Pyttel, B.; Schwerdt, D.; Berger, C. Very high cycle fatigue—Is there a fatigue limit? Int. J. Fatigue 2011, 33, 49–58. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. Statistical distributions of transition fatigue strength and transition fatigue life in duplex S-N fatigue curves. Theor. Appl. Fract. Mec 2015, 80, 31–39. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Geng, H.S.; Chiandussi, G.; Rossetto, M. Duplex S-N fatigue curves: Statistical distribution of the transition fatigue life. Frattura e Integrità Strutturale 2014, 30, 417–423. [Google Scholar] [CrossRef]

- Schuller, R.; Fitzka, M.; Irrasch, D.; Tran, D.; Pennings, B.; Mayer, H. VHCF properties of nitrided 18Ni maraging steel thin sheets with different Co and Ti content. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 518–527. [Google Scholar] [CrossRef]

- Tridello, A.; Biffi, C.A.; Fiocchi, J.; Bassani, P.; Chiandussi, G.; Rossetto, M.; Tuissi, A.; Paolino, D.S. VHCF response of as-built SLM AlSi10Mg specimens with large loaded volume. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1918–1928. [Google Scholar] [CrossRef]

- Zhang, J.W.; Lu, L.T.; Wu, P.B.; Ma, J.J.; Wang, G.G.; Zhang, W.H. Inclusion size evaluation and fatigue strength analysis of 35CrMo alloy railway axle steel. Mater. Sci. Eng. A 2013, 562, 211–217. [Google Scholar] [CrossRef]

- Sakai, T. Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use. J. Solid Mech. Mater. Eng. 2009, 3, 425–439. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. A general model for crack growth from initial defect in very-high-cycle fatigue. Proced. Struct. Integr. 2017, 3, 411–423. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | V |

|---|---|---|---|---|---|---|

| % | 0.39 | 1 | 0.4 | 0.4 | 5.3 | 0.9 |

| Material | Ed (GPa) | σu (MPa) | HV (HV) |

|---|---|---|---|

| H13 | 211.7–211.9 | 1987–2021 | 554–570 |

| H13-ESR | 212.8–212.9 | 2085–2105 | 555–562 |

| Material | Specimen | (μm) | (μm) |

|---|---|---|---|

| H13 | Hourglass | 21 | 41 |

| H13 | Gaussian | 19 | 56 |

| H13-ESR | Hourglass | 10 | 23 |

| H13-ESR | Gaussian | 15 | 31 |

| - | SS | DOF | MS | p-Value |

|---|---|---|---|---|

| Process | 0.0388 | 1 | 0.0364 | 0.000 * |

| Size | 0.0138 | 1 | 0.0138 | 0.002 * |

| Interaction | 0.0002 | 1 | 0.0002 | 0.727 |

| Error | 0.0697 | 55 | 0.0013 | - |

| Total | 0.1224 | 58 | - | - |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tridello, A. VHCF Response of Two AISI H13 Steels: Effect of Manufacturing Process and Size-Effect. Metals 2019, 9, 133. https://doi.org/10.3390/met9020133

Tridello A. VHCF Response of Two AISI H13 Steels: Effect of Manufacturing Process and Size-Effect. Metals. 2019; 9(2):133. https://doi.org/10.3390/met9020133

Chicago/Turabian StyleTridello, Andrea. 2019. "VHCF Response of Two AISI H13 Steels: Effect of Manufacturing Process and Size-Effect" Metals 9, no. 2: 133. https://doi.org/10.3390/met9020133

APA StyleTridello, A. (2019). VHCF Response of Two AISI H13 Steels: Effect of Manufacturing Process and Size-Effect. Metals, 9(2), 133. https://doi.org/10.3390/met9020133