Microstructure, Micro-Indentation, and Scratch Behavior of Cr Films Prepared on Al alloys by Using Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Phase Structures

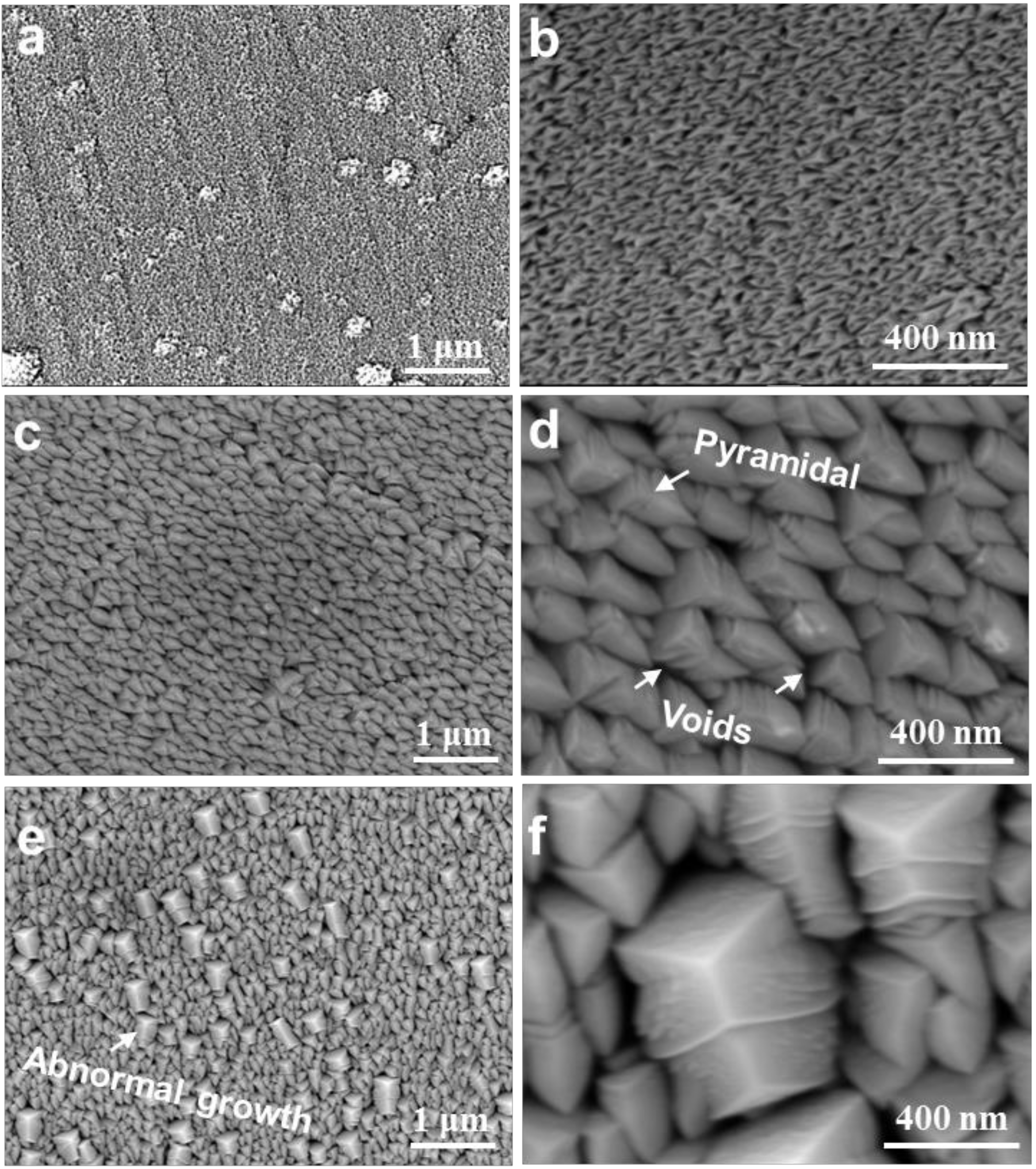

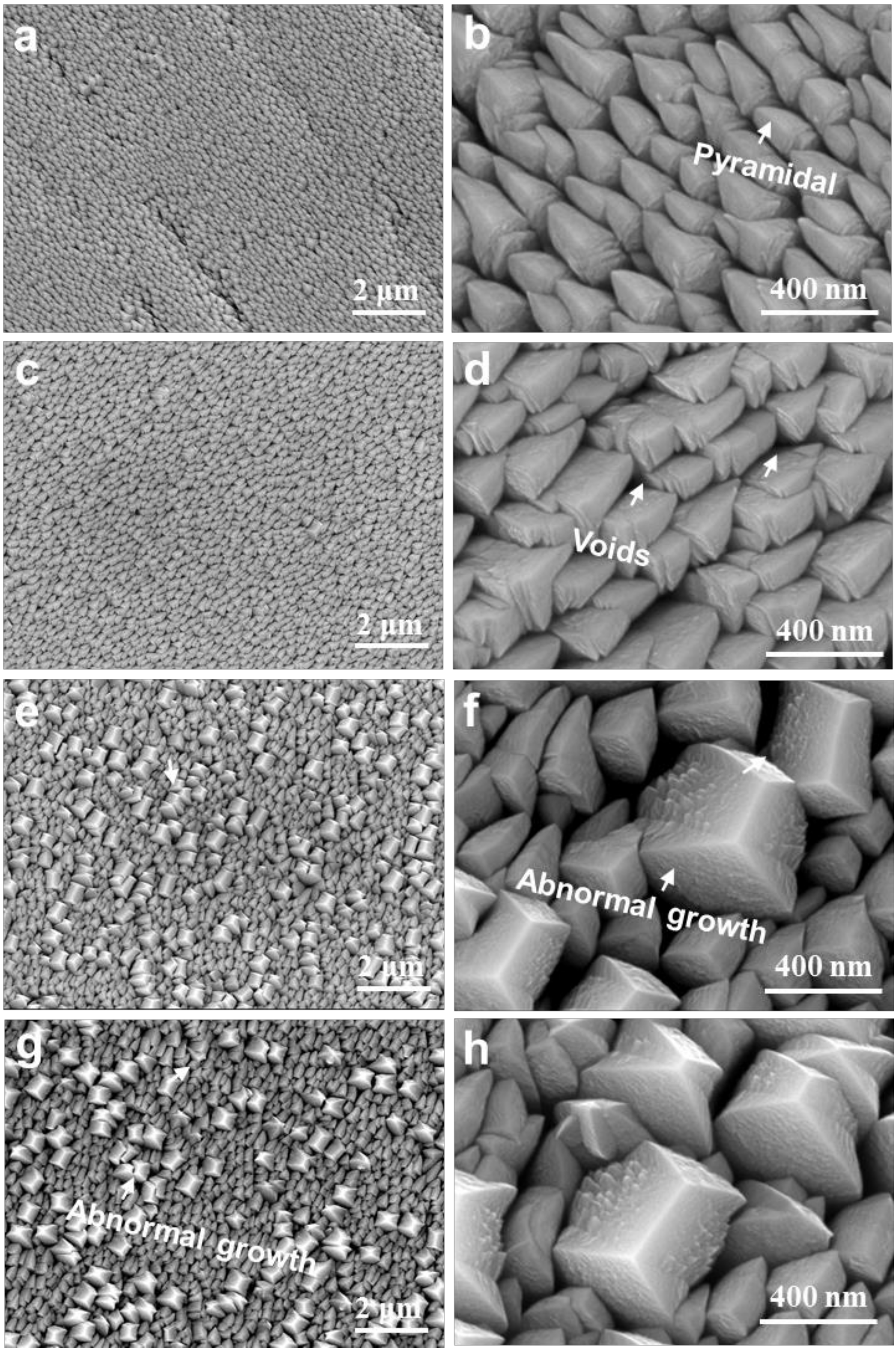

3.2. Top Surface Morphologies

3.3. Cross-Sectional and Fracture Morphologies

3.4. Micro-Indentation Behavior

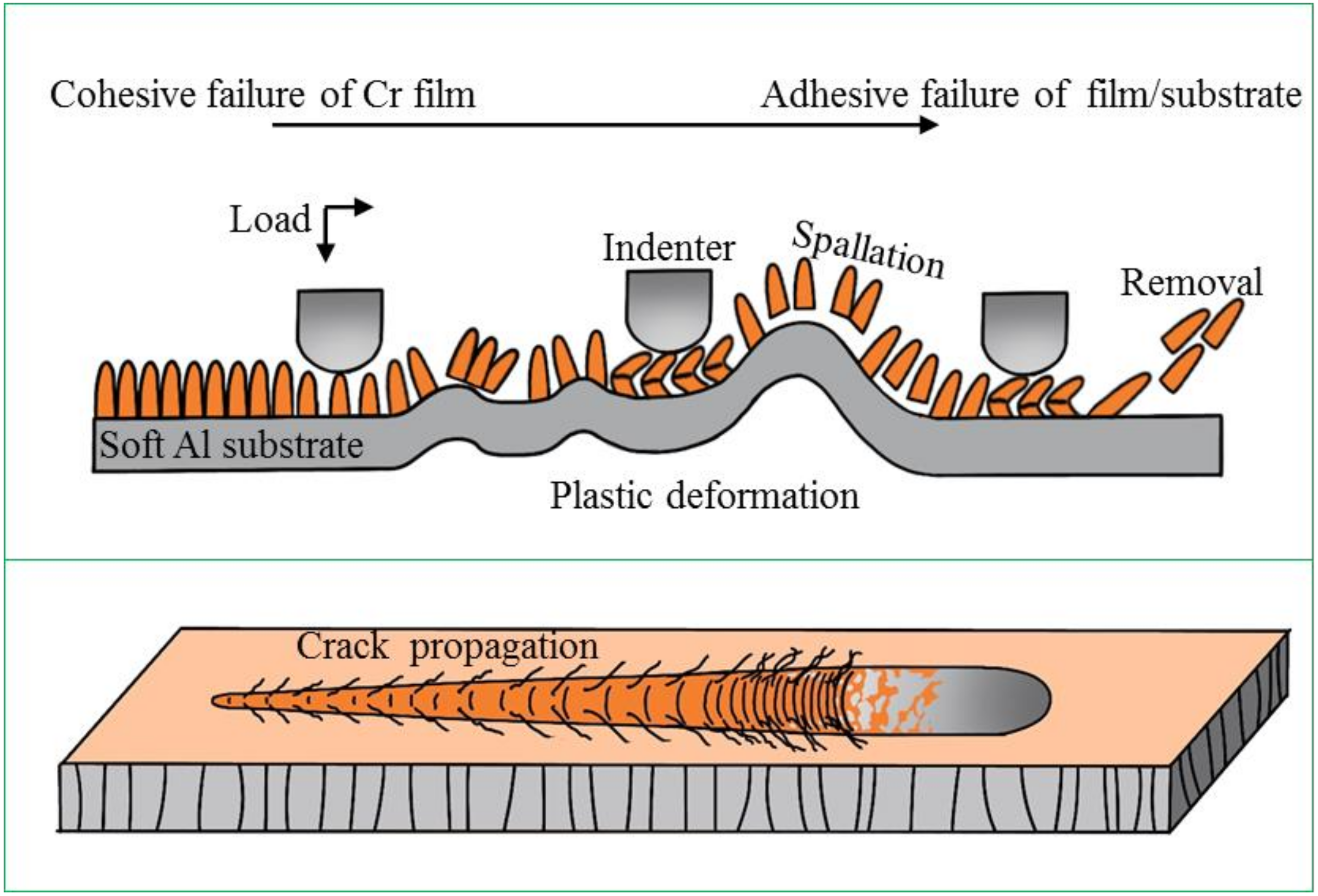

3.5. Scratch Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mello, C.B.; Mansur, R.A.F.; Santos, N.M. Experimental study of mechanical and tribological behavior of nitrogen ion-implanted chromium thin films. Surf. Coat. Technol. 2017, 312, 123–127. [Google Scholar] [CrossRef]

- Hu, M.; Shen, M.; Liu, Z.; Guo, C.; Li, Q.; Zhu, S. Self-ion bombarded Cr films: Crystallographic orientation and oxidation behaviour. Corros. Sci. 2018, 143, 212–220. [Google Scholar] [CrossRef]

- Bikulčius, G.; Češunienė, A.; Selskienė, A.; Pakštas, V.; Matijošius, T. Dry sliding tribological behavior of Cr coatings electrodeposited in trivalent chromium sulphate baths. Surf. Coat. Technol. 2017, 315, 130–138. [Google Scholar] [CrossRef]

- Liang, A.; Ni, L.; Liu, Q.; Zhang, J. Structure characterization and tribological properties of thick chromium coating electrodeposited from a Cr (III) electrolyte. Surf. Coat. Technol. 2013, 218, 23–29. [Google Scholar] [CrossRef]

- Daure, J.L.; Carrington, M.J.; Shipway, P.H.; McCartney, D.G.; Stewart, D.A. A comparison of the galling wear behaviour of PVD Cr and electroplated hard Cr thin films. Surf. Coat. Technol. 2018, 350, 40–47. [Google Scholar] [CrossRef]

- Wang, S.F.; Lin, H.C.; Bor, H.Y.; Tsai, Y.L.; Wei, C.N. Characterization of chromium thin films by sputter deposition. J. Alloy. Compd. 2011, 509, 10110–10114. [Google Scholar] [CrossRef]

- Sidelev, D.V.; Bestetti, M.; Bleykher, G.A.; Krivobokov, V.P.; Grudinin, V.A.; Franz, S.; Vicenzo, A.; Shanenkova, Y.L. Deposition of Cr films by hot target magnetron sputtering on biased substrates. Surf. Coat. Technol. 2018, 350, 560–568. [Google Scholar] [CrossRef]

- Li, H.T.; Jiang, B.L.; Yang, B. Study on crystalline to amorphous structure transition of Cr coatings by magnetron sputtering. Appl. Surf. Sci. 2011, 258, 935–939. [Google Scholar] [CrossRef]

- Paturaud, C.; Farges, G.; Sainte Catherine, M.C.; Machet, J. Correlation between hardness and embedded argon content of magnetron sputtered chromium films. Thin Solid Films 1999, 347, 46–55. [Google Scholar] [CrossRef]

- Chiang, K.T.K.; Wei, R. Growth morphology and corrosion resistance of magnetron sputtered Cr films. Surf. Coat. Technol. 2011, 206, 1660–1665. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Oliveira, J.C.; Cavaleiro, A. Effect of peak target power on the properties of Cr thin films sputtered by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode. Surf. Coat. Technol. 2014, 258, 249–256. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Cavaleiro, A.; Oliveira, J.C. Additional control of bombardment by deep oscillation magnetron sputtering: Effect on the microstructure and topography of Cr thin films. Thin. Solid. Films. 2016, 619, 250–260. [Google Scholar] [CrossRef]

- Straumanis, M.E.; Weng, C.C. The precise lattice constant and the expansion coefficient of chromium between 10 and 60 °C. Acta Crystallogr. 1955, 8, 367–371. [Google Scholar] [CrossRef]

- Feng, Y.C.; Laughlin, D.E.; Lambeth, D.N. Formation of crystallographic texture in rf sputter-deposited Cr thin films. J. Appl. Phys. 1994, 76, 7311–7316. [Google Scholar] [CrossRef]

- Karabacak, T. Thin-film growth dynamics with shadowing and re-emission effects. J. Nanophotonics 2011, 5, 052501–052518. [Google Scholar] [CrossRef] [Green Version]

- Bland, R.; Kominiak, G.; Mattox, D. Effect of ion bombardment during deposition on thick metal and ceramic deposits. J. Vac. Sci. Technol. 1974, 11, 671–674. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Yalisove, S.M.; Rek, Z.U. Evolution of anisotropic microstructure and residual stress in sputtered Cr films. J. Appl. Phys. 2002, 92, 7183–7192. [Google Scholar] [CrossRef]

- Polakova, H.; Kubasek, M.; Cerstvy, R.; Musil, J. Control of structure in magnetron sputtered thin films. Surf. Coat. Technol. 2001, 142–144, 201–205. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Lee, J.W.; Lew, W.; Li, B. Influence of bias voltage on the hardness and toughness of CrAlN coatings via magnetron sputtering. Surf. Coat. Technol. 2012, 206, 5103–5107. [Google Scholar] [CrossRef]

- Rebholz, C.; Leyland, A.; Schneider, J.M.; Voevodin, A.A.; Matthews, A. Structure hardness and mechanical properties of magnetron-sputtered titanium-aluminium boride films. Surf. Coat. Technol. 1999, 120, 412–417. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Cheng, C.M. Relationships between hardness, elastic modulus and the work of indentation. Appl. Phys. Lett. 1998, 73, 614–616. [Google Scholar] [CrossRef]

- Pellicer, E.; Pané, S.; Sivaraman, K.M.; Ergeneman, O.; Suriñach, S.; Baró, M.D.; Nelson, B.J.; Sort, J. Effects of the anion in glycine-containing electrolytes on the mechanical properties of electrodeposited Co–Ni films. Mater. Chem. Phys. 2001, 130, 1380–1386. [Google Scholar] [CrossRef]

- Macías, H.A.; Yate, L.; Coy, L.E.; Olaya, J.J.; Aperador, W. Effect of nitrogen flow ratio on microstructure, mechanical and tribological properties of TiWSiNx thin film deposited by magnetron co-sputtering. Appl. Surf. Sci. 2018, 456, 445–456. [Google Scholar] [CrossRef]

- Kabir, M.S.; Munroe, P.; Zhou, Z.F.; Xie, Z.H. Study of the structure, properties, scratch resistance and deformation behavior of graded Cr-CrN-Cr(1-x)AlxN coatings. Ceram. Int. 2018, 40, 11364–11373. [Google Scholar] [CrossRef]

- Sha, C.; Zhou, Z.; Xie, Z.; Munroe, P.J. Scratch response and tribological behaviour of CrAlNiN coatings deposited by closed field unbalanced magnetron sputtering system. Surf. Coat. Technol. 2019, 367, 30–40. [Google Scholar] [CrossRef]

- Sveen, S.; Andersson, J.M.; Saoubi, R.M.; Olsson, M. Scratch adhesion characteristics of PVD TiAlN deposited on high speed steel, cemented carbide and PCBN substrates. Wear 2013, 308, 133–141. [Google Scholar] [CrossRef]

- Kim, H.K.; La, J.H.; Kim, K.S.; Lee, S.Y. The effects of the H/E ratio of various Cr-N interlayers on the adhesion strength of CrZrN coatings on tungsten carbide substrates. Surf. Coat. Technol. 2015, 284, 230–234. [Google Scholar] [CrossRef]

- Heinke, W.; Leyland, A.; Matthews, A.; Berg, G.; Friedrich, C.; Broszeit, E. Evaluation of PVD nitride coatings using impact scratch and Rockwell-C adhesion tests. Thin Solid Films 1995, 270, 431–438. [Google Scholar] [CrossRef]

- Karimi, A.; Wang, Y.; Cselle, T.; Morstein, M. Fracture mechanisms in nanoscale layered hard thin films. Thin Solid Films 2002, 420, 275–280. [Google Scholar] [CrossRef]

- Bull, S.J. Failure modes in scratch adhesion testing. Surf. Coat. Technol. 1991, 50, 25–32. [Google Scholar] [CrossRef]

- Kabir, M.S.; Munroe, P.; Zhou, Z.; Xie, Z. Scratch adhesion and tribological behaviour of graded Cr/CrN/CrTiN coatings synthesized by closed-field unbalanced magnetron sputtering. Wear 2017, 380, 163–175. [Google Scholar] [CrossRef]

| Sample | Cr Power (kW) | Bias (V) | Sputtering Time (h) | Sputtering Pressure (Pa) | Argon Flux (sccm) |

|---|---|---|---|---|---|

| DC1 | 2.0 | 10 | 2 | 0.2–0.3 | 16 |

| DC2 | 2.0 | 30 | 2 | 0.2–0.3 | 16 |

| DC3 | 2.0 | 70 | 2 | 0.2–0.3 | 16 |

| DC4 | 2.0 | 110 | 2 | 0.2–0.3 | 16 |

| DC5 | 0.2 | 70 | 2 | 0.2–0.3 | 16 |

| DC6 | 0.8 | 70 | 2 | 0.2–0.3 | 16 |

| DC7 | 1.4 | 70 | 2 | 0.2–0.3 | 16 |

| Sample | H (GPa) | E (GPa) | Wt (nJ) | Wp (nJ) | ηp | H/E | H3/E2 |

|---|---|---|---|---|---|---|---|

| 2024 Al | 1.44 | 90 | 0.682 | 0.643 | 0.94 | 0.016 | 0.0003 |

| DC1 | 3.81 | 130 | 0.371 | 0.322 | 0.86 | 0.0293 | 0.0032 |

| DC2 | 3.60 | 129 | 0.389 | 0.346 | 0.89 | 0.0279 | 0.0028 |

| DC3 | 4.56 | 167 | 0.314 | 0.247 | 0.78 | 0.0273 | 0.0034 |

| DC4 | 4.87 | 169 | 0.317 | 0.292 | 0.92 | 0.0288 | 0.0040 |

| DC5 | 3.31 | 81.5 | 0.518 | 0.431 | 0.83 | 0.0406 | 0.0054 |

| DC6 | 4.19 | 127 | 0.363 | 0.297 | 0.81 | 0.0328 | 0.0045 |

| DC7 | 4.33 | 164 | 0.347 | 0.286 | 0.82 | 0.0264 | 0.0030 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Zhang, F.; Yan, S.; Li, H.; He, J.; Yin, F. Microstructure, Micro-Indentation, and Scratch Behavior of Cr Films Prepared on Al alloys by Using Magnetron Sputtering. Metals 2019, 9, 1330. https://doi.org/10.3390/met9121330

Ding Y, Zhang F, Yan S, Li H, He J, Yin F. Microstructure, Micro-Indentation, and Scratch Behavior of Cr Films Prepared on Al alloys by Using Magnetron Sputtering. Metals. 2019; 9(12):1330. https://doi.org/10.3390/met9121330

Chicago/Turabian StyleDing, Yi, Fanyong Zhang, Shu Yan, Hongtao Li, Jining He, and Fuxing Yin. 2019. "Microstructure, Micro-Indentation, and Scratch Behavior of Cr Films Prepared on Al alloys by Using Magnetron Sputtering" Metals 9, no. 12: 1330. https://doi.org/10.3390/met9121330

APA StyleDing, Y., Zhang, F., Yan, S., Li, H., He, J., & Yin, F. (2019). Microstructure, Micro-Indentation, and Scratch Behavior of Cr Films Prepared on Al alloys by Using Magnetron Sputtering. Metals, 9(12), 1330. https://doi.org/10.3390/met9121330