Effect of Heat Treatment on the Microstructure and Properties of Ultrafine WC–Co Cemented Carbide

Abstract

1. Introduction

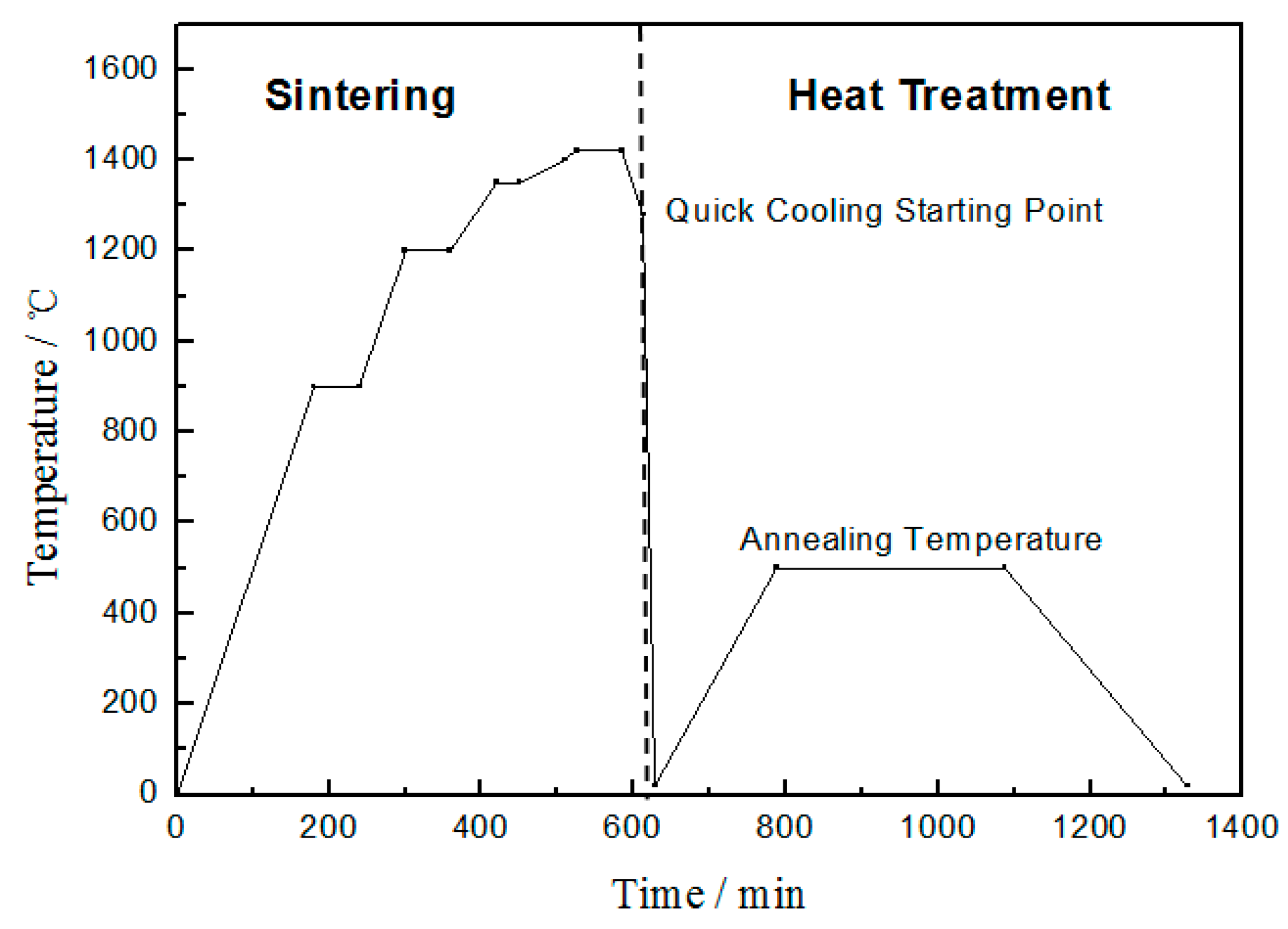

2. Experimental Methods

3. Results and Discussion

3.1. Analysis of Conventional Properties

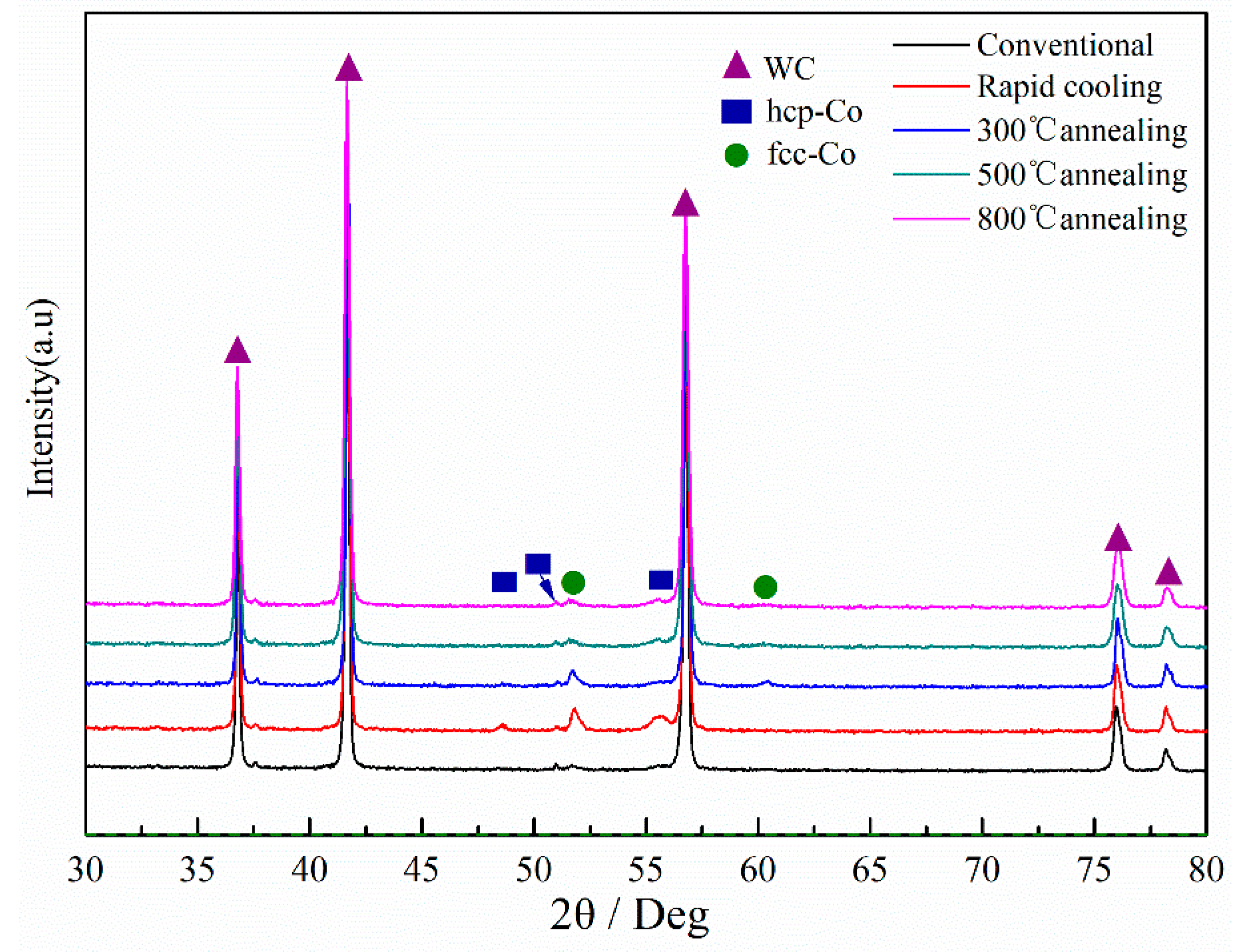

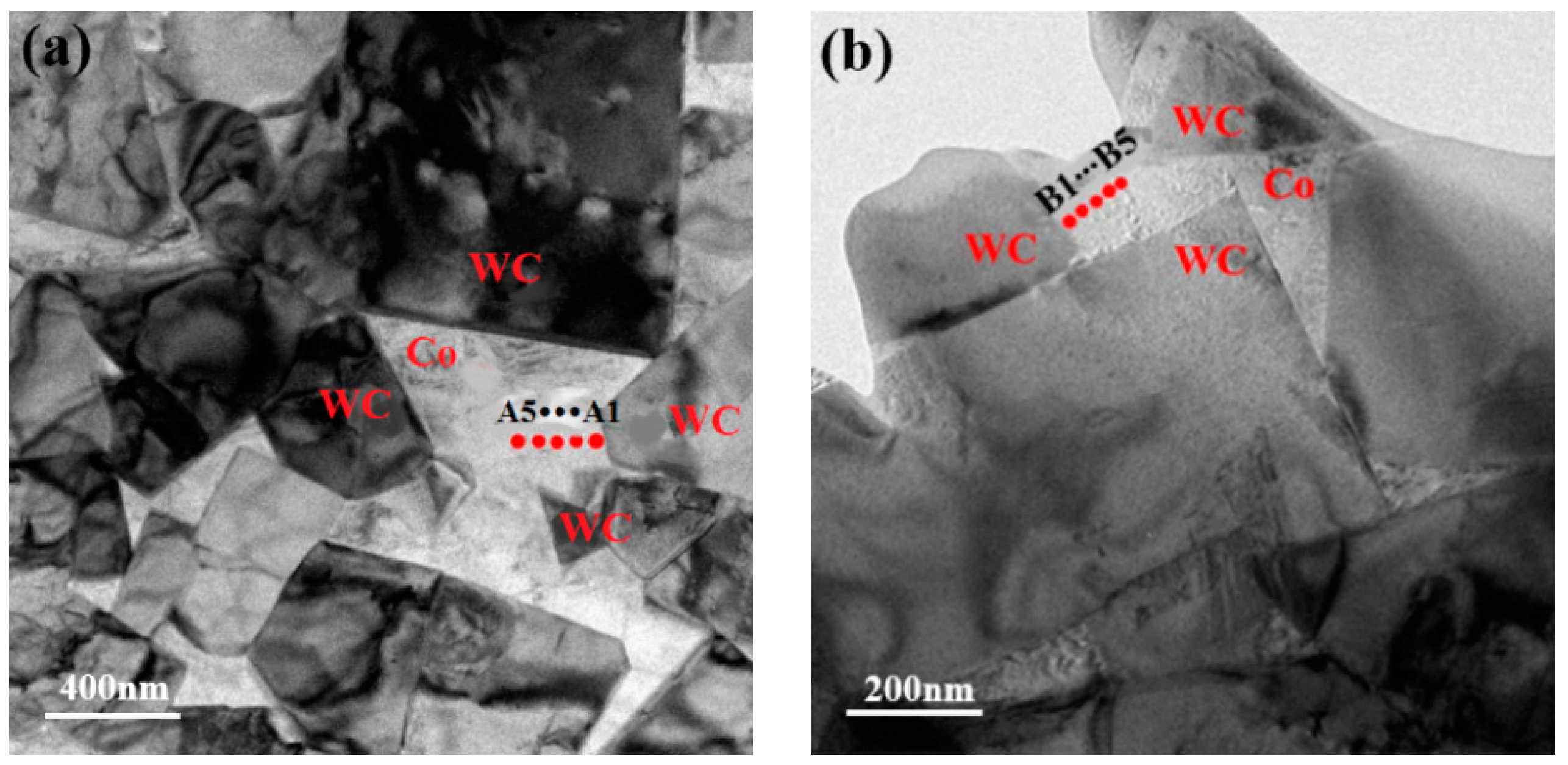

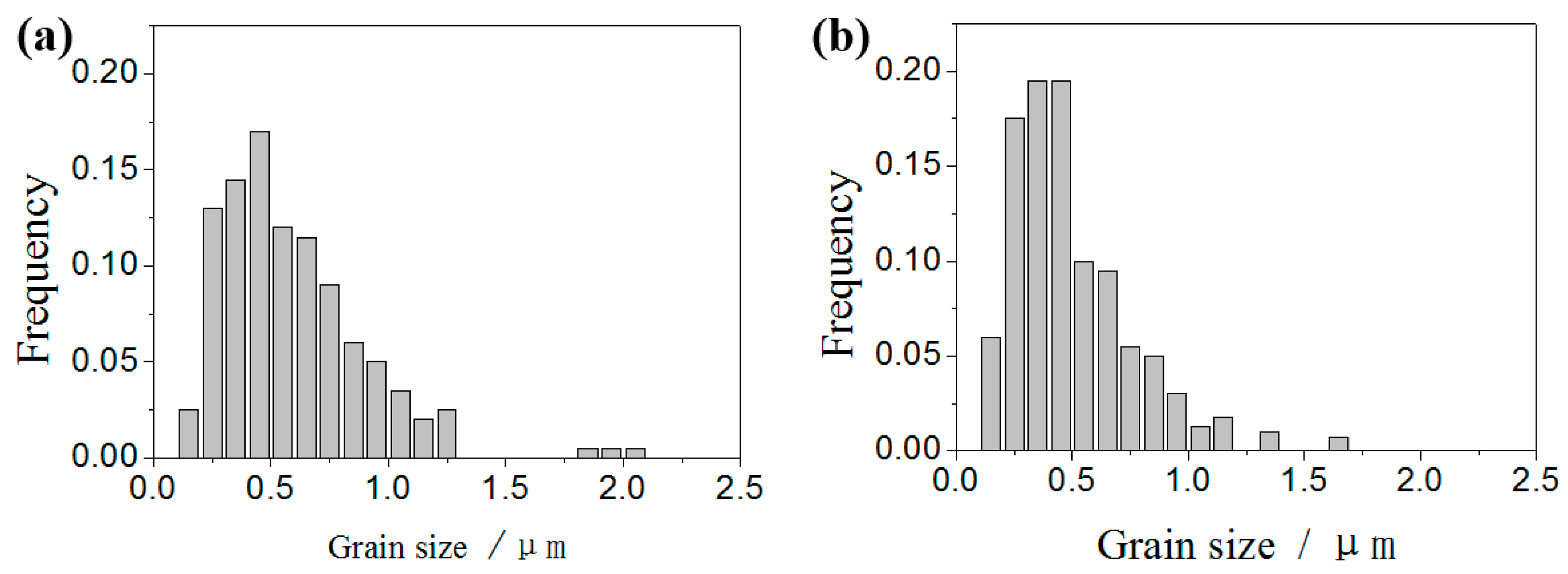

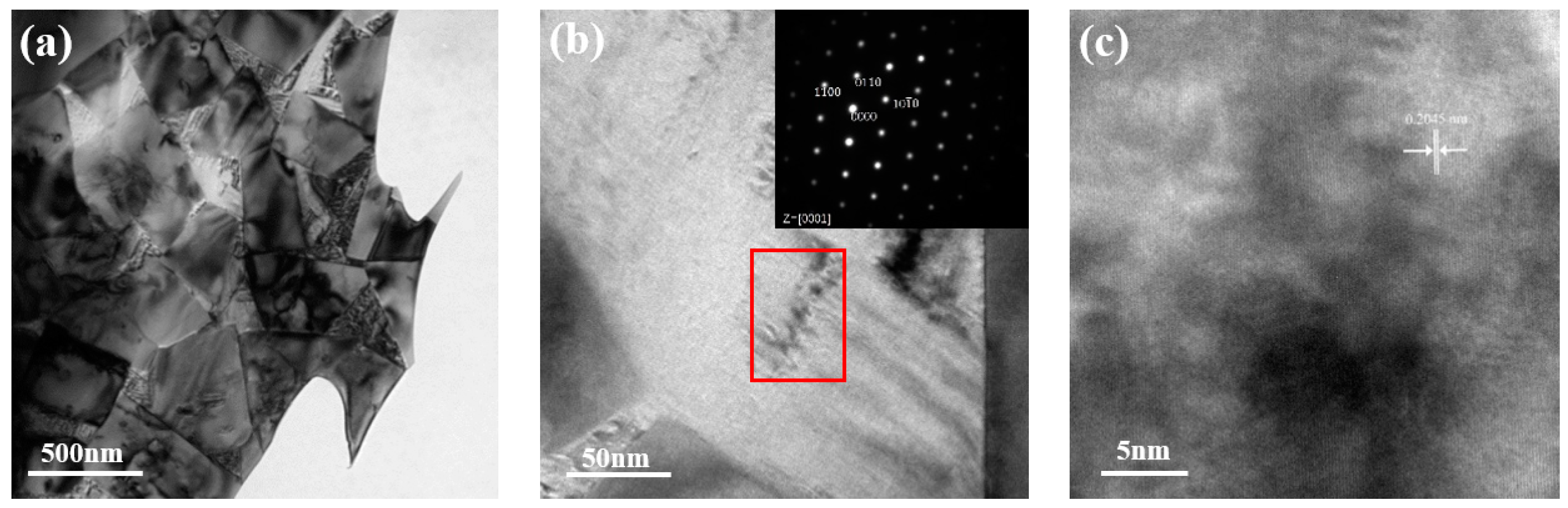

3.2. Effect of Heat Treatment on the Microstructure of Ultra-Fine Cemented Carbide

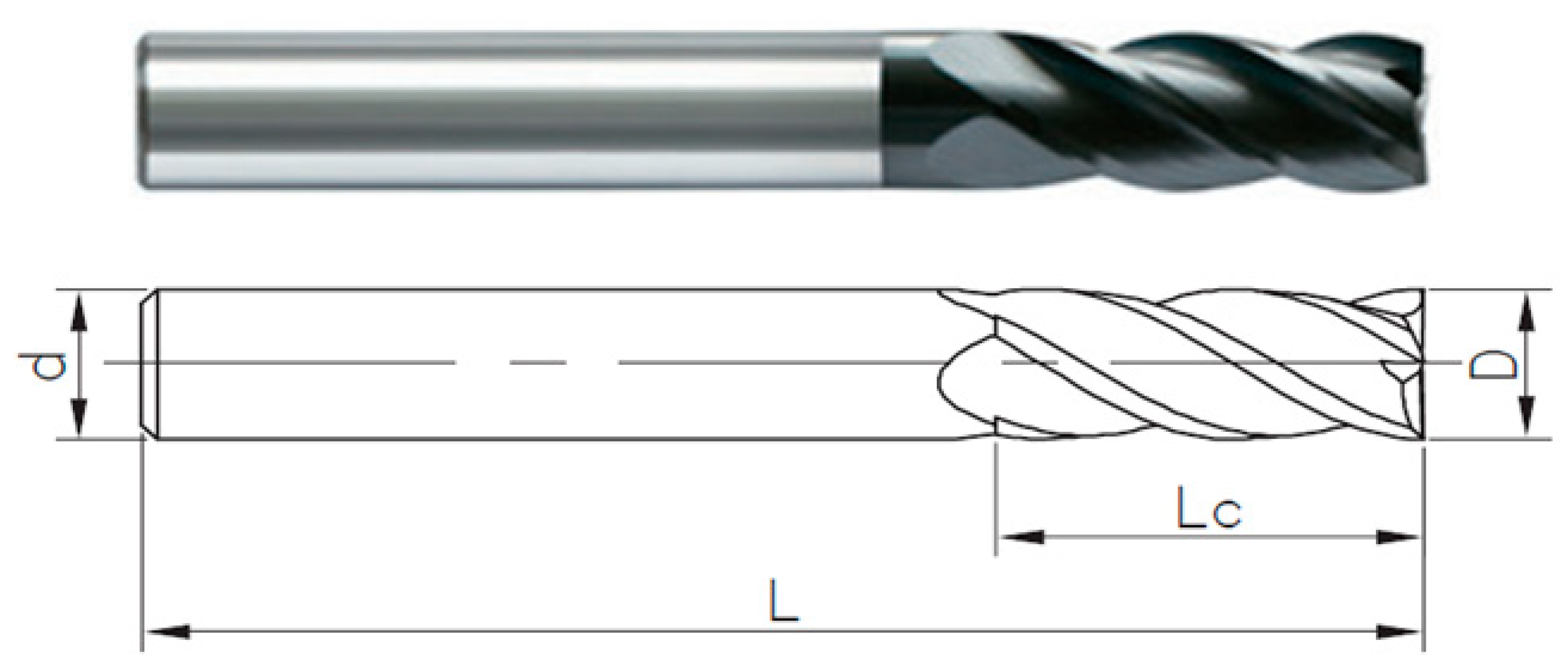

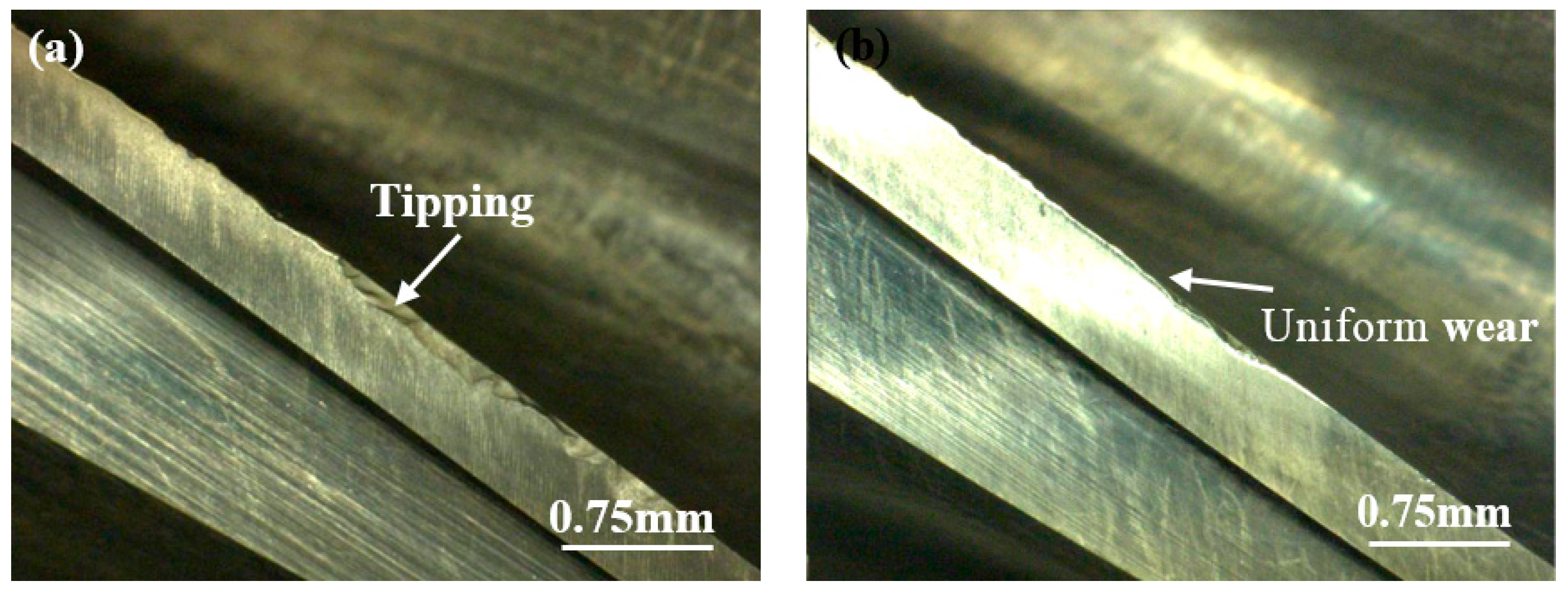

3.3. Cutting Experiment

4. Conclusions

- (1)

- Microstructural differences in the ultrafine-grained WC–Co cemented carbides treated by conventional and rapid cooling processes were mainly reflected in the Co phase. With the rapid cooling treatment, the solid solubility of the W and the proportion of fcc Co in the Co phase increased. In terms of the effect on the hard phase (WC), the rapid cooling treatment inhibited the precipitation of the W and C atoms on the surface of WC particles which resulted in rounding of the WC grain edges and refinement of the WC grains.

- (2)

- The presence of nanosized particles increased the dispersion strengthening of the Co phase which improved the comprehensive properties of the ultrafine-grained WC–Co cemented carbide and increased the hardness, wear resistance, and toughness of the alloys.

- (3)

- The ultrafine-grained WC–Co cemented carbide with good hardness and toughness was obtained by strengthening the Co phase through an appropriate heat treatment process, and the service life of the ultrafine-grained WC–Co cemented carbide was improved under actual cutting conditions.

Author Contributions

Funding

Conflicts of Interest

References

- Tumanov, V.I.; Funke, V.F.; Trukhanova, Z.S.; Novikova, T.A.; Kuznetsova, K.F. The heat treatment of tungsten carbide-cobalt alloys. Trans. Poroshkovaya Metall. 1964, 2, 57–60. [Google Scholar] [CrossRef]

- Jonsson, H.; Aronsson, B. Microstructure and hardness of cobalt-rich Co-W-C alloys after ageing in the temperature range 400–1000 °C. J. Inst. Met. 1969, 97, 281–288. [Google Scholar]

- Jonsson, H. Studies of the binder phase in WC-Co cemented carbides heat-treated at 650 °C. Powder Metall. 1972, 15, 1–10. [Google Scholar] [CrossRef]

- Jonsson, H. Studies of the binder phase in WC-Co cemented carbides heat-treated at 950 °C. Planseeber. Pulvermetall. 1975, 1, 37–55. [Google Scholar]

- Wirmark, G.; Dunlop, G.L. Phase transformation in the binder phase of Co-W-C cemented carbides. In Science of Hard Materials; Springer: Boston, MA, USA, 1983; pp. 311–328. [Google Scholar]

- Parker, S.R.; Whiting, M.J.; Yeomans, J.A. Control of carbon content in WC-Co hard metal by heat treatment in reducing atmospheres containing methane. Int. J. Refract. Met. Hard Mater. 2017, 66, 204–210. [Google Scholar] [CrossRef]

- Sunny, Z.; Apurbba, K.S. Microstructure and wear performance of heat treated WC-12Co microwave clad. Vacuum 2016, 131, 213–222. [Google Scholar]

- Yuan, Y.G.; Ding, J.J.; Wang, Y.K.; Sun, W.Q. Fabrication of functionally gradient ultrafine grained WC-Co composites. Appl. Mech. Mater. 2013, 423–426, 885–889. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Guisbiers, G.; Pereira, S.; Barradas, N.P.; Alves, E.; Senos, A.M.R.; Vieira, M.T. Annealing Ni nanocrystalline on WC-Co. J. Alloy. Compd. 2009, 482, 131–136. [Google Scholar] [CrossRef]

- Ho, W.Y.; Chen, C.W.; Wang, D.Y.; Ho, W.Y. Cutting performance of TiAlSiN coated cemented carbide tool with post-deposition heat treatment. Adv. Mater. Res. 2009, 79–82, 767–770. [Google Scholar] [CrossRef]

- Saito, Y.; Isozaki, T.; Masuda, A.; Fukumoto, K.; Chosa, M.; Ito, T.; Bauer, C.E.; Inspektor, A.; Oles, E.J. Adhesion strength of diamond film on cemented carbide insert. Diam. Relat. Mater. 1993, 2, 1391–1395. [Google Scholar] [CrossRef]

- Chae, K.W.; Park, J.K.; Lee, W.S. Adhesion strength of diamond films on heat-treated WC-Co cutting tools. Diam. Relat. Mater. 2007, 16, 1992–1995. [Google Scholar] [CrossRef]

- Delfosse, D.; Cherradi, N.; Ilschner, B. Numerical and experimental determination of residual stresses in graded materials. Compos. Part B Eng. 1997, 28, 127–141. [Google Scholar] [CrossRef]

- Thakur, D.; Ramamoorthy, B.; Vijayaraghavan, L. Influence of different post treatments on tungsten carbide cobalt inserts. Mater. Lett. 2008, 62, 4403–4406. [Google Scholar] [CrossRef]

- Routala, P.; Norton, J.T. Tungsten-Cobalt-Carbon System. Trans. AIME 1952, 4, 1045–1050. [Google Scholar] [CrossRef]

- Andrén, H.-O. Microstructures of cemented carbides. Mater. Des. 2001, 22, 491–498. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R. Cemented carbide phase diagrams: A review. Int. J. Refract. Met. Hard Mater. 2011, 29, 405–418. [Google Scholar] [CrossRef]

- Gu, L.; Huang, J.; Tang, Y.; Xie, C.; Gao, S. Influence of different post treatments on microstructure and properties of WC-Co cemented carbides. J. Alloy. Compd. 2015, 620, 116–119. [Google Scholar] [CrossRef]

- Tan, Y.; Cai, H.; Liu, Z.; Zhu, W.; Ma, B. TEM Investigation of WC-Co Cemented Carbides after Heat Treatment. Rare Met. Mater. Eng. 1997, 26, 58–62. [Google Scholar]

- Andrén, H.-O. Microstructure development during sintering and heat-treatment of cemented carbides and cermets. Mater. Chem. Phys. 2001, 67, 209–213. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, L. Effects of heat treatment on the mechanical properties of coarse-grained cemented carbide. Rare Met. Cem. Carbides 2012, 40, 45–47. [Google Scholar]

- Wang, C.X.; Jiang, C.H.; Ji, V. Thermal stability of residual stresses and work hardening of shot peened tungsten cemented carbide. J. Mater. Process. Technol. 2017, 240, 98–103. [Google Scholar] [CrossRef]

- Fang, Z.Z. Correlation of transverse rupture strength of WC-Co with hardness. Int. J. Refract. Met. Hard Mater. 2005, 23, 119–127. [Google Scholar] [CrossRef]

- Cha, S.I.; Lee, K.H.; Ryu, H.J.; Hong, S.H. Effect of size and location of spherical pores on transverse rupture strength of WC-Co cemented carbides. Mater. Sci. Eng. A 2008, 486, 404–408. [Google Scholar] [CrossRef]

- Li, J.Y.; He, P. Study on microstructure and properties of WC-Co cemeneted carbide. Rare Met. Mater. Eng. 1995, 24, 53–58. [Google Scholar]

- Xiao, M.D.; Xiao, W.; Jiang, J.L. Cobalt phase structure of cemented carbide. Mater. Sci. Eng. Powder Metall. 2010, 15, 611–614. [Google Scholar]

- Konyashin, I.; Lachmann, F.; Ries, B.; Mazilkin, A.A.; Straumal, B.B.; Kübel, C.; Llanes, L.; Baretzky, B. Strengthening zones in the Co matrix of WC–Co cemented carbides. Scr. Mater. 2014, 83, 17–20. [Google Scholar] [CrossRef]

- Makhele-Lekala, L.; Luyckx, S.; Nabarro, F.R.N. Semi-empirical relationship between the hardness, grain size and mean free path of WC-Co. Int. J. Refract. Met. Hard Mater. 2001, 19, 245–249. [Google Scholar] [CrossRef]

- Tillwick, D.L.; Joffe, I. Precipitation and magnetic hardening in sintered WC-Co composite materials. J. Phys. D 1973, 6, 1585–1597. [Google Scholar] [CrossRef]

- Wawrzik, S.; Buchegger, C.; Lengauer, W.; van den Berg, H.; Rödiger, K.; Wolf, M.; Helldörfer, A.; Bernardi, J.; Gruber, J. Precipitation of intermetallic phases in coarse-grained hardmetals by low-temperature annealing. In Proceedings of the EuroPM 2015, Reims, France, 4–7 September 2015. [Google Scholar]

| Heat Treatment Process | Ms% | Hc | TRS (MPa) | HV30 | KIC (MPa·m1/2) |

|---|---|---|---|---|---|

| Conventional alloy | 87 ± 2 | 235 ± 12 | 4053 ± 65 | 1580 ± 30 | 10.3 ± 0.3 |

| 1280 °C rapid cooling | 87 ± 2 | 245 ± 12 | 4205 ± 58 | 1612 ± 28 | 10.2 ± 0.2 |

| 1280 °C rapid cooling + 300 °C annealing | 88 ± 1 | 240 ± 11 | 4293 ± 53 | 1610 ± 26 | 10.5 ± 0.1 |

| 1280 °C rapid cooling + 500 °C annealing | 87 ± 1 | 235 ±10 | 4253 ± 50 | 1602 ± 25 | 10.8 ± 0.1 |

| 1280 °C rapid cooling + 800 °C annealing | 87 ± 3 | 236 ±12 | 4181 ± 55 | 1593 ± 27 | 10.3 ± 0.3 |

| Heat Treatment Process | Co(hcp)(100)(°) | Co(fcc)(200)(°) | Co(hcp)/Co(fcc) | ||

|---|---|---|---|---|---|

| Standard | Actual | Standard | Actual | ||

| Conventional alloy | 48.68 | 48.42 | 60.63 | 60.07 | 0.23 |

| 1280 °C rapid cooling | 48.24 | 59.97 | 0.16 | ||

| 1280 °C rapid cooling + 300 °C annealing | 48.38 | 60.04 | 0.17 | ||

| 1280 °C rapid cooling + 500 °C annealing | 48.38 | 60.05 | 0.36 | ||

| 1280 °C rapid cooling + 800 °C annealing | 48.41 | 60.08 | 0.41 | ||

| Sites | W | Cr | Co | Sites | W | Cr | Co |

|---|---|---|---|---|---|---|---|

| A1 | 6.15 | 3.09 | 88.77 | B1 | 10.54 | 1.8 | 87.64 |

| A2 | 9.27 | 1.83 | 87.72 | B2 | 9.57 | 1.57 | 88.85 |

| A3 | 7.81 | 2.84 | 89.34 | B3 | 8.98 | 1.67 | 85.26 |

| A4 | 7.96 | 2.65 | 89.37 | B4 | 8.82 | 1.44 | 84.61 |

| A5 | 7.01 | 1.61 | 91.36 | B5 | 9.77 | 1.6 | 88.64 |

| Speed (rpm) | fz (mm/rev) | ap (mm) | ae (mm) | Cutting Mode | Cooling Mode | Workpiece Material |

|---|---|---|---|---|---|---|

| 611 | 0.04 | 12.7 | 6.35 | groove milling | 7% water-based emulsion | Inconel 718 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, Z.; Li, Z.; Chang, F.; Dai, P. Effect of Heat Treatment on the Microstructure and Properties of Ultrafine WC–Co Cemented Carbide. Metals 2019, 9, 1302. https://doi.org/10.3390/met9121302

Xiang Z, Li Z, Chang F, Dai P. Effect of Heat Treatment on the Microstructure and Properties of Ultrafine WC–Co Cemented Carbide. Metals. 2019; 9(12):1302. https://doi.org/10.3390/met9121302

Chicago/Turabian StyleXiang, Zhongnan, Zhanjiang Li, Fa Chang, and Pinqiang Dai. 2019. "Effect of Heat Treatment on the Microstructure and Properties of Ultrafine WC–Co Cemented Carbide" Metals 9, no. 12: 1302. https://doi.org/10.3390/met9121302

APA StyleXiang, Z., Li, Z., Chang, F., & Dai, P. (2019). Effect of Heat Treatment on the Microstructure and Properties of Ultrafine WC–Co Cemented Carbide. Metals, 9(12), 1302. https://doi.org/10.3390/met9121302