Hybrid Machine Learning Optimization Approach to Predict Hot Deformation Behavior of Medium Carbon Steel Material

Abstract

1. Introduction

2. Material and Experimental Procedures

3. Artificial Neural Network Approach

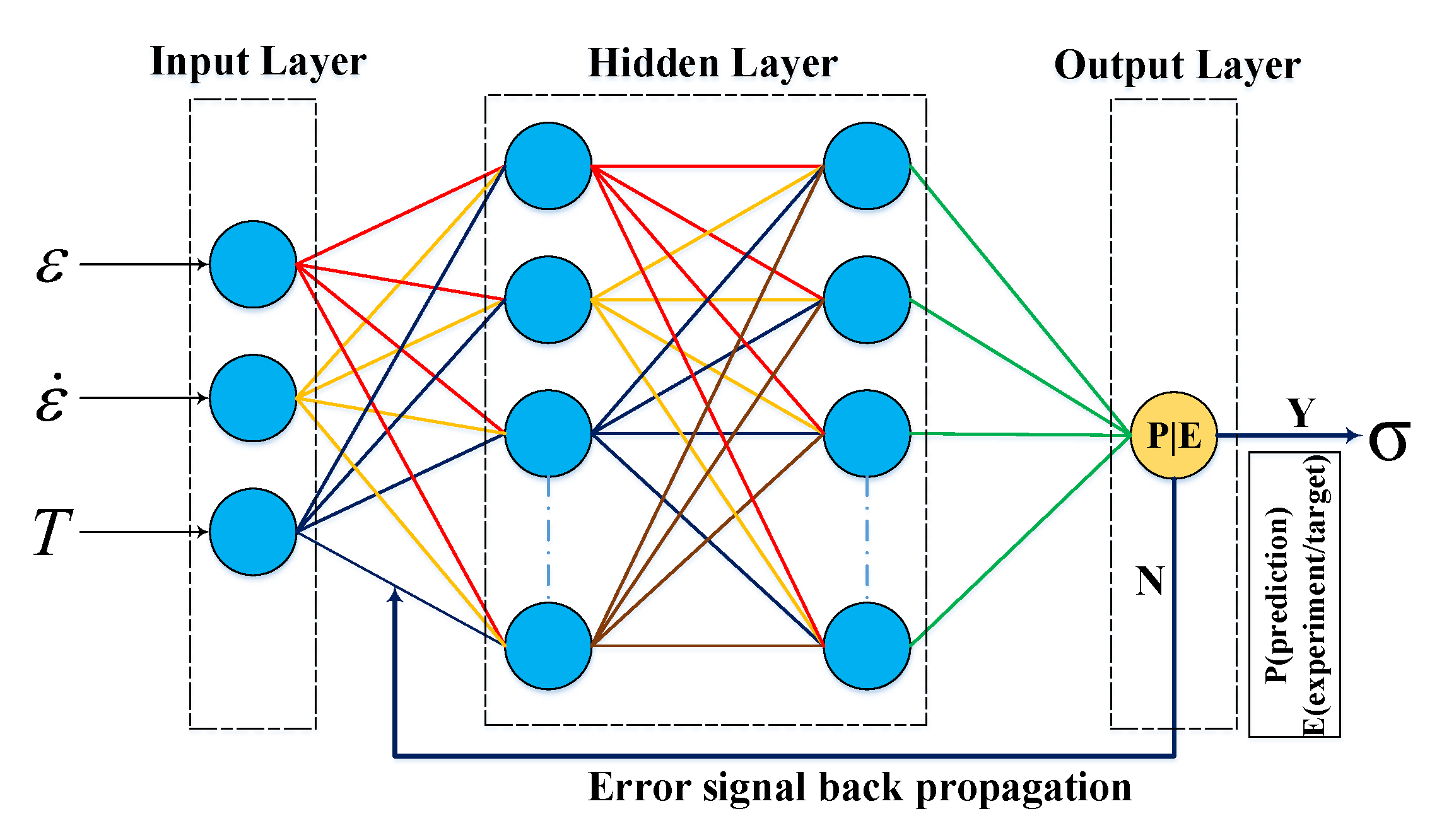

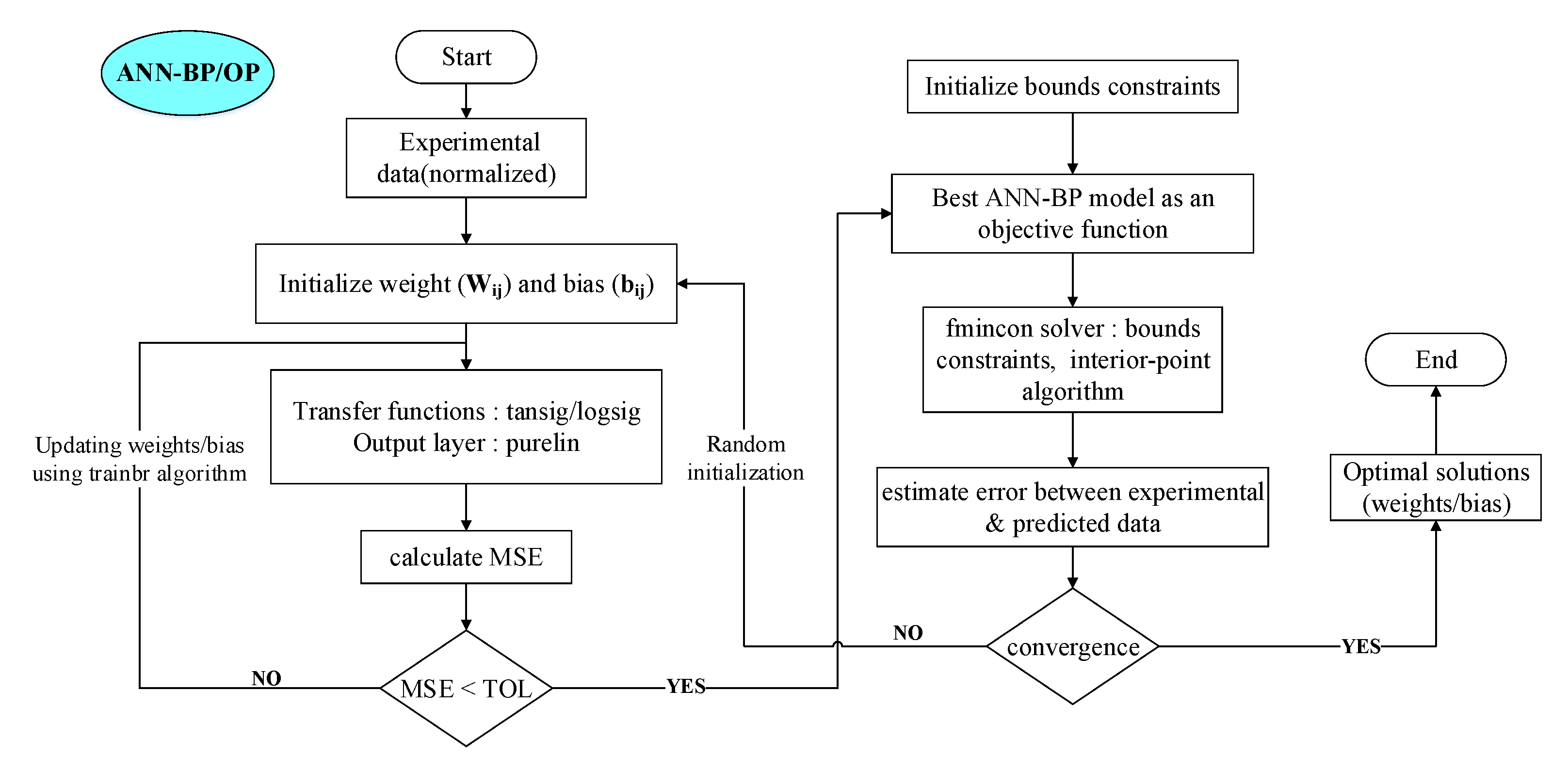

3.1. Flow Stress Modeling of AISI-1045 Steel Using an ANN with Back-Propagation Algorithm

3.2. Optimization Procedures for Obtaining the Best Trained ANN-BP Model

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| JC | Johnson–Cook |

| MJC | modified Johnson–Cook |

| MZA | modified Zerilli–Armstrong |

| AC | Arrhenius-type constitutive |

| ANN | artificial neural network |

| BP | back-propagation |

| SS | stress–strain |

| FE | finite element |

| SEM | scanning electron microscopy |

| FESEM | field emission scanning electron microscopy |

| EDS | energy dispersive X-ray spectroscopy |

| strain (mm/mm) | |

| strain rate (s) | |

| T | deformation temperature (C) |

| flow stress (MPa) | |

| ML | Machine learning |

| n | number of samples |

| HN | number of neurons in hidden layer |

| IN | number of variables in input layer |

| NO | number of variables in output layer |

| NT | number of training data |

| normalized data | |

| X | measurements from experiment |

| minimum value of experimental data | |

| maximum value of experimental data | |

| TANSIG | Tan-Sigmoid |

| LOGSIG | Log-Sigmoid |

| coefficient of determination | |

| RMSE | root mean square error |

| MSE | mean square error |

| AARE | average absolute relative error |

| OP | optimization procedures |

| fmincon | find minimum of constrained nonlinear multivariable function |

| IP | interior-point |

| GA | genetic algorithm |

| TOL | Tolerance |

| network weights | |

| network biases | |

| IW | weights in hidden layer |

| LW | weights in output layer |

| b1 | biases in hidden layer |

| b2 | biases in output layer |

| trainbr | Bayesian regularization |

| trainlm | Levenberg-Marquardt |

| learngdm | Gradient descent with momentum weight and bias learning function |

References

- Rhim, S.-H.; Oh, S.-I. Prediction of serrated chip formation in metal cutting process with new flow stress model for AISI 1045 steel. J. Mater. Process. Technol. 2006, 171, 417–422. [Google Scholar] [CrossRef]

- He, Y.-B.; Pan, Q.-L.; Chen, Q.; Zhang, Z.-Y.; Liu, X.-Y.; Li, W.-B. Modeling of strain hardening and dynamic recrystallization of ZK60 magnesium alloy during hot deformation. Trans. Nonferrous Met. Soc. 2012, 22, 246–254. [Google Scholar] [CrossRef]

- Zhan, H.; Wang, G.; Kent, D.; Dargusch, M. Constitutive modelling of the flow behaviour of a β titanium alloy at high strain rates and elevated temperatures using the Johnson–Cook and modified Zerilli–Armstrong models. Mater. Sci. Eng. A 2016, 612, 71–79. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Narala, S.K.R.; Pundir, R.S. Constitutive flow stress formulation, model validation and FE cutting simulation for AA7075-T6 aluminum alloy. Mater. Sci. Eng. A 2014, 605, 176–185. [Google Scholar] [CrossRef]

- Chen, G.; Ren, C.; Ke, Z.; Li, J.; Yang, X. Modeling of flow behavior for 7050-T7451 aluminum alloy considering microstructural evolution over a wide range of strain rates. Mech. Mater. 2016, 95, 146–157. [Google Scholar] [CrossRef]

- Lee, K.; Murugesan, M.; Lee, S.M.; Kang, B.S. A comparative study on Arrhenius-type constitutive models with regression methods. Trans. Mater. Proc. 2017, 26, 18–27. [Google Scholar] [CrossRef][Green Version]

- He, Z.; Wang, Z.; Lin, Y.; Fan, X. Hot Deformation Behavior of a 2024 Aluminum Alloy Sheet and its Modeling by Fields-Backofen Model Considering Strain Rate Evolution. Metals 2019, 9, 243. [Google Scholar] [CrossRef]

- Murugesan, M.; Jung, D.W. Johnson Cook Material and Failure Model Parameters Estimation of AISI-1045 Medium Carbon Steel for Metal Forming Applications. Materials 2019, 12, 609. [Google Scholar] [CrossRef]

- Murugesan, M.; Jung, D.W. Two flow stress models for describing hot deformation behavior of AISI-1045 medium carbon steel at elevated temperatures. Heliyon 2019, 5, 1347. [Google Scholar] [CrossRef]

- Li, H.Y.; Wang, X.F.; Duan, J.Y.; Liu, J.J. A modified Johnson Cook model for elevated temperature flow behavior of T24 steel. Mater. Sci. Eng. A 2013, 577, 138–146. [Google Scholar] [CrossRef]

- He, A.; Xie, G.; Zhang, H.; Wang, X. A comparative study on Johnson–Cook, modified Johnson–Cook and Arrhenius-type constitutive models to predict the high temperature flow stress in 20CrMo alloy steel. Mater. Des. 2013, 52, 677–685. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behavior in modified 9Cr–1Mo steel. Comput. Mater. Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Li, H.; He, L.; Zhao, G.; Zhang, L. Constitutive relationships of hot stamping boron steel B1500HS based on the modified Arrhenius and Johnson–Cook model. Mater. Sci. Eng. A 2013, 580, 330–348. [Google Scholar] [CrossRef]

- Li, H.-Y.; Li, Y.-H.; Wang, X.-F.; Liu, J.-J.; Wu, Y. A comparative study on modified Johnson Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict the hot deformation behavior in 28CrMnMoV steel. Mater. Des. 2013, 49, 493–501. [Google Scholar] [CrossRef]

- Lei, B.; Chen, G.; Liu, K.; Wang, X.; Jiang, X.; Pan, J.; Shi, Q. Constitutive Analysis on High-Temperature Flow Behavior of 3Cr-1Si-1Ni Ultra-High Strength Steel for Modeling of Flow Stress. Metals 2019, 9, 42. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Lin, P. A Comparative Study on Arrhenius and Johnson–Cook Constitutive Models for High-Temperature Deformation of Ti2AlNb-Based Alloys. Metals 2019, 9, 123. [Google Scholar] [CrossRef]

- Yang, L.-C.; Pan, Y.-T.; Chen, I.-G.; Lin, D.-Y. Constitutive Relationship Modeling and Characterization of Flow Behavior under Hot Working for Fe–Cr–Ni–W–Cu–Co Super-Austenitic Stainless Steel. Metals 2015, 5, 1717–1731. [Google Scholar] [CrossRef]

- Li, J.; Liu, J. Strain Compensation Constitutive Model and Parameter Optimization for Nb-Contained 316LN. Metals 2019, 9, 212. [Google Scholar] [CrossRef]

- Zhu, Y.; Zeng, W.; Sun, Y.; Feng, F.; Zhou, Y. Artificial neural network approach to predict the flow stress in the isothermal compression of as-cast TC21 titanium alloy. Comput. Mater. Sci. 2011, 50, 1785–1790. [Google Scholar] [CrossRef]

- Guo, L.-F.; Li, B.-C.; Zhang, Z.-M. Constitutive relationship model of TC21 alloy based on artificial neural network. Trans. Nonferrous Met. Soc. China 2013, 23, 1761–1765. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V.; Gogia, A.K. Neural network modeling to evaluate the dynamic flow stress of high strength armor steels under high strain rate compression. Def. Technol. 2014, 10, 334–342. [Google Scholar] [CrossRef]

- Xiao, X.; Liu, G.Q.; Hu, B.F.; Zheng, X.; Wang, L.N.; Chen, S.J.; Ullah, A. A comparative study on Arrhenius-type constitutive equations and artificial neural network model to predict high-temperature deformation behavior in 12Cr3WV steel. Comput. Mater. Sci. 2011, 62, 227–234. [Google Scholar] [CrossRef]

- Li, H.-Y.; Wei, D.-D.; Li, Y.-H.; Wang, X.-F. Application of artificial neural network and constitutive equations to describe the hot compressive behavior of 28CrMnMoV steel. Comput. Mater. Sci. 2012, 35, 557–562. [Google Scholar] [CrossRef]

- Li, G.J.F.; Li, Q.; Li, H.; Li, Z. A comparative study on Arrhenius-type constitutive model and artificial neural network model to predict high-temperature deformation behaviour in Aermet100 steel. Mater. Sci. Eng. A 2011, 528, 4774–4782. [Google Scholar]

- Peng, W.; Zeng, W.; Wang, Q.; Yu, H. Comparative study on constitutive relationship of as-cast Ti60 titanium alloy during hot deformation based on Arrhenius-type and artificial neural network models. Mater. Des. 2013, 51, 95–104. [Google Scholar] [CrossRef]

- Quan, G.-Z.; Lv, W.-Q.; Mao, Y.-P.; Zhang, Y.-W.; Zhou, J. Prediction of flow stress in a wide temperature range involving phase transformation for as-cast Ti–6Al–2Zr–1Mo–1V alloy by artificial neural network. Mater. Des. 2013, 50, 51–61. [Google Scholar] [CrossRef]

- Ashtiani, H.R.R.; Shahsavari, P. A comparative study on the phenomenological and artificial neural network models to predict hot deformation behavior of AlCuMgPb alloy. J. Alloys Compd. 2016, 687, 263–273. [Google Scholar] [CrossRef]

- Stendal, J.A.; Bambach, M.; Eisentraut, M.; Sizova, I.; Weiß, S. Applying Machine Learning to the Phenomenological Flow Stress Modeling of TNM-B1. Materials 2019, 9, 220. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, G.; Sun, J.; Zou, D. A comparative study on constitutive relationship of as-cast 904L austenitic stainless steel during hot deformation based on Arrhenius-type and artificial neural network models. Comput. Mater. Sci. 2013, 67, 93–103. [Google Scholar] [CrossRef]

- Huang, C.; Jia, X.; Zhang, Z. A Modified Back Propagation Artificial Neural Network Model Based on Genetic Algorithm to Predict the Flow Behavior of 5754 Aluminum Alloy. Materials 2018, 11, 855. [Google Scholar] [CrossRef]

- Rath, S.; Talukdar, P.; Singh, A.P. Application of Artificial Neural Network for Flow Stress Modelling of Steel. Am. J. Neural Netw. Appl. 2017, 3, 36–39. [Google Scholar] [CrossRef][Green Version]

- Rao, S.G.R.N.; Nandy, T.K.; Bhattacharjee, A. Artificial neural network approach for prediction of Titanium alloy Stress-Strain Curve. Procedia Eng. 2012, 38, 3709–3714. [Google Scholar]

- Wu, R.H.; Liu, J.T.; Chnag, H.B.; Hsu, T.Y.; Ruan, X.Y. Predication of the flow stress of 0.4C-1.9Cr-1.5Mn-1.0Ni-0.2Mo steel during hot deformation. J. Mater. Process. Technol. 2001, 116, 211–218. [Google Scholar] [CrossRef]

- Senthilkumar, V.; Balaji, A.; Arulkirubakaran, D. Application of constitutive and neural network models for prediction of high temperature flow behavior of Al/Mg based nanocomposite. Comput. Mater. Sci. 2013, 23, 1737–1750. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.-M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Aghasafari, P.; Salmi, H.A.M. Artificial Neural Network Modeling of Flow Stress in Hot Rolling. Comput. Mater. Sci. 2013, 54, 872–879. [Google Scholar] [CrossRef][Green Version]

- Carpenter, W.C.; Barthelemy, J.F. Common Misconceptions about Neural Networks as Approximators. ASCE J. Comput. Civ. Eng. 1994, 8, 345–358. [Google Scholar] [CrossRef]

- Carpenter, W.C.; Hoffman, M.E. Training backprop neural networks. J. AI Expert 1995, 10, 30–33. [Google Scholar]

- Oreta, A.W.C.; Kawashima, K. Neural network modeling of confined compressive strength. J. Struct Eng. 2003, 129, 554–561. [Google Scholar] [CrossRef]

- Razavi, S.V.; EI-Shafie, A.H.; Mohammadi, P. Artificial neural networks for mechanical strength prediction of lightweight mortar. Sci. Res. Essays 2011, 6, 3406–3417. [Google Scholar] [CrossRef]

- Murugesan, M.; Kang, B.S.; Lee, K. Multi-Objective Design Optimization of Composite Stiffened Panel Using Response Surface Methodology. J. Compos. Res. 2015, 28, 297–310. [Google Scholar] [CrossRef]

- Chuan, W.; Lei, Y.; Jianguo, Z. Study on Optimization of Radiological Worker Allocation Problem Based on Nonlinear Programming Function-fmincon. In Proceedings of the International Conference on Mechatronics and Automation, Tianjin, China, 3–6 August 2014. [Google Scholar]

| C | Fe | Mn | P | S |

|---|---|---|---|---|

| 0.42–0.50 | 98.51–98.98 | 0.60–0.90 | ≤0.04 | ≤0.05 |

| Number of samples | 384 data (268 (Training) + 58 (validation) + 58 (Testing)) |

| Input layer | three variables |

| Hidden layer functions | LOGSIG and TANSIG |

| Number of neurons | two ≤ HNs ≤ 30 |

| Output layer | one variable |

| Output layer function | Purelin |

| network type | multi-layer feed-forward |

| net algorithm | back-propagation |

| Training functions | Trainbr and Trainlm |

| Learning function | LEARNGDM |

| Performance function | MSE |

| Neurons | MSE | Neurons | MSE | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TANSIG | LOGSIG | TANSIG | LOGSIG | ||||||

| Trainbr | Trainlm | Trainbr | Trainlm | Trainbr | Trainlm | Trainbr | Trainlm | ||

| 2 | 311.190 | 314.301 | 311.187 | 565.457 | 18 | 0.730 | 12.535 | 0.705 | 13.121 |

| 4 | 99.431 | 42.762 | 43.316 | 42.352 | 20 | 2.139 | 14.458 | 1.874 | 13.095 |

| 6 | 14.149 | 15.586 | 11.079 | 87.875 | 22 | 0.555 | 6.252 | 0.486 | 1.187 |

| 8 | 13.219 | 20.846 | 5.767 | 9.807 | 24 | 1.202 | 9.919 | 1.383 | 1.713 |

| 10 | 3.417 | 10.782 | 4.128 | 28.448 | 26 | 1.141 | 23.703 | 1.078 | 2.008 |

| 12 | 2.562 | 4.871 | 2.361 | 13.318 | 28 | 0.776 | 2.097 | 0.642 | 18.675 |

| 14 | 1.405 | 17.683 | 1.504 | 5.243 | 30 | 1.144 | 9.715 | 0.930 | 6.473 |

| 16 | 1.082 | 8.037 | 1.066 | 3.351 | |||||

| ANN Transfer Function | Test Conditions | R2 | Overall-R2 | AARE (%) | Overall-AARE (%) | |

|---|---|---|---|---|---|---|

| TANSIG | 0.05–1.0 s | 923 K | 0.9918 | 0.9980 | 1.6397 | 1.8059 |

| 1023 K | 0.9990 | 1.4028 | ||||

| 1123 K | 0.9995 | 2.1722 | ||||

| 1223 K | 0.9998 | 2.0092 | ||||

| LOGSIG | 0.05–1.0 s | 923 K | 0.9971 | 0.9991 | 0.8637 | 1.3348 |

| 1023 K | 0.9996 | 0.8927 | ||||

| 1123 K | 0.9997 | 1.4321 | ||||

| 1223 K | 0.9998 | 2.1507 | ||||

| ANN Transfer Function | Test Conditions | R2 | Overall-R2 | AARE (%) | Overall-AARE (%) | |

|---|---|---|---|---|---|---|

| TANSIG | 0.05–1.0 s | 923 K | 0.9940 | 0.9989 | 1.1582 | 1.1229 |

| 1023 K | 0.9997 | 0.7282 | ||||

| 1123 K | 0.9998 | 1.0089 | ||||

| 1223 K | 0.9999 | 1.5963 | ||||

| LOGSIG | 0.05–1.0 s | 923 K | 0.9960 | 0.9988 | 1.0972 | 1.5017 |

| 1023 K | 0.9992 | 1.3804 | ||||

| 1123 K | 0.9996 | 1.7752 | ||||

| 1223 K | 0.9999 | 1.7541 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murugesan, M.; Sajjad, M.; Jung, D.W. Hybrid Machine Learning Optimization Approach to Predict Hot Deformation Behavior of Medium Carbon Steel Material. Metals 2019, 9, 1315. https://doi.org/10.3390/met9121315

Murugesan M, Sajjad M, Jung DW. Hybrid Machine Learning Optimization Approach to Predict Hot Deformation Behavior of Medium Carbon Steel Material. Metals. 2019; 9(12):1315. https://doi.org/10.3390/met9121315

Chicago/Turabian StyleMurugesan, Mohanraj, Muhammad Sajjad, and Dong Won Jung. 2019. "Hybrid Machine Learning Optimization Approach to Predict Hot Deformation Behavior of Medium Carbon Steel Material" Metals 9, no. 12: 1315. https://doi.org/10.3390/met9121315

APA StyleMurugesan, M., Sajjad, M., & Jung, D. W. (2019). Hybrid Machine Learning Optimization Approach to Predict Hot Deformation Behavior of Medium Carbon Steel Material. Metals, 9(12), 1315. https://doi.org/10.3390/met9121315