Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemical Composition

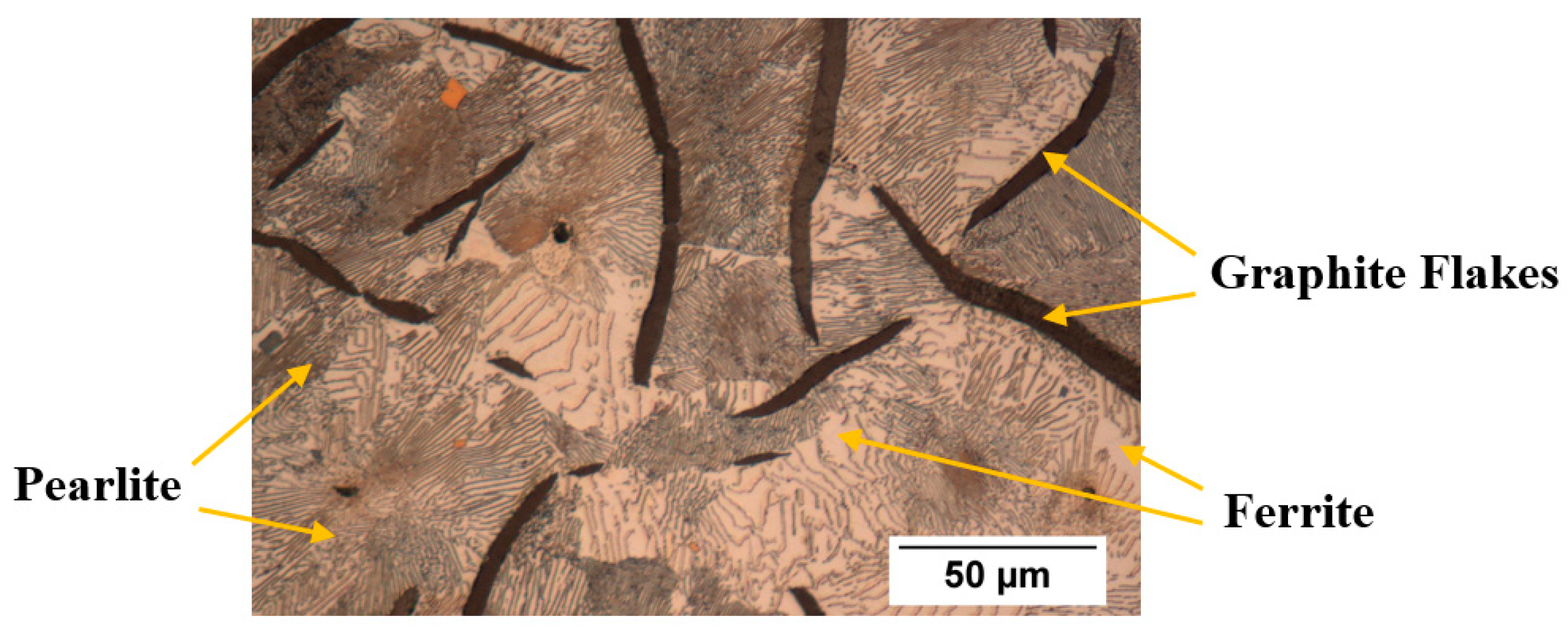

2.2. As-Cast Gray Cast Iron

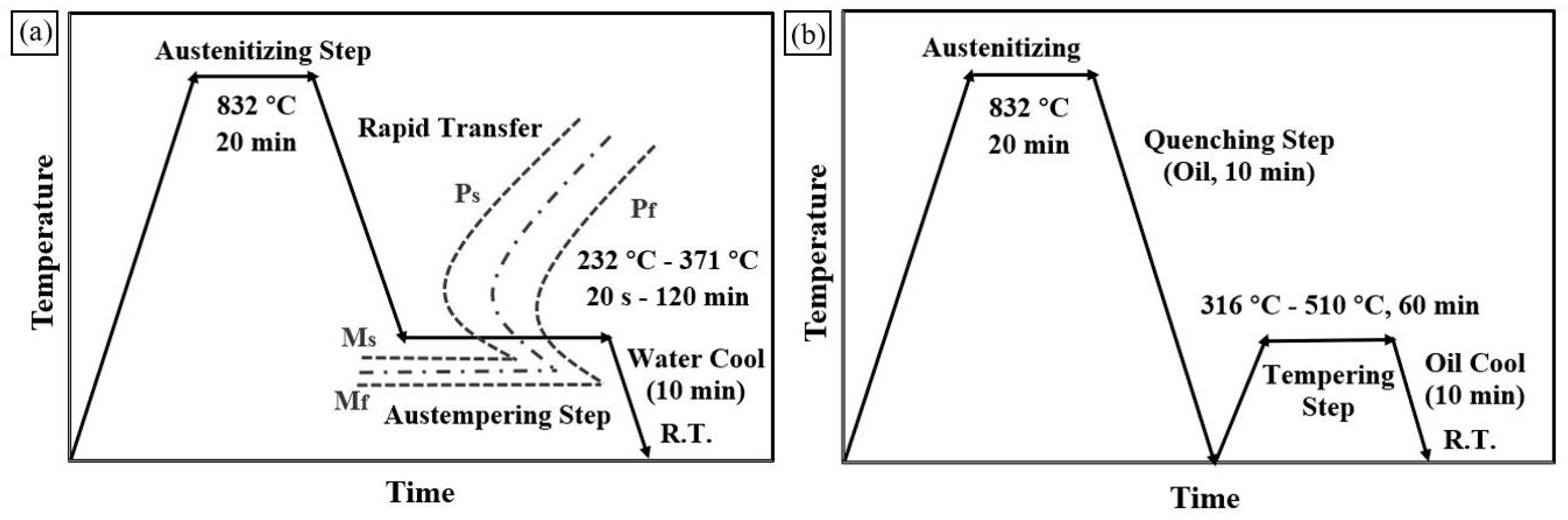

2.3. Austempering Heat Treatment

2.4. Quenching and Tempering Heat Treatment

2.5. Metallurgical Evaluation

2.6. Rotational Ball-on-Disk Sliding Wear Test

2.7. Rockwell C Hardness Measurement

3. Results

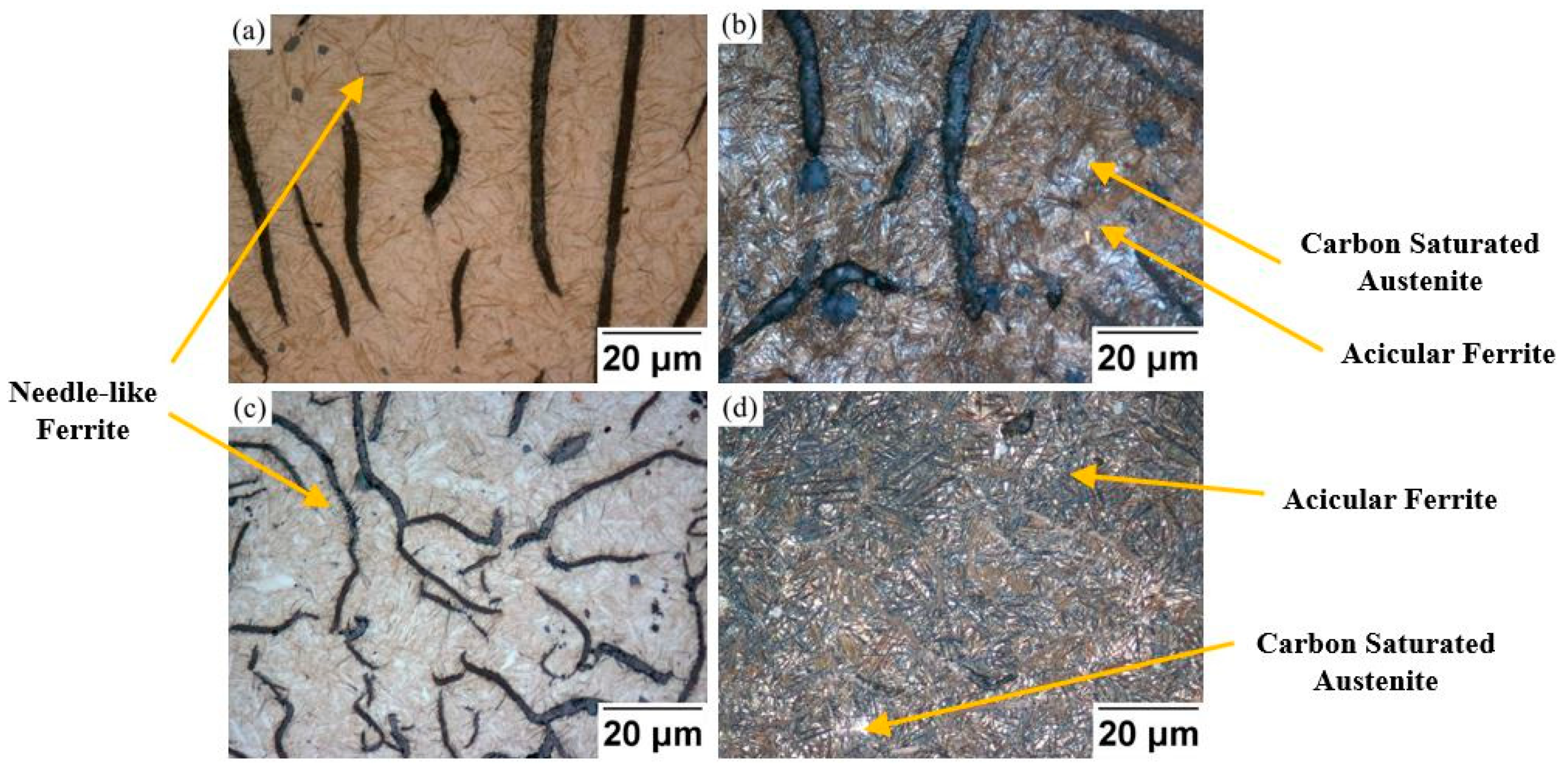

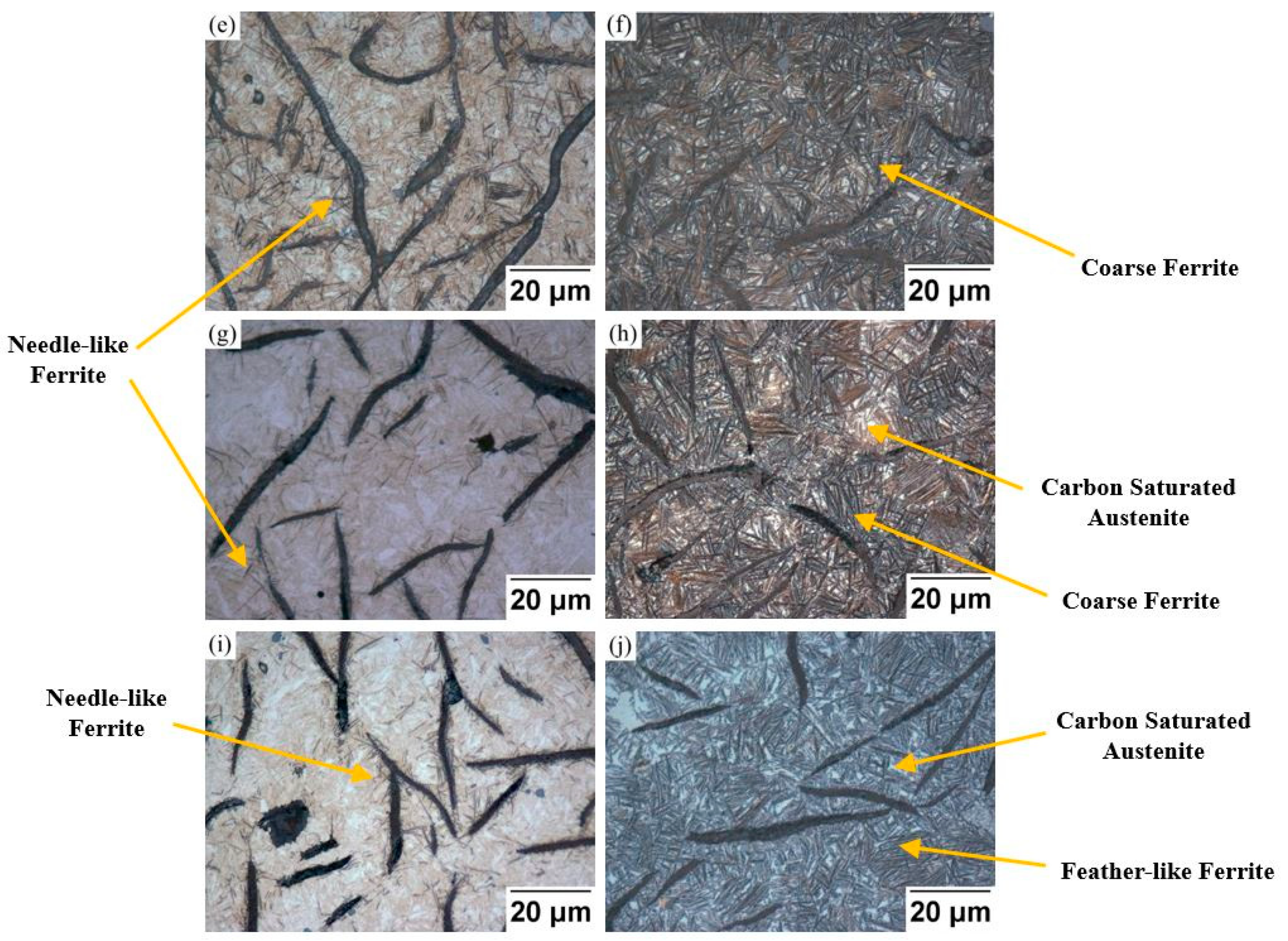

3.1. Metallurgical Evaluation of AGI and QTGI

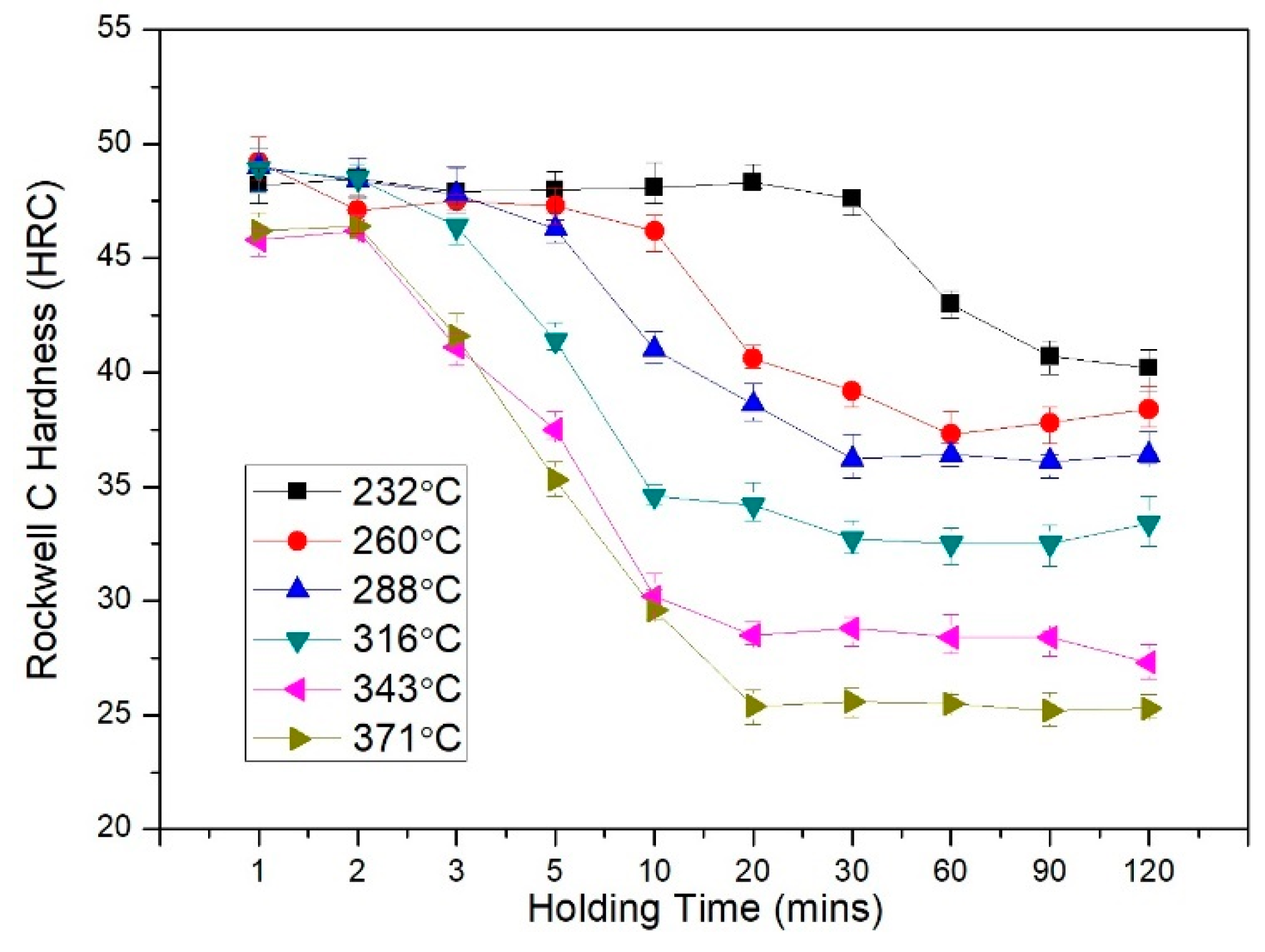

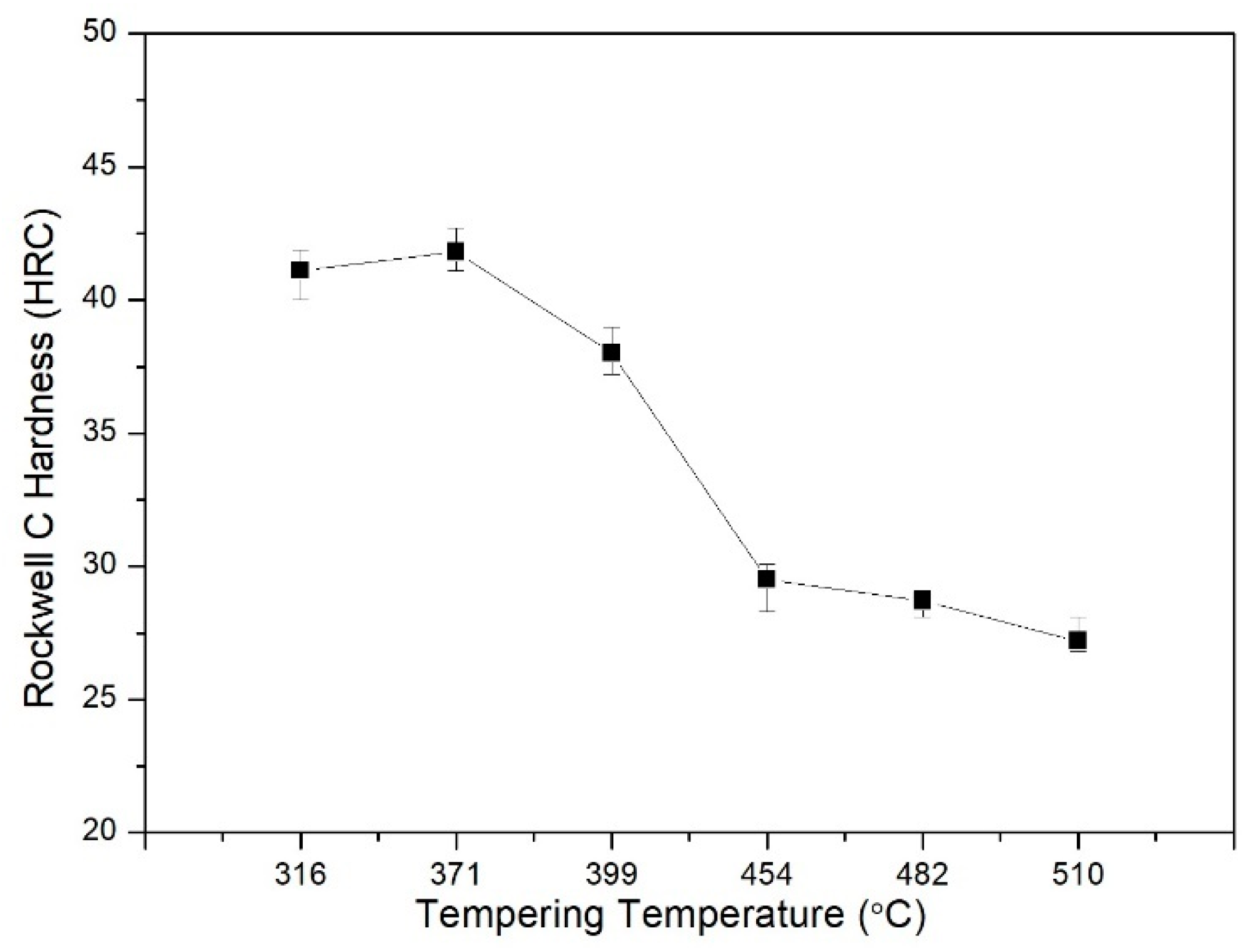

3.2. Hardness Measurement

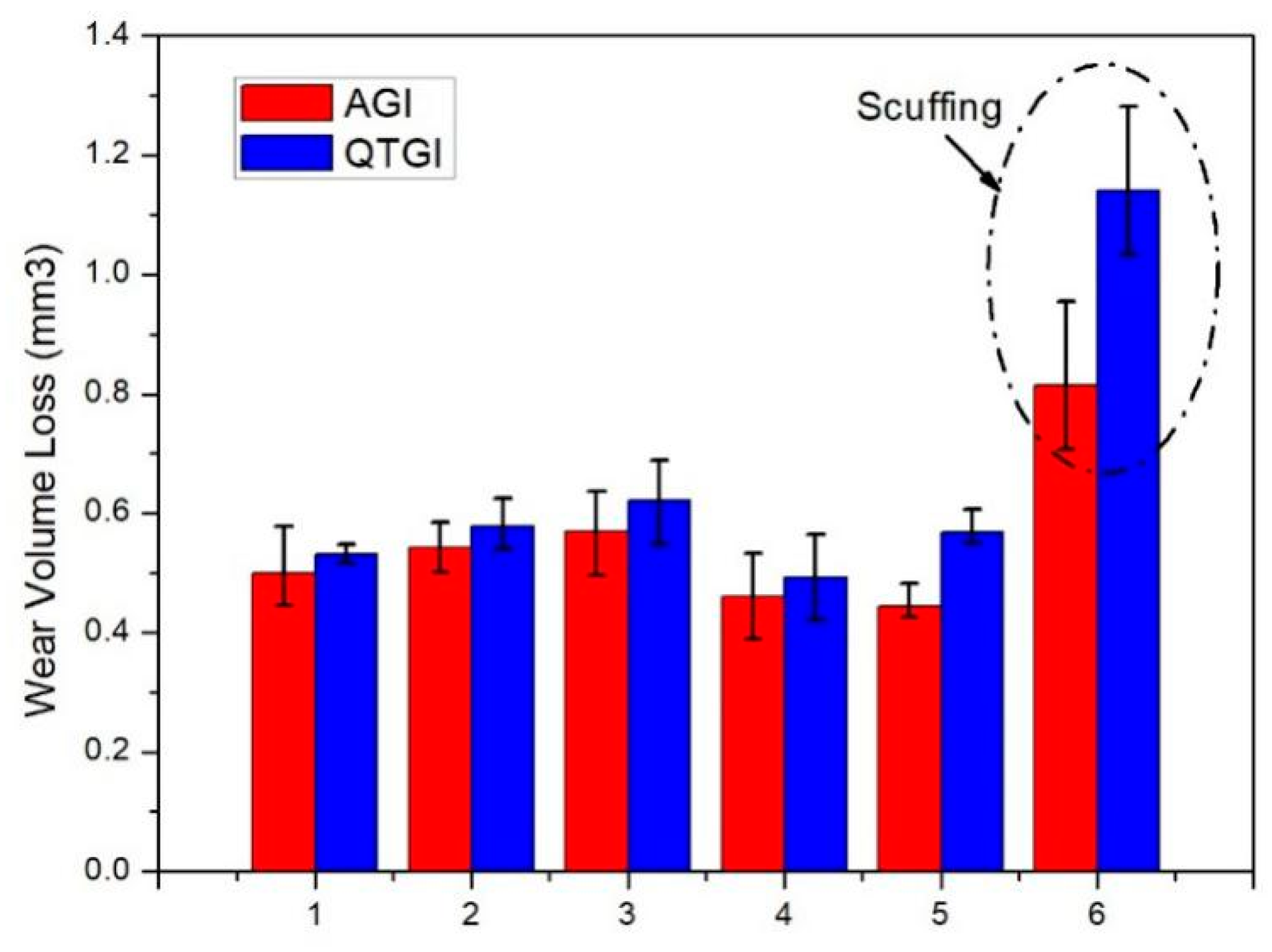

3.3. Ball-on-Disk Rotational Wear Tests

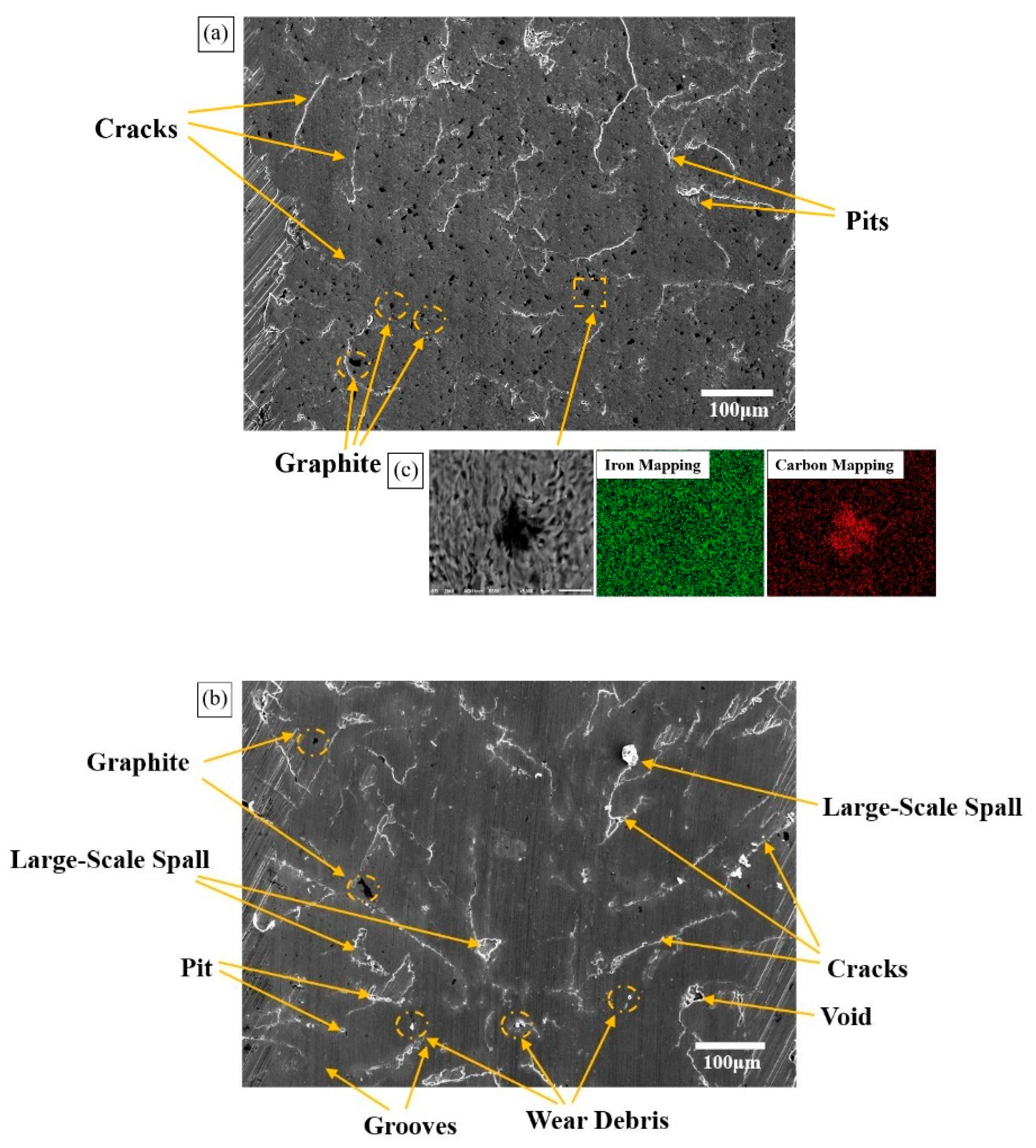

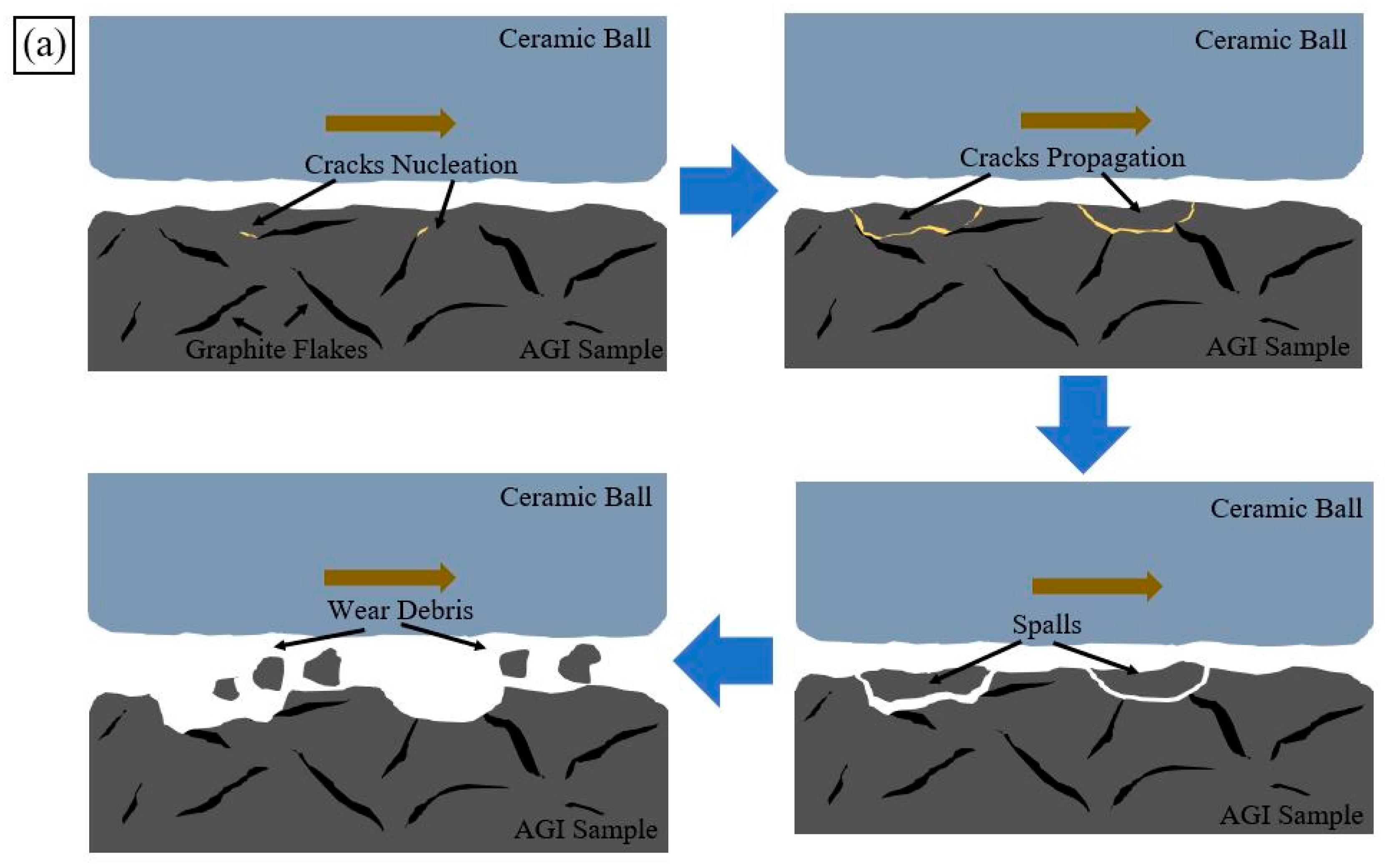

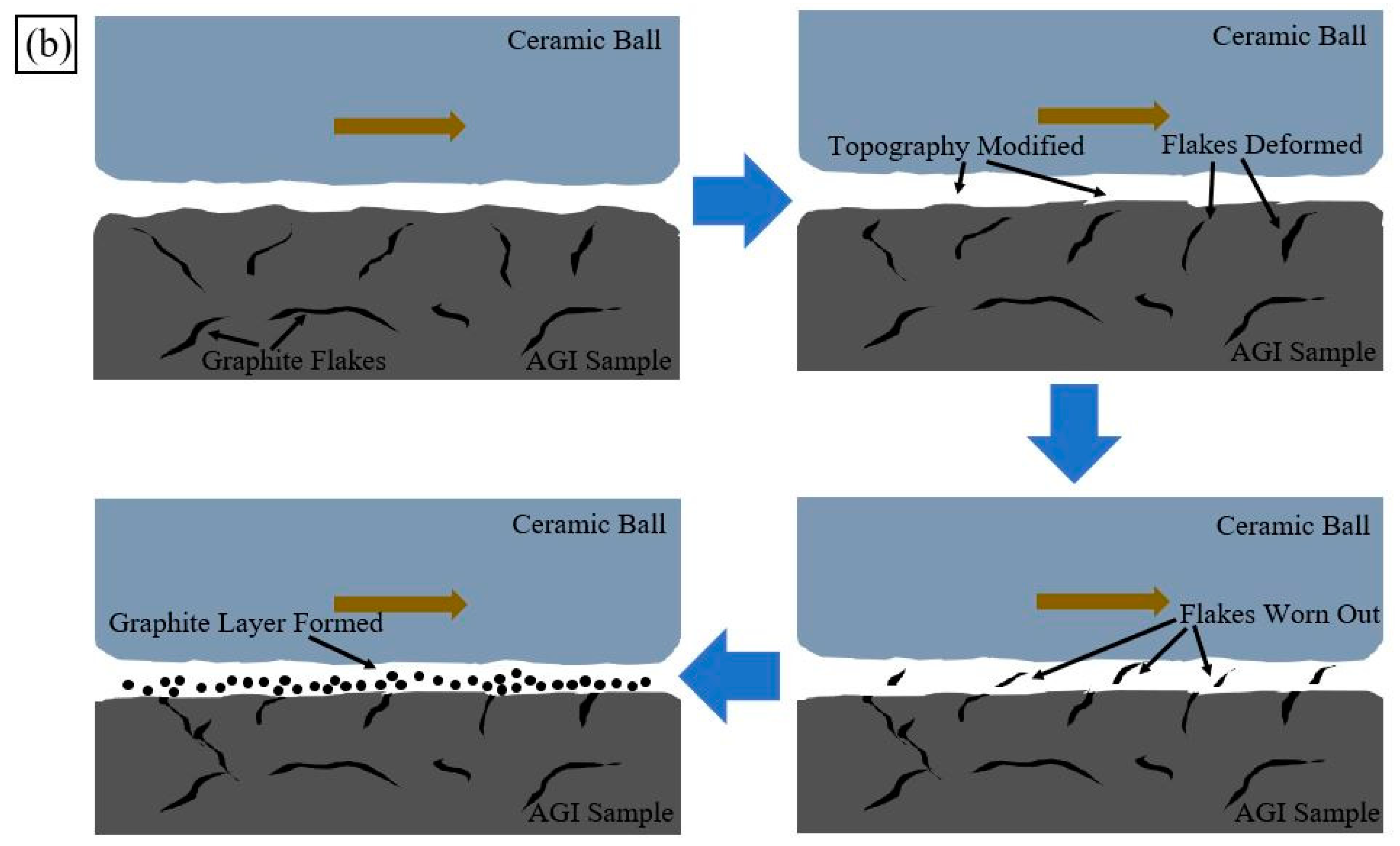

3.4. Worn Surface Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ASTM International. ASTM Standard A247-Standard Test Method for Evaluating the Microstructure of Graphite in Iron Castings; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Bain, E.C. Functions of the Alloying Elements in Steel; American Society for Metals: Materials Park, OH, USA, 1939. [Google Scholar]

- Hassani, A.; Habibollahzadeh, A.; Sadeghinejad, S. Influence of Vanadium and Chromium Additions on the Wear Resistance of a Gray Cast Iron. Int. J. Min. Metall. Mater. 2012, 19, 602–607. [Google Scholar] [CrossRef]

- Sarkar, T.; Bose, P.; Sutradhar, G. Mechanical and Tribological Characteristics of Copper Alloyed Austempered Gray Cast Iron (AGI). Mater. Today Proc. 2018, 5, 3664–3673. [Google Scholar] [CrossRef]

- Vadiraj, A.; Balachandran, G.; Kamaraj, M.; Kazuya, E. Mechanical and Wear Behavior of Quenched and Tempered Alloyed Hypereutectic Gray Cast Iron. Mater. Des. 2011, 32, 2438–2443. [Google Scholar] [CrossRef]

- Vadiraj, A.; Balachandran, G.; Kamaraj, M.; Gopalakrisshna, B.; Rao, K. Structure-Property Correlation in Austempered Alloyed Hypereutectic Gray Cast Irons. Mater. Sci. Eng. A 2010, 527, 782–788. [Google Scholar] [CrossRef]

- Balachandran, G.; Vadiraj, A.; Kamaraj, M.; Kazuya, E. Mechanical and Wear Behavior of Alloyed Gray Cast Iron in the Quenched and Tempered and Austempered Conditions. Mater. Des. 2011, 2, 4042–4049. [Google Scholar] [CrossRef]

- Vadiraj, A.; Balachandran, G.; Kamaraj, M.; Gopalakrishna, B.; Rao, K. Studies on Mechanical and Wear Properties of Alloyed Hypereutectic Gray Cast Irons in the As-Cast Pearlitic and Austempered Conditions. Mater. Des. 2010, 31, 951–955. [Google Scholar] [CrossRef]

- Ghaderi, A.; Ahmadabadi, M.; Ghasemi, H. Effect of Graphite Morphologies on the Tribological Behavior of Austempered Cast Iron. Wear 2003, 255, 410–416. [Google Scholar] [CrossRef]

- Sarkar, T.; Sutradhara, G. Investigation of Austenitizing Temperature on Wear Behavior of Austempered Gray Iron (AGI). IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012048. [Google Scholar] [CrossRef]

- Solic, S.; Godec, M.; Schauperl, Z.; Donik, C. Improvement in Abrasion Wear Resistance and Microstructure Changes with Deep Cryogenic Treatment of Austempered Ductile Cast Iron (ADI). Metall. Mater. Trans. A 2016, 47, 5058–5070. [Google Scholar] [CrossRef]

- Sahin, Y.; Erdogan, M.; Kilicli, V. Wear Behavior of Austempered Ductile Irons with Dual Matrix Structures. Mater. Sci. Eng. A 2007, 444, 31–38. [Google Scholar] [CrossRef]

- Haseeb, A.; Islam, M.; Bepari, M. Tribological Behavior of Quenched and Tempered, and Austempered Ductile Iron at the Same Hardness Level. Wear 2000, 244, 15–19. [Google Scholar] [CrossRef]

- PourAsiabi, H.; Saghafian, H.; Pourasiabi, H. Effect of Austempering Process on Microstructure and Wear Behavior of Ductile Iron Containing Mn-Ni-Cu-Mo. Met. Mater. Int. 2013, 19, 67–76. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.; Sun, X.; Shaw, M.; Seaton, P. Characteristics of the Transformation of Retained Austenite in Tempered Austempered Ductile Iron. J. Mater. Eng. Perform. 2017, 26, 2095–2101. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.; Qiu, F.; Zou, Q.; Yang, H. A Review: Phase Transformation and Wear Mechanisms of Single-Step and Dual-Step Austempered Ductile Iron. J. Mater. Res. Technol. 2019. [Google Scholar] [CrossRef]

- Wang, C.; Du, X.; Li, S.; Sun, Y.; Yang, P. Morphology and Crystallography of Ausferrite in Austempered Ductile Iron. Metals 2017, 7, 238. [Google Scholar] [CrossRef]

- Konca, E.; Tur, K.; Koc, E. Effects of Alloying Elements (Mo, Ni, and Cu) on the Austemperability of GGG-60 Ductile Cast Iron. Metals 2017, 7, 320. [Google Scholar] [CrossRef]

- Sellamuthu, P.; Smuel, D.; Dinakaran, D.; Premkumar, V. Austempered Ductile Iron (ADI): Influence of Austempering Temperature on Microstructure, Mechanical and Wear Properties and Energy Consumption. Metals 2018, 8, 53. [Google Scholar] [CrossRef]

- ASTM International. ASTM Standard E18-16-Standard Test Methods for Rockwell Hardness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Amran, Y.; Katsman, A.; Schaaf, P.; Bamberger, M. Influence of Copper Addition and Temperature on the Kinetics of Austempering in Ductile Iron. Metall. Mater. Trans. B 2010, 41, 1052–1058. [Google Scholar] [CrossRef]

- Gorny, M.; Tyrala, E.; Lopez, H. Effect of Copper and Nickel on the Transformation Kinetics of Austempered Ductile Iron. J. Mater. Eng. Perform. 2014, 23, 3505–3510. [Google Scholar] [CrossRef]

- Wang, B.; Barber, G.; Tao, C.; Han, X.; Sun, X. Tribological Performance of Austempered and Tempered Ductile Iron. Metall. Mater. Trans. B 2018, 49, 2261–2269. [Google Scholar] [CrossRef]

- Panneerelvam, S.; Martis, C.; Putatunda, S.; Boileau, J. An investigation on the Stability of Austenite in Austempered Ductile Cast Iron (ADI). Mater. Sci. Eng. A 2015, 626, 237–246. [Google Scholar] [CrossRef]

- Tyrala, E.; Gorny, M.; Kawalec, M.; Muszynska, A.; Lopez, H. Evaluation of Volume Fraction of Austenite in Austempering Process of Austempered Ductile Iron. Metals 2019, 9, 893. [Google Scholar] [CrossRef]

- Zahiri, S.; Pereloma, E.; Davies, C. Model for Prediction of Processing Window for Austempered Ductile Iron. Mater. Sci. Technol. 2002, 18, 1163–1167. [Google Scholar] [CrossRef]

- Mutavdzic, M.; Lazic, V.; Milosavljevic, D.; Aleksandrovic, S.; Nikolic, R.; Cukic, R. Determination of the Optimal Tempering Temperature in the Hard Facing of the Forging Dies. Mater. Eng. 2012, 19, 95–103. [Google Scholar]

- Chandra, T.; Ionescu, M.; Mantovani, D. Effect of Tempering on Mechanical Properties and Microstructure of 1 9% Cr Heat Treatment Steel. Mater. Sci. Forum 2012, 706–709, 841–846. [Google Scholar]

- Materkowski, J.; Krauss, G. Tempered Martensite Embrittlement in SAE 4340 Steel. Metall. Mater. Trans. A 1979, 10, 1643–1651. [Google Scholar] [CrossRef]

- Wei, M.; Wang, S.; Wang, L.; Cui, X.; Chen, K. Effect of Tempering Conditions on Wear Resistance in Various Wear Mechanisms of H13 Steel. Tribol. Int. 2011, 44, 898–905. [Google Scholar] [CrossRef]

- Yang, J.; Putatunda, S. Improvement in Strength and Toughness of Austempered Ductile Cast Iron by A Novel Two-Step Austempering Process. Mater. Des. 2004, 25, 219–230. [Google Scholar] [CrossRef]

- Dong, C.; Wu, H.; Wang, X. Effect of Tempering Temperatures on Microstructure and Properties of 0.28C-0.22Ti Wear Resistance Steel. Mater. Sci. Technol. 2018, 34, 86–94. [Google Scholar] [CrossRef]

| Elements | Percentage |

|---|---|

| Carbon, C | 3.53% |

| Silicon, Si | 2.71% |

| Manganese, Mn | 0.74% |

| Chromium, Cr | 0.12% |

| Copper, Cu | 0.94% |

| Sulfur, S | 0.03% |

| Phosphorous, P | 0.08% |

| Iron, Fe | Remainder |

| Heat Treatment Designs | ||

|---|---|---|

| Austempering Heat Treatment (AGI) | ||

| Austenitizing Process: | Temperature: 832 °C; | |

| Time: 20 min; | ||

| Medium Temp Salt Bath Furnace | ||

| Austempering Process: | Temperatures: 232 °C, 260 °C, 288 °C, | |

| 316 °C, 343 °C, 371 °C; | ||

| Times: 1 min, 2 min, 3 min, 6 min, 10 min, 20 min, 30 min, 60 min, 90 min and 120 min; | ||

| Water Cool; | ||

| Low Temp Salt Bath Furnace | ||

| Quenching and Tempering Heat Treatment (QTGI) | ||

| Austenitizing Process: | Temperature: 832 °C; | |

| Time: 20 min; | ||

| Oil Cool; | ||

| Medium Temp Salt Bath Furnace | ||

| Tempering Process: | Temperatures: 316 °C, 371 °C, 399 °C, 454 °C, 482 °C, 510 °C; | |

| Time: 60 min; | ||

| Oil Cool; | ||

| Electrical Heating Furnace | ||

| Experiments | ||

| Metallurgical Evaluations | ||

| Sample | AGI and QTGI Coupons (15 mm × 15 mm × 15 mm) | |

| Etching | 3% Nital for 2 s or 3 s | |

| Test Facility | Optical Microscopy with 500× Magnification | |

| Sample Size | 16 | |

| Hardness Measurements | ||

| Sample | AGI and QTGI Sample Coupons/Disks | |

| Test Facility | Rockwell Hardness Tester | |

| Repetition | 3 Times | |

| Sample Size | 234 | |

| Wear Tests | ||

| Upper Sample | Alumina Ball (Diameter: 7.94 mm; Hardness: 75 HRC; | |

| Surface Roughness (Ra): 10 nm) | ||

| Lower Sample | AGI and QTGI Disks (Diameter: 64 mm; Thickness: 11 mm; Surface Roughness (Ra): ≈ 300 nm) | |

| Normal Load | 300 N | |

| Rotational Speed | 240 rpm | |

| Lubricant | PAO4 Base Oil | |

| Test Duration | 30 min | |

| Test Facility | Rotational Ball-on-Disk Sliding Configuration | |

| Repetition | 3 Times | |

| Sample Size | 36 | |

| Group Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Austempering Temperature (°C) | 232 | 260 | 288 | 316 | 343 | 371 |

| Hardness (HRC) | 42.3 | 42 | 37.4 | 28.9 | 28.1 | 26.8 |

| Tempering Temperature (°C) | 316 | 371 | 399 | 454 | 482 | 510 |

| Hardness (HRC) | 41.1 | 41.8 | 38 | 29.5 | 28.7 | 27.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Han, X.; Barber, G.C.; Pan, Y. Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness. Metals 2019, 9, 1329. https://doi.org/10.3390/met9121329

Wang B, Han X, Barber GC, Pan Y. Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness. Metals. 2019; 9(12):1329. https://doi.org/10.3390/met9121329

Chicago/Turabian StyleWang, Bingxu, Xue Han, Gary C. Barber, and Yuming Pan. 2019. "Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness" Metals 9, no. 12: 1329. https://doi.org/10.3390/met9121329

APA StyleWang, B., Han, X., Barber, G. C., & Pan, Y. (2019). Wear Behavior of Austempered and Quenched and Tempered Gray Cast Irons under Similar Hardness. Metals, 9(12), 1329. https://doi.org/10.3390/met9121329